Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

144results about How to "Avoid Stretch Deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

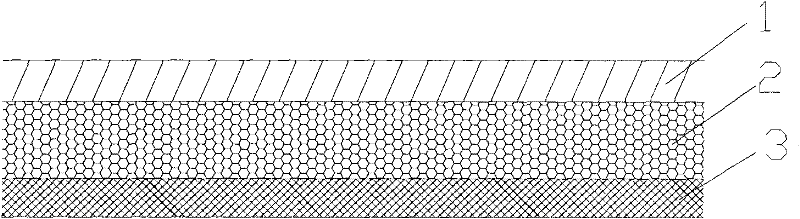

Cling film laminate structure

InactiveUS20050196630A1Eliminate and substantially reduce contamination problemLow peelSynthetic resin layered productsAbsorbent padsPolyolefinSingle site

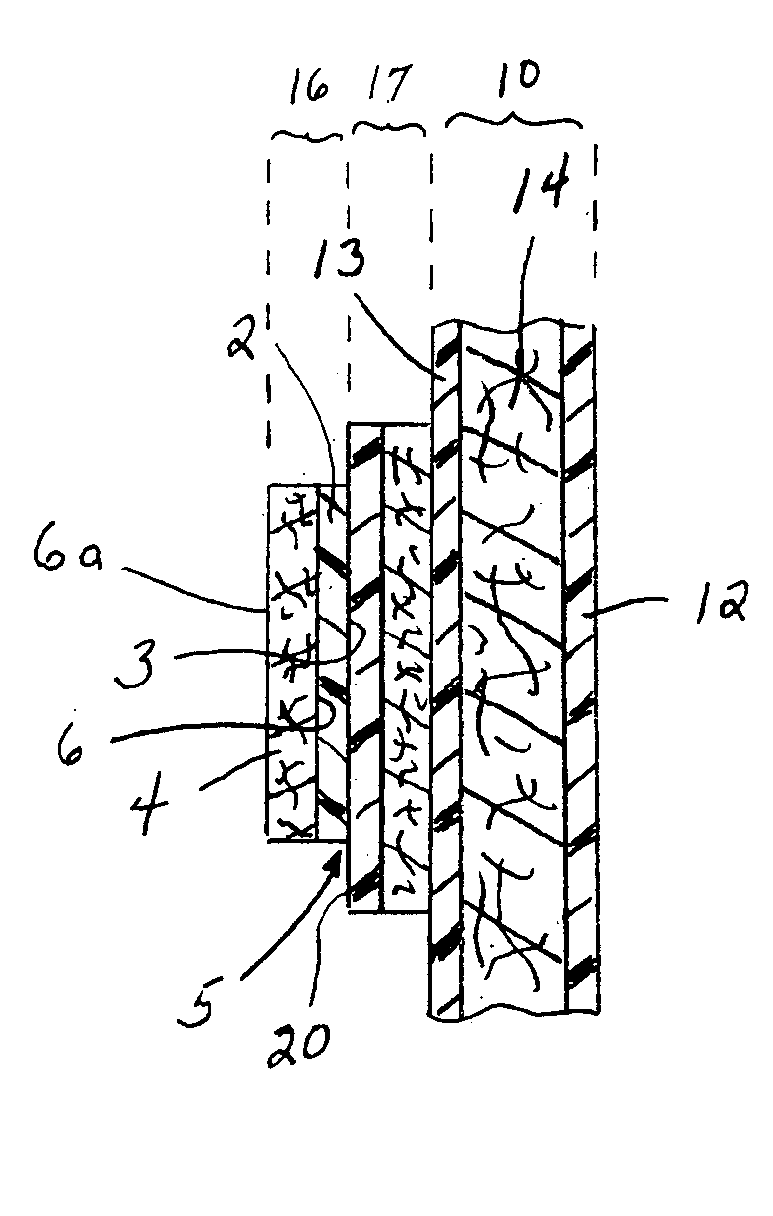

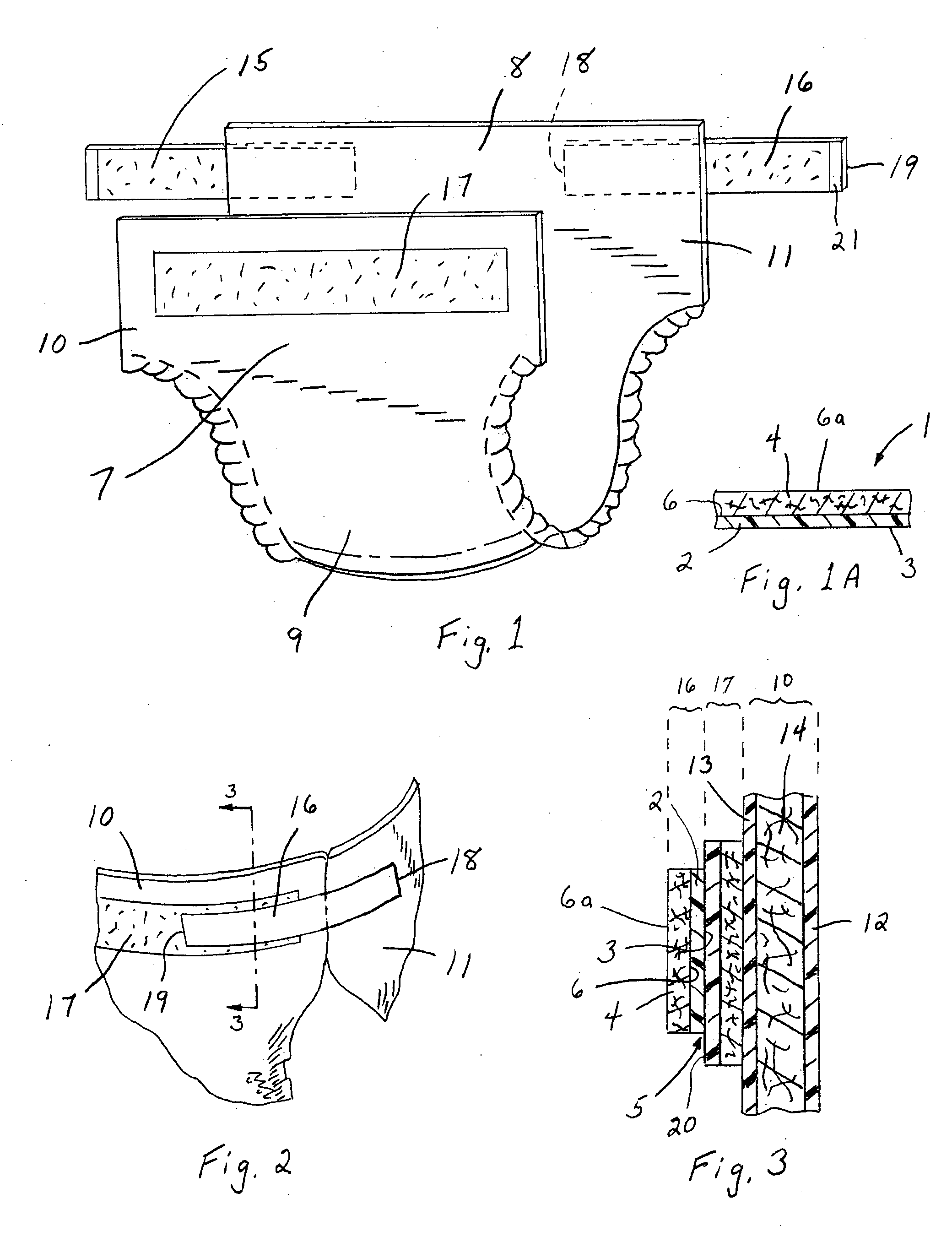

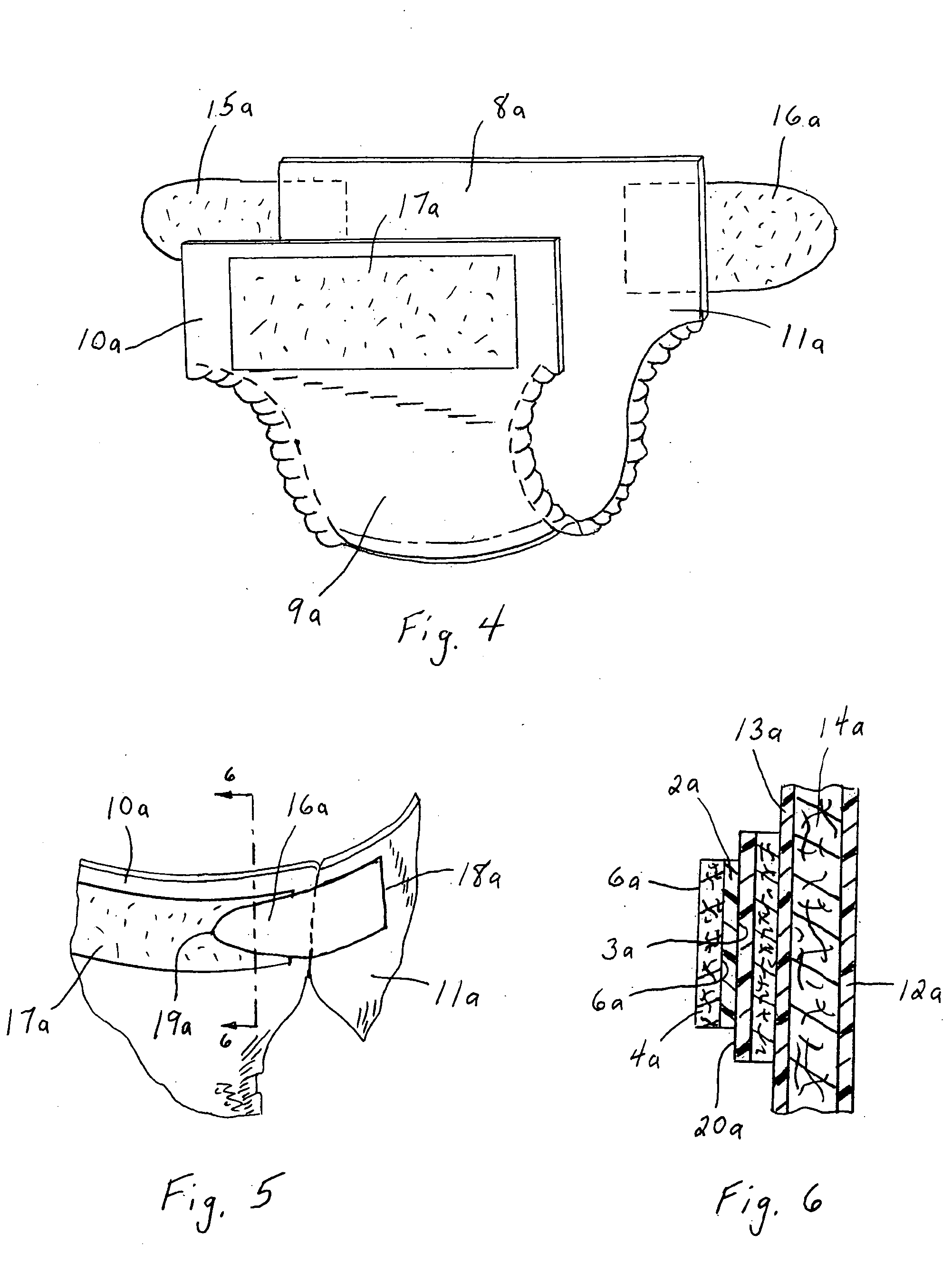

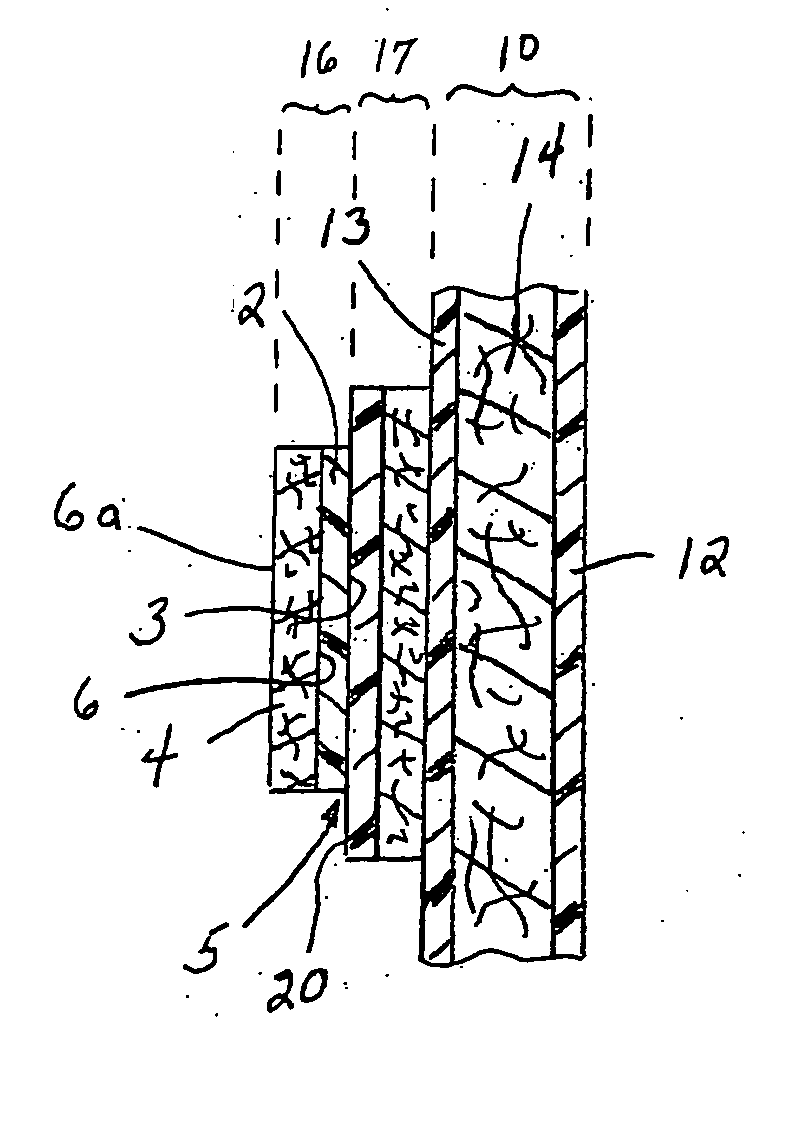

A cling film laminate structure, a process for making the laminate, and use of the laminate in a fastening system for various goods is disclosed. The laminate is composed of a cling layer having autoadhesive surface properties bonded to a substantially non-stretchable carrier layer. The carrier layer is formed of a material which eliminates, or substantially limits, stretching of the cling layer. An ethylene-based or propylene-based metallocene or single site catalyzed polyolefin provides the autoadhesive surface properties for the cling layer. Preferably, the carrier layer is comprised of a nonwoven material, or a thermoplastic film. A laminate composed of a cling layer and a non-stretchable carrier layer is particularly useful as a fastening system for a package, envelope, tape or disposable soft goods article.

Owner:CARPER JAMES D +2

Cling film laminate structure

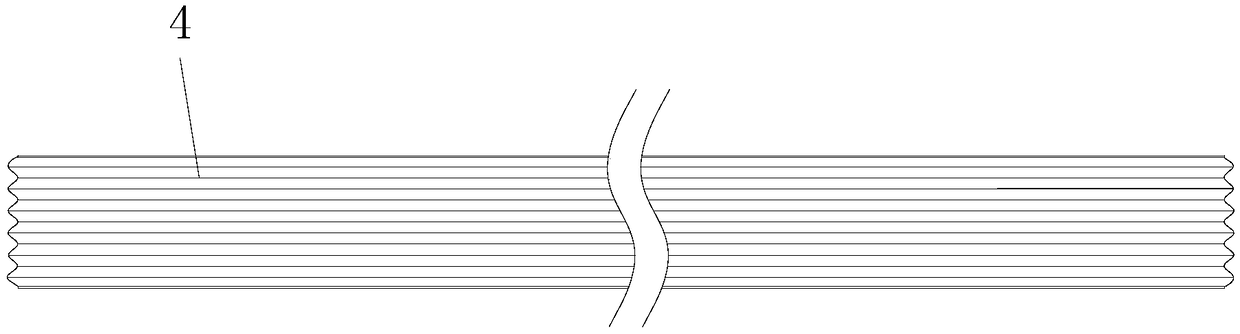

InactiveUS20050158567A1Avoid Stretch DeformationReduce capacityPersonal careAdhesive articlesPolyolefinEngineering

A cling film laminate structure a process for making the laminate and use of the laminate in a fastening system for various goods is disclosed. The laminate is composed of a cling film layer having autoadhesive surface properties bonded to a substantially non-stretchable carrier layer. The carrier layer is formed of a material which eliminates, or substantially limits, stretching of the cling film layer. An ethylene-based or propylene-based metallocene or single site catalyzed polyolefin provides the autoadhesive surface properties for the cling film layer. Preferably, the carrier layer is comprised of a nonwoven material, or a thermoplastic film. A laminate composed of a cling film layer and a non-stretchable carrier layer is particularly useful as a fastening system for a package, envelope, tape or disposable soft goods article.

Owner:BOSTIK INC

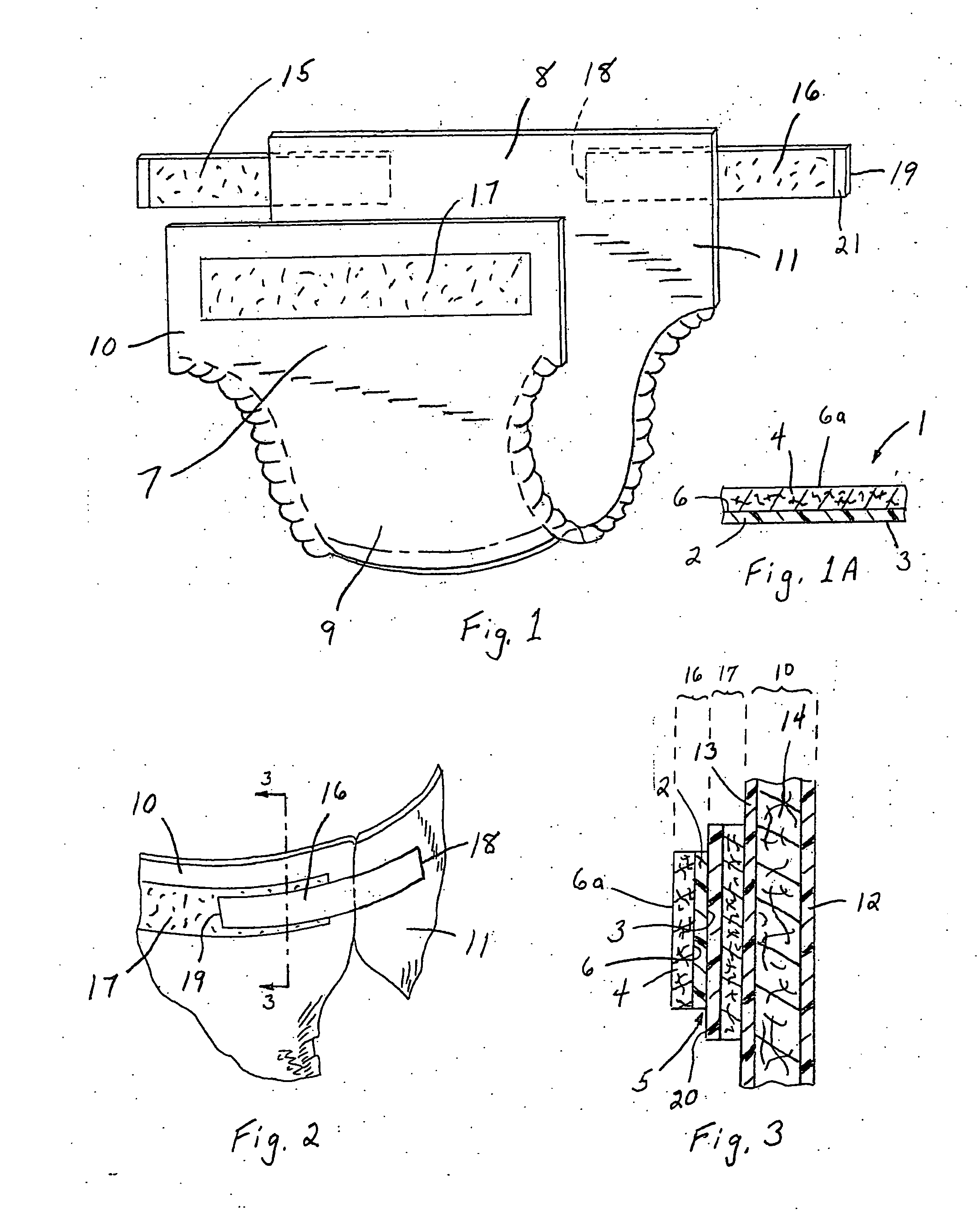

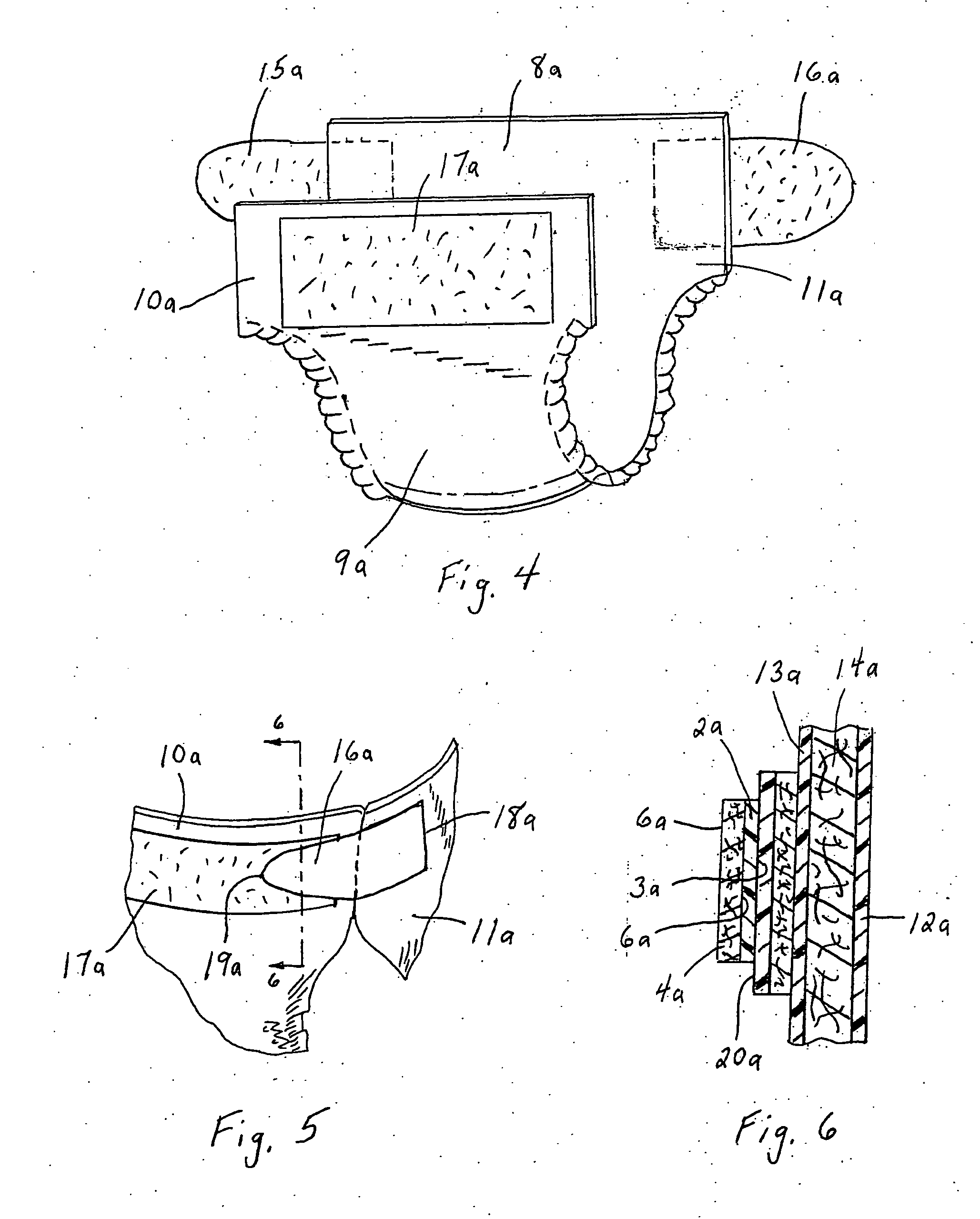

Cling film fastening system for disposable soft goods

InactiveUS20050096613A1Avoid stretchingAvoid deformationFibreboardPaper/cardboard articlesPolyolefinEngineering

A unique laminate structure, a process for making the laminate, and use of the laminate in a fastening system for disposable soft goods is disclosed. The laminate is composed of a cling film layer having autoadhesive surface properties bonded to a flexible, but substantially non-stretchable, base carrier layer. The base carrier layer is formed of a material which eliminates, or substantially limits, any stretching of the cling film. The cling film layer includes a thermoplastic polymer coating that provides autoadhesive surface properties selected from the group consisting of polyolefins, acrylic modified polyolefins, vinyl acetate modified polyolefins and acrylic polymer. Preferably, the polyolefin may be polypropylene or polyethylene. Preferably, the carrier or base layer is comprised of a nonwoven material, or a thermoplastic film. A laminate composed of a cling film layer and a non-stretchable base layer is particularly useful as a fastening system for a disposable diaper or a feminine care pad with low peel, but high shear strength.

