Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of graphene/Fe3O4/polyaniline ternary wave-absorbing composite material

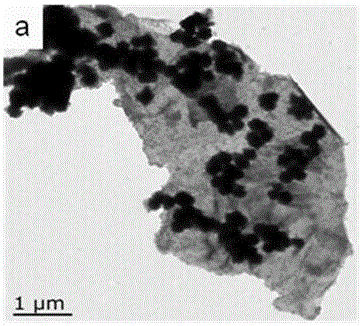

The invention discloses a preparation method of a graphene / Fe3O4 / polyaniline ternary wave-absorbing composite material, and relates to the technical field of ternary composite conductive material production. The method is characterized in that a process using aniline monomer to directly reduce graphene oxide is used, and the coordination interaction of the graphene oxide and Fe3O4 is used to prepare the graphene / Fe3O4 / polyaniline ternary composite material, so that the goal of greenization of the nano composite material preparation and compounding and refinement of the wave-absorbing material structure can be realized. In the composite material, polyaniline organically wraps the surface of the compound of Fe3O4 and graphene to form a specific layer-by-layer assembled structure. The specific surface area is greatly increased by the laminated graphene sheets, and more interfacial polarization and interfaces are caused by the layered structure and the core-shell structure. The prepared ternary composite material is capable of realizing impedance matching and is beneficial to the attenuation effect of electromagnetic waves by the additional interfacial polarization and multiple interfaces caused by the layer-by-layer assembled structure.

Owner:YANGZHOU UNIV

Integrated lobster-rice farming method

InactiveCN108782384AGo greenCompositeClimate change adaptationPisciculture and aquariaShrimpFresh water

The invention discloses an integrated lobster-rice farming method, which includes the following steps of: (1) lobster cultivation; (2) lobster seedling release; (3) lobster seedling management; (4) first season lobster catching; (5) rice-lobster farming; (6) second season lobster catching; (7) reserved lobster seedings; (8) rice harvest; (9) lobster wintering. The invention relates to the breedingof fresh-water lobster cultivation with rice planting. The whole process does not use chemical fertilizers, chemical pesticides and hormones to produce ecological, high-quality lobsters and rice. Theeconomic benefit of fresh-water lobster cultivation with rice planting combined model is five thousand yuan more than fresh water alone, and two thousand yuan more than rice cultivation per mu, and fully realizes the green, compound, high-potency and scale of the agricultural industry.

Owner:九江凯瑞生态农业开发有限公司

Multi-layer pipe quick liquid-filled forming method and system

The invention relates to a multi-layer pipe quick liquid-filled forming method and system; according to the invention, a technical problem that plates in two layers or more than two layers are formed by using pressure uniformly loaded by a liquid and the liquid filling speed can be increased can be solved; pipes in a plurality of layers are sleeved together and clamped by upper and lower half molds; no pretreatment is needed between the pipes in the plurality of layers; additional oil guide cylinders are sleeved at the right ends of the pipes in the plurality of layers; a left pushing head is inserted into the left ends of the pipes in the plurality of layers; a right pushing head is inserted into the additional oil guide cylinders; the pipes in the plurality of layers, the left pushing head, the right pushing head and the additional oil guide cylinders form a liquid chamber; through the additional oil guide cylinders, a forming medium is filled into the liquid chamber; after the liquid chamber is full of the forming medium, the right pushing head is moved to seal the right ends of the pipes in the plurality of layers; the forming medium is filled into the liquid chamber in the pipes from the left or right pushing head so as to supercharge; meanwhile, the left pushing head and the right pushing head are axially moved and fed to the pipes so as to ensure the sealing of the pipes; and the pipes in the plurality of layers are in close contact with each other due to the effect of the forming medium, so that the layers of a formed pipe are also closely combined with each other.

Owner:SHANGHAI HUIZHONG AUTOMOTIVE MFG

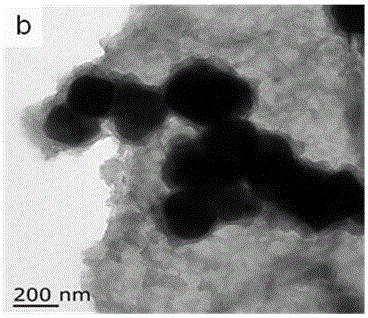

Manufacturing method for discrete thermo-electricity separated ALPCB (Aluminum Printed Circuit Board)

InactiveCN104159404AHigh composite strengthCompositePrinted circuit manufactureElectricityBiochemical engineering

The invention discloses a manufacturing method for an ALPCB (Aluminum Printed Circuit Board) with an ultra-high heat conduction coefficient. The manufacturing method comprises the following steps: 1, the manufacture of an optical drawing template; 2, the manufacture of a copper-aluminium composite base plate; 3, the process for performing rough shape cutting on the copper-aluminium composite base plate, PP pieces and copper foils and drilling peripheral holes; 4, the manufacture of a heat conduction bonding pad, and the processing for forming a groove in a resin coated copper foil; 5, the process for press-fitting; 6, the manufacture of circuits and CCD target-shooting holes; 7, the process for resistance welding, and letter and surface processing; 8, the process for drilling a product functional hole; 9, the process for formation to obtain the finished product, namely the ALPCB with the ultra-high heat conduction coefficient. According to the invention, the manufacturing precision is high, the product practicability and durability are effectively improved, the property of the manufactured ALPCB is stable, and the quick and ultra-high heat conduction effect is achieved.

Owner:简玉苍

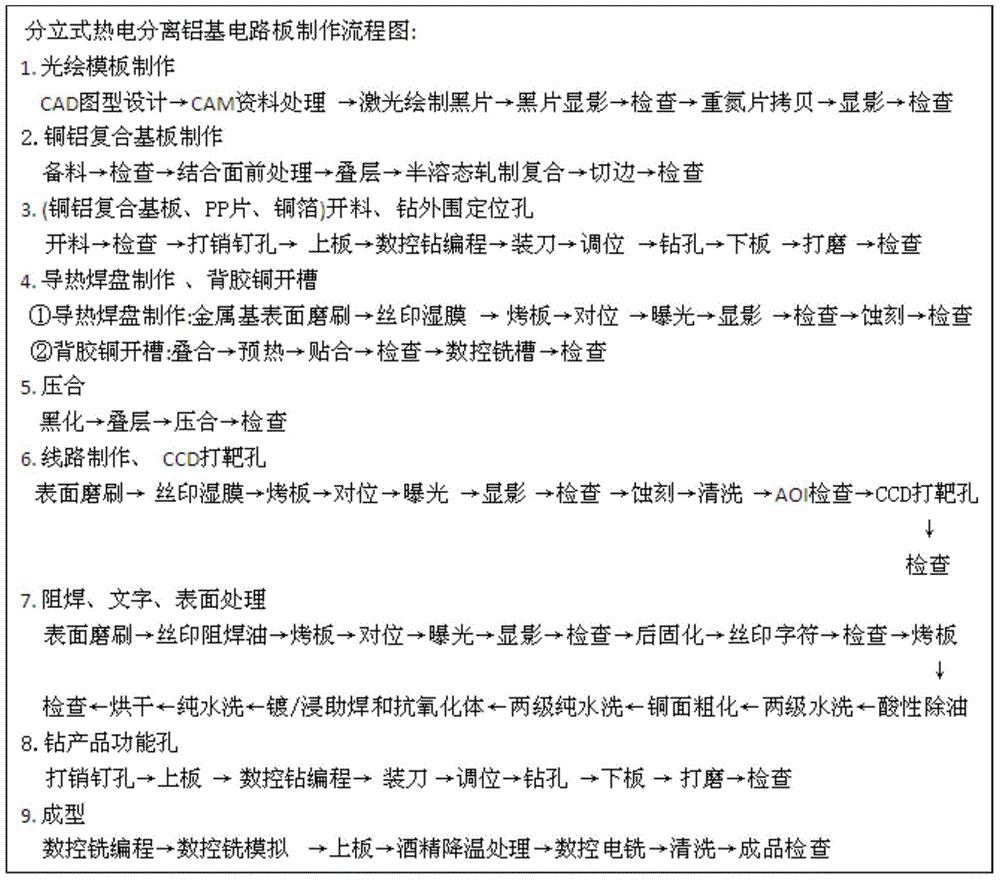

Accumulator distribution type fuel injection pump

InactiveCN1455845AImprove reliabilityPrevent partial wearPositive displacement pump componentsFuel injecting pumpsHigh pressureDiesel engine

An accumulator distribution type fuel injection pump usea as a fuel injection pump for low-pollution diesel engine low in fuel consumption and capable of meeting an exhaust emission control requirements, wherein a high-pressure fuel accumulated in an accumulating chamber is distributedly fed to each cylinder through a distribution shaft, functional members forming high-pressure routes such as a plunger, an injection control valve for fuel injection control, the accumulating chamber, and the distribution shaft are disposed inside a hydraulic base (Hb), and a plunger part for accumulating fuel into the accumulating chamber is installed in the hydraulic base.

