Method of reducing fly ash carbon content of circulating fluidized bed boiler

A fly ash carbon content, circulating fluidized bed technology, used in fluidized bed combustion equipment, combustion methods, indirect carbon dioxide emission reduction, etc. The comprehensive utilization of ash and other issues can increase the combustion reaction rate and residence time, and reduce the carbon content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

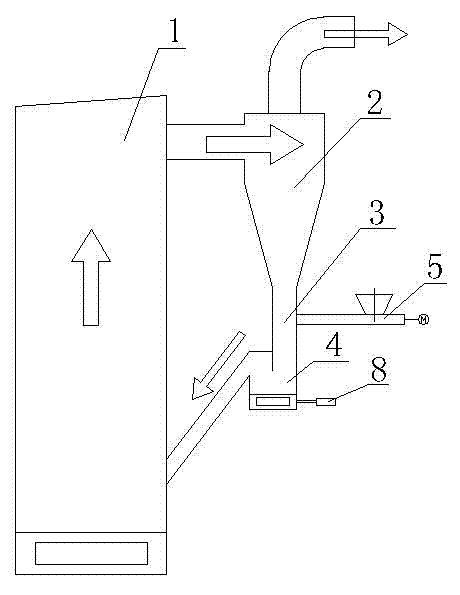

[0020] Such as figure 1 As shown, the circulating fluidized bed boiler of this embodiment includes a furnace 1, a cyclone separator 2, a standpipe 3, and a return device 4. The method of this embodiment for reducing the carbon content of fly ash in a circulating fluidized bed boiler includes Proceed as follows:

[0021] 1) Install the screw feeder 5 horizontally at a distance of 500mm~2000mm from the top of the riser 3. According to long-term field tests and experience, the negative pressure in the space within 500mm from the top of the riser 3 is large, and the fly ash is sent to the riser 3 Unable to enter the circulating fluidized bed ash circulation system, and directly escape from the cyclone separator 2, the fly ash cannot be reburned. The positive pressure in the space beyond 2000mm from the top of the riser 3 is large, and the screw feeder 5 sends the fly ash into The riser 3 is very difficult. The screw feeder 5 is installed at a distance of 500mm~2000mm from the top of...

Embodiment 2

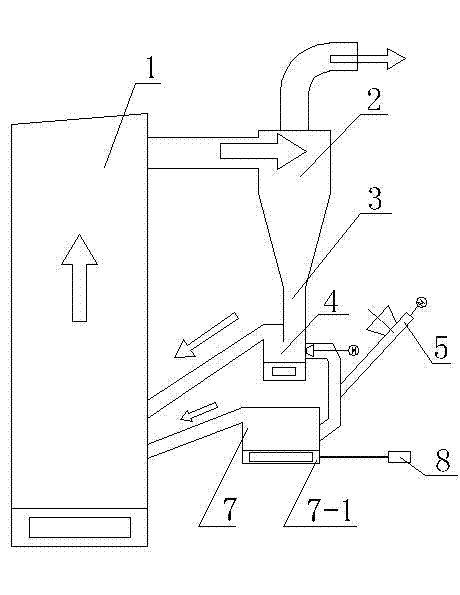

[0024] Such as figure 2 As shown, the structure of the circulating fluidized bed boiler of this embodiment is the same as that of Embodiment 1. A method for reducing the carbon content of fly ash from a circulating fluidized bed boiler of this embodiment includes the following steps:

[0025] 1) Separately set up fly ash bubbling fluidized bed 7 in the circulating fluidized bed boiler ash circulation system, install cone valve 7-2 on the return device 4, and connect the fly ash outlet at the cone valve 7-2. The feed pipe 7-3 of the ash bubbling fluidized bed 7 is installed with a screw feeder 5 inclined downward on the upper part of the feed pipe 7-3, and the furnace 1 is connected to the outlet of the fly ash bubbling fluidized bed 7, and The air inlet chamber 7-1 at the bottom of the ash bubbling fluidized bed 7 is connected to an oxygen-enriched air generator 8;

[0026] 2) When the circulating fluidized bed boiler is in operation, the circulating ash particles undergoing combu...

Embodiment 3

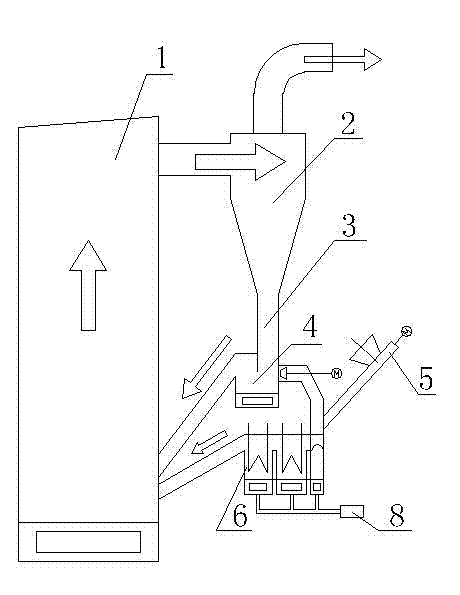

[0028] Such as image 3 As shown, the circulating fluidized bed boiler of this embodiment includes a furnace 1, a cyclone separator 2, a standpipe 3, a return device 4, and an external bed 6. The method of this embodiment reduces carbon content in fly ash of a circulating fluidized bed boiler The steps of the measurement method are as follows:

[0029] 1) Install the screw feeder 5 on the upper part of the feed pipe 6-2 of the external bed 6 inclined downward, and connect the oxygen-enriched air generator 8 at the air inlet chamber 6-1 at the bottom of the external bed 6;

[0030] 2) When the circulating fluidized bed boiler is in operation, the circulating ash particles undergoing combustion enter the cyclone separator 2 from the furnace 1 with the air flow, and after the separation action of the cyclone separator 2, the separated circulating ash particles descend through the standpipe 3 to return Feeding device 4, part of the circulating ash is returned directly to the furnace 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com