Owner:BOSTIK INC

Method for improving overlength high frequency circuit board hole site working accuracy

ActiveCN103079353AHigh precisionEliminates loss of hole position accuracyPrinted circuit manufactureDislocationMicroetching

The invention discloses a method for improving overlength high frequency circuit board hole site working accuracy. Through an interactive design of subsection drill holes and locating holes, the continuity and the consistency of a front section of drill holes and a rear section of drill holes are ensured, and the problems of dislocation, offset and the like are solved; an original mechanical plate grinding method is replaced with a chemical microetching method, so that the problem that the hole site accuracy is reduced caused by tensile deformation of panels is eliminated; and through baking before processing a circuit board and a finished product is delivered, so that the humidity in the board is effectively removed, the coefficient of thermal expansion of the panels is stabilized, and the problem of accuracy variation caused by deformation or tortuosity of the panels is solved. According to the method for improving overlength high frequency circuit board hole site working accuracy, the drilling accuracy of the overlength high frequency circuit board is effectively improved, the problems of disability in assembly, and severe signal interference caused by severe hole shift in an earlier stage are solved, the percent of pass of the overlength high frequency circuit board is improved, meanwhile, the product quality of enterprises is promoted, and the scrapping of products is reduced.

Owner:SHENZHEN BOMIN ELECTRONICS

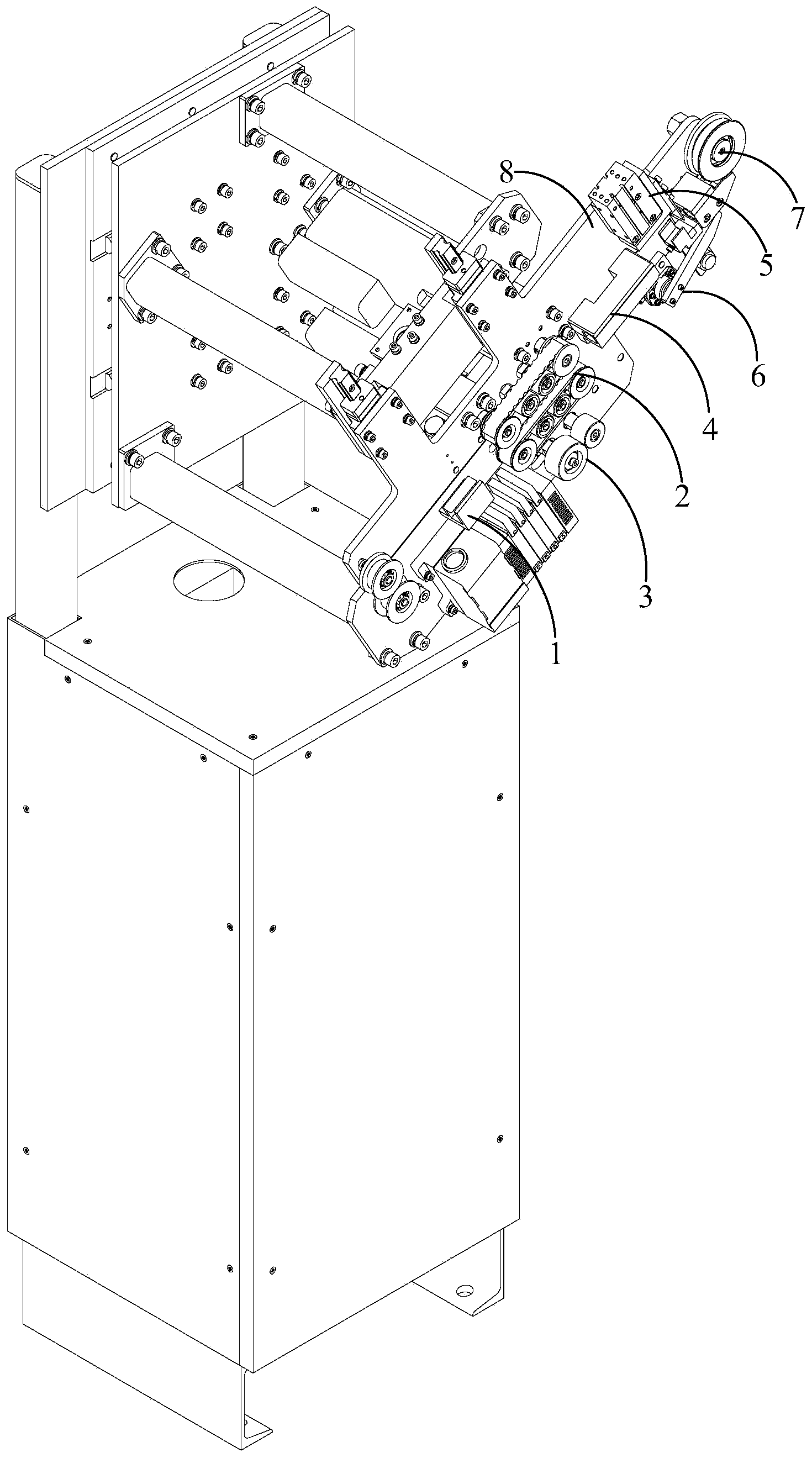

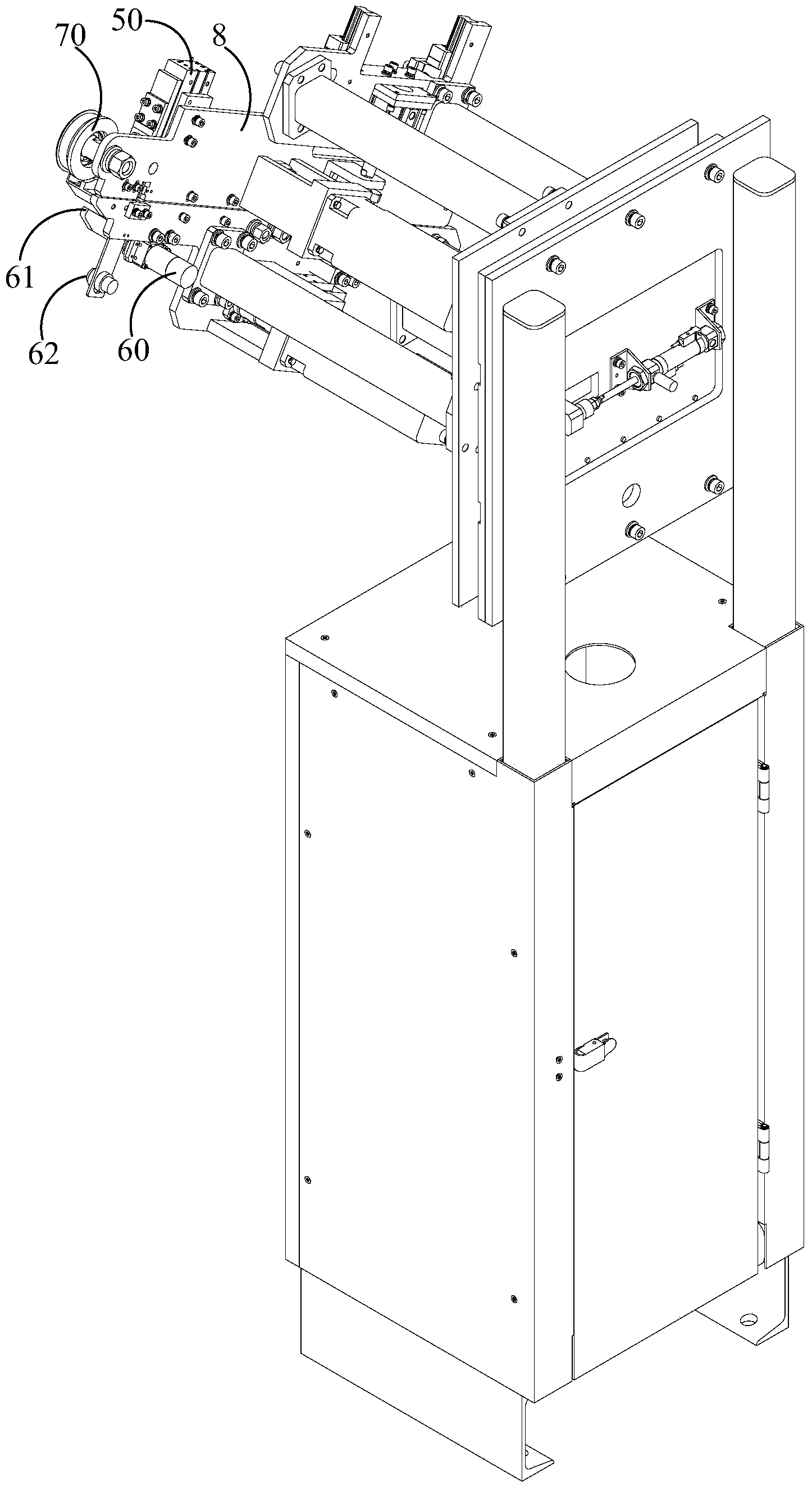

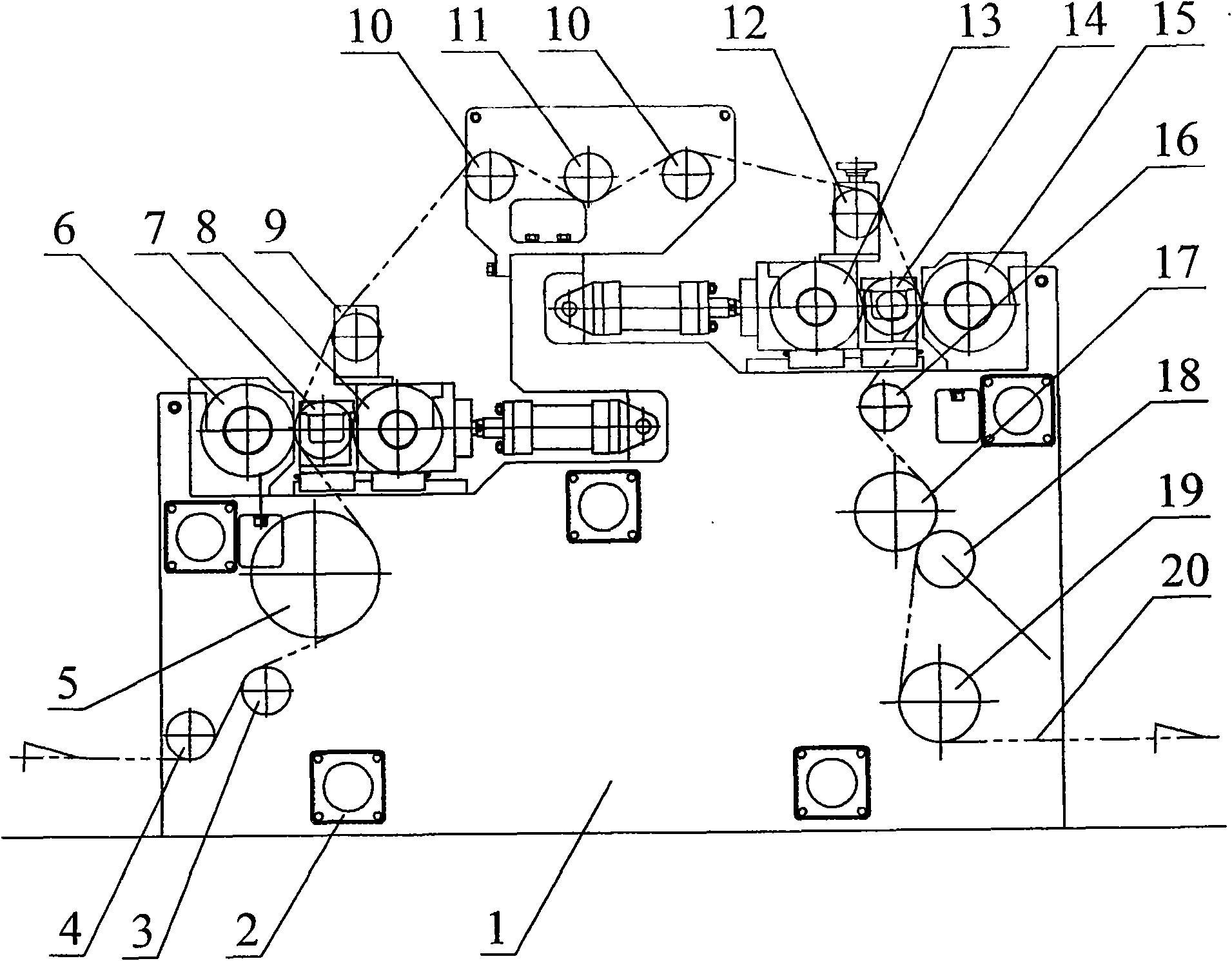

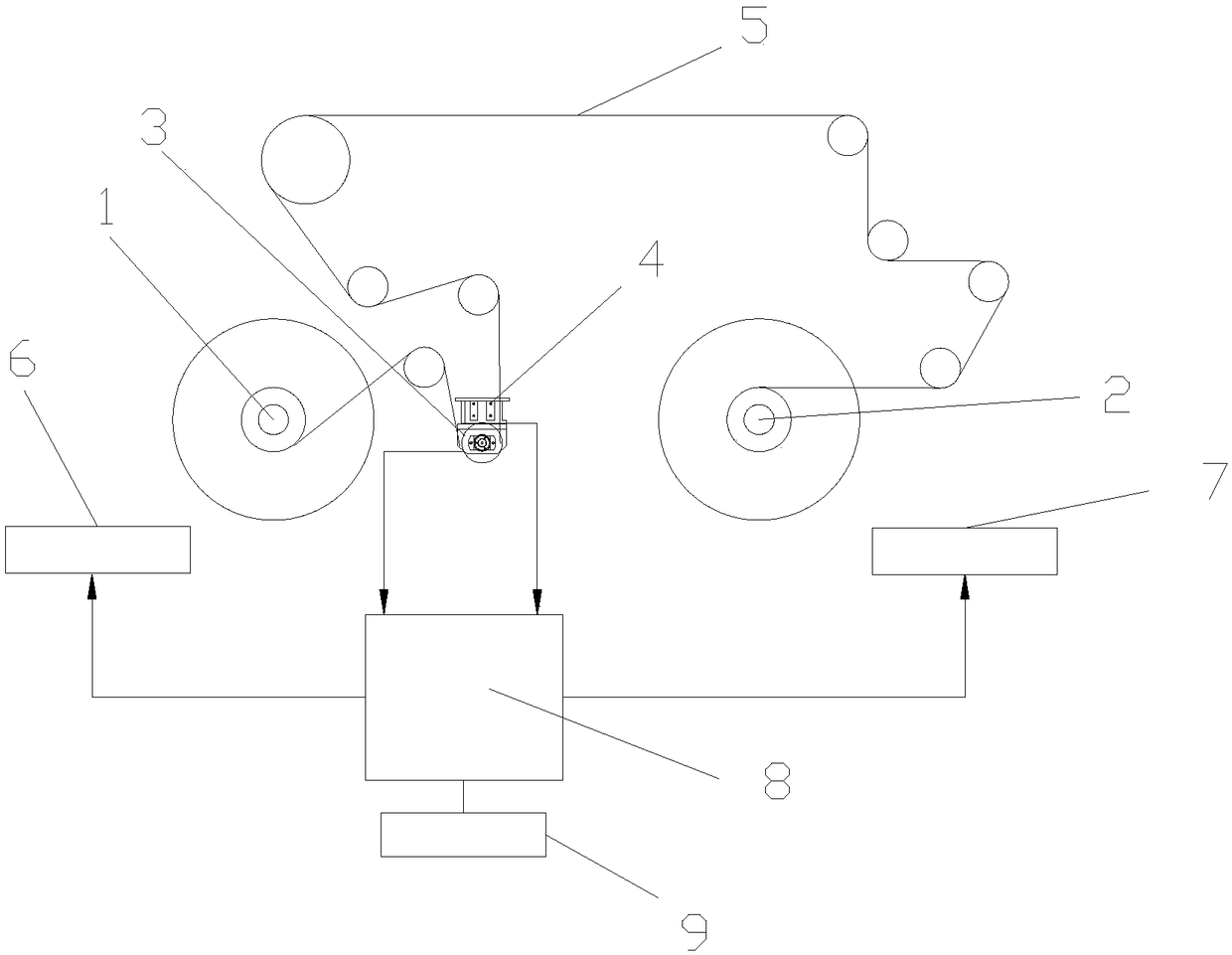

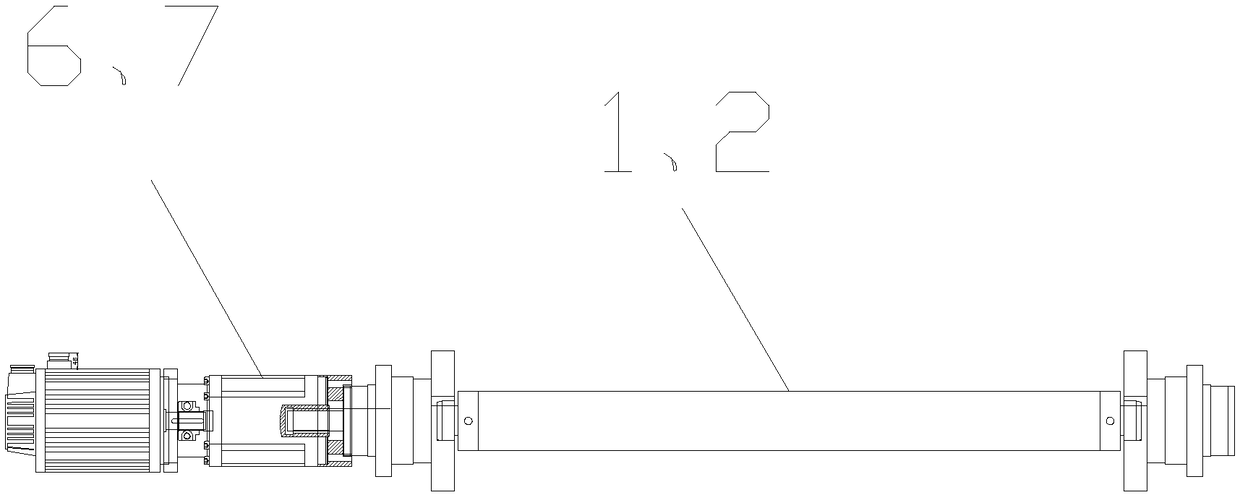

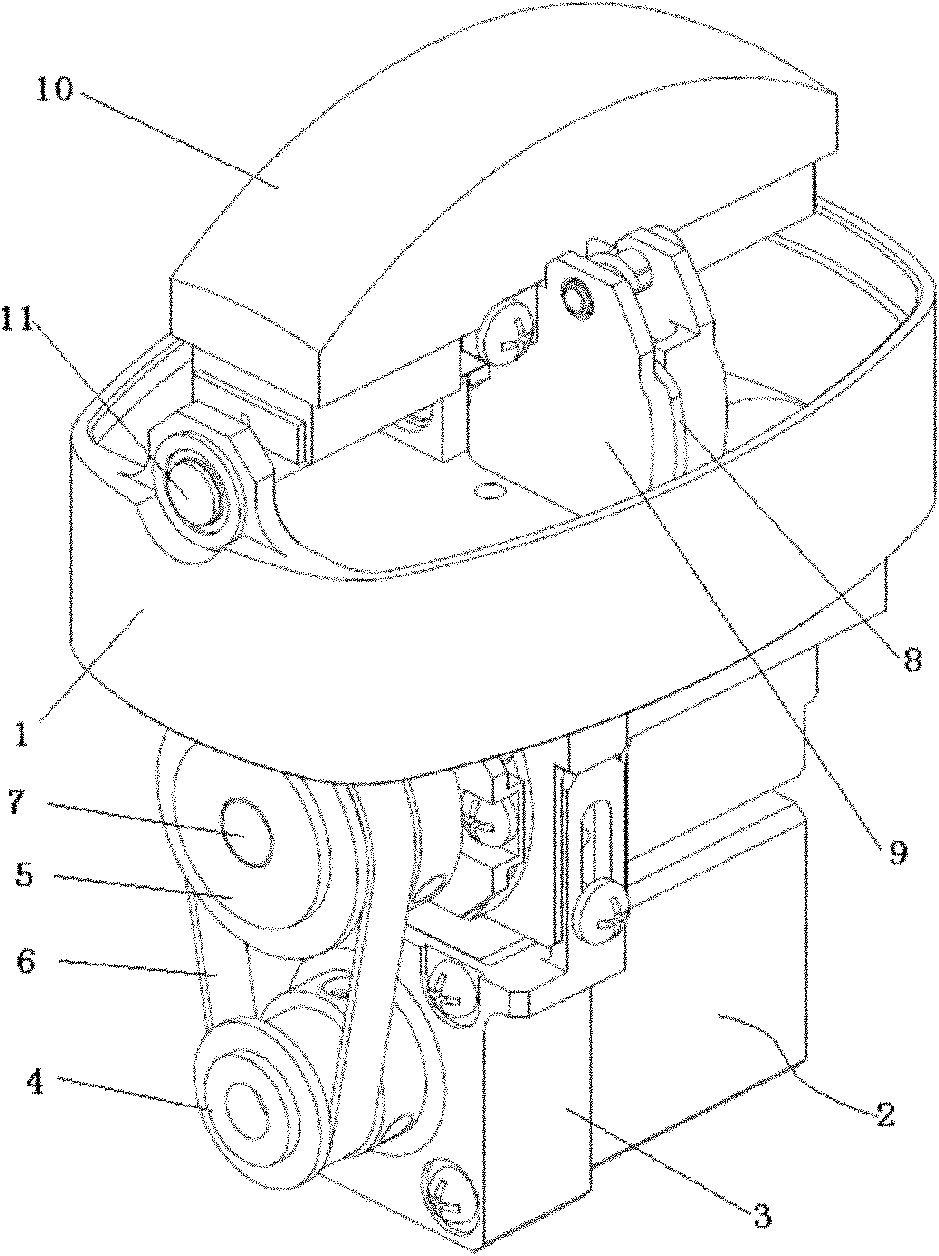

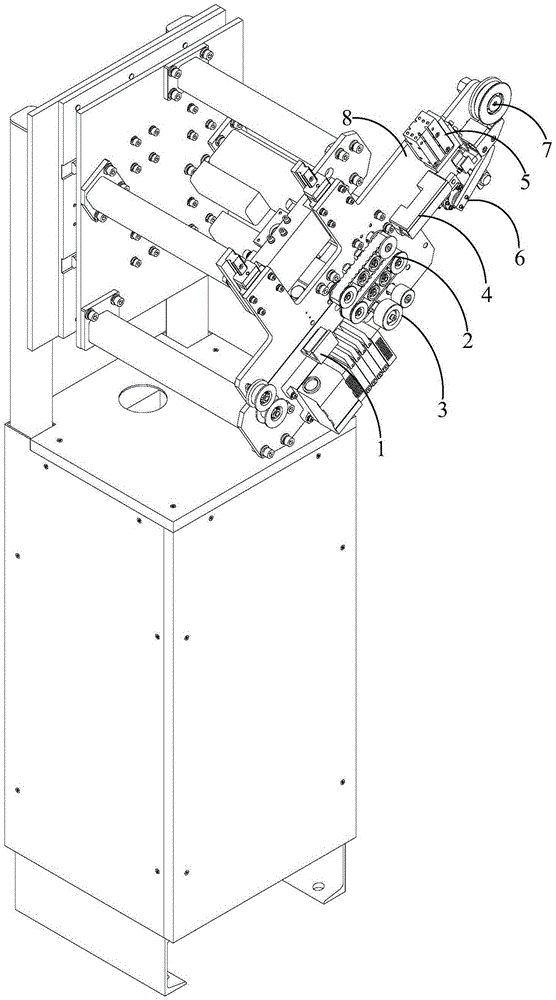

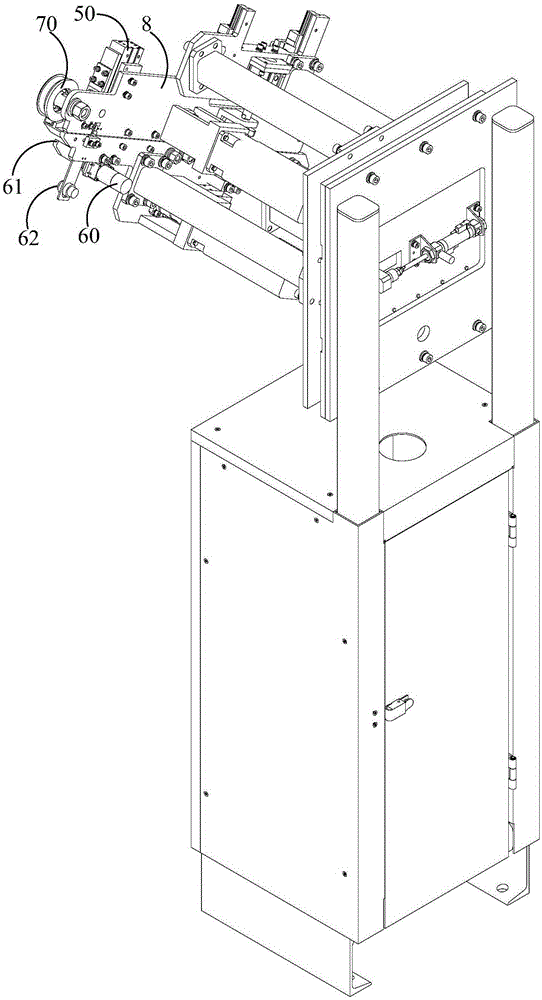

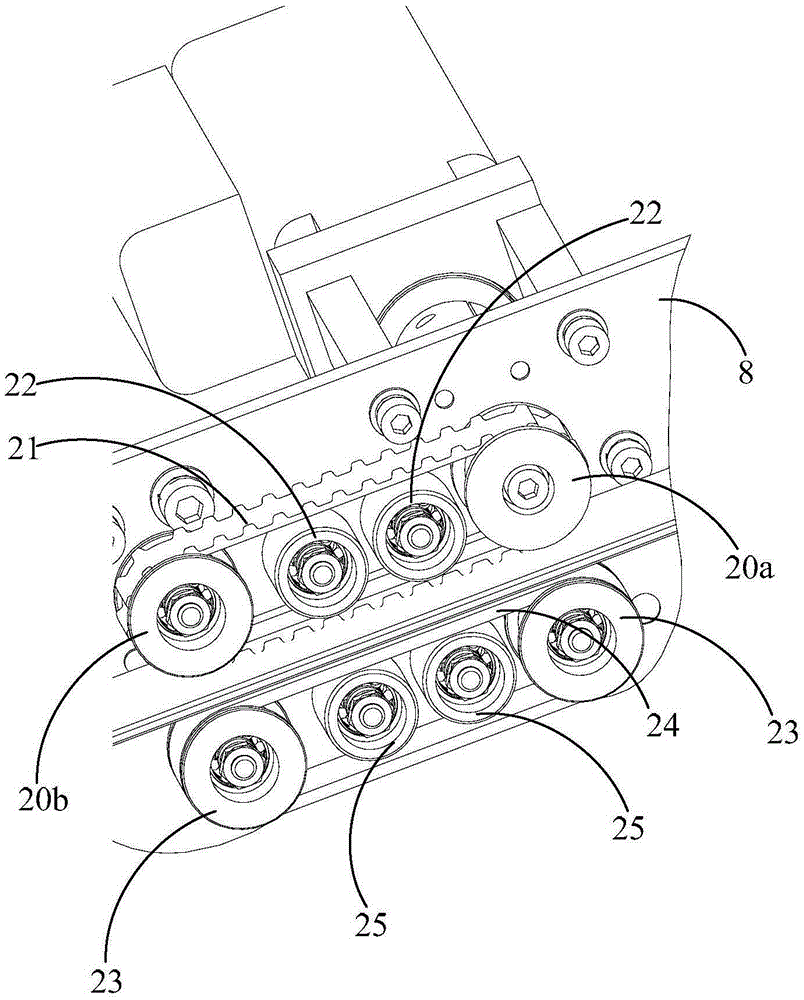

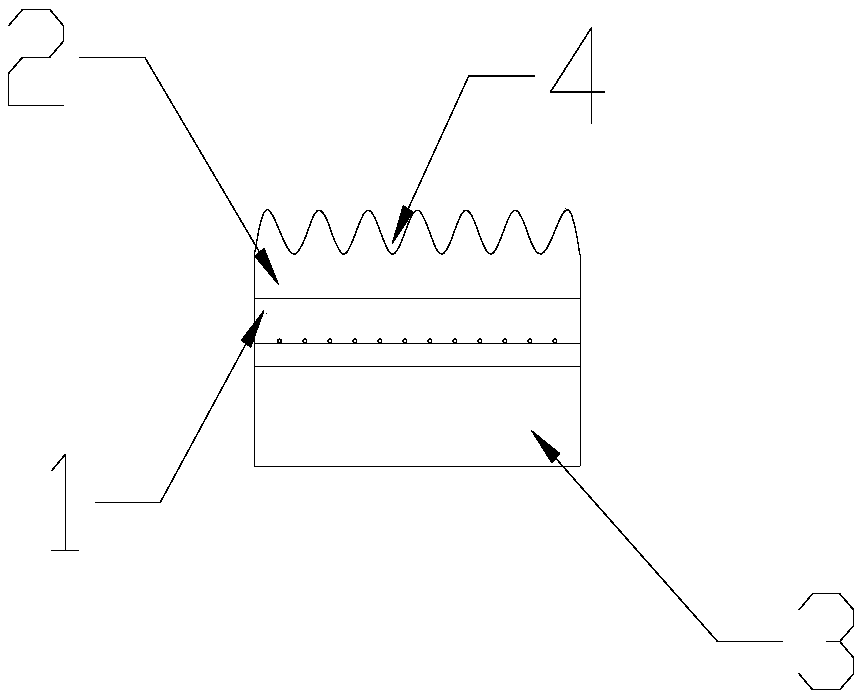

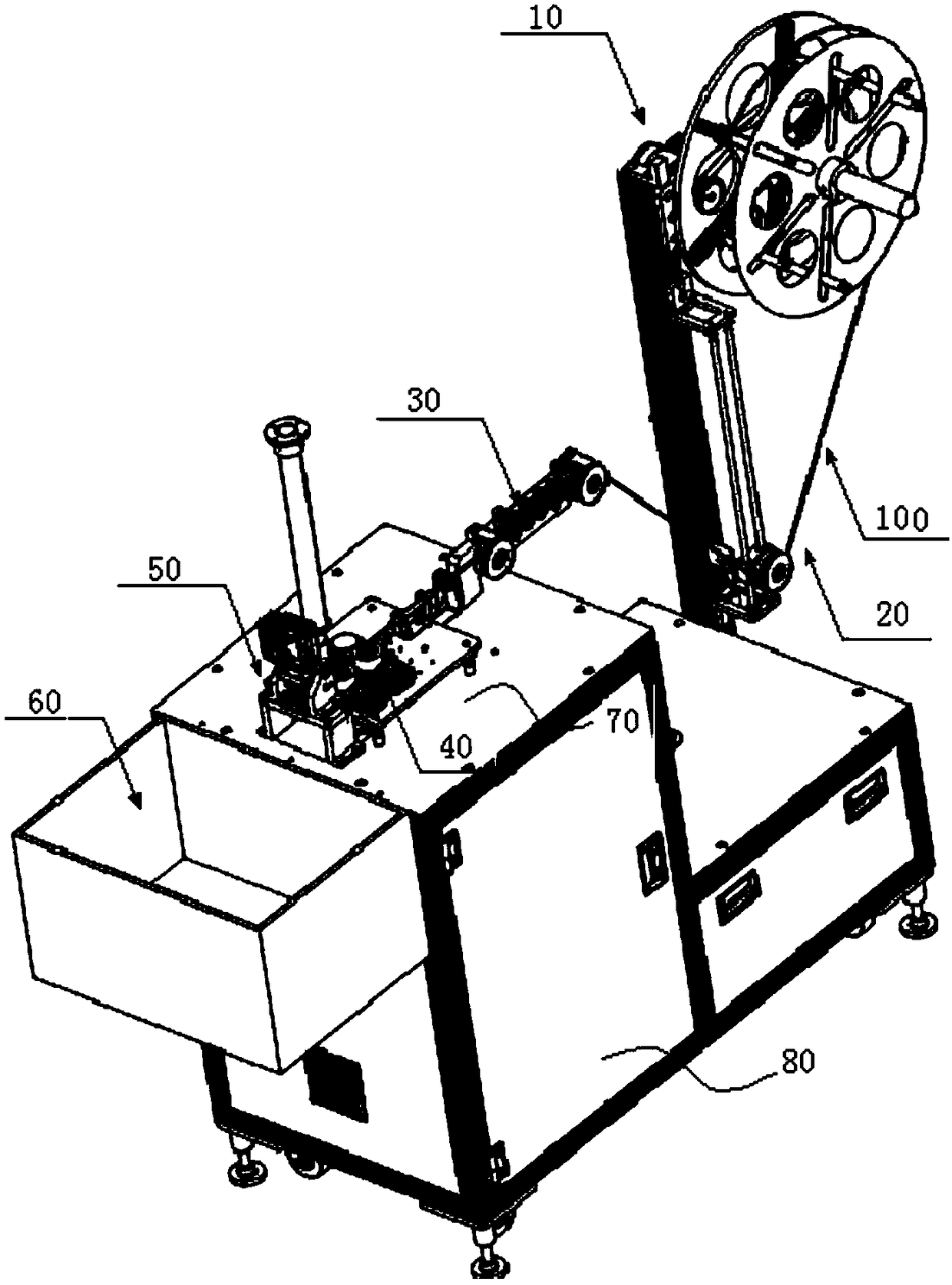

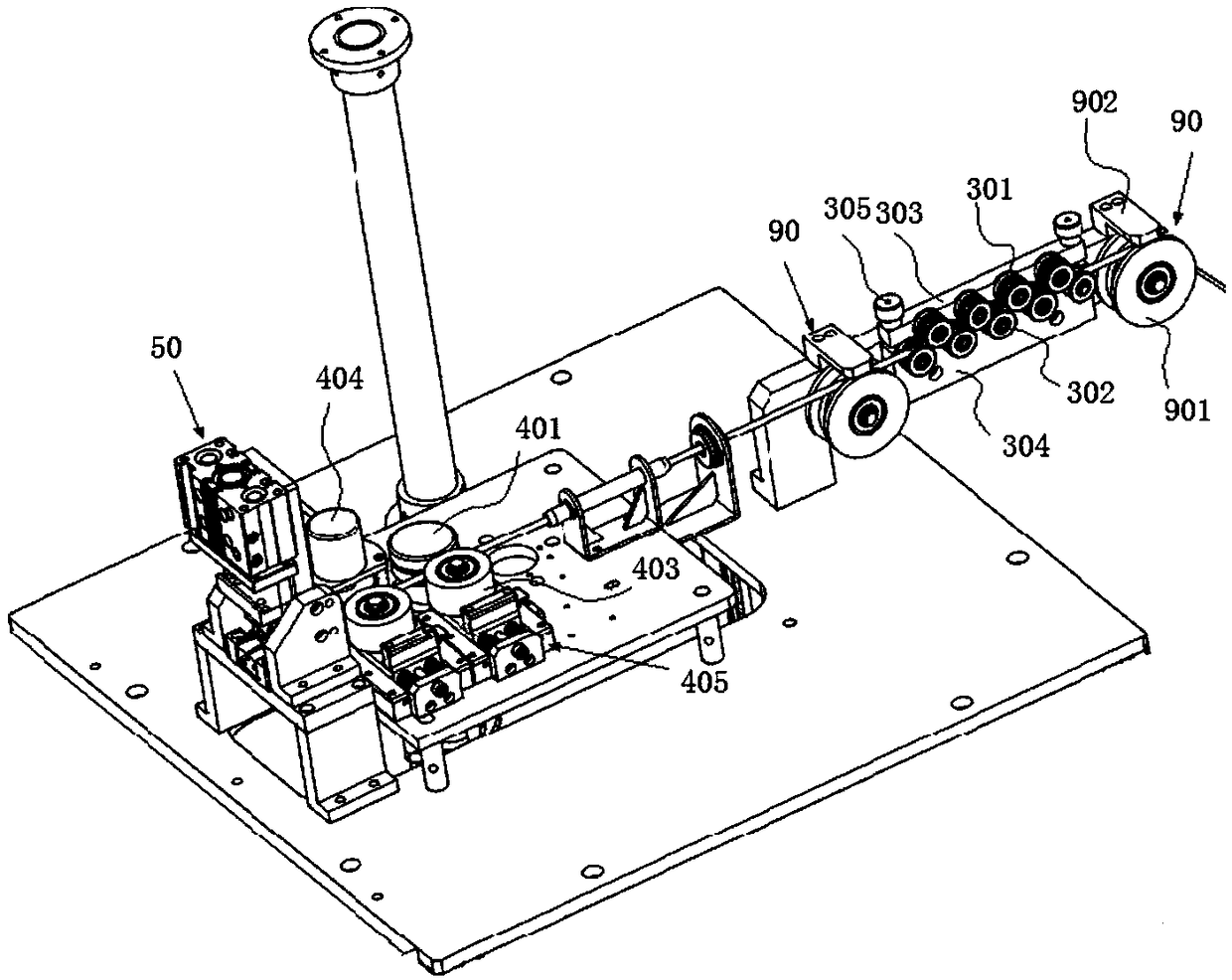

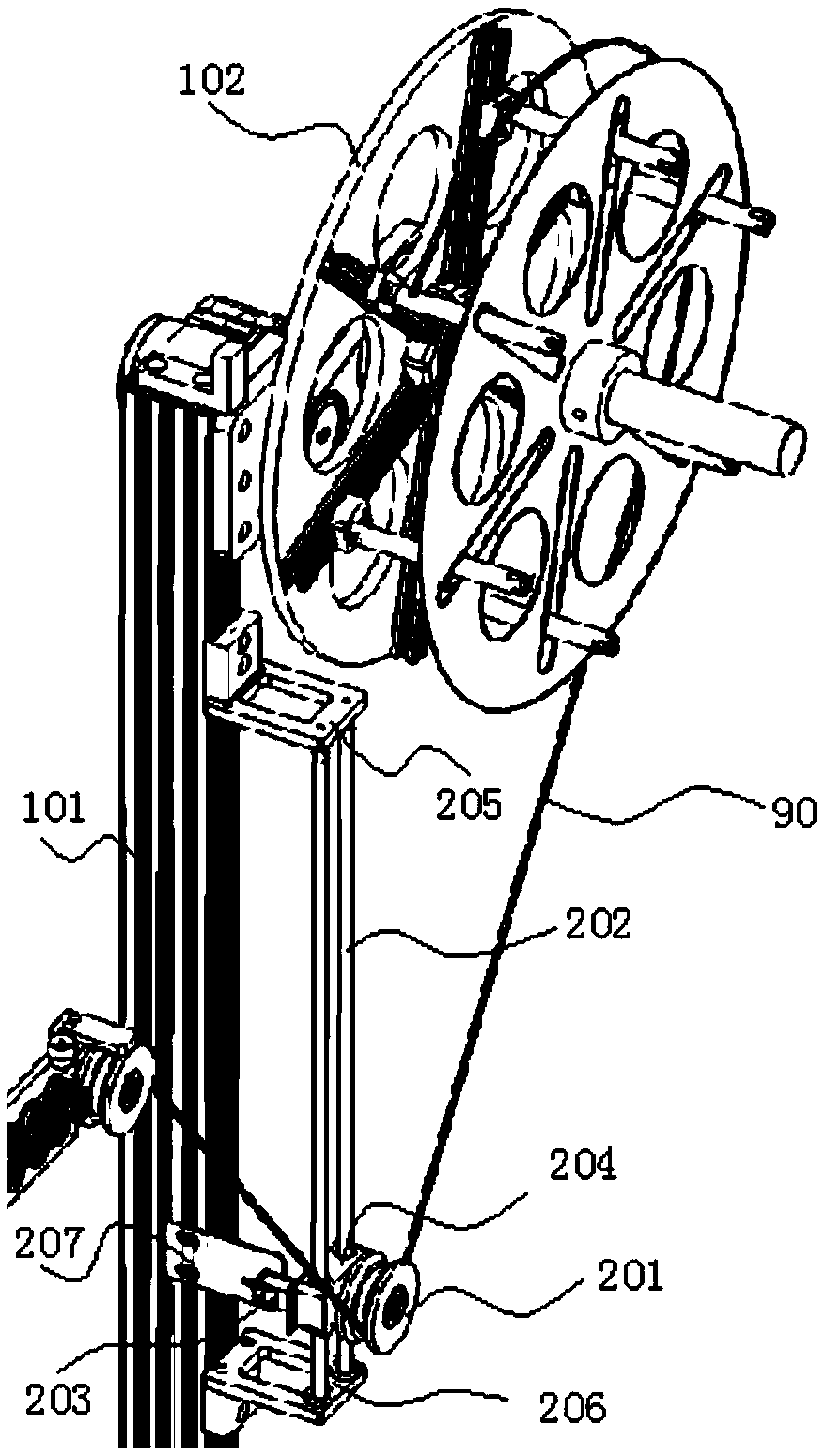

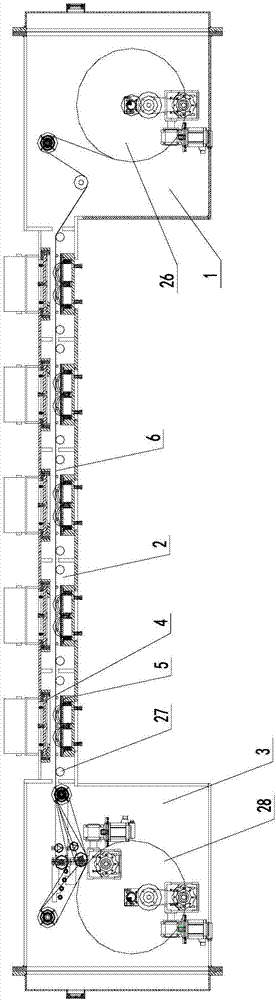

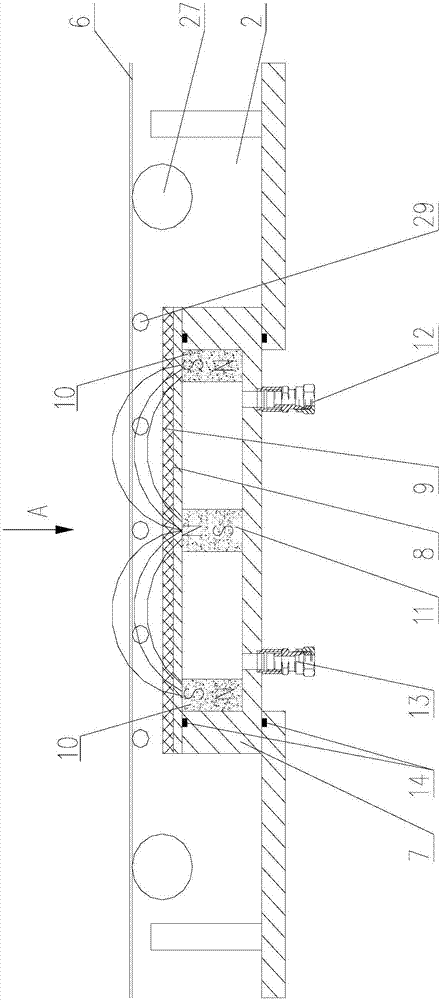

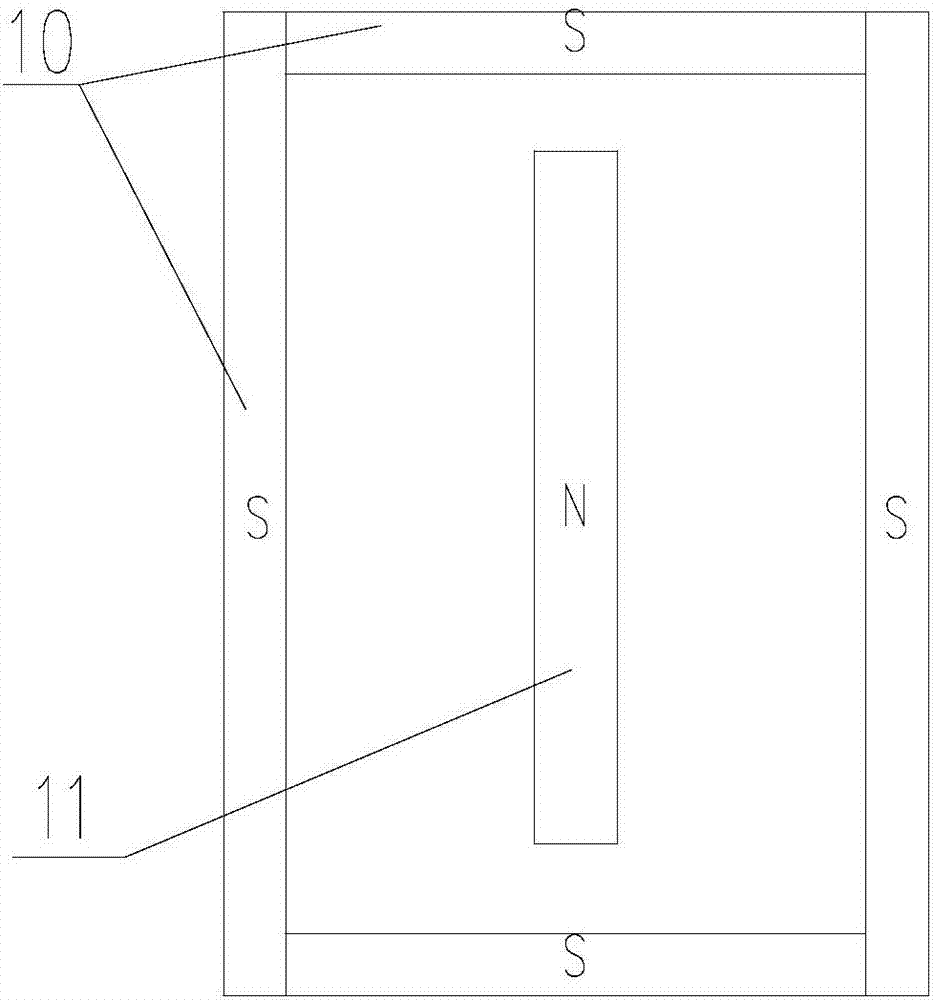

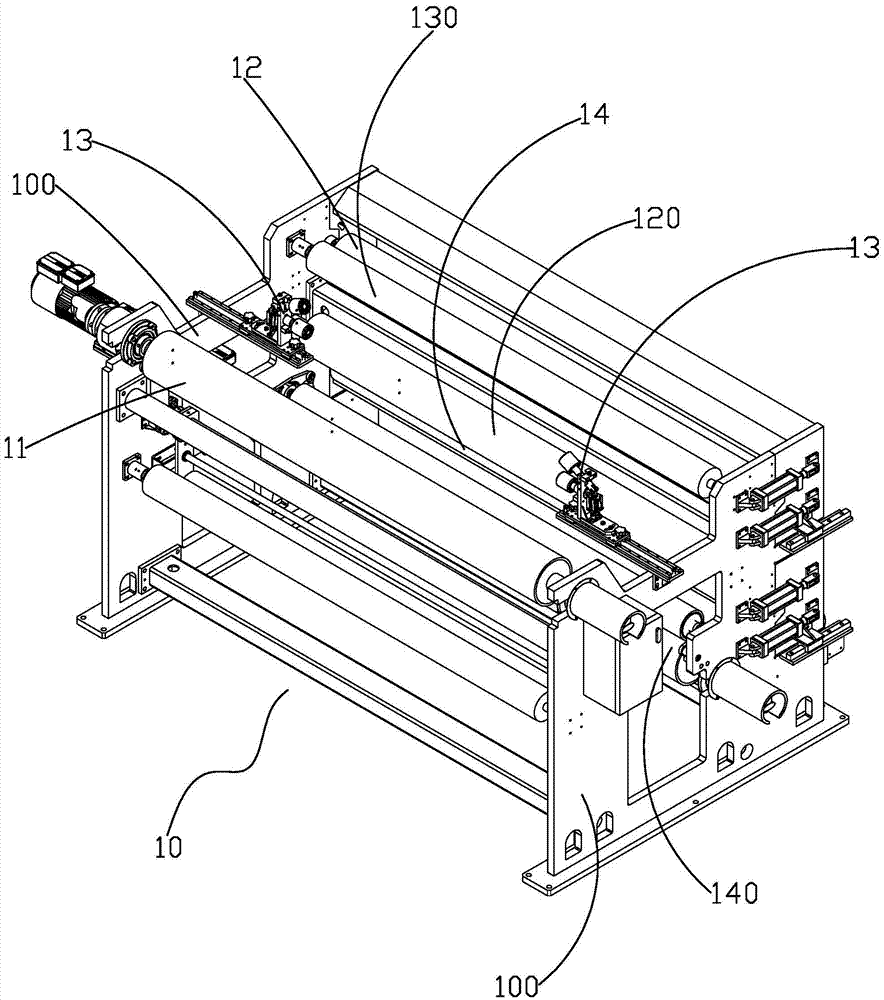

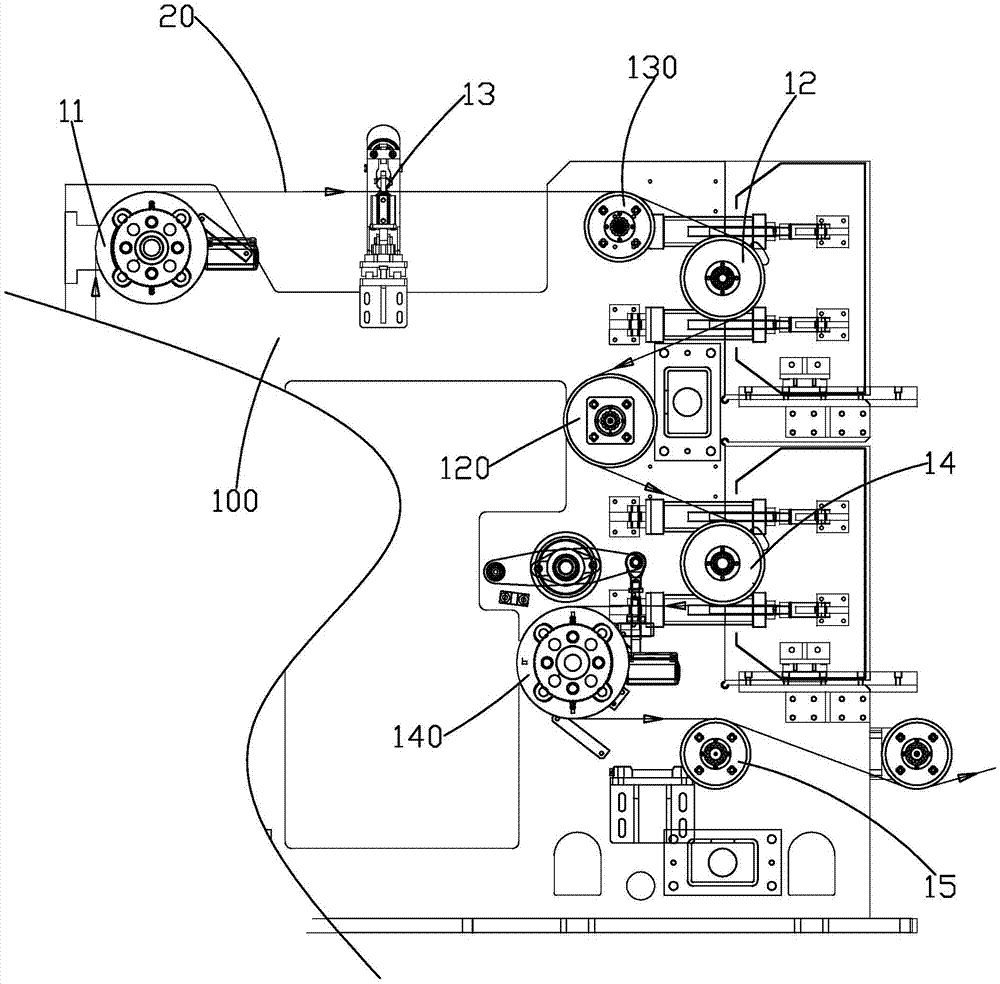

Sealing strip bonding equipment

ActiveCN103707955AAvoid Stretch DeformationGuaranteed bonding positionVehiclesArticle deliveryEngineeringControl unit

The invention discloses sealing strip bonding equipment, and relates to auxiliary equipment of the car production process. The sealing strip bonding equipment not only guarantees the bonding quality of a sealing strip, but also improves production efficiency. The sealing strip bonding equipment comprises a storage unit, a conveying unit, a bonding unit, a cutting-off unit, a detection unit and a control unit, wherein the storage unit is used for storing the sealing strip and conveying the sealing strip