Owner:YANMAR CO LTD

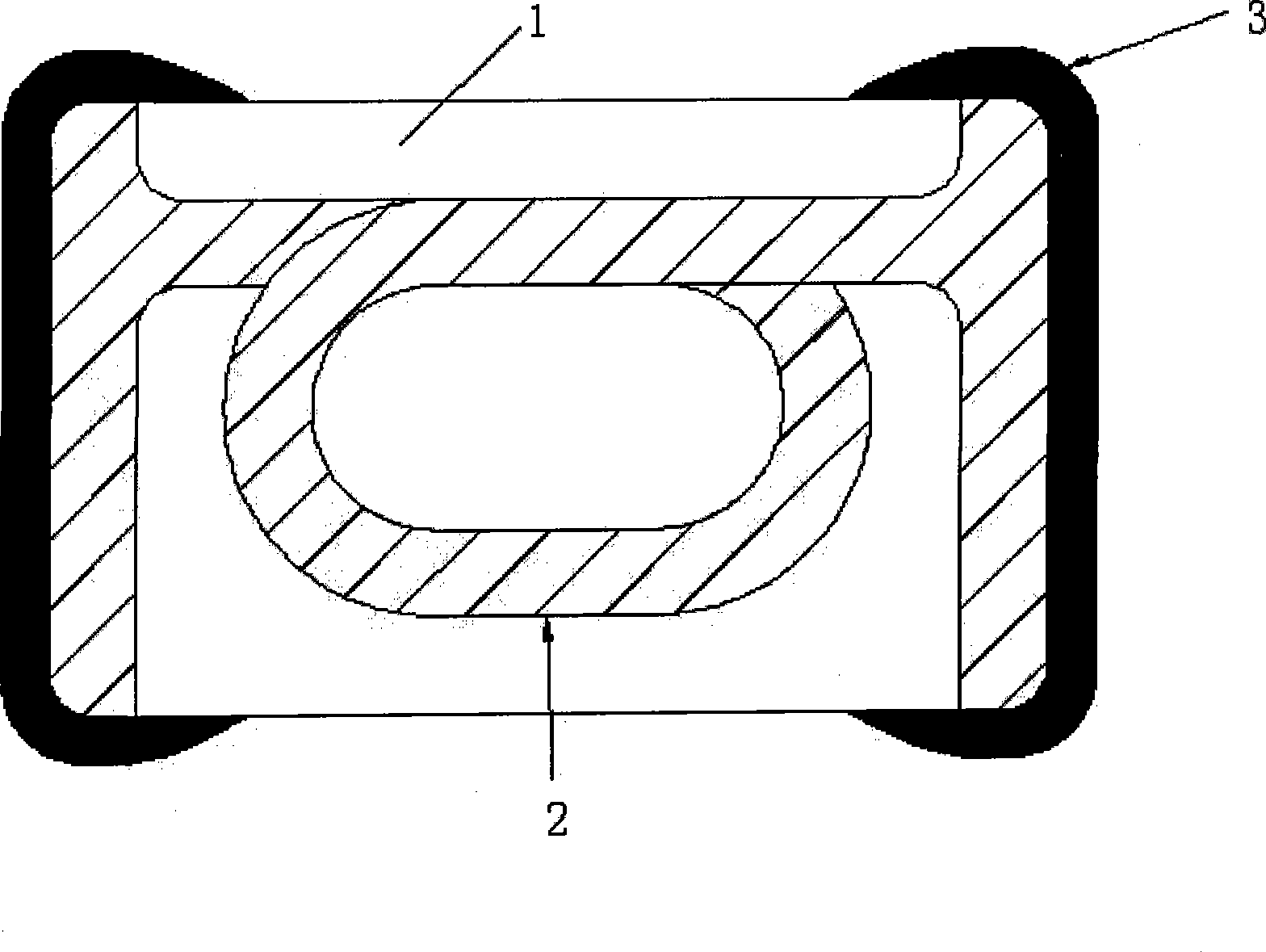

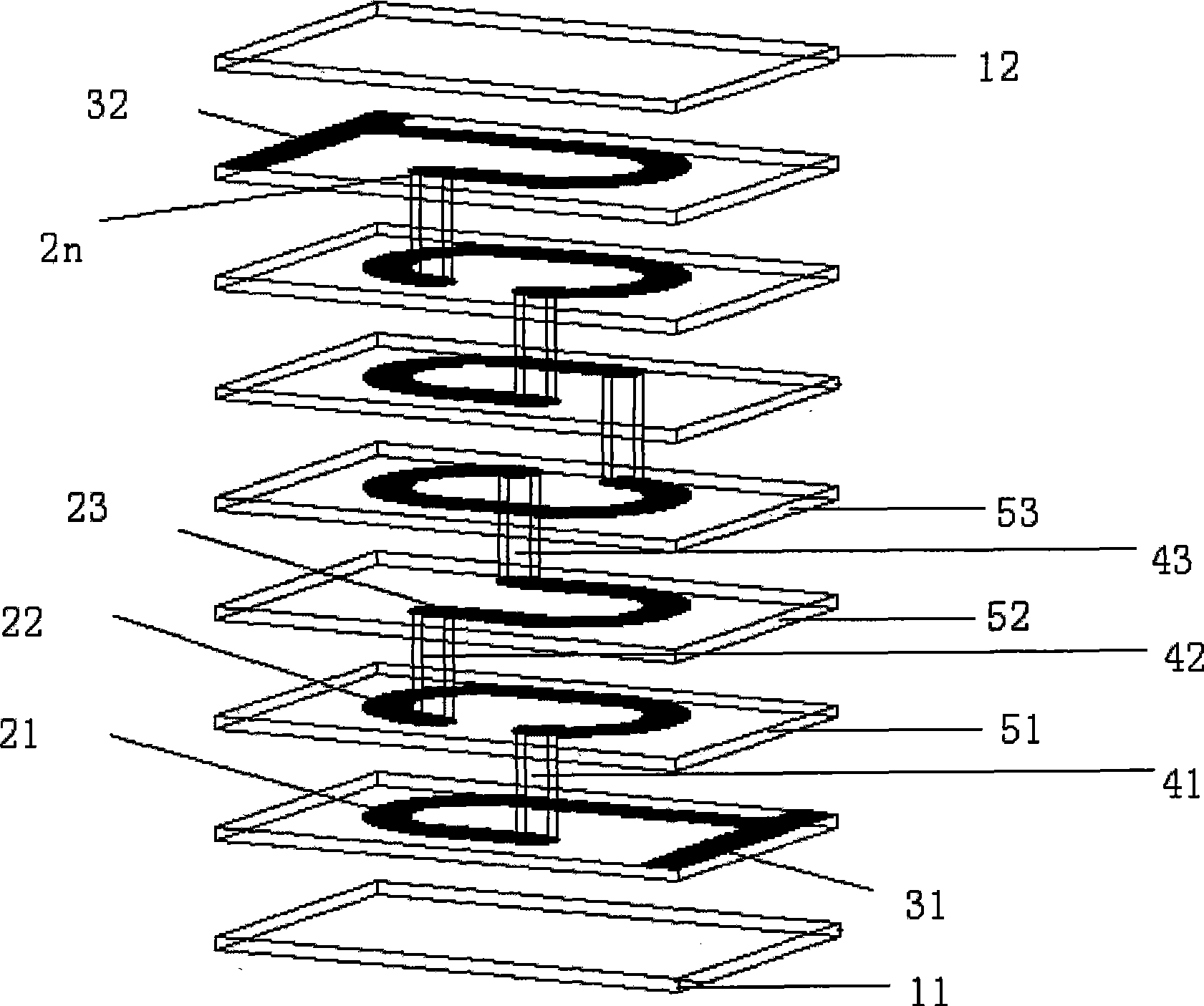

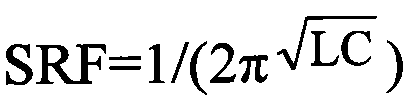

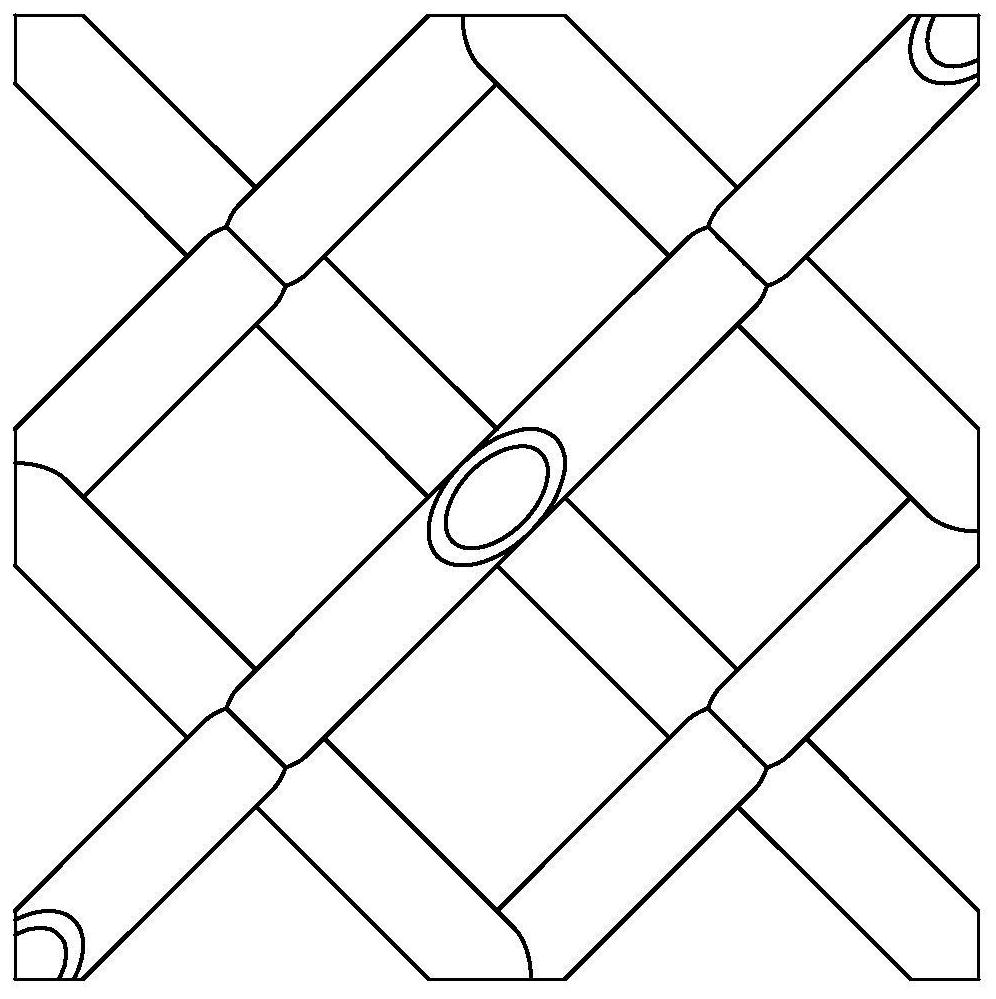

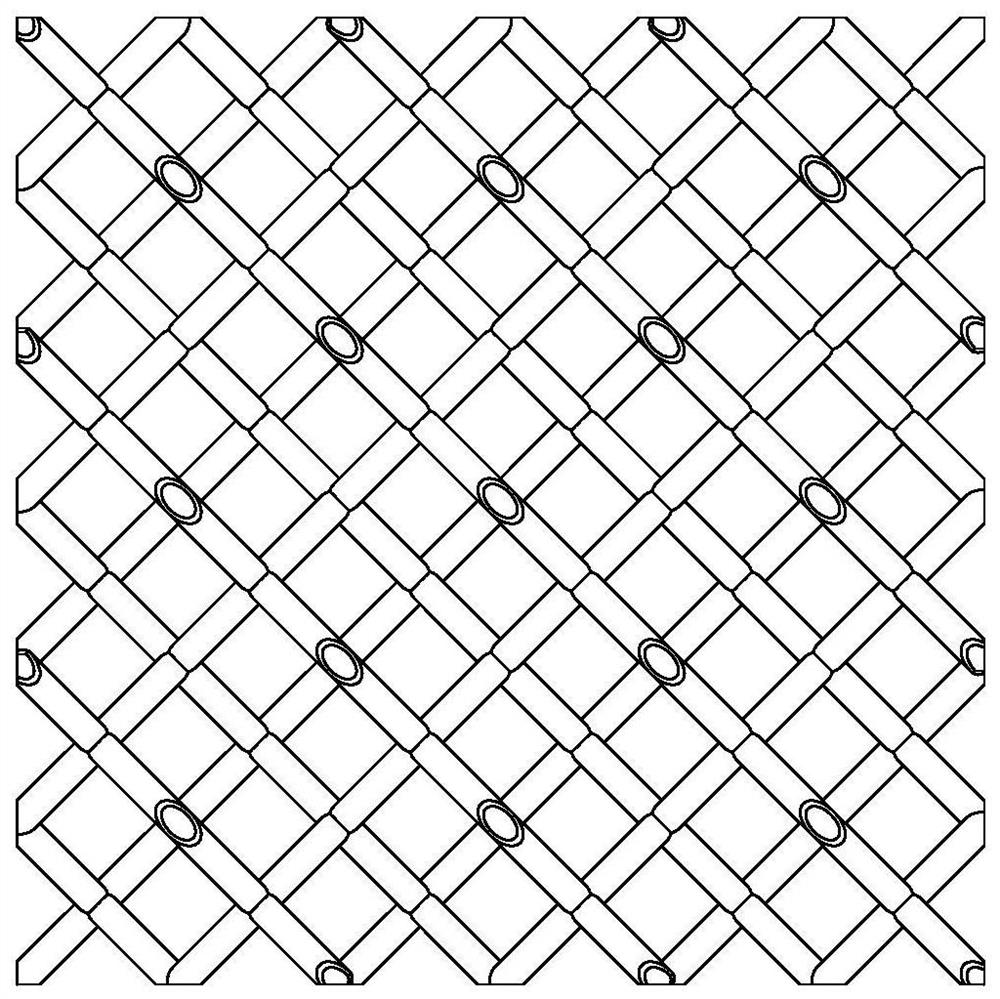

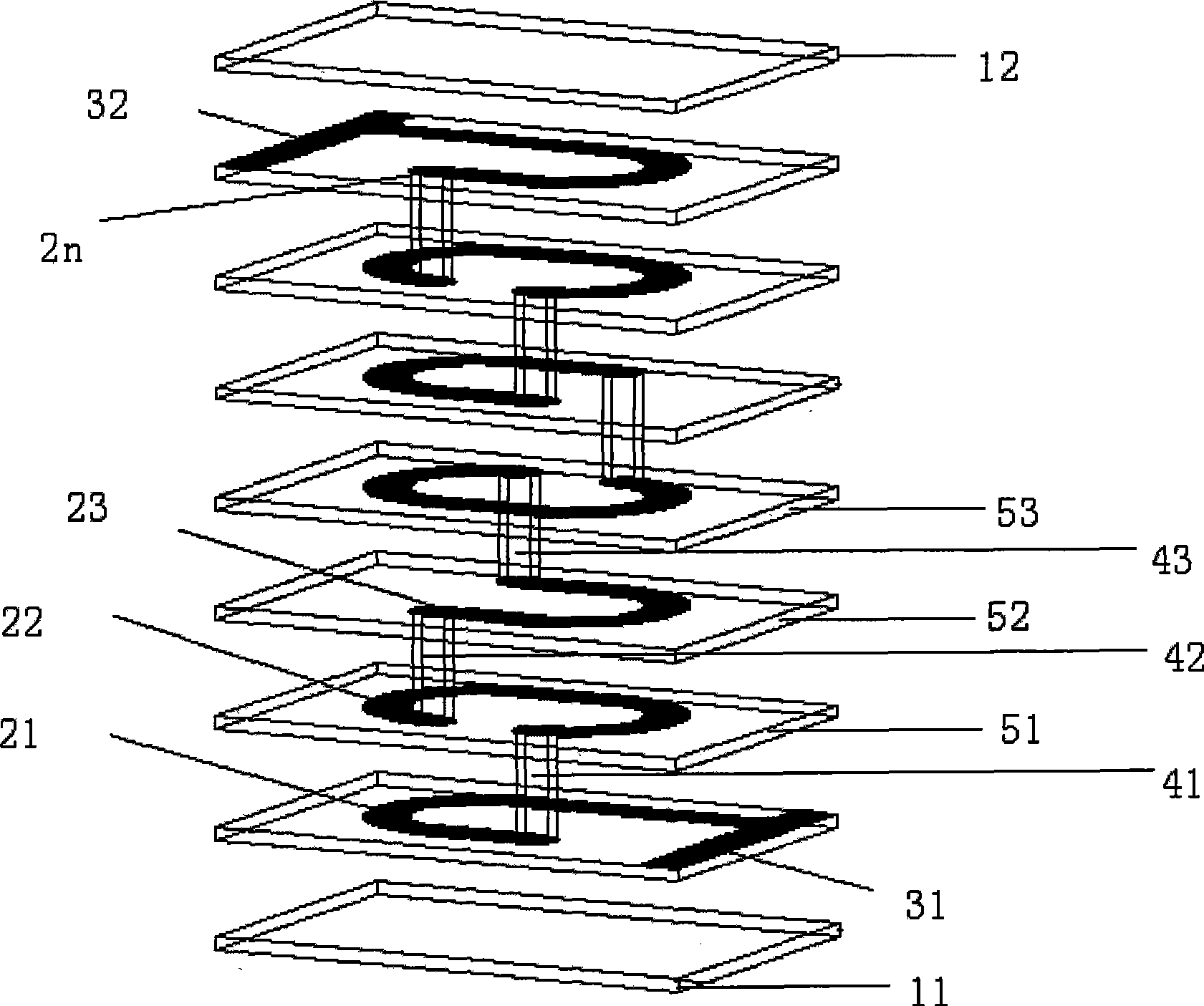

Inductor and manufacturing method thereof

ActiveCN101521087ACompositeTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresFerrite substrateEngineering

The invention is suitable for the field of electronics, and provides an inductor and a manufacturing method thereof. The inductor comprises a ferrite substrate, a conductive coil arranged in the ferriThe invention is suitable for the field of electronics, and provides an inductor and a manufacturing method thereof. The inductor comprises a ferrite substrate, a conductive coil arranged in the ferrite substrate, and terminal electrodes which are positioned at two end parts of the ferrite substrate and used for electrically connecting with the conductive coil. The conductive coil comprises a plurte substrate, and terminal electrodes which are positioned at two end parts of the ferrite substrate and used for electrically connecting with the conductive coil. The conductive coil comprises a plurality of layers of electrode patterns which are connected layer upon layer spirally. The layers of the electrode patterns are electrically connected through electric connecting elements to form a spirality of layers of electrode patterns which are connected layer upon layer spirally. The layers of the electrode patterns are electrically connected through electric connecting elements to form a spiral ellipse-like shape. In the inductor provided by the invention, the conductive coil adopts an ellipse-like spiral structure so as to make the inductor realize the specific inductive characteristic aal ellipse-like shape. In the inductor provided by the invention, the conductive coil adopts an ellipse-like spiral structure so as to make the inductor realize the specific inductive characteristic and the impedance characteristic and integrates the inductor and beads into a whole.nd the impedance characteristic and integrates the inductor and beads into a whole.

