Alcohol dehydration steam heating system

A heating system and alcohol dehydration technology, applied in the field of heating systems, can solve the problems of reduced heat transfer efficiency, high exhaust gas temperature, and reduced service life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

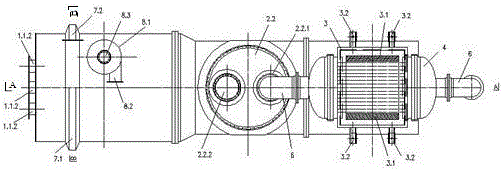

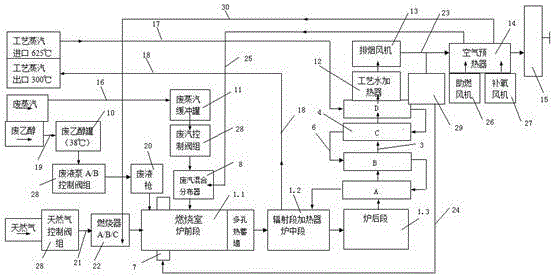

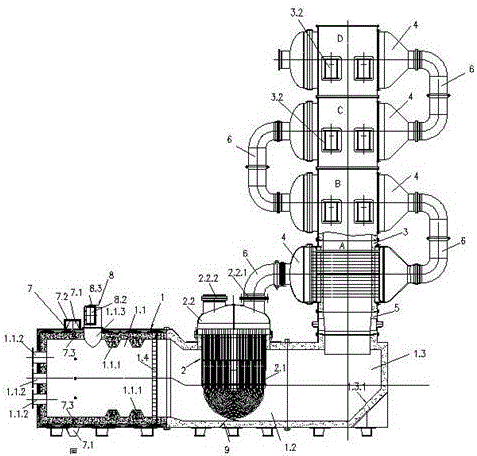

[0037]Embodiment 1: A kind of alcohol dehydration steam heating system, comprising ethylene oxide heating furnace 1, waste ethanol tank 10, waste steam buffer tank 11, process water heater 12, exhaust fan 13, air preheater 14 and chimney 15. The ethylene oxide heating furnace 1 is sequentially divided into a combustion chamber 1.1 in the front section, a radiation heating chamber 1.2 in the middle section, and a convection heating chamber 1.3 in the rear section. The combustion chamber 1.1 is a horizontal circular straight cylinder, and the material of the combustion chamber 1.1 is made of external Q235B The metal shell and internal corundum material are poured, and the material of radiation heating chamber 1.2 and convection heating chamber 1.3 is composed of external Q235B metal shell and internal ceramic fiber cotton block. Two protruding rings 1.1.1 are arranged near the rear end of the combustion chamber 1.1, and the protruding rings 1.1.1 are made of refractory material, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com