to the conveying unit, the conveying unit is used for conveying the sealing strip to the bonding unit, the bonding unit is used for bonding the sealing strip to the edge of a car door, the cutting-off unit is used for cutting off the sealing strip after the car door is bonded with the sealing strip, the detection unit is used for detecting whether the car door is thoroughly bonded with the sealing strip, if yes, the cutting-off unit executes the motion of cutting off the sealing strip, if not, the cutting-off unit does not execute the cutting-off motion, and the control unit is respectively in electric connection with the other units, and used for controlling the conveying, bonding and cutting-off motions of the sealing strip. The sealing strip bonding equipment is mainly used for bonding the sealing strip.

Owner:精诚工科汽车系统有限公司

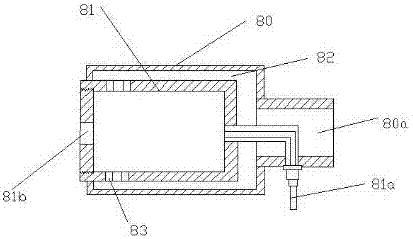

Motor assembly for driving liquid lens, camera module and electronic equipment

The invention provides a motor assembly for driving a liquid lens, a camera module and electronic equipment. The motor assembly includes: a stator portion; a mover portion movable in an optical axis direction with respect to the stator portion; a connecting elastic sheet which is connected with the liquid lens and the mover portion, wherein the mover portion drives the connecting elastic sheet toextrude or pull the liquid lens when being subjected to acting force in the optical axis direction; and a limiting part which moves along with the mover portion, has the same displacement as the moverportion, and is used for limiting the height change range of the connecting elastic sheet in the optical axis direction. According to the technical scheme, the motor used for driving the liquid lenscan meet the performance requirements of automatic focusing and / or optical anti-shake and the like, and the reliability of the motor under abnormal working conditions such as impact and falling is improved.

Owner:HUAWEI TECH CO LTD

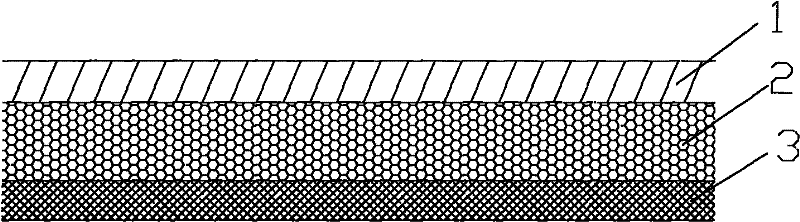

Medical composite non-woven fabric

InactiveCN102452191AEasy to sterilizeImprove hygieneLayered productsAbsorbent padsIsolation effectViscose

The invention relates to a medical composite non-woven fabric. The medical composite non-woven fabric is formed by a spunbond non-woven fabric layer, a melt-blown non-woven fabric layer and a viscose non-woven fabric layer, wherein the melt-blown non-woven fabric layer is located between the spunbond non-woven fabric layer and the viscose non-woven fabric layer, the viscose non-woven fabric layer contains 3-9% (by weight) inorganic oxide composite powder, and the inorganic oxide composite powder contains 80-90% (by weight) of Tio2, 3-8% (by weight) of Al2O3 and 2-8% (by weight) of Sio2. The medical composite non-woven fabric has the advantages of being convenient to disinfect and sterilize, having excellent hygienic properties and hygroscopicity, being directly usable for surface injury, capable of preventing tensile deformation and easy to apply, and the like; and the medical composite non-woven fabric also has better isolation effect and air permeability, and is comfortable to wear.