Owner:SHENZHEN ZHENHUA FU ELECTRONICS

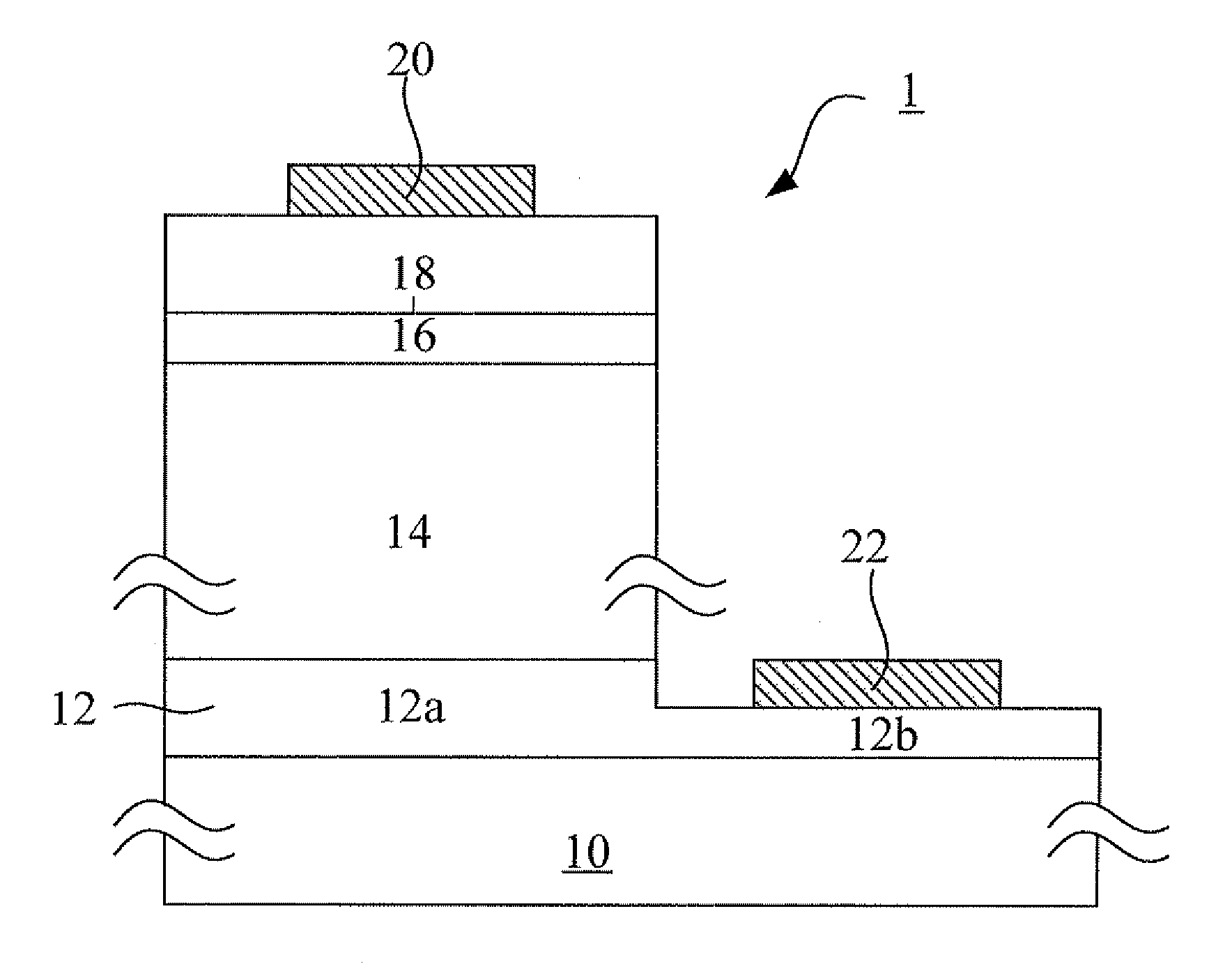

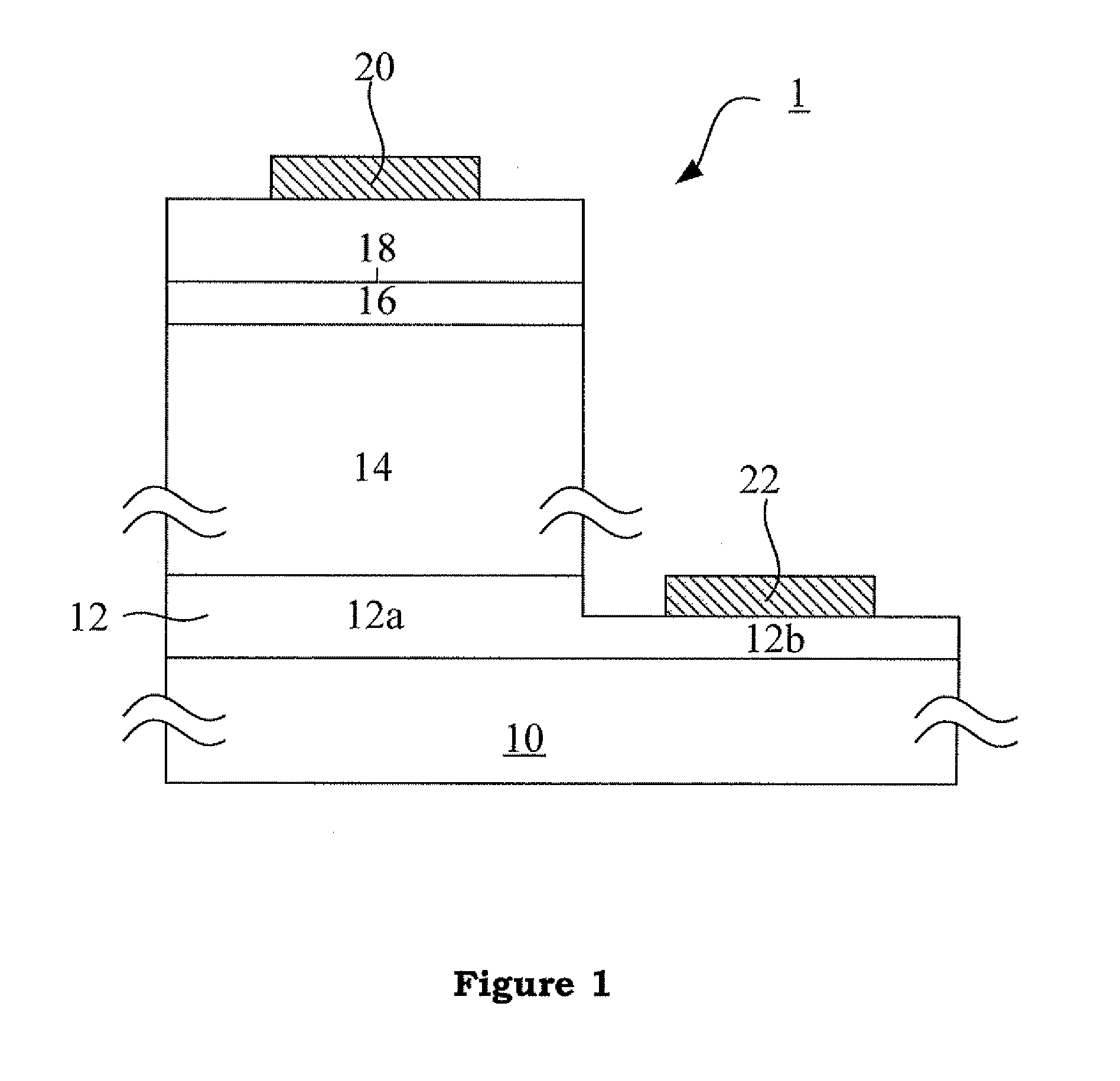

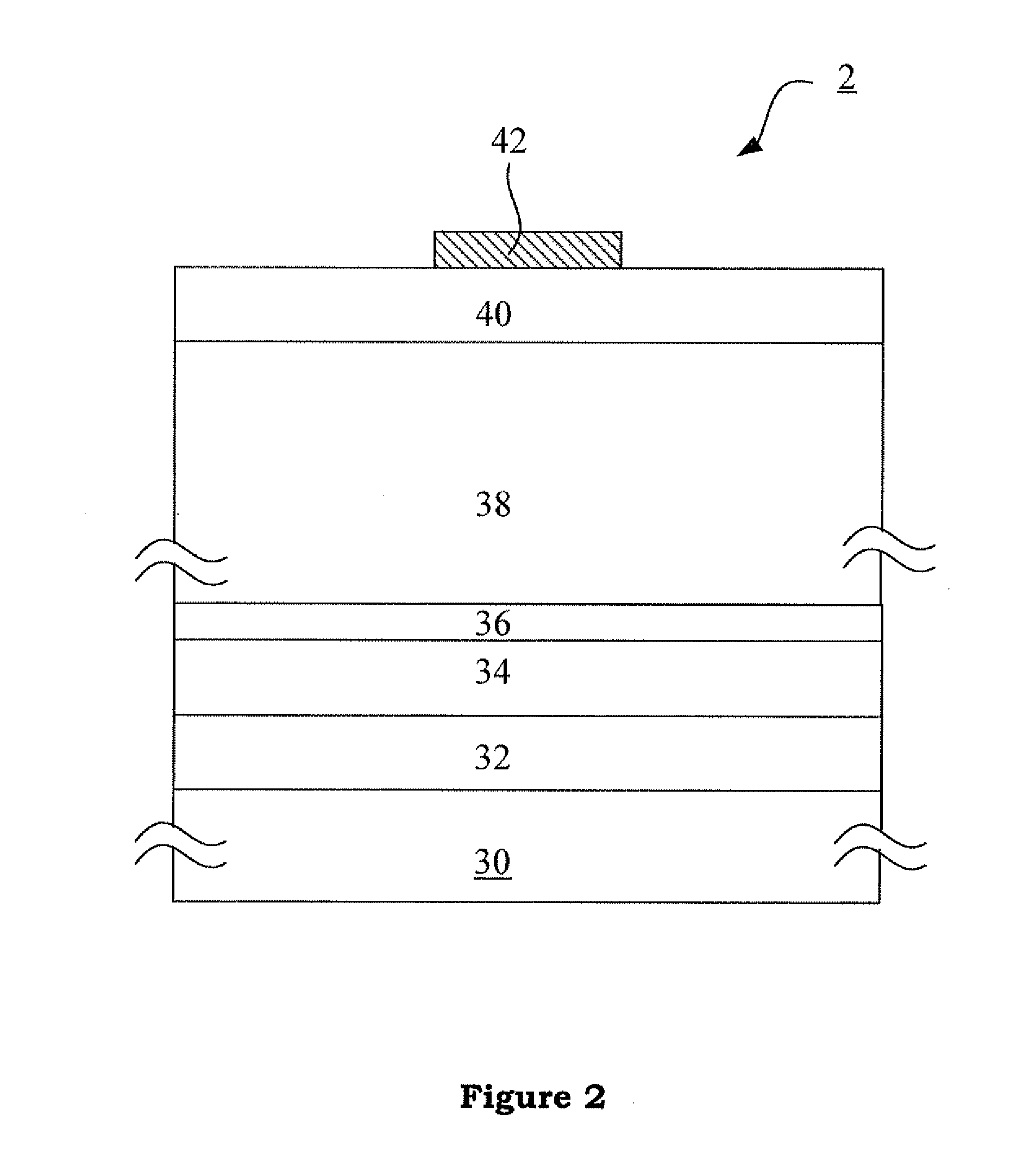

Light emitting device with graded composition hole tunneling layer

InactiveUS20130228806A1Easy to transportImprove luminous efficiencyNanoopticsSemiconductor lasersQuantum wellElectron blocking layer

A light emitting device with graded composition hole tunneling layer is provided. The device comprises a substrate and an n-type semiconductor layer is disposed on the substrate, in which the n-type semiconductor layer comprises a first portion and a second portion. A graded composition hole tunneling layer is disposed on the first portion of the n-type semiconductor layer. An electron blocking layer is disposed on the graded composition hole tunneling layer. A p-type semiconductor layer is disposed on the electron blocking layer. A first electrode is disposed on the p-type semiconductor layer, and a second electrode is disposed on the second portion of the n-type semiconductor layer and is electrical insulated from the first portion of the n-type semiconductor. The graded composition hole tunneling layer is used as the quantum-well to improve the transport efficiency of the holes to increase the light emitting efficiency of the light emitting device.

