Solid hazardous waste and liquid hazardous waste cooperative disposal incinerator and disposal method

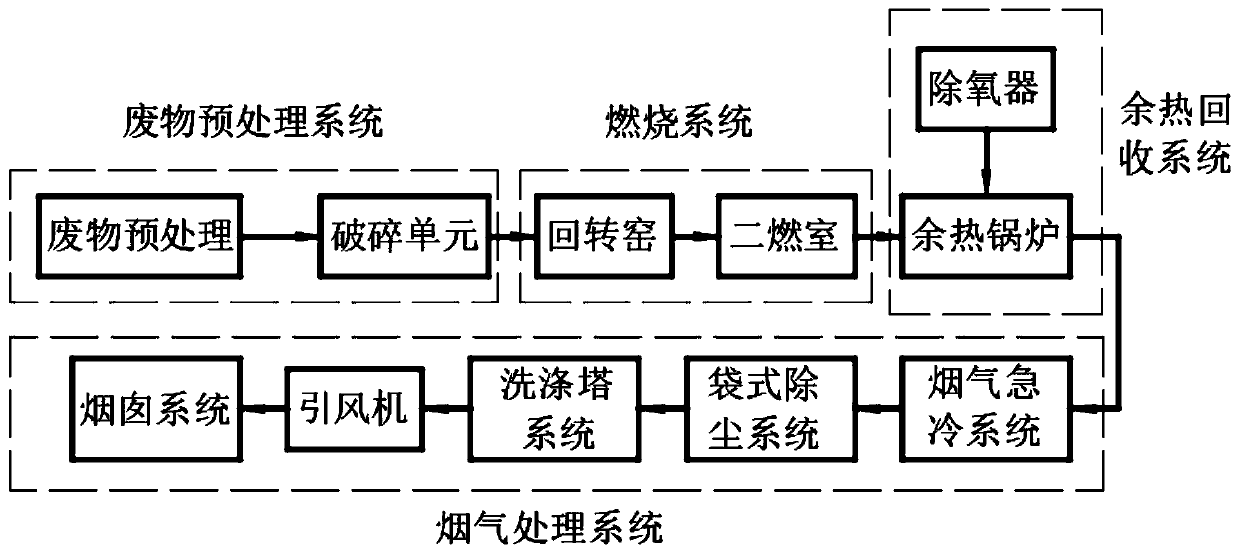

A hazardous waste and co-processing technology, applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problems of insufficient capacity of liquid waste, weak disposal capacity of liquid hazardous waste, single phase state, etc., and achieve improved disposal capacity and good combustion Temperature, stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