Owner:CHANGSHU XINTEDU GARMENTS

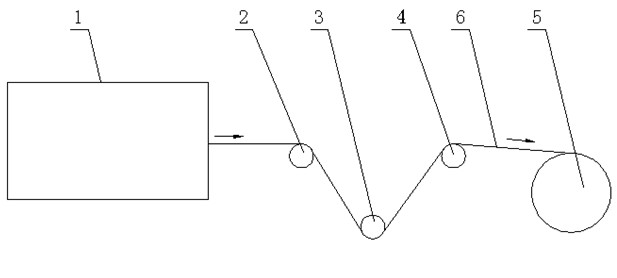

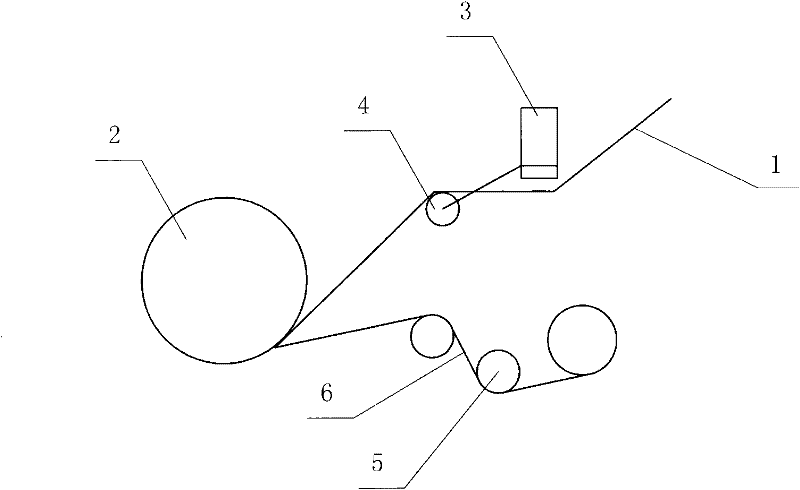

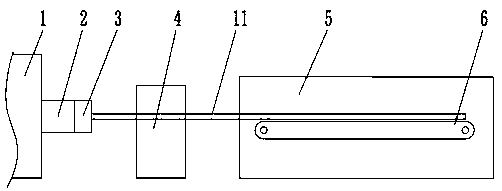

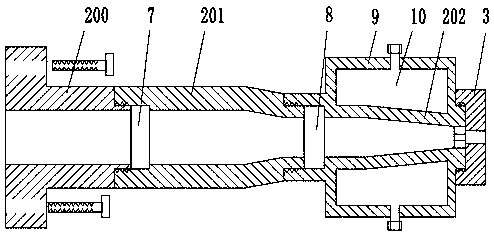

Winding device for ultrathin metal lithium strip

The invention discloses a winding device for an ultrathin metal lithium strip. The device comprises a winding machine and two pairs of pinch rollers, wherein the two pairs of pinch rollers are parallelly arranged; and one pair of pinch rollers is connected with the die orifice of a metal lithium strip extruder, and the other pair of pinch rollers is connected with the winding machine. The two pairs of pinch rollers are arranged in front of the winding machine and used for controlling the tension of the metal lithium strip, and the metal lithium strip can be uniformly stressed during winding and cannot be subjected to overhigh stress during roll changing, so that the ultrathin metal lithium strip can be smoothly wound, and the phenomena that the ultrathin metal lithium strip is subjected to tensile deformation or broken during winding or roll changing are avoided; and in addition, the pinch rollers are water-cooled rollers, and a forced cooling device is arranged between the two pairs of pinch rollers and used for cooling the metal lithium strip which flows out of the die orifice of the metal lithium strip extruder, so that the strength of the cooled metal lithium strip is increased, and the phenomena that the metal lithium strip is subjected to tensile deformation or broken during winding or roll changing are avoided.

Owner:CHONGQING UNIV

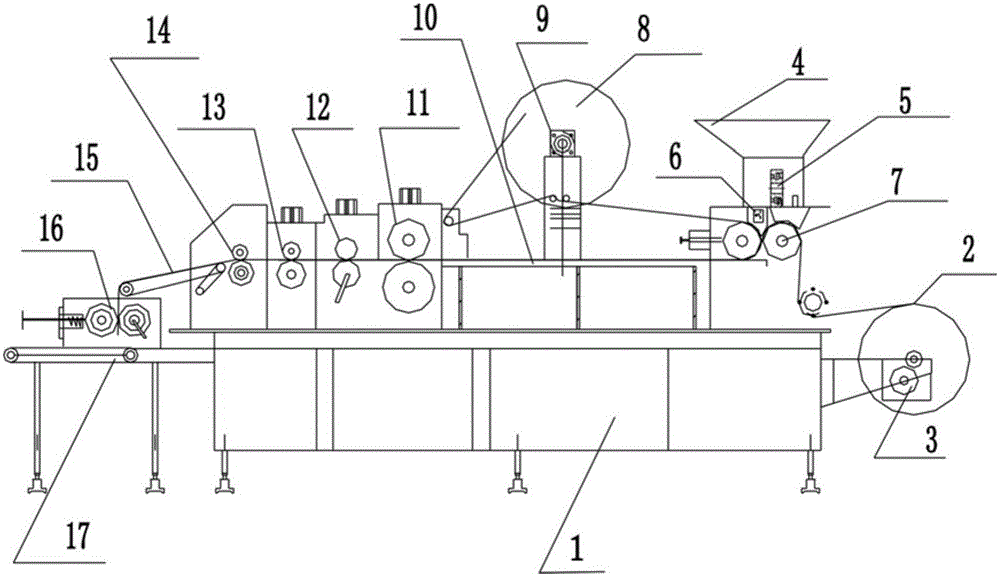

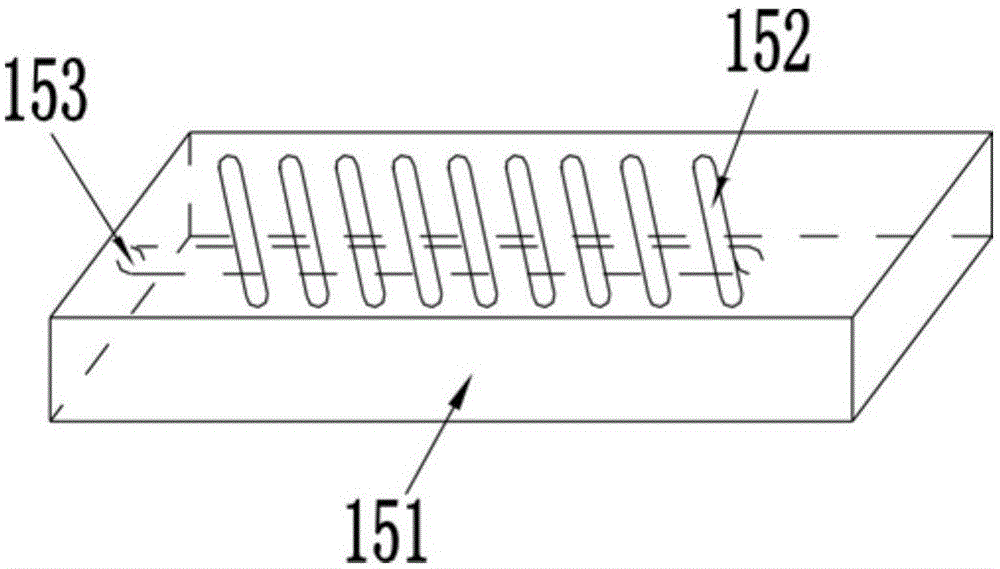

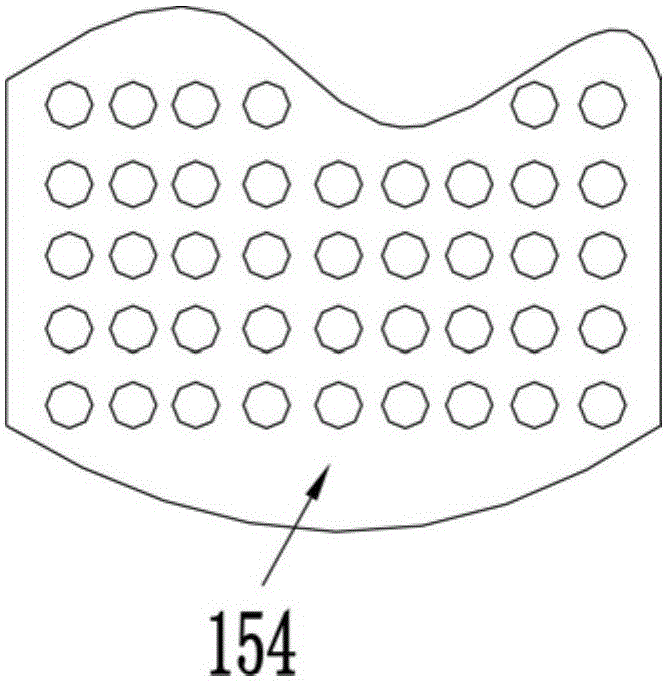

Full-automatic hobbing cutter type coating slicing machine

The invention provides a full-automatic hobbing cutter type coating slicing machine. The coating slicing machine comprises a rack arranged on the ground, wherein the rack is sequentially provided with a non-woven fabric reel, a gel material bucket and an embossed film reel; a coating mechanism is arranged between the gel material bucket and the non-woven fabric reel; a gel amount controller is arranged under the gel material bucket; a pre-cured plate is arranged under the embossed film reel; the rack is further provided with a molding mechanism, a calibration mechanism and a traction mechanism; a longitudinal cutting unit and a transverse cutting unit are further arranged behind the traction mechanism; and a conveyor belt is arranged behind the transverse cutting unit. The full-automatic hobbing cutter type coating slicing machine is full-automatic gel production equipment which integrates double-roller compounding, rolling, longitudinal cutting, transverse cutting and molding of gel and base materials, so that gel products are obtained by compounding and molding the raw materials, cutting and enabling the materials to directly fall onto the conveyor belt in one process.