Owner:NAT CHIAO TUNG UNIV

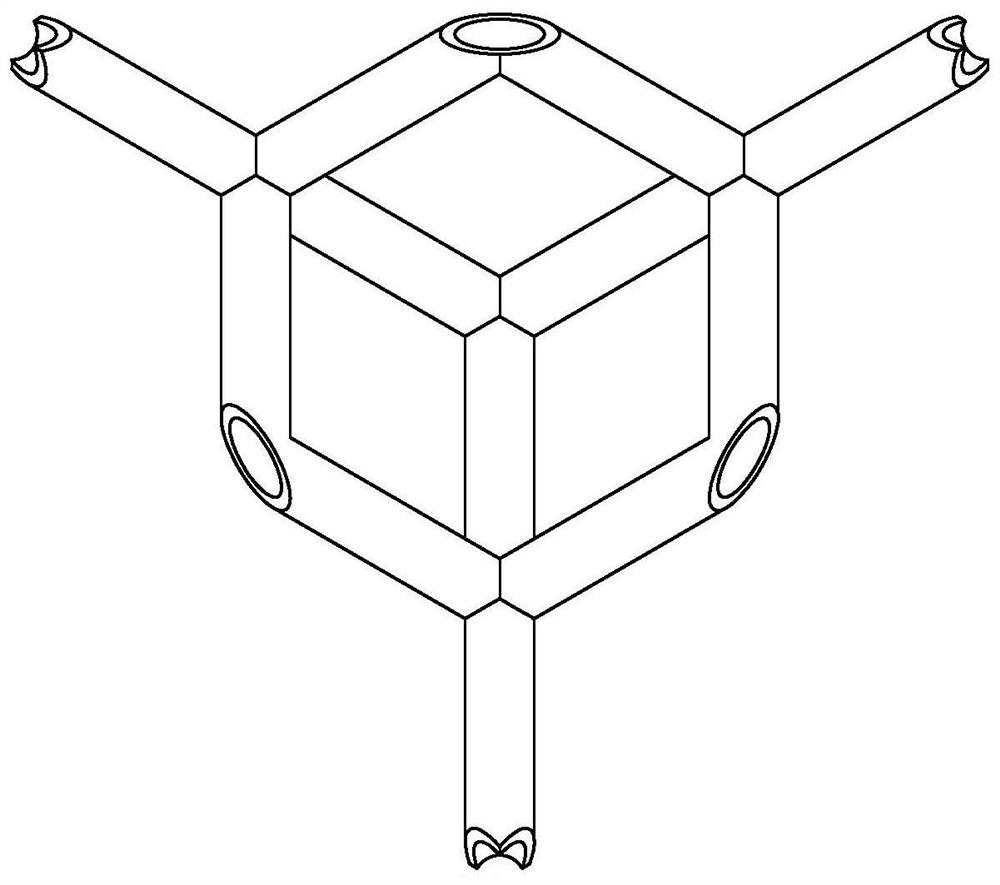

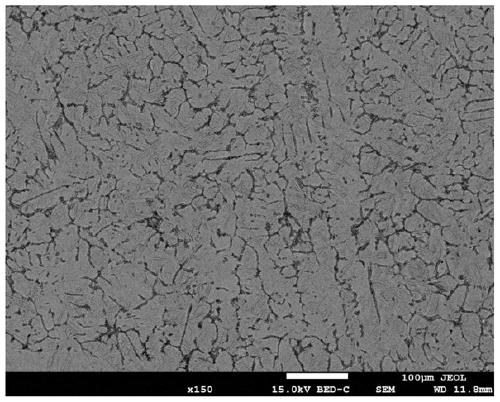

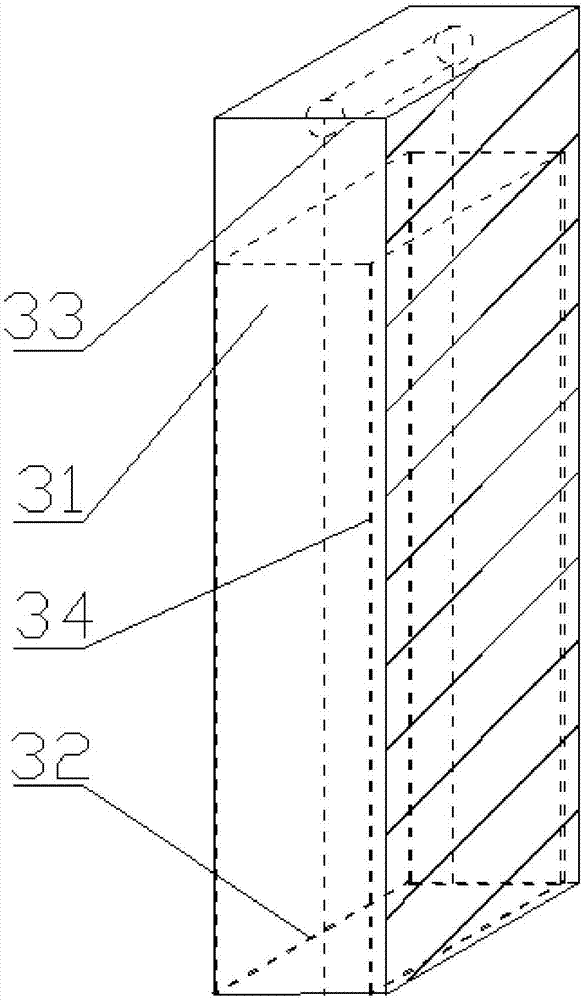

Lattice magneto-rheological intelligent vibration reduction structure, magneto-rheological vibration isolating device and manufacturing method of lattice magneto-rheological intelligent vibration reduction structure

PendingCN112555327APollution abilityWide range of stiffness adjustmentGeometric CADSpringsPhysicsMagneto

The invention discloses a lattice magneto-rheological intelligent vibration reduction structure, a magneto-rheological vibration isolating device and a manufacturing method of the lattice magneto-rheological intelligent vibration reduction structure. The lattice magneto-rheological intelligent vibration reduction structure comprises a plurality of lattice unit cells which are periodically and orderly arranged in a three-dimensional space and connected with one another; each lattice unit cell comprises spatially distributed joints and hollow rods connected between the joints; and the hollow rods are filled with magnetorheological fluid. The preparation method of the structure comprises the following steps that a three-dimensional model is constructed through computer modeling software, andcombining a high-precision stereolithography (SLA) technology, a lattice structure with a proper structure size is prepared; and meanwhile, the magneto-rheological vibration isolating body of the intelligent structure is prepared in combination with extrusion type magneto-rheological vibration isolating device product parameters, and the magneto-rheological vibration isolating body is applied to vibration isolating device products.

Owner:CHONGQING UNIV

Method and device for aircraft main control system test

ActiveCN110525685ADoes not affect normal useSimple structureAircraft components testingControl systemEmbedded system

The invention provides a method for an aircraft main control system test. The method comprises the following steps: obtaining an operation instruction; sending the operation instruction to an analog driver, wherein the analog driver is installed on an aircraft floor; and performing the corresponding main control system test by the analog driver according to the operation instruction.

Owner:CHINA SPECIAL TYPE FLIER RES INST

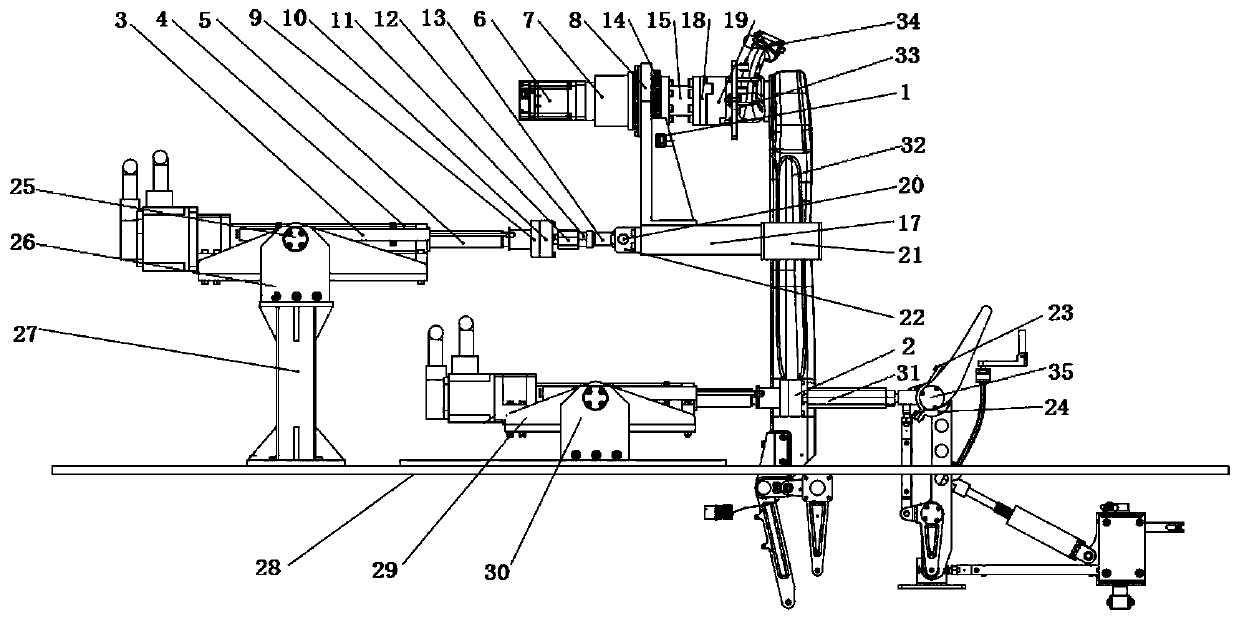

Arc additive manufacturing in-situ alloying device and method capable of achieving alternate wire melting and powder supply

PendingCN110004398AAchieve alloyingCompositeAdditive manufacturing apparatusMolten spray coatingArthrobotrysElectric arc

The invention discloses an arc additive manufacturing in-situ alloying device and method capable of achieving alternate wire melting and powder supply. The device comprises a spraying device, a wire melting device and a turnover workbench. Through the gas power spraying device, in-situ spraying of multiple kinds of pure metal powder, alloy powder and metal-ceramic composite powder can be achieved,and alloying and compounding of an arc additive manufacturing material can be achieved to the greatest degree. When the gas power spraying device carries out in-situ powder spraying, generated high-speed gas jet flow carrying powder particle impacts on the surface of a deposition layer, the function of stress peening is achieved, a pressure stress layer is introduced, surface roughness is reduced, and the structure performance of an arc additive manufacturing metal component is optimized. The device completely depends on existing welding equipment existing spraying equipment in the market, additional equipment research and development expenditures are not needed, the powder spraying process and the subsequent arc wire filling process are controlled by programming of a six-axis joint robot, automatic operation can be carried out, and the work efficiency is high.

Owner:TIANJIN UNIV

Ultraviolet-resistant corrosion-resistant thin coating type water-based fireproof coating material and preparation method thereof

InactiveCN113845820AGuaranteed fire performanceCompositeFireproof paintsRubber derivative coatingsEpoxyUltraviolet lights

The invention discloses an ultraviolet-resistant corrosion-resistant thin coating type water-based fireproof coating material, which comprises a water film, a flaky substance and an auxiliary agent, wherein the water film is prepared from the following substances in parts by weight: 30 to 60 parts of deionized water, 25 to 40 parts of a waterborne epoxy resin, 20 to 40 parts of chlorinated rubber emulsion, 10 to 20 parts of polytetrafluoroethylene emulsion, 5 to 15 parts of polyacrylic acid, 3 to 5 parts of polyethylene and 2 to 4 parts of chlorosulfonated polyethylene, the scaly substance is selected from one of flake graphite, glass flakes, flake mica or basalt flakes, the auxiliary agent comprises one or more of an ultraviolet light absorber, a light stabilizer, wear-resistant micro powder, a defoaming agent and a leveling agent, the mass percentage of the water film is 82-93%, the mass percentage of the scaly substance is 5-10%, and the mass percentage of the assistant is 2-8%. According to the invention, large-area basalt scales are used as an additive component of a thin-coating type water-based fireproof coating material, so that the salt spray resistance of the coating material can be improved on the premise of ensuring the adhesive force of the coating material, and the coating material has multiple properties.