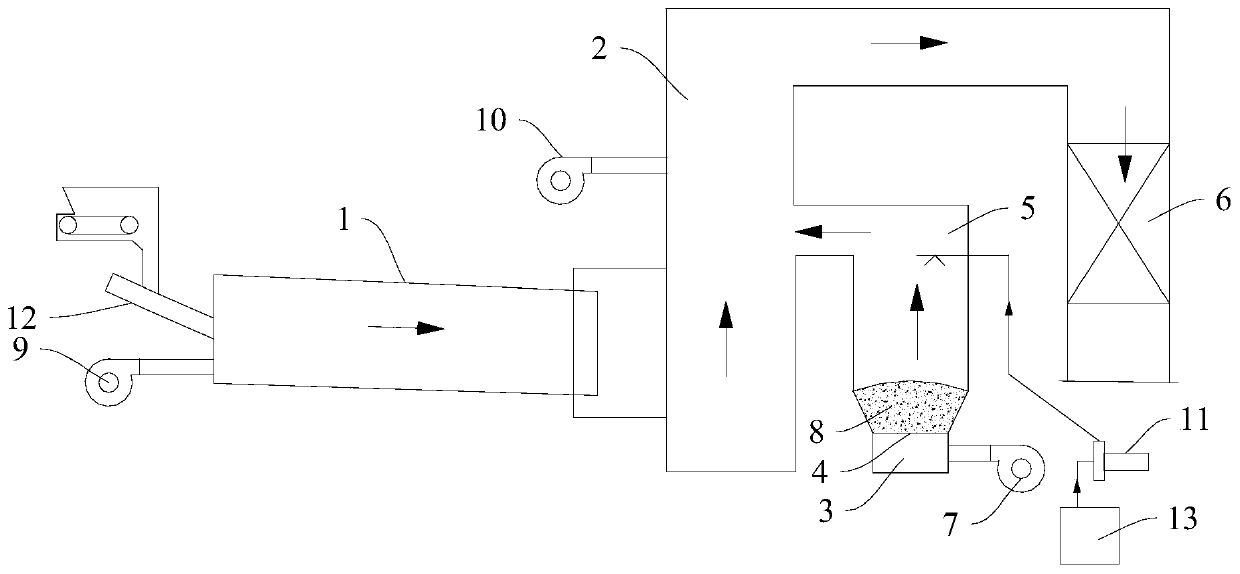

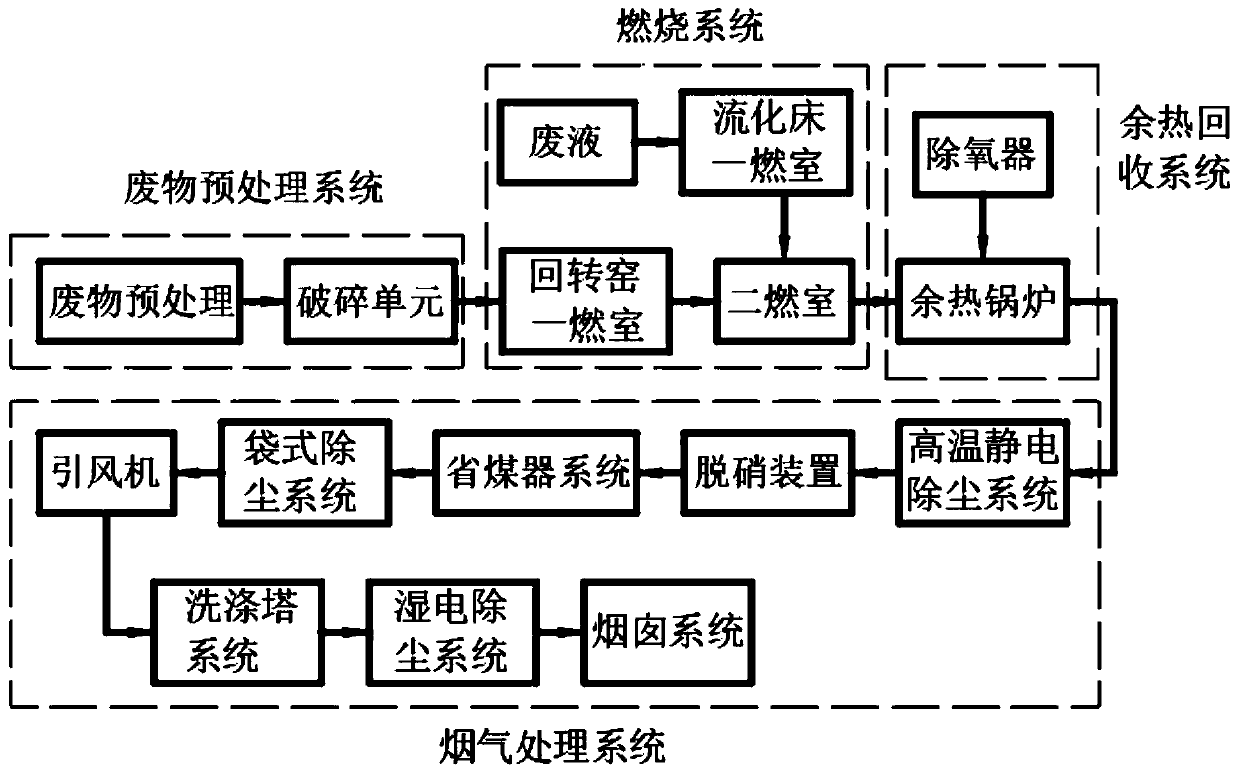

[0046] Such as figure 2 As shown, an incinerator for the co-combustion of solid and liquid hazardous wastes. The present invention adds a fluidized bed special for waste liquid incineration on the basis of the traditional rotary kiln one-chamber and two-chamber incinerator system. The combustion chamber shares the second combustion chamber with the first combustion chamber of the rotary kiln to form a hazardous waste incineration system with a rotary kiln and a fluidized bed combustion chamber.

[0047] The cooperative combustion device of the present application includes a rotary furnace, a combustion chamber 1, a fluidized bed, a combustion chamber 5, and a second combustion chamber 2. The furnace of the first combustion chamber 1 of the rotary kiln is provided with an inlet, a combustion-supporting air inlet of the rotary kiln and a flue gas outlet. The inlet is connected to a solid waste feeder 12, and the combustion-supporting air inlet of the rotary kiln is connected to a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com