Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

93results about How to "Does not cause deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

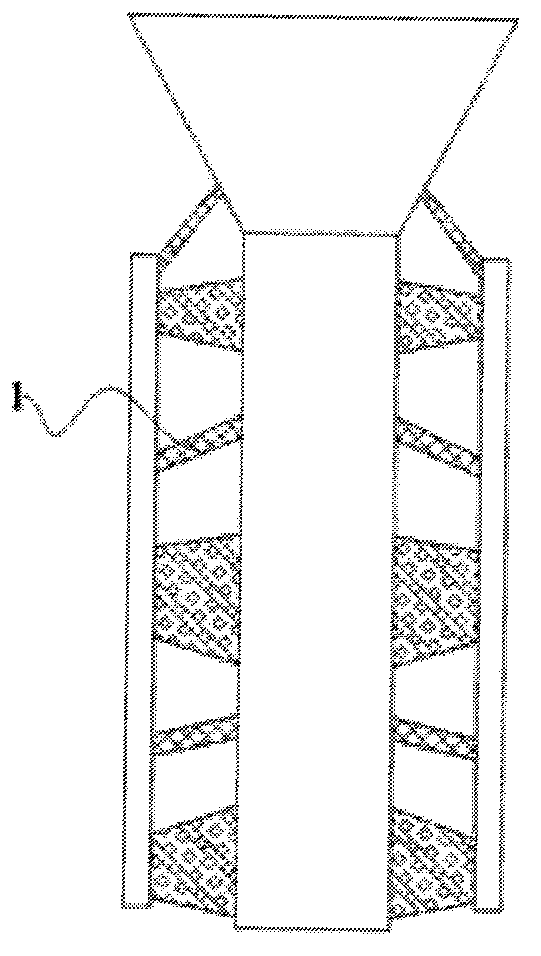

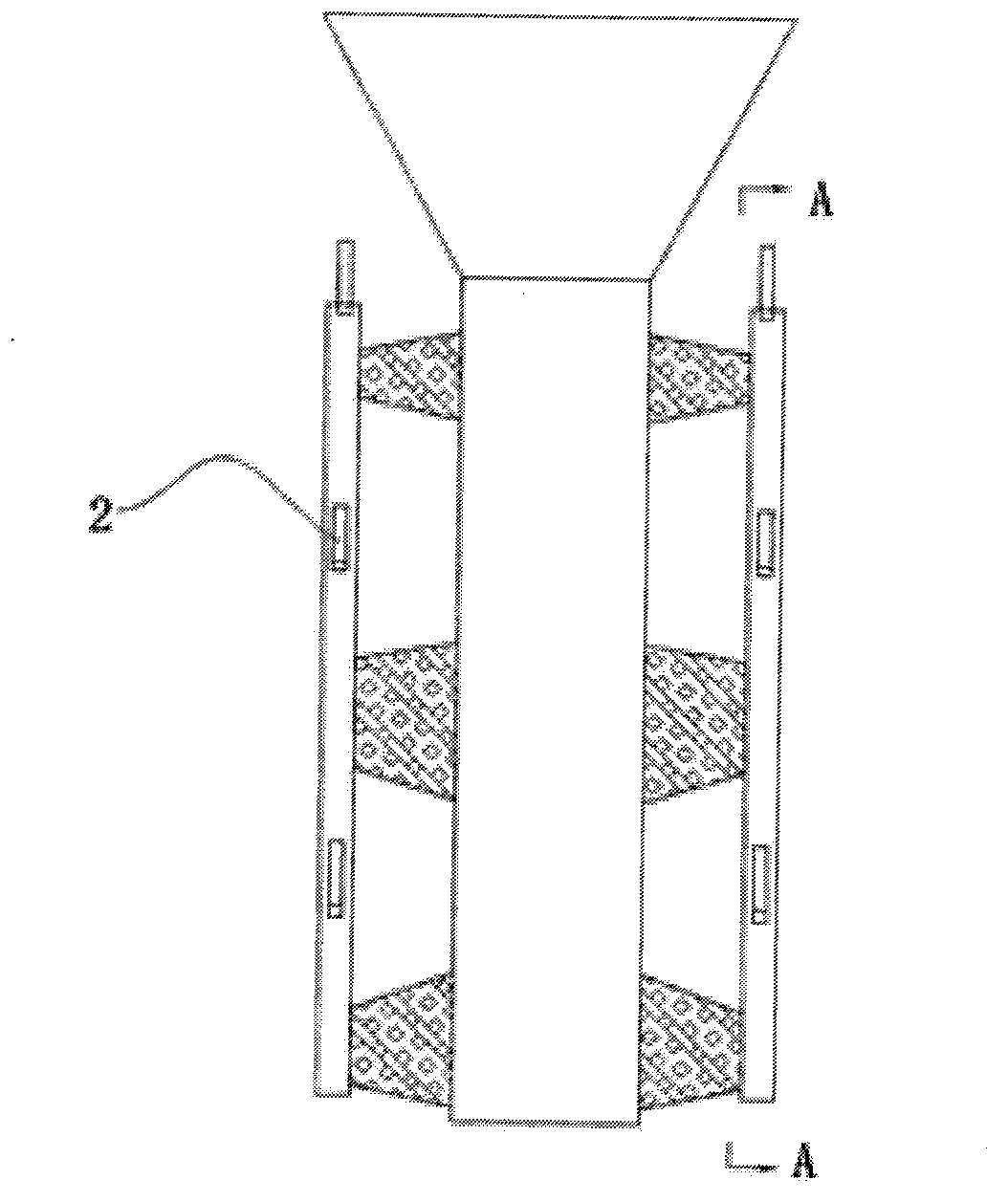

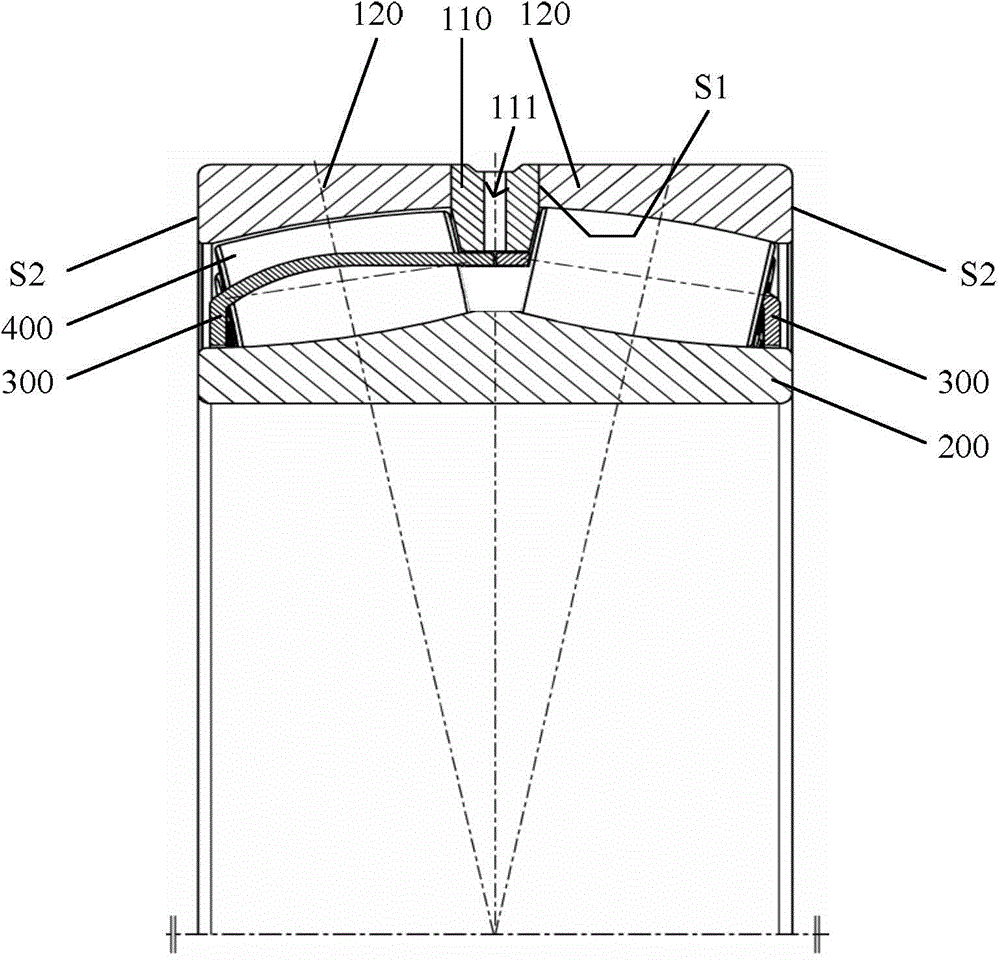

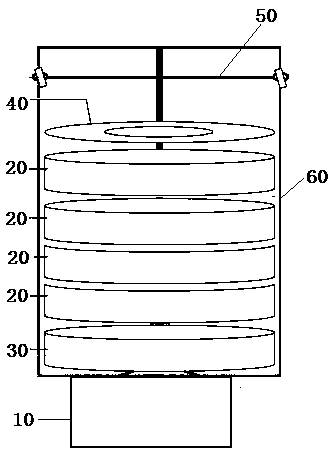

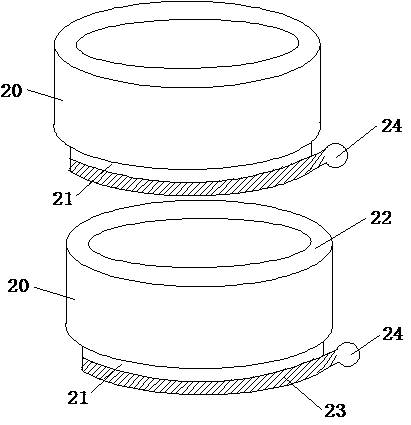

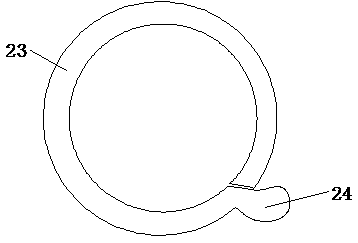

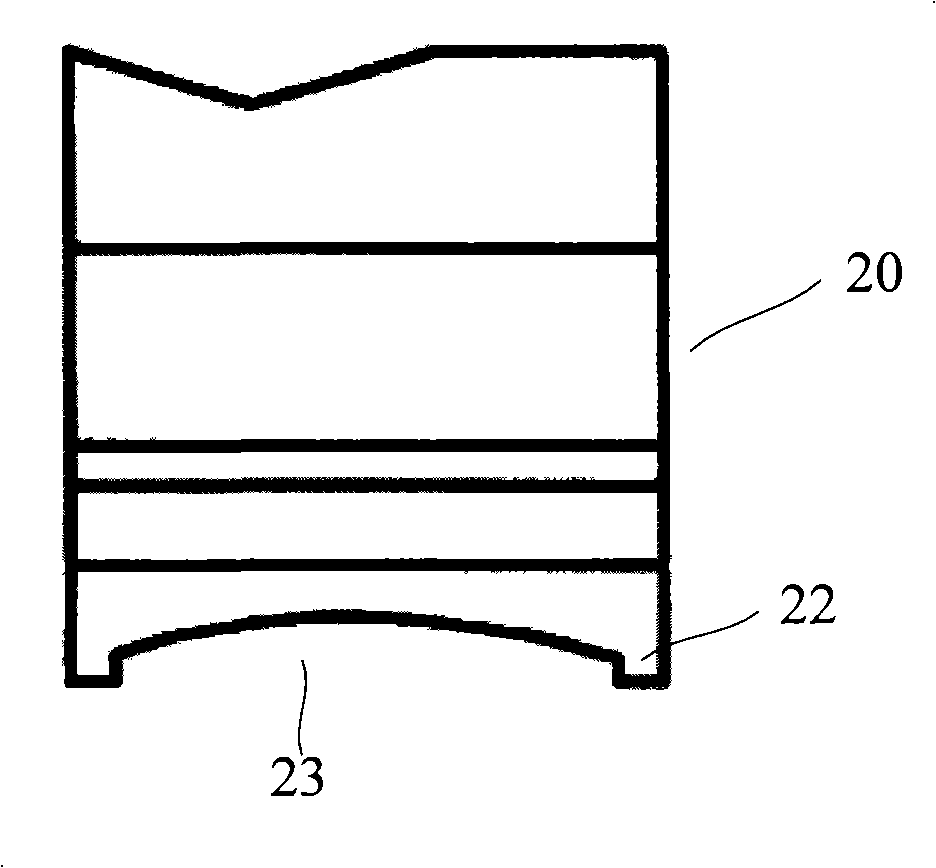

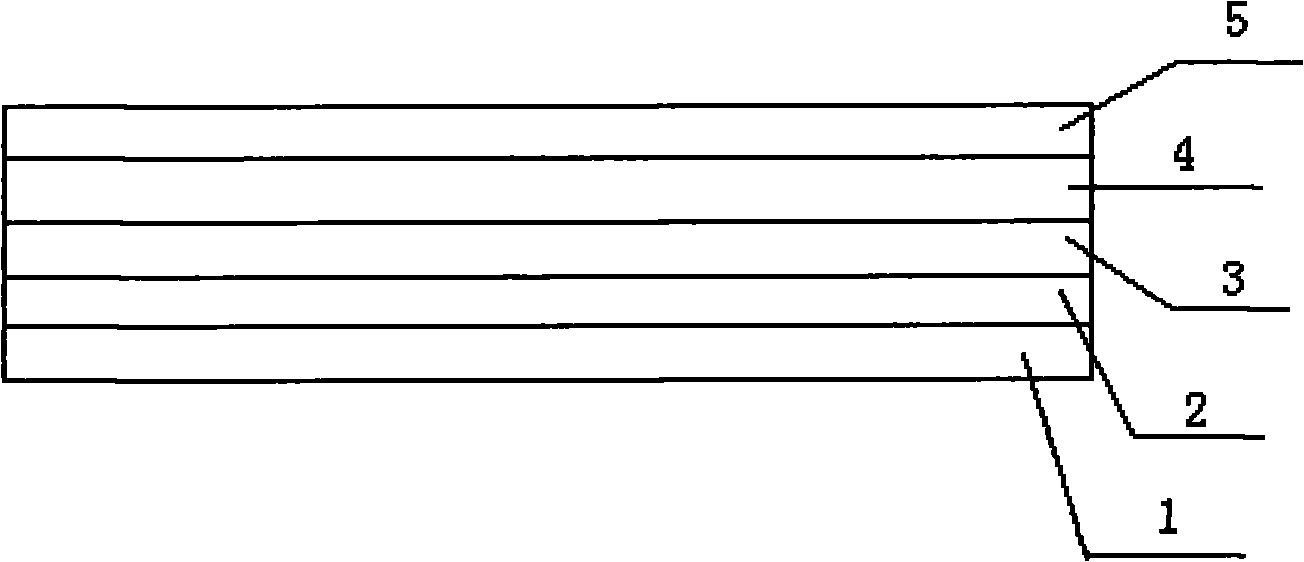

Blood vessel bracket prosthesis

ActiveCN102100587ADoes not cause deformationNo discountStentsBlood vesselsTectorial membraneProsthesis

