Hot-blowing adjustable nozzle

A technology of nozzles and nozzle cores, applied in lighting and heating equipment, measuring devices, instruments, etc., can solve the problems of uneven heating of working fluid, insufficient fuel combustion, etc., and achieve the advantages of simple structure, easy processing, and improved atomization quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

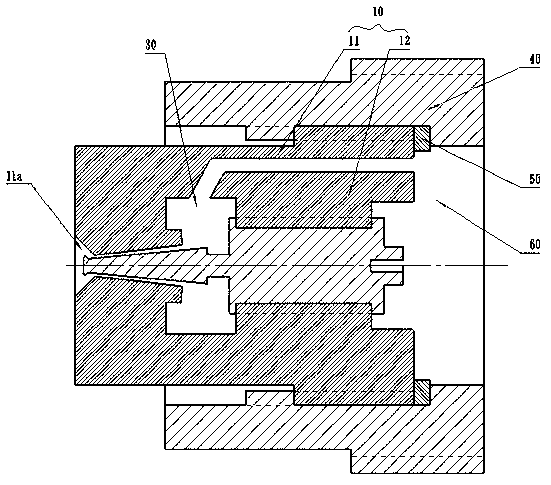

[0030] see figure 1 , the preferred embodiment of the present invention provides a heat-blow adjustable nozzle, which includes a nozzle body 10 and a nozzle core 20 movably installed in the nozzle body 10; wherein, the nozzle body 10 includes a nozzle housing 11 and a The installation part 12 for installing the nozzle core 20 in the housing 11; the inner wall surface of the nozzle housing 11 and the outer wall surface of the installation part 12 form a fuel passage 30; The heat blowing adjustable nozzle of the present invention is installed on the supercharger, which can make the heating of the working medium uniform.

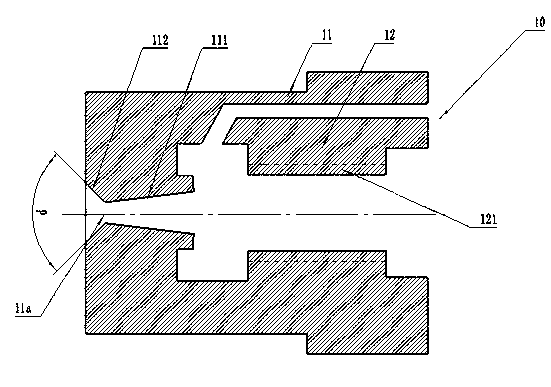

[0031] See figure 2 , the outer periphery of the nozzle housing 11 is provided with connecting threads, the spout 11a is arrange...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com