Owner:HANGZHOU YU FU LONG MEDICAL DEVICES CO LTD

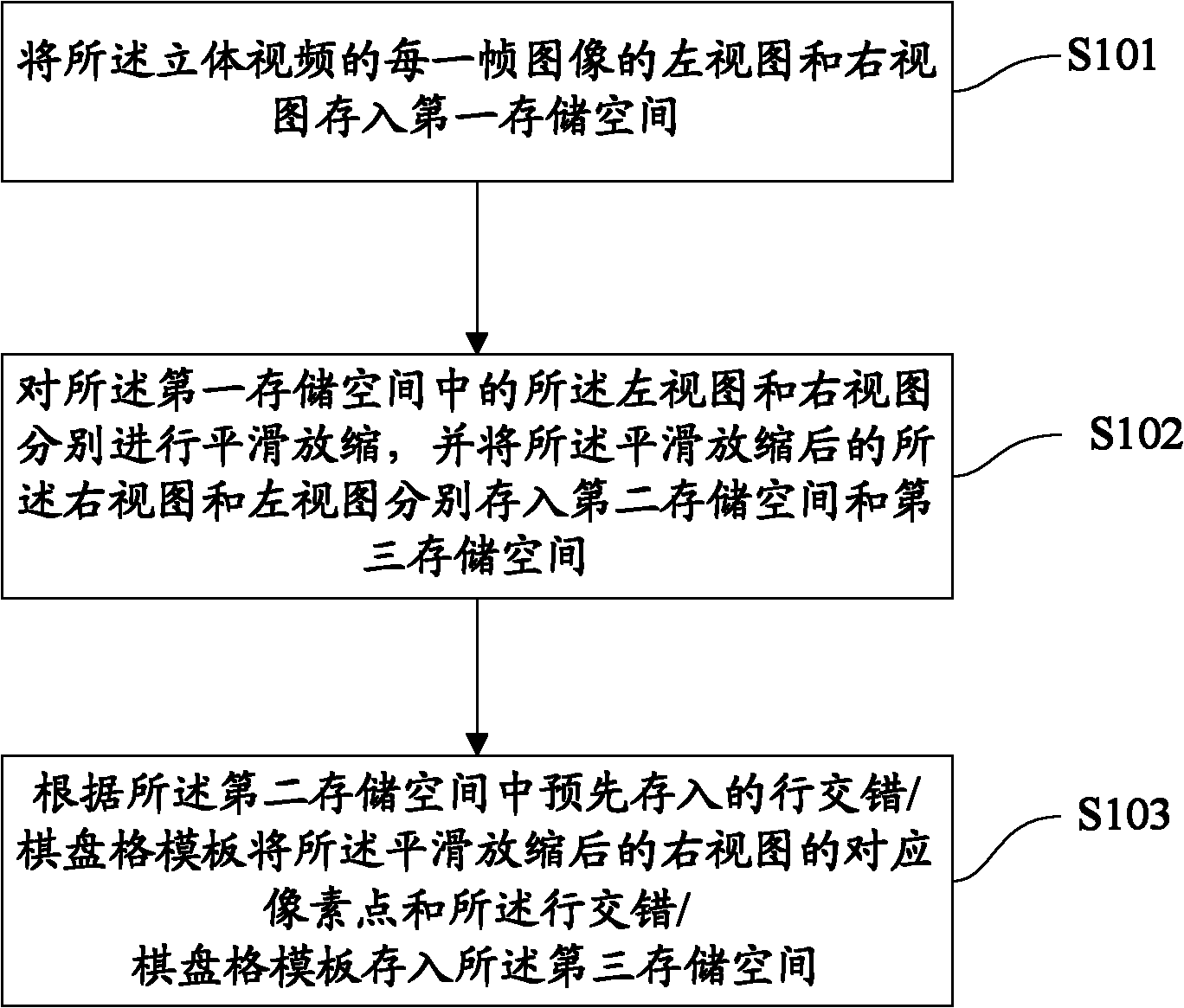

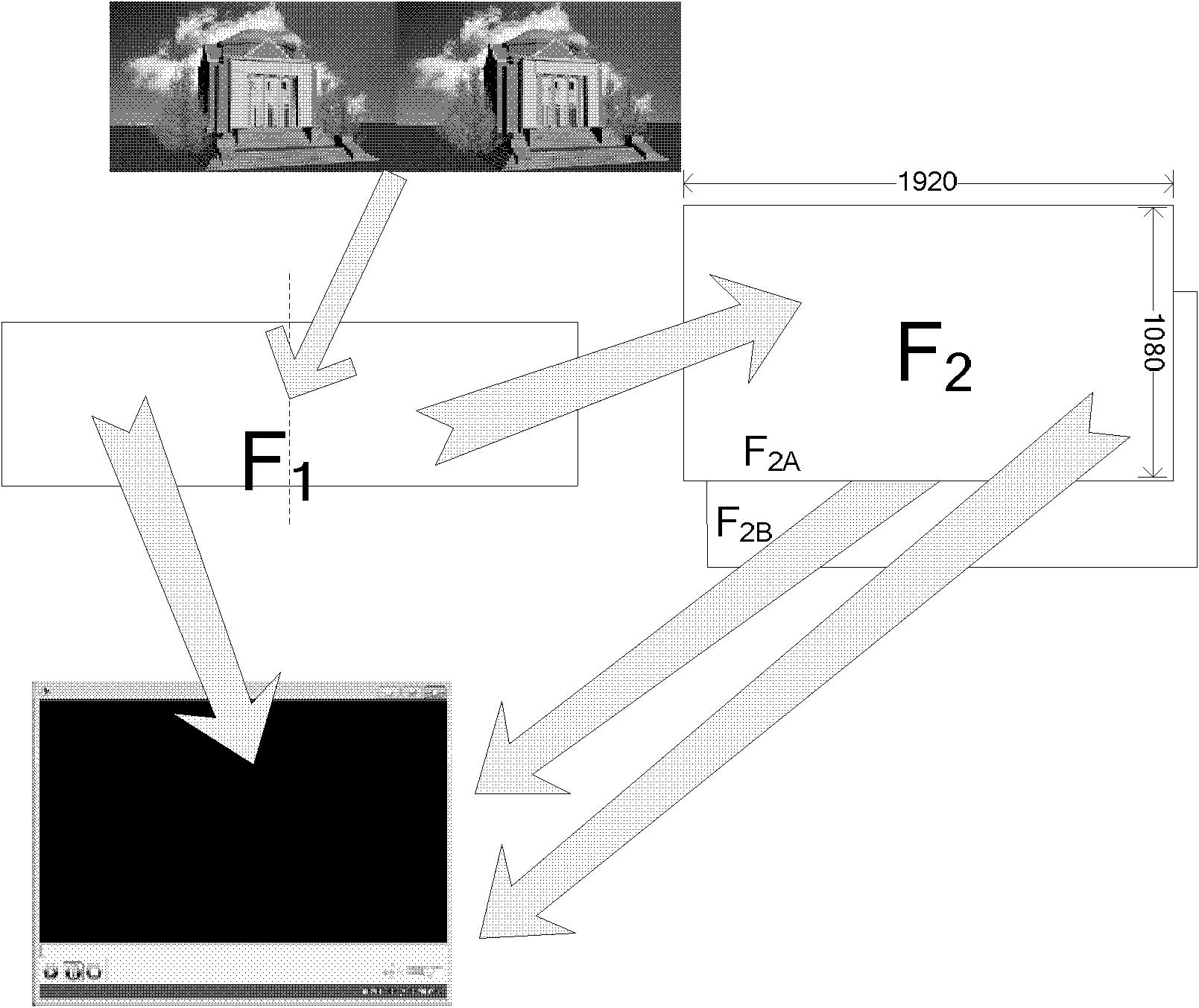

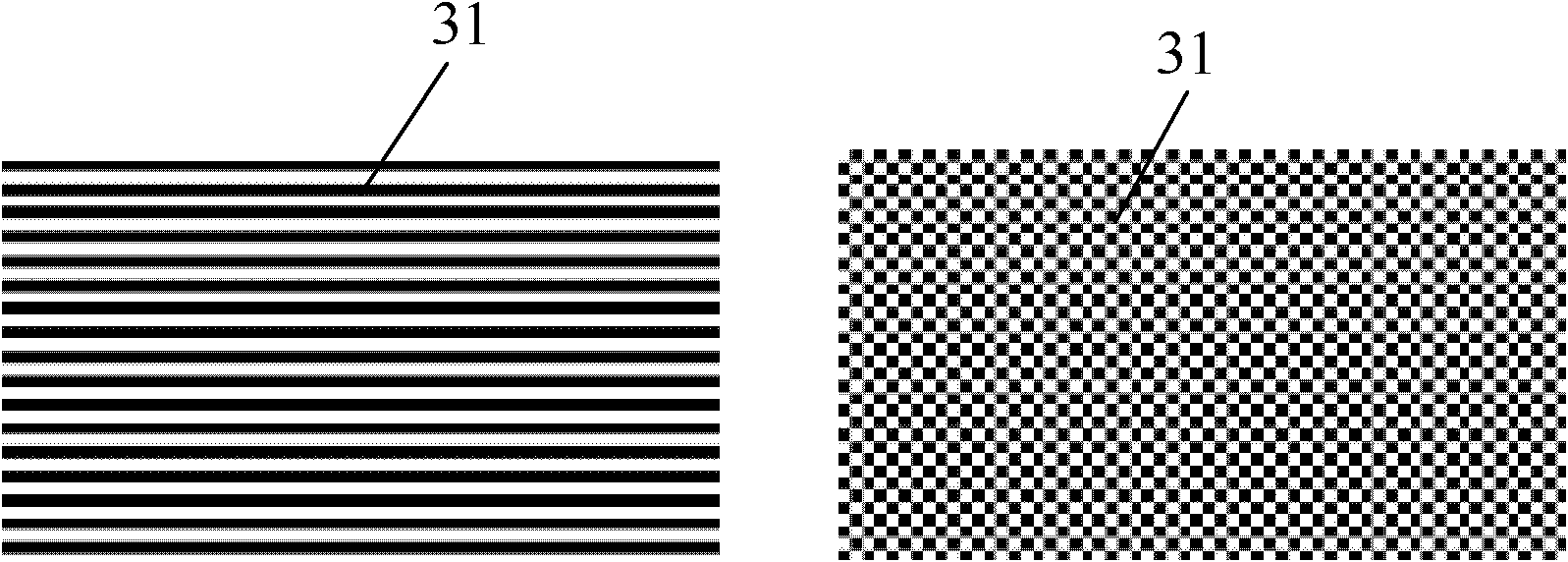

Line-staggered and tessellated rendering method and device for three-dimensional video

ActiveCN102137268ASmooth playbackAvoid Stretch DeformationSteroscopic systemsStandards conversionComputer graphics (images)Computer science

Owner:TSINGHUA UNIV

Multifunctional laser holography stamping process

InactiveCN101579963AStrong optical effectLaser effect is goodSpecial ornamental structuresRotary pressesLaser patterningLaser holography

The invention discloses a multifunctional laser holography stamping process. The traditional laser holography compression press uses the process of single-version roller one-step embossing, which has adverse impact on subsequent laser pattern pressing due to the existing version gap. The invention mainly use a stander, a beam, a tension pulley, a stator a, a pre-heating wheel, a first stamping station, a tension-control group, a second stamping station, a stator bb, an ironing wheel, a rubber clamping wheel, a cooling wheel, a printing film, a photoelectric eye and a PLC control circuit. The invention has the beneficial effects that due to utilization of two-station stamping process, plastic film can go through laser holography embossing twice, stagger the version gap and can not be blurred; lowering the temperature requirement on wheel surface of the wheel is favor of stamped pictures and texts of the film to be more plump and saturated; more intensive optical effect is generated to achieve better laser effect; the quality of laser holography stamping on the plastic film is improved greatly.