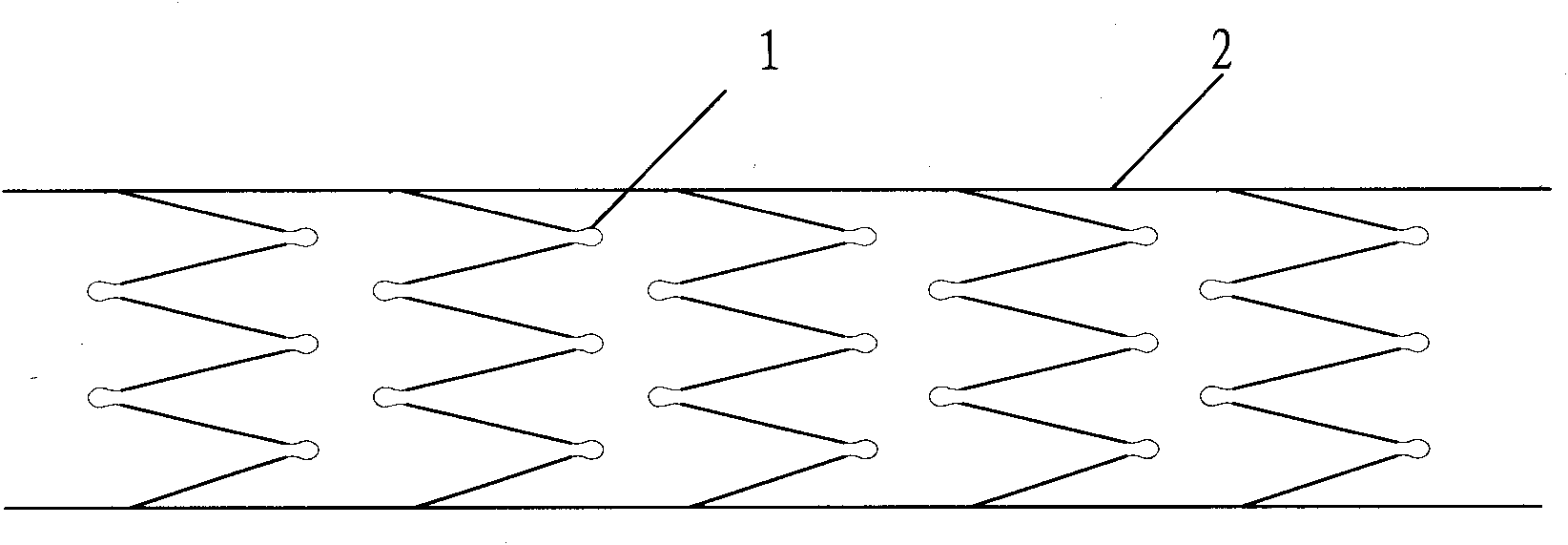

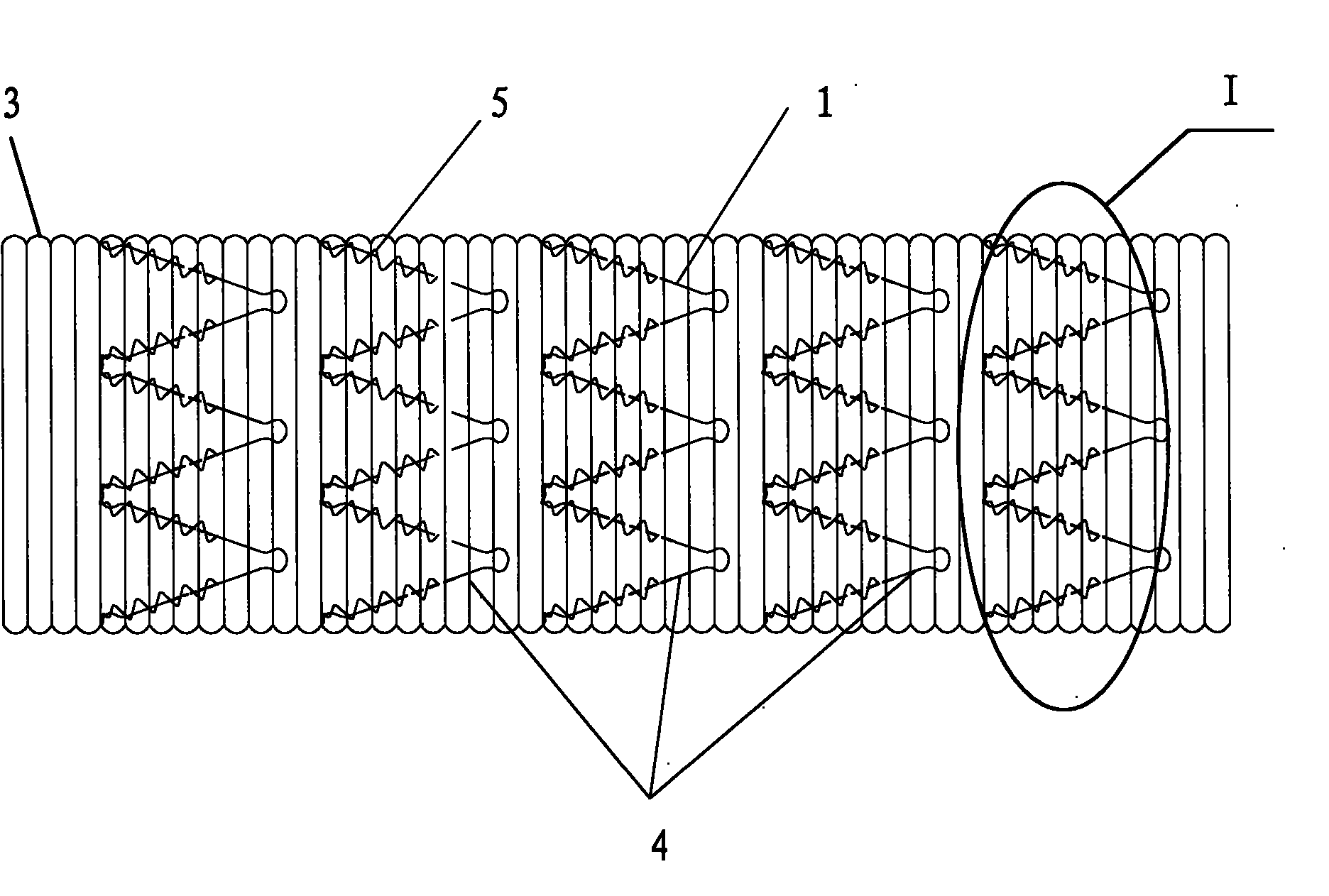

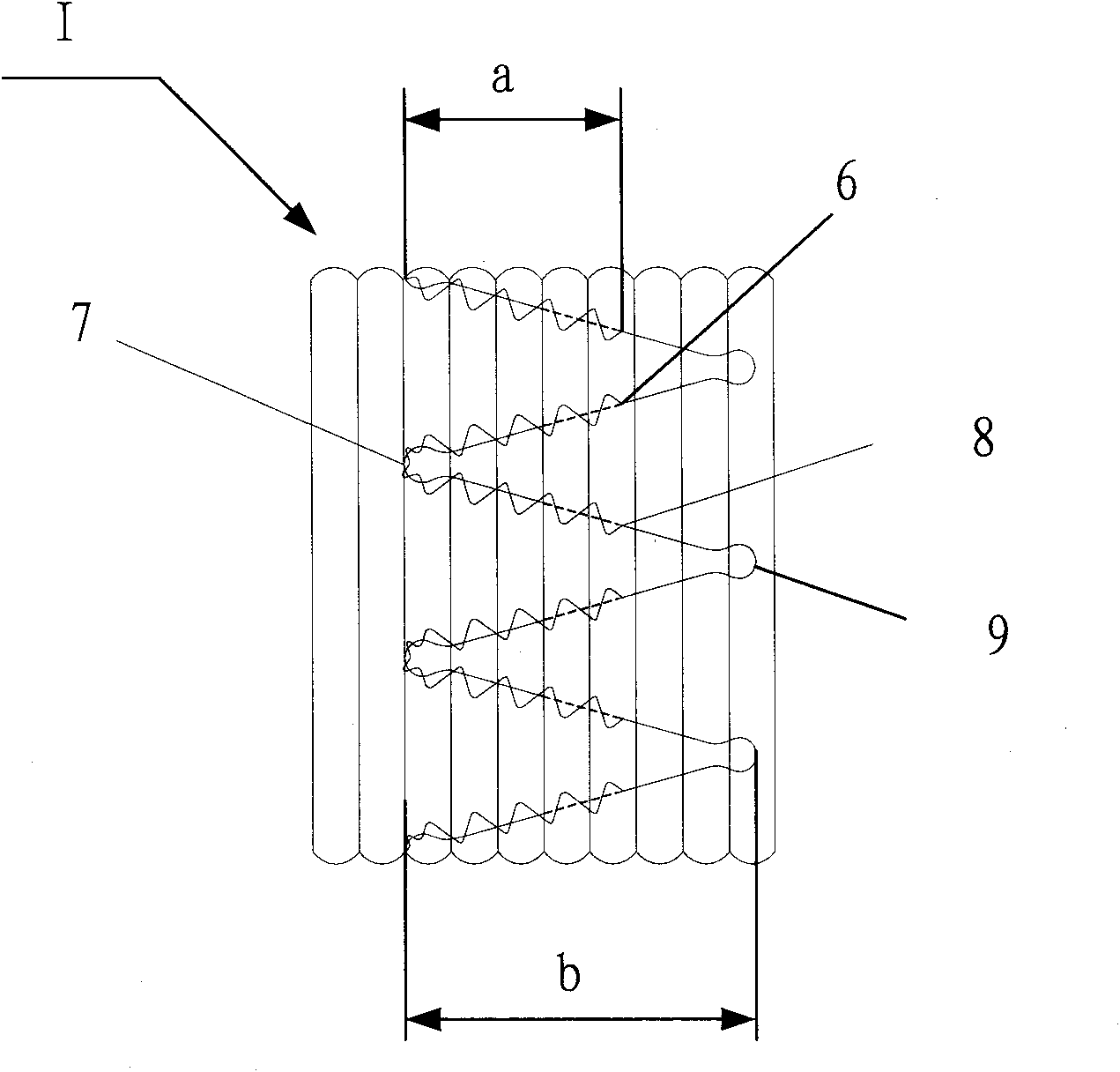

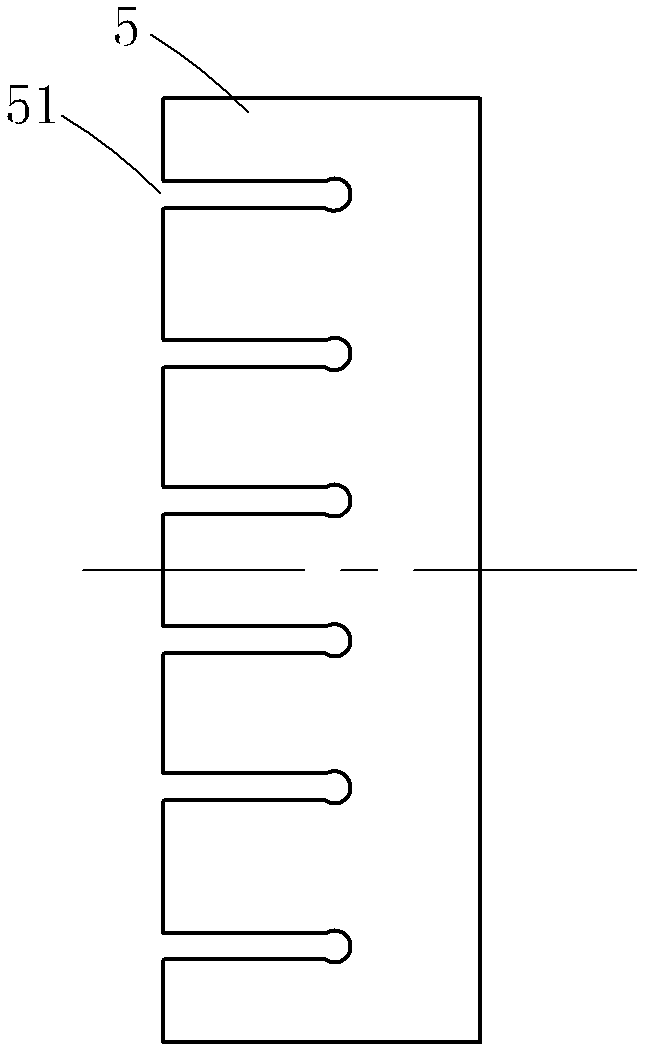

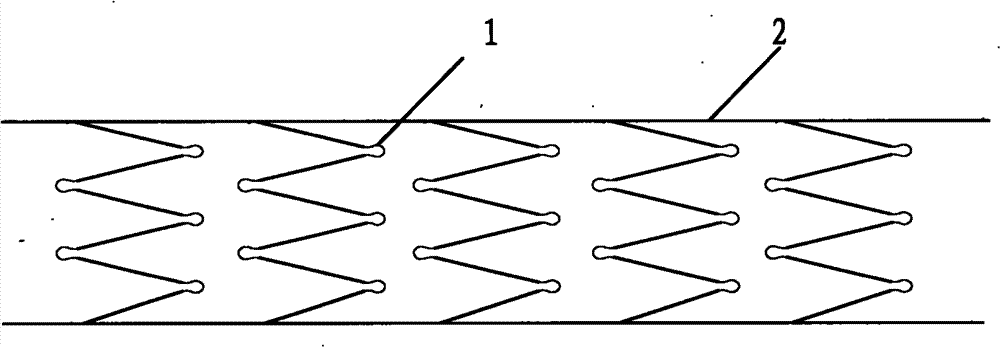

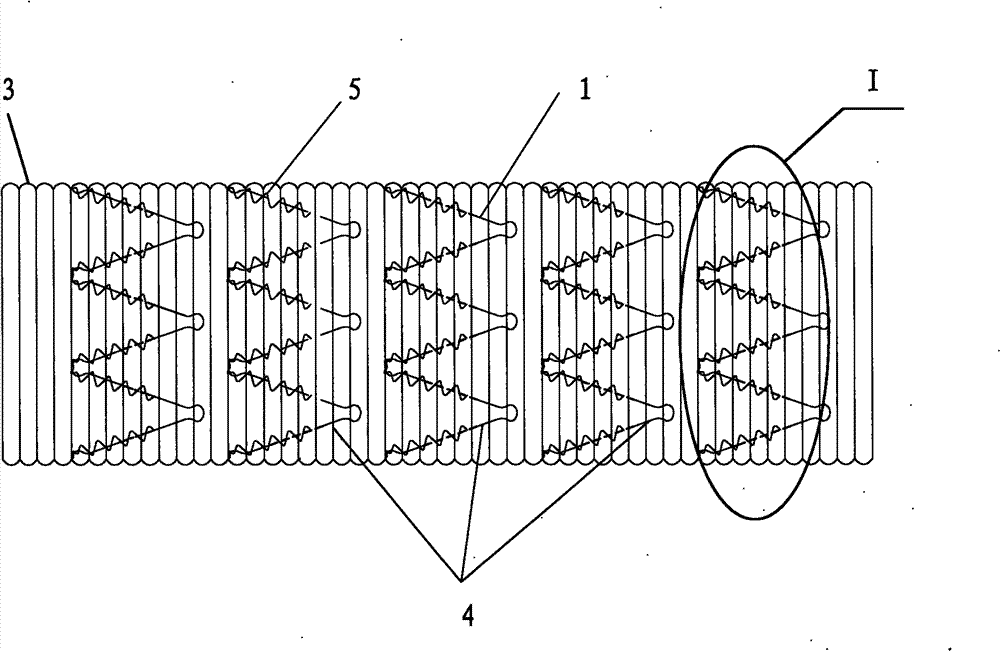

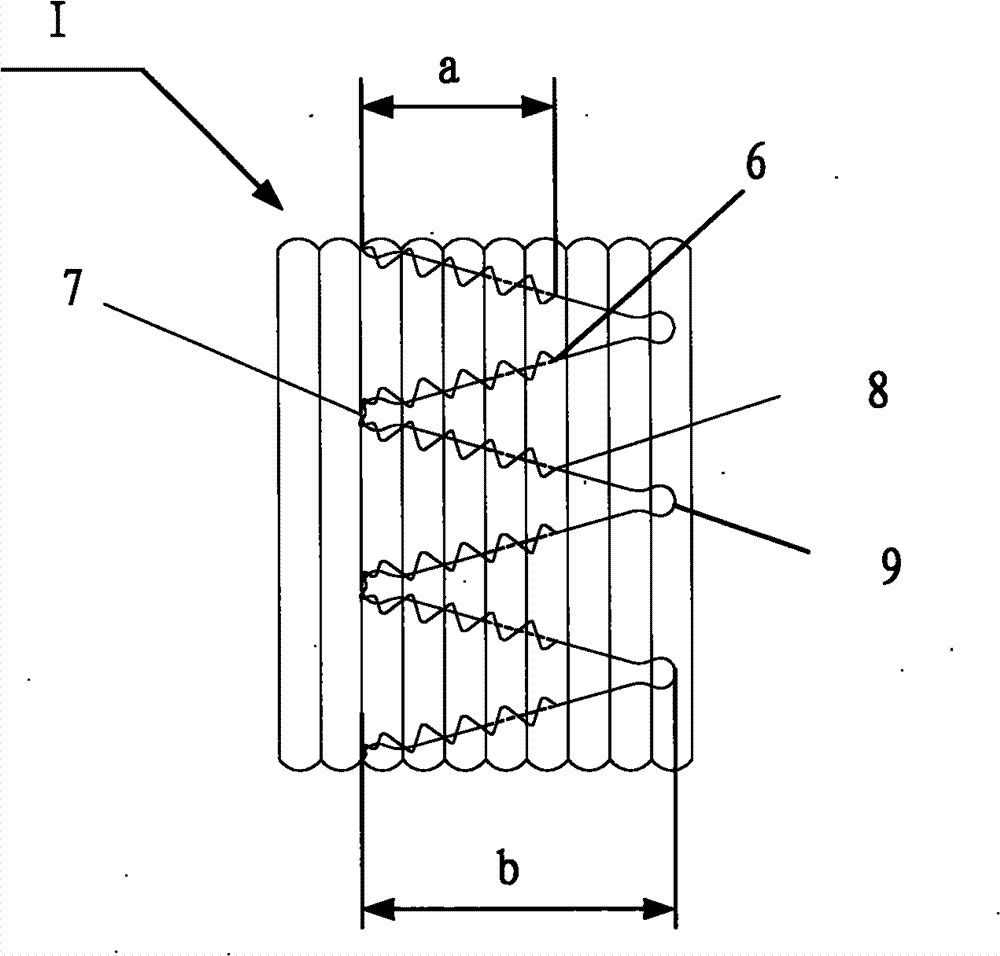

The invention discloses a blood vessel bracket prosthesis. The blood vessel bracket prosthesis comprises an artificial blood vessel prosthesis and a self-elasticity bracket, wherein the artificial blood vessel prosthesis is fixed on the outer side of the self-elasticity bracket through a suture line; the self-elasticity bracket consists of a plurality of self-expansion rings; the self-expansion rings are partially sutured on the artificial blood vessel prosthesis; a tube body of the artificial blood vessel prosthesis has a corrugate shape; the plurality of self-expansion rings are dispersedly arranged in the artificial blood vessel prosthesis at uniform intervals; and parts near the sides of the self-expansion rings, are sutured on the artificial blood vessel prosthesis. The blood vessel bracket prosthesis can avoid blood vessel deformation caused by that a tectorial membrane bracket is folded after being implanted into a human body and can avoid other problems caused by blood vessel deformation.

