Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Control combustion temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

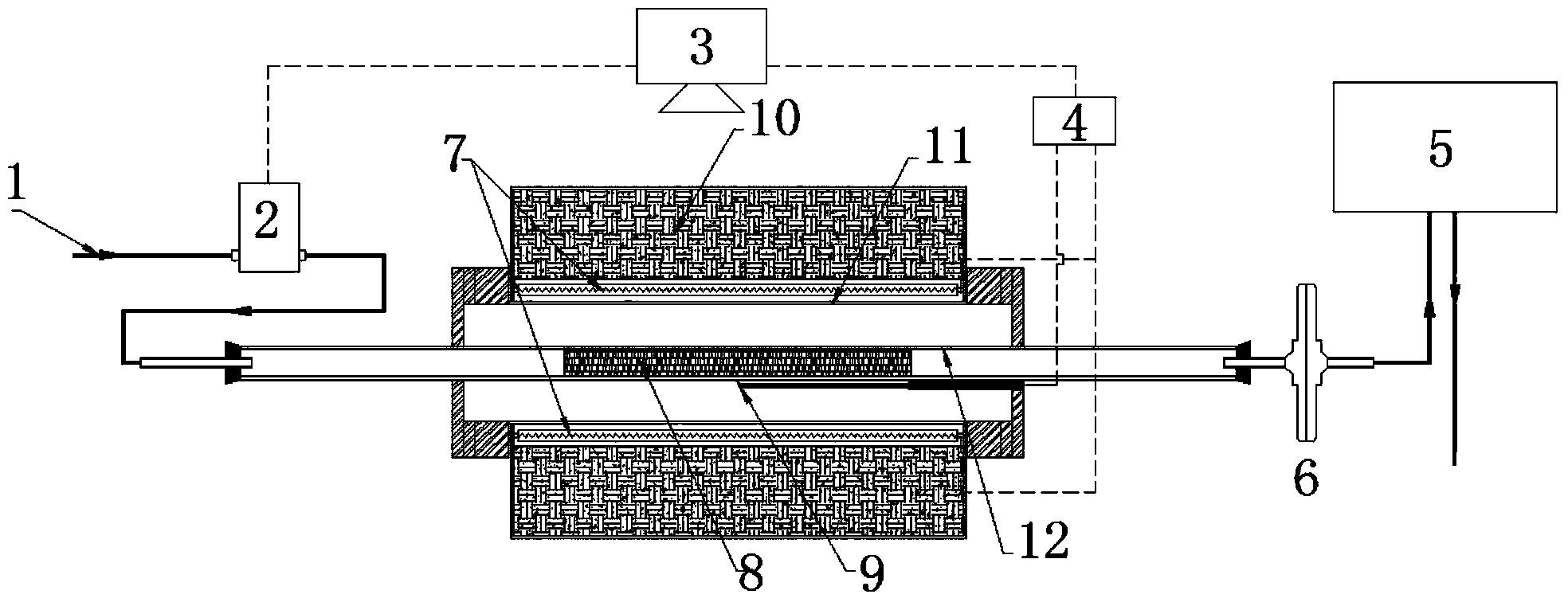

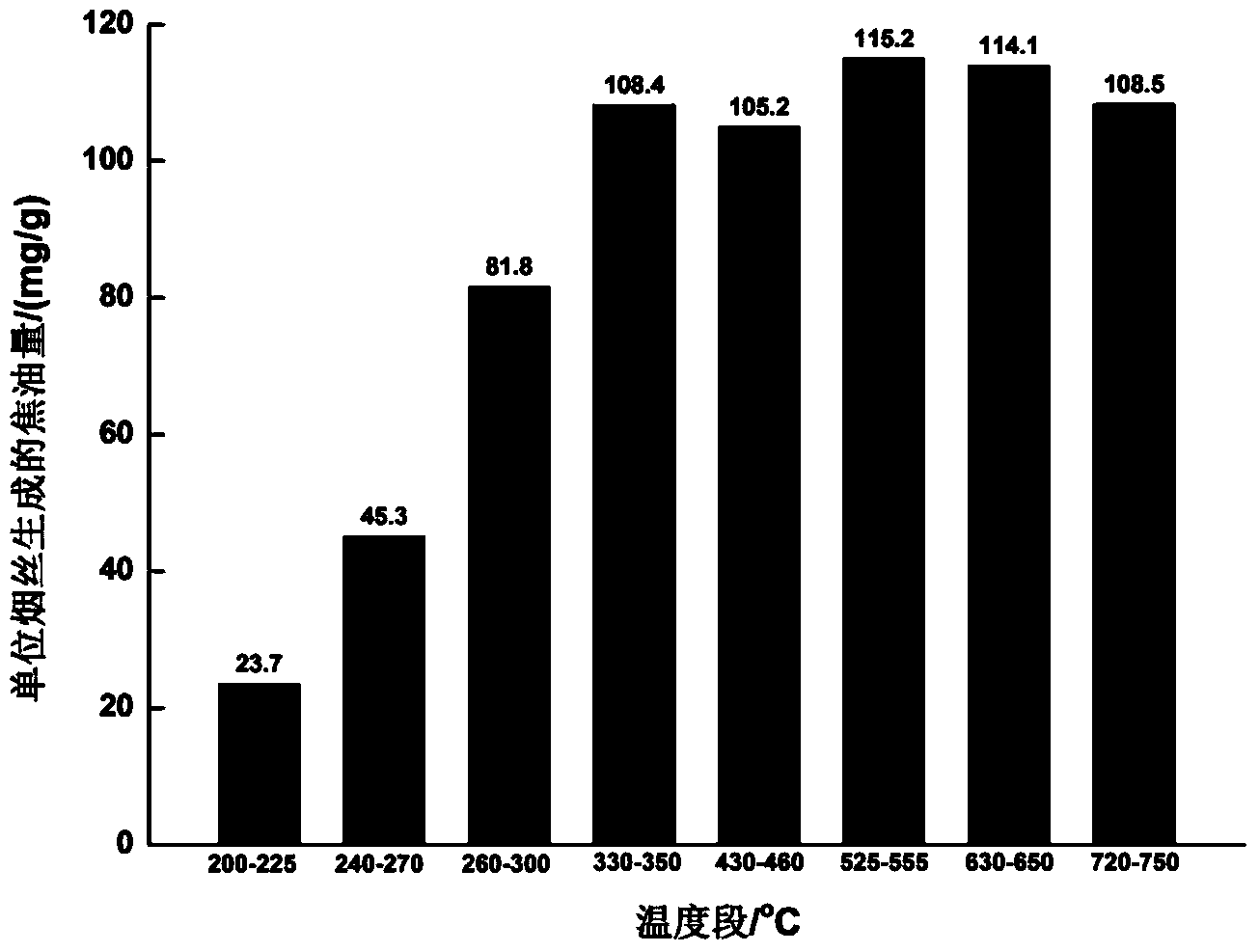

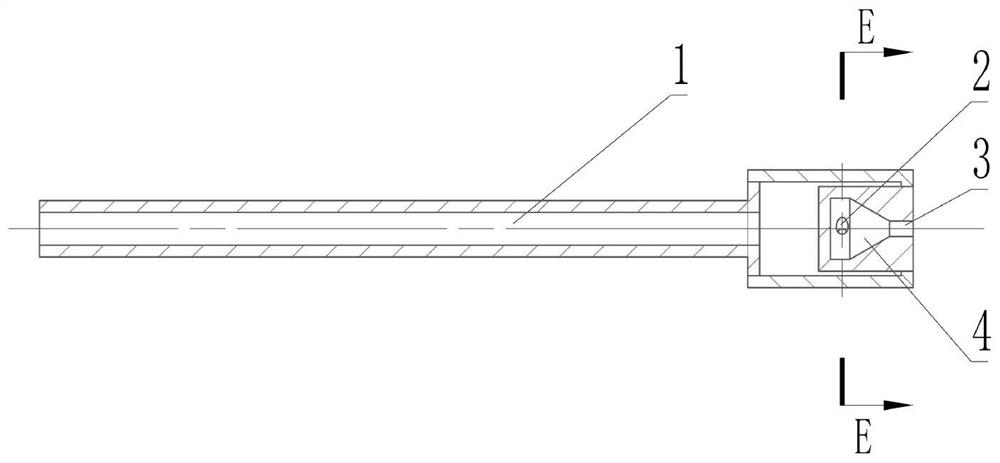

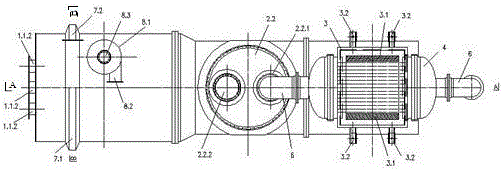

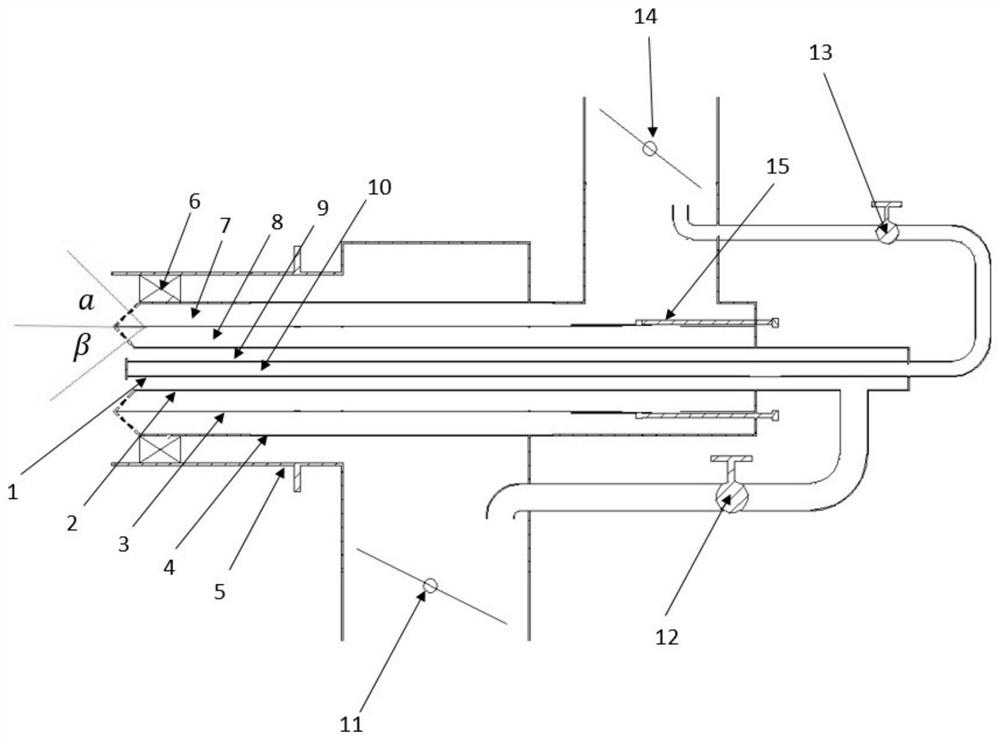

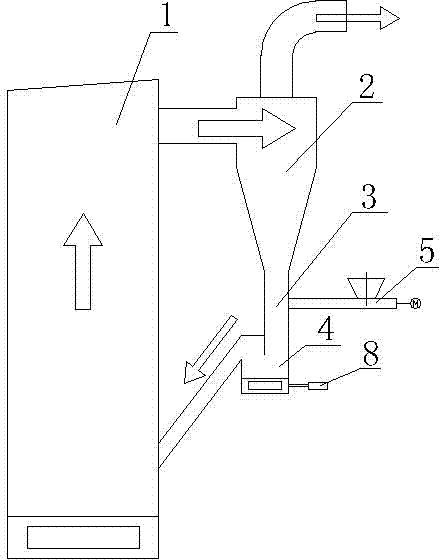

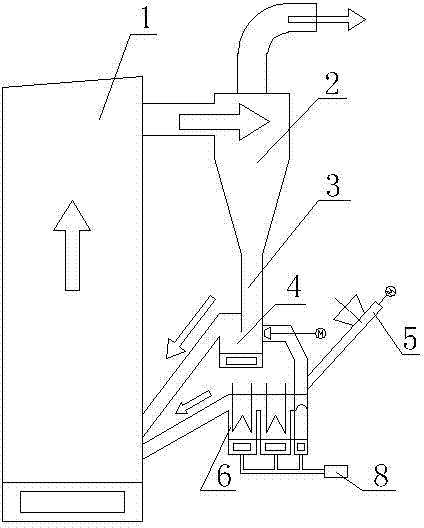

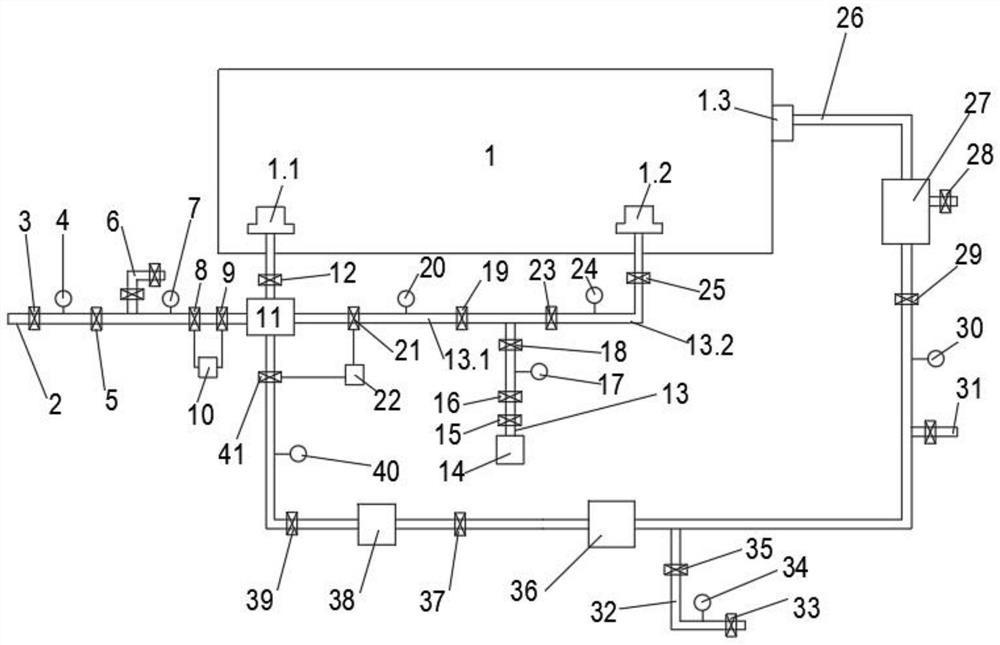

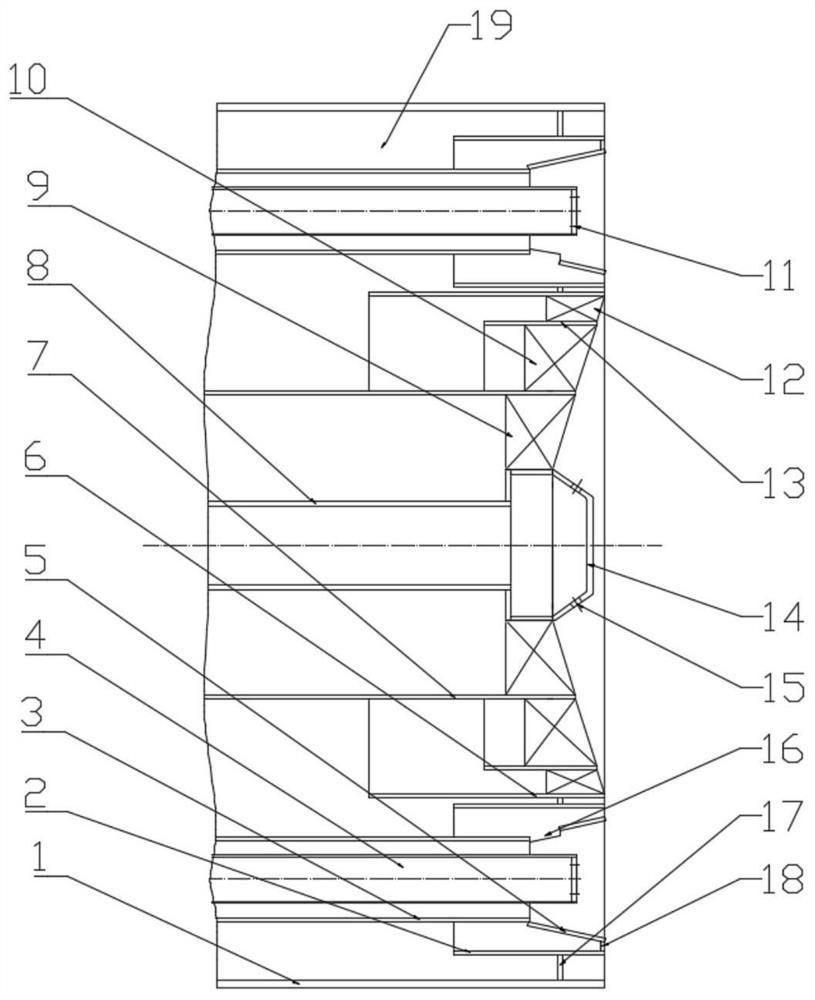

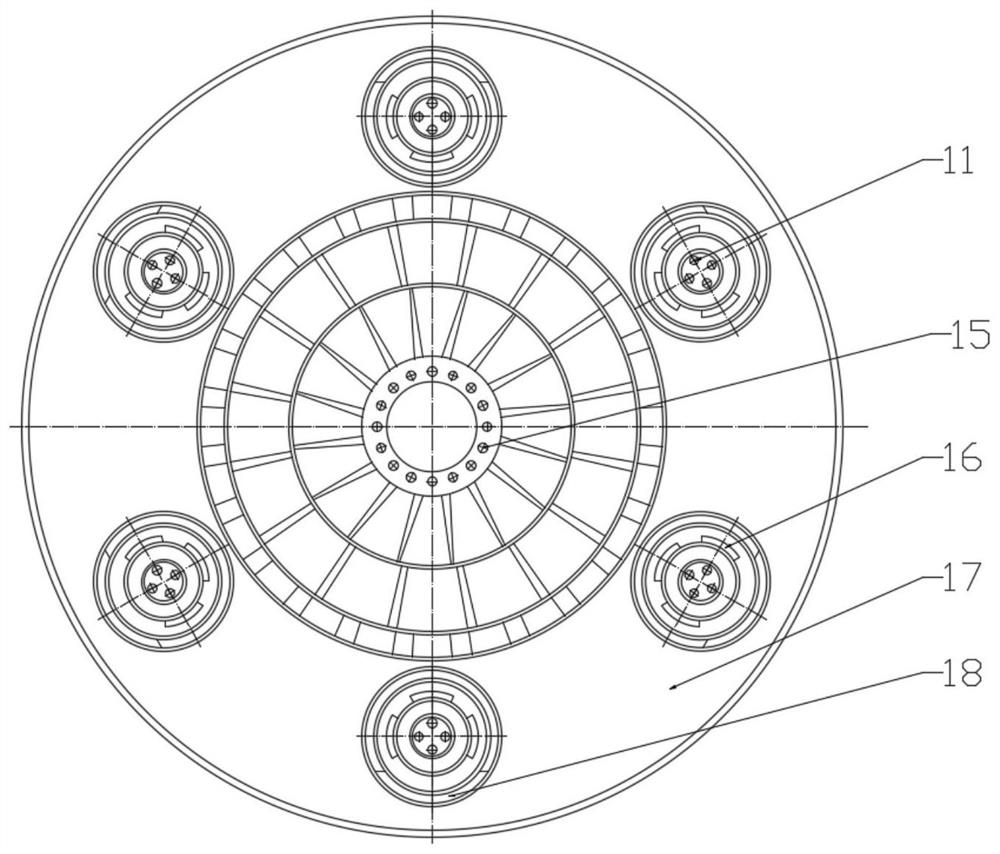

Tobacco pyrolysis and combustion reactor, analysis system and method

ActiveCN104267140AControl combustion temperatureControl burn timeChemical analysis using combustionTobacco devicesTarCoal tar

The invention belongs to the field of tobacco industry and relates to a tobacco pyrolysis and combustion reactor, an analysis system and a method. The tobacco pyrolysis and combustion reactor, the analysis system and the method have the benefits that the fast pyrolysis and combustion reaction of a lot of tobacco shreds under different atmosphere and different temperature conditions can be realized, and the online detection can be carried out on gas phase components like CO, CO2, O2 and H2 in flue gas; meanwhile, a Cambridge filter is used for collecting particle phase components, so that the generation situations of moisture, tar, nicotine, aroma components and / or other harmful components (NH3, HCN, phenol, crotonaldehyde, polycyclic aromatic hydrocarbon, benzopyrene and the like) can be obtained. Through the analysis system, an experimental platform is provided for the mechanism study on the generation of main flue gas components in the tobacco pyrolysis and combustion processes.

