Supercharger and ultrahigh-pressure common rail system with supercharger

A supercharger and supercharging chamber technology, which is applied in the direction of charging system, machine/engine, internal combustion piston engine, etc., can solve the problems of low work efficiency, high fuel consumption control, and violent pressure fluctuation of the supercharger, and achieve hysteresis The effect of shortening the combustion period, optimizing the whole working condition, and improving the atomization quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention will be described in detail below in conjunction with specific embodiments.

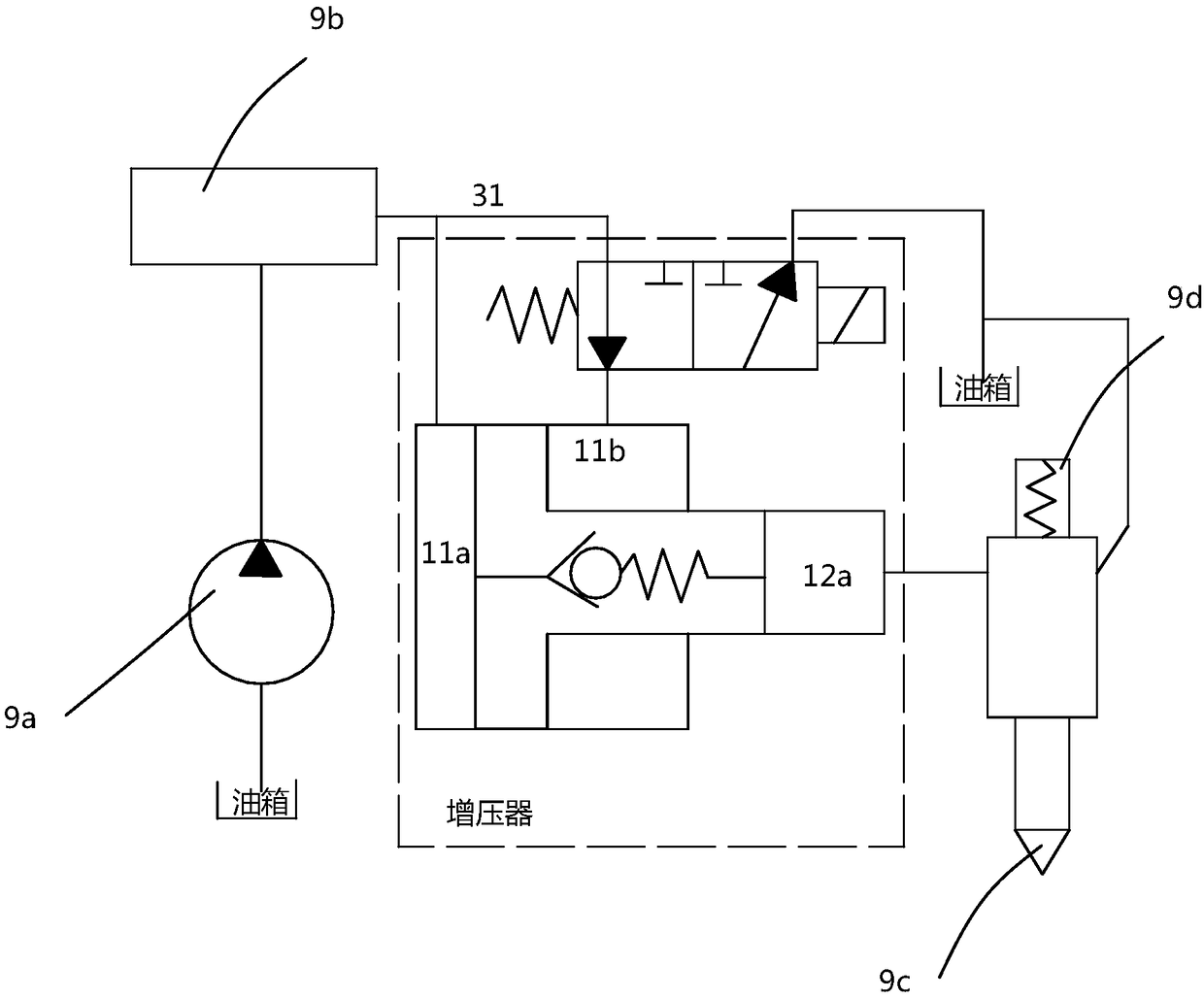

[0017] A supercharger of the present invention is used to realize ultra-high pressure injection, and is mainly used in equipment such as internal combustion engines to achieve ultra-high pressure fuel injection, so as to achieve various purposes such as improving the atomization quality of internal combustion engines, improving combustion efficiency, and reducing costs. Some ultra-high pressure injection systems have complex structures, some equipment design and manufacture are costly and bulky, and some require substantial changes to existing structures, lack of versatility, and complicated control and maintenance processes, which affect ultra-high pressure injection technology Applications. In order to solve the above problems, the present invention provides a supercharger with simple structure and principle and convenient control for realizing high-pressure injection, and base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com