Owner:SHANGHAI FORWARD MASCH CO LTD

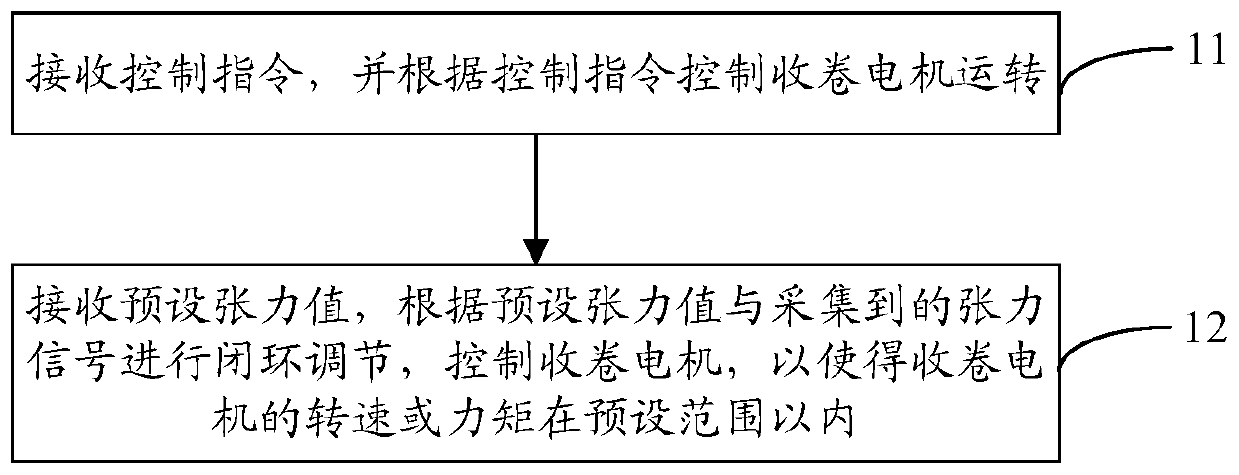

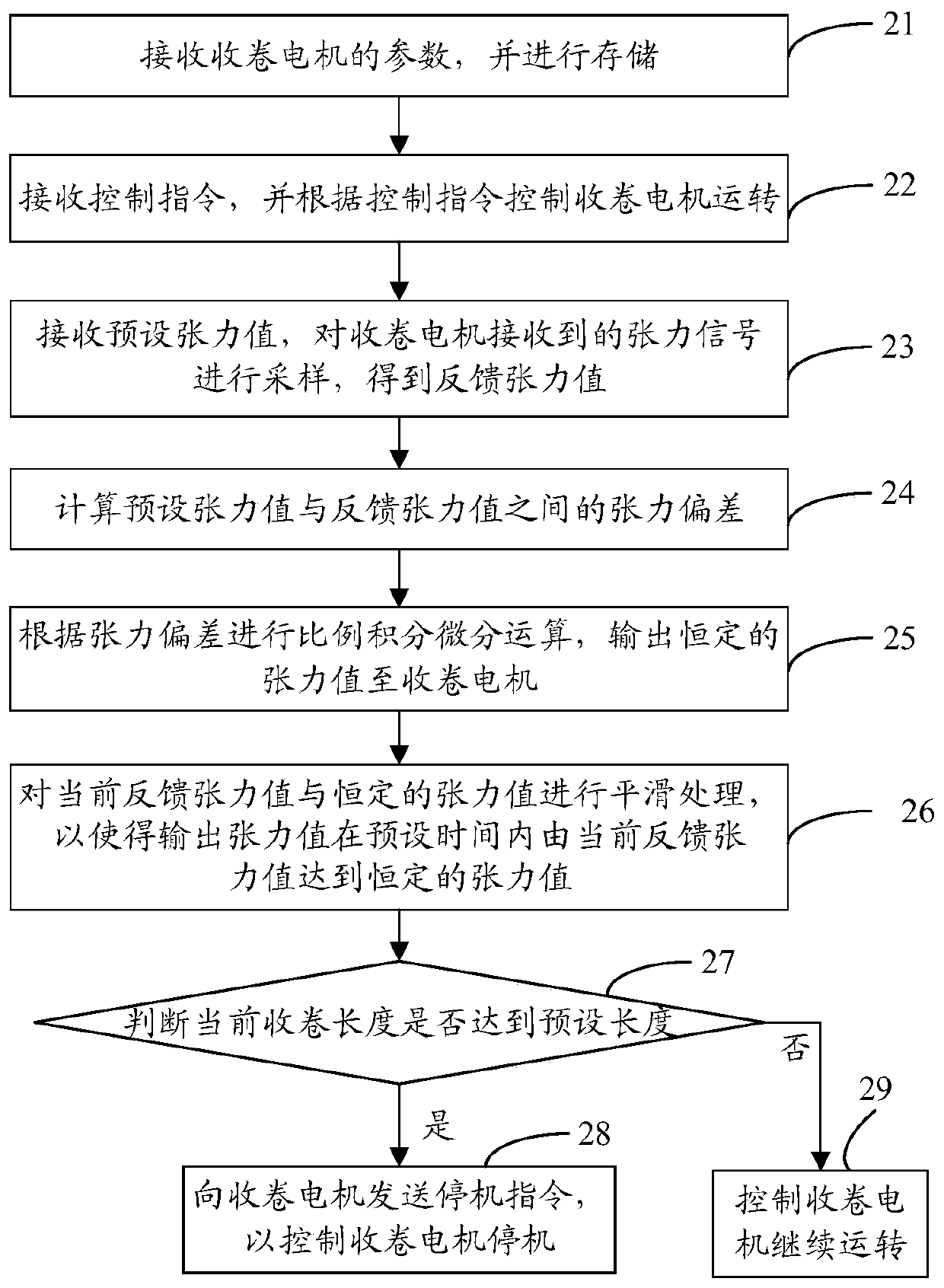

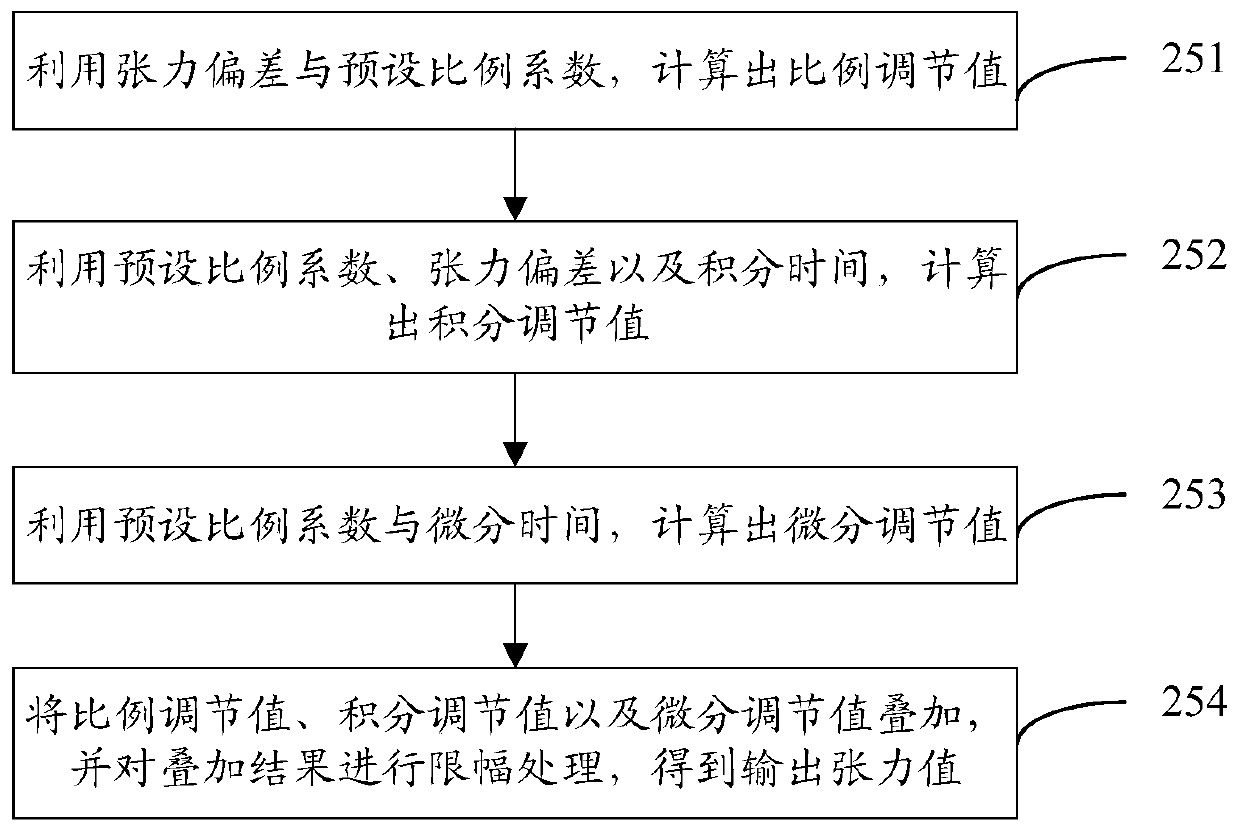

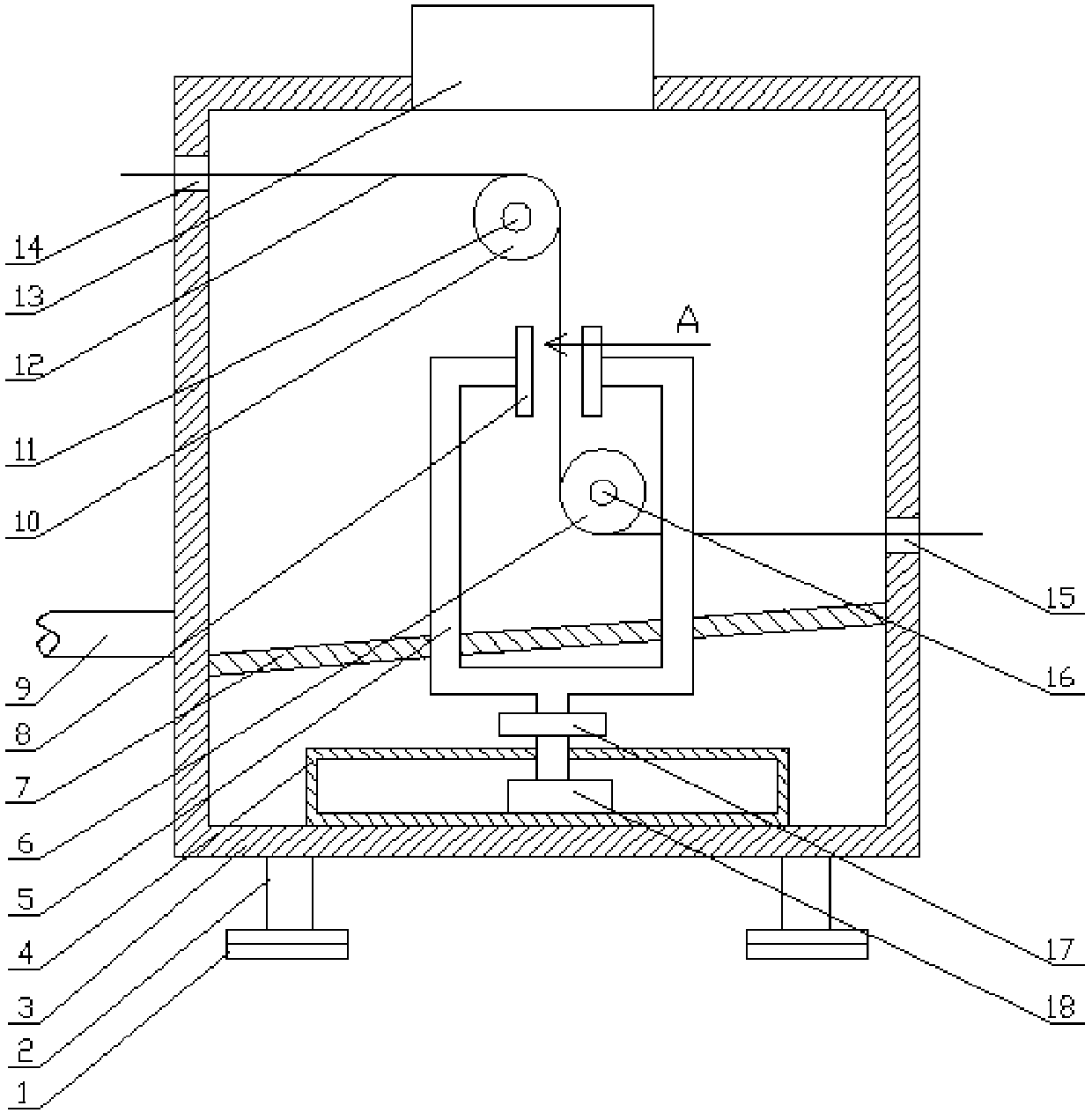

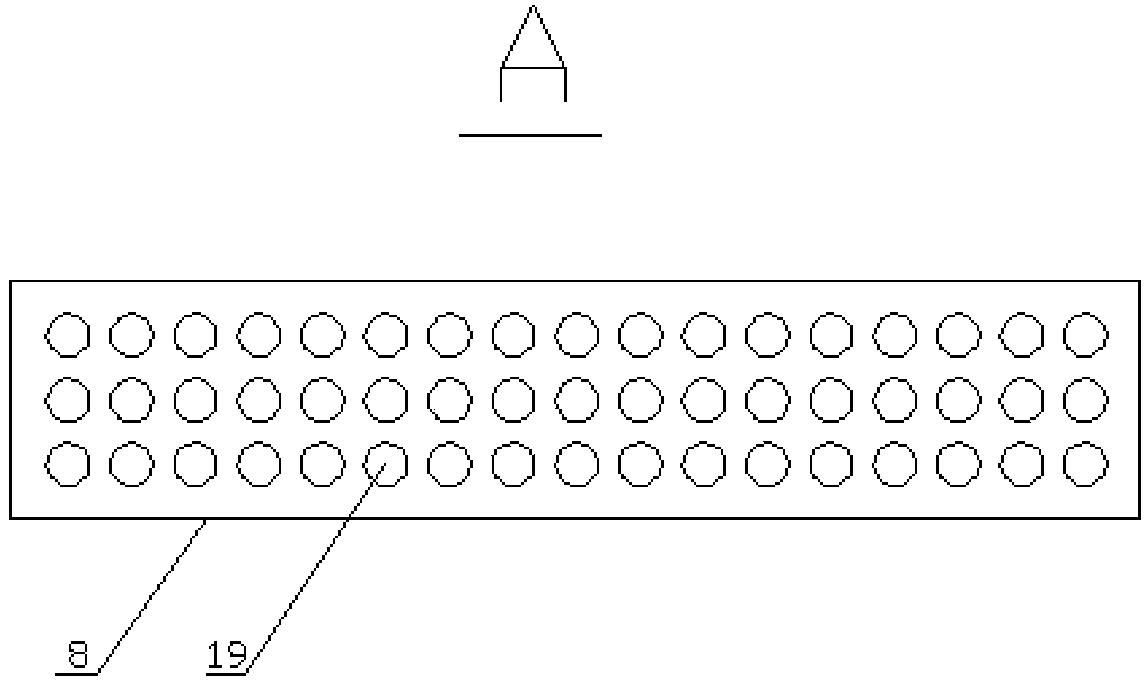

Winding control method, device and system and computer storage medium

The invention discloses a winding control method, device and system and a computer storage medium. The winding control method is applied to the winding system, and the winding system involves a winding motor; and the method comprises the following steps of receiving a control instruction and controlling the winding motor to operate according to the control instruction; and receiving a preset tension value, carrying out closed-loop adjustment according to the collected tension signal and the preset tension value, and controlling the winding motor, so that the rotating speed or moment of the winding motor is within a preset range. According to the winding control method, device and system, the tension control precision can be improved, and the winding quality is guaranteed.

Owner:苏州安驰控制系统有限公司

A textile washing device

InactiveCN105780347BOffset the impactAvoid Stretch DeformationTextile treatment machine arrangementsTextile treatment by spraying/projectingWater flowMechanical engineering

The invention relates to the textile field and particularly relates to a textile fabric flushing device. Through the textile fabric flushing device, the textile fabric can be thoroughly cleaned, and the fabric texture can be improved while tensile deformation of the fabric caused by water flow impact and consequent influence on the fiber structure of the fabric are prevented. The textile fabric flushing device comprises a box body, wherein the box body is of a cuboid hollow structure; a partition plate is arranged in the box body; the box body is divided into two spaces by the partition plate; the partition plate is placed obliquely; a drain pipe is arranged on the side wall of the box body and communicated with the inside of the box body and positioned above the partition plate; a feed port and a discharge port are formed in the two side walls of the box body respectively and communicated with the inside of the box body and are of a rectangular structure; and a liquid box is arranged on the lower surface inside the box body and is of a cuboid hollow structure. The textile fabric flushing device has the advantages of high efficiency and low cost and is suitable for cleaning textile fabric.

Owner:苏州新德龙纺织有限公司

Method for controlling material winding speed

The invention provides a method for controlling a material winding speed. Through the method, the material winding circumference is detected so as to exactly adjust a rotation angle speed of a winding roller; the change of rotation speeds of the winding roller is buffered through fluctuation of a floating roller relative to a balance position, so as to realize the match between the winding speed and a transportation line speed, prevent materials from being stretched and deformed, and improve the material winding and storing quality. The control method comprises: the materials are transported to the winding roller through a conveying belt so as to complete the winding with laying cloth; and the floating roller is suspended and supported below the materials so as to adjust the rotation angle speed omega of the winding roller. Compared with the prior art, the rotation angle speed omega of the winding roller in the method provided by the invention satisfies the expression: omega =V / C, wherein V is the linear velocity of the conveying belt; C is the circumference of the material winding on the winding roller; during the winding process, an included angle between the balance position of the floating roller and a horizontal reference line is set as a0; and an angle formed by the fact that the floating roller each additionally rotates a delta a relative to the balance position is detected, namely the material winding circumference is correspondingly increased with a length of delta C.

Owner:MESNAC

Special textile fabric cleaning machine

PendingCN107164897AAvoid Stretch DeformationAvoid dirty cleaningTextile treatment machine arrangementsLiquid/gas/vapor fabric treatmentLiquid tankIndustrial engineering

The invention relates to a textile machine, in particular to a special textile fabric cleaning machine. According to the adopted technical scheme, the special textile fabric cleaning machine comprises a box body, wherein a cleaning liquid tank is arranged on the lower surface of the inside of the box body, a water pump is arranged in the cleaning liquid tank and is in sleeved connection with a liquid feeding pipe, the liquid feeding pipe is of a U-shaped structure, an air bubble generating device is arranged on the U-shaped structure of the liquid feeding pipe and comprises a first sleeve, a second sleeve is sleeved in the first sleeve, a cavity is formed between the first sleeve and the second sleeve, a water inlet pipe is arranged at one end of the first sleeve and is connected with the liquid feeding pipe, a high-pressure pump is arranged on the liquid feeding pipe, an air inlet pipe is arranged at one end of the second sleeve and is connected with a high-pressure air source, and an air-liquid outlet is arranged at the end, away from the air inlet pipe, of the second sleeve and faces a textile fabric. The special textile fabric cleaning machine has the advantages of being reasonable in structure and good in cleaning effect and ensuring product quality.

Owner:JIANGYAN CITY NEW STYLE TEXTILE

Transmission and tension control system and control method thereof

PendingCN108217270AImprove stabilityImprove toughnessArticle deliveryWebs handlingControl systemEconomic benefits

The invention discloses a transmission and tension control system. The system comprises a speed measuring sensor, a tension sensor and a control device; the speed measuring sensor is arranged betweenan unwinding shaft and a winding shaft and measures the radius of the unwinding shaft; the speed measuring sensor is connected to the control device and transmits data; the tension sensor measures thetension of a film belt, is connected to the control device and transmits the data; and the control device controls the rotating speed of the unwinding shaft and the winding shaft. The system has theadvantages that the equipment control response is high, the sensitivity is high, the rotating speed of the winding shaft and the unwinding shaft can be adjusted in real time, the control link is reduced, the production costcan be lowered on the premise that the equipment function and the product quality are not reduced, and the economic benefits of manufacturers can be improved.

Owner:浙江德龙科技有限公司

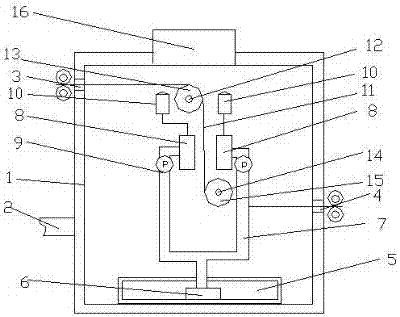

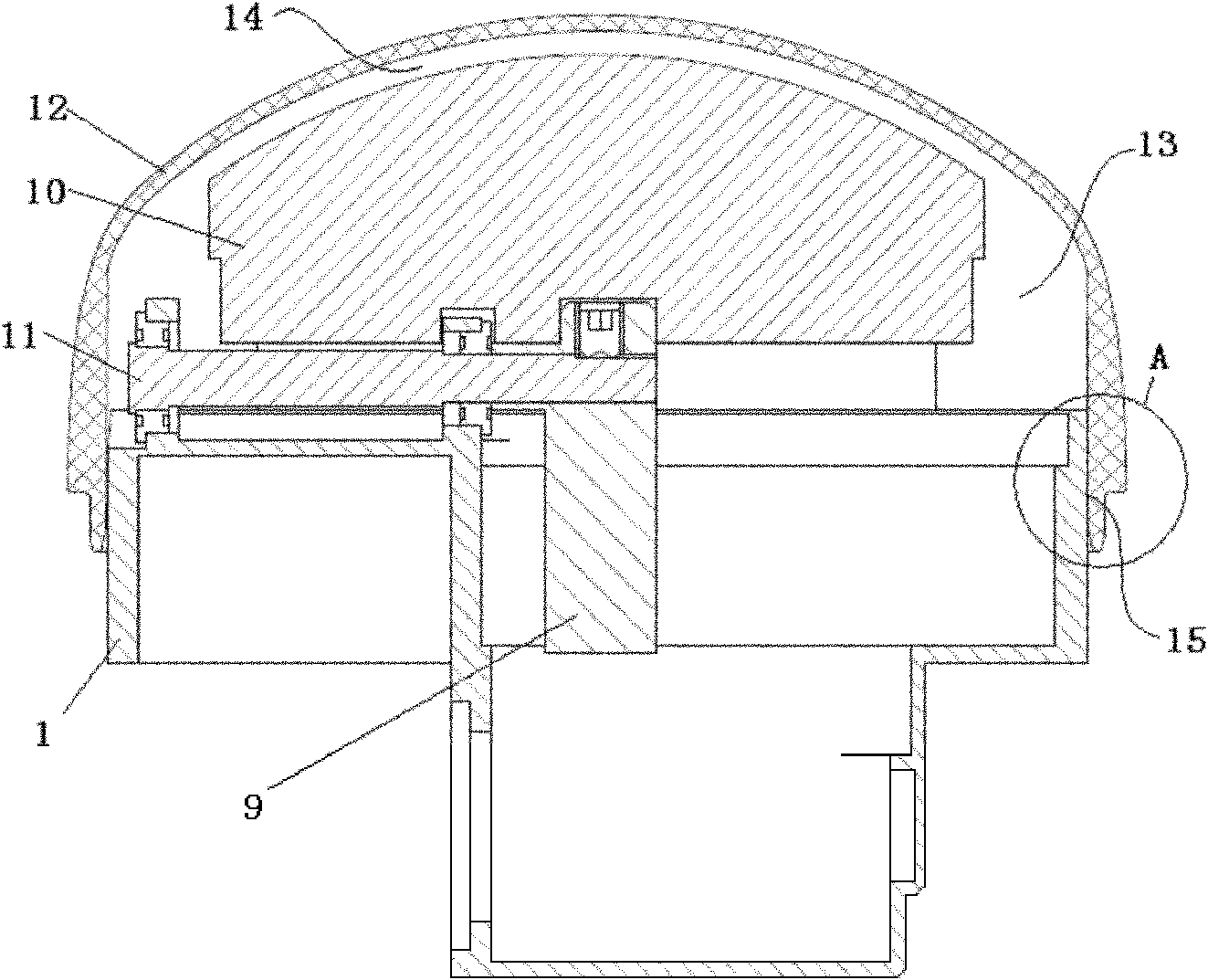

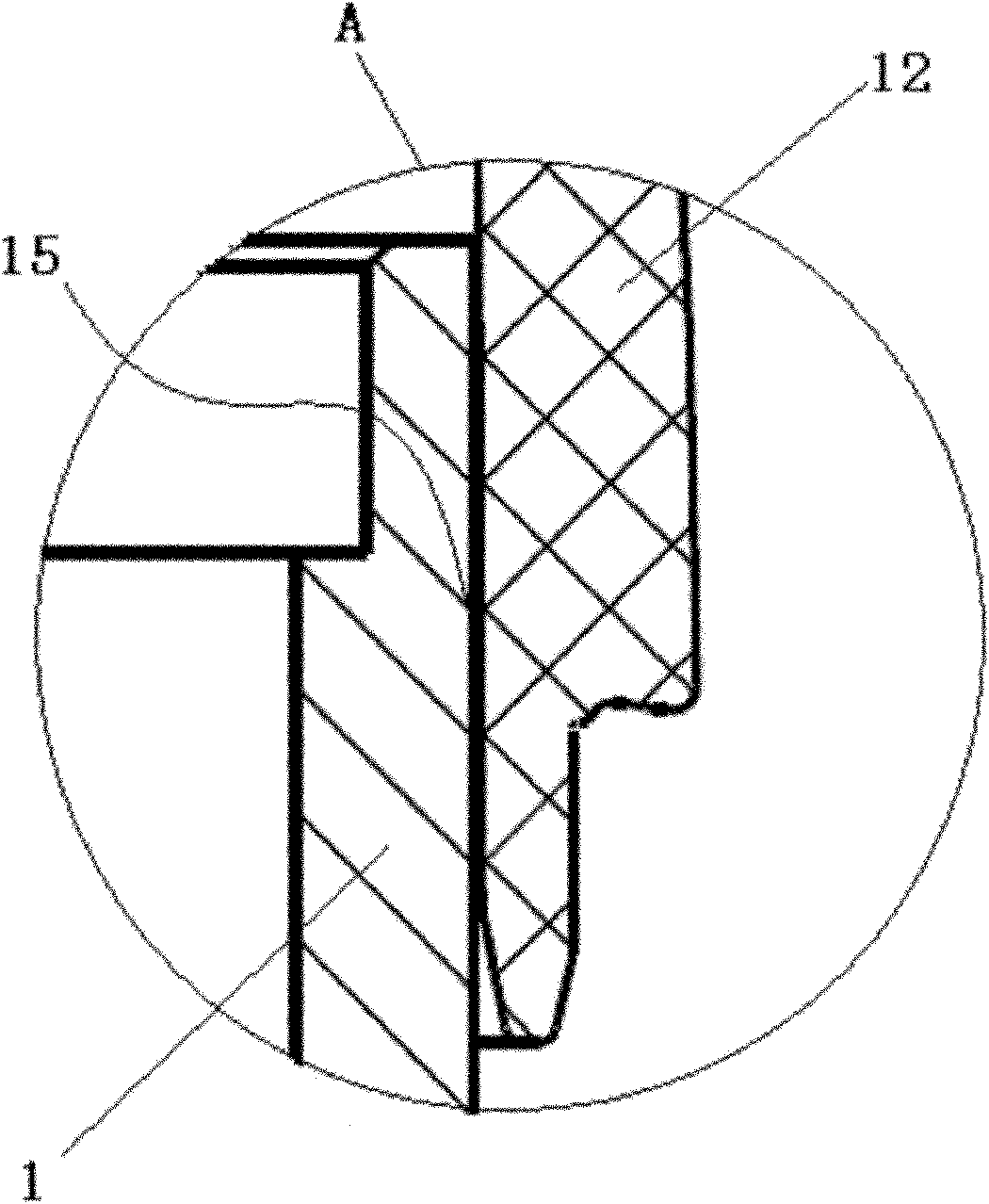

Three-dimensional (3D) mechanical probe

ActiveCN102370497AEnough deformationGuaranteed sealing performanceUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsEngineering

The invention discloses a three-dimensional (3D) mechanical probe, which comprises a sound window, a base, a restraining body and an elastic sealing ring, wherein the sound window and the base are fixedly connected and form a sealed space, the sound window is provided with a first matching wall, the base is provided with a second matching wall, the first matching wall is sheathed with the second matching wall, the sealing ring is arranged between the first matching wall and the second matching wall and is tightly pressed to deform, and the restraining body limits the deformation of the sound window. Through the sealing ring with the compression deformation quantity between the first matching wall and the second matching wall, the sealing between the sound window and the base can be effectively ensued, the coupling liquid seepage is prevented, through the arrangement of the restraining body, the sound window is prevented from deforming through being expanded by the sealing ring, the sufficient deformation quality of the sealing ring is ensued, and the sealing performance between the base and the sound window is further ensured.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD +1

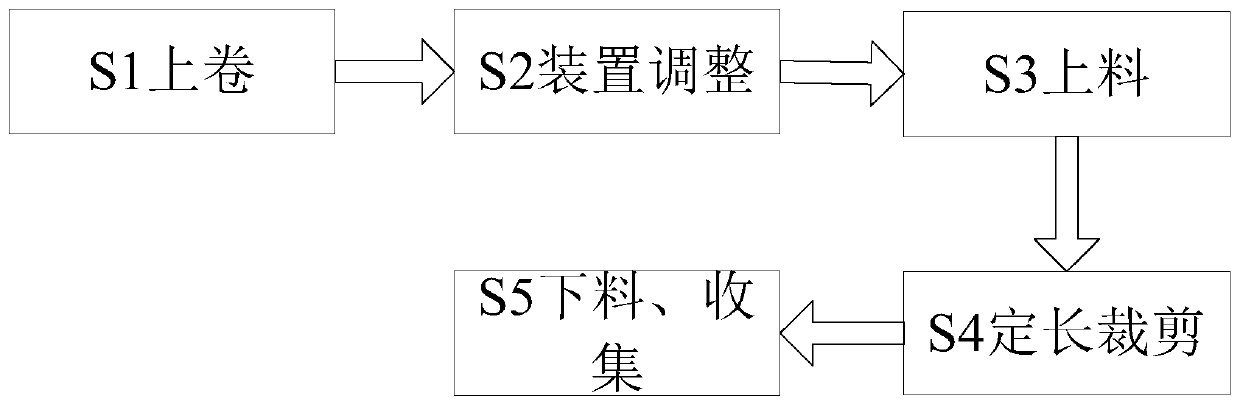

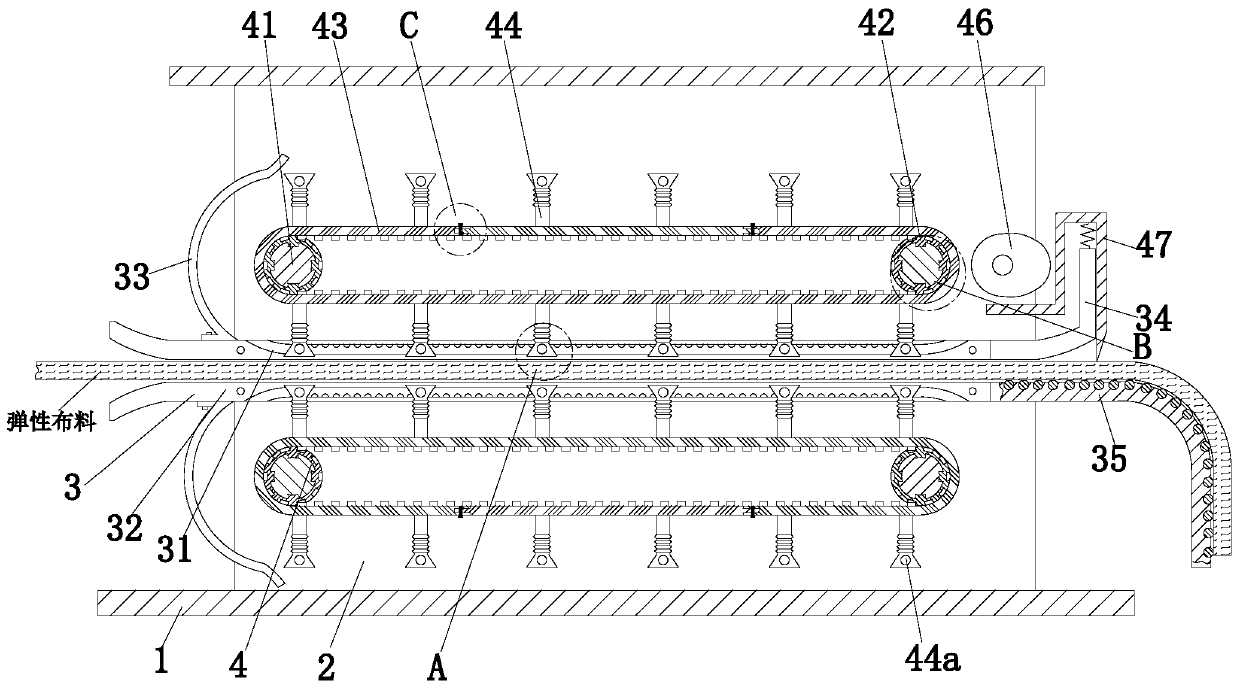

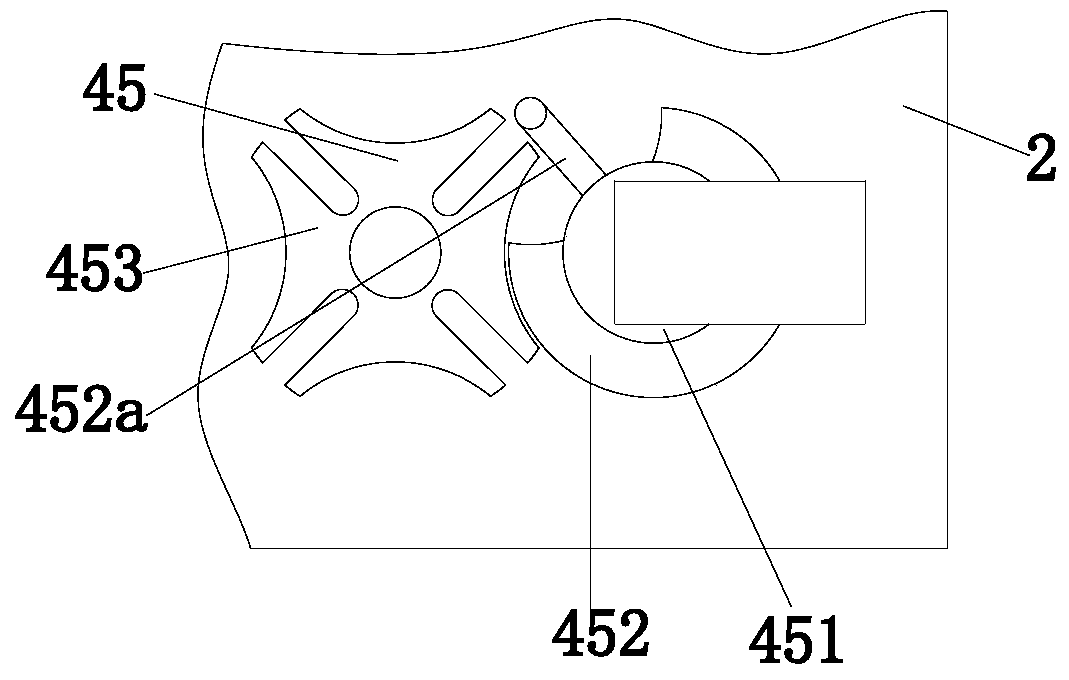

Elastic cloth fixed-length cutting method

The invention relates to an elastic cloth fixed-length cutting method. According to the elastic cloth fixed-length cutting method, an automatic cutting device is adopted, wherein the automatic cuttingdevice comprises a bottom plate, a mounting frame, a material placing mechanism and a cutting mechanism; a specific method when the automatic cutting device performs fixed-length cutting on the elastic cloth comprises the steps of carrying out winding, device adjustment, feeding, fixed-length cutting, blanking and collecting. The mounting frame is mounted at the upper end of the bottom plate; thematerial placing mechanism and the cutting mechanism are mounted on the side wall of the mounting frame; the material placing mechanism is located in the middle of the cutting mechanism; and the cutting mechanism comprises a first rotating roller, a second rotating roller, a conveying belt, a vacuum suction cup, a driving branched chain, a rotating cam and a lifting cutter plate. The elastic cloth is cut into the cloth blocks with the same length through the cooperation of the material placing mechanism and the cutting mechanism, the elastic cloth can be pressed and limited in the cutting process, the stretching deformation is prevented, the distance of each movement of the elastic cloth can be changed according to the actual situation, and then the length of the fixed length cutting is changed.