Owner:CHINA TOBACCO FUJIAN IND +1

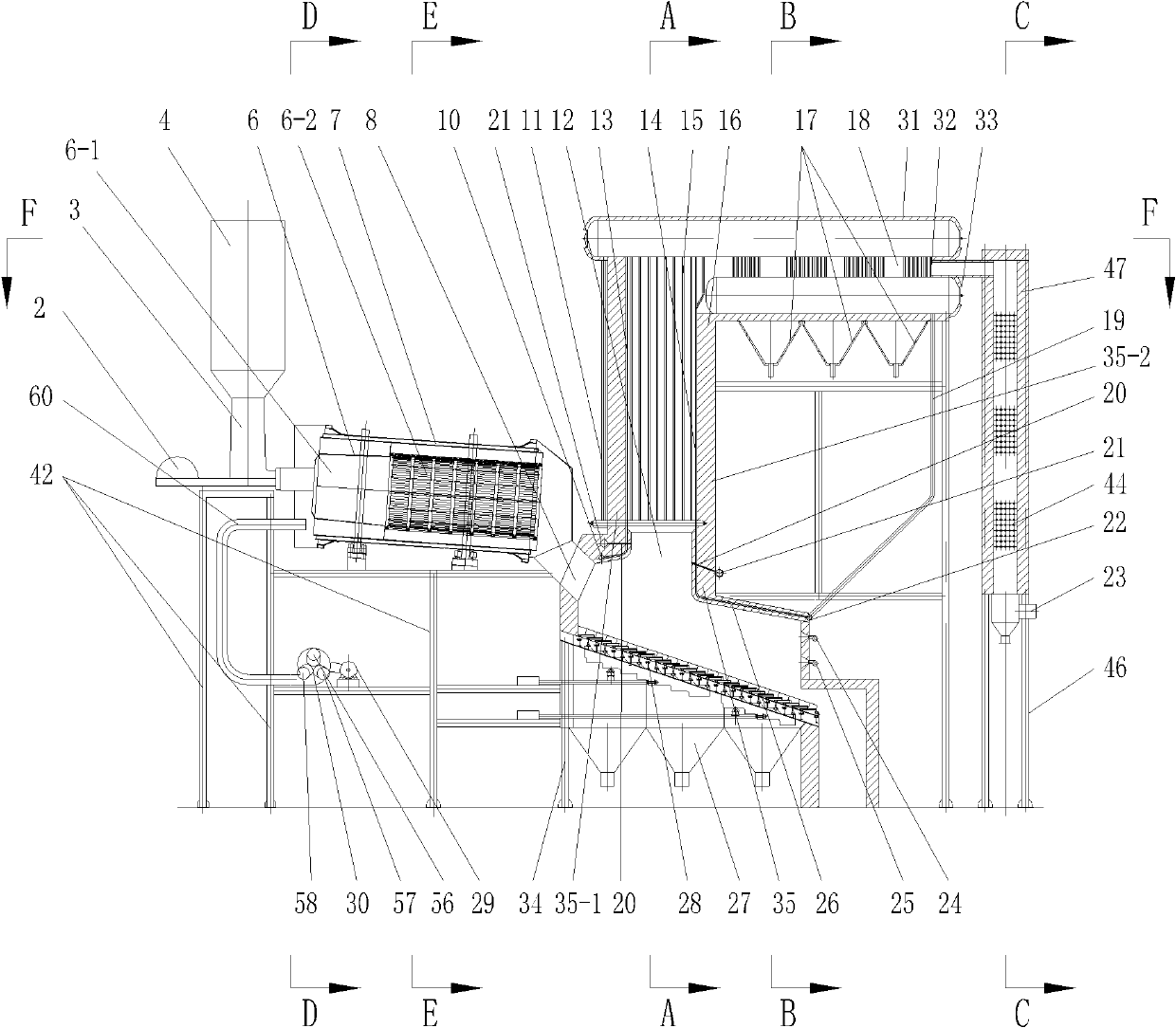

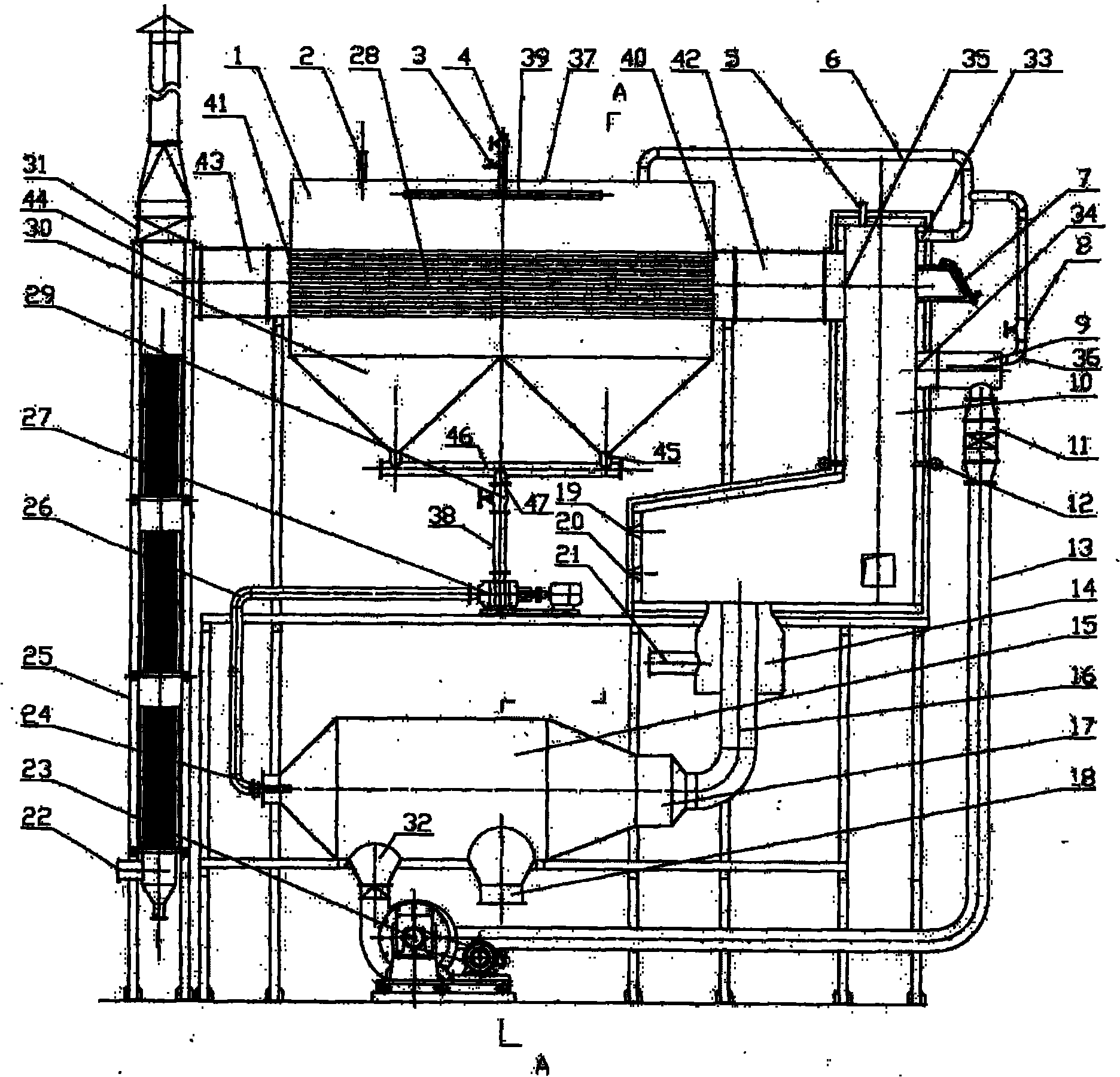

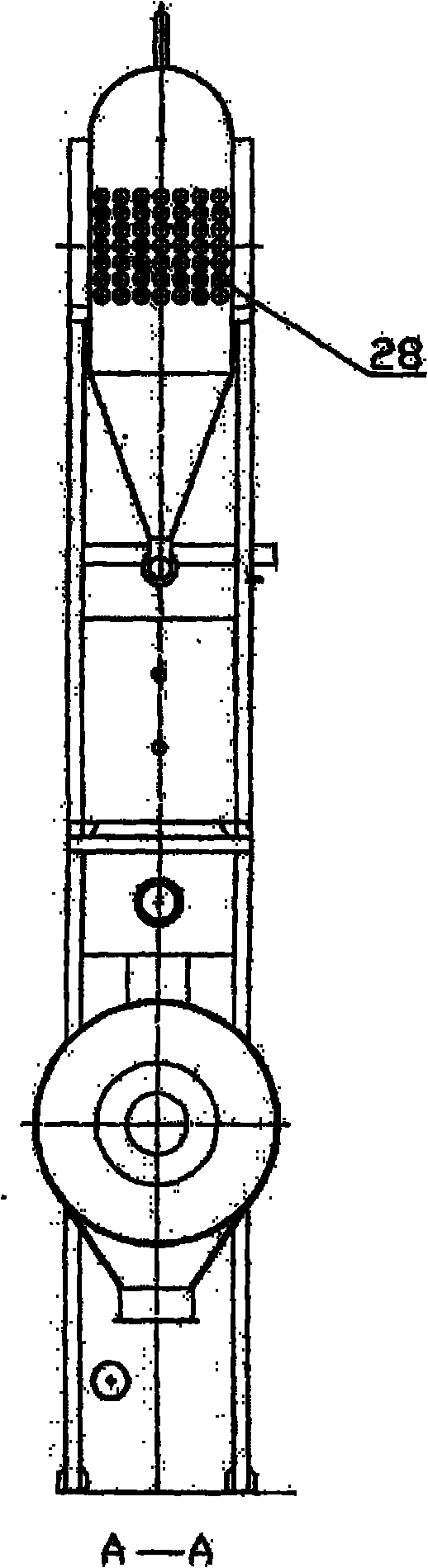

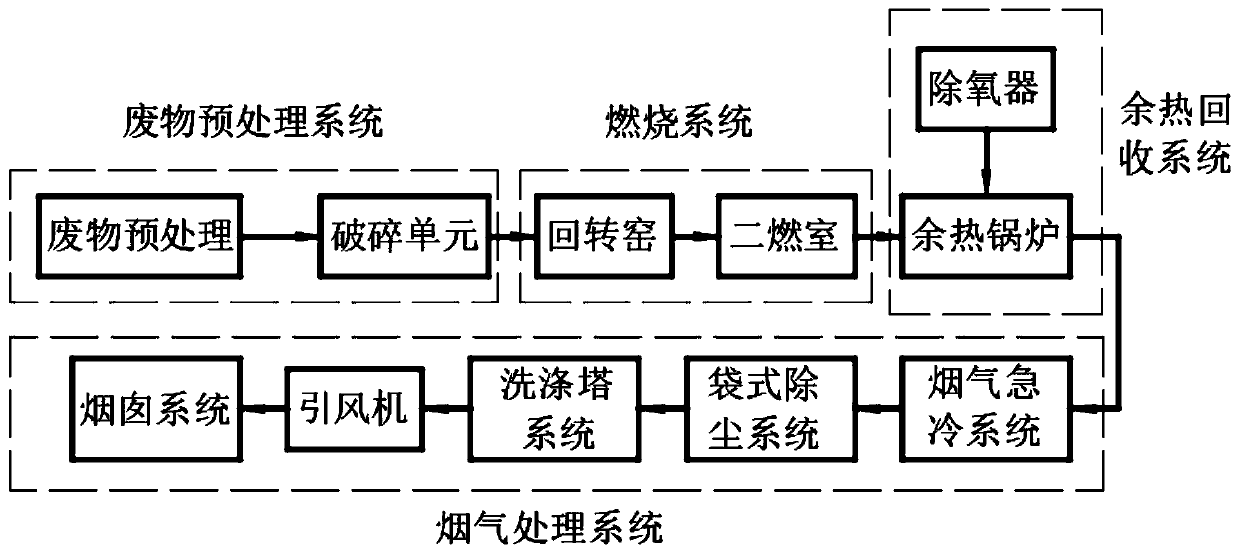

Three-dimensional hierarchical air supply combined waste incinerator

InactiveCN102168853ASmall granularityLow shape requirementIncinerator apparatusAir preheaterAir interface

The invention relates to a three-dimensional hierarchical air supply combined waste incinerator, in particular to a waste incinerator. The waste incinerator provided by the invention solves the problems of single function and narrow application range of the traditional waste incinerator. In the waste incinerator provided by the invention, the lower end of a feeding device is communicated with one end of a rotary drying pyrolysis device; the other end of the rotary drying pyrolysis device is communicated with a grate type incinerator; the feeding device and the rotary drying pyrolysis device are fixedly installed on a first bracket; two groups of secondary air spray pipes are both communicated with a secondary air main pipe; one group of the two groups of secondary air spray pipes is positioned above a rear arch and arranged on the outer side wall of a rear wall, and the other group of secondary air spray pipes are arranged at the lower end of a front wall; each group of secondary air spray pipes is communicated with a hearth; a high-temperature smoke interface is communicated with a horizontal flue through a pipeline; an intermediate-temperature smoke interface is communicated with a tail flue through a pipeline; and an air interface is communicated with the air outlet of an air preheater through a pipeline. The waste incinerator provided by the invention is used for incinerating waste.

Owner:HARBIN INST OF TECH

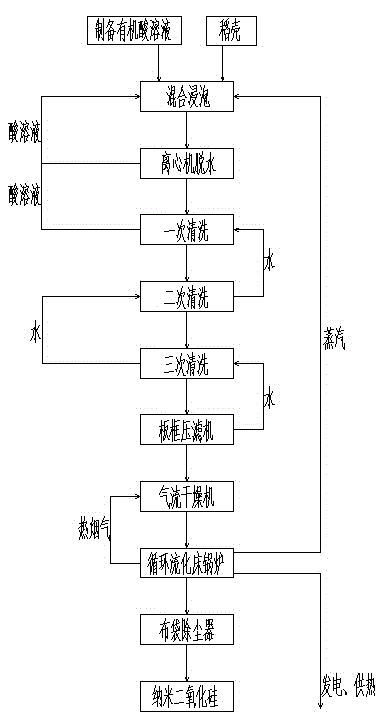

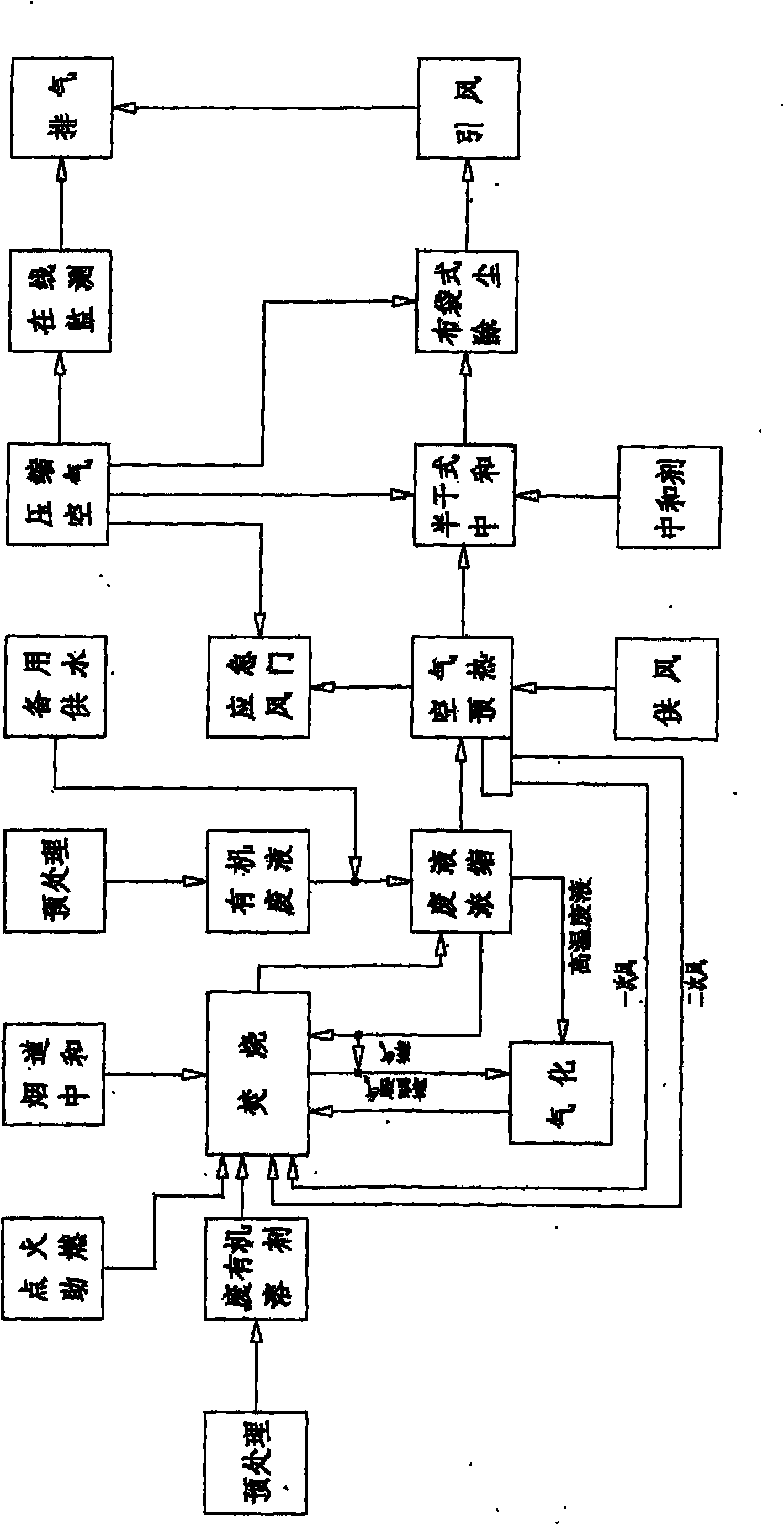

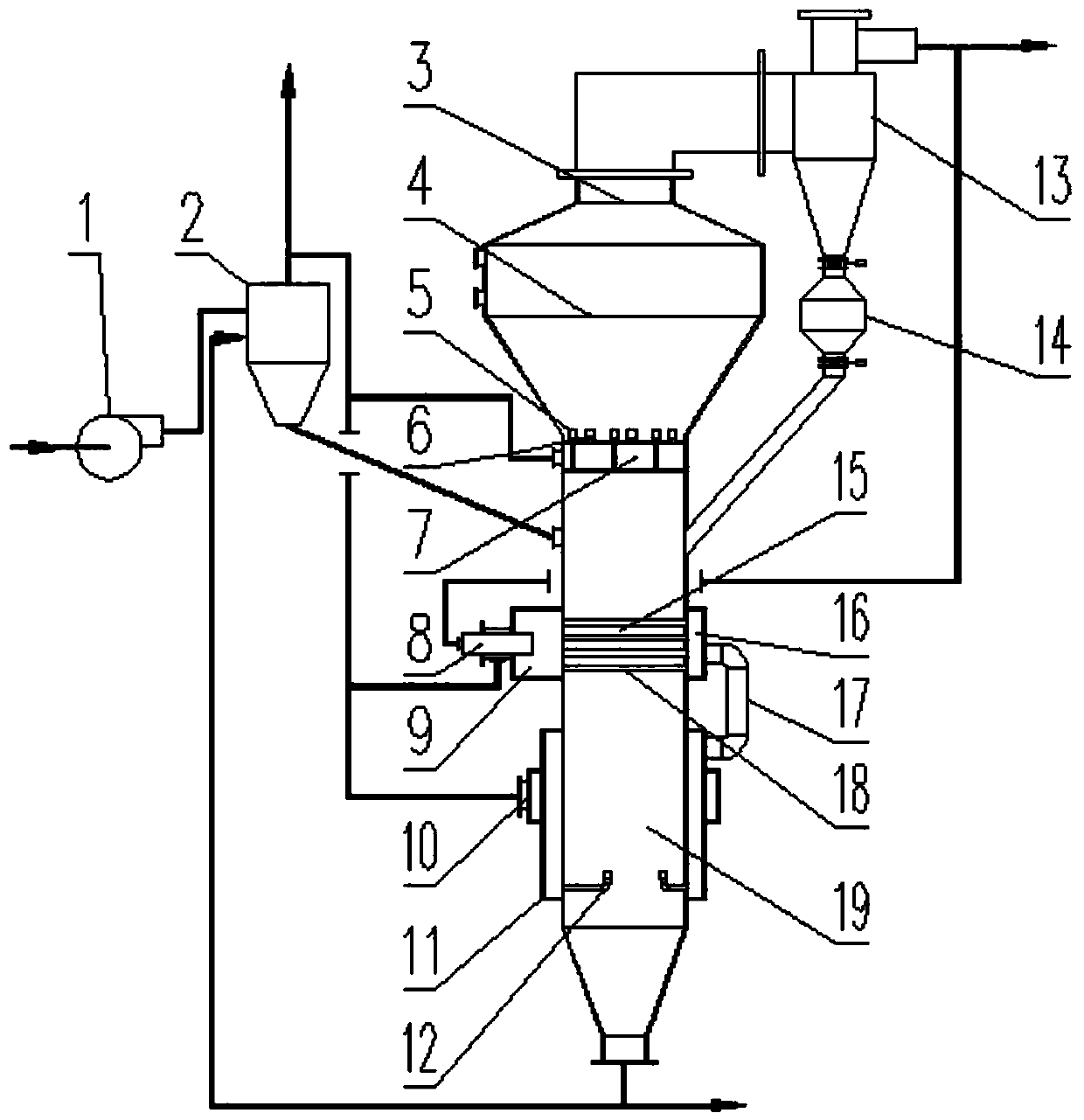

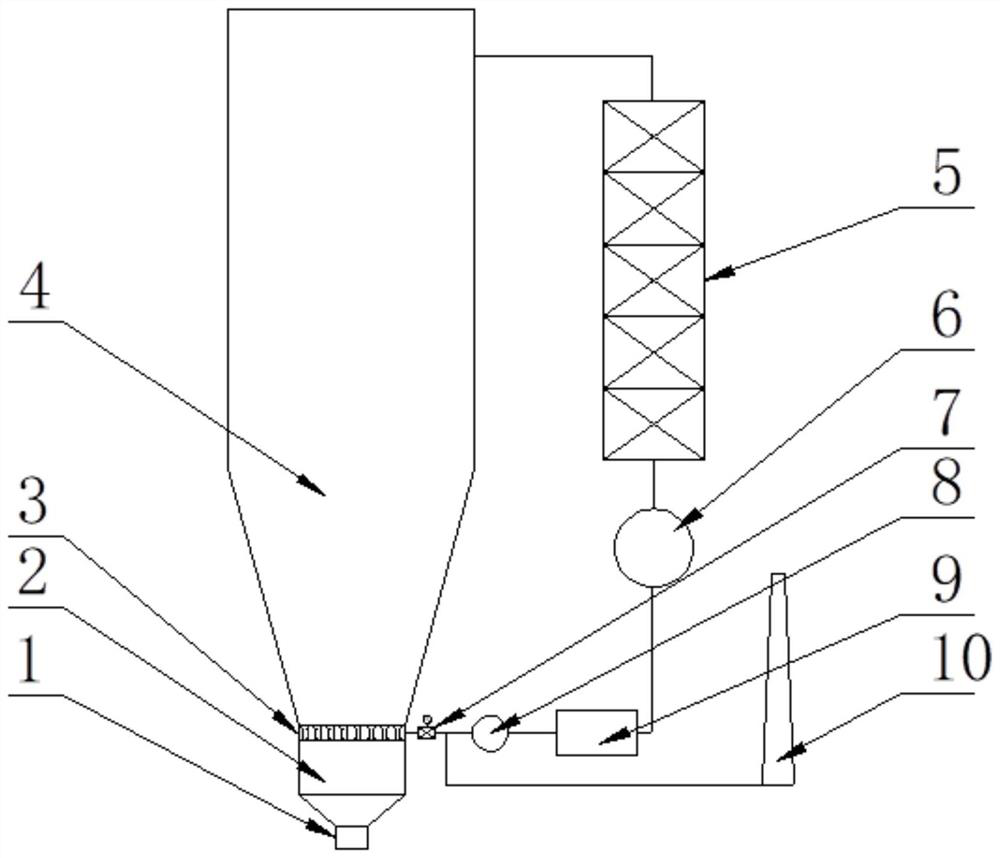

Method using circulating fluidized bed for rice hull organic acid pretreatment and combustion to prepare nanometer SiO2

InactiveCN104787770AReduce pollutionReduce manufacturing costMaterial nanotechnologySilicaOrganic acidFlue gas

The invention discloses a method using a circulating fluidized bed for rice hull organic acid pretreatment and combustion to prepare nanometer SiO2, belongs to the technical field of chemical engineering, and solves the problems in the existing method of utilizing the rice hulls to prepare high-purity silicon dioxide. The method comprises the following steps: step 1, preparing an organic acid solution for pretreating the rice hulls; step 2, placing the rice hulls into the organic acid solution to be soaked; step 3, utilizing a centrifugal machine to dehydrate the soaked rice hulls, and then using clear water to repeatedly clean the rice hulls; step 4, pumping the cleaned rice hulls and water together into a plate-and-frame filter press to be compressed and dehydrated until the moisture of the rice hulls is 30%; step 5, drying the rice hulls until the water content is 15% below; step 6, feeding the rice hulls into a circulating fluidized bed boiler to be combusted, feeding the rice hull ash after being burnt into a bag type dust remover along with the flue gas, and grinding the rice hull ash collected by the bag type dust remover, so as to obtain the nanoscale active silicon dioxide with the particle size of 50-80 nm and the purity of 98.0-99.6%. The method disclosed by the invention is used for preparing the nanometer SiO2.

