Ultraviolet-resistant corrosion-resistant thin coating type water-based fireproof coating material and preparation method thereof

A technology of UV-resistant and fire-resistant coatings, applied in fire-resistant coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve problems such as affecting the adhesion and fire resistance of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

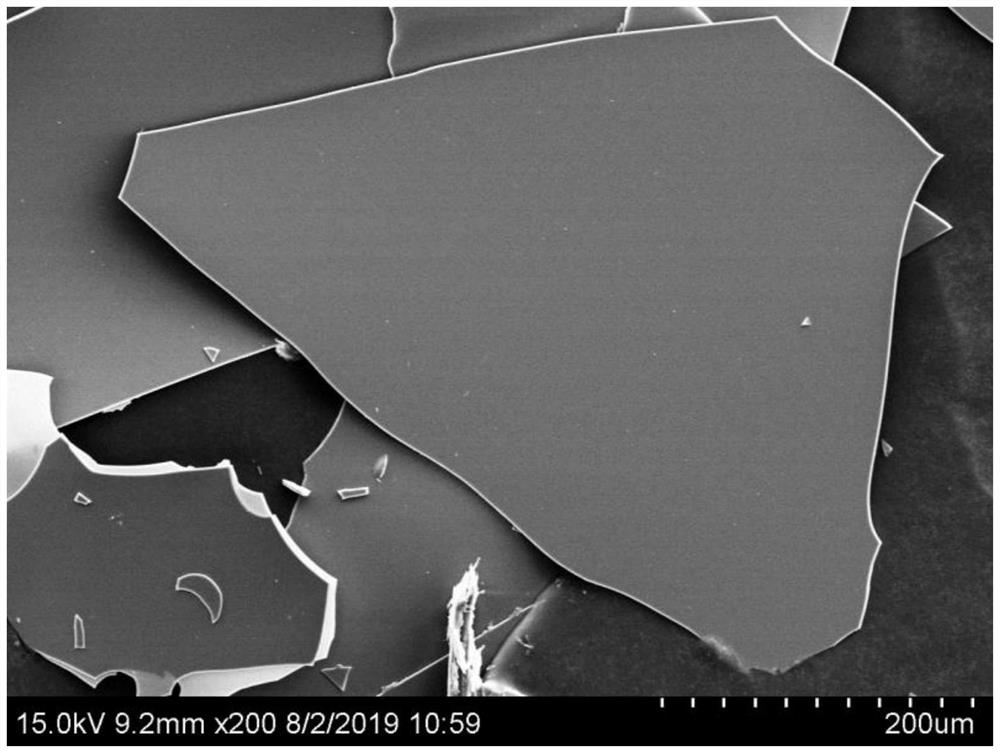

Image

Examples

Embodiment 1

[0020] A thin-coated water-based fireproof coating with UV resistance and corrosion resistance, comprising the following components in parts by weight: 50 parts of deionized water, 30 parts of water-based epoxy resin, 30 parts of chlorinated rubber emulsion, 15 parts of polytetrafluoroethylene emulsion, polytetrafluoroethylene emulsion, 10 parts of acrylic acid, 4 parts of polyethylene, 3 parts of chlorosulfonated polyethylene, 16.5 parts of basalt flakes, 2 parts of ultraviolet absorber UV-327, 1 part of light stabilizer UV-3853, 0.5 parts of ceramic powder, 0.5 parts of nano zirconium phosphate , 0.5 parts of nano-zirconia, 0.5 parts of nano-barium sulfate, 2 parts of polydimethylsiloxane and 2 parts of acrylic leveling agent. Among them, the preparation method of basalt scales is as follows: put basalt ore particles into a high-temperature fluidized furnace, heat to 1300°C after vacuuming, cool the melt to -30°C with low-temperature nitrogen, and then naturally place it to r...

Embodiment 2

[0023] A kind of anti-ultraviolet and corrosion-resistant thin coating water-based fireproof coating, comprising the following components in parts by weight: 60 parts of deionized water, 40 parts of water-based epoxy resin, 20 parts of chlorinated rubber emulsion, 10 parts of polytetrafluoroethylene emulsion, polytetrafluoroethylene 15 parts of acrylic acid, 5 parts of polyethylene, 2 parts of chlorosulfonated polyethylene, 8.5 parts of flake graphite, 10.5 parts of UV-5310 for ultraviolet absorber, 2 parts of nano-zirconia, 1 part of polyether type defoamer and carboxymethyl fiber Vegetable 0.5 parts.

[0024] The preparation method of the ultraviolet-resistant and corrosion-resistant thin-coated water-based fireproof coating of this embodiment is: weigh each component by weight: deionized water, water-based epoxy resin, chlorinated rubber emulsion, polytetrafluoroethylene emulsion, polyacrylic acid , polyethylene and chlorosulfonated polyethylene, add ultraviolet absorber UV...

Embodiment 3

[0026] A kind of anti-ultraviolet and corrosion-resistant thin coating water-based fireproof coating, comprising the following components in parts by weight: 30 parts of deionized water, 25 parts of water-based epoxy resin, 40 parts of chlorinated rubber emulsion, 20 parts of polytetrafluoroethylene emulsion, polytetrafluoroethylene 5 parts of acrylic acid, 3 parts of polyethylene and 4 parts of chlorosulfonated polyethylene, 15.4 parts of basalt flakes, 3 parts of ceramic powder, 0.3 parts of nano zirconium phosphate, 3.3 parts of ultraviolet absorber UV-15777, 11 parts of light stabilizer UV-54111, poly 2 parts dimethyl siloxane and 2 parts carboxymethyl cellulose. Among them, the preparation method of basalt scales is: put basalt ore particles into a high-temperature fluidized furnace, heat to 800°C after vacuuming, cool the melt to -50°C with low-temperature nitrogen, and then naturally place it to room temperature. The cooled basalt ore solids are stripped and sliced by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com