Owner:SHANGHAI MICROPORT ENDOVASCULAR MEDTECH (GRP) CO LTD

Device for measuring change of material residual stress

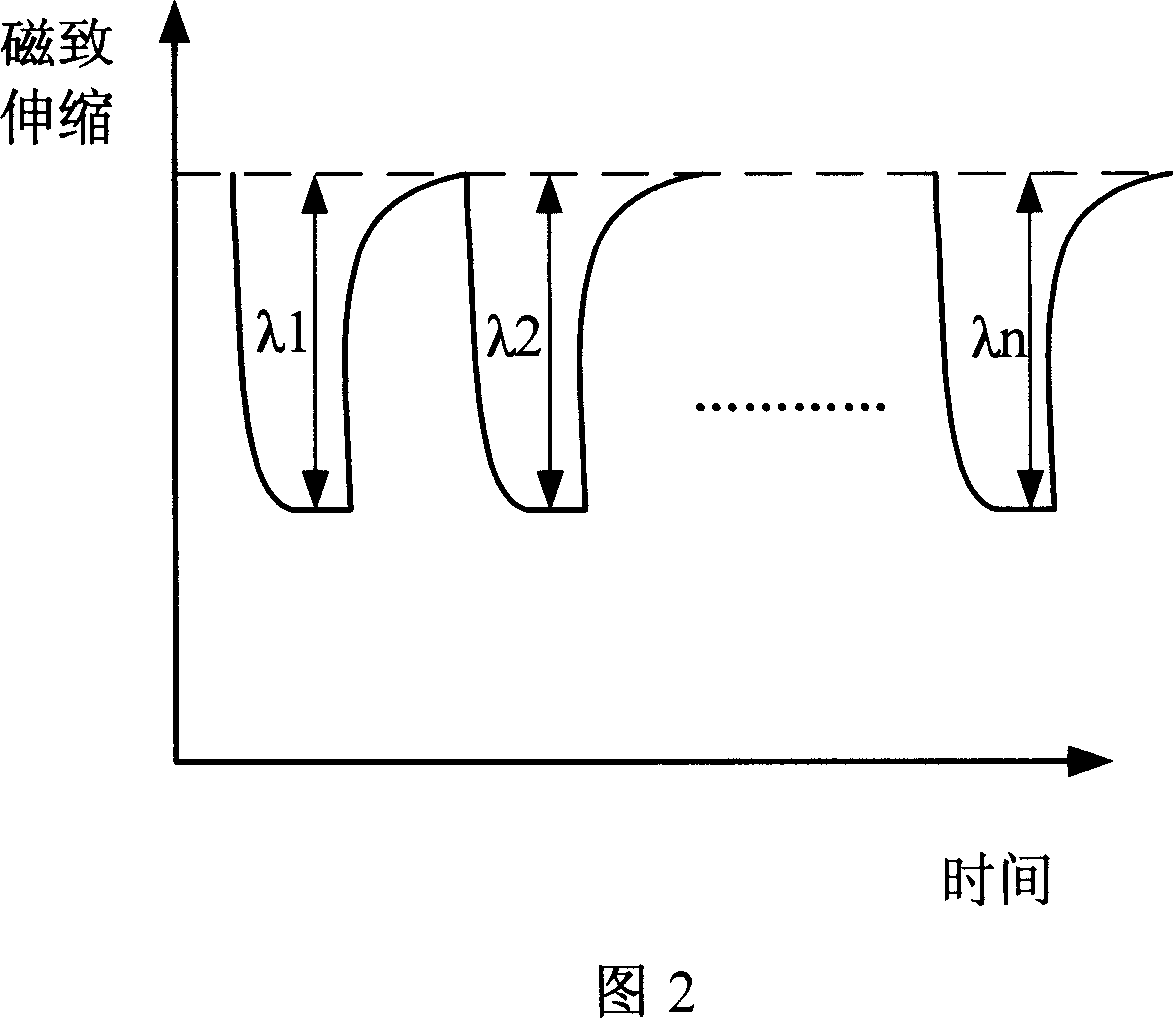

ActiveCN101013105ADoes not cause material deformationDoes not cause deformationForce measurement by measuring magnetic property varationMagnetic property measurementsData processingAcoustics

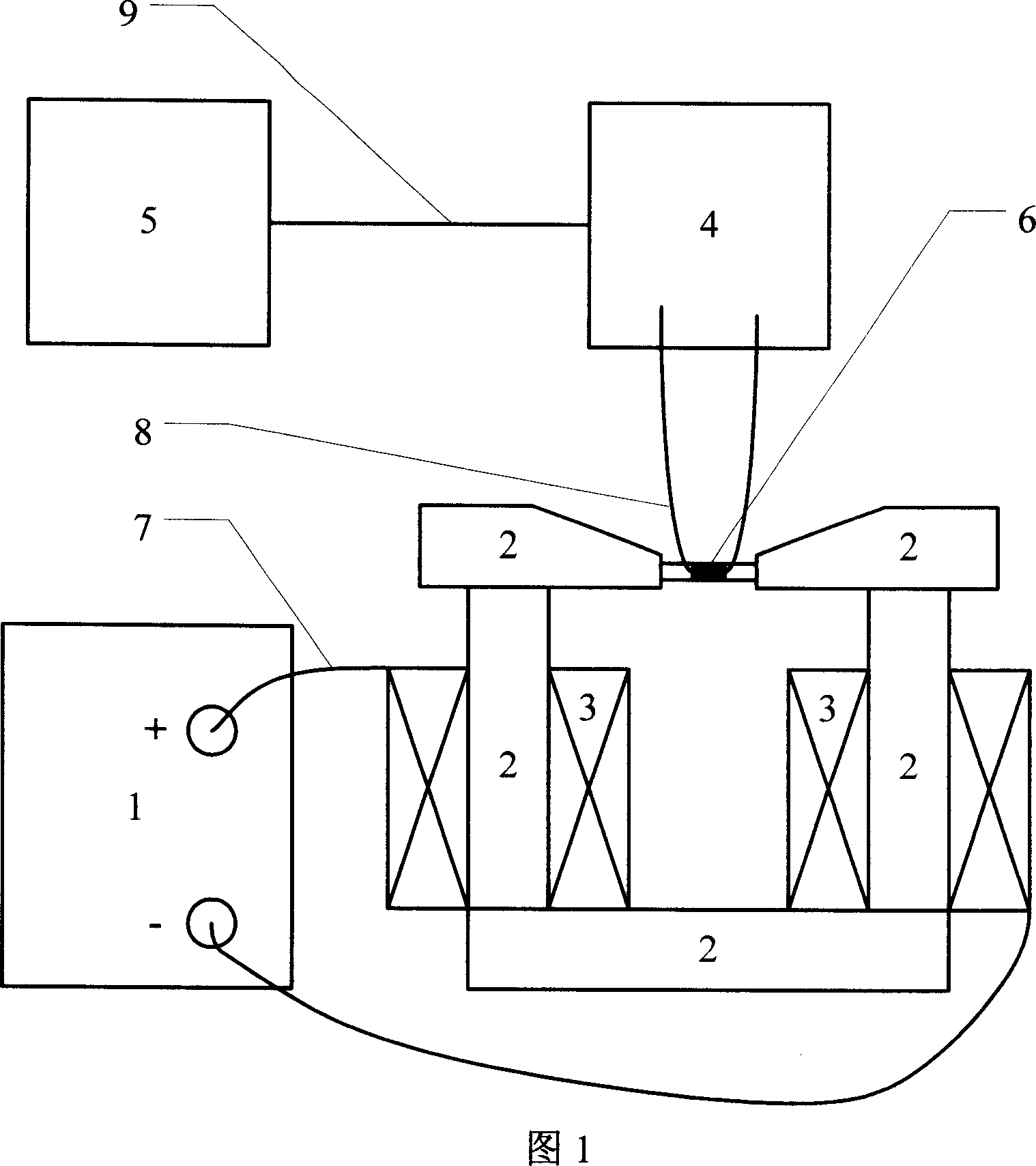

A device and method to measure material residual stress changes, its characteristic is using magnetostrictive to measure residual stress changes of ferromagnetic material, which includes two parts, the measurement system and data processing method. The measurement system includes two parts, the magnetic field generation equipment and the equipment to measure and record magnetostrictive. The equipment to measure and record magnetostrictive includes the resistance strain slice, the dynamic strain device and the computer acquisition system. The data processing method uses a formula to process the initial magnetostrictive average and the final magnetostrictive average, to obtain the residual stress changes instance. It solves the problems to reduce, control and measure residual stress in existing technology. The invention is characterized by fast, efficient, no material deformation, and so on.

Owner:WUHAN JINGTAI TECH CO LTD

Method for manufacturing harmonic reducer of robot

The invention discloses a method for manufacturing a harmonic reducer of a robot, which belongs to the technical field of harmonic reducer processing and includes the steps of manufacturing flexible gears and the steps of manufacturing rigid gears. The steps of manufacturing the flexible gears include: forging solid billets of the flexible gears; performing heat treatment for the solid billets of the flexible gears to reach the hardness of HRC (Rockwell hardness) 38-40; turning the solid billets of the flexible gears after heat treatment into thin-wall semi-finished flexible gears; supporting inner cavities of the semi-finished flexible gears by a flexible gear tensioning fixture; and grinding the supported semi-finished flexible gears to form external gear rings of the flexible gears on a grinder. By the method, the efficiency and the precision of machining the flexible gears and the rigid gears are improved, the hardness of the flexible gears is enhanced, the service life of the harmonic reducer is prolonged, and the method is widely applied to production of harmonic reducers.

Owner:SHANDONG SHKE MACHINERY MFG

Etching knife die and processing method thereof

ActiveCN102632520AWill not deformDoes not cause deformationMetal working apparatusNumerical controlMilling cutter

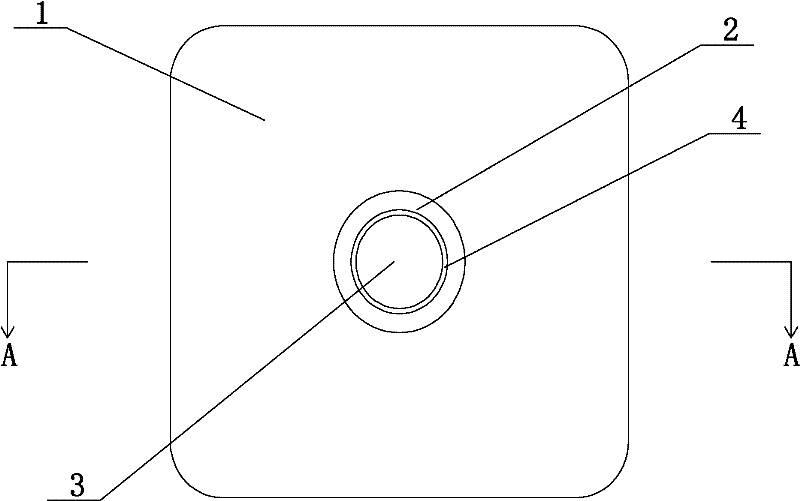

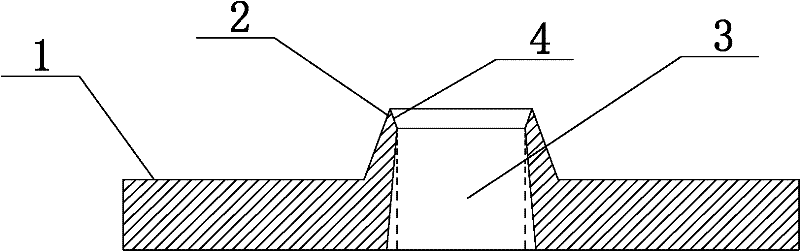

The invention discloses an etching knife die comprising a template and one or more knife arranged on the template, wherein a knife edge is arranged on the knife; the cross section of a blanking hole below the knife is trapezoidal; and the lower-end diameter of the blanking hole is greater than the upper-end diameter of the blanking hole. The invention also discloses a processing method of the etching knife die. The method comprises the steps of cutting to form a vertical blanking hole by utilizing a milling cutter through a CNC (Computer Numerical Control) precision carving machine and carrying out turn-by-turn downward expanding cutting from top to bottom on the inner wall of the straight hole by utilizing a dovetail cutter through the CNC precision carving machine to ensure that the cross section of the inner wall of the blanking hole is of a trapezoid which is small in upper part and big in lower part, wherein the included angles of the side edges and the bottom face of the trapezoid are 78-89 DEG. The etching knife die and the processing method thereof, disclosed by the invention, have the advantages that automatic waste discharge can be realized; the blanking piece is avoided being pulled when passing through the blanking hole to ensure that the blanking is smooth, the knife die is not pressed, the deformation and the breakdown of the etching knife die are not created; therefore, the product accuracy can be increased and the service life of the knife die is prolonged.

Owner:陈泳泳

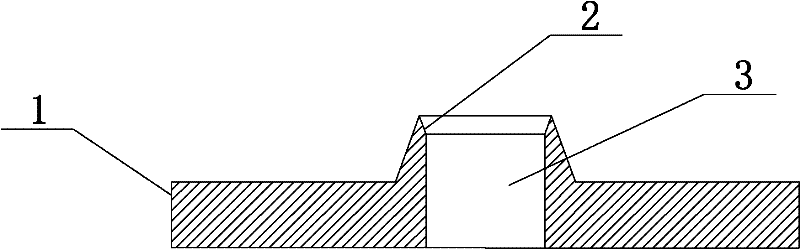

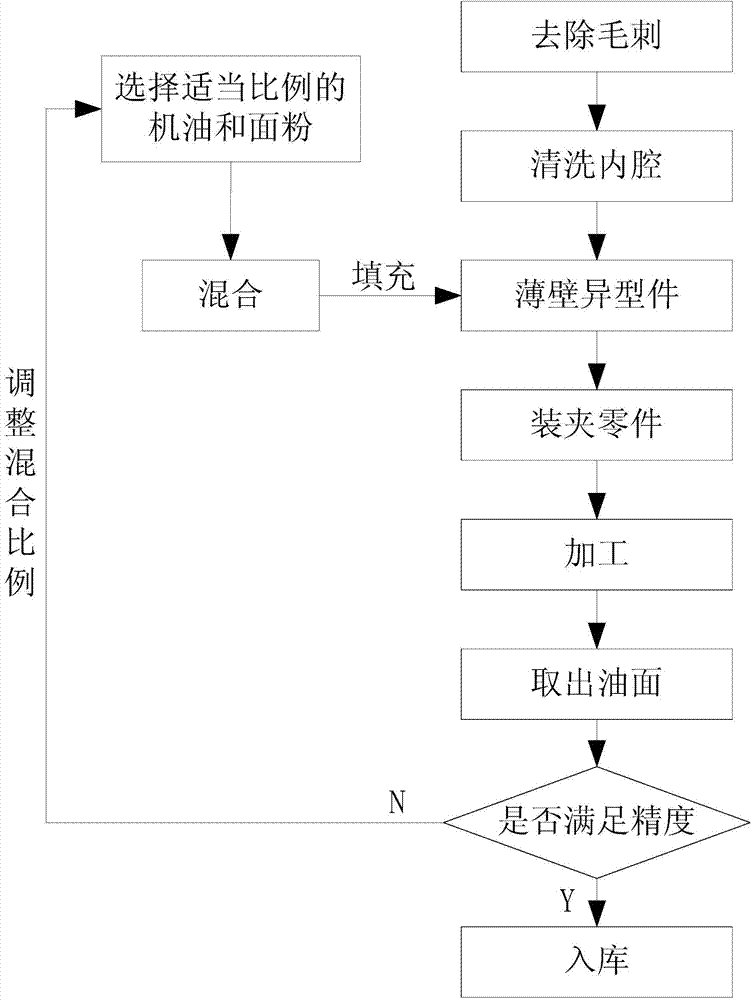

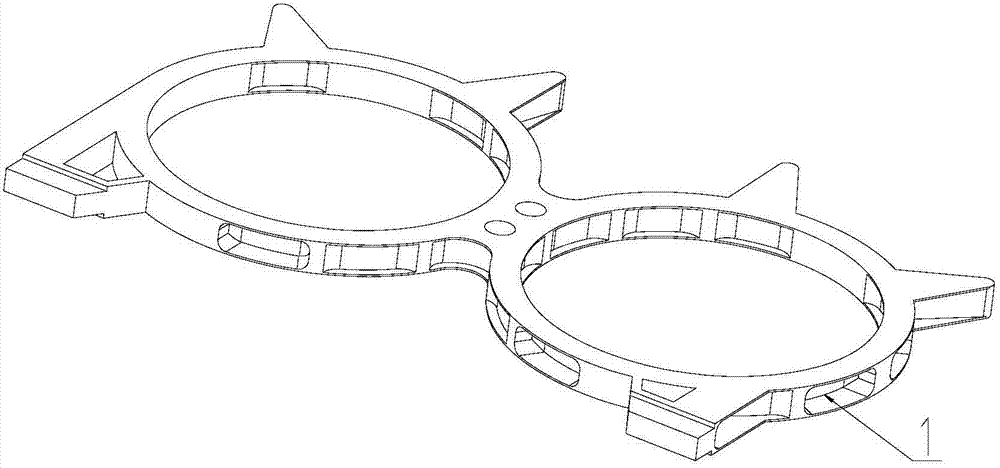

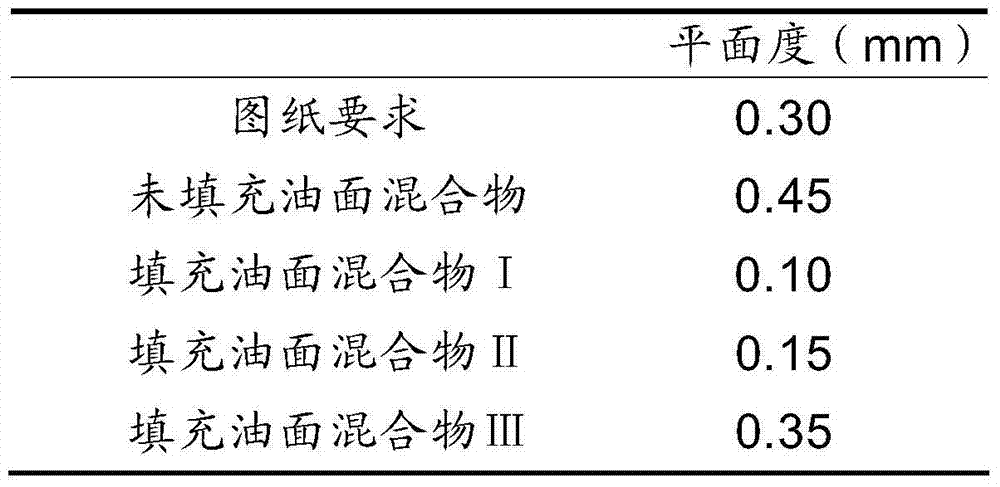

Padding supporting method for enhancing thin-walled workpiece machined rigidity

ActiveCN104259883AEasy to makeLow costPositioning apparatusMetal-working holdersAviationMachining deformation

Disclosed is a padding supporting method for enhancing thin-walled workpiece machined rigidity. Engine oil and flour are mixed according to a specific ratio and then padded into a cavity of a thin-walled workpiece, the whole rigidity of the thin-walled workpiece is improved, natural vibration frequency of the workpiece is changed, flutter is reduced, cut machined deformation of the thin-walled workpiece is reduced, the problem that workpiece surface qualities are affected due to poor rigidity and flutter can be solved, and machining accuracy and surface qualities of the thin-walled workpiece can be guaranteed. By means of the successful development of the padding supporting method, the difficulty of machining of the thin-walled workpiece during model development can be technologically solved, the machining scheme of the thin-walled workpiece and mixing ratio parameter of engine oil and flour can provide high reference value and certain guiding significance for high-efficiency precise machining of numerous thin-walled irregular workpieces which are high in accuracy requirements, complicated in structures and especially not easy to clamp in national defence industry fields of aviation, aerospace, weaponry and the like, and the padding supporting method for enhancing the thin-walled workpiece machined rigidity can be used for guiding actual production.