Owner:HARBIN INST OF TECH

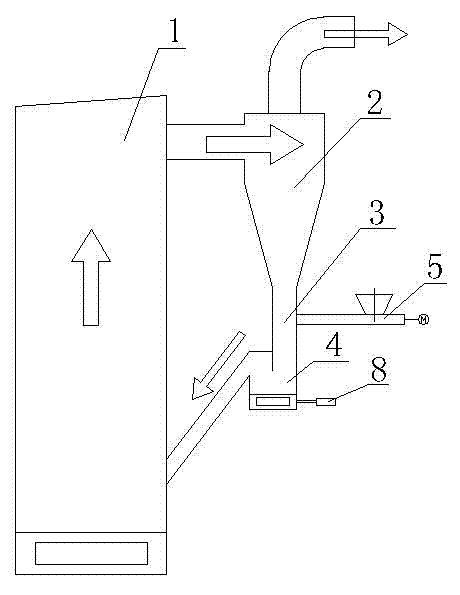

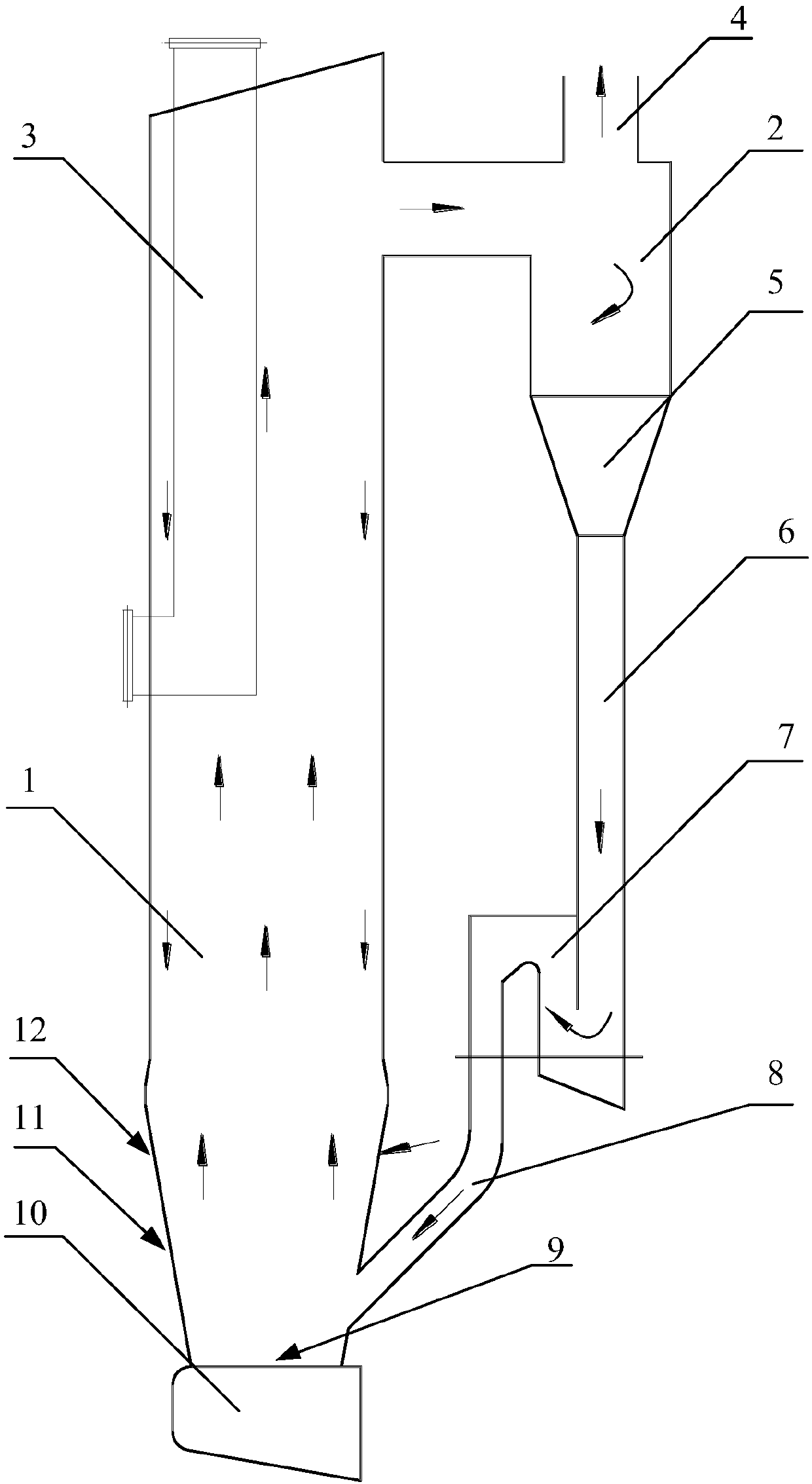

Method of reducing fly ash carbon content of circulating fluidized bed boiler

InactiveCN102927564AReduce carbon contentControl combustion temperatureFluidized bed combustionIndirect carbon-dioxide mitigationFlue gasFluidized bed

The invention discloses a method of reducing fly ash carbon content of a circulating fluidized bed boiler, wherein the method comprises the following steps when the circulating fluidized bed boiler comprises a hearth, a cyclone separator, a vertical pipe and a feedback device: 1) mounting a helical feeder on the upper part of the vertical part, and connecting an oxygen-enriched air generator at the air inlet chamber on the bottom part of the feedback device; and 2) when the circulating fluidized bed boiler operates, the helical feeder conveys the fly ash to the upper part of the vertical part, the fly ash enters the feedback device through the vertical pipe, the coke in the fly ash in the feedback device and the oxygen-enriched air generated by the oxygen-enriched air generator generate an oxygen-enriched combustion reaction, in the reaction, the percent by volume of the oxygen in the oxygen-enriched air is controlled to control the combustion temperature of the fly ash, and the fly ash and the flue gas return to the hearth after the reaction. The method disclosed by the invention can be applied on circulating fluidized bed boilers of burning inferior coal, and the method can greatly increase the combustion reaction speed and standing time of the coke in the fly ash in the high temperature region of the circulating fluidized bed boiler and greatly reduce the fly ash carbon content of the circulating fluidized bed boiler.

Owner:CHONGQING UNIV

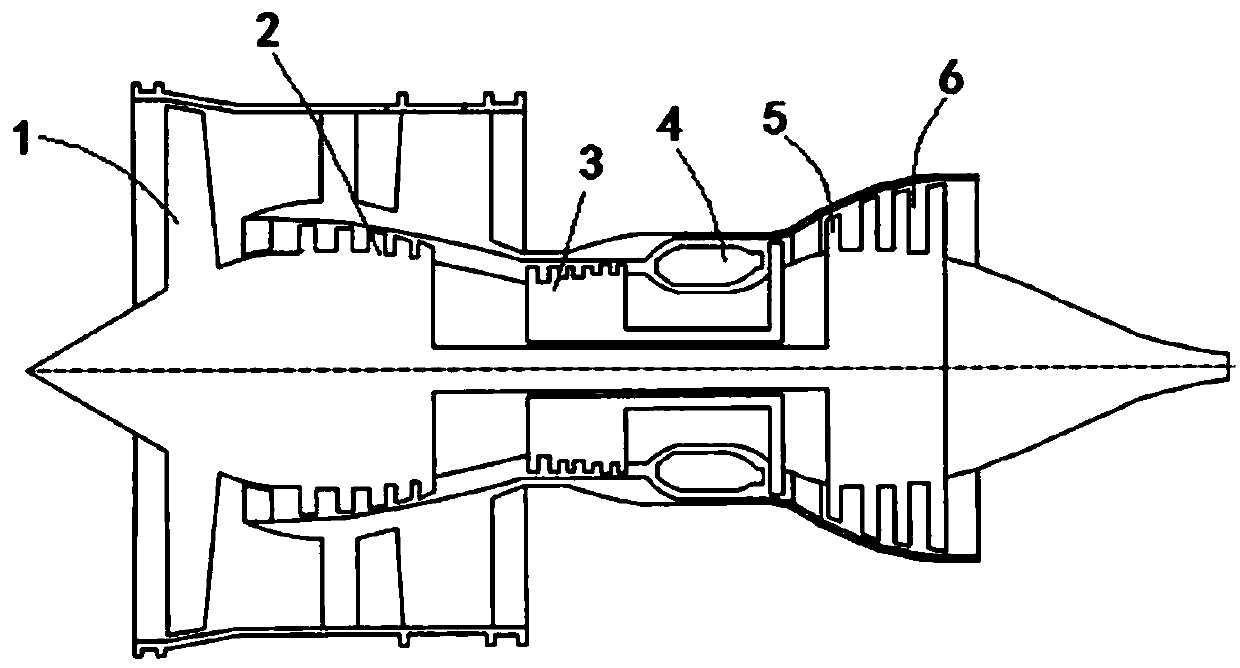

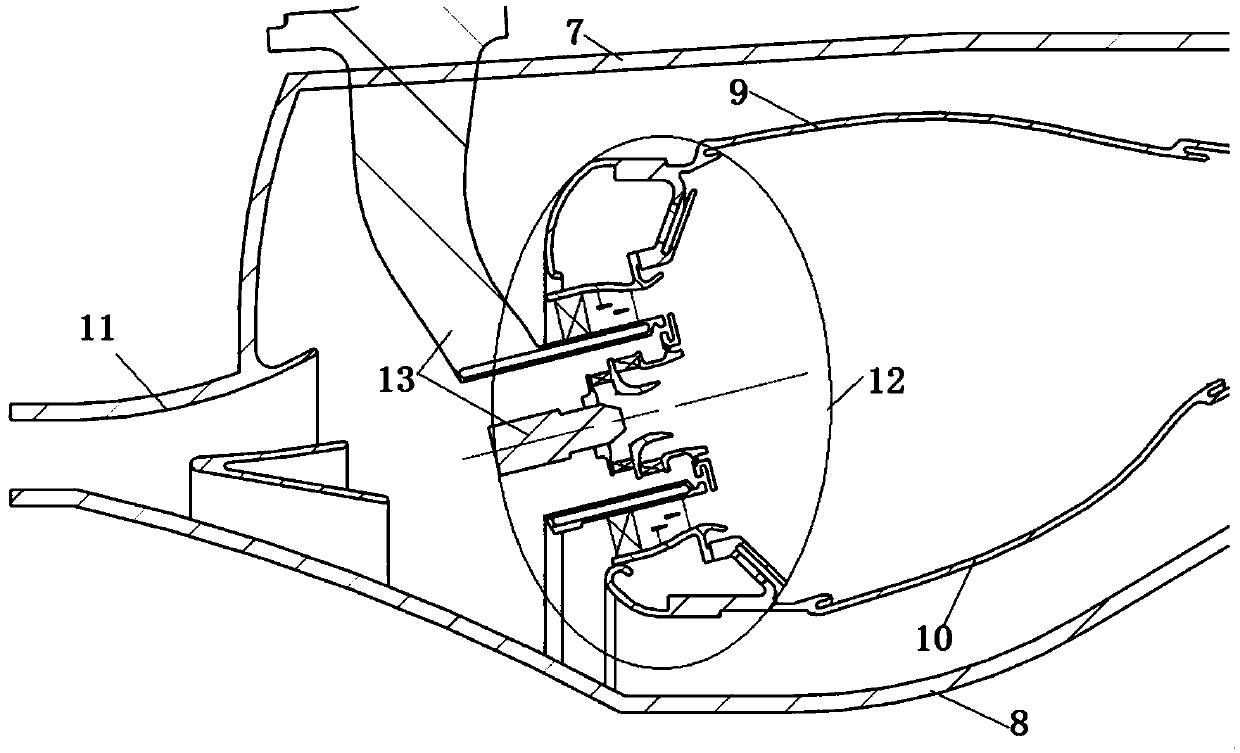

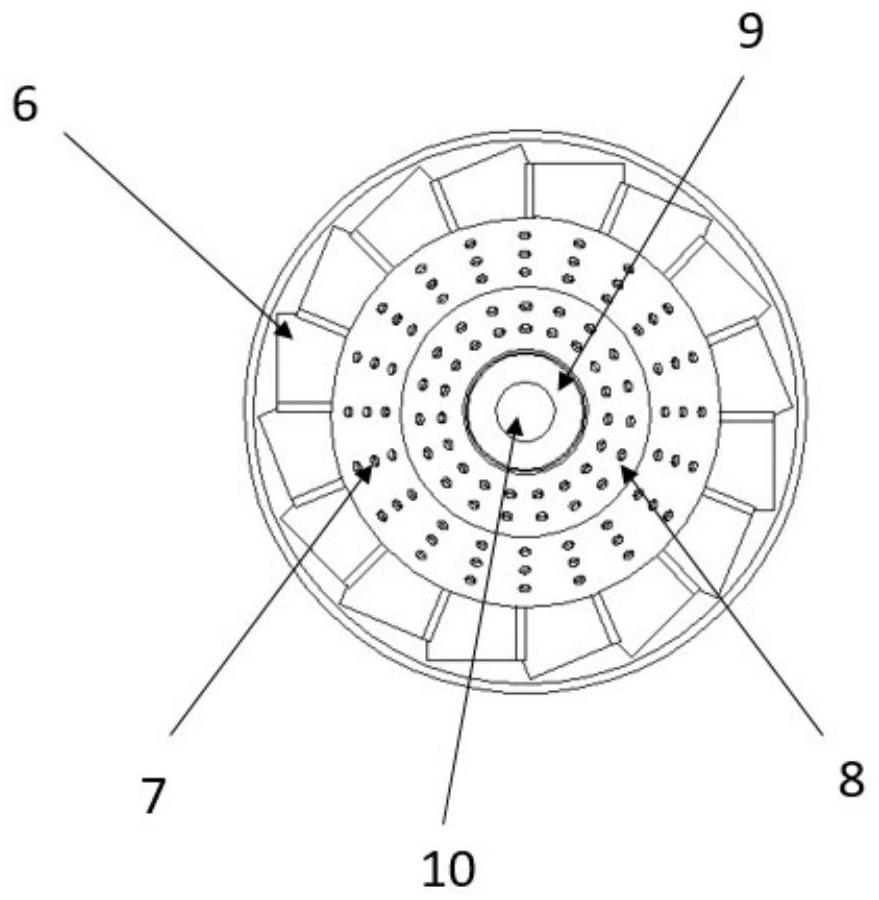

Low-pollution combustion chamber and combustion control method thereof

ActiveCN110657452ASmall penetration depthEvenly distributedBurnersContinuous combustion chamberCombustion chamberEngineering

The invention relates to a low-pollution combustion chamber and a combustion control method thereof. The low-pollution combustion chamber comprise a combustion chamber head, the combustion chamber head comprises a primary combustion stage and a pre-combustion stage, and the primary combustion stage comprises a primary combustion stage channel and a primary combustion stage swirler arranged in theprimary combustion stage channel. The low-pollution combustion chamber is characterized in that the primary combustion stage further comprises a pre-mold plate arranged in the primary combustion stagechannel, the pre-mold plate is divided into an outer-layer pre-mold plate and an inner-layer pre-mold plate in the radial direction, wherein the spraying point position and the spraying direction offuel oil of the primary combustion stage are arranged to control the primary combustion stage fuel oil to be sprayed into the primary combustion stage channel through a primary combustion stage fuel oil spray hole, the primary combustion stage direct-injection oil mist is partially formed, and the other part of the the primary combustion stage fuel oil is sprayed on the pre-mold plate close to theinner side of the primary combustion stage channel or sprayed on the two layers of pre-mold plates. Through cooperation of the double-layer pre-mold plate and the spraying point position and the spraying direction, and the combustible mixed gas is distributed more uniformly in a flame tube under different working conditions.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

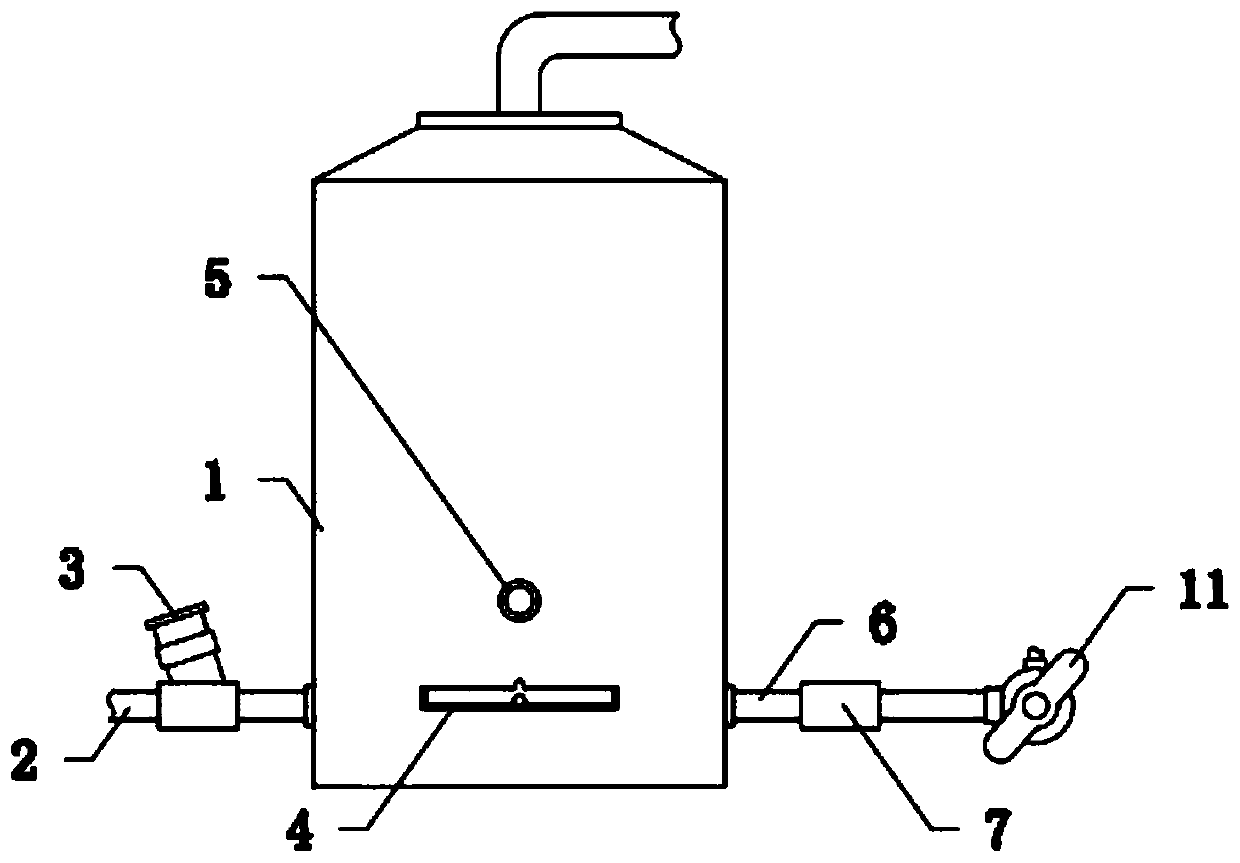

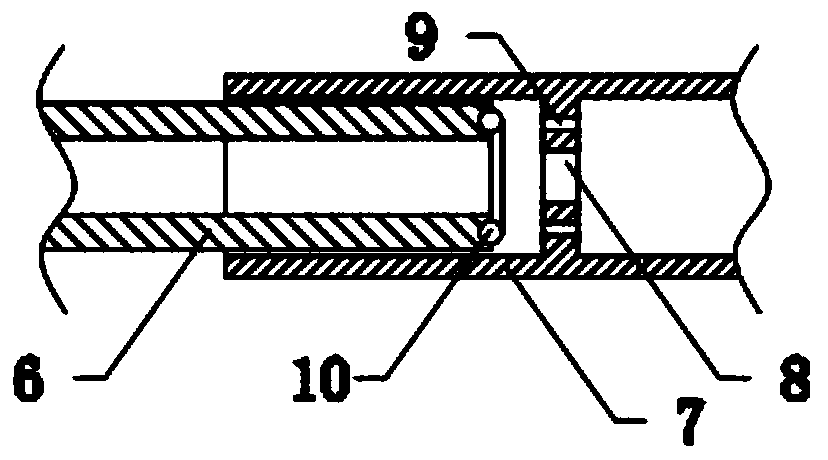

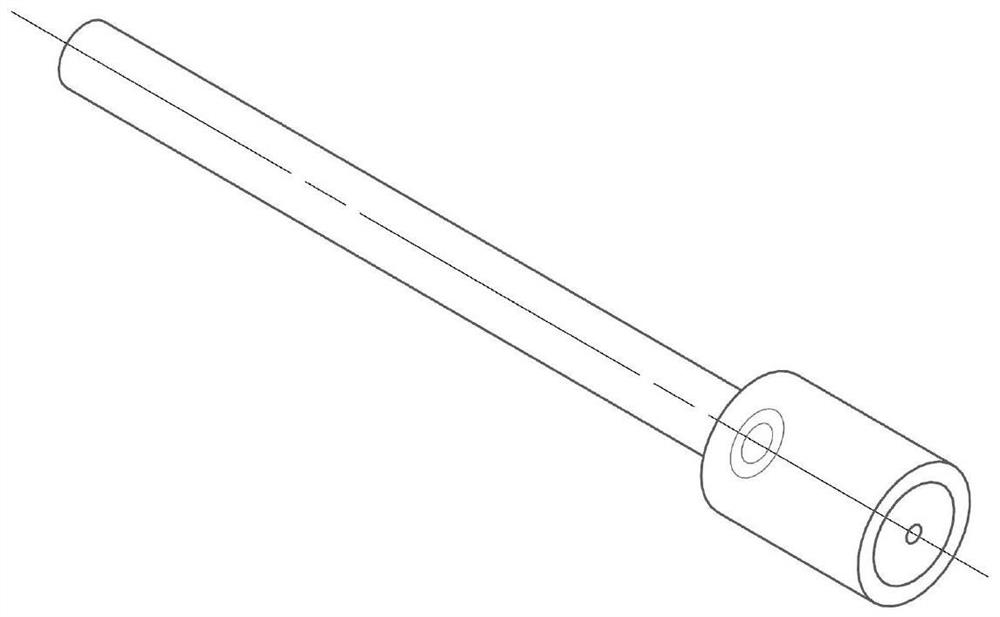

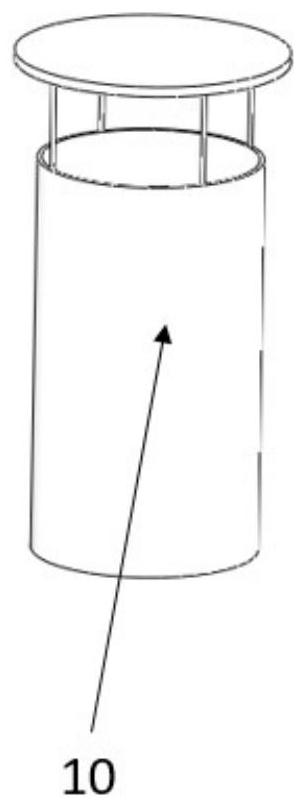

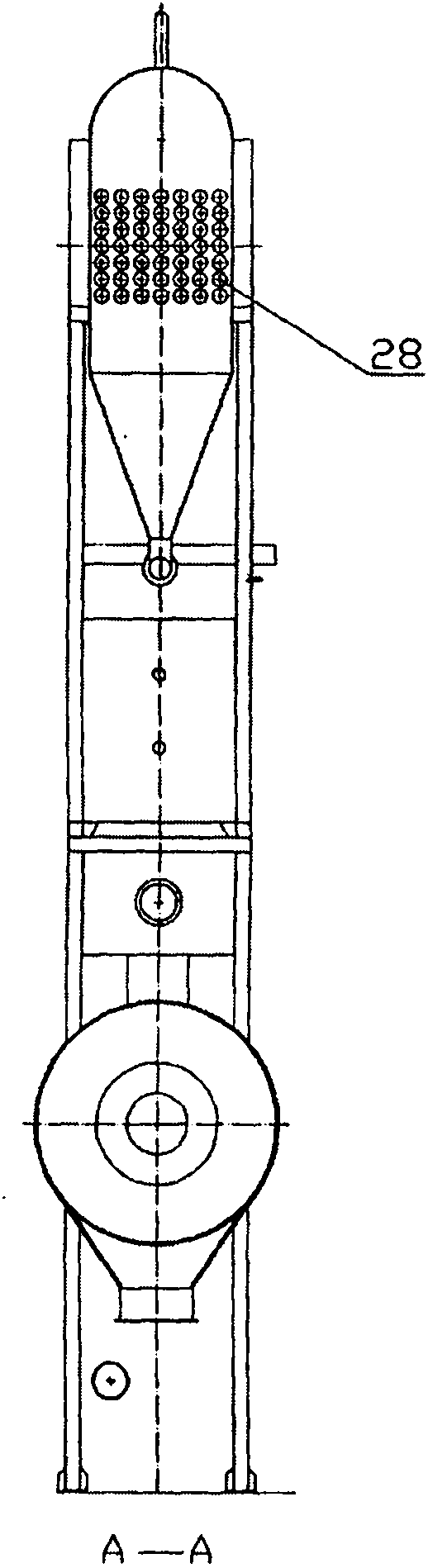

Flameless combustion chamber for Stirling engine and implementation method of flameless combustion chamber