Owner:烟台华恒节能科技有限公司

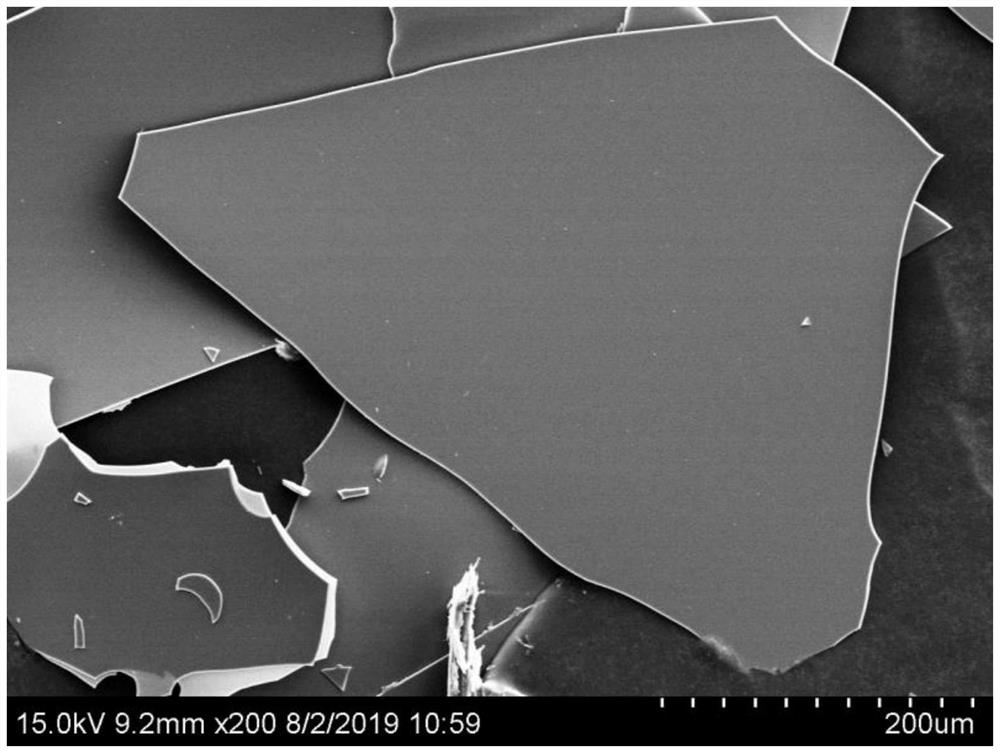

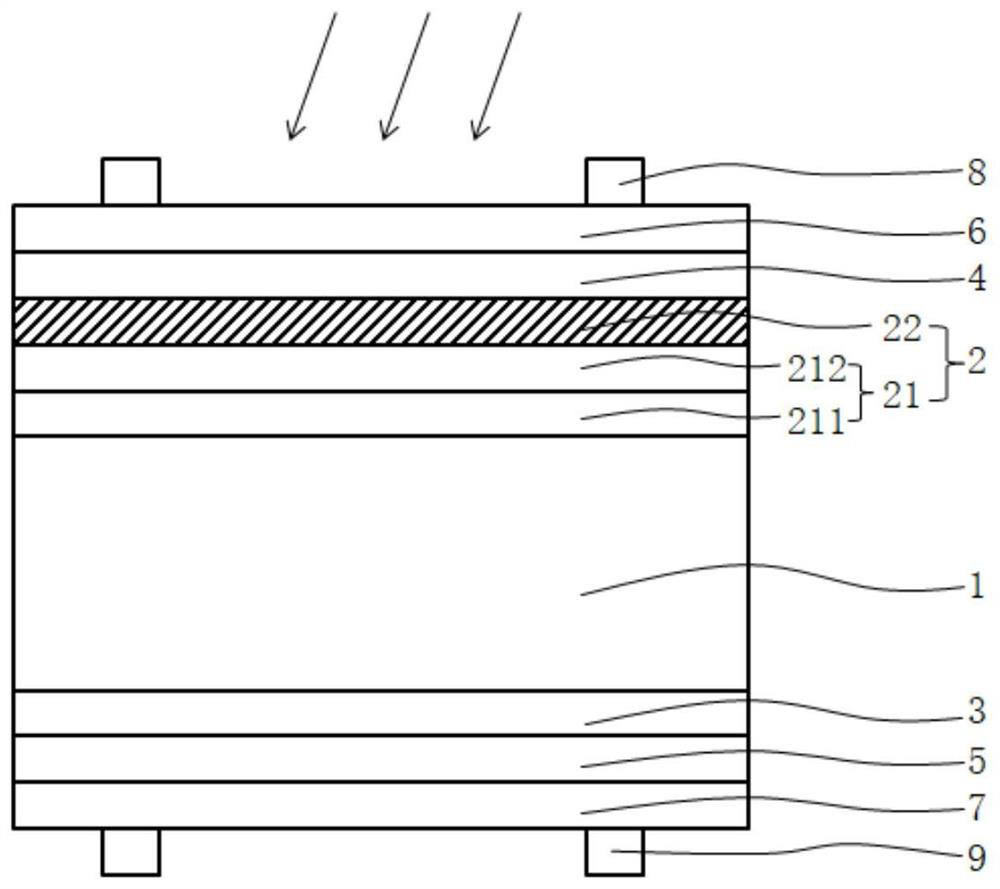

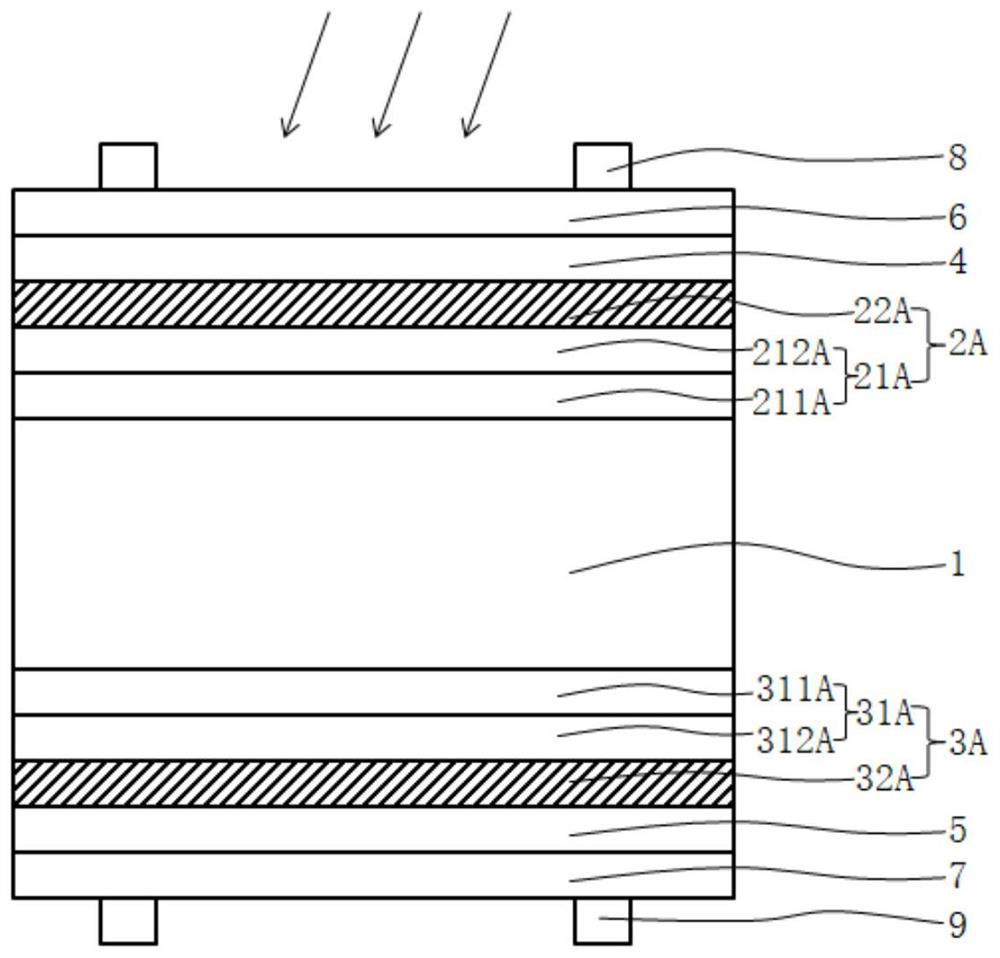

Heterojunction cell and preparation method thereof

ActiveCN113471312AIncrease short circuit currentImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationPhysicsChemistry

The invention provides a heterojunction cell and a preparation method thereof. The heterojunction cell comprises a semiconductor substrate layer and an intrinsic semiconductor composite layer. The intrinsic semiconductor composite layer is located on the surface of at least one side of the semiconductor substrate layer, and the intrinsic semiconductor composite layer comprises a bottom intrinsic layer and a wide-band-gap intrinsic layer located on the surface of the side, back on to the semiconductor substrate layer, of the bottom intrinsic layer, and the band gap of the wide-band-gap intrinsic layer is larger than that of the bottom intrinsic layer. The band gap of the wide-band-gap intrinsic layer is large, when sunlight irradiates the heterojunction cell, photons with energy smaller than that of the band gap of the wide-band-gap intrinsic layer cannot be absorbed in a parasitic mode, the parasitic absorption of the intrinsic semiconductor composite layer on the sunlight is reduced, and therefore the absorption of the semiconductor substrate layer on the sunlight is increased, photon-generated carriers generated by the semiconductor substrate layer are increased, so that the short circuit current of the heterojunction cell can be improved, and the conversion efficiency of the heterojunction cell can be improved.

Owner:ANHUI HUASUN ENERGY CO LTD

Composite yarn

The invention relates to a composite yarn, which is characterized in that, by weight fraction, it comprises 10%-15% cotton yarn, 15%-17% linen yarn, 14%-20% silk, 25% %-31% milk protein yarn, 20%-30% PROVISCOSE yarn, the diameters of the cotton yarn, linen yarn, silk, milk protein yarn and PROVISCOSE yarn are 0.008mm, 0.010mm, 0.008mm, 0.012mm respectively , 0.012mm. The cotton yarn, the linen yarn, the silk, the milk protein yarn and the PROVISCOSE yarn are twisted in a helical shape in the S direction. The composite yarn is made from pretreatment→blowing→carding→drawing→roving→spinning→winding. Cotton yarn, linen yarn, silk yarn, milk protein yarn and PROVISCOSE yarn have the same number of strands.

Owner:CHANGSHOU XINKANGSHENG CHEM FIBER CO LTD

Composite yarn

The invention relates to a composite yarn, which is characterized in that, by weight fraction, it includes 10%-15% silk, 15%-17% viscose yarn and 14%-20% polyester formed by cross-twisting. Yarn, 25%-31% methyl gram yarn, 20%-30% PROVISCOSE spinning, the diameters of the silk, viscose yarn, polyester yarn, methyl gram yarn, and PROVISCOSE spinning are 0.008mm and 0.010mm respectively. mm, 0.008mm, 0.012mm, 0.012mm. The silk, the viscose yarn, the polyester yarn, the keto yarn and the PROVISCOSE yarn are helically twisted in the S direction. Composite yarn is made by pretreatment→blowing→carding→drawing→roving→spinning→winding. The number of strands of silk, viscose yarn, polyester yarn, said kesu yarn and said PROVISCOSE spun yarn is the same.

Owner:CHANGSHOU XINKANGSHENG CHEM FIBER CO LTD

Tensile-resistant and anti-breakage film material and preparation method thereof

InactiveCN107880361AHigh tensile strengthHigh elongation at breakBenzoylformic acidMethyl dihydrojasmonate

The invention discloses a tensile-resistant and anti-breakage film material. The film material is prepared from raw materials in parts by weight as follows: 50-100 parts of polyethylene, 3-8 parts ofdiethylenetriamine, 5-11 parts of methyl oleate, 4-9 parts of methyl benzoylformate, 7-15 parts of dimethylolurea, 4-8 parts of tetrabutyl orthosilicate, 11-20 parts of octanedioic acid and 3-7 partsof methyl dihydrojasmonate. The tensile-resistant and anti-breakage film material has greatly improved tensile strength and elongation at break, has excellent tensile strength at the low temperature,has the wide use range and can be better applied to food and medicine fields.

Owner:鲁忠华

Preparation method of composite high-energy biomass fuel rod

ActiveCN110684580AConducive to high energyHigh energyBiofuelsSolid fuelsProcess engineeringHeat of combustion

The invention discloses a preparation method of a composite high-energy biomass fuel rod, belonging to the technical field of biomass fuels. According to the invention, a silicon dioxide aerogel is used for loading treatment of biomass straw powder and the like, thereby increasing the contact surface area of a fuel; inorganic and plant straw powders are organically combined for use; the produced biomass fuel rod is good in bonding degree, high in heat energy value, large in surface area, high in combustion efficiency, small in combustion pollution and beneficial for ecological environment construction, facilitates fuel storage, has sufficient combustion contact area and can prevent the fuel from damp and wetting-back; and thus, the combustion quality of the fuel is improved, and the problem of poor combustion heat energy value due to wetting of the fuel is overcome.

Owner:安徽省宗正农业科技开发股份有限公司

Composite yarn

The invention relates to a composite yarn, which is characterized in that, in terms of weight fraction, it includes 10%-15% nylon yarn, 15%-17% acrylic yarn, 14%-20% acrylic yarn formed by cross-twisting. Gramme yarn, 25%-31% milk protein yarn, 20%-30% HEPE yarn, the diameters of nylon yarn, acrylic yarn, methyl gram yarn, milk protein yarn and HEPE yarn are 0.008mm and 0.010mm respectively, 0.008mm, 0.012mm, 0.012mm. Nylon yarn, acrylic yarn, methacrylic yarn, milk protein yarn and HEPE yarn are twisted helically in S direction. Composite yarn is made by pretreatment→blowing→carding→drawing→roving→spinning→winding. Nylon yarn, acrylic yarn, acrylic yarn, milk protein yarn and HEPE yarn have the same number of shares.

