Self-lubricating mute gear and manufacturing process thereof

A self-lubricating, gear technology, applied in gear lubrication/cooling, belt/chain/gear, components with teeth, etc., can solve the problems of reducing gear strength, difficult process, internal vibration, etc., to reduce wear rate, combine Good degree, good effect of compound degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

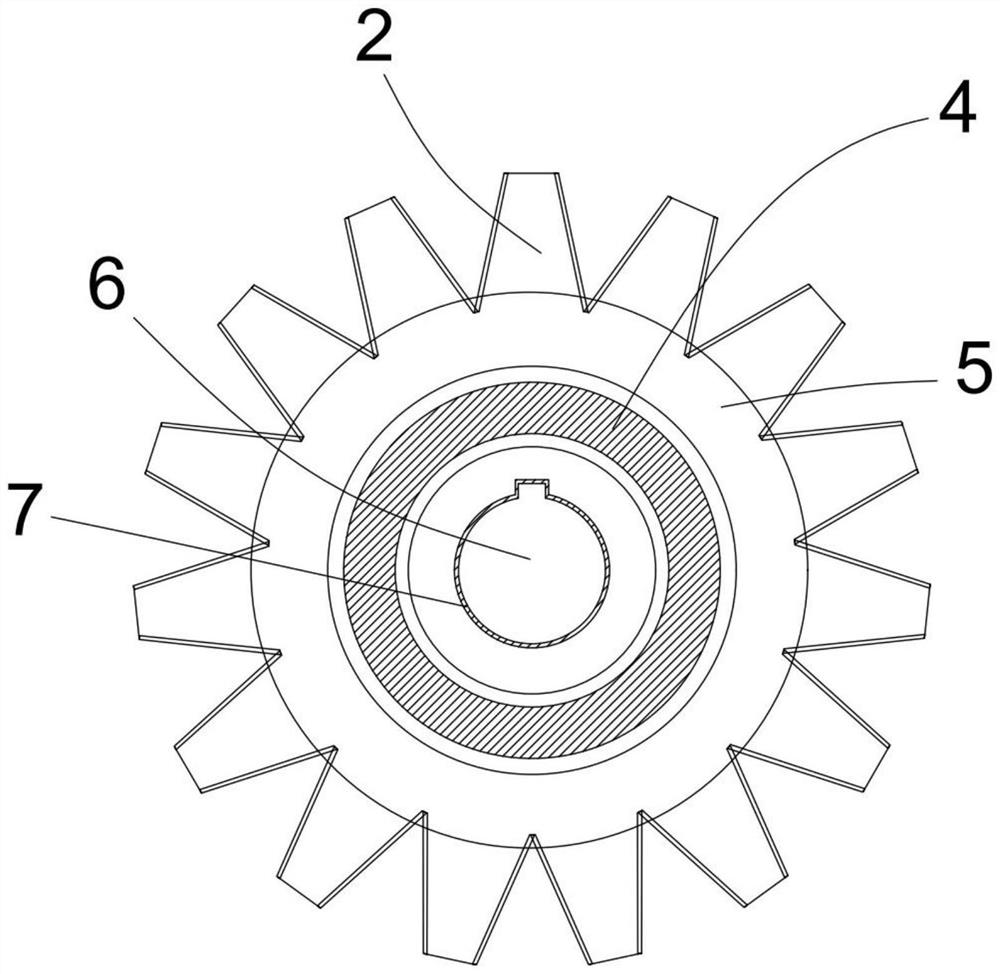

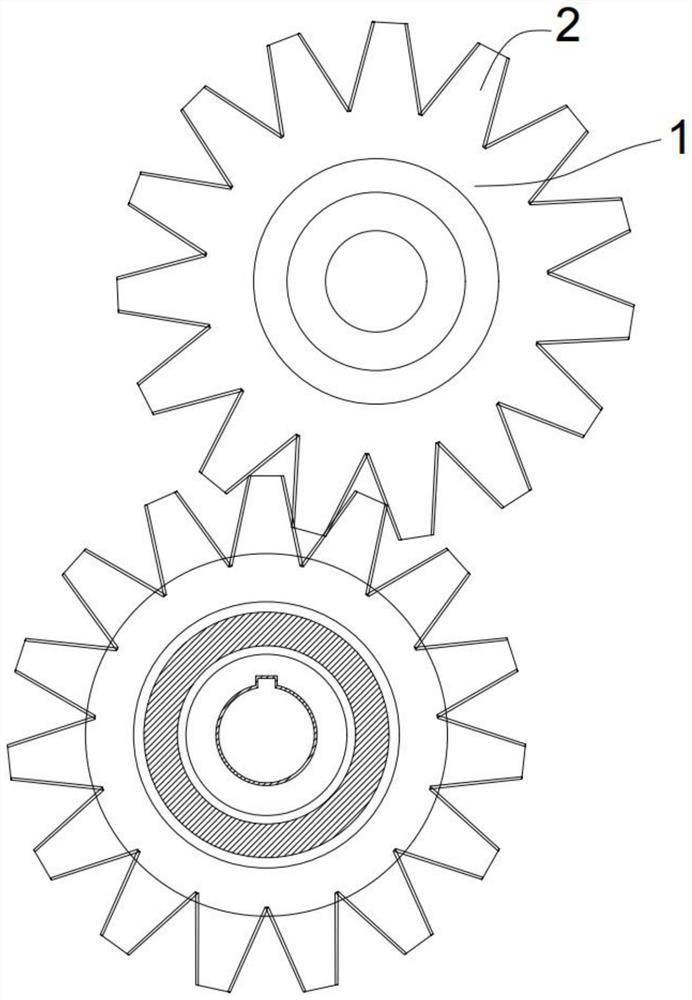

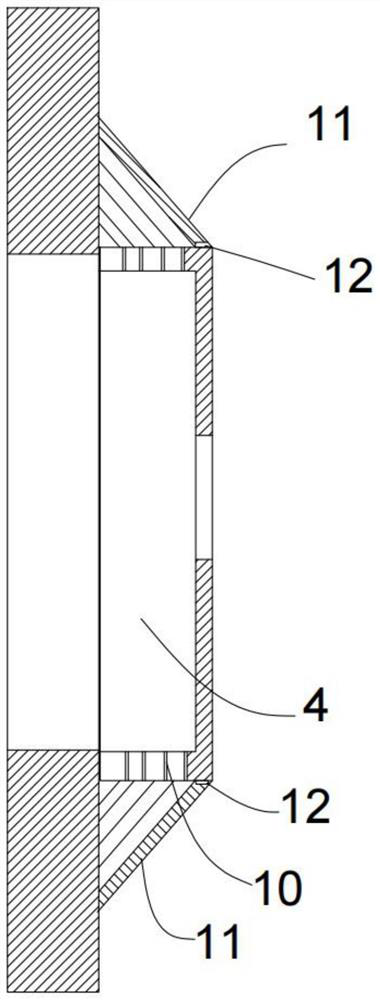

[0028] like figure 1 As shown, the present invention proposes a self-lubricating silent gear, which includes an annular body 1, and the circumference of the annular body 1 is integrally formed with a tooth body 2, and a nylon layer 3 is provided on the surface between the tooth bodies 2. The surface between the 2 is the contact surface of the tooth body 2 when the gears mesh, and the nylon layer 3 is provided, while the annular body 1 and the tooth body 2 are metal materials commonly used for gears, which can be steel with quenched and tempered steel, Hardened steel, carburized and quenched steel and nitrided steel, etc., are provided with a positioning block 8 on the opposite surface of the tooth body 2, which is convenient to occlude and fix with the metal material during ny...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com