PendingCN107883406AImprove uniformityImprove efficiencyContinuous combustion chamberIndirect carbon-dioxide mitigationStirling engineCombustion chamber

The invention discloses a flameless combustion chamber for a Stirling engine and an implementation method of the flameless combustion chamber. The flameless combustion chamber comprises a combustion chamber housing, a combustor and a heat exchanger; the housing consists of an upper housing part and a lower housing part; an exhaust pipe is arranged at the top of the housing; a heat exchanger barrelis arranged at the bottom of the housing; the lower housing part is connected with the top of the heat exchanger barrel into a whole; the top of the heat exchanger barrel, the lower housing part andthe upper housing part form a combustion chamber space; a hot cavity of the Stirling engine is formed in the lower end of the heat exchanger barrel; the top of the heat exchanger barrel separates thecombustion chamber from the hot cavity; the combustor and the heat exchanger are arranged in the housing from the top to the bottom sequentially; the heat exchanger comprises a circle of heat exchangepipes arranged in a reverse-U-shaped manner; and one ends of the heat exchange pipes communicate with the hot cavity of the Stirling engine, and the other ends of the heat exchange pipes communicatewith a reheater, thus a circuiting working medium system is formed. The implementation method comprises the step that the combustion chamber is used for combustion. The flameless combustion chamber and the implementation method have the characteristics that the combustion chamber is uniform in temperature, the combustion efficiency is high and the safety and reliability are achieved. The flamelesscombustion chamber is particularly suitable for the Stirling engine for use.

Owner:SHANGHAI MICROPOWERS

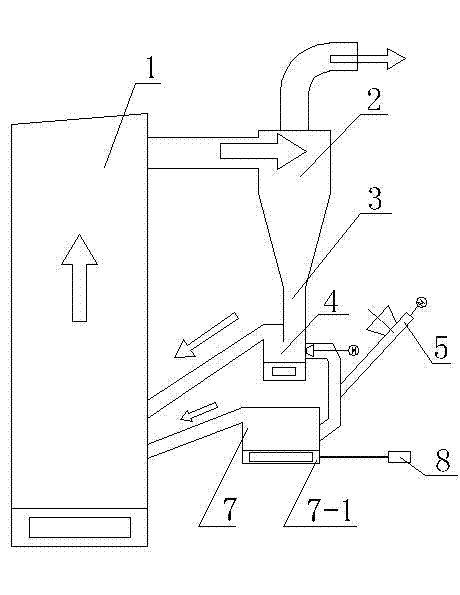

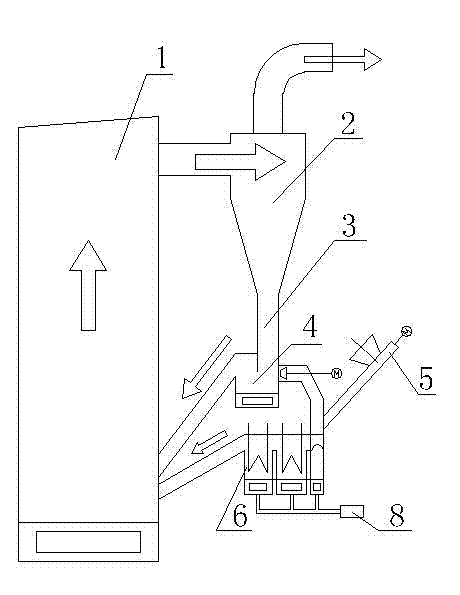

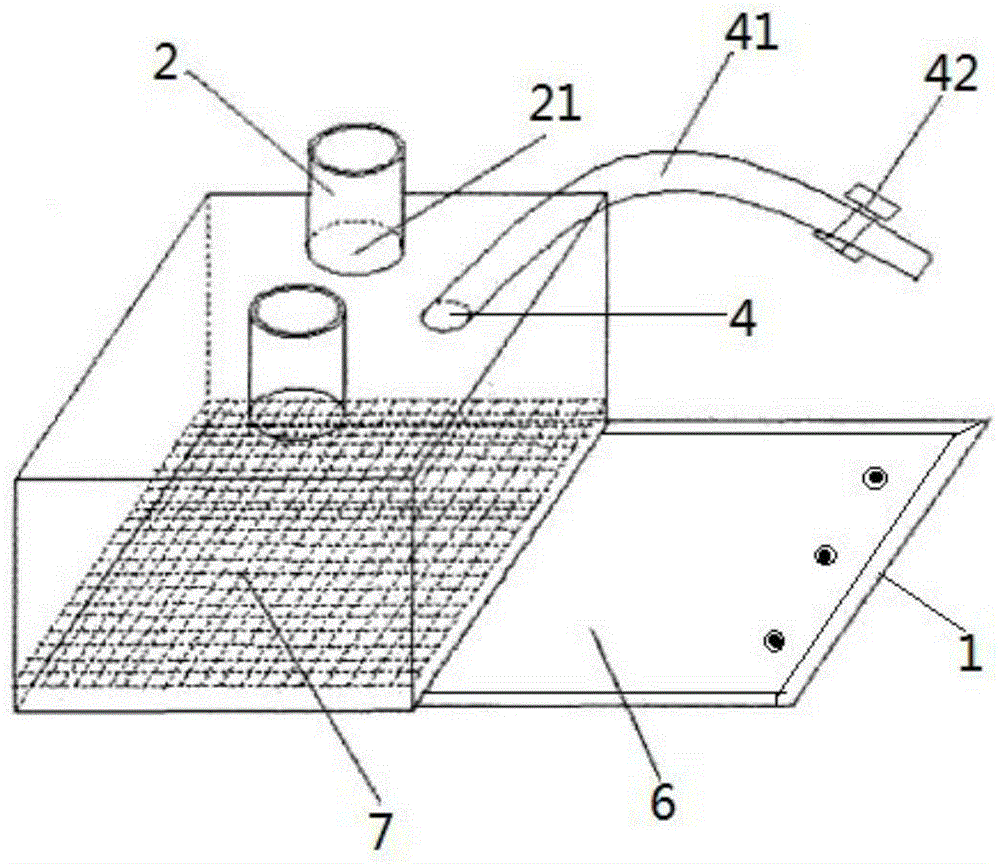

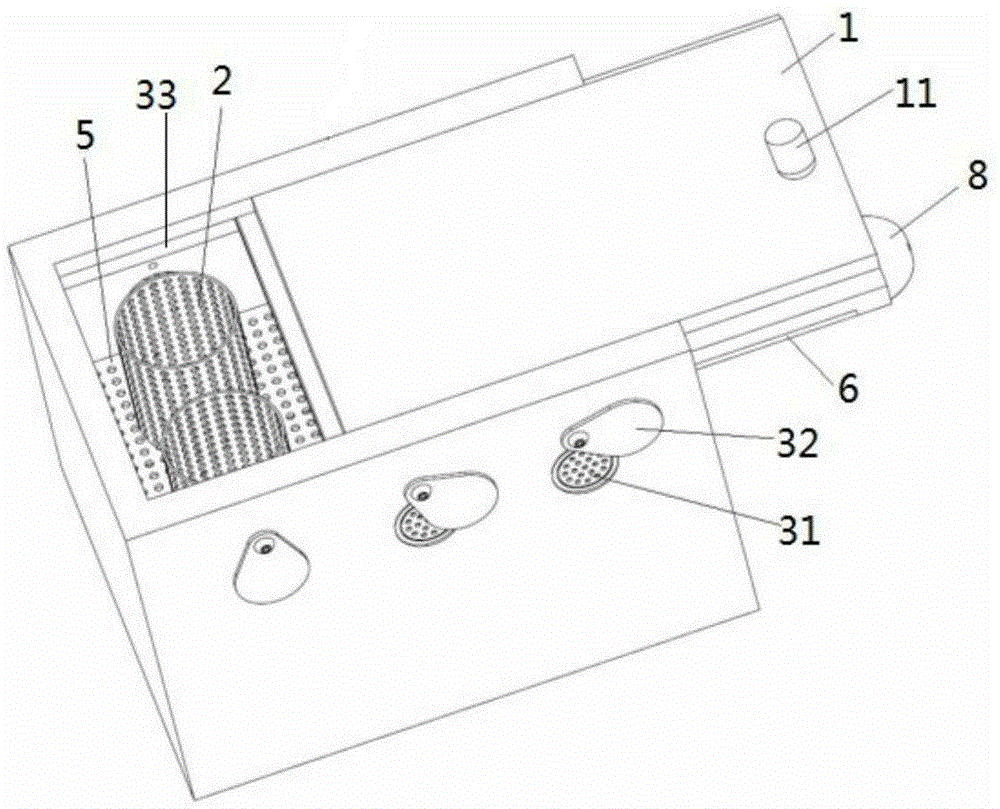

Moxibustion therapeutic apparatus

InactiveCN105287196AAccurate point and pointEasy to adjustDevices for heating/cooling reflex pointsCombination devicesEngineeringSmoke

The invention relates to a moxibustion therapeutic apparatus. The moxibustion therapeutic apparatus has the beneficial effects that the moxibustion therapeutic apparatus comprises a box; an opening is formed in the top surface of the box; a wind board is arranged at the opening; moxa insertion holes are formed in the bottom surface of the box; moxa stick sleeves used for placing moxa sticks penetrate through the moxa insertion holes; a plurality of heat adjusting holes are formed in the side of the box; accordingly, the moxibustion therapeutic apparatus can be suitable for large area moxibustion therapy, is accurate in determining acupoints at fixed points and convenient in adjustment and accurate control of temperature and is safe and reliable; further, a smoke vent is formed in the side of the box and a smoke discharge pipe is connected with the smoke vent and comprises an adjustable hose and a length adjustable smoke discharge support pipe connected with one end of the adjustable hose, thus forming s moxa smoke channel to effectively discharge moxa smoke.

Owner:SHANGHAI ZHENAI HEALTH CONSULTING

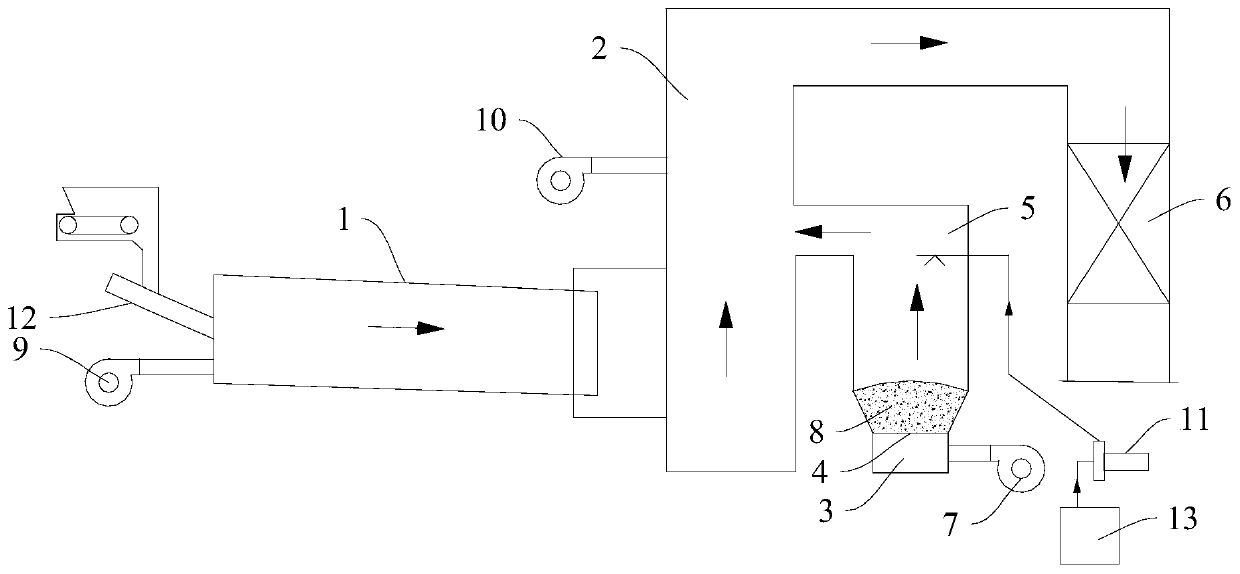

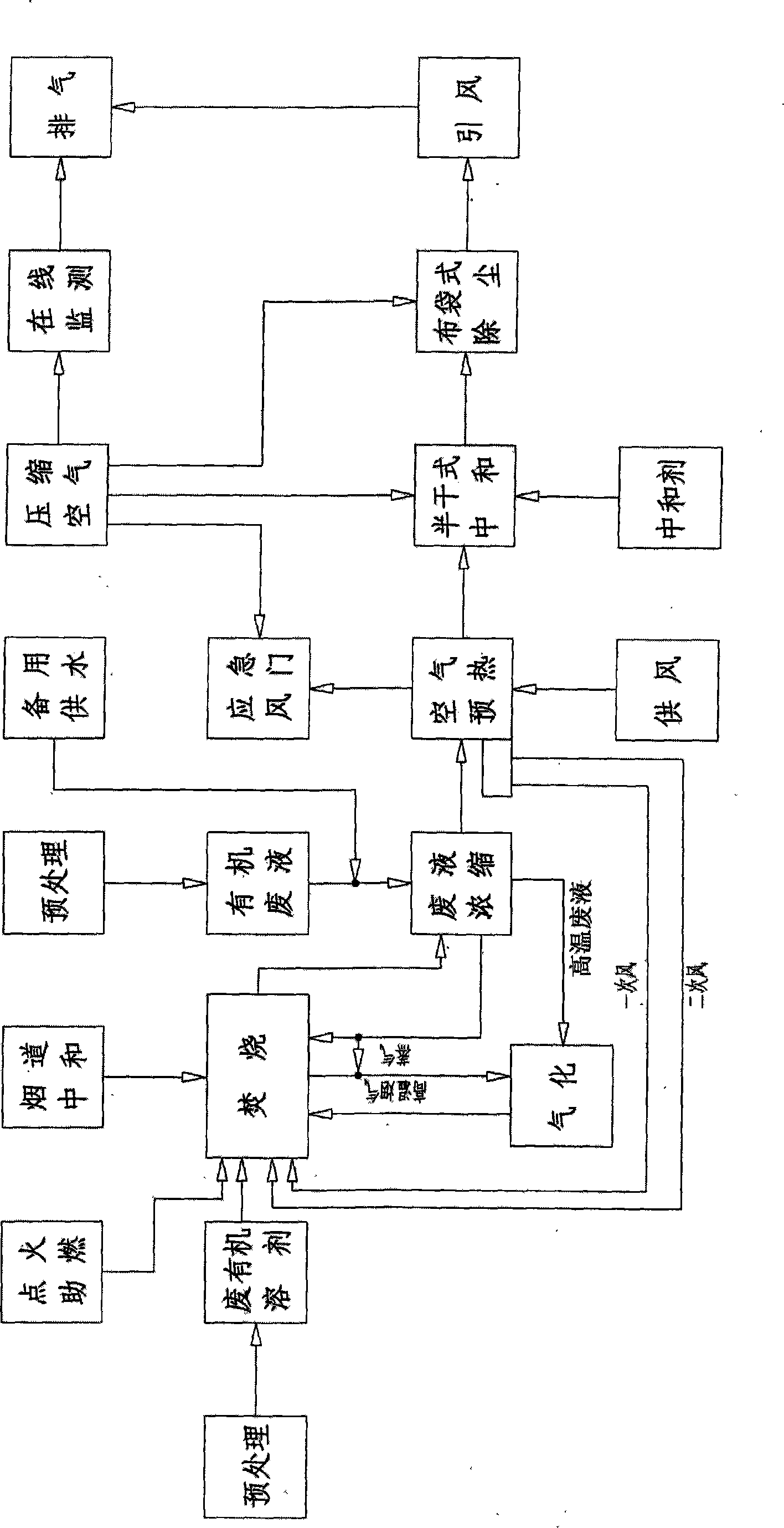

Processing method and device for incinerating toxic waste liquid by smoke concentration and gasification

ActiveCN102042602AControl combustion temperatureSuppress generationIncinerator apparatusLiquid wasteCooling effect

The invention discloses a processing method for incinerating toxic waste liquid by smoke concentration and gasification. The processing method comprises the following steps of: firstly, preprocessing a high-calorific value waste organic solvent and low-calorific value toxic waste liquid in the toxic waste liquid; delivering the high-calorific value waste organic solvent in an incinerator for burning through a waste organic solvent burner to generate high-temperature flue gas, concentrating the low-calorific value toxic waste liquid in the toxic waste liquid with the generated high-temperatureflue gas to form steam and concentrated high-temperature low-calorific value toxic waste liquid; and conveying the concentrated high-temperature low-calorific value toxic waste liquid subjected to gasification into the incinerator through a gas burner and burning together with the high-calorific value waste organic solvent. In the processing method, the burning temperature of the incinerator can be controlled more accurately to inhibit the generation of NOx. In the process of processing the low-calorific value toxic waste liquid, the waste heat of the incinerator is reasonably utilized by stages, the splat-cooling effect on the exhausted high-temperature flue gas is achieved at the same time, and the regeneration of toxic substances is inhibited. The invention also discloses a processing device used for the processing method.