Owner:CHANGSHOU XINKANGSHENG CHEM FIBER CO LTD

Method and system for rapid liquid filling forming of multilayer tube

The invention relates to a multi-layer pipe quick liquid-filled forming method and system; according to the invention, a technical problem that plates in two layers or more than two layers are formed by using pressure uniformly loaded by a liquid and the liquid filling speed can be increased can be solved; pipes in a plurality of layers are sleeved together and clamped by upper and lower half molds; no pretreatment is needed between the pipes in the plurality of layers; additional oil guide cylinders are sleeved at the right ends of the pipes in the plurality of layers; a left pushing head is inserted into the left ends of the pipes in the plurality of layers; a right pushing head is inserted into the additional oil guide cylinders; the pipes in the plurality of layers, the left pushing head, the right pushing head and the additional oil guide cylinders form a liquid chamber; through the additional oil guide cylinders, a forming medium is filled into the liquid chamber; after the liquid chamber is full of the forming medium, the right pushing head is moved to seal the right ends of the pipes in the plurality of layers; the forming medium is filled into the liquid chamber in the pipes from the left or right pushing head so as to supercharge; meanwhile, the left pushing head and the right pushing head are axially moved and fed to the pipes so as to ensure the sealing of the pipes; and the pipes in the plurality of layers are in close contact with each other due to the effect of the forming medium, so that the layers of a formed pipe are also closely combined with each other.

Owner:SHANGHAI HUIZHONG AUTOMOTIVE MFG

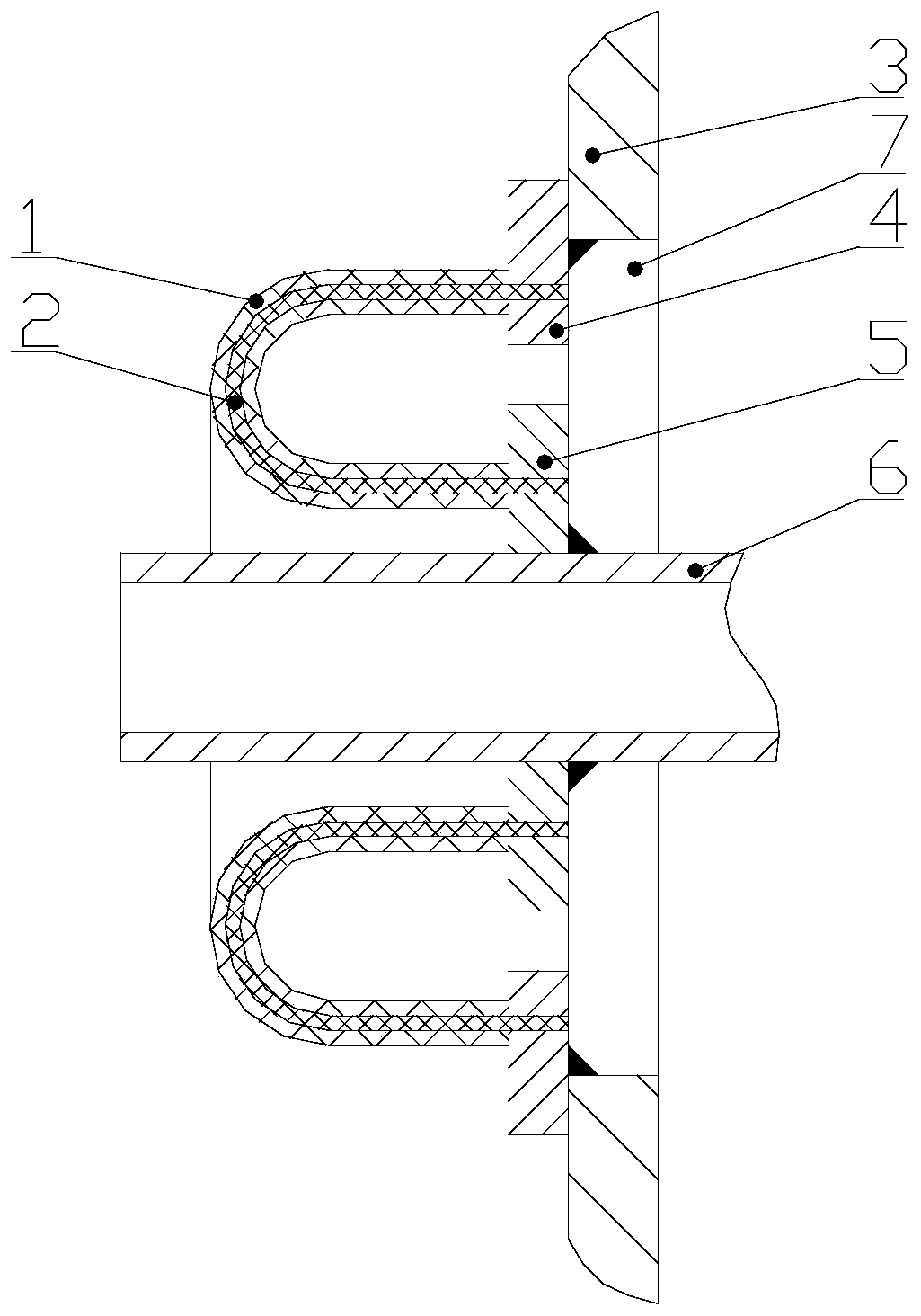

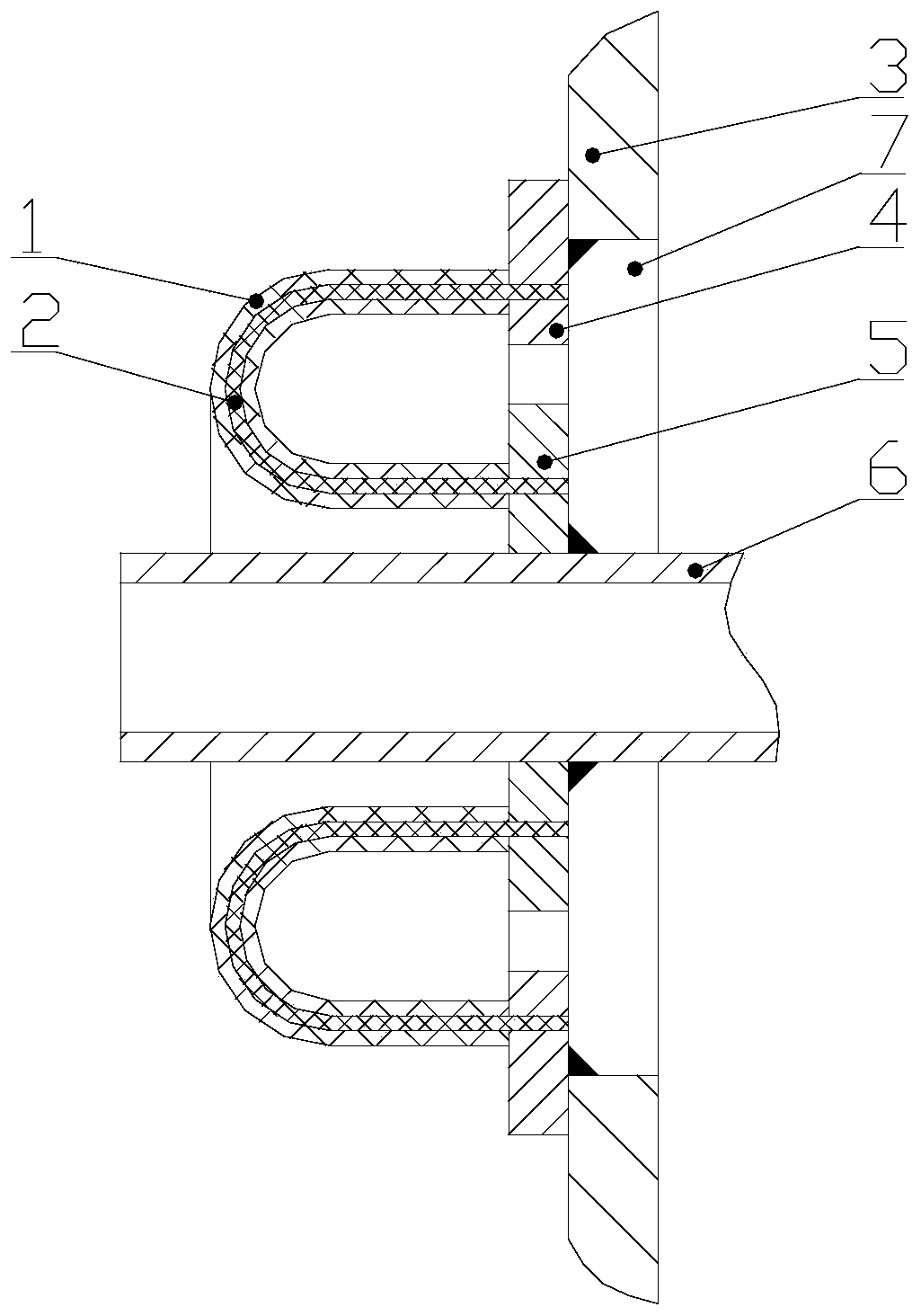

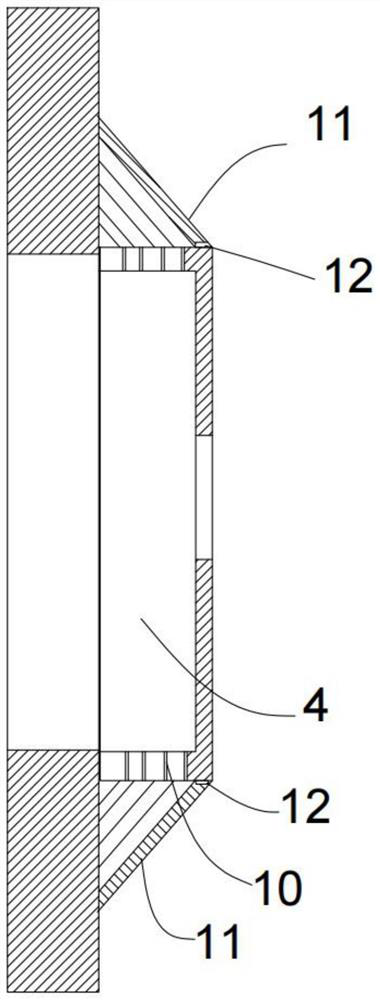

Pressure vessel pipeline sealing vibration isolation device

The invention discloses a pressure vessel pipeline sealing vibration isolation device. The device structurally comprises a metal inner ring, a metal outer ring and an annular rubber cover, wherein themetal inner ring is arranged on a pipeline in a sleeving mode and is in sealing connection with the outer wall of the pipeline, the metal outer ring is connected with a pressure vessel body, the metal outer ring is arranged around the periphery of a pipeline extending-in hole of the pressure vessel body, a gap is formed between the metal outer ring and the metal inner ring, the annular rubber cover covers the gap between the metal outer ring and the metal inner ring, a plurality of carbon fiber lines are arranged in the rubber cover, and the two ends of each carbon fiber line are connected with the metal inner ring and the metal outer ring correspondingly. According to the device, the structure is compact, the static rigidity and the dynamic rigidity in the axial direction and radial direction of the pipeline are smaller than the required rigidity of vibration isolation between the pipeline and a pressure vessel, meanwhile, under the action of the carbon fiber lines, rubber which is used for vibration isolation can bear the pressure of the pressure vessel, and the rubber cannot be damaged by too large deformation caused by the fact that the rubber bears the high pressure, so thatthe rubber has a long service life.

Owner:SOUTHEAST UNIV

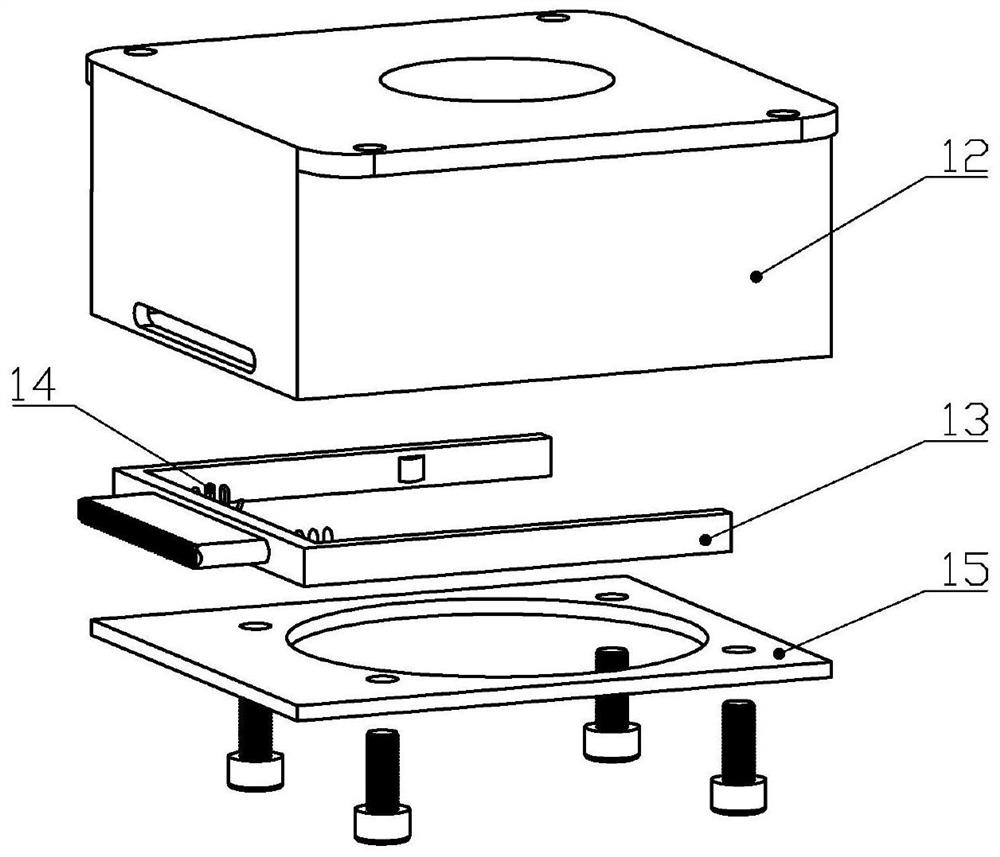

Multi-sensor quick dismounting device based on three-coordinate measuring machine and use method

The invention discloses a multi-sensor quick dismounting device based on a three-coordinate measuring machine and a use method. At present, a commercial CMM is generally fixedly provided with a type of sensors, and the diversity of measurement requirements cannot be met. The multi-sensor quick dismounting device comprises a magnetic base module, a common connector base module and a special connector module which are sequentially connected from top to bottom. The magnetic base module comprises a base, a rotating disc, a permanent magnet, a middle frame, a first magnet yoke, a magnetic isolation belt and a second magnet yoke. The common connector base module comprises a common base. The special connector module comprises a Morse taper shank and a measuring sensor. According to the invention, by adjusting the magnetic poles of the permanent magnets above the two separated magnet yokes, the adsorption force of the magnet yokes to the special connector module below the magnet yokes is adjusted, so that the special connector module is stably adsorbed, and meanwhile, different measurement sensors can be quickly switched. And the CMM application range is expanded. In addition, the multi-sensor quick dismounting device can be obtained by upgrading and transforming a measuring head mounting structure on the basis of an existing CMM.