Owner:安徽金弘润新材料科技有限公司

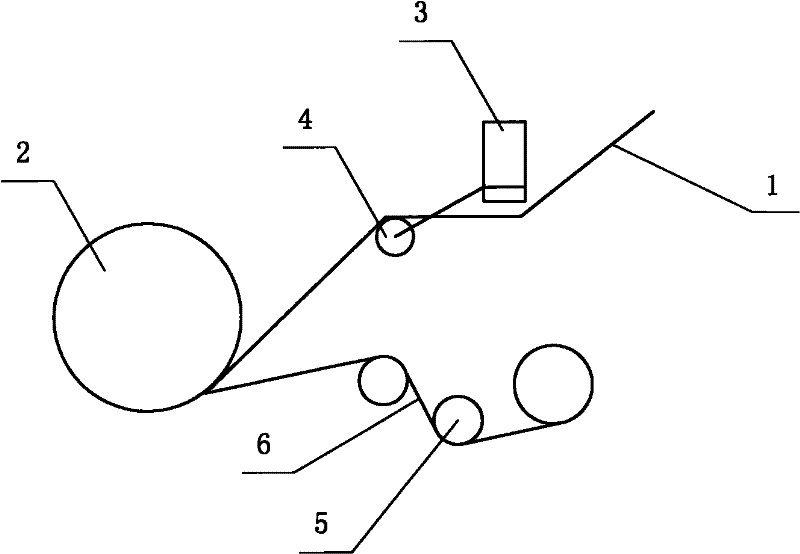

A kind of sealing strip bonding equipment

ActiveCN103707955BAvoid Stretch DeformationGuaranteed bonding positionVehiclesArticle deliveryEngineeringControl unit

The invention discloses sealing strip bonding equipment, and relates to auxiliary equipment of the car production process. The sealing strip bonding equipment not only guarantees the bonding quality of a sealing strip, but also improves production efficiency. The sealing strip bonding equipment comprises a storage unit, a conveying unit, a bonding unit, a cutting-off unit, a detection unit and a control unit, wherein the storage unit is used for storing the sealing strip and conveying the sealing strip to the conveying unit, the conveying unit is used for conveying the sealing strip to the bonding unit, the bonding unit is used for bonding the sealing strip to the edge of a car door, the cutting-off unit is used for cutting off the sealing strip after the car door is bonded with the sealing strip, the detection unit is used for detecting whether the car door is thoroughly bonded with the sealing strip, if yes, the cutting-off unit executes the motion of cutting off the sealing strip, if not, the cutting-off unit does not execute the cutting-off motion, and the control unit is respectively in electric connection with the other units, and used for controlling the conveying, bonding and cutting-off motions of the sealing strip. The sealing strip bonding equipment is mainly used for bonding the sealing strip.

Owner:精诚工科汽车系统有限公司

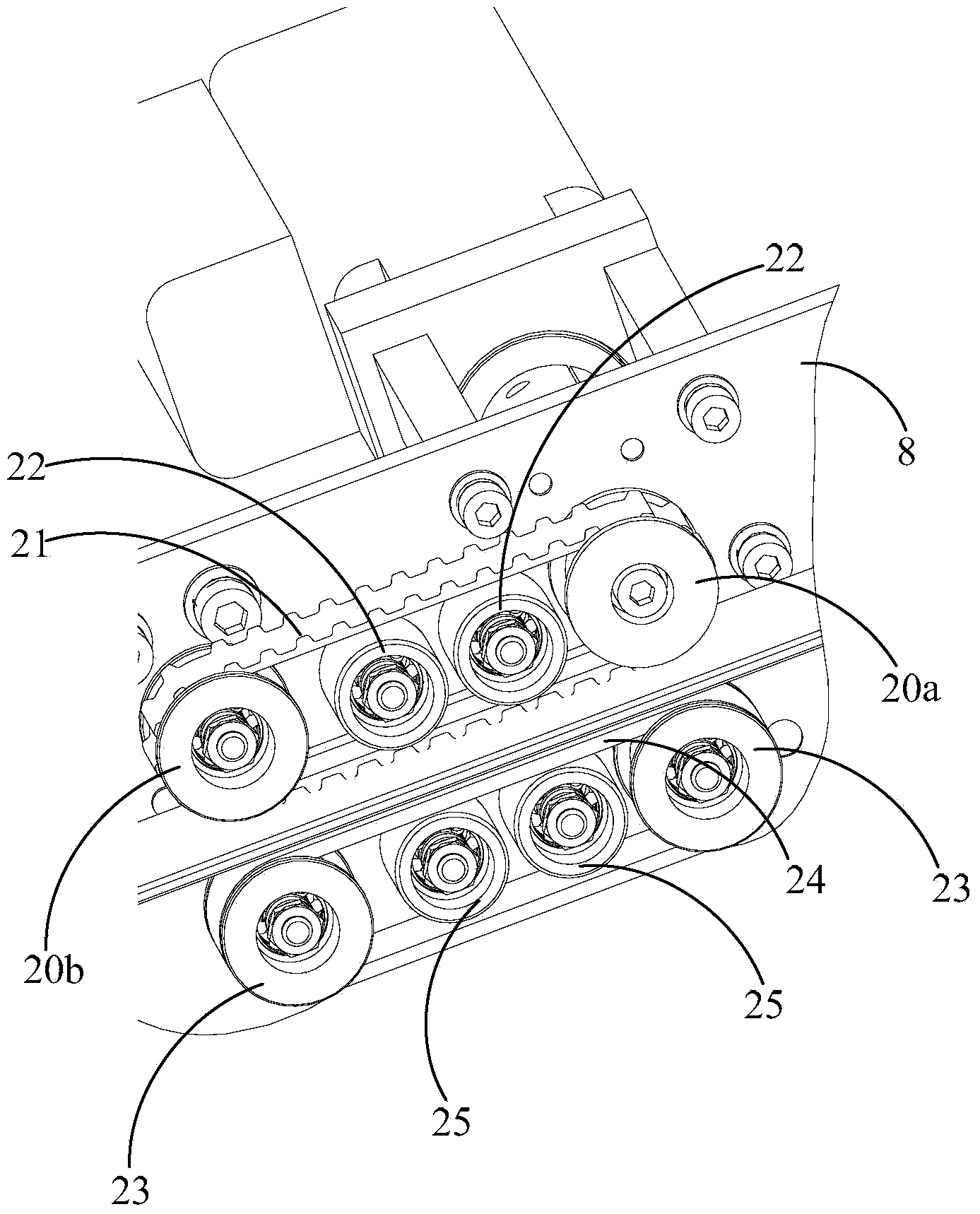

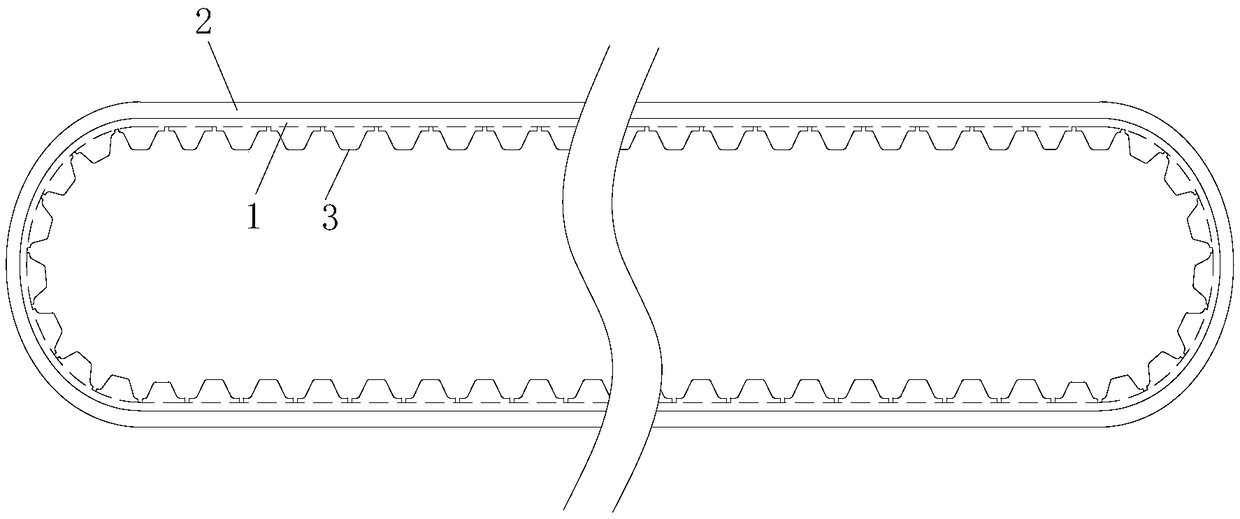

Synchronization conveying belt and preparing method thereof

PendingCN108910399AAvoid damageAvoid scratchesEdge grinding machinesConveyorsEngineeringSolid particle

The invention discloses a synchronization conveying belt which comprises a synchronization conveying belt body and a plurality of belt teeth arranged on the inner side of the synchronization conveyingbelt body. The synchronization conveying belt is characterized in that the synchronization conveying belt body comprises an inner ring layer and an outer ring layer which are compounded together, thebelt teeth are molded on the inner side of the inner ring layer, a plurality of grooves are formed in the outer surface of the outer layer, and the walking direction of the grooves is parallel to theconveying direction of the synchronization conveying belt. According to the synchronization conveying belt, the grooves are formed in the outer side face of the outer ring layer, dust or small solidparticles carried on conveyed materials can naturally fall into the grooves in the conveying process, and belt face damage or conveyed material scraping caused by extrusion of the conveyed materials to the dust or small solid particles is avoided. In addition, the outer ring layer and the inner ring layer are compounded and connected, the overall synchronization conveying belt is not provided with a connector, and the strength of the synchronization conveying belt is guaranteed. The invention further provides a preparing method of the synchronization conveying belt.

Owner:佛山市加德纳机械配件有限公司

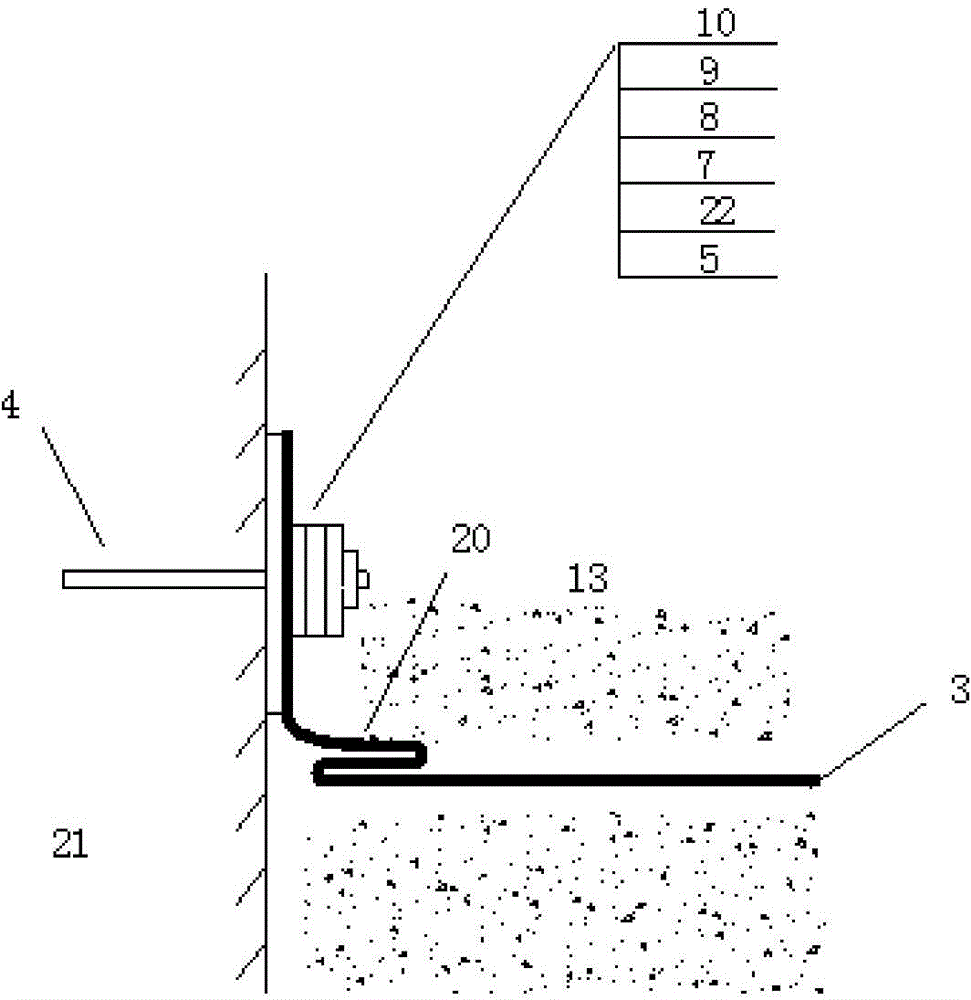

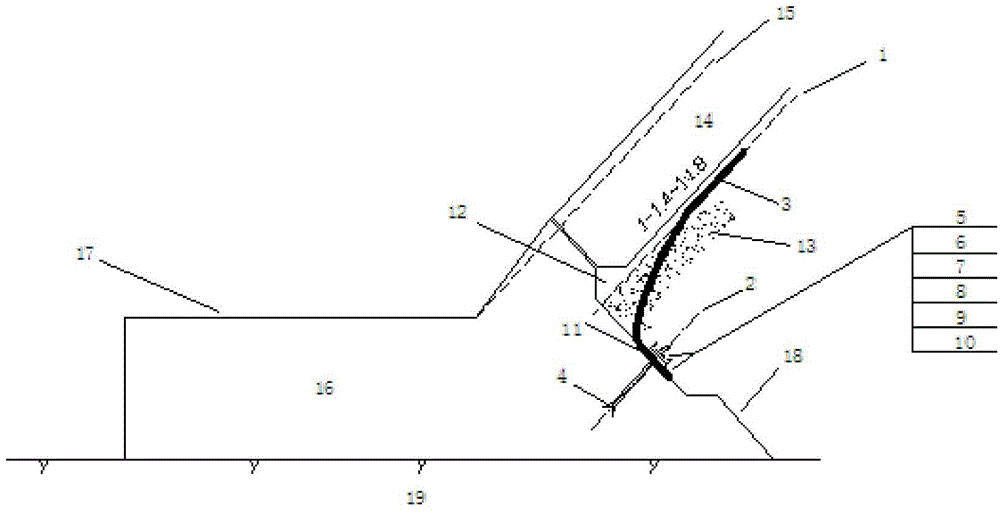

Method for eliminating clamp effect on seepage-proofing film anchoring part of high film faced rockfill dam by compensating displacement

ActiveCN104060580AReduce displacementFree injuryEarth-fill damsRock-fill damsSealantReservoir storage

The invention provides a method for eliminating a clamp effect on a seepage-proofing film anchoring part of a high film faced rockfill dam by the compensating displacement principle aiming at a problem that the anchoring part at the periphery of the seepage-proofing film on an upstream dam face has high possibility of generating the clamp effect which can damage the film after the reservoir storage of the high film faced rockfill dam is completed. The method comprises the following steps: arranging a film anchoring line to be lower than a dam face film laying line; using a flat section of a toe slab as a film placing region to enable a dam face seepage-proofing film to be laid to enter an anchoring device from top to bottom conveniently; indenting an anchoring basal plane of a concrete toe slab to the inclined surface of the toe slab (on the seepage-proofing downstream side), and forming a small cavity at the upper part of the dam face film laying line to effectively reduce displacement of a dam body material at the anchoring part and to accommodate the film above the film laying line when the film laying line moves to the anchoring line after the reservoir storage of the dam is completed. According to the invention, stainless steel anchoring compressing parts are adopted to enable distance between fastening bolts to be increased by 0.5-1 time so as to accelerate construction speed; anchoring basal planes are coated with soft sealant, so that water can be stopped, and particles are prevented from entering to ensure that the film is free of damage when the film laying line moves to the anchoring line.

Owner:HOHAI UNIV

Full-automatic optical fiber cutting machine

PendingCN108748304AImprove cutting efficiency and cutting accuracyLow costMetal working apparatusEngineeringAssurance quality

The invention discloses a full-automatic optical fiber cutting machine. The full-automatic optical fiber cutting machine comprises a feeding device, a tensioning device, a straightening device, a traction device, a cutting device and a material receiving box, wherein the feeding device, the tensioning device, the straightening device, the traction device, the cutting device and the material receiving box are arranged in sequence in the transmission direction of optical fiber. The optical fiber is wound around the feeding device, bypasses the tensioning device, and sequentially passes through the straightening device and the traction device, then is cut off by the cutting device and falls into the material receiving box. According to the full-automatic optical fiber cutting machine, a full-automatic operation mode is adopted, the optical fiber is cut into the optical fiber with required length after the optical fiber is straightened by the feeding device, the tensioning device, the straightening device, the traction device, the cutting device and the material receiving box in sequence, so that the cutting efficiency and the cutting precision of the optical fiber are improved, the cost is reduced, and the quality is guaranteed; and in the whole process, only coiled material wound with optical fiber needs to be placed manually, labor is greatly saved compared with manual cutting,and one person with more machines can be realized, efficiency is further improved, and labor costs are reduced. In addition, the full-automatic optical fiber cutting machine further has the characteristics of simple structure, high speed, stable quality, convenient adjustment and high universality.