Owner:上海煜工环保科技有限公司

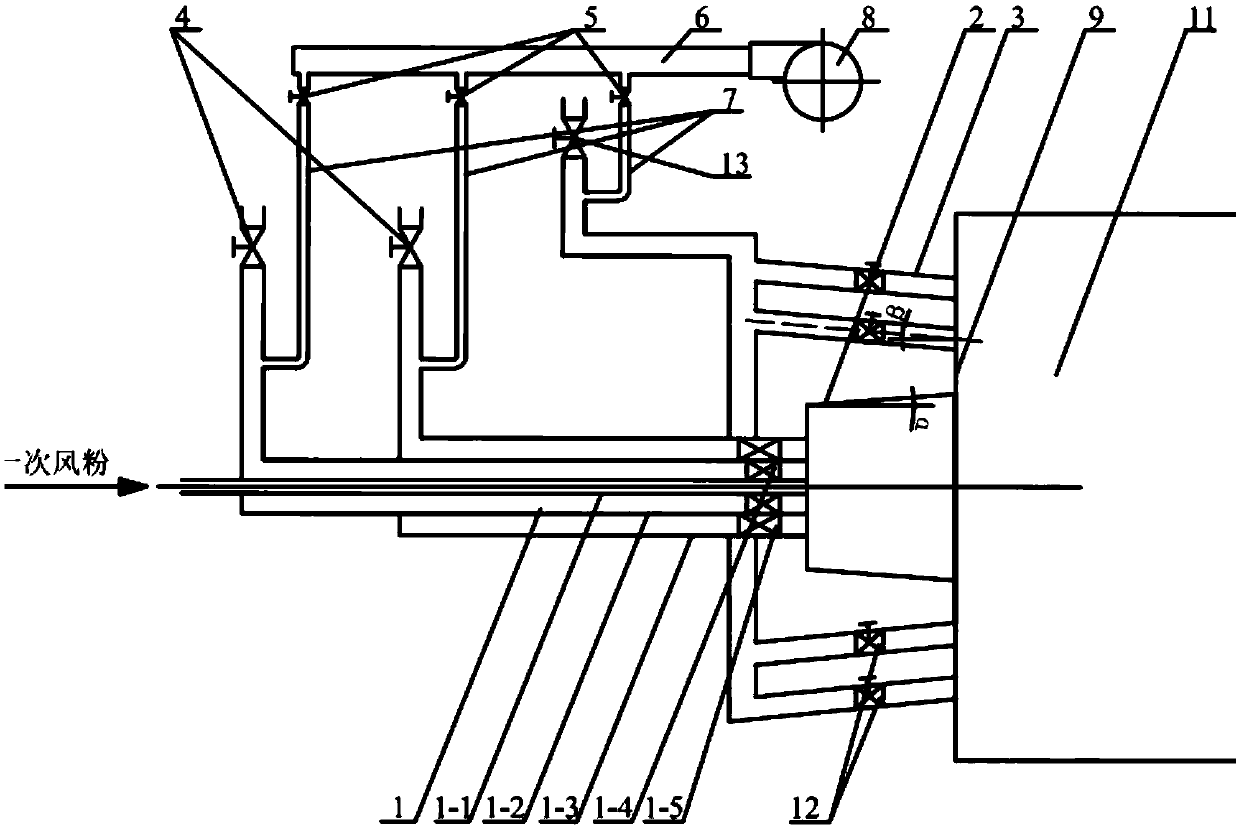

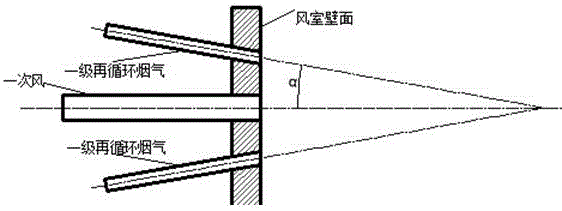

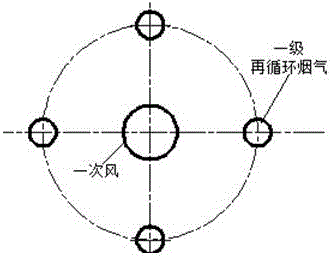

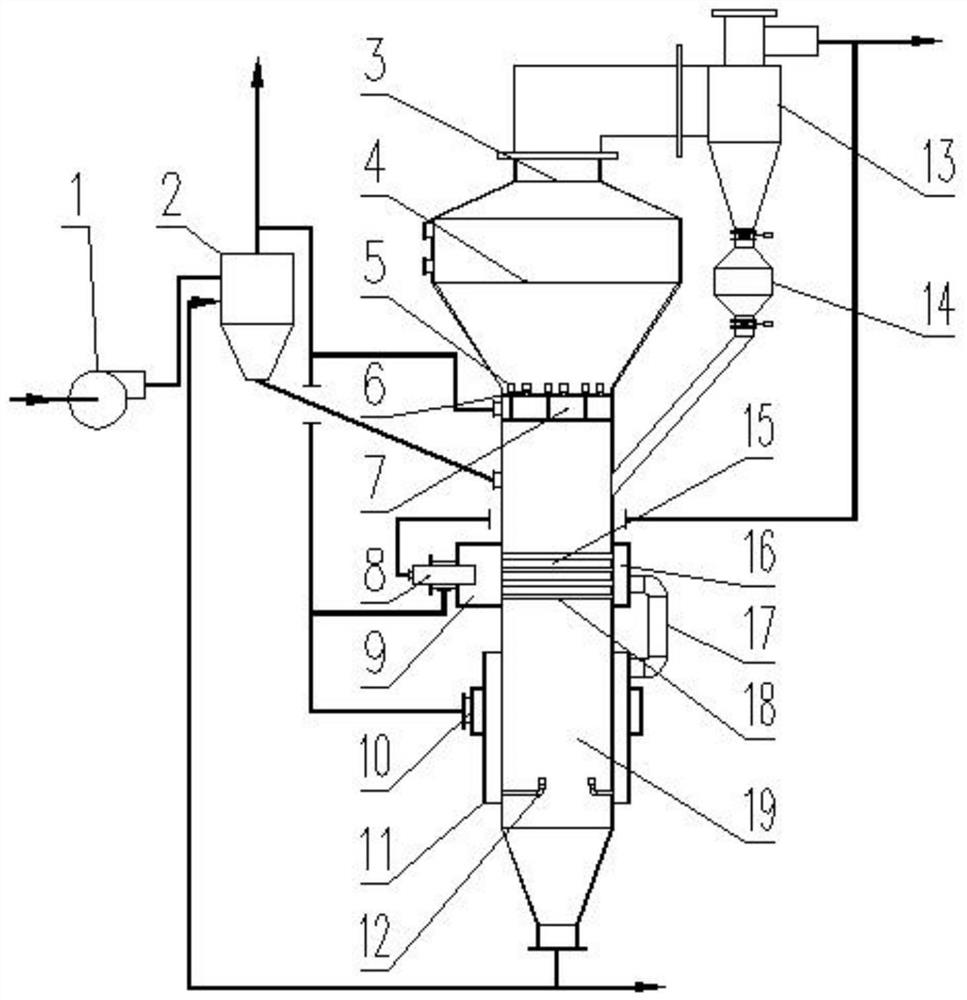

Swirling combustion device provided with pre-combustion chamber and adopting flue gas recirculation multiple radial grading

InactiveCN109631023AReduce generationControl combustion temperaturePulverulent fuel combustion burnersCombustion apparatusCombustion systemCombustion chamber

The invention relates to a swirling combustion device, in particular to a swirling combustion device provided with a pre-combustion chamber and adopting flue gas recirculation multiple radial grading.The problems of poor low-load stable combustion performance, high NOx emission, high fly ash combustible matter content and serious slagging of an industrial pulverized coal boiler at present are solved. The swirling combustion device comprises a pulverized coal combustion system and a flue gas recirculation system, the pulverized coal combustion system comprises a swirling pulverized coal burner, the pre-combustion chamber and a plurality of separation air spraying openings, the flue gas recirculation system comprises a recirculation flue gas pipeline valve, a recirculation flue gas pipeline, a recirculation flue gas branch pipeline and a recirculation fan, the swirling pulverized coal burner is arranged on a boiler through the pre-combustion chamber, the swirling pulverized coal burnercomprises a primary air pipe, a swirling inner secondary air pipe, a swirling outer secondary air pipe, a secondary air pipeline valve and a separation air pipeline valve, one end of the swirling inner secondary air pipe is mounted in one end of the primary air pipe in an inserted mode, and one end of the swirling outer secondary air pipe is mounted in the other end of the swirling inner secondaryair pipe in an inserted mode. The invention belongs to the field of industrial boiler equipment.

Owner:HARBIN INST OF TECH

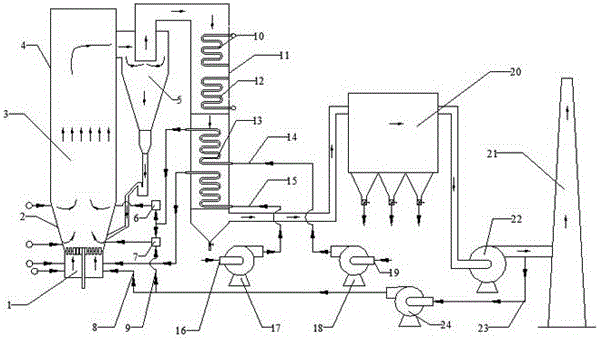

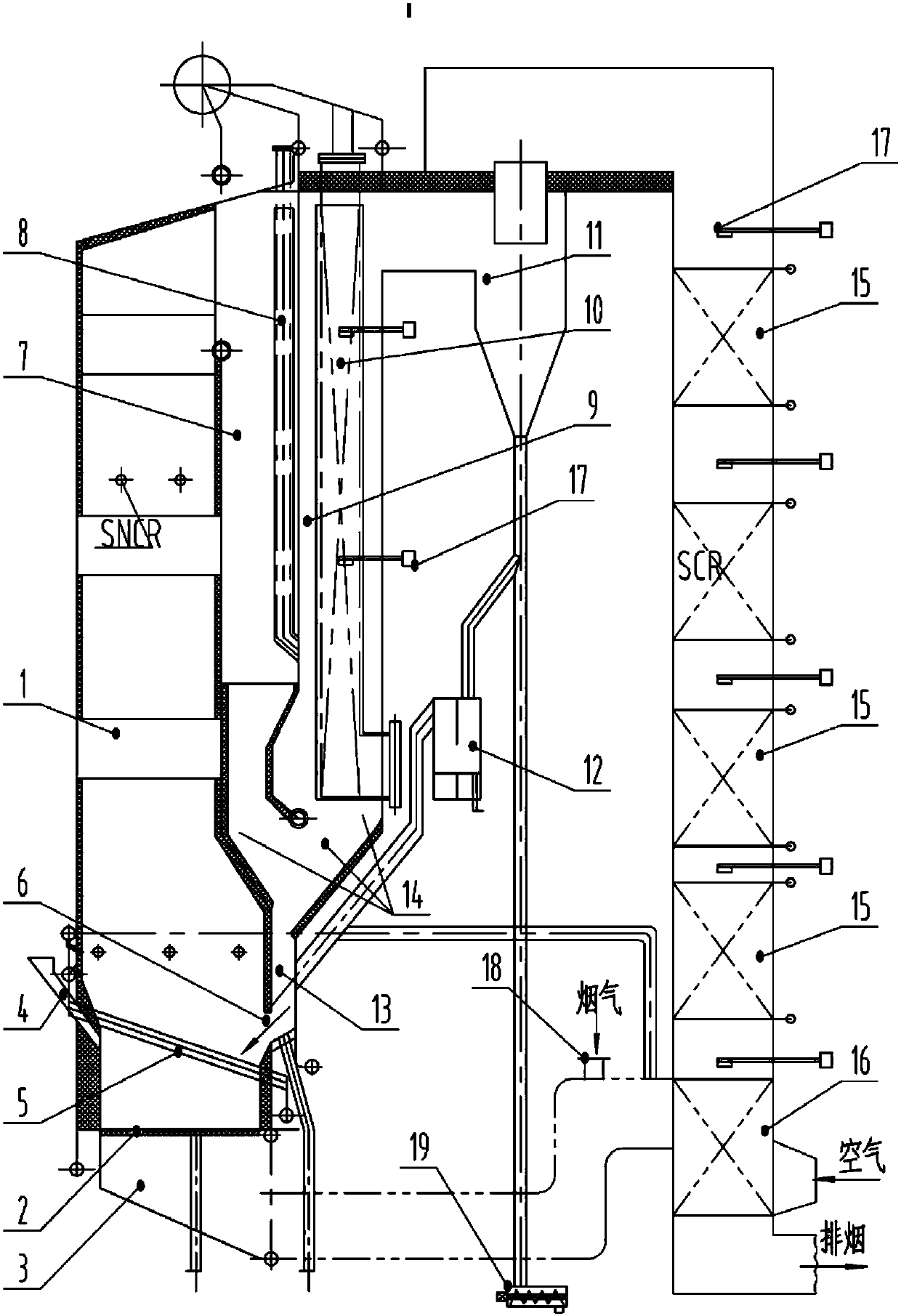

Low-nitrogen combustion device for fluidized bed boiler

ActiveCN106642090AImprove temperature distribution uniformityReduce burning intensityFluidized bed combustionStaged combustionFlue gasCoupling

The invention relates to a low-nitrogen combustion device for a fluidized bed boiler. According to the principle of oxynitride generation, through coupling of air staging and recycled flue gas staging technologies, a combustion area with three stages of the strong reducing property, the weak reducing property and oxidability is formed in the height direction of a hearth, meanwhile, the combustion intensity of a dense-phase area of the hearth is remarkably alleviated, the combustion temperature of the dense-phase area of the hearth is controlled, the distribution uniformity of the overall temperature of the hearth is improved, and generation of temperature type oxynitride is restrained; and meanwhile, generation of fuel type oxynitride is greatly lowered, and generated oxynitride can be restored into nitrogen.