Owner:HANGZHOU DIANZI UNIV

Device for microwave plating of nano-diamond film

ActiveCN110373651ASave energySave materialChemical vapor deposition coatingEngineeringMicrowave shielding

The invention discloses a device for microwave plating of a nano-diamond film, wherein the device mainly comprises a microwave generator, a microwave transmitting loudspeaker, a process air inlet pipe, a microwave shielding layer, a rotary tray, a water cooling system, a vacuum system and a film coating shell, wherein the film coating shell is a cavity with sealing performance. When the device works, the process gas enters the microwave transmitting loudspeaker through an air inlet pipe, the process gas is cracked and plasmatized by microwaves, and carbon atoms are used as carbon source materials of the diamond-plated film after cracking and plasmatization. The device for microwave plating of the nano-diamond film realizes the SP2 and SP3 type nano-diamond coating by changing the microwavefrequency and the process gas medium. The microwave coating efficiency is remarkable, the thickness of the coated nano-diamond film is uniform, the surface is smooth and flat, the substrate to be coated is not easy to damage, and the device for microwave plating of the nano-diamond film has a very wide application prospect in various industrial fields.

Owner:成都道启弘环境科技有限公司

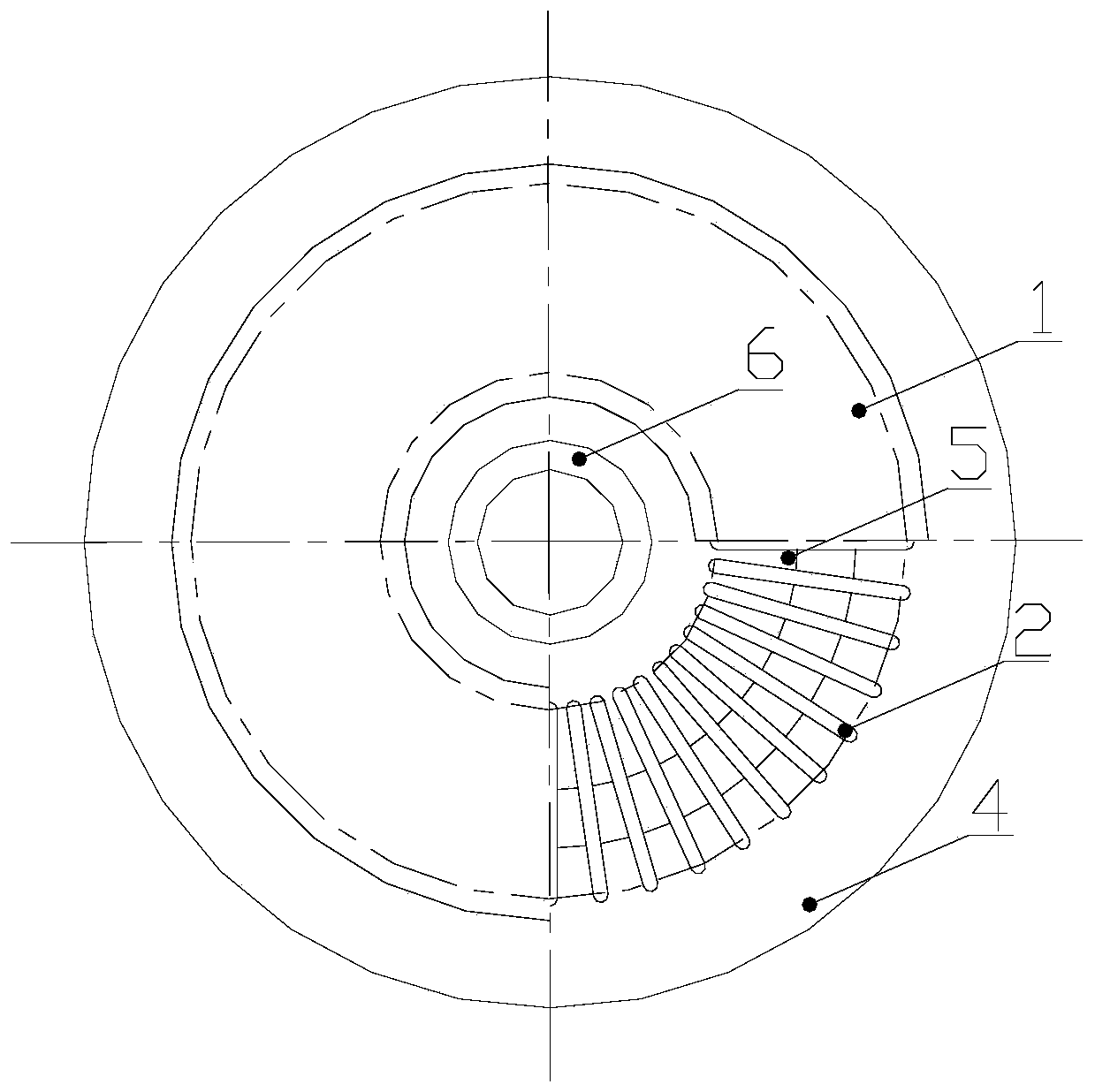

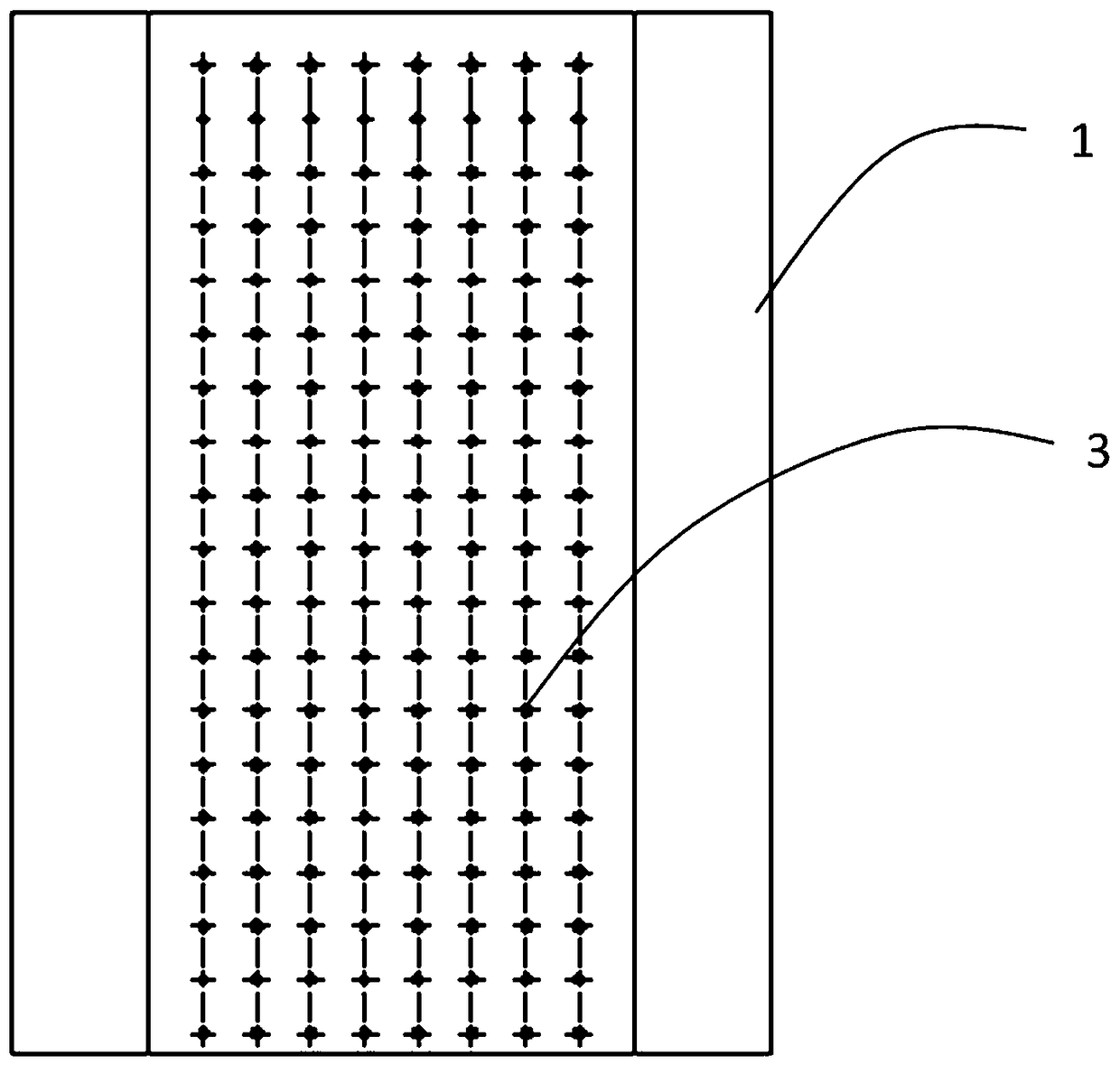

A composite ald air guiding device

ActiveCN105925959BImproved air distributionImprove uniformityChemical vapor deposition coatingEngineeringComposite structure

The invention discloses a composite ALD gas guiding device which comprises a main structure, a gas guiding hole array (3) and a gas extraction hole (4), wherein the main structure is composed of plane steps (1) and a circular arc wall (2). According to the ALD gas guiding device provided by the invention, gas is guided by performing gas extraction on a reaction cavity, so that the gas flow distribution in the reaction cavity can be improved and the uniformity of a prepared thin film can be effectively improved; and meanwhile, a composite structure is utilized for greatly saving space, so that composite ALD gas guiding device can be served as a mechanism for supporting a sample hole in the reaction cavity when bearing the gas guiding function, and function composition can be achieved.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

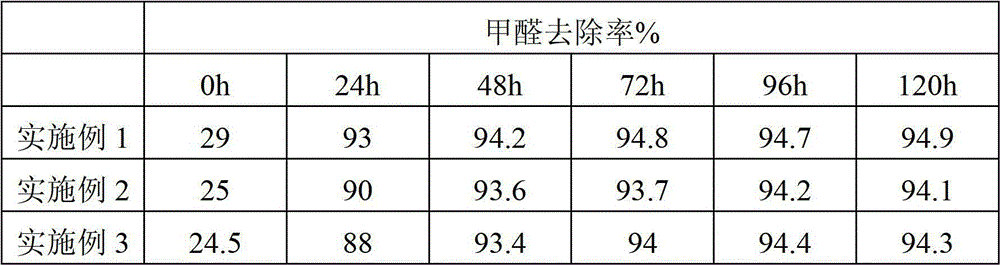

Compound-function wallpaper and preparation method thereof

ActiveCN102777004BImprove the shortcomings of single functionCompositeCovering/liningsManufacturing technologyNonwoven fabric

The invention discloses compound-function wallpaper and a preparation method thereof. The compound-function wallpaper is sequentially formed by a substrate layer, a glue sticking layer and a decoration layer from bottom to top, wherein the substrate layer is non-woven paper, non-woven cloth or plain weaving fabric which is processed by flame retardant finishing liquid; the glue sticking layer is formed by a binding agent, flame retardant powder, formaldehyde removing ultrafine powder and an additive; the formaldehyde removing ultrafine powder is formed by titanium dioxide ultrafine powder, zinc oxide ultrafine powder, tin oxide ultrafine powder, zinc sulfide ultrafine powder, ferric oxide ultrafine powder and diatomite ultrafine powder; and the decoration layer is a printing layer or an electrostatic flocking layer which is processed by the flame retardant finishing liquid. According to the compound-function wallpaper and the preparation method, disclosed by the invention, the flame retardant processing in each manufacturing technology stage of the compound-function wallpaper is realized, the all-directional fire flame retardant can be achieved, and the moisture regain is low; compound powder which can be used for catalyzing, resolving and removing formaldehyde in indoor environment is adopted for replacing common adsorptive material, thus the formaldehyde in the environment can be completely removed, and the repeatability does not exist; and selected anti-bacteria and mildew-proof anion far infrared products are both mature products in a market, and the multifunctional complex of the wallpaper is realized.

