Method using circulating fluidized bed for rice hull organic acid pretreatment and combustion to prepare nanometer SiO2

A circulating fluidized bed and organic acid technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as discontinuous combustion, increased difficulty and cost of wastewater treatment, and difficult treatment. Achieve the effect of improving purity and production efficiency, high output and added value, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

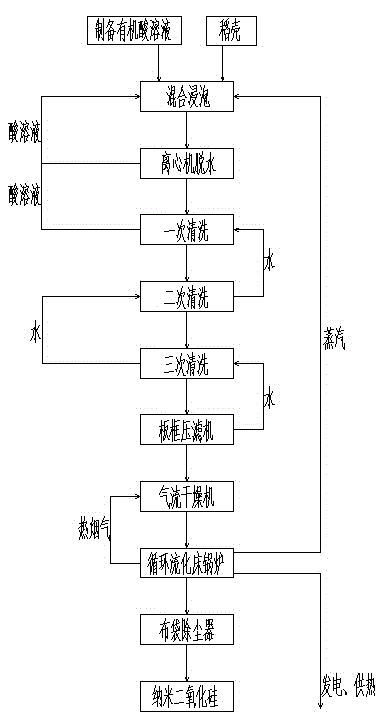

Image

Examples

Embodiment 1

[0039] Use oxalic acid to prepare an organic acid solution with a mass concentration of 5%; mix with 12L of organic acid solution to soak 1Kg of rice husk, soak the rice husk in the organic acid solution, and soak for 5 hours at a temperature of 60-90°C treatment; when the dried rice husks are sent to the circulating fluidized bed boiler for combustion, the combustion temperature in the furnace is set at 750°C; the flue gas discharged from the circulating fluidized bed boiler can be recovered through cloth bags with a purity of 99% to 99.2%, and the average Amorphous nano-silica rice husk ash with a particle size of 55nm.

[0040] Going one step further:

[0041] Use oxalic acid to prepare an organic acid solution with a mass concentration of 5%; mix with 12L of organic acid solution to soak 1Kg of rice husk, soak the rice husk in the organic acid solution, and soak for 5 hours at a temperature of 60°C; When the dried rice husk is sent to the circulating fluidized bed boiler ...

Embodiment 2

[0044] Use oxalic acid to prepare an organic acid solution with a mass concentration of 2.5%; mix with 12L of organic acid solution to soak 1Kg of rice husk, soak the rice husk in the organic acid solution, and soak for 5 hours at a temperature of 60-90°C treatment; when the dried rice husks are fed into the circulating fluidized bed boiler for combustion, the combustion temperature in the furnace is set at 750°C; the flue gas discharged from the circulating fluidized bed boiler can be recovered through cloth bags with a purity of 98.5% to 99.0%, with an average Amorphous nano-silica rice husk ash with a particle size of 65nm.

[0045] Going one step further:

[0046] Use oxalic acid to prepare an organic acid solution with a mass concentration of 2.5%; mix with 12L of organic acid solution to soak 1Kg of rice husk, soak the rice husk in the organic acid solution, and soak for 5 hours at a temperature of 60°C; When the dried rice husk is sent to the circulating fluidized bed ...

Embodiment 3

[0049] Use oxalic acid to prepare an organic acid solution with a mass concentration of 5%; mix with 12L of organic acid solution to soak 1Kg of rice husk, soak the rice husk in the organic acid solution, and soak for 2 hours at a temperature of 60-90°C treatment; when the dried rice husks are fed into the circulating fluidized bed boiler for combustion, the combustion temperature in the furnace is set at 750°C; the flue gas discharged from the circulating fluidized bed boiler can be recovered through cloth bags with a purity of 98.2% to 98.8%, with an average Amorphous nano-silica rice husk ash with a particle size of 55nm.

[0050] Going one step further:

[0051] Use oxalic acid to prepare an organic acid solution with a mass concentration of 5%; mix with 12L of organic acid solution to soak 1Kg of rice husk, soak the rice husk in the organic acid solution, and soak for 2 hours at a temperature of 60°C; When the dried rice husk is sent to the circulating fluidized bed boil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com