Owner:BEIJING CPCEP ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

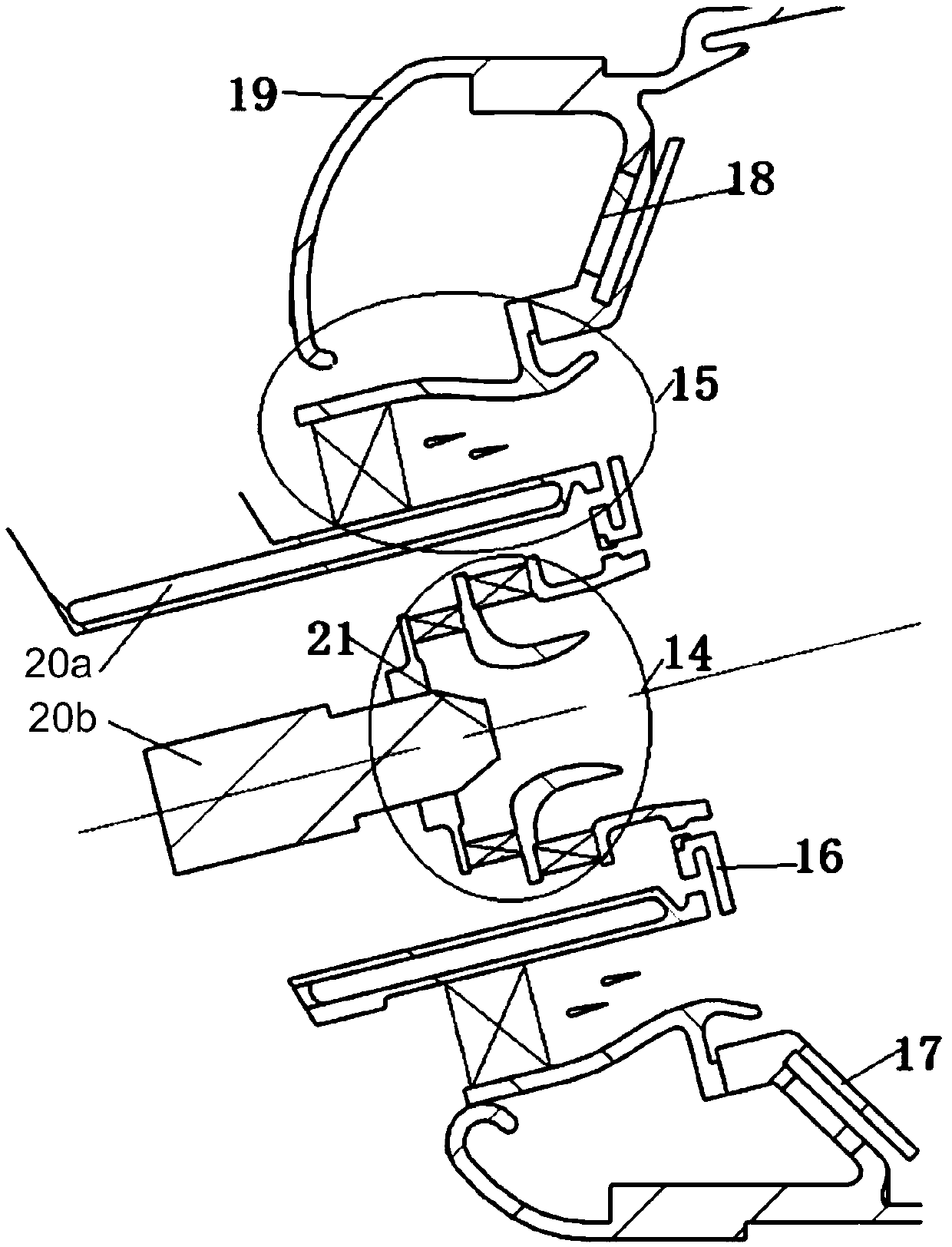

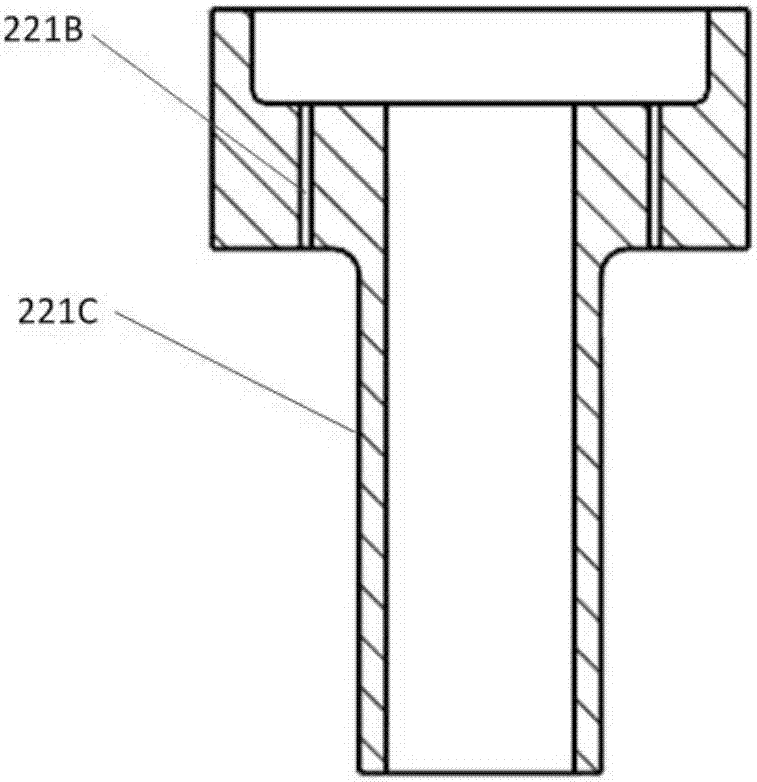

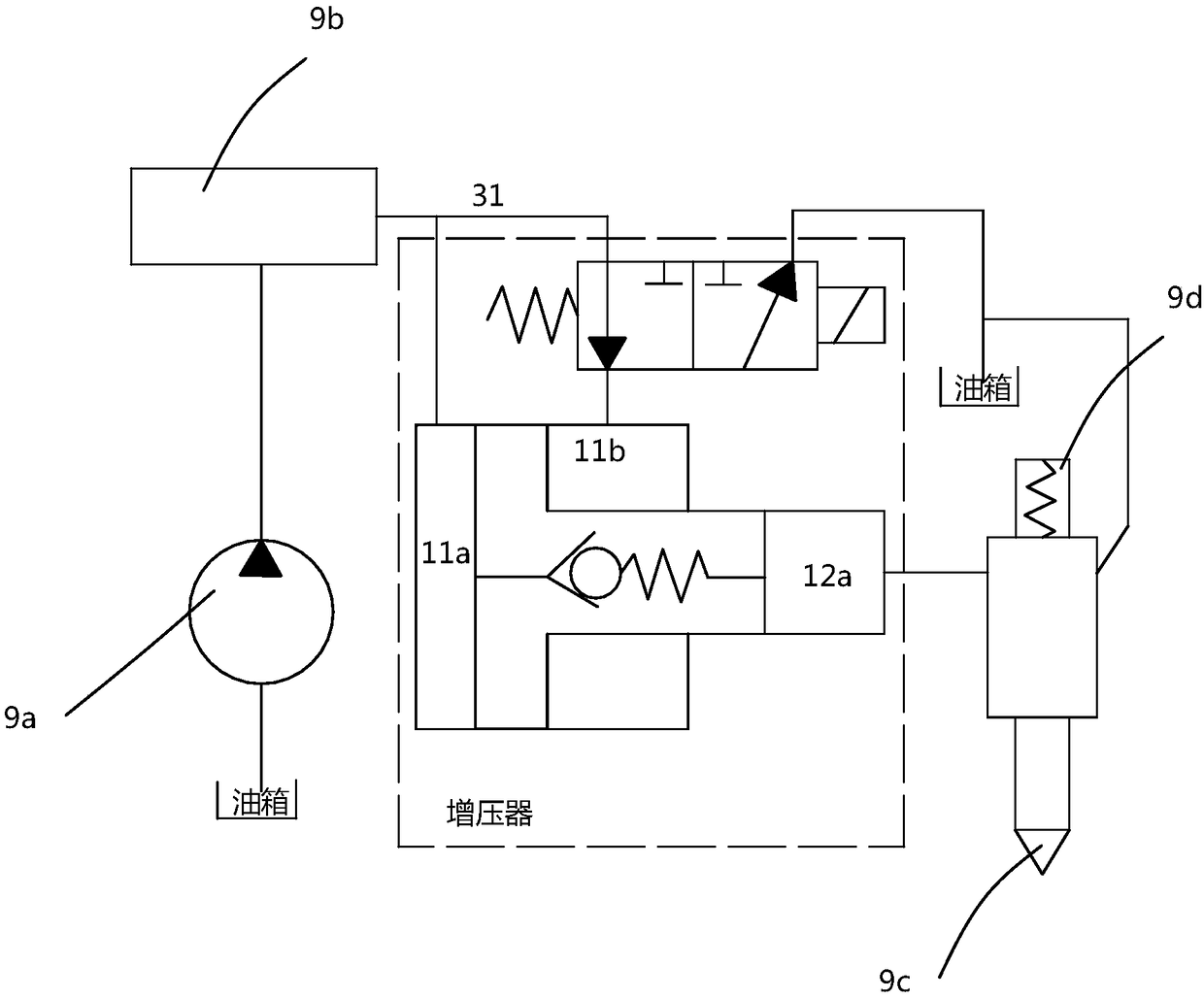

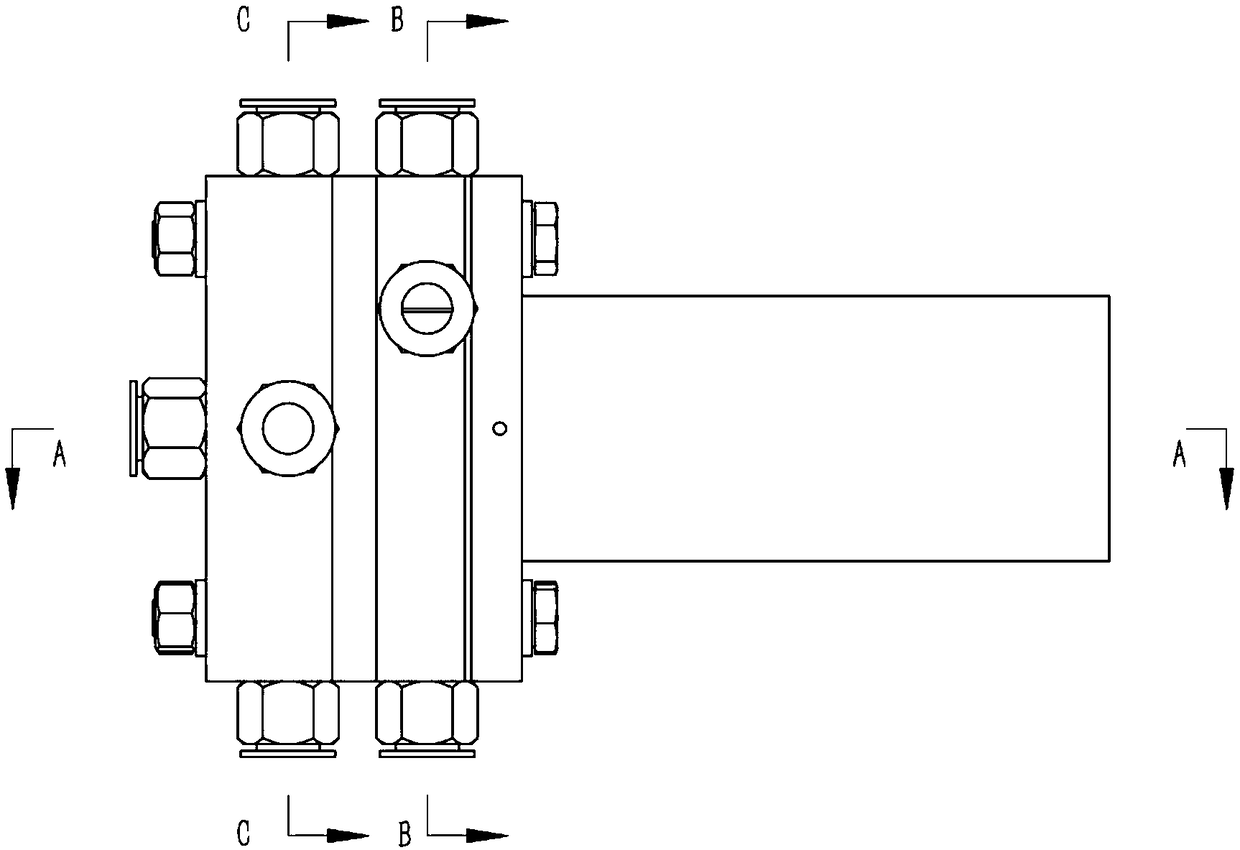

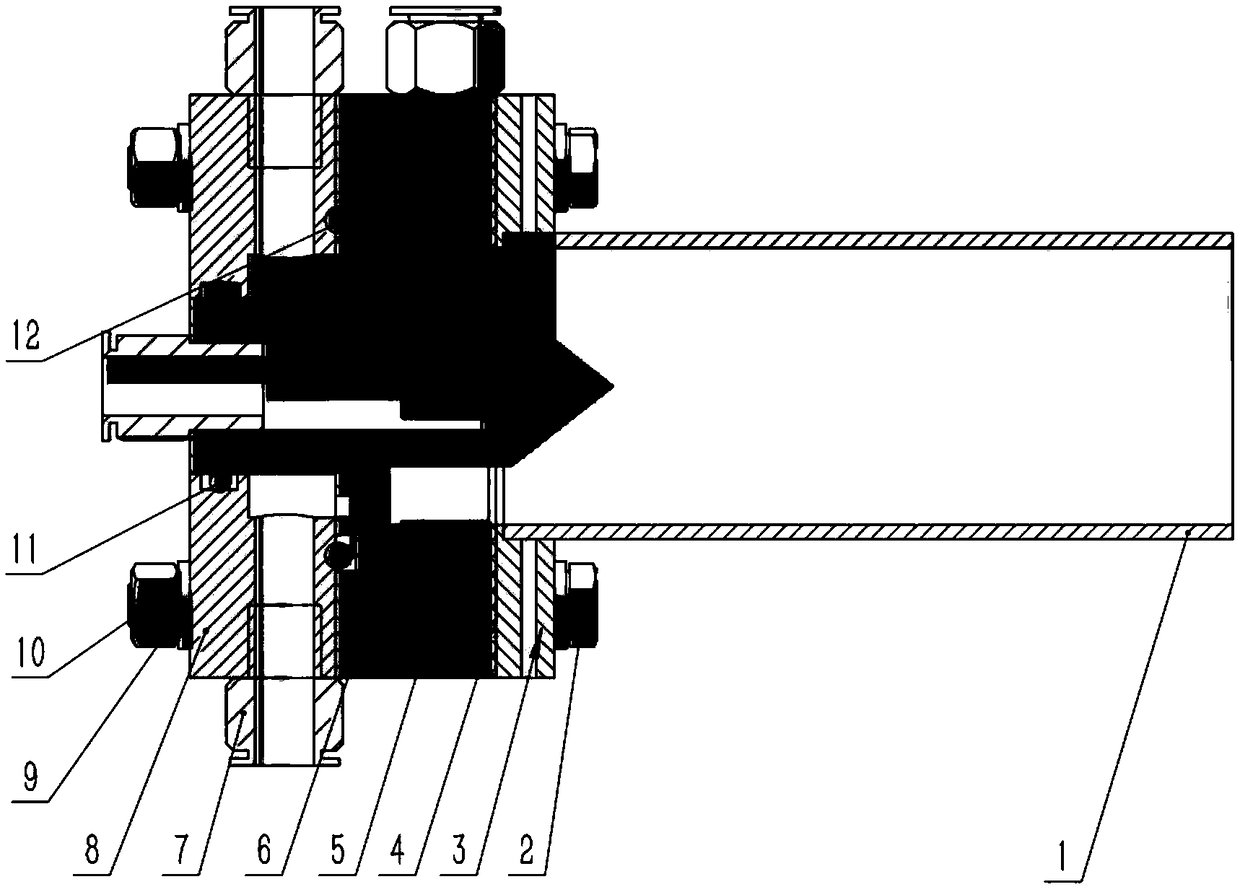

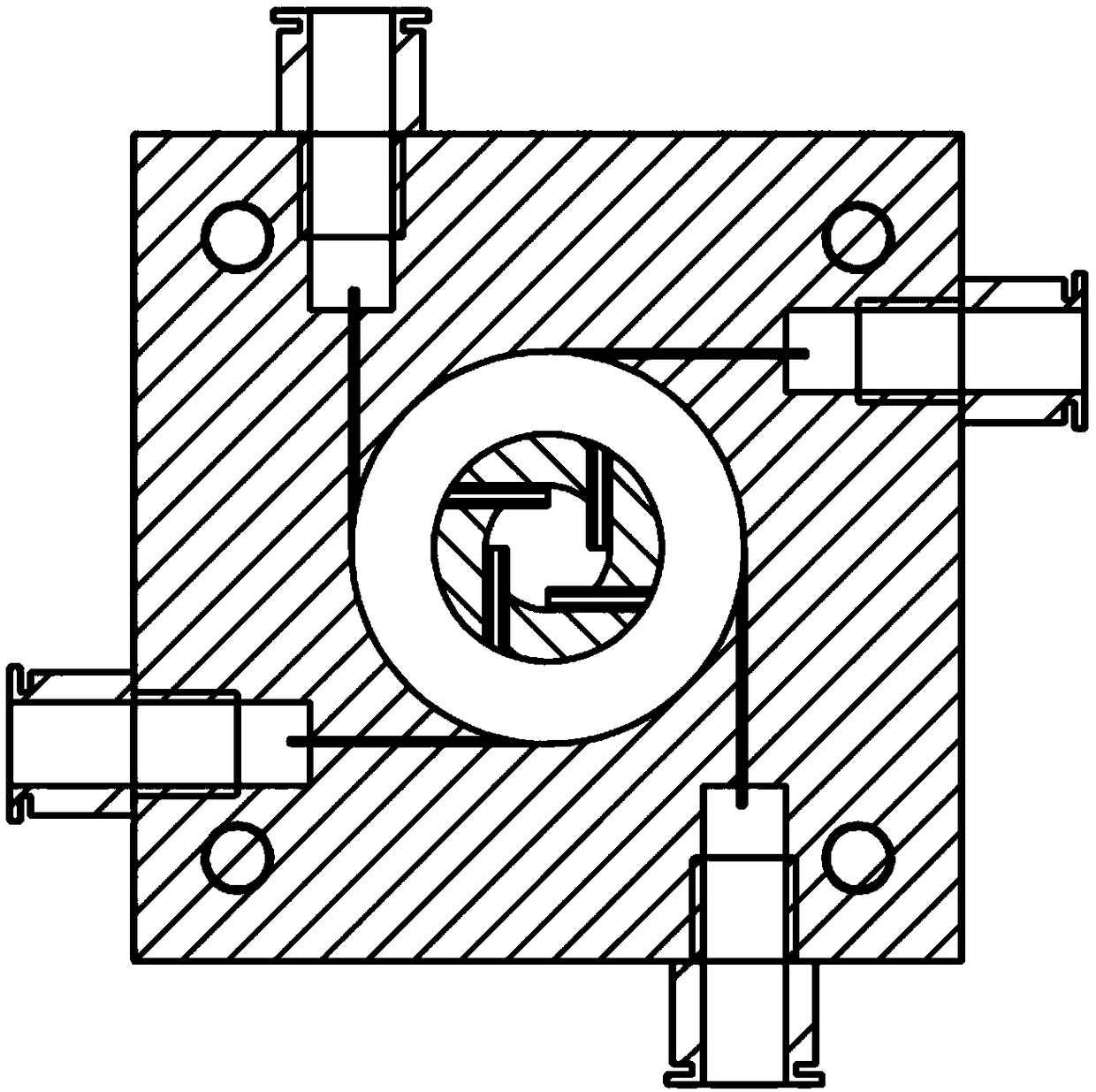

Supercharger and ultrahigh-pressure common rail system with supercharger

PendingCN108869131AImprove atomization qualityControl combustion temperatureInternal combustion piston enginesFuel injecting pumpsForced inductionPressure rise

The invention belongs to the technical field of high-pressure injection, and particularly relates to a supercharger and an ultrahigh-pressure common rail system with the supercharger. The superchargercan achieve ultrahigh-pressure oil injection, and the variable-oil-injection-rate high-pressure injection can be achieved by using the common rail system. On the one hand, high-pressure injection canimprove the atomization quality, so that the ignition delay period is shortened, but the problem that the fuel injection amount is excessively large possibly occurs. By means of the ultrahigh-pressure common rail system, the oil injection rate can be adjusted to control the oil amount of premixed combustion, and more reasonable gas mixture time, and spatial distribution and the like are formed, so that an oil injection rate curve is controllable. The curve is matched with the change of the rotating speed and load of a diesel engine, so that the combustion temperature and the pressure rise rate are controlled, and the purpose of optimizing the full-work condition is achieved.

Owner:NAVAL UNIV OF ENG PLA +1

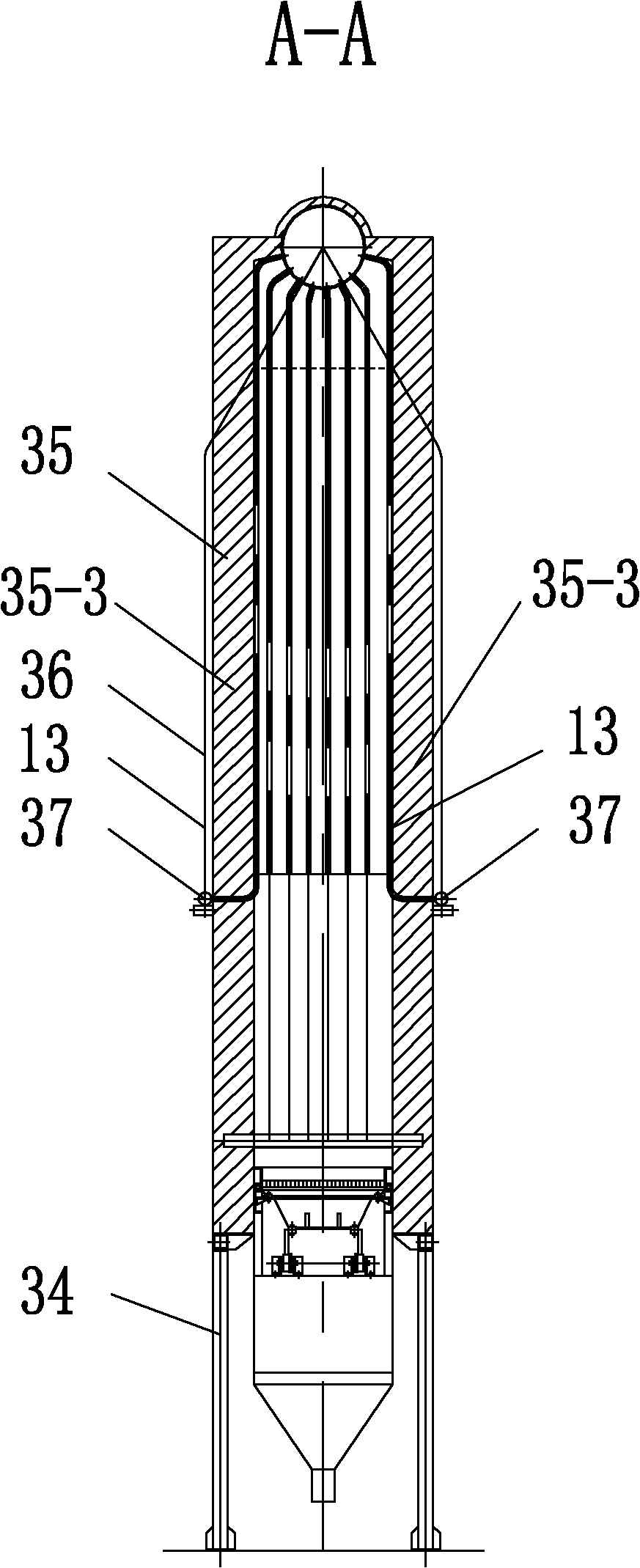

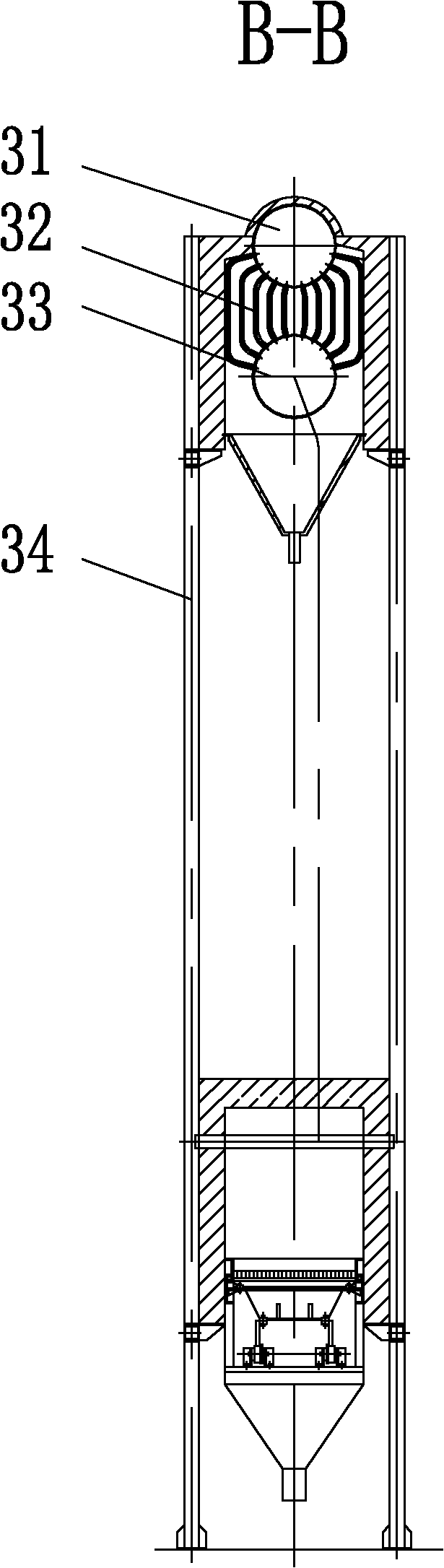

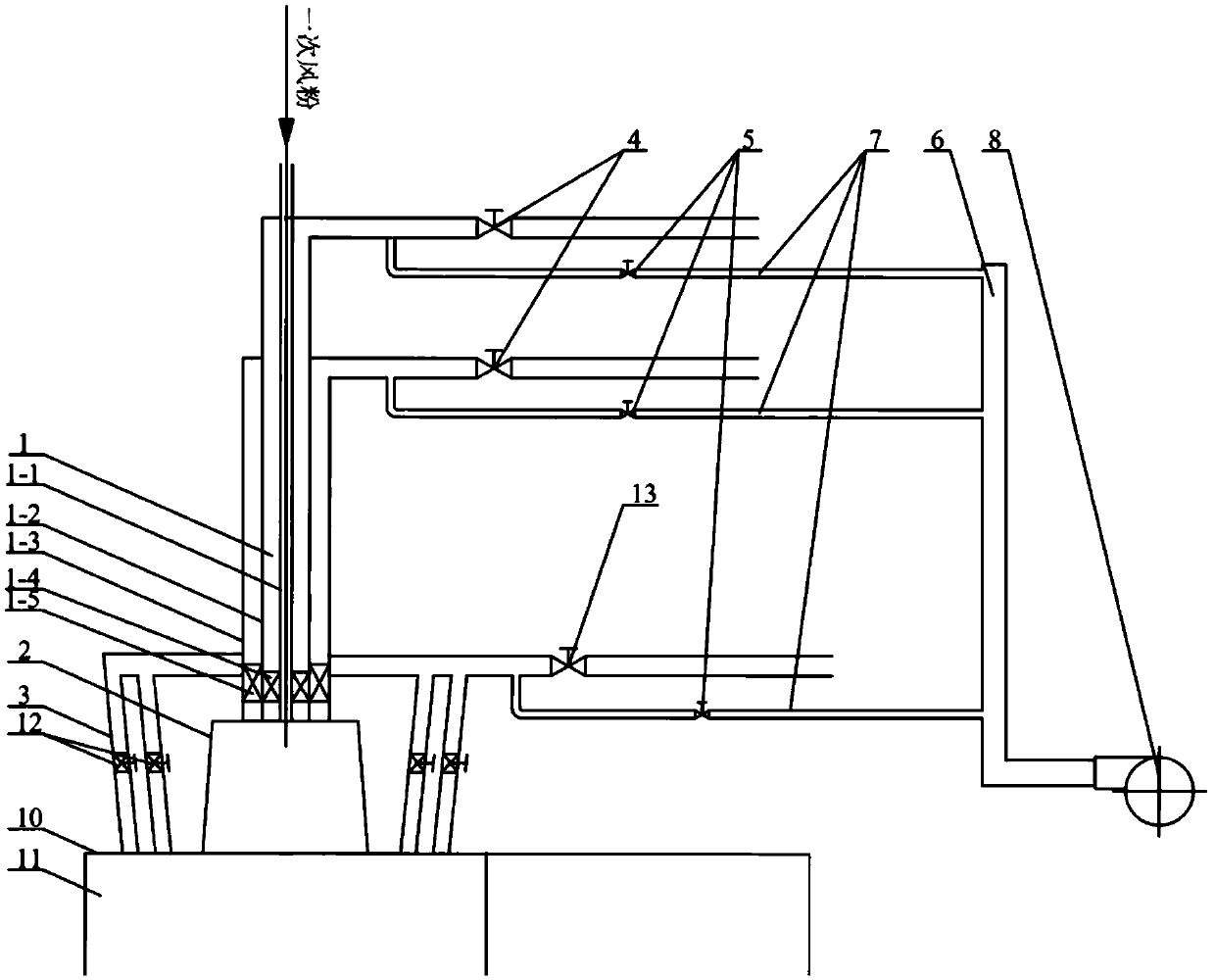

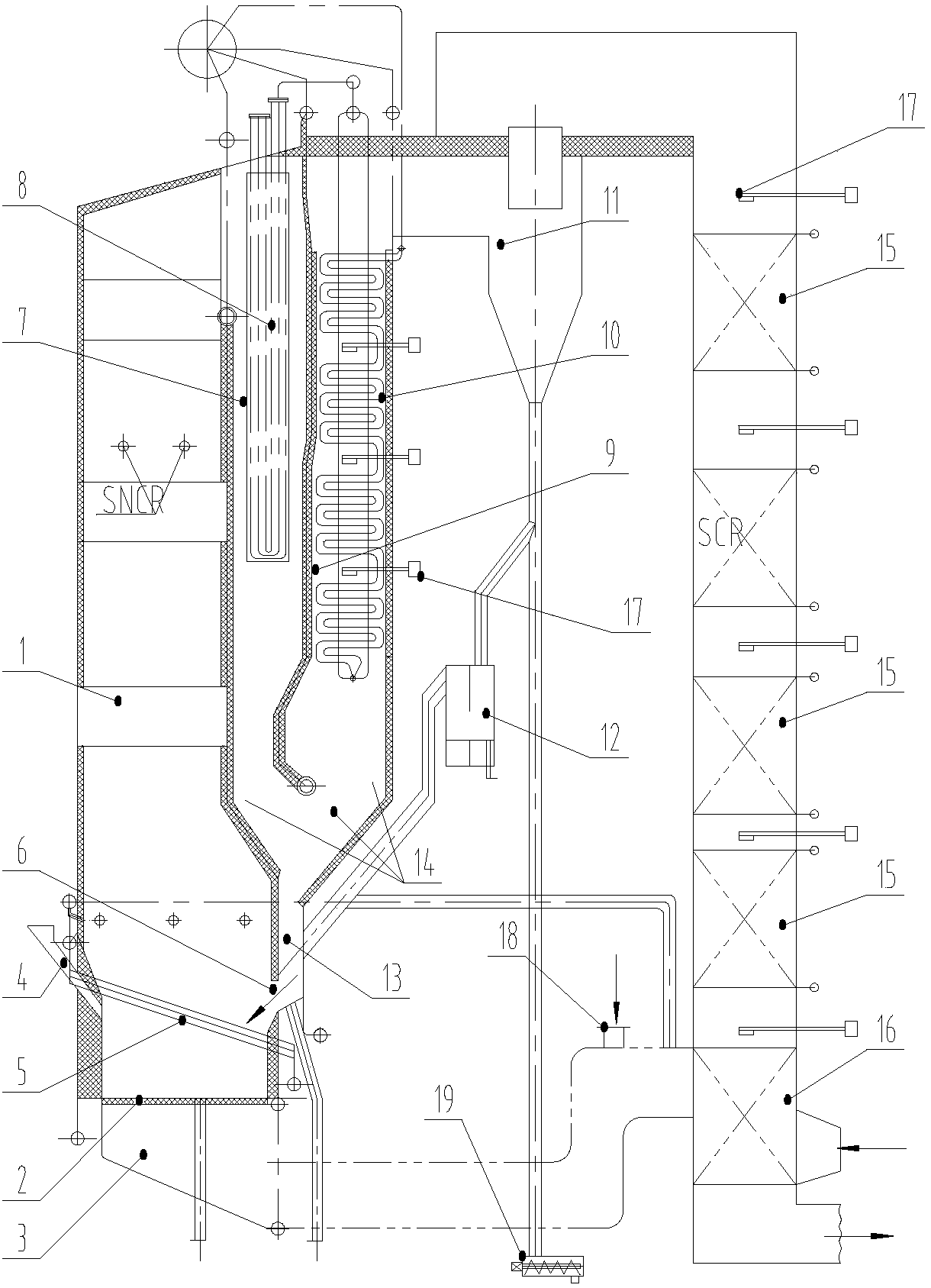

Superheated steam boiler of pure combustion high-sodium coal two-stage medium-temperature separation circulating fluidized bed

PendingCN107763593ALower combustion temperatureReduce gasification releaseFluidized bed combustionSteam generation using pressureGastric tube feedingHigh sodium

The invention discloses a superheated steam boiler of a pure combustion high-sodium coal two-stage medium-temperature separation circulating fluidized bed. The superheated steam boiler of the pure combustion high-sodium coal two-stage medium-temperature separation circulating fluidized bed comprises a hearth; the lower side of the hearth communicates with an isobaric air chamber through a small air cap air distribution plate; a feed pipe, a buried pipe and a return port are arranged at the lower part of the hearth; an outlet of the hearth is turned to downwards move to connect with a first water cooling cavity; the lower part of the first water cooling cavity is gradually shrunk to downwards move to turn for enlargement to connect with a first-grade acceleration settlement separator; the low part of the first-grade acceleration settlement separator is connected with a settlement tank; the bottom of the settlement tank is connected with the return port; the upper part of the first-gradeacceleration settlement tank is connected with a second water cooling cavity; a snakelike pipe low-temperature superheater is arranged at the upper part of the second water cooling cavity; and an outlet of the second water cooling is serially connected with a two-grade volute cyclone separator. First and second water cooling diaphragm wall cavities are formed in the outlet of the hearth for performing the pollution reducing design and prevention of the sodium and potassium high-temperature corrosion on heated surfaces easiest to be polluted, so that the bad coking deposition phenomenon is solved, and the better effect is achieved.