Owner:昆山宇辰光通自动化科技有限公司

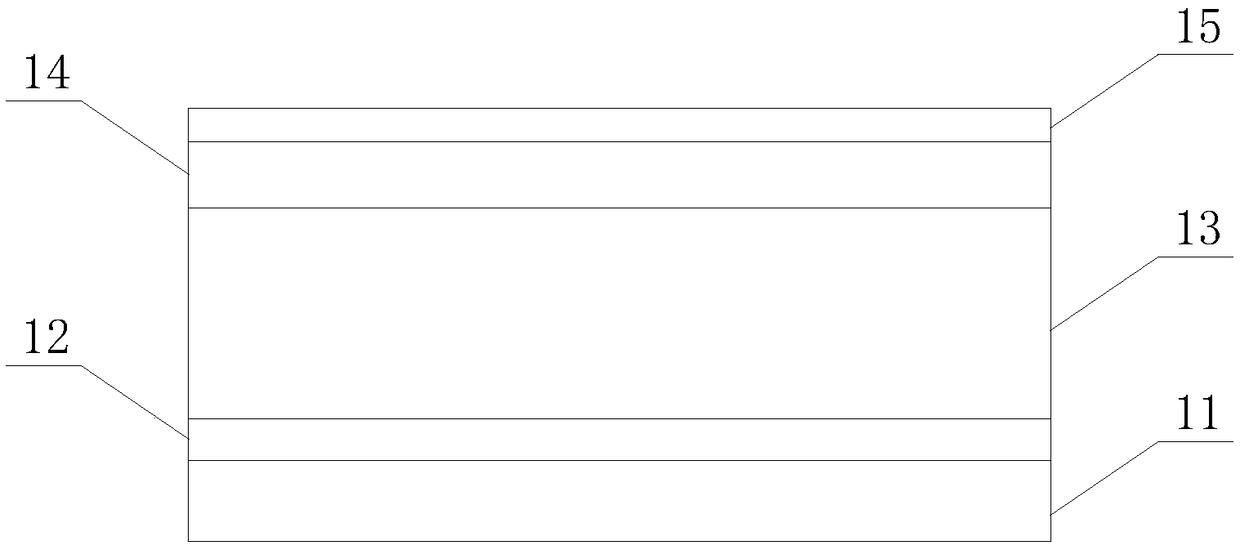

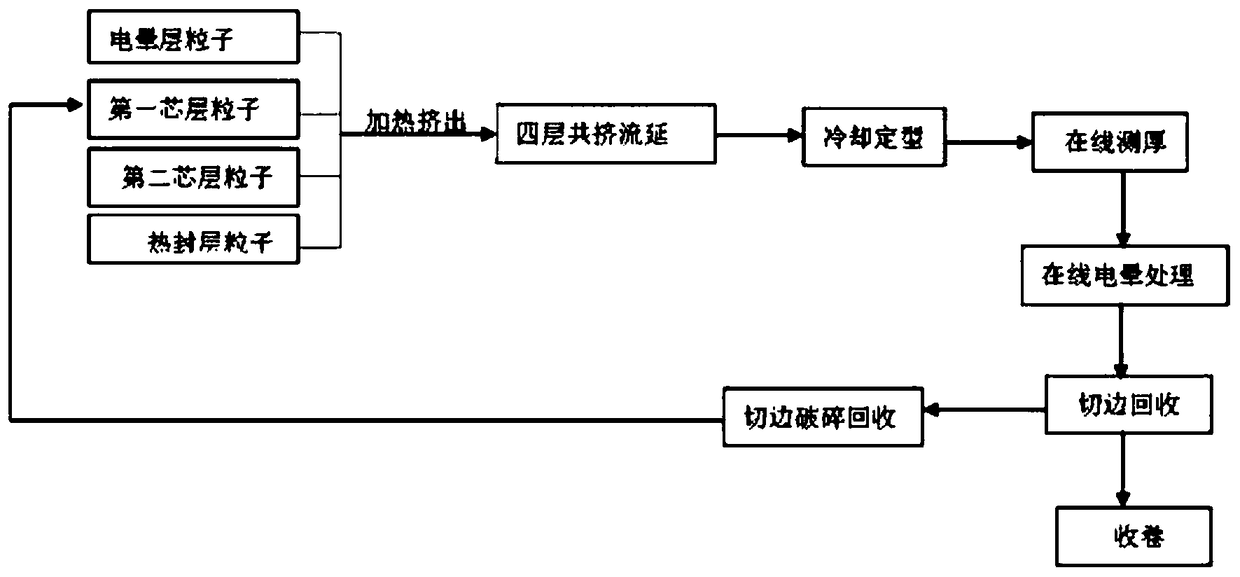

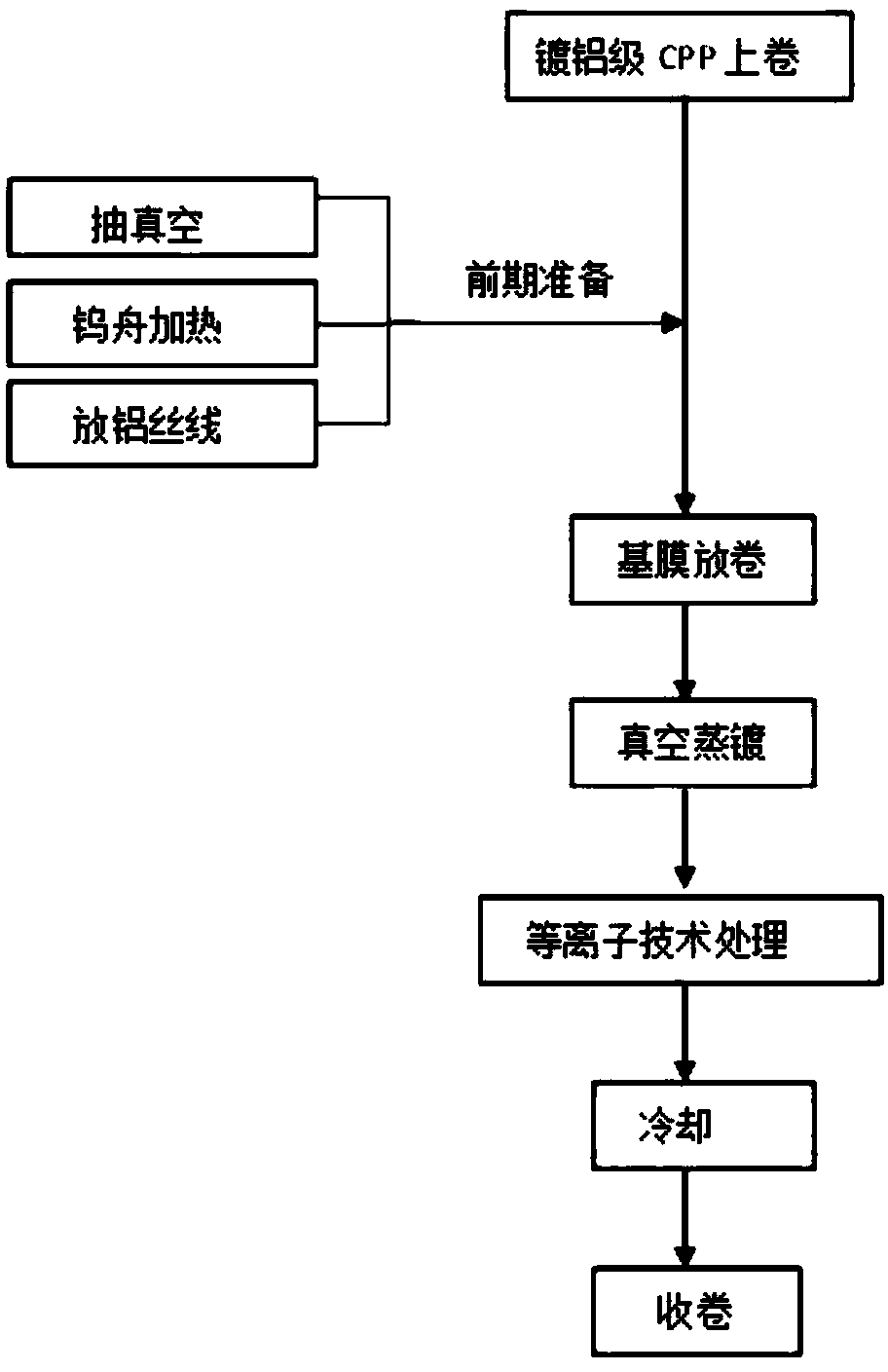

High thermal adhesive strength and high barrier aluminum laminated film and production method thereof

ActiveCN109016760AAluminum plated with high adhesionEnhance and maintain barrier propertiesFlexible coversWrappersCycloalkeneThermal adhesive

The invention relates to a high thermal adhesive strength and high barrier aluminum laminated film and a production method thereof. The film successively consists of a heat seal layer, a second core layer, a first core layer, a corona layer and an aluminum plated layer. The heat seal layer includes ternary copolymerized PP and an anti-block agent in a mass ratio of (95-99):(2-4), the second core layer includes homopolymerized PP, the first core layer includes random copolymerized PP, and the corona layer includes binary copolymerized PP, a cycloalkene copolymer and a high viscosity elastomer in a mass ratio of (68-72):(16-18):(12-14), and the melt flow rate of the high viscosity elastomer is 6.5-7.5g / 10min. The thicknesses of the heat seal layer, the second core layer, the first core layerand the corona layer are 15-17micron, 50-52micron, 8-10micron and 23-25micron respectively. The aluminum laminated film provided by the invention has high laminated aluminum adhesion, and oxygen barrier, moisture barrier and odor barrier performance obviously superior to traditional aluminum laminated films, and is suitable for use as different high-speed automatic packaging composite membrane base materials.

Owner:HUANGSHAN NOVEL

Automatic fabric tension control system suitable for knitting open-width wet processing unit

ActiveCN102517827AAvoid Stretch DeformationGuaranteed qualityTextile treatment carriersTextile treatment rollersControl systemStructural engineering

The invention relates to an automatic fabric tension control system suitable for a knitting open-width wet processing unit. The system comprises at least more than two groups of wet processing units, wherein adjacent wet processing units are in station connection to form the open-width wet processing unit; drum / roller group stations and roller groups which are matched with the drum / roller groups are arranged in box bodies of the wet processing units; and the system is characterized in that: the drum / roller groups are main driving components; and the roller groups comprise driving rollers and driven rollers which are matched with each other. The invention has outstanding characteristics that: the drums / rollers, rollers and traction rollers in each wet processing unit are main driving components; numerical values of various driving mechanisms can be directly set according to differences of fabric composition and technical requirements of fabrics machined by the unit, so that the fabrics do not have tension, the fabrics are prevented from being subjected to tensile deformation in each wet processing unit, and the quality of the fabrics is guaranteed.

Owner:绍兴东升数码科技有限公司

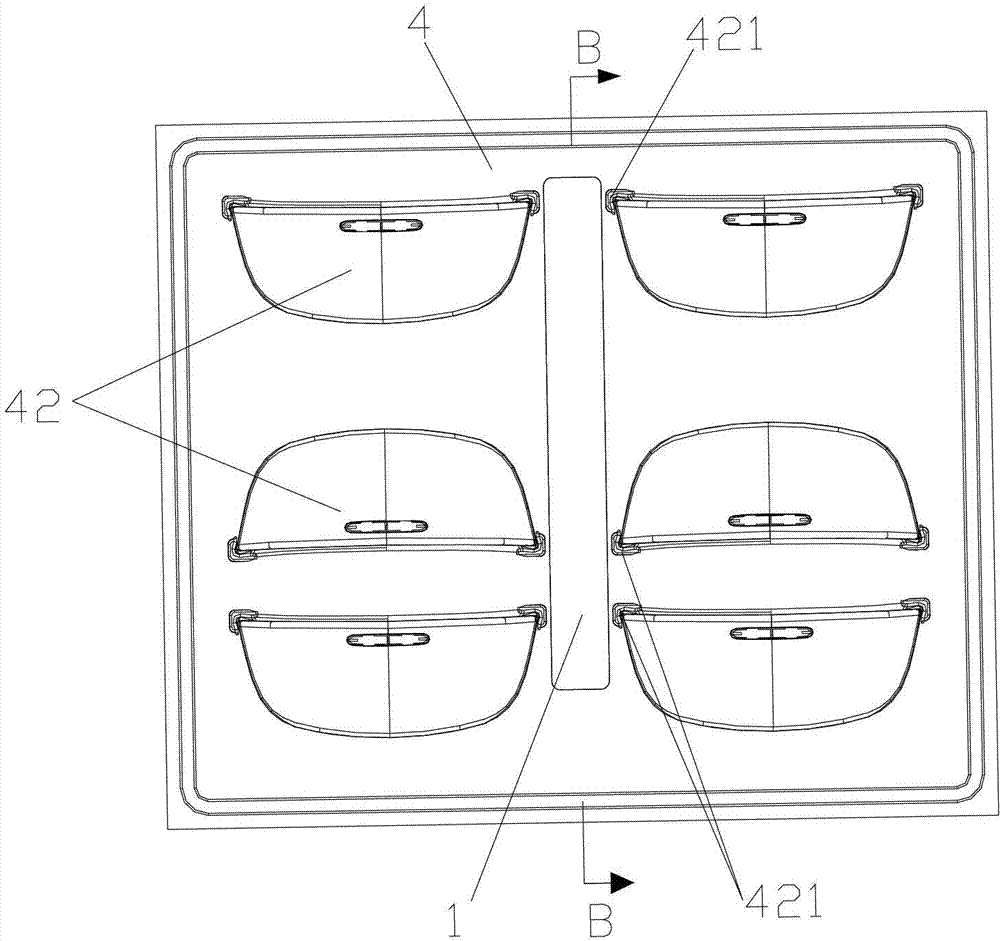

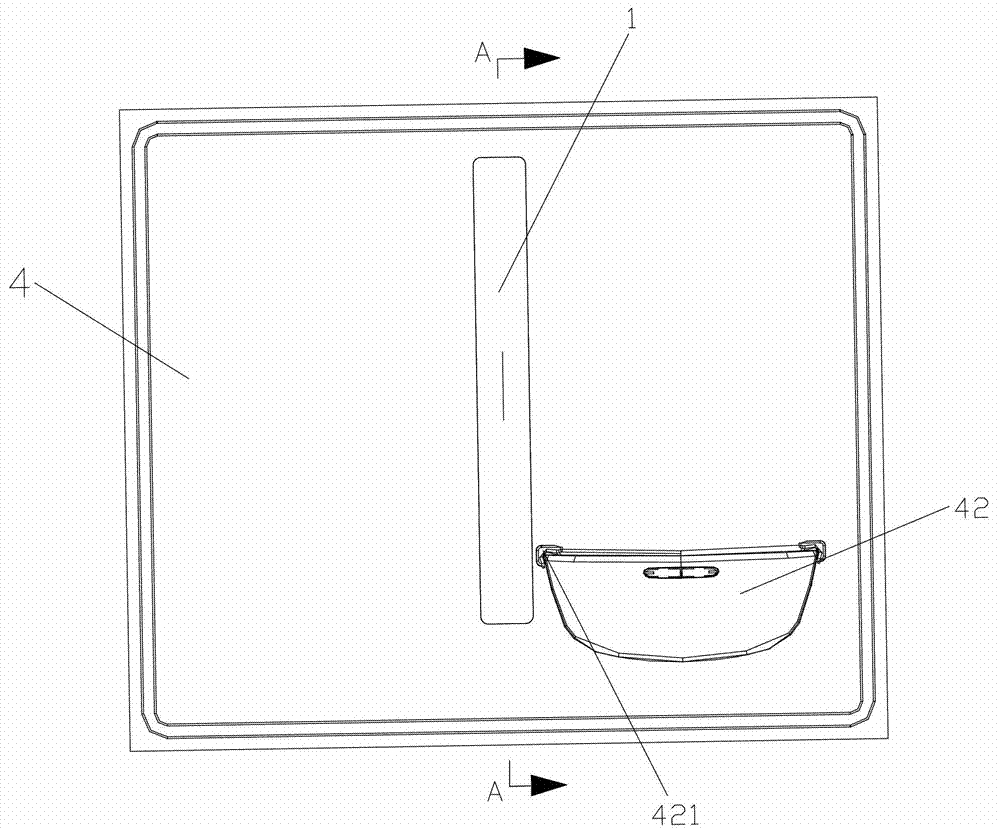

Blister mold

Owner:SHANGHAI TONGLING AUTOMOTIVE TECH INC

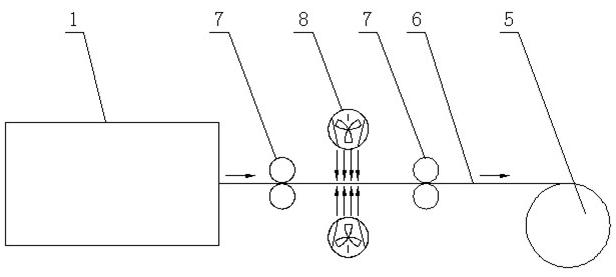

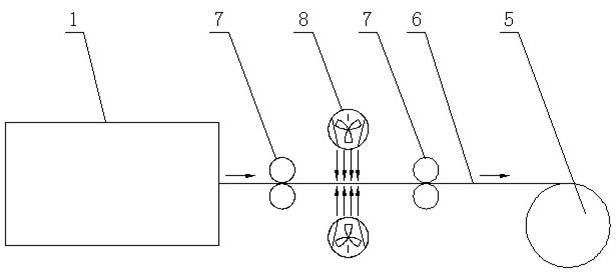

PECVD-based enhanced graphene film coating device and method

PendingCN107217241AAny thickness controlFlexible and convenient to useChemical vapor deposition coatingChemical reactionRadio frequency

The invention discloses a PECVD-based enhanced graphene film coating device and method. The device comprises a plurality of vacuum chambers including an uncoiling chamber, a plurality of coating chambers and a coiling chamber which are connected in sequence. In each coating chamber, the upper side and the lower side of a foam nickel base material are provided with a radio frequency discharge plate and a plasma magnetic control enhancement device correspondingly. The method comprises the steps that in the coating chambers, the radio frequency discharge plates are started for discharging, plasma is generated, the plasma magnetic control enhancement devices form closed loop magnetic fields below the radio frequency discharge plates, the plasma makes spiral rotation under the action of the magnet fields, and therefore the density of the plasma is increased, and a film layer is deposited on the surface of each foam nickel base material. By means of the PECVD-based enhanced graphene film coating device and method, the chemical reaction speed of plasma gas is increased, and the thickness of the deposited film layers is also greatly increased and can be up to four to eight times that of a film prepared by a traditional coating device. Meanwhile, the surface temperature of the foam nickel base materials can be increased to 600 or over, the graphene film forming condition is enhanced, and the graphene film forming speed is increased.

Owner:石家庄市汇椿腾科技有限公司

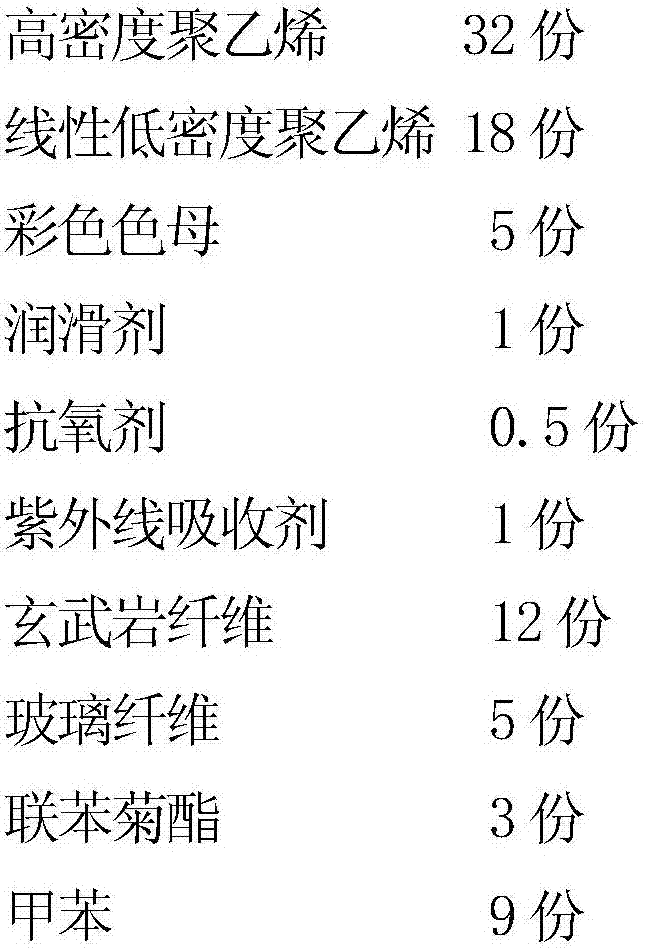

Colorful anti-ultraviolet polyethylene cable outer sheath material

InactiveCN107141573AImprove insulation performanceFireproofPlastic/resin/waxes insulatorsLow-density polyethyleneLinear low-density polyethylene

The invention discloses a colorful anti-ultraviolet polyethylene cable outer sheath material. The material is prepared from 25 to 42 parts by weight of high density polyethylene, 12 to 22 parts by weight of linear low density polyethylene, 2 to 5 parts by weight of colorful master batches, 1 to 3 parts by weight of a lubricant, 0.2 to 0.5 part by weight of an antioxidant, 1 to 3 parts by weight of an ultraviolet absorber, 8 to 12 parts by weight of basalt fibers, 3 to 8 parts by weight of glass fibers, 2 to 4 parts by weight of bifenthrin, 6 to 12 parts by weight of toluene, and 5 to 8 parts by weight of capsaicin. The colorful anti-ultraviolet polyethylene cable outer sheath material has excellent anti-ultraviolet and anti-aging performances and excellent mechanical properties, can prevent fading of the cable for a long time, can prevent rat and termite eating and can prolong an optical cable service life.

Owner:浙江嘉顺光电材料有限公司

Corona machine

InactiveCN105437573AImprove corona stabilityEffective horizontal expansionFlat articlesMechanical engineeringCorona

The invention discloses a corona machine. The corona machine comprises a corona machine main body; and a front pull roll, a first corona roll, two unwinding rolls, a second corona roll and a rear pull roll are mounted on the corona machine main body. A workpiece can be unwound effectively in the transverse direction through the two unwinding rolls, the wide workpiece is prevented from being stretched and deforming, and the corona machine is suitable for workpieces with different widths; and meanwhile, the front pull roll and the rear pull roll are respectively arranged in the front and at the rear of the first corona roll and the second corona roll, the workpiece is pulled through the front pull roll and the rear pull roll, when the workpiece enters the first corona roll and the second corona roll, stable tension is formed on the width of the workpiece and the workpiece is tightly attached to roll surfaces of the first corona roll and the second corona roll, then air is prevented from entering space between the width of the workpiece and the first coronal roll or space between the width of the workpiece and the second coronal roll, reverse surface corona is prevented effectively, and corona stability of the corona machine disclosed by the invention is improved.

Owner:ZHONGSHAN SONGDE NEW MATERIAL EQUIP CO LTD

Production method of wind turbine blade preform

InactiveCN107379709ARealize automated productionIncrease productivityLamination ancillary operationsLaminationTurbine bladeMechanical engineering

The invention discloses a production method of a wind turbine blade preform. The method comprises steps as follows: 1, unwinding is performed; 2, cutting is performed; 3, cloth is grabbed by a mechanical arm and stacked on a transfer frame conveyed by a first conveying line; 4, the cloth is sewn; 5, the cloth on the transfer frame is jacked up by a jacking and cloth taking mechanism and sent to a metal detection mechanism, and after passing through the metal detection mechanism, the cloth enters a stacking and discharging mechanism for discharging; 6, the unloaded transfer frame is jacked up by a jacking and translation mechanism and sent to an input end of a second conveying line; 7, the unloaded transfer frame is conveyed backwards by the second conveying line to an output end of the second conveying line; 8, the unloaded transfer frame is jacked up by the jacking and translation mechanism and sent to an input end of the first conveying line; 9, the unloaded transfer frame is received by the jacking and translation mechanism arranged at the bottom of the input end of the first conveying line, and the steps are circularly executed by starting from the step 3. Automatic production of the wind turbine blade preform is realized, and the production efficiency is effectively improved.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

Anisotropic rubber material and preparation method thereof

The invention discloses an anisotropic rubber material and a preparation method thereof. The anisotropic rubber material comprises the following components in parts by weight: 100 parts of raw rubber,5-30 parts of white carbon black, 1-5 parts of hydroxyl silicone oil, 2-10 parts of silica powder, 5-50 parts of short fibers, 1-5 parts of a silane coupling agent, 2-8 parts of a diluent and 0.5-5 parts of a cross-linking agent. The short fibers are axially oriented along the extruded sealing strip, so that the extruded rubber material has anisotropism, tensile deformation is prevented in the axial direction of the rubber strip, high elasticity of the rubber material is kept in the vertical direction of the rubber strip, and the problem of stretching of a common rubber sealing strip in the assembling process can be effectively solved. And meanwhile, compared with an extruded rubber strip containing a continuous framework material, the production process is simple, and the extrusion continuity is good.

Owner:PINGHU ALLIED IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com