Owner:BEIJING SATELLITE MFG FACTORY

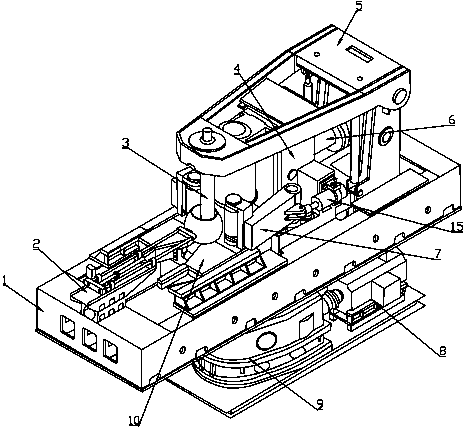

Spherical ring rolling machine

ActiveCN103978133AAccurate measurementControlling the rolling processMetal rollingSlide plateEngineering

The invention discloses a spherical ring rolling machine, which comprises a lathe bed, a driving device, a measuring device, a bracket, a mandrel, a king roller seat, a support and a main feed oil cylinder, wherein the measuring device, the bracket, the mandrel, the king roller seat, the main feed oil cylinder and the support are arranged on the lathe bed from left to right in sequence. A slide rail and a fixing plate are arranged on the inner wall of the lathe bed; the support comprises a support seat and a support arm, rollers are arranged on two sides of the support seat and the two sides of the support seat are arranged in the slide rail of the lathe bed through the rollers. The measuring device comprises an adjusting seat, a supporting seat, a sliding plate and a measuring component. The king roller seat is fixedly arranged on the fixing plate of the lathe bed, and a king roller is arranged on the king roller seat. The mandrel is arranged on the free end of the support arm, an upper sleeve of the mandrel is arranged on the free end of the support arm, and a lower sleeve of the mandrel is arranged on the support seat. The main feed oil cylinder is arranged on the king roller seat and the support seat, and the bracket is arranged on the end of the support seat. The spherical ring rolling machine is suitable for processing medium and large spherical valve cores and has the characteristics of high processing precision and capability of improving the labor intensity.

Owner:浙江远大重工锻压有限公司

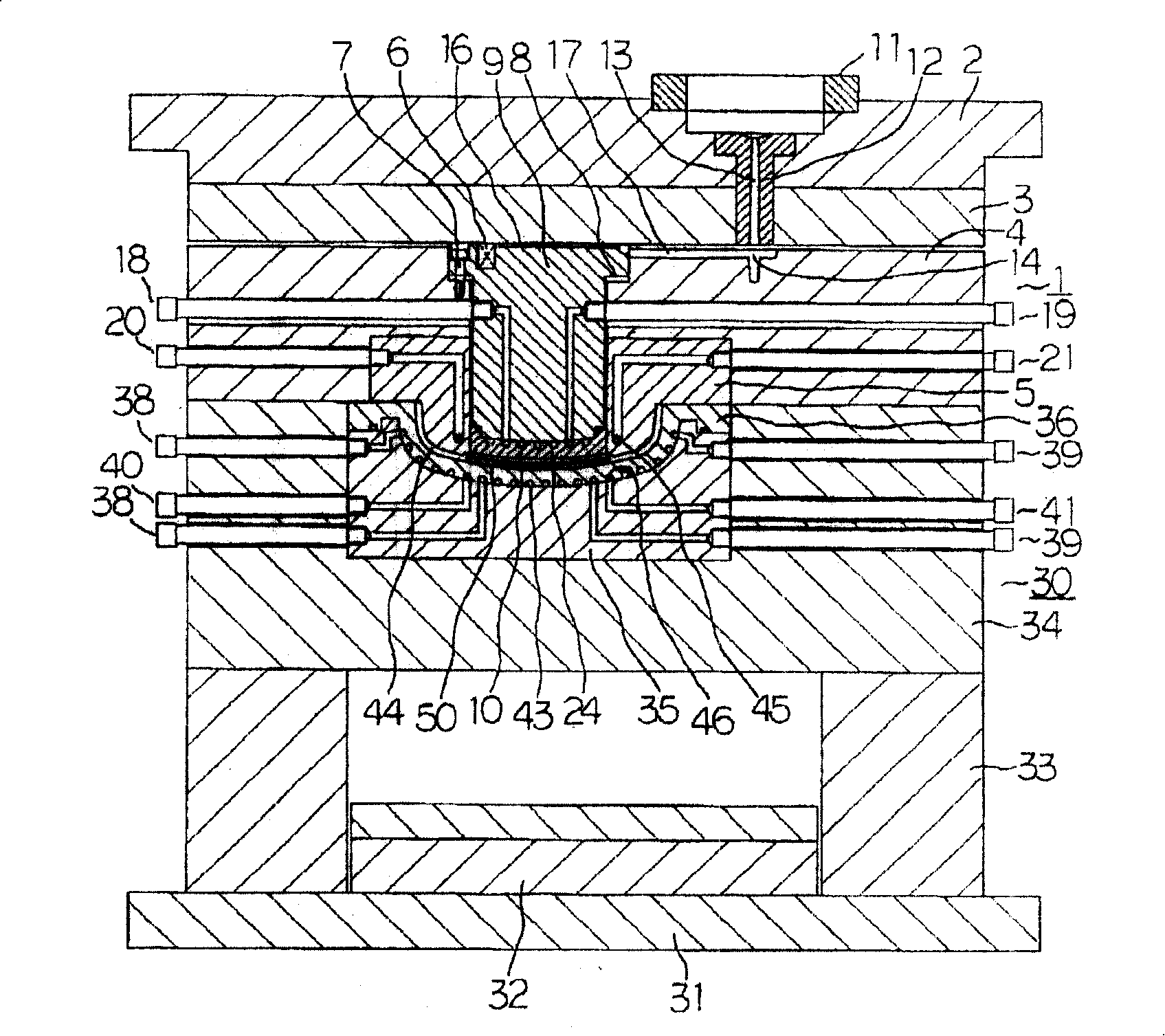

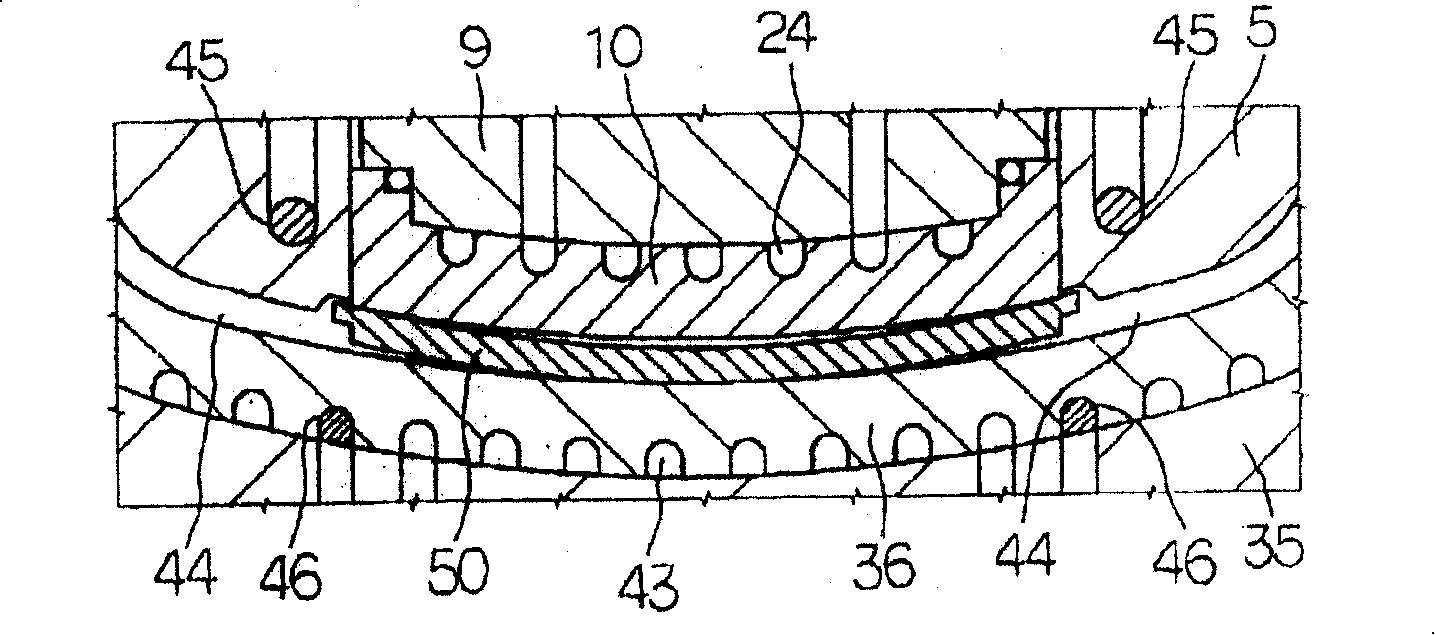

Embedded forming method and mold for embedded forming

The invention is to solve the problem that when embedded parts are embedded, and a secondary injection moulding mode is used to mould the embedded parts which become an integrated product, the secondary injected and moulded product and the integrated product are not caused to deform as far as possible. After embedded parts (50A) made of thermoplastic synthetic resin are arranged inside a mould under the state of breaking the mould, the mould is closed. A bush (10A) is used to extrude the embedded parts (50A) into a female die (36). Subsequently, the embedded parts (50A) are heated up and softened. On one hand, the bush (10A) is moved far from the female die(36); on the other hand, the composite resin material flows into and is injected into the bush (10A) before the composite resin material is guided inside a mould cavity (44A) between a male die (5A) and the female die (36) so as to cool and harden the connected embedded parts (50A) and the secondary moulded products (51A) by cooling the surface of the male die (5A) and the female die (36).

Owner:FUJISEIKO

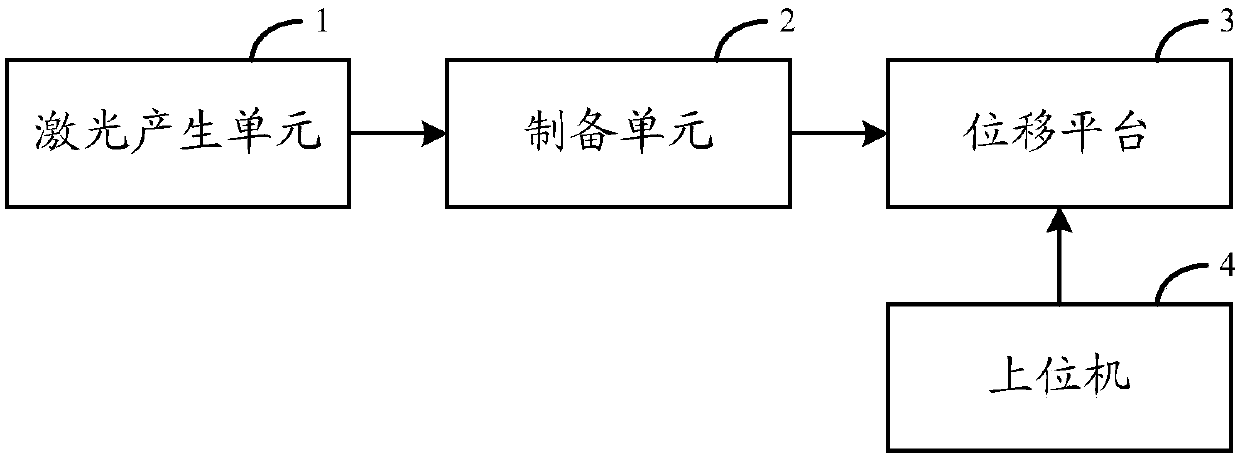

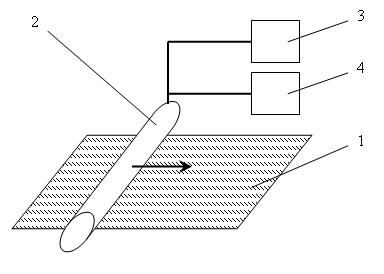

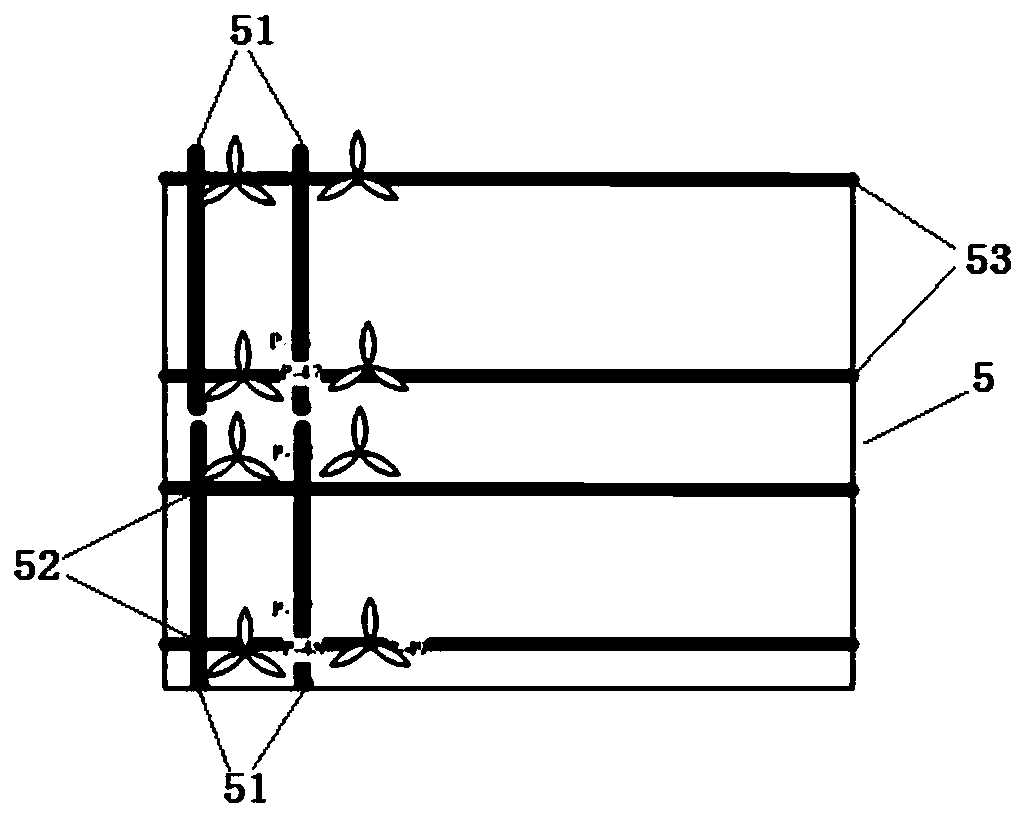

System and method for preparing micro-nano optical fiber Bragg gratings

ActiveCN107608022ACycle controllableImprove reflectivityCladded optical fibreOptical waveguide light guideMicro nanoGrating

The invention is applicable to the technical field of gratings, and provides a method and a system for preparing micro-nano optical fiber Bragg gratings. The system comprises a laser generating unit,a preparation unit, a displacement platform and an upper computer. Samples can be arranged on the displacement platform, and each sample is a micro-nano optical fiber coated with a layer of curing adhesive; the laser generating unit is used for generating femtosecond laser with preset power values and transmitting the femtosecond laser to the preparation unit; the preparation unit is used for focusing the femtosecond laser on the micro-nano optical fibers; the displacement platform can move under the control of the upper computer, so that radial scanning can be carried out by the femtosecond laser along the micro-nano optical fibers, and preliminarily arranged Bragg gratings can be cured on the micro-nano optical fibers. The method and the system in an embodiment of the invention have theadvantages that tedious grating sensitivity enhancement treatment procedures can be omitted when the micro-nano optical fiber Bragg gratings are prepared by the aid of the method and the system, grating periods can be controlled, and the micro-nano optical fiber Bragg gratings are high in reflectivity; the Bragg gratings prepared by the aid of the method and the system are cured on the surfaces ofthe micro-nano optical fibers and are extremely sensitive to external environments, and the system is low in cost.

Owner:SHENZHEN UNIV

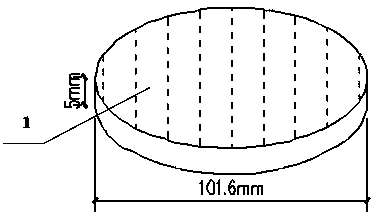

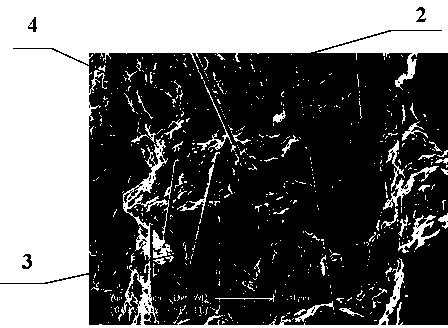

Sample preparation method of scanning electron microscope of basalt fiber and asphalt mixed material fracture

InactiveCN103808549AGood reproducibilityGood for microscopic observationPreparing sample for investigationMaterial analysis by measuring secondary emissionScanning electron microscopeElectron microscope

The invention relates to a sample preparation method of a scanning electron microscope of a basalt fiber and asphalt mixed material fracture, which relates to the technical field of sample preparation of a material for testing of a scanning electron microscope. The method comprises the steps of first preparing an asphalt mixed material Marshall cylindrical test piece doped with basalt fibers by a Marshall standard compaction method, then cutting the cylindrical test piece to obtain bar-shaped test pieces, and cutting each of two opposite edges of each bar-shaped test piece of the mixed material along the height direction to form a small incision; performing water bath on the test pieces to achieve heat balance; and clamping two sides of the incisions of each test piece, fracturing the bar-shaped test piece of the mixed material and air-drying the fractured test piece. The obtained test piece fracture is relatively smooth, thus being favorable for the micro-observation on basalt fibers of the scanning electron microscope, so that the bonding situation between the basalt fibers and the asphalt mixed material and the reinforcement effect of the fibers during fracturing of the asphalt mixed material can be accurately mastered.