Owner:贵州新能源开发投资股份有限公司

Dual-fuel hot compression engine

InactiveCN101008338AReduce the compression ratioReduce energy consumptionInternal combustion piston enginesCombustion chamberThermal compression

The invention relates to a dual-fuel thermal compression engine, comprising a piston in the piston cylinder while the piston is hinged to the connecting rod via piston pin. The upper part of the piston cylinder is arranged with a cylinder cover of engine; the upper part of the piston is arranged with a diesel burning room whose top is arranged with gas burning room with dual injectors through to the main burning room of diesel; the main burning room is arranged with a diesel inlet and a diesel outlet; the gas burning room is arranged with a gas inlet and a splash plug. The invention burns the gas in the gas burning room to supply high temperature and high pressure to burn diesel, to operate the diesel engine at low compression ratio and improve the thermal efficiency.

Owner:田恩泽 +1

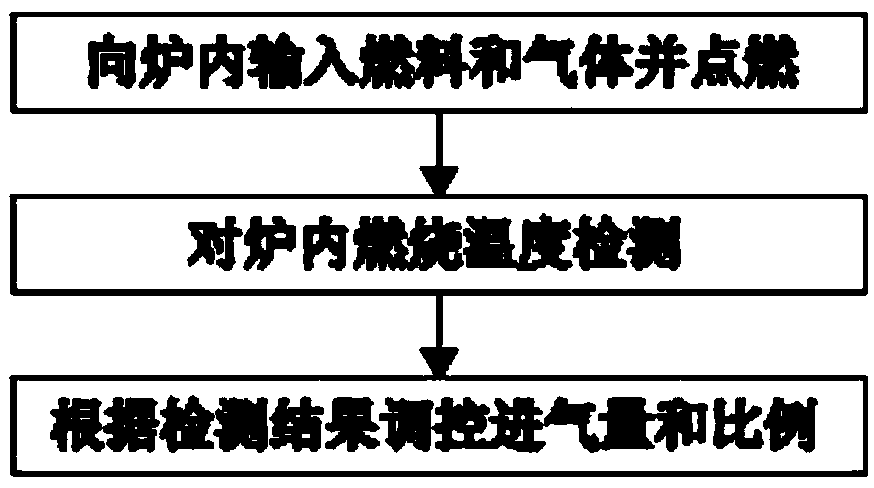

Air inlet control method for oxygen-enriched hot blast stove

InactiveCN110260355AControl combustion temperatureQuality assuranceFuel supply regulationBlast furnace detailsEngineeringProduct gas

The invention discloses an air inlet control method for an oxygen-enriched hot blast stove, and particularly relates to an air inlet control method of the oxygen-enriched hot blast stove. The air inlet control method of the oxygen-enriched hot blast stove comprises the following specific steps that S1, fuel and gas are input into a furnace and ignition is carried out; S2, the combustion temperature in the furnace is detected, wherein A, the detection temperature is within the range of 900 DEG C to 1400 DEG C and is regarded as normal combustion, and regulation and control is not needed, B, the detection temperature is greater than 1400 DEG C and is regarded as an abnormal combustion temperature, and the regulation and control is needed, and C, the detection temperature is less than 900 DEG C and is regarded as the abnormal combustion temperature and the regulation and control is needed; and S3, the air inflow and the proportion are regulated and controlled according to a detection result. The ironmaking is guaranteed to be within a stable temperature range, the temperature can be accurately controlled by means of a mode of intelligent temperature detection and regulation and control, the use of manpower for controlling the temperature is reduced, the functions of saving resources is achieved while the normal work is ensured.

Owner:王俊英 +2

Integrated pressure rotational flow atomizing nozzle of gas turbine and combustor with nozzle

PendingCN114234234ASmall sizeControl combustion temperatureContinuous combustion chamberCombustion chamberCombustor

The invention belongs to the technical field of gas turbines, and particularly relates to an integrated pressure rotational flow atomizing nozzle of a gas turbine and a dual-fuel gas turbine combustor with the nozzle. The nozzle provided by the invention adopts the integrated design of the fuel channel, the swirler and the fuel nozzle, is compact in overall size, can be conveniently applied to various combustors, and can meet good fuel atomization of a gas turbine under different working conditions through multi-group or multi-point arrangement; high-pressure fuel oil is jetted to the downstream of an air flowing channel of the second-stage air radial swirler through a nozzle and mixed with strong swirling air to form uniform mixed oil gas to be combusted in the combustion chamber, the combustion temperature in the combustion chamber can be effectively controlled by adjusting the swirling degree and the air flow of the two-stage swirler, combustion is stable, and the combustion efficiency is improved. And the purpose of reducing emission of nitrogen oxides is achieved.

Owner:中国船舶重工集团公司第七0三研究所

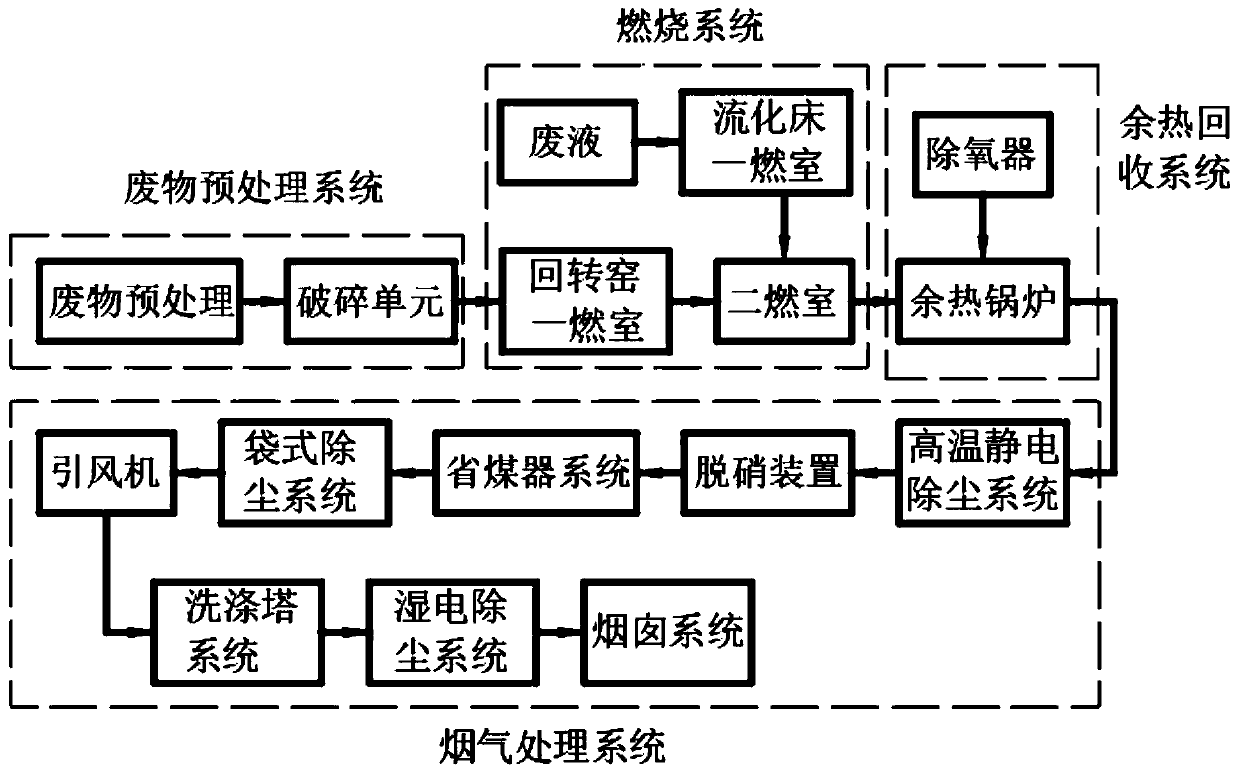

Solid hazardous waste and liquid hazardous waste cooperative disposal incinerator and disposal method

PendingCN111156523ALow disposal capacityImprove disposal capacityFluidized bed combustionIncinerator apparatusLiquid wasteCombustion chamber

The invention discloses a solid hazardous waste and liquid hazardous waste cooperative disposal incinerator and a disposal method. The solid hazardous waste and liquid hazardous waste cooperative disposal incinerator comprises a first rotary kiln combustion chamber, a first fluidized bed combustion chamber, a second combustion chamber and a rear smoke channel. The first rotary kiln combustion chamber is provided with a feed port, a rotary kiln combustion-supporting air inlet and a waste gas outlet. The first fluidized bed combustion chamber is provided with a fluidized air inlet and a waste gas outlet. A hearth of the first fluidized bed combustion chamber is filled with a quartz sand bed material. A waste liquid spraying device is arranged on the upper side of the quartz sand bed material. The fluidized air inlet is connected with a fluidization draught fan. The waste liquid spraying device is externally connected with a waste liquid pump. The second combustion chamber is provided with two waste gas inlets, a secondary air inlet and a waste gas outlet. The two waste gas inlets are connected with the waste gas outlet of the first rotary kiln combustion chamber and the waste gas outlet of the first fluidized bed combustion chamber correspondingly. Liquid is incinerated in the first fluidized bed combustion chamber, solid is incinerated in a rotary kiln, the corresponding materials are converted into gas-phase substances in the first combustion chambers, and then the gas-phase substances enter the common second combustion chamber, so that the problem that the liquid waste disposal capacity of an existing rotary kiln is not sufficient can be solved.

Owner:台州市德长环保有限公司 +1

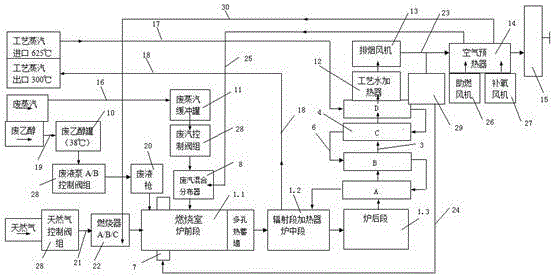

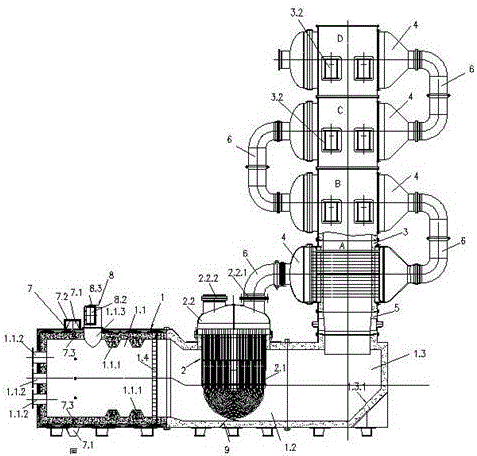

Alcohol dehydration steam heating system

ActiveCN106439860AReduce the temperatureReduce the amount of fuelCombustion technology mitigationSteam superheatersAir preheaterDistributor

The invention relates to an alcohol dehydration steam heating system. The alcohol dehydration steam heating system comprises an oxirane heating furnace, a waste alcohol tank, a waste steam buffer tank, a process water heater, a smoke exhaust fan, an air preheater and a chimney, wherein a process steam pipeline is connected with a heat exchanger on the topmost end of a flue, a radiation heater is connected with a process steam output pipeline, waste alcohol is connected with the waste alcohol tank through a waste alcohol conveying pipeline, the waste alcohol tank is connected with a waste liquid gun through the waste alcohol conveying pipeline, the waste liquid gun is arranged in a waste liquid gun inlet, natural gas is connected with a burner through a natural gas pipeline, the burner is arranged in a burner inlet, the smoke exhaust fan is arranged on the topmost end of the flue, the smoke exhaust fan is connected with the air preheater through a smoke exhaust pipeline, the air preheater is connected with the chimney through the smoke exhaust pipeline, a circulation air compensation pipeline which is connected with a circulation air compensation device is additionally arranged on the smoke exhaust pipeline between the smoke exhaust fan and the air preheater, and a recycling pipeline which is connected with a waste steam mixed distributor is additionally arranged on the air preheater.

Owner:JIANGSU JINNIU ENVIRONMENTAL ENG EQUIP

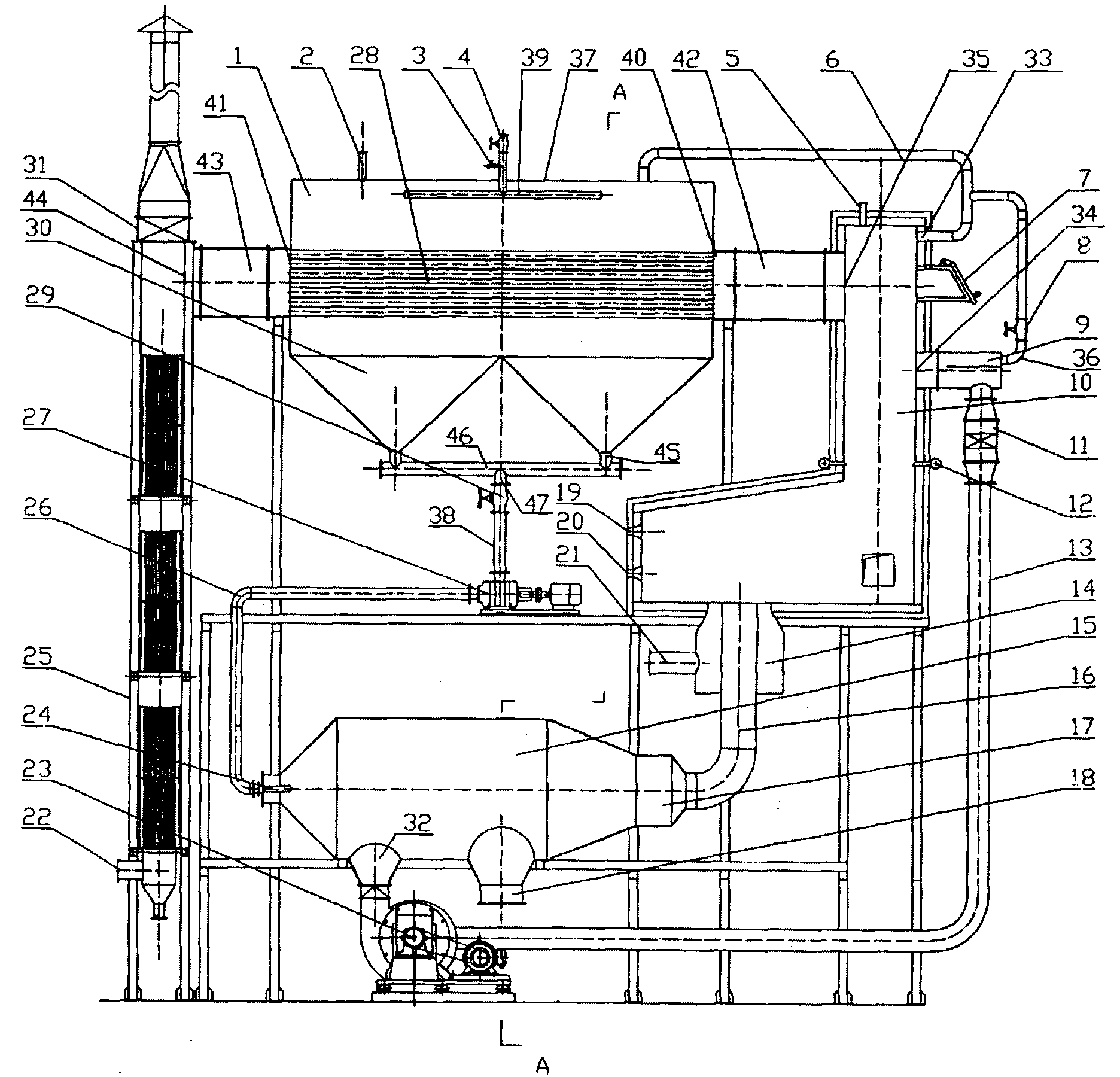

Circulating fluidized bed boiler system

InactiveCN108036309AControl combustion temperatureImprove controllabilityFluidized bed combustionApparatus for fluidised bed combustionCombustionFlue gas

The invention discloses a circulating fluidized bed boiler system. The circulating fluidized bed boiler system comprises a hearth and a hearth bed surface arranged at the bottom of the hearth, whereinthe hearth bed surface is communicated with a primary air chamber for blasting air; the top of the hearth is communicated with a separator device for separating high-temperature flue gas; the bottomof the separator device is communicated with the bottom of the hearth; a secondary air inlet is formed in the lower part of the side wall of the hearth; a fuel inlet for supplementing fuel powder is formed in the side wall of the hearth between the secondary air inlet and the hearth bed surface; pulverized coal directly falls onto the bed surface through the fuel inlet and heaps up to form a combusting dense phase region, so that the problem that effective combustion is difficultly formed because the pulverized coal is directly blown into the separator by inlet air is avoided and combustion ofthe pulverized coal is more thorough; in addition, through a circulating action of the separator, the thoroughness of combustion and the controllability of the combustion environment in the furnace are improved, the harmful substance content of emitted waste gas is reduced, and thus the technical problems that the existing circulating fluidized bed boiler difficultly meets novel technical requirements on low emission and high-efficiency combustion and the like are solved.

Owner:QINGDAO CLEAR ENVIRONMENT PROTECTION BOILER ENG

Pure combustion high sodium coal two-stage medium temperature separation circulating fluidized bed saturated steam boiler

PendingCN107726285AHigh calorific valueExcellent fire burnout performanceFluidized bed combustionSteam boilersCycloneHigh sodium

The invention discloses a pure combustion high sodium coal two-stage medium temperature separation circulating fluidized bed saturated steam boiler. The circulating fluidized bed saturated steam boiler comprises a hearth, wherein the lower portion of the hearth communicates with a uniform pressure wind chamber through a small wind cap wind distribution plate, and a feed pipe, a buried pipe and a material return opening are arranged at the lower portion of the hearth; an outlet of the hearth turns downwards and is connected with a first water cooling cavity, the lower portion of the first watercooling cavity gradually shrinks, turns downwards and then increases, the lower portion of the first water cooling cavity is connected with a first-stage accelerated sedimentation separator, the lower portion of the first-stage accelerated sedimentation separator is connected with a subsider, and the bottom of the subsider is connected with the material return opening; and the upper portion of the first-stage accelerated sedimentation separator is connected with a second water cooling cavity, a membrane type wall water cooling shield is arranged at the upper portion of the second water cooling cavity, and an outlet of the second water cooling cavity is connected with a second-stage volute cyclone separator in series. The outlet of the hearth is provided with the first water cooling membrane type wall cavity and the second water cooling membrane type wall cavity, the contamination reduction design and sodium and potassium high temperature corrosion avoidance are carried out on a heating surface which is most prone to being polluted, the phenomena of serious coking and ash deposition are eliminated, and good effects are achieved.

Owner:贵州新能源开发投资股份有限公司

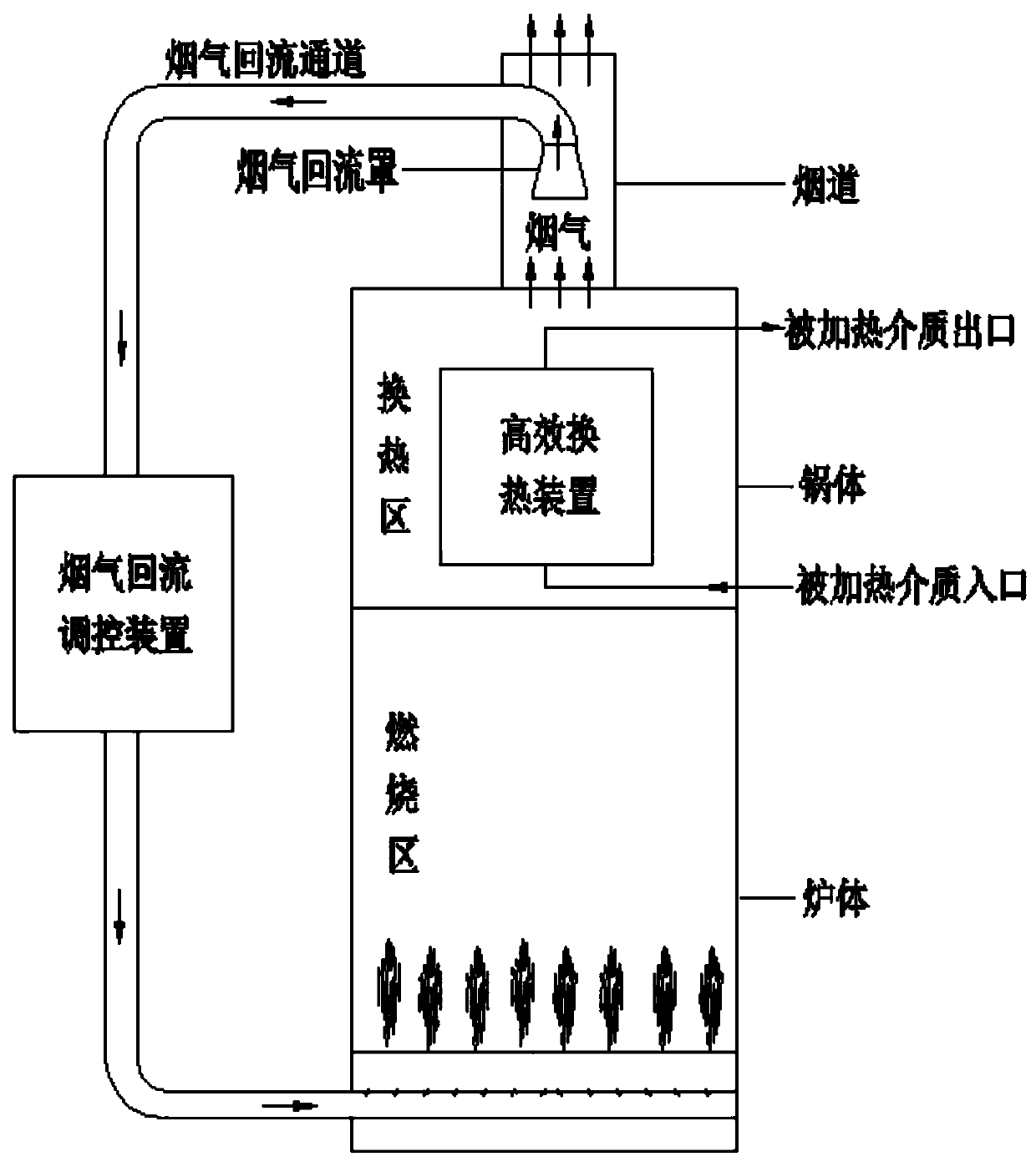

Device and method for regulating and controlling combustion temperature of porous solid fuel and increasing heat exchange efficiency after combustion

PendingCN110296392AEmission reductionControl combustion temperatureSolid fuel combustionCombustion apparatusCombustionFlue gas

The invention discloses a device and method for regulating and controlling combustion temperature of porous solid fuel and increasing heat exchange efficiency after combustion. The device and the method are characterized in that the device comprises a furnace body, a boiler body, a flue and a flue gas backflow channel, a combustion area is arranged in the furnace body, a heat exchange area is arranged in the boiler body, an efficient heat exchange device is arranged in the heat exchange area, and a flue gas backflow cover and a flue gas backflow regulating and controlling device are arranged on the flue gas backflow channel; and the method comprises the specific regulating and controlling steps that a, the flue gas backflow cover and the flue gas backflow regulating and controlling devicelead out part of flue gas from the flue to be sufficiently premixed with air inside or outside the furnace body before entering the combustion area and then enters the combustion area of the furnace body, the oxygen concentration in the combustion area in the furnace body is regulate and controlled, and the combustion temperature of the porous solid fuel is regulated and controlled; b. the efficient heat exchange device in the boiler body can enhance the heat exchange efficiency of the heat exchange area and control the flue gas temperature at the outlet of the flue; and c. porous solid fuel is produced by a retorting process.