Owner:吕世静

Composite insulation storage equipment and application method thereof

The invention discloses composite insulation storage equipment and an application method thereof, belonging to the field of storage equipment. The composite insulation storage equipment comprises a main storage room and an assistant storage room, wherein the main storage room is arranged on the ground, and the assistant storage room is arranged on the main storage room; a feeding mechanism and a discharging mechanism which are liftable and communicate with the assistant storage room are respectively arranged at the two ends of the main storage room; a conveying mechanism I connected with the upper ends of the feeding mechanism and the discharging mechanism is arranged at the bottom of the assistant storage room, a conveying mechanism II connected with the lower ends of the feeding mechanism and the discharging mechanism is arranged under the main storage room, and the conveying mechanism I and the conveying mechanism II are each provided with a plurality of material carrying plates; all components of the storage equipment are made of insulating materials or / and materials wrapped with insulating layers. As the assistant storage room which automatically runs in order is additionally arranged on the main storage room, material storing and material taking are skillfully and efficiently combined together to form a circulation system, the storage space can be enlarged, and labor is saved. The first in first out of stored materials can be realized, and the working efficiency can be efficiently improved. Accidents such as electric shock, etc. can be prevented.

Owner:国网山东省电力公司聊城供电公司 +1

Inductor and manufacturing method thereof

ActiveCN101521087BCompositeTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresFerrite substrateEngineering

The invention is suitable for the field of electronics, and provides an inductor and a manufacturing method thereof. The inductor comprises a ferrite substrate, a conductive coil arranged in the ferriThe invention is suitable for the field of electronics, and provides an inductor and a manufacturing method thereof. The inductor comprises a ferrite substrate, a conductive coil arranged in the ferrite substrate, and terminal electrodes which are positioned at two end parts of the ferrite substrate and used for electrically connecting with the conductive coil. The conductive coil comprises a plurte substrate, and terminal electrodes which are positioned at two end parts of the ferrite substrate and used for electrically connecting with the conductive coil. The conductive coil comprises a plurality of layers of electrode patterns which are connected layer upon layer spirally. The layers of the electrode patterns are electrically connected through electric connecting elements to form a spirality of layers of electrode patterns which are connected layer upon layer spirally. The layers of the electrode patterns are electrically connected through electric connecting elements to form a spiral ellipse-like shape. In the inductor provided by the invention, the conductive coil adopts an ellipse-like spiral structure so as to make the inductor realize the specific inductive characteristic aal ellipse-like shape. In the inductor provided by the invention, the conductive coil adopts an ellipse-like spiral structure so as to make the inductor realize the specific inductive characteristic and the impedance characteristic and integrates the inductor and beads into a whole.nd the impedance characteristic and integrates the inductor and beads into a whole.

Owner:SHENZHEN ZHENHUA FU ELECTRONICS

A kind of preparation method of composite high-energy biomass fuel rod

ActiveCN110684580BImprove porosity structureImprove reunionsBiofuelsSolid fuelsProcess engineeringEnvironmental engineering

The invention discloses a method for preparing a composite high-energy biomass fuel rod. The invention belongs to the technical field of biomass fuel. The invention uses silica aerogel to carry out loading treatment on biomass straw powder, etc. to increase the fuel contact surface area. The organic combination of inorganic and plant straw powder can produce biomass fuel rods with good cohesiveness, high heat energy value, large surface area, high combustion efficiency, and low combustion pollution, which is conducive to the construction of the ecological environment and can be beneficial to the production of fuel. For storage, there is a sufficient combustion contact area and can avoid the fuel from getting damp and regaining moisture, thereby improving its combustion quality, and at the same time avoiding the problem of poor combustion heat value caused by the fuel being damp.

Owner:安徽省宗正农业科技开发股份有限公司

Light emitting device with graded composition hole tunneling layer

InactiveUS8829652B2Easy to transportImprove luminous efficiencySemiconductor/solid-state device manufacturingNanoopticsQuantum wellElectron blocking layer

A light emitting device with graded composition hole tunneling layer is provided. The device comprises a substrate and an n-type semiconductor layer is disposed on the substrate, in which the n-type semiconductor layer comprises a first portion and a second portion. A graded composition hole tunneling layer is disposed on the first portion of the n-type semiconductor layer. An electron blocking layer is disposed on the graded composition hole tunneling layer. A p-type semiconductor layer is disposed on the electron blocking layer. A first electrode is disposed on the p-type semiconductor layer, and a second electrode is disposed on the second portion of the n-type semiconductor layer and is electrical insulated from the first portion of the n-type semiconductor. The graded composition hole tunneling layer is used as the quantum-well to improve the transport efficiency of the holes to increase the light emitting efficiency of the light emitting device.

Owner:NAT CHIAO TUNG UNIV

Accumulator distribution type fuel injection pump

InactiveCN100494664CSmall sizeSmall volumePositive displacement pump componentsFuel injecting pumpsControl valvesHigh pressure

Owner:YANMAR CO LTD

Multi-element compound microbial fertilizer and production method thereof

The invention discloses a multi-element compound microorganism fertilizer. The multi-element compound microorganism fertilizer is a potassium-rich multi-element compound microorganism fertilizer which is made by using potassium-oxide-rich potassic shale and humic acid as main raw materials, using bacillus mucilaginosus SCUP-76-8 as a potassium-solubilizing strain, using bacillus megaterium as a phosphate-solubilizing strain, using Frankia fgc6 as a nitrogen-fixing strain and performing fermental cultivation on the potassic shale and the humic acid. A production method of the multi-element compound microorganism fertilizer comprises the following steps: preparing potassic shale powder, humic acid powder, castor cake powder, a potassium-solubilizing bacteria fermentation liquor, a phosphate-solubilizing bacteria fermentation liquor and a nitrogen-fixing bacteria fermentation liquor respectively, uniformly mixing the potassic shale powder, the potassium-solubilizing fermentation liquor and the phosphate-solubilizing bacteria fermentation liquor in the mass volume ratio of 1:1:0.8, aerobically fermenting the mixture under a certain condition for 7-9 days, and naturally drying the fermented mixture; uniformly mixing the humic acid powder, the castor cake powder and the nitrogen-fixing bacteria fermentation liquor in the mass volume ratio of (5-8):1:1, aerobically fermenting the mixture under a certain condition for 10-12 days, and naturally drying the fermented mixture; and uniformly drying the activated potassic shale powder and the nitrogen-fixing bacteria humic acid as well as the castor cake powder in the mass ratio of (58-63):(37-42), and drying the mixture to obtain a finished product.

Owner:SHANXI LUTU BIOTECH CO LTD

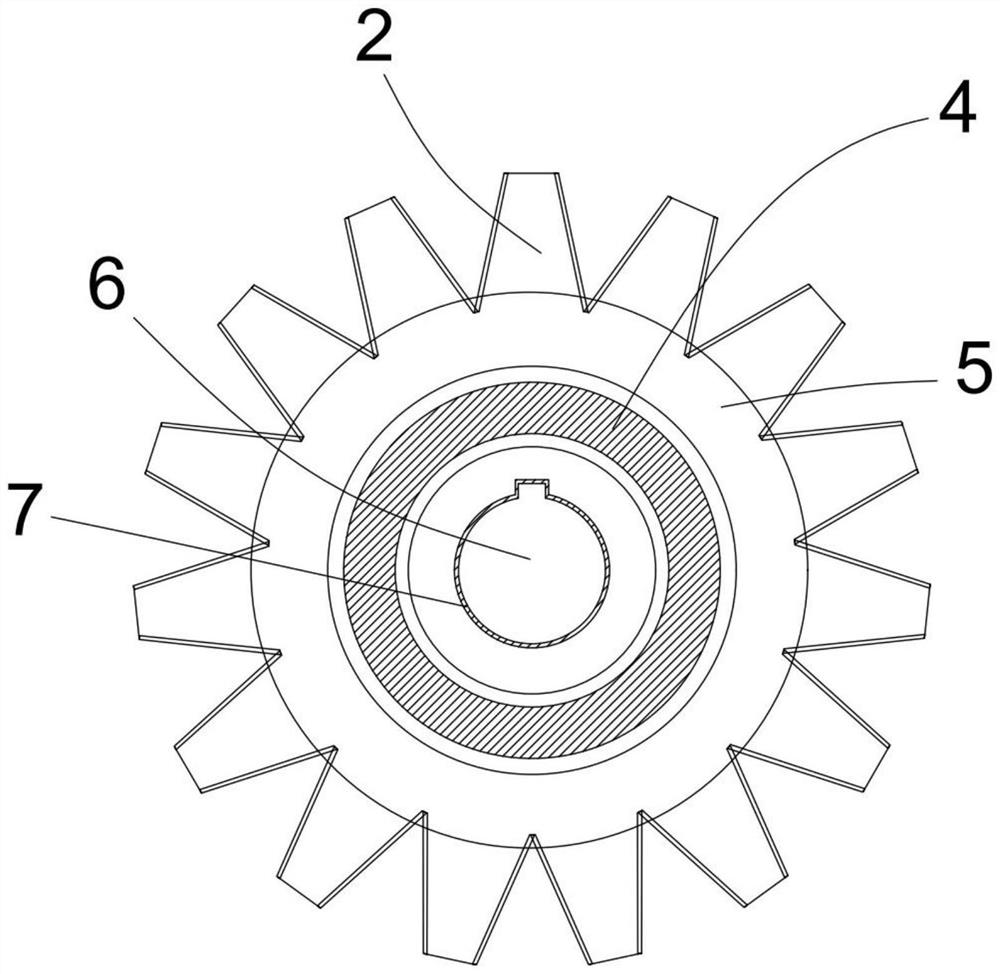

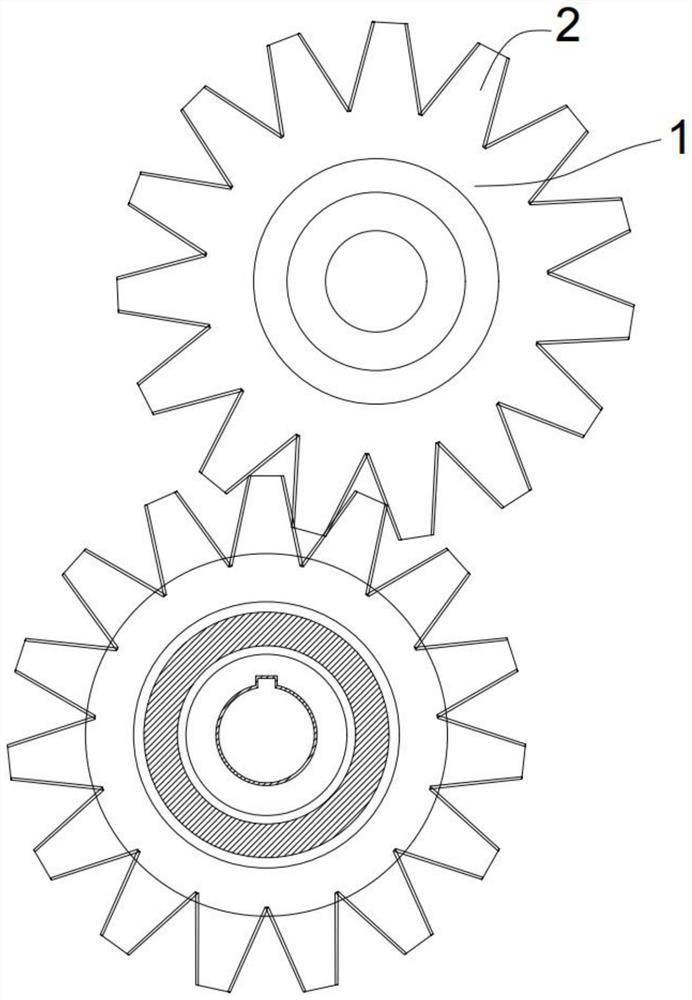

Self-lubricating mute gear and manufacturing process thereof

PendingCN114321324AReal-time lubricationReduce wear ratePortable liftingGear lubrication/coolingOil canGear wheel

The self-lubricating mute gear comprises an annular body, tooth bodies are integrally formed on the circumference of the annular body, the annular body and the tooth bodies are made of metal, and nylon layers are arranged on the faces between the tooth bodies; an annular oil cavity is formed in the center of the annular body, an oil uniformizing device is arranged around the oil cavity, and the preparation process comprises the steps of S1, blank taking and milling, and S2, mold injection molding; according to the gear, the oil cavity integrally formed with the gear body is formed, and the oil homogenizing device is arranged outside the oil cavity, so that when the gear runs at a high speed, lubricating oil can be sprayed out from the side wall in the oil cavity under the action of centrifugal force, is uniformly dispersed out through the umbrella-shaped oil guide sheet and slowly permeates into the gear body, and the lubricating oil can be uniformly dispersed out through the umbrella-shaped oil guide sheet; the gear can be lubricated in real time; nylon is compounded on the meshing face of the gear, it is guaranteed that the wear rate of the gear is reduced, and due to the fact that the gear is made of a metal material, the metal material is low in shrinkage rate, and precision can still be kept.

Owner:苏州金亿精密齿轮有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com