Owner:YANGZHOU UNIV

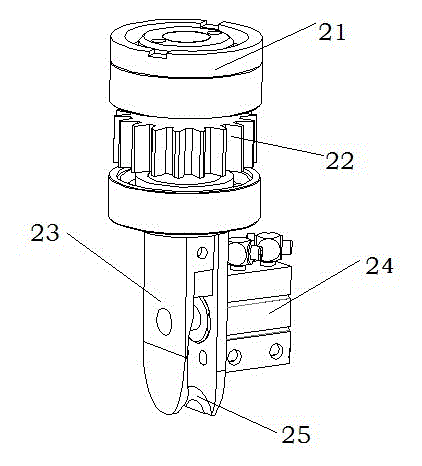

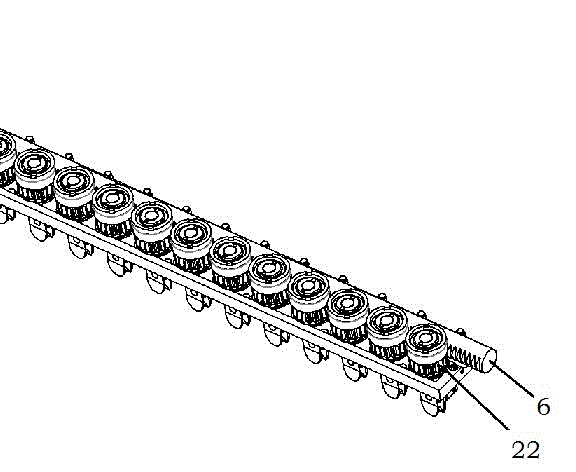

Automatic pipe grasping device

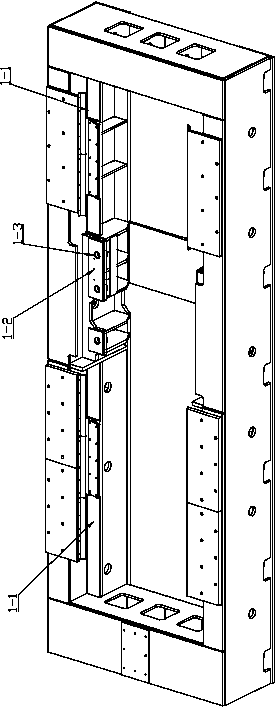

ActiveCN103143912ALight equipmentCompact structureGripping headsMetal working apparatusEngineeringElectrical and Electronics engineering

The invention relates to a pipe grasping device, in particular to an automatic tube grasping device used for grasping a vertically hung U-shaped pipe. The automatic pipe grasping device comprises a bracket and a plurality of clamping jaws; each clamping jaw comprises a top clamp seat, a transmission element and a pair of clamping boards; the clamp seats of the clamping jaws are arranged on the bracket in parallel; the transmission elements are connected with the clamping boards; the transmission elements are arranged on the clamp seats; the transmission elements can drive the clamping boards to rotate around the axial lines of the transmission elements; the clamping boards are controlled to be on and off through clamping jaw driving devices; the transmission elements are connected with directional control devices; and the directional control devices control the transmission elements to rotate. The automatic pipe grasping device provided by the invention can be used for realizing that multiple vertically-hung long U-shaped copper pipes are simultaneously grasped, the grasping way is simple and efficient, the device is light and convenient, the structure is compact, the occupied space is small, and the copper pipes cannot be distorted, thus, the condition for automatically feeding pipes efficiently is realized, and the guarantee for breaking through efficient and automatic pipe sleeving technique is provided.

Owner:江苏惠扬产业投资发展集团有限公司

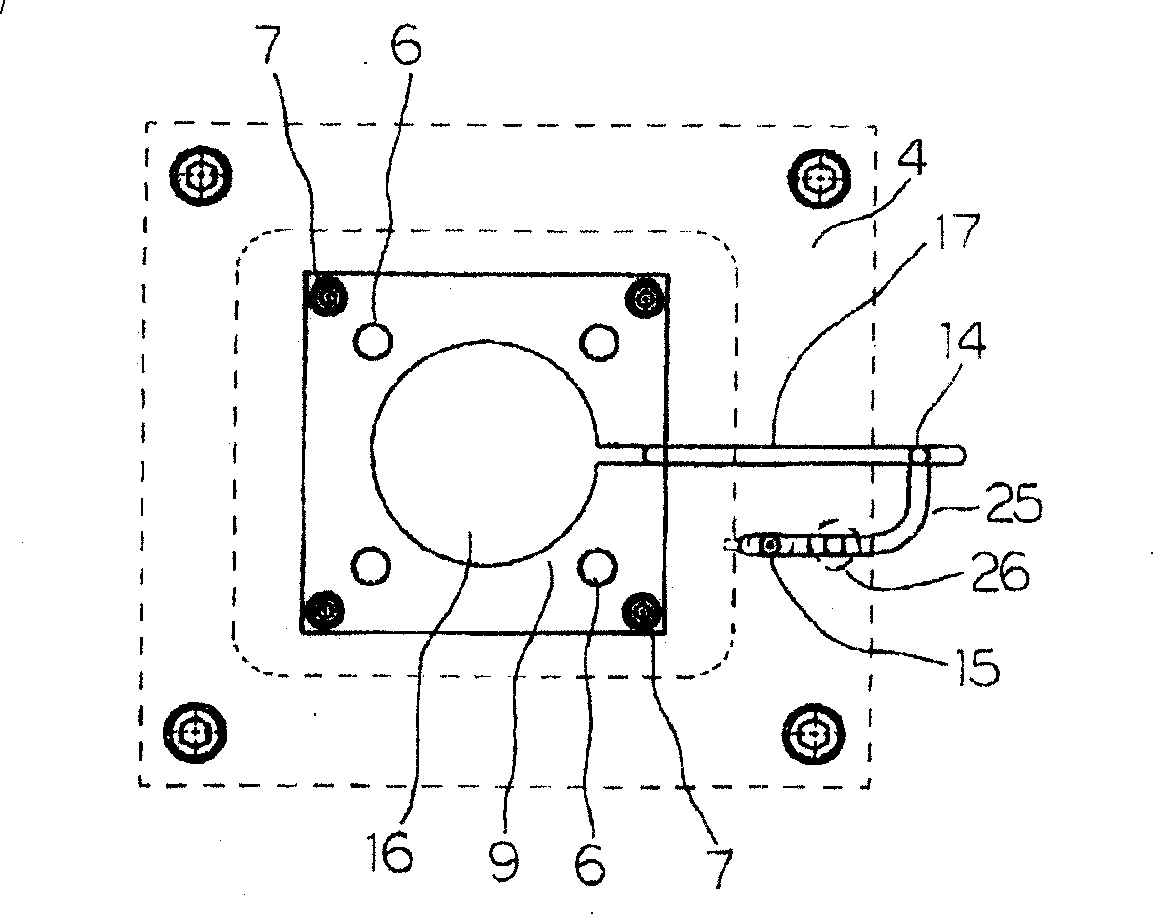

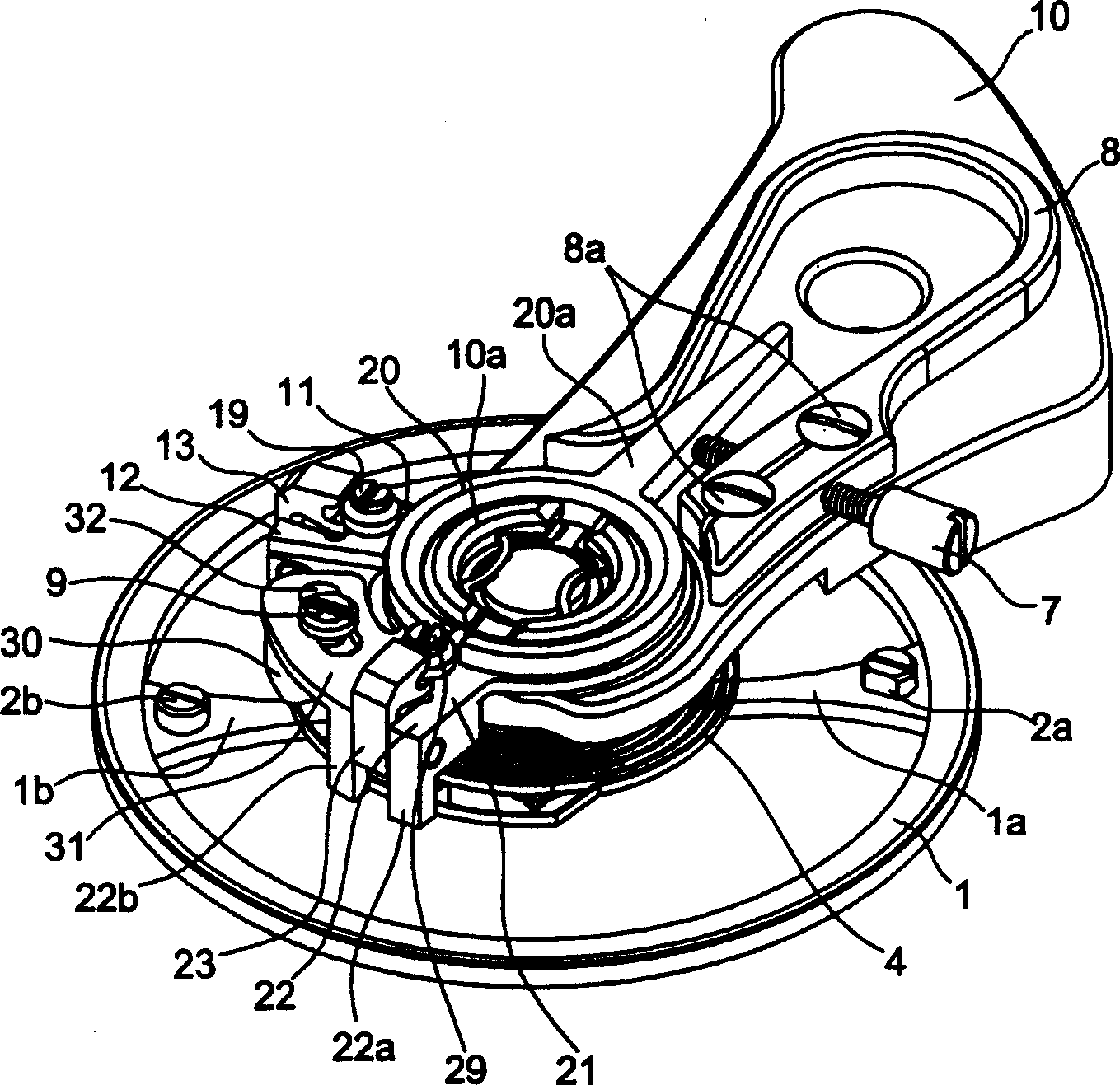

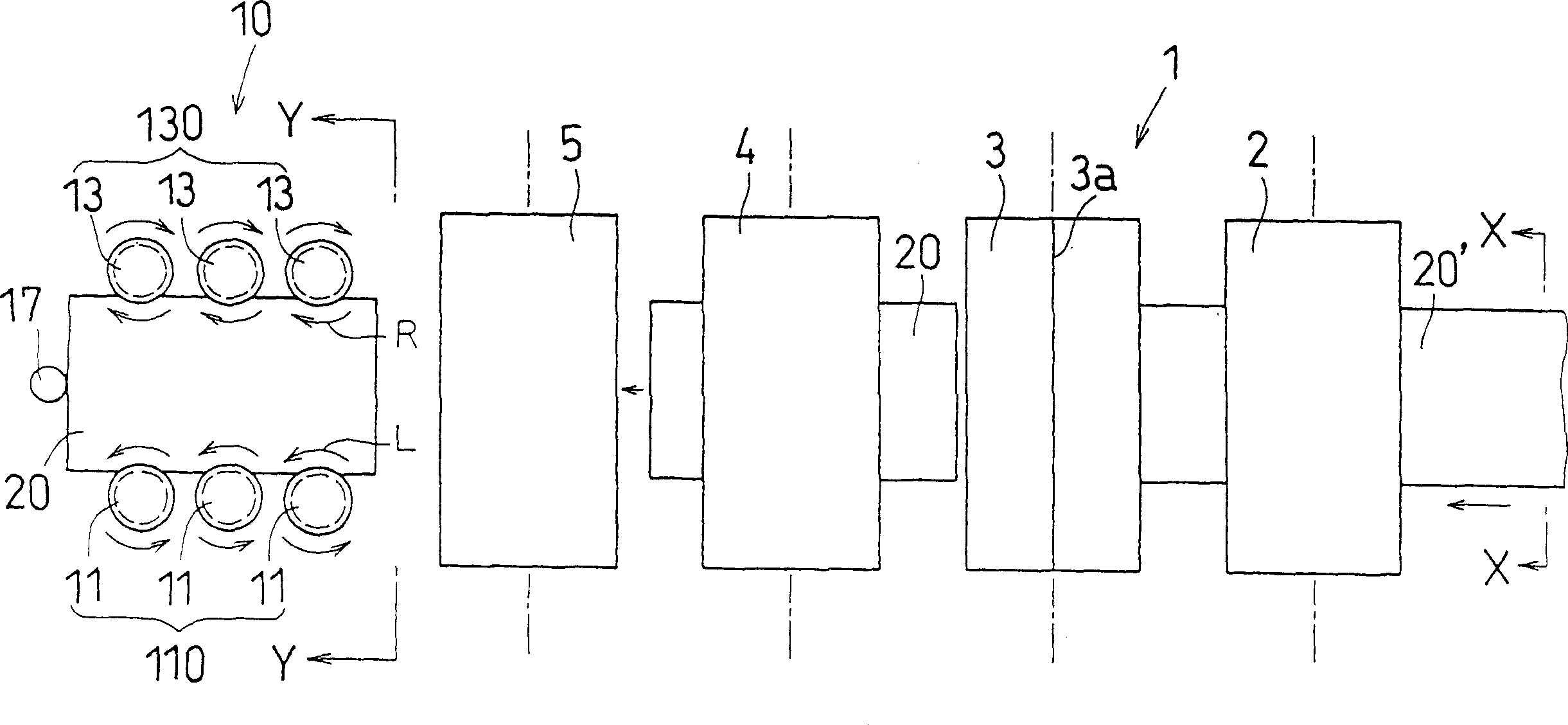

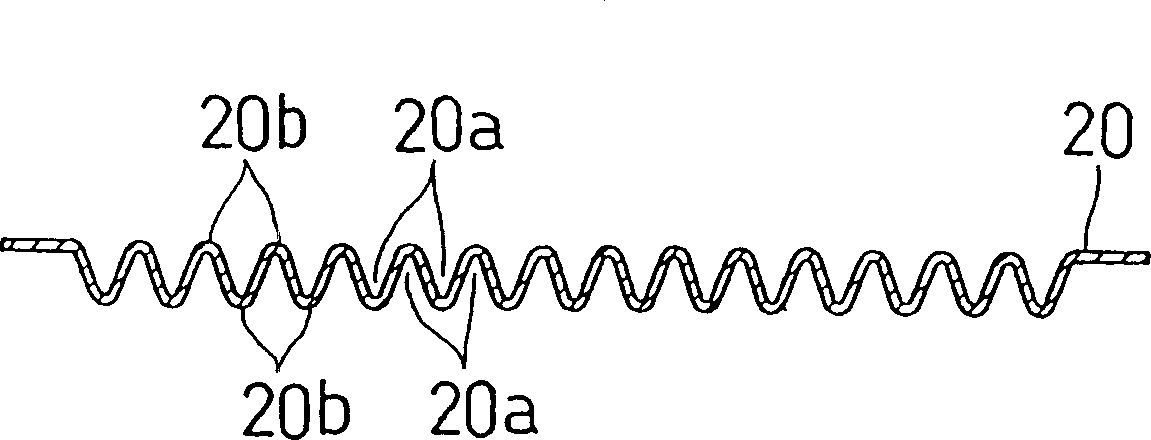

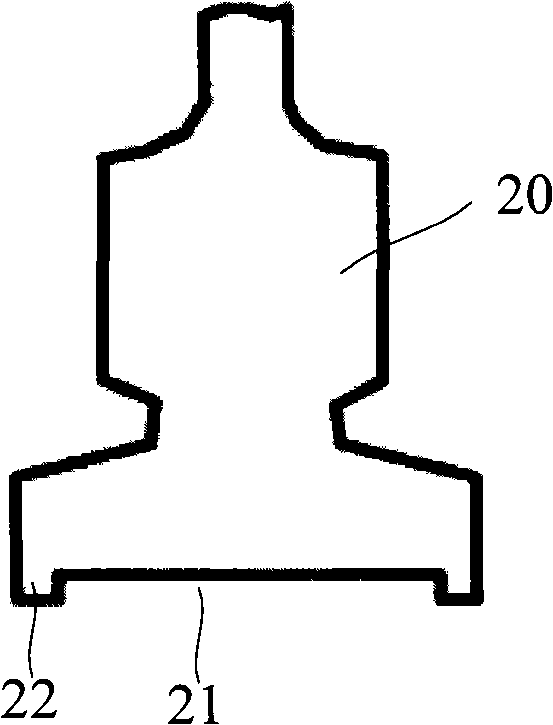

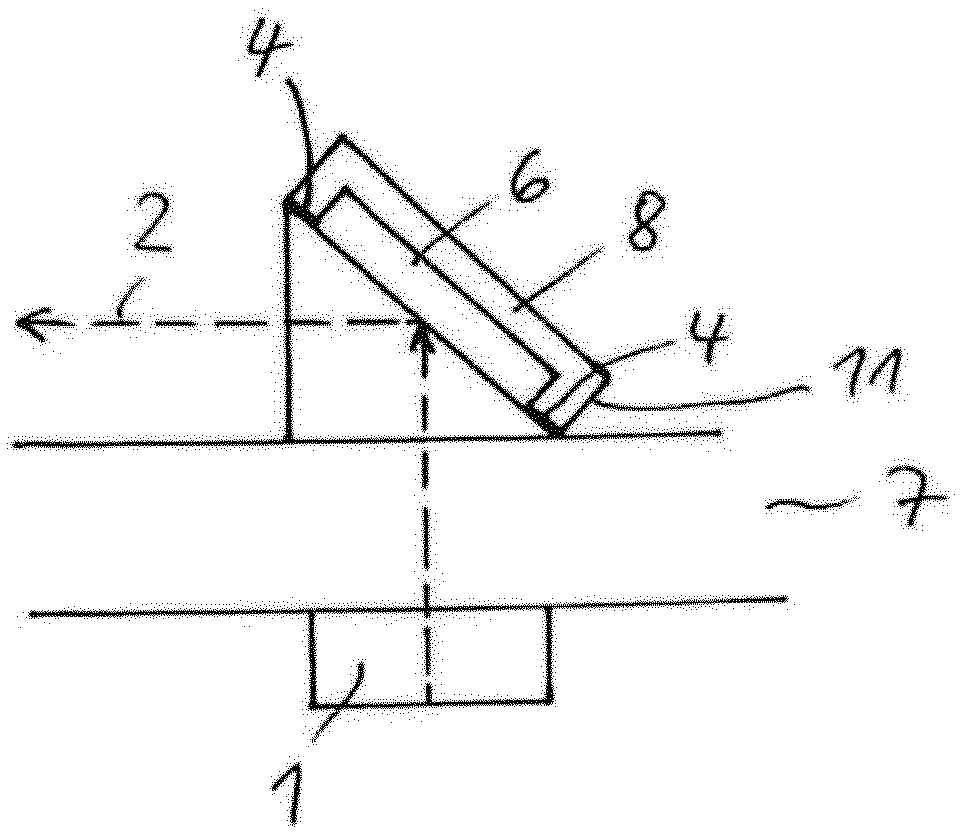

Device for the fine adjustment of a balance spring

ActiveCN1726436ADoes not cause deformationFrequency stabilisation mechanismFrequency setting mechanismBalance springEngineering

The present invention provides a device for the fine adjustment of a balance spring. In order particularly to put a watch into beat and adjust the isochronism, in addition to the poising screws ( 2 a, 2 b) of the balance ( 1 ) and the fine adjusting screw ( 7 ) pressing on the index tail 20 a to alter the orientation of the index ( 20 ), the device includes, on the one hand, two screws ( 19, 29 ) respectively fixed in the balance cock ( 10 ) and in the index ( 20 ) to manoeuvre clamps by means of L-shaped rocking elements ( 13, 23 ) to fix the end of the balance spring and define its useful length, and on the other hand, a screw ( 9 ) for immobilising the index ( 20 ) in a determined position, these three screws ( 9, 19, 29 ) enabling a fine adjustment to be carried out.

Owner:格拉斯许特钟表有限公司

Method for manufacturing micronanostructure on surface of block amorphous alloy

The invention relates to a method for manufacturing a micronanostructure on the surface of a material, in particular to the method for manufacturing the micronanostructure on the surface of a block amorphous alloy. The method is characterized by comprising the following steps of: completely cleaning oxide, oils and fats from the surface of the block amorphous alloy in a conventional way; making the surface of the block amorphous alloy, required to be processed, in a vacuum or inert gas protection state in a proper way; and rolling the surface required to be processed under the action of a given pressure with a roller-shaped die which is heated to an enough high temperature so as to obtain the block amorphous alloy surface with the micronanostructure. The surface manufactured by the methodis high in quality, low in processing cost, high in processing efficiency and flexible in technical operation.

Owner:JIANGSU UNIV

Casting method for pouring and molding thin-wall investment pattern steel casting

ActiveCN103506574ADoes not cause shrinkageWill not cause looseningFoundry mouldsFoundry coresWaxMetallurgy

The invention discloses a casting method for pouring and molding a thin-wall investment pattern steel casting, aiming to prevent the casting from cavity-shrinking, loosening or deforming. The method comprises the following steps: a. first preparing multiple wire-shaped metal materials with diameter of 0.5-1mm and length of 50-100mm and coating the outer surface of each wire-shaped metal material with a layer of wax with thickness of 0.1-0.2mm; b. inserting the wire-shaped metal materials from the last step into an assembled wax module, wherein the inserting thickness is 4-8mm; c. coating and smearing the wire-shaped metal materials with slurry and sands together with the wax module; d. after forming a module shell on the surface of the wax module, firstly destroying parts of module shell on the surface of the other end of the wire-shaped metal materials, drawing out the wire-shaped metal materials, and then performing dewaxing and roasting; e. finally pouring molten steel, wherein cavities which are formed in the module shell after the wire-shaped metal materials are drawn out can be used for drainage. By virtue of the method, the pass percent of the castings is enhanced.

Owner:JIASHAN SINHAI PRECISION CASTING

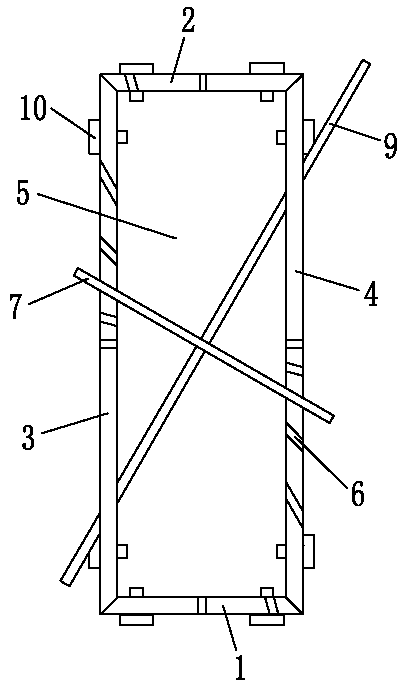

Manufacturing die for multi-angle sandwich rock mass reinforcing test

ActiveCN107607380ADoes not cause deformationImprove integrityClimate change adaptationPreparing sample for investigationSheet steelPolyvinyl chloride

The invention relates to a manufacturing die for multi-angle sandwich rock mass reinforcing test. The manufacturing die aims at effectively solving the problems of improving of integral stability of the member, higher strength and deformation ability, and saving of labor and materials in the multi-angle sandwich rock mass and anchor rod reinforcing technology. The manufacturing die is characterized in that a front steel plate, a back steel plate, a left steel plate and a right steel plate are arranged on a bottom plate to form an oblong-shaped groove; the upper end of the oblong-shaped grooveis provided with a plurality of pairs of groove openings; a blocking plate is arranged in any pair of groove openings and extends into the oblong-shaped groove; a plurality of pairs of reserved anchorrod holes are formed in the side walls of the oblong-shaped groove, a PVC (polyvinyl chloride) pipe is arranged in any pair of reserved anchor rod holes, and the middle part of each PVC pipe penetrates through a center hole in the corresponding blocking plate. The manufacturing die has the advantages that the better strength, rigidity, stability and other mechanical properties are realized; the deformation of a specimen in the casting process is avoided, and the integrity of the specimen is improved.

Owner:HUAQIAO UNIVERSITY

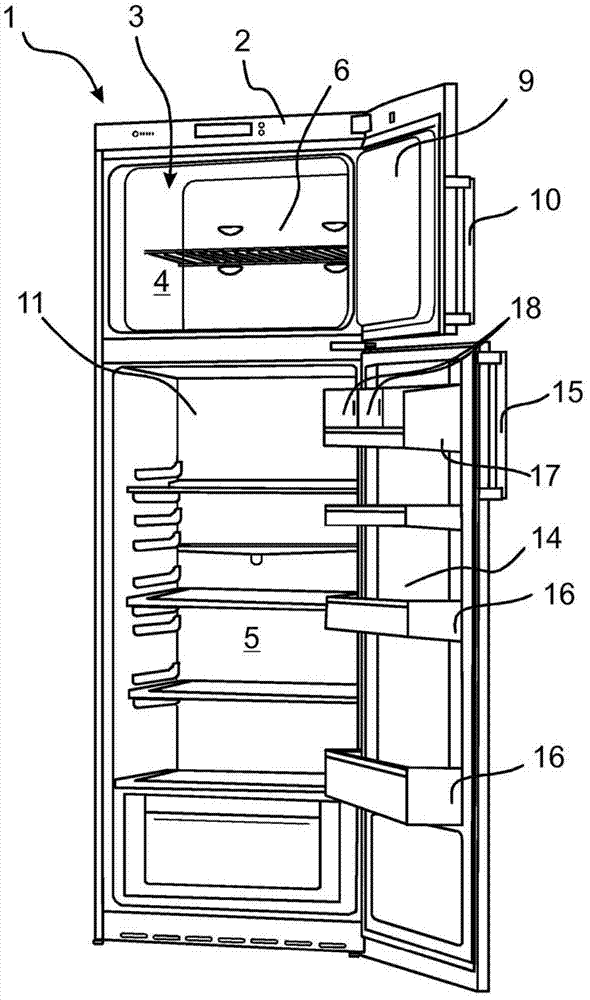

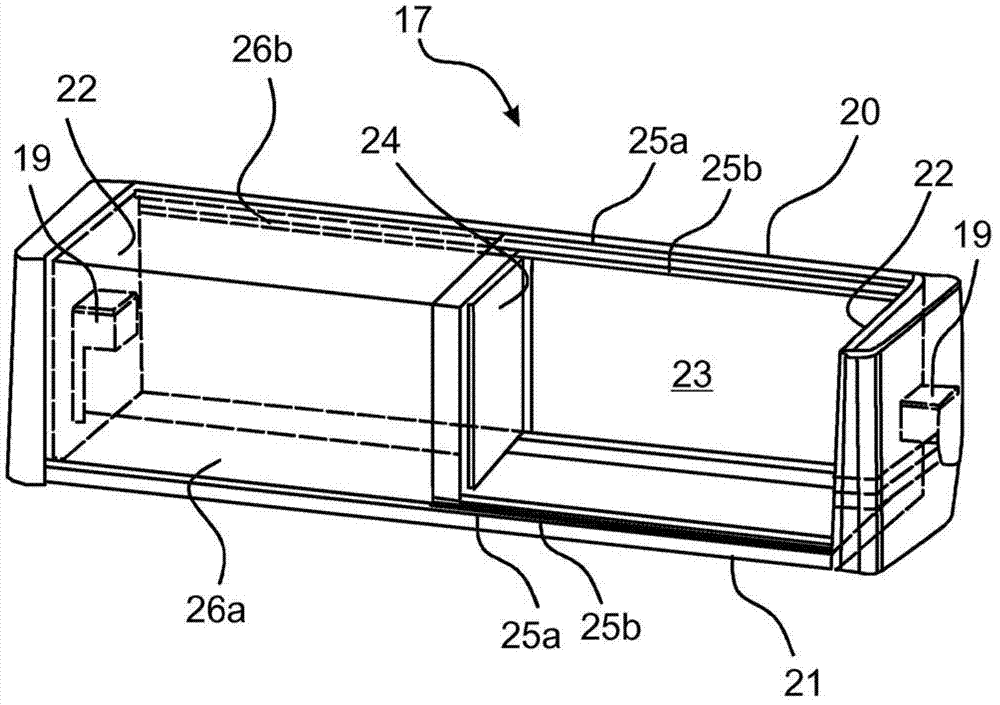

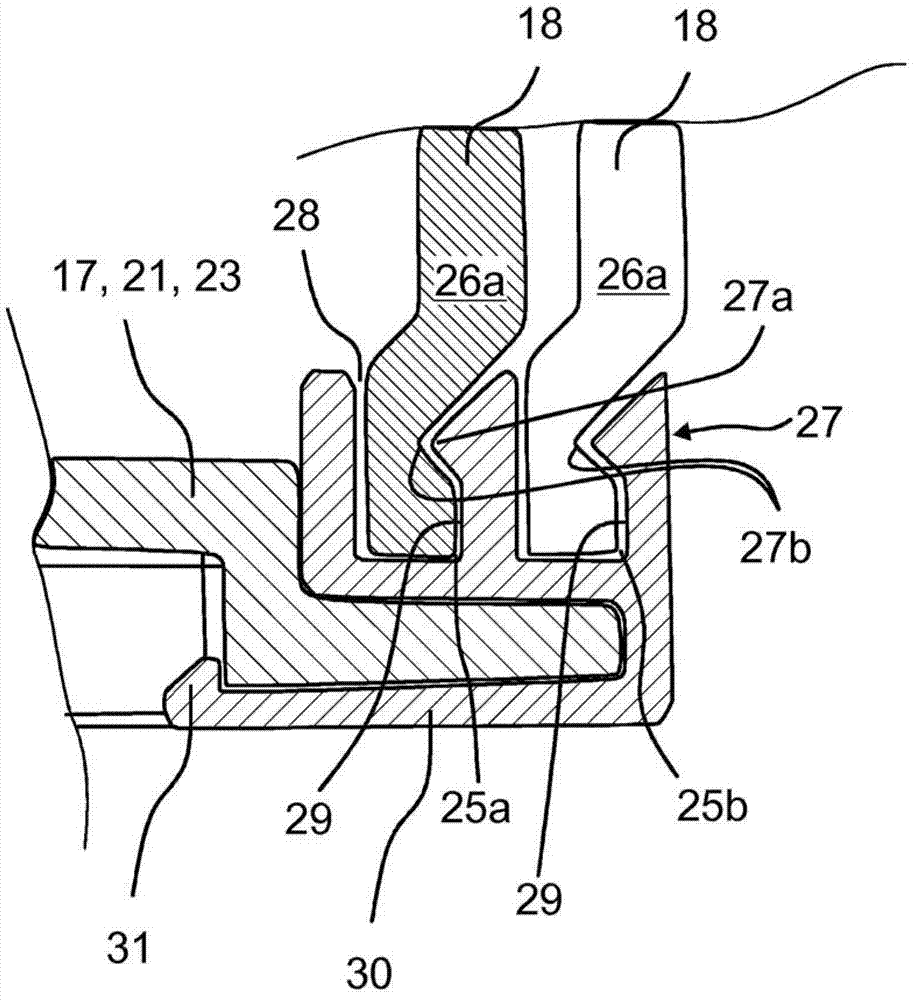

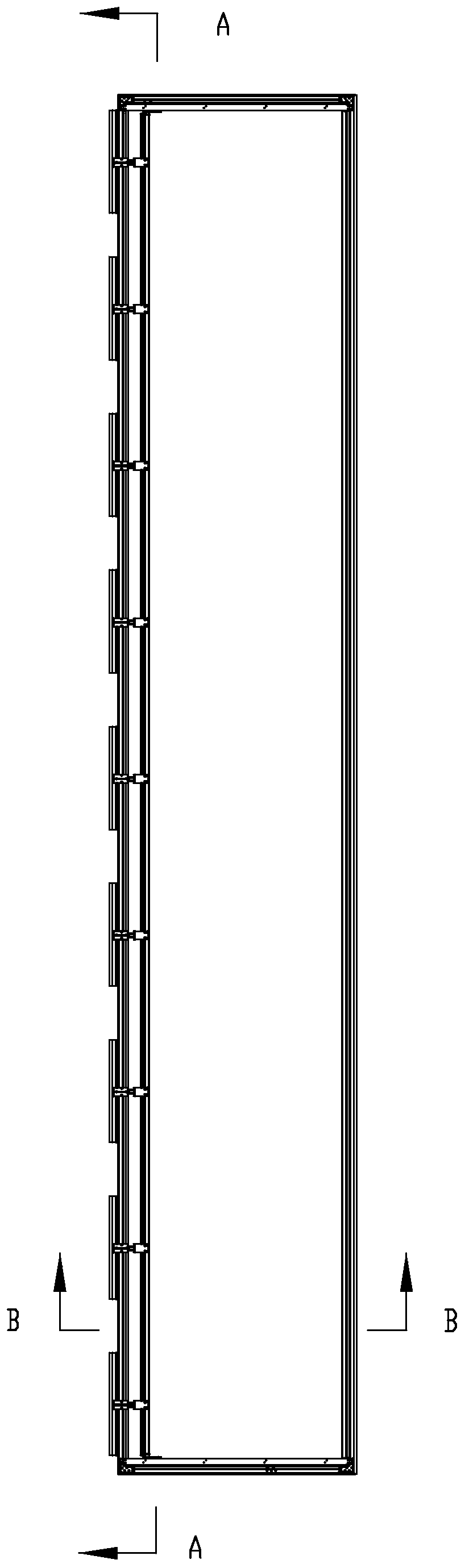

Refrigerator comprising a storage compartment with a sliding door

ActiveCN102782428AReduce or eliminate the risk of looseningPrevent looseningDomestic cooling apparatusLighting and heating apparatusPlastic materialsEngineering

The invention relates to a refrigerator, especially a household refrigerator (1), comprising a storage compartment (17) for products to be refrigerated, that can be closed by at least one sliding door (18) comprising at least one guiding section (26a, 26b) mounted in a movable manner in an associated groove (25a, 25b) of the storage compartment (17). According to the invention, the at least one guiding section (26a, 26b) and the associated groove (25a, 25b) are formed in the region of contacting storage surfaces with a combination of different materials, especially plastic materials, and / or the at least one guiding section (26a, 26b) is held in the associated groove (25a, 25b) by an engaging means (27).

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Self-aligning roller bearing

ActiveCN104791380AEasy to assembleLimit gyroscopic motionRolling contact bearingsBearing componentsSpherical roller bearingEngineering

A self-aligning roller bearing comprises an outer ring, an inner ring arranged inside the outer ring, a retainer which is positioned between the outer ring and the inner ring and has a pocket and two columns of rollers which are circumferentially arranged at intervals and positioned inside the pocket. The outer ring is axially divided into two outer-ring units. A guide ring is axially arranged between the two outer-ring units. The guide ring radially extends between the two columns of rollers and is positioned on the outside of the retainer. According to the invention, the problem that existing self-aligning roller bearings are complex to assemble and bearings are easy to deform during assembling of the bearings is solved, the influence of gyratory motion of the rollers is minimized, and the difficulty of processing the outer ring in the wide series self-aligning roller bearing is reduced.

Owner:SCHAEFFLER TECH AG & CO KG

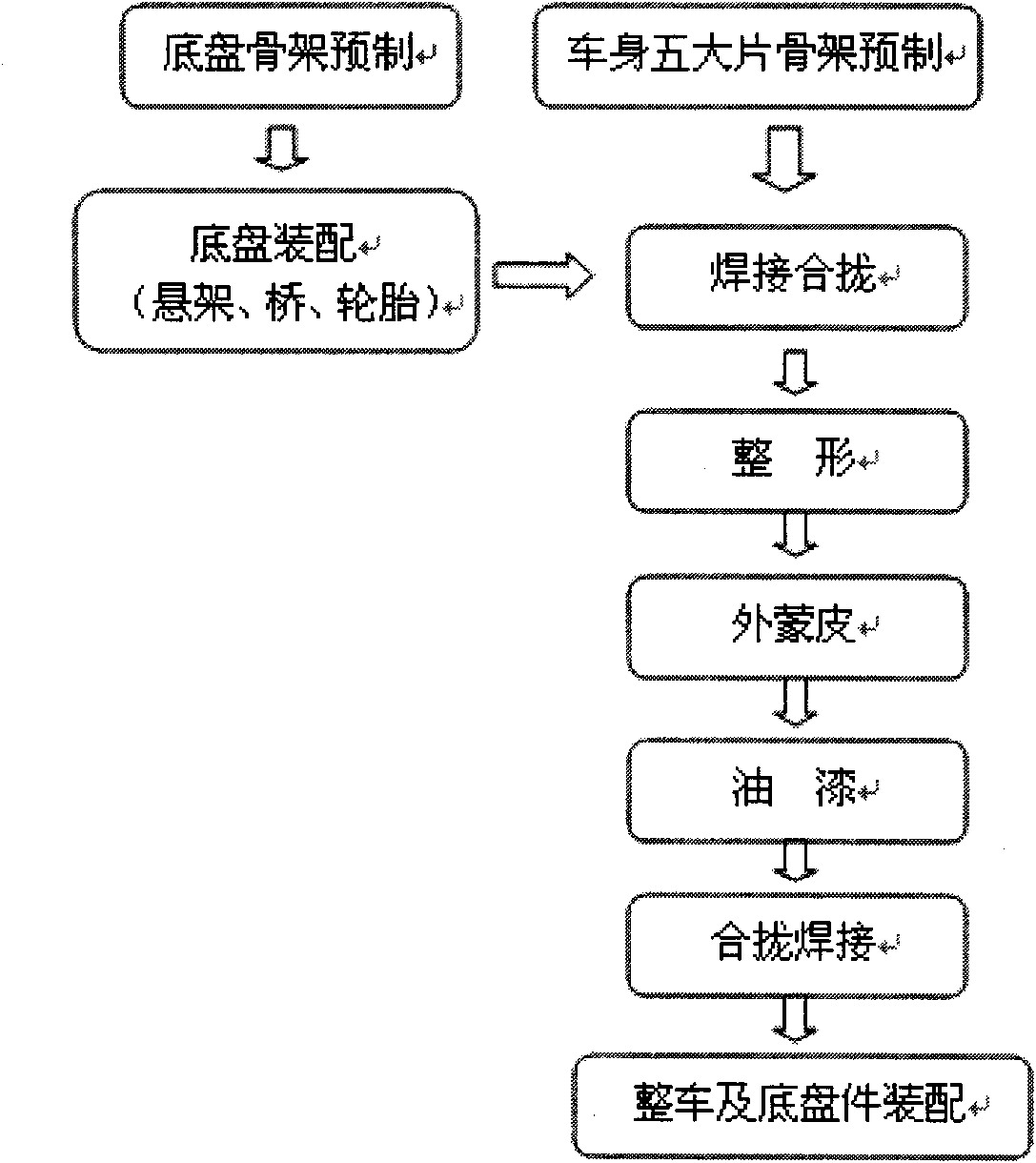

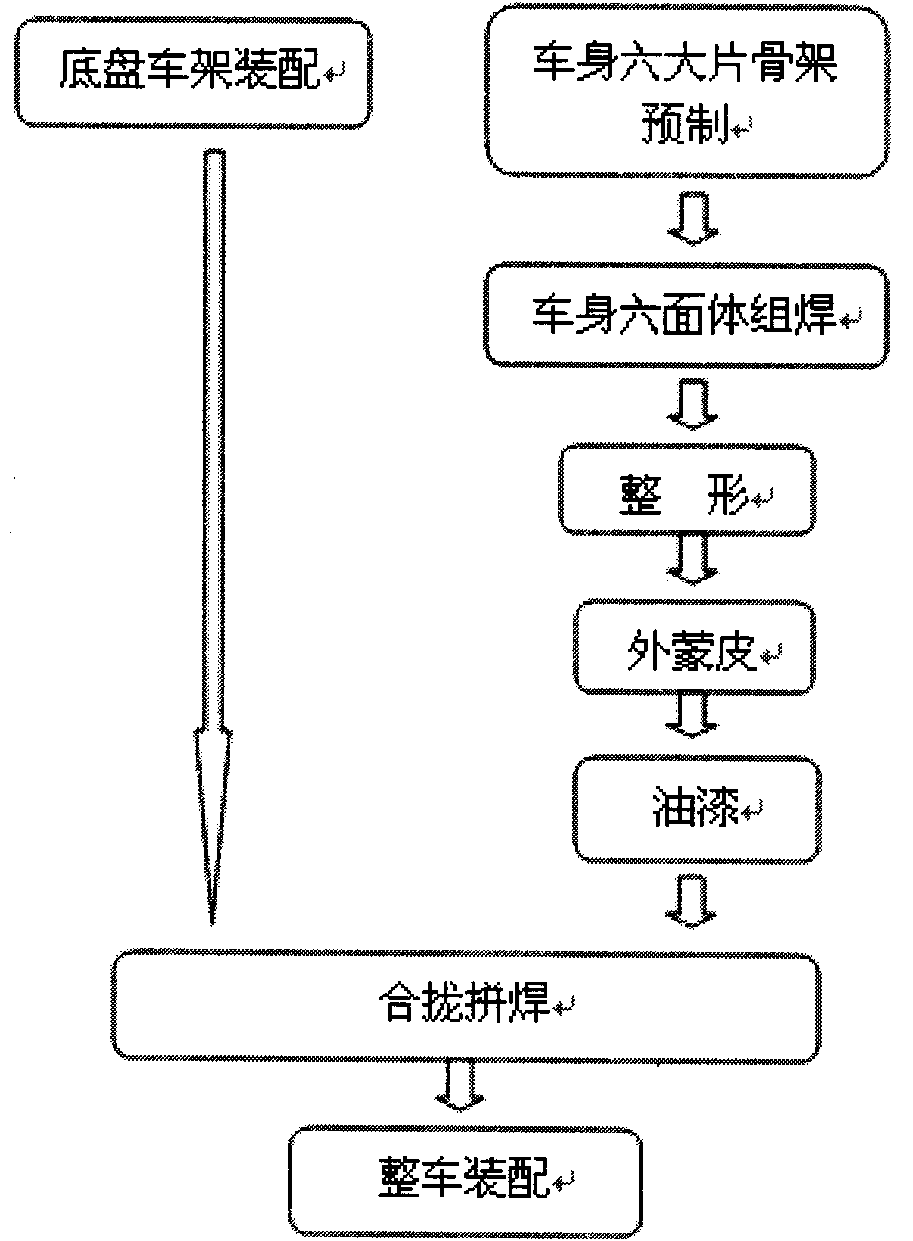

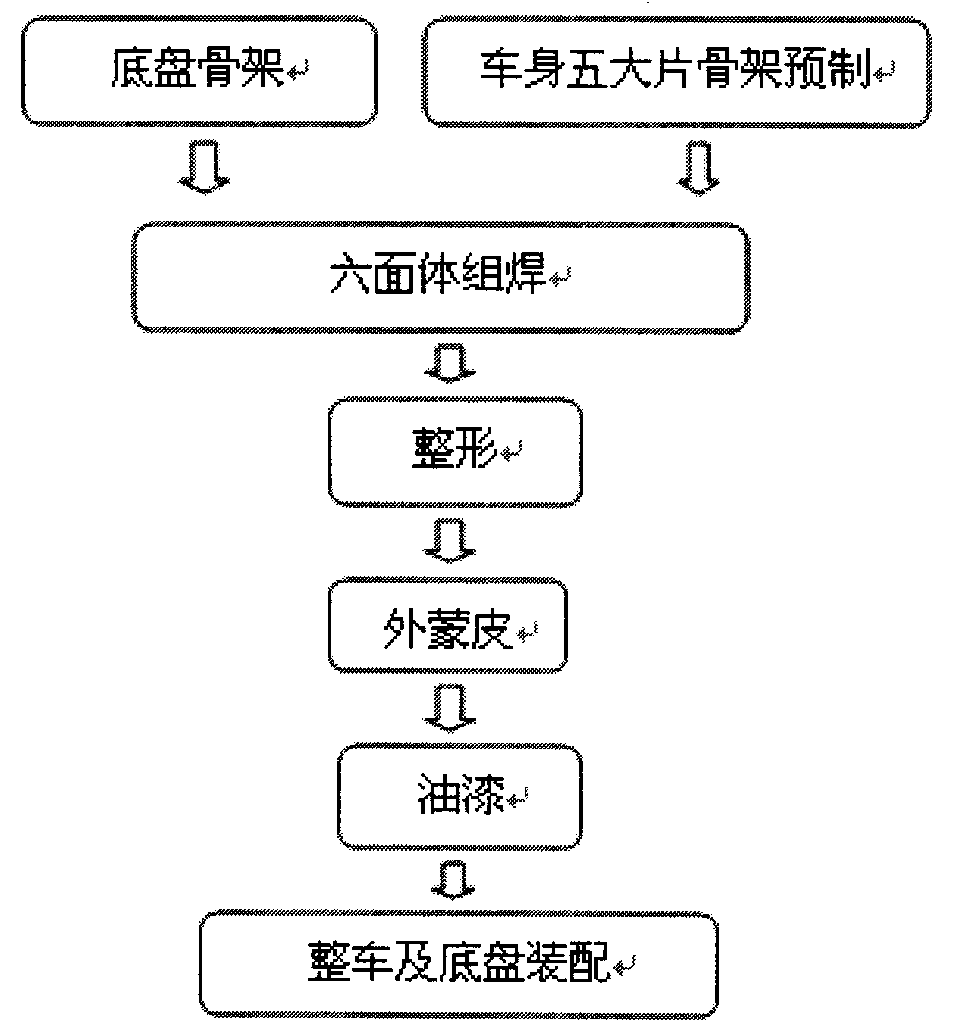

Skeleton assembly process of full-loading passenger car

InactiveCN102107692AGuaranteed accuracyMeet the dimensional accuracy requirementsVehiclesEngineeringWeld seam

The invention discloses a skeleton assembly process of a full-loading passenger car, which is characterized by comprising: after prefabricating the chassis skeleton, directly assembling a suspension rack, a bridge and tires, then welding and merging the prefabricated five skeletons of the car body with the assembled suspension rack, bridge and tires; and assembling the whole car and the chassis accessories via welded seam polishing, skeleton calibration, external covering and painting. Compared with the existing skeleton assembly process of the full-loading passenger car, the assembly process can be matched with the existing work position procedures without increasing apparatus investment in the prior art; and the difficulty in assembling the suspension and the bridge due to a small operation space in the prior art is reduced, the deformation of the chassis caused by non-uniform stress can be avoided, the precision of the sizes of the skeleton parts can be ensured, the assembly cost is lowered and the assembly efficiency the improved.

Owner:HENAN SHAOLIN AUTO

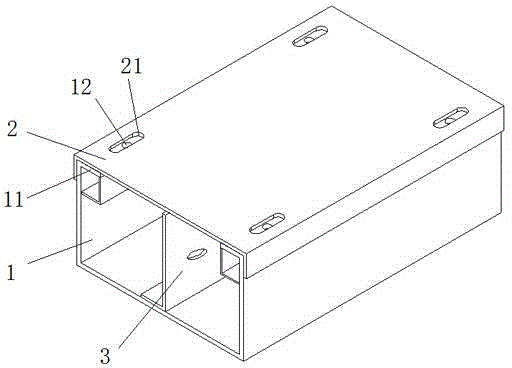

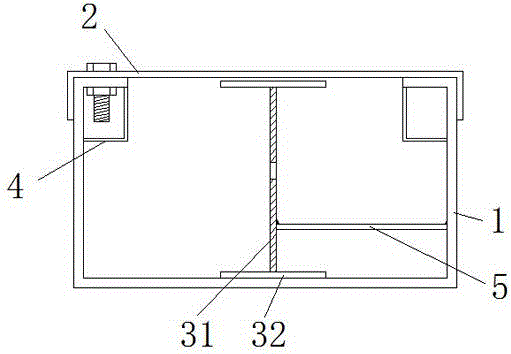

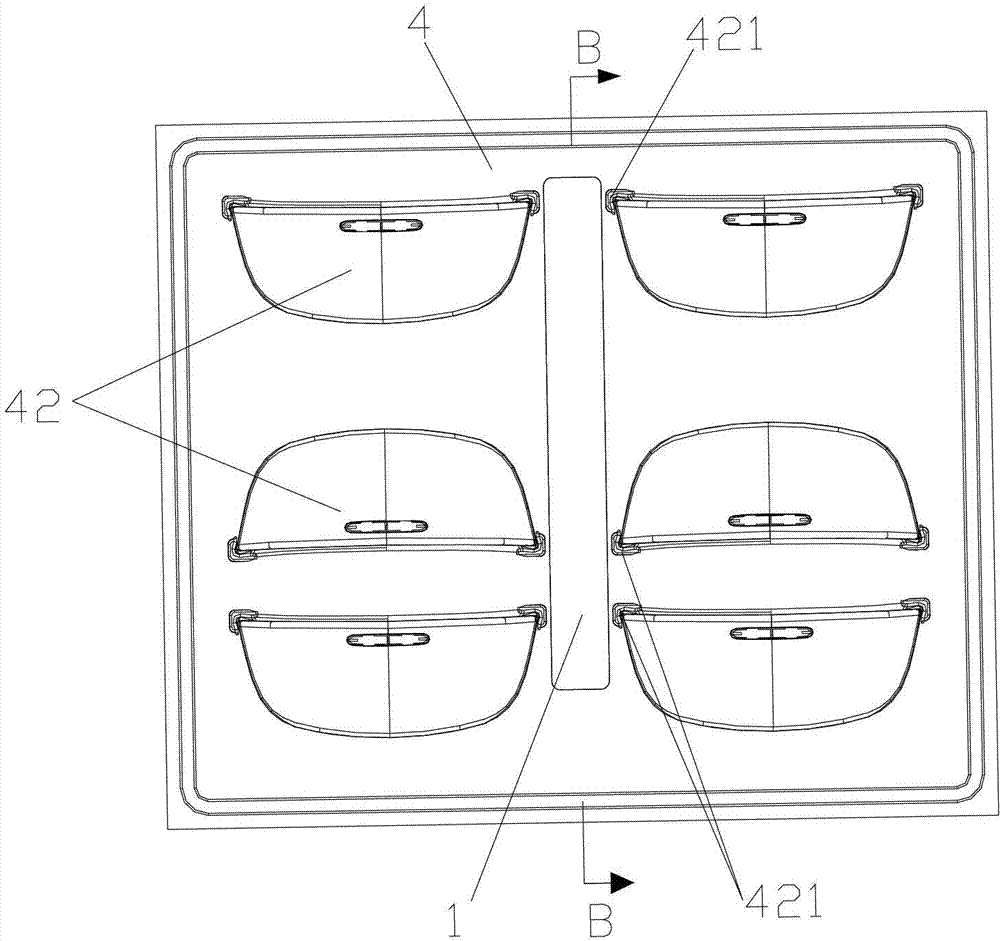

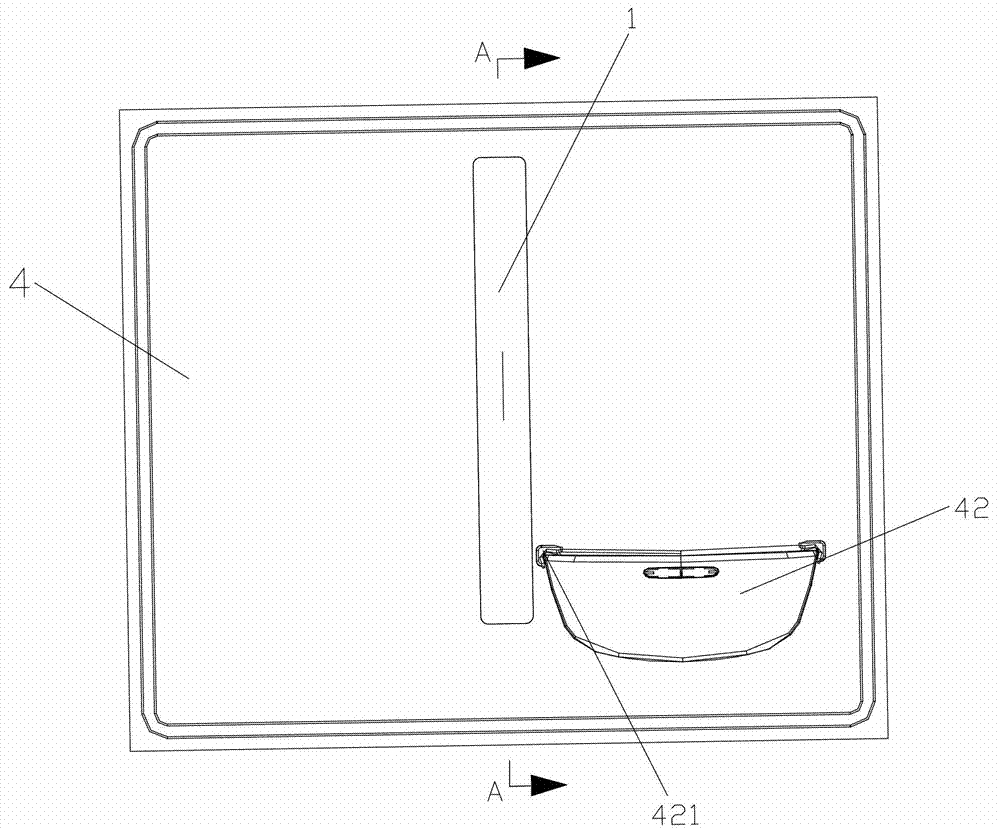

Safe computer room trunking

InactiveCN104466832AWill not deformDoes not cause deformationElectrical apparatusTrunkingEngineering

A safe computer room trunking comprises a bottom box and a cover plate, where the upper end of the bottom box is open. A bearing edge bending towards the interior of the bottom box and used for supporting the cover plate is arranged at the upper end of the bottom box, a threaded hole is formed in the bearing edge, a long-strip hole is formed in the position, corresponding to the threaded hole, of the cover plate, and the cover plate and the bottom box are fixed in the manner that a bolt penetrates through the threaded hole and the long-strip hole at the same time; a separation board is arranged inside the bottom box, wherein the separation box and a channel inside the bottom box are identical in direction. According to the safe computer room trunking, the bottom box and the cover plate are connected through the bolt, the connection mode is simple, connection is firm, and deformation of the trunking can be avoided. In addition, the separation box is arranged inside the bottom box to separate wires, later check is facilitated, and accidents caused by disorder of the wires can be avoided. The separation board also can play a role of supporting the cover plate, so the strength of the cover plate is enhanced.

Owner:BRAUN ELEVATOR CO LTD

Blister mold

Owner:SHANGHAI TONGLING AUTOMOTIVE TECH INC

Vibration screen mesh easy to assemble and disassemble

InactiveCN108435534AEasy to take outDoes not cause deformationSievingScreeningMechanical engineeringTextile

The invention discloses a vibration screen mesh easy to assemble and disassemble. The vibration screen mesh easy to assemble and disassemble comprises a plurality of screen meshes, wherein an upper notch is arranged on the top part of each screen mesh; a lower bulge is arranged on the bottom part each screen mesh; each lower bulge can be placed fitting to the corresponding upper notch; a sealing rubber strip is adhered and fixed to the bottom part of each lower bulge, is hollow, and is in an annular shape after being adhered; the inner diameter of each annular shape is larger than the outer diameter of screen cloth; one end of each sealing rubber strip is sealed; the other end of each sealing rubber strip stretches out of the outer side of each screen mesh; and a ball part air bag is arranged at the stretching end of each sealing rubber strip. According to the vibration screen mesh easy to assemble and disassemble provided by the invention, principles of hollow sealing rings and sucking balls are ingeniously utilized, and each two adjacent layers of screen meshes are automatically separated after the screening is accomplished, so that the operation can be carried out simply and conveniently, the testing accuracy of the screen mesh cannot be affected, and the service life of the screen mesh is prolonged.

Owner:叶子豪

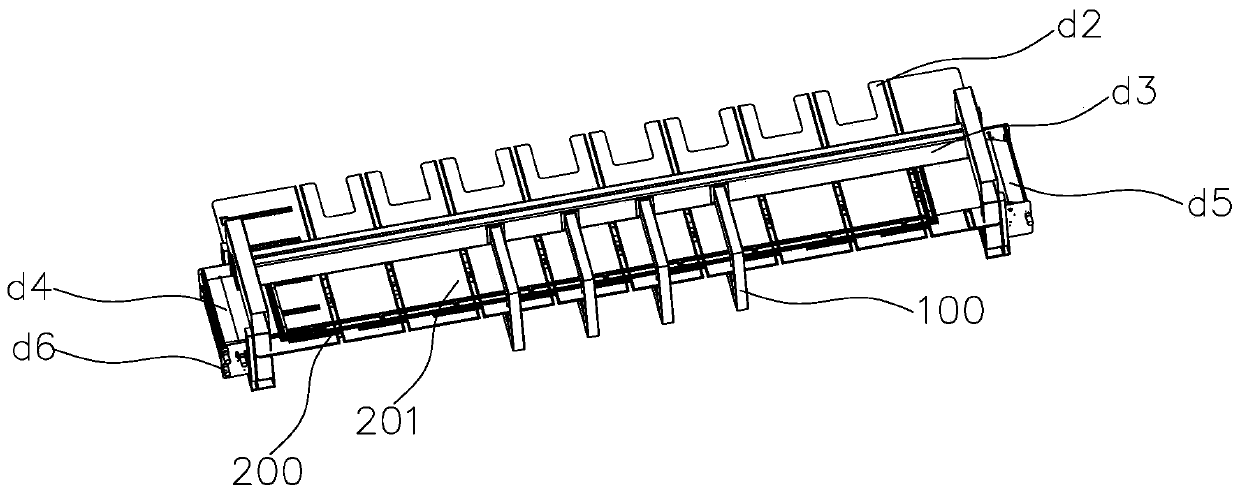

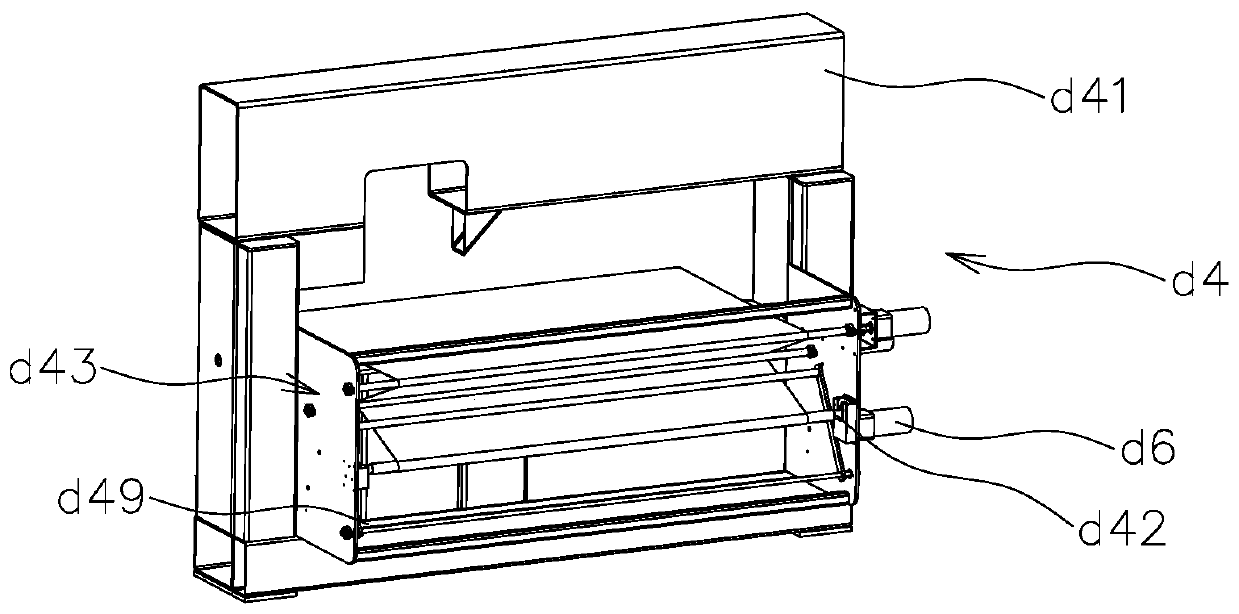

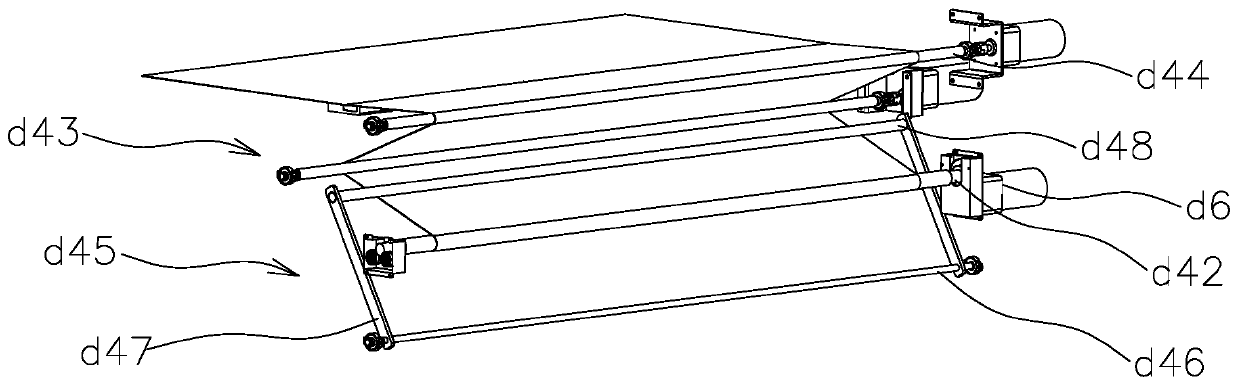

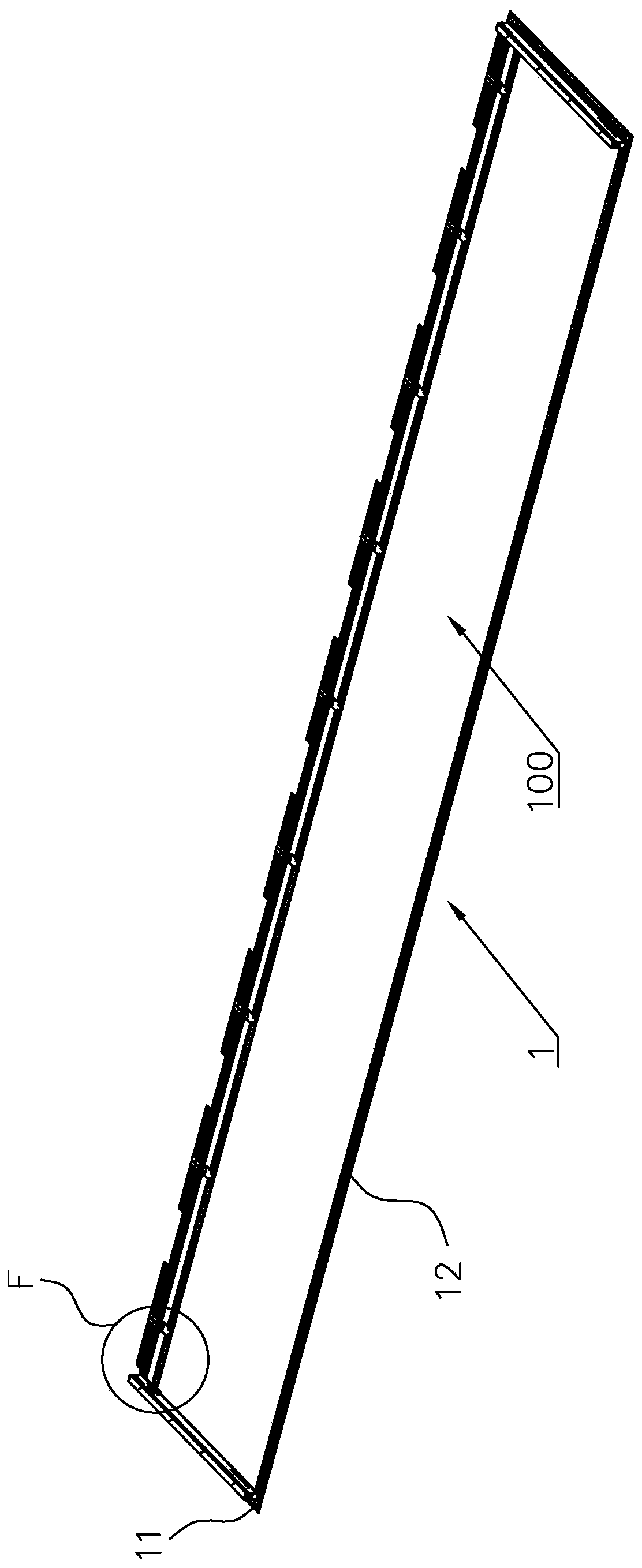

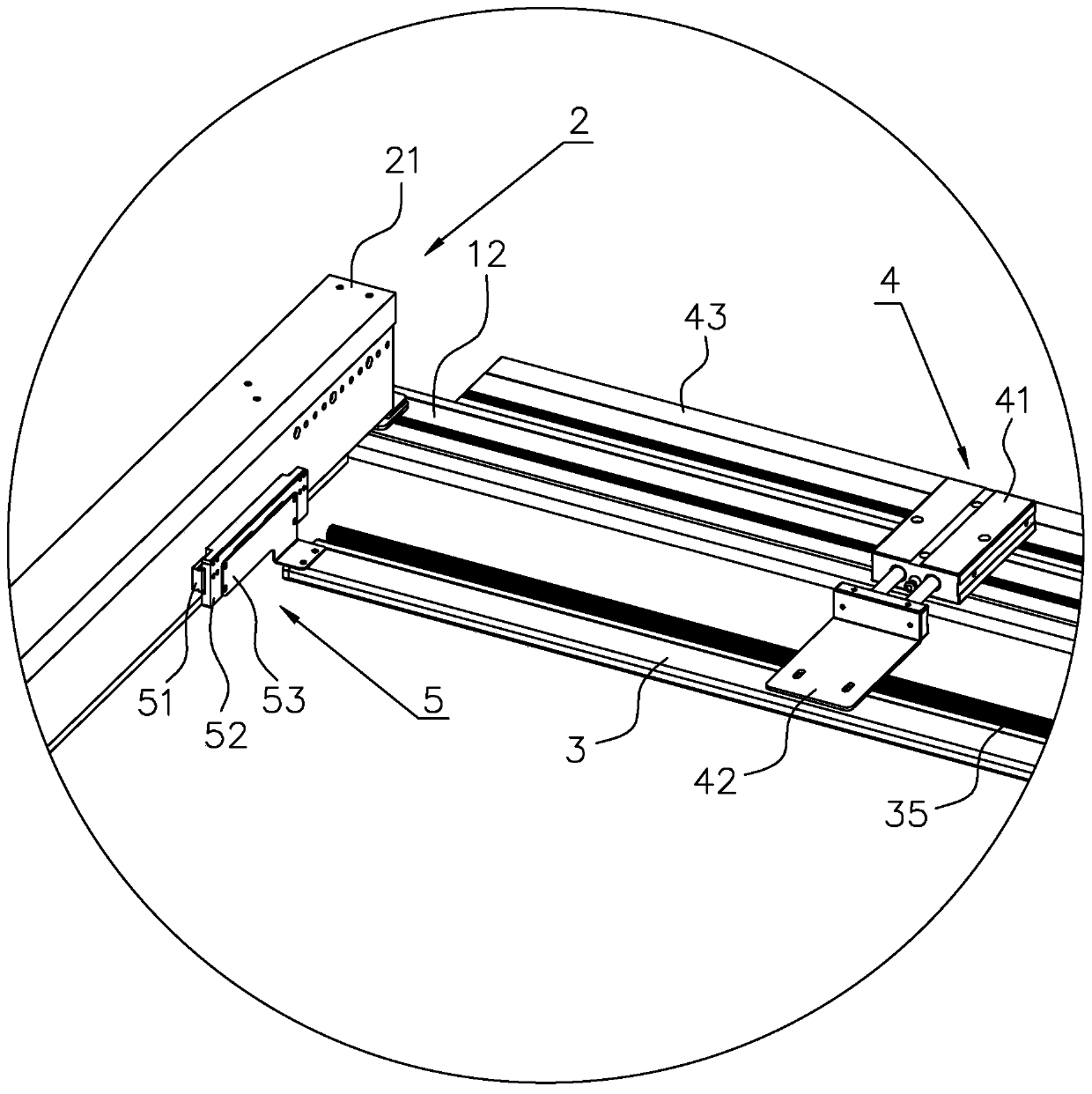

Automatic cloth clamping and changing embroidery equipment with left and right cloth rollers

PendingCN110607617AReduce operating proceduresIncrease productivityFeedersTextileMechanical engineering

The invention belongs to the technical field of embroidery equipment, and particularly relates to automatic cloth clamping and changing embroidery equipment with left and right cloth rollers. The automatic cloth clamping and changing embroidery equipment with the left and right cloth rollers comprises a rack, wherein a bedplate which is arranged under cloth in an embroidery process is arranged onthe rack; an cloth clamping air frame is arranged on the bedplate and connected with the rack; an embroidering area is arranged in the center of the cloth clamping air frame; a mounting beam is arranged over the bedplate and connected with the rack; a first cloth roller assembly and a second cloth roller assembly for cloth winding are respectively arranged at two ends of the rack; and a driving assembly is further connected to the first cloth roller assembly and / or the second cloth roller assembly, and can drive the first cloth roller assembly or the second cloth roller assembly to rotate. Thecloth is clamped by the cloth clamping air frame, and the first cloth roller assembly and the second cloth roller assembly are arranged at the two ends of the rack respectively, so that the cloth isensured to be in a straightening state in the embroidering and conveying processes, the cloth does not need to be cut into pieces in specified sizes before embroidering, the operation process is saved, and the production efficiency is improved.

Owner:赵海

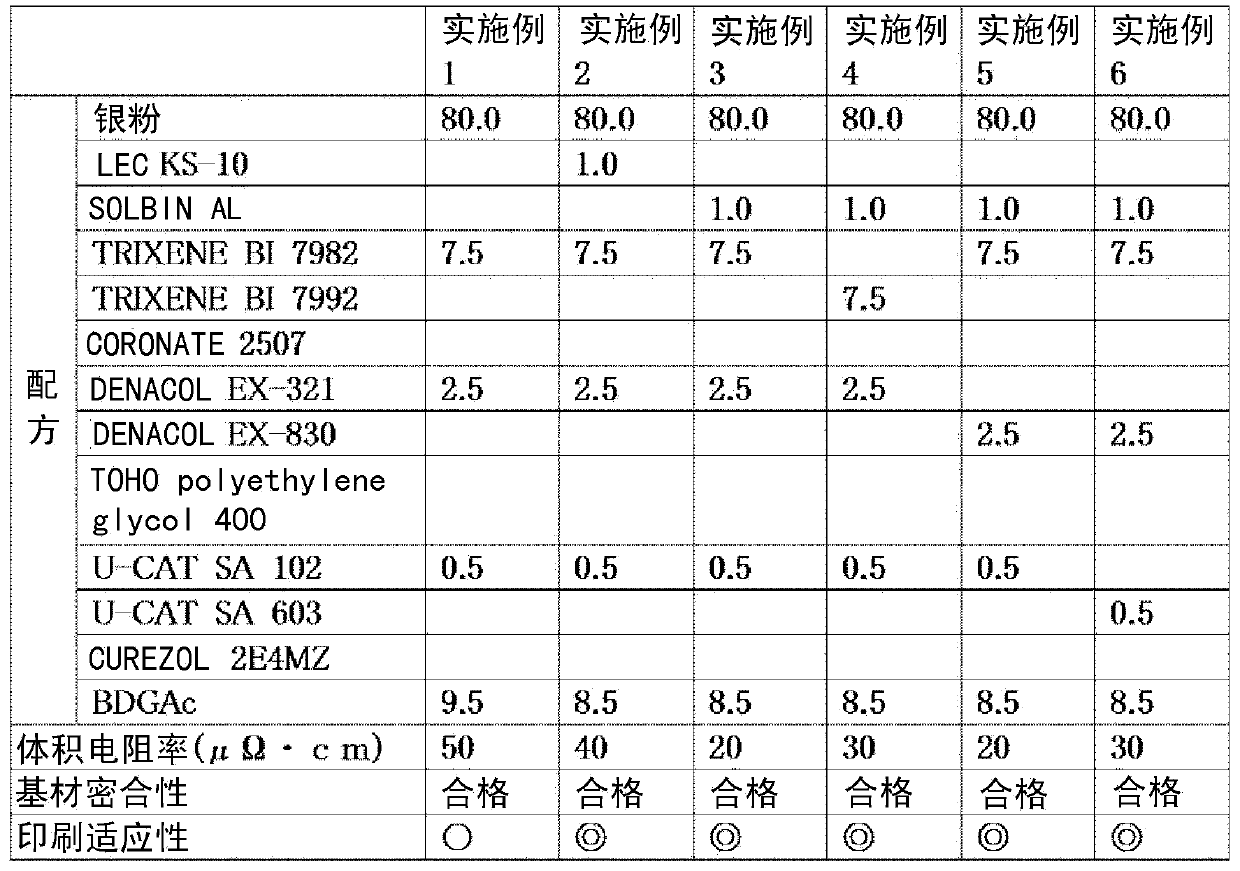