Owner:CHONGQING FURAN TECH

System and method for comprehensive utilization of wallpaper processing waste

ActiveCN111550792BImplement co-processingRealize joint productionIncinerator apparatusCarbonizationWaste treatment

The invention discloses a comprehensive utilization system and method for waste treatment for wallpaper processing. The comprehensive utilization system includes: a filter, a reactor, and the reactor is sequentially connected from top to bottom by a crushing pyrolysis chamber, an air chamber, and a secondary carbonization chamber. The inner cavity of the secondary carbonization chamber is fixed with a horizontal heating pipe, the outer side of the activation chamber is fixed with a secondary combustion chamber, the outlet at the bottom of the filter and the activated carbon inlet on the side of the secondary carbonization chamber connected. The production method is: the finished activated carbon filters the air containing high concentration of organic waste gas; the bed material and waste wood undergo crushing and pyrolysis reactions in the crushing pyrolysis chamber to generate carbonized material and biomass gas; The organic matter in the activated carbon undergoes pyrolysis and carbonization reaction; activation reaction. The invention can realize the coordinated treatment of waste wood and organic waste gas, and can realize the joint production of heat energy and high-quality activated carbon.

Owner:ANHUI BAUHINIA WALLPAPER

Multi-stage adjustable low-nitrogen gas burner suitable for coke oven gas

PendingCN112161267ASuppress generationReduce manufacturing costGaseous fuel burnerCombustorEmission standard

The invention discloses a multi-stage adjustable low-nitrogen gas burner suitable for coke oven gas. A rotational flow device is arranged between a secondary fuel barrel and a burner box shell; a combustion air inlet is formed in the side face of the burner box shell; a combustion air baffle is arranged at the combustion air inlet; the combustion air inlet is divided into two paths, wherein one path communicates with a center air barrel through a center air adjusting valve, and the other path communicates with the burner box shell; a gas fuel inlet is formed in the outer side of the burner boxshell; a main gas fuel adjusting baffle is arranged at the gas fuel inlet; and the gas fuel inlet is divided into three paths, wherein the first path communicates with a center fuel barrel through acenter fuel adjusting valve, the second path communicates with a primary fuel barrel through an adjusting device, and the third path communicates with the secondary fuel barrel. The burner can meet the emission standard.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

Method of reducing fly ash carbon content of circulating fluidized bed boiler

InactiveCN102927564BReduce carbon contentControl combustion temperatureFluidized bed combustionIndirect carbon-dioxide mitigationFlue gasFluidized bed

The invention discloses a method of reducing fly ash carbon content of a circulating fluidized bed boiler, wherein the method comprises the following steps when the circulating fluidized bed boiler comprises a hearth, a cyclone separator, a vertical pipe and a feedback device: 1) mounting a helical feeder on the upper part of the vertical part, and connecting an oxygen-enriched air generator at the air inlet chamber on the bottom part of the feedback device; and 2) when the circulating fluidized bed boiler operates, the helical feeder conveys the fly ash to the upper part of the vertical part, the fly ash enters the feedback device through the vertical pipe, the coke in the fly ash in the feedback device and the oxygen-enriched air generated by the oxygen-enriched air generator generate an oxygen-enriched combustion reaction, in the reaction, the percent by volume of the oxygen in the oxygen-enriched air is controlled to control the combustion temperature of the fly ash, and the fly ash and the flue gas return to the hearth after the reaction. The method disclosed by the invention can be applied on circulating fluidized bed boilers of burning inferior coal, and the method can greatly increase the combustion reaction speed and standing time of the coke in the fly ash in the high temperature region of the circulating fluidized bed boiler and greatly reduce the fly ash carbon content of the circulating fluidized bed boiler.

Owner:CHONGQING UNIV

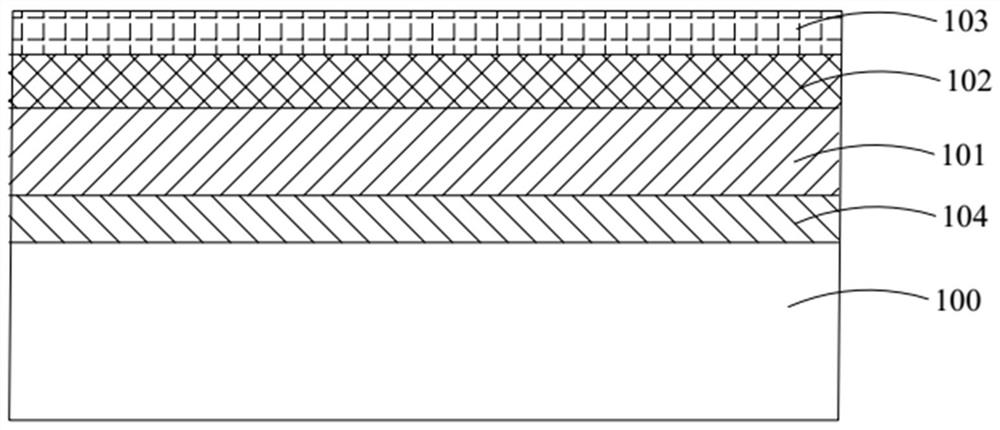

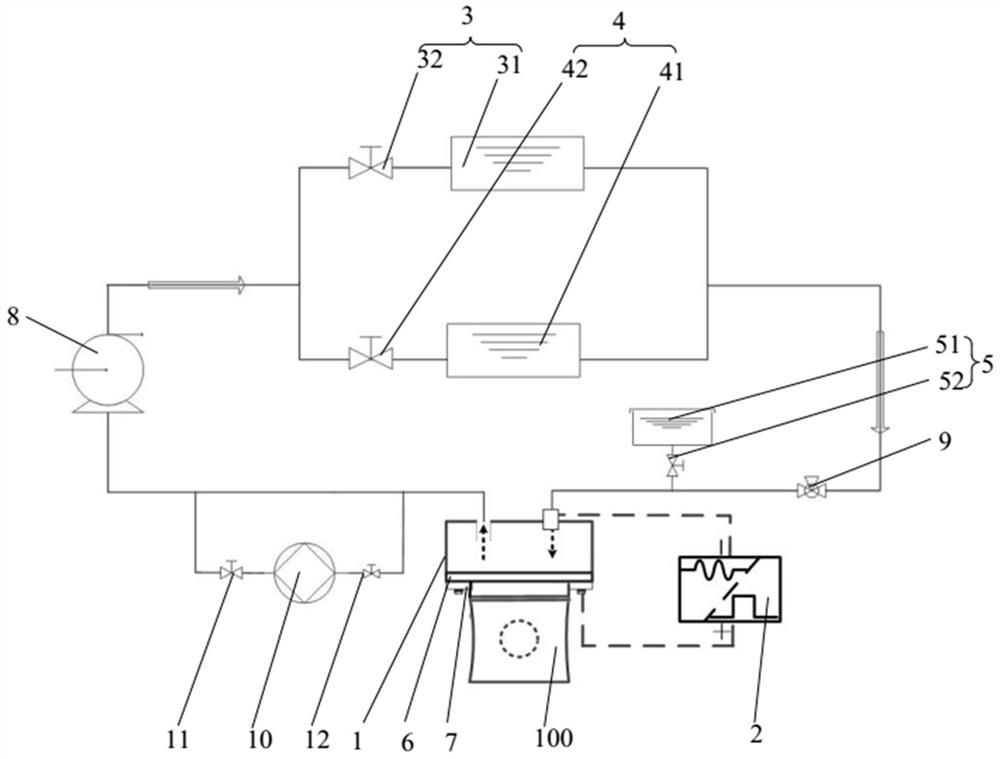

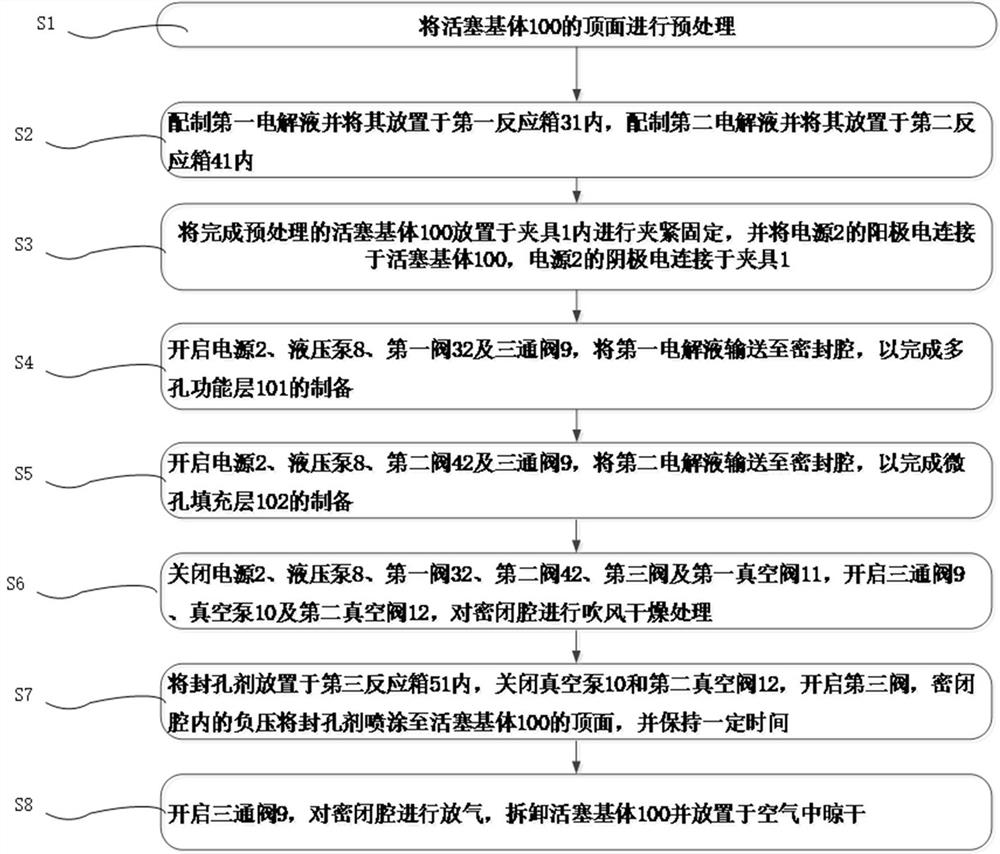

Piston, piston manufacturing device and piston manufacturing method

ActiveCN111535935BImprove high temperature resistanceAccelerated corrosionCellsTanksThermodynamicsMachining

The invention belongs to the technical field of machining, and discloses a piston, a piston manufacturing device and a piston manufacturing method. The piston includes: a piston base; a porous functional layer, which is arranged on the top surface of the piston base; a microporous filling layer, which is arranged on the top surface of the porous functional layer, and the hole diameter in the micropore filling layer is smaller than that in the porous functional layer. The diameter of the hole; the sealing layer, which is arranged on the top surface of the micropore filling layer, is used to block the holes in the micropore filling layer. While the microporous filling layer of the piston plays the role of transition between the porous functional layer and the sealing layer, the microporous filling layer plays a role of filling the porous functional layer to a certain extent. The sealing layer acts as a plug to prevent the corrosive medium from entering the pores of the porous functional layer and the microporous filling layer to corrode them, thereby improving the corrosion resistance of the piston. In addition, air can be filled in the pores of the porous functional layer and the micropore filling layer, which effectively reduces the volume specific heat capacity of the coating.

Owner:WEICHAI POWER CO LTD

Waste treatment comprehensive utilization system and method for wallpaper processing

ActiveCN111550792AImplement co-processingRealize joint productionIncinerator apparatusCarbonizationWaste treatment

The invention discloses a waste treatment comprehensive utilization system and method for wallpaper processing. The comprehensive utilization system comprises filters and a reactor, the reactor consists of a crushing pyrolysis chamber, an air chamber, a secondary carbonization chamber and an activation chamber which are sequentially connected from top to bottom, a heating pipe in the horizontal direction is fixed in an inner cavity of the secondary carbonization chamber, a secondary combustion chamber is fixed on the outer side of the activation chamber, and a discharge opening in the bottom of each filter is connected with an activated carbon inlet in the side part of the secondary carbonization chamber. A production method comprises the following steps that the finished product of the active carbon filters the air containing the high-concentration organic waste gas, bed materials and waste wood are subjected to crushing and pyrolysis reactions in a crushing and pyrolysis chamber to generate carbonized materials and biomass gas, the carbonized material is completely separated out of volatile matters, organic matters in the saturated activated carbon are subjected to pyrolysis andcarbonization reactions, and activating reaction is conducted. According to the system and the method, the cooperative treatment of the waste wood and the organic waste gas can be achieved, and the co-production of heat energy and high-quality activated carbon can be achieved.

Owner:ANHUI BAUHINIA WALLPAPER

Processing method and device for incinerating toxic waste liquid by smoke concentration and gasification

ActiveCN102042602BControl combustion temperatureSuppress generationIncinerator apparatusCooling effectToxic material

Owner:上海煜工环保科技有限公司

Low-nitrogen combustion transformation method and system for medium-grade kiln

PendingCN114061317AEmission reductionSuppress generationMaintainance of heating chambersIncreasing energy efficiencyEngineeringAir blower

The invention discloses a low-nitrogen combustion transformation method and system of a medium-grade kiln, and belongs to the technical field of low-nitrogen combustion. The transformation method comprises the following steps: dismounting a coal burning device, arranging two fuel gas inlets, introducing natural gas, air and circulating flue gas into the head fuel gas inlet, and introducing air into the middle fuel gas inlet. The system comprises a medium-grade kiln, a natural gas pipeline, an air header pipe, a head air pipeline, a middle air pipeline, a flue gas circulating pipeline, a steam pipeline, a mixer I, an air blower, a filter, a mixer II, an induced draft fan and the like. Circulating flue gas is introduced into the head fuel gas inlet to inhibit combustion, so that insufficient combustion is performed at the front end of the middle-grade kiln, and then air is introduced into the middle fuel gas inlet to promote sufficient combustion at the middle-rear end in the middle-grade kiln so as to promote carbon monoxide to generate carbon dioxide, so that the emission amount of nitrogen oxide is reduced. Compared with a common coal-to-gas technology, the emission of nitrogen oxides can be reduced by more than 35%.

Owner:辽宁中石新亚能源发展有限公司

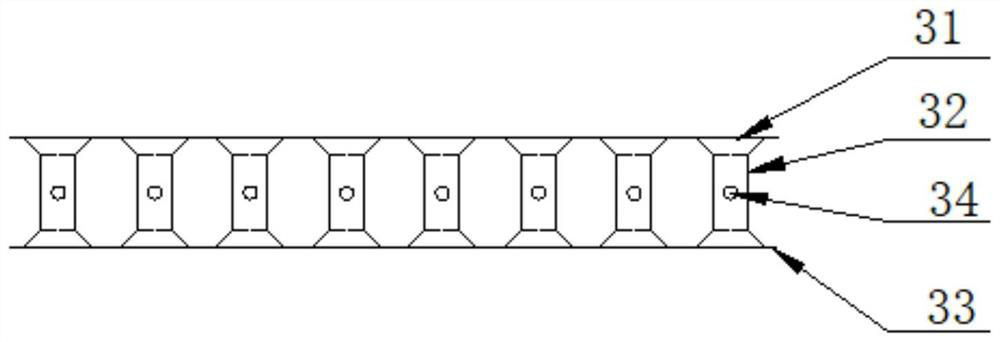

Air distribution plate structure for biomass boiler, boiler system and operation method

PendingCN111998334AEasy dischargeImprove stabilityFluidized bed combustionApparatus for fluidised bed combustionForeign matterThermodynamics

The invention discloses an air distribution plate structure for a biomass boiler, a boiler system and an operation method. The air distribution plate structure comprises an air distribution plate upper plate, a resistance pipe and an air distribution plate lower plate. Through holes are evenly formed in the air distribution plate upper plate and the air distribution plate lower plate. The upper end of the resistance pipe is connected with the air distribution plate upper plate, and the lower end of the resistance pipe is connected with the air distribution plate lower plate. A recirculation hole is formed in the pipe wall of the resistance pipe. The resistance pipe communicates with the through holes of the air distribution plate upper plate and the air distribution plate lower plate. According to the air distribution plate, certain resistance is set through a Venturi pipe, fluidized air can be evenly distributed conveniently, and the combustion efficiency can be better improved; due to the structure of the Venturi pipe, foreign matter in the boiler can be discharged conveniently, the combustion stability of the boiler can be better improved, and the operation period of the boilercan be prolonged; and in the boiler system based on the air distribution plate, certain resistance is set for the air distribution plate through the Venturi pipe, fluidized air can be evenly distributed conveniently, the combustion efficiency can be better improved, and a smoke recirculation branch is arranged at an outlet of an induced draft fan to communicate with the air distribution plate.

Owner:HUANENG CLEAN ENERGY RES INST

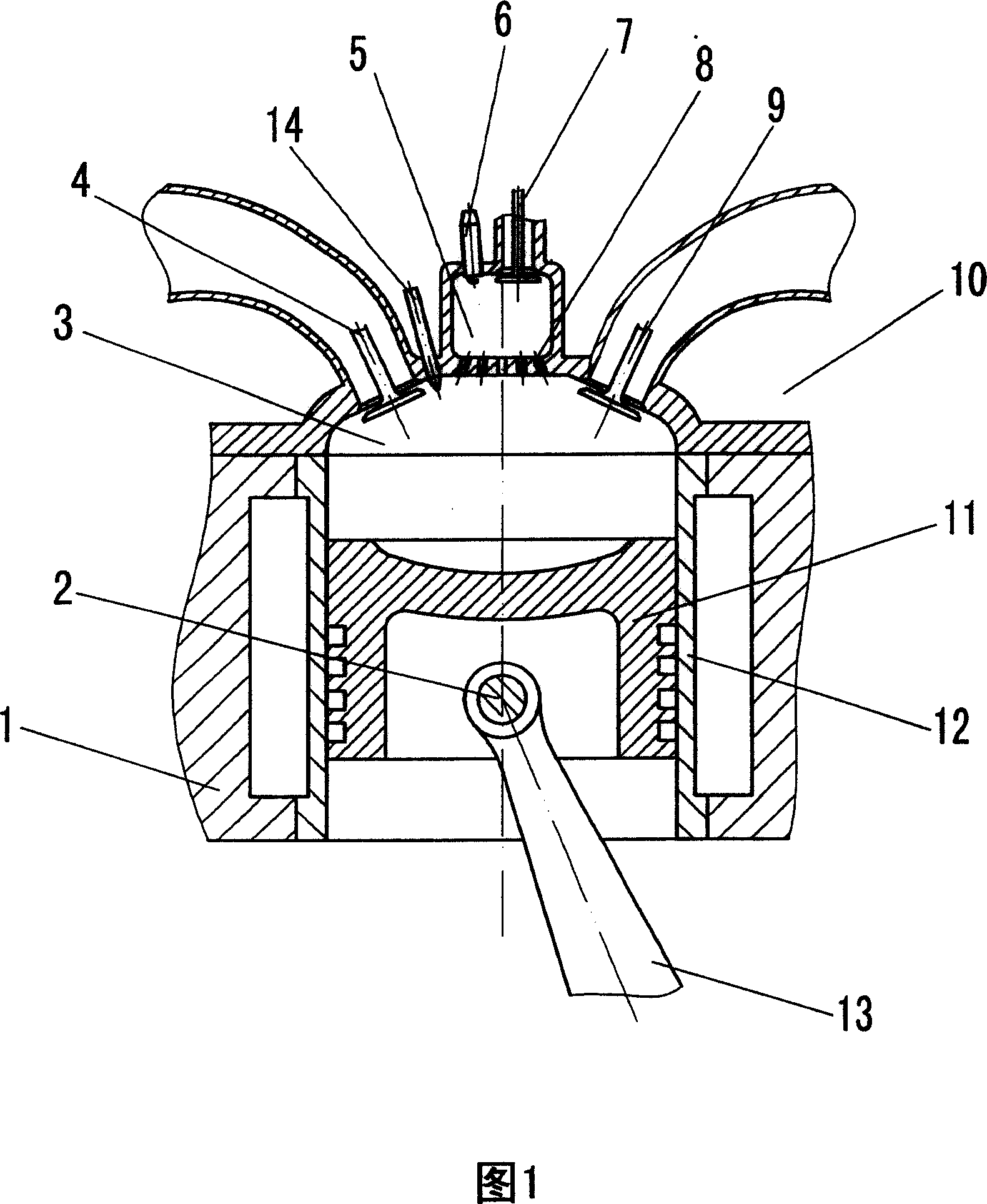

A Porous Jet Burner Based on Internal and External Swirl to Promote Liquid Fuel Atomization

The invention discloses a porous jet flow combustor capable of promoting atomization of liquid fuel based on internal and external rotational flow, and belongs to the field of combustion. The porous jet flow combustor comprises a quartz glass tube, a hexagonal screw, a front cover, a copper gasket, a rapid pipe connector, a rear cover, a gasket, a hexagonal nut, a small O-shaped ring and a large O-shaped ring and further comprises an external rotational flow block and a jet flow-internal rotational flow block. The external rotational flow block is provided with tangential inlets tangential to the inner wall face and gas inlet holes which correspondingly communicate with the tangential inlets, and therefore an introduced oxidizing agent forms the external rotational flow in close fit with the wall face. The jet flow-internal rotational flow block is provided with evenly-distributed internal rotational inlets. The external rotational flow block and the jet flow-internal rotational flow block form a two-rotational-flow structure. The porous jet flow combustor aims at achieving the technical effects that atomization and evaporation of liquid fuel during combustion are promoted, the mixing efficiency of the liquid fuel during combustion is improved, stable flame combustion is achieved, and the combustion efficiency is improved; the flame temperature is freely adjusted and controlled; and the service life of the combustor is prolonged.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A decoupling gas burner and its use method

ActiveCN111121005BIncreased circulation volume ratioIncrease entrainment perimeterCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelThermodynamicsEngineering

The invention provides a decoupling gas burner and its use method. The decoupling gas burner includes a central gas pipe arranged coaxially, a primary air cylinder body, a secondary air cylinder body and Outer cylinder body; an annular air chamber is formed between the outer cylinder body and the first-stage air cylinder body, and the end plate of the air chamber is arranged at the end of the air chamber near the furnace; At least one central gas injection hole is arranged on the outer peripheral surface of the pipe end cover; an annular primary air passage is formed between the central gas pipe and the primary air cylinder body, and the end of the primary air passage near the furnace is provided with a primary wind swirl blade; A secondary air channel is formed between the primary air cylinder body and the secondary air cylinder body. The end of the secondary air channel near the furnace is provided with a secondary wind swirl blade, and the end of the secondary air channel is far away from the furnace and connected to the ventilation chamber. The invention adopts a new staged combustion method to reduce thermal NO while ensuring combustion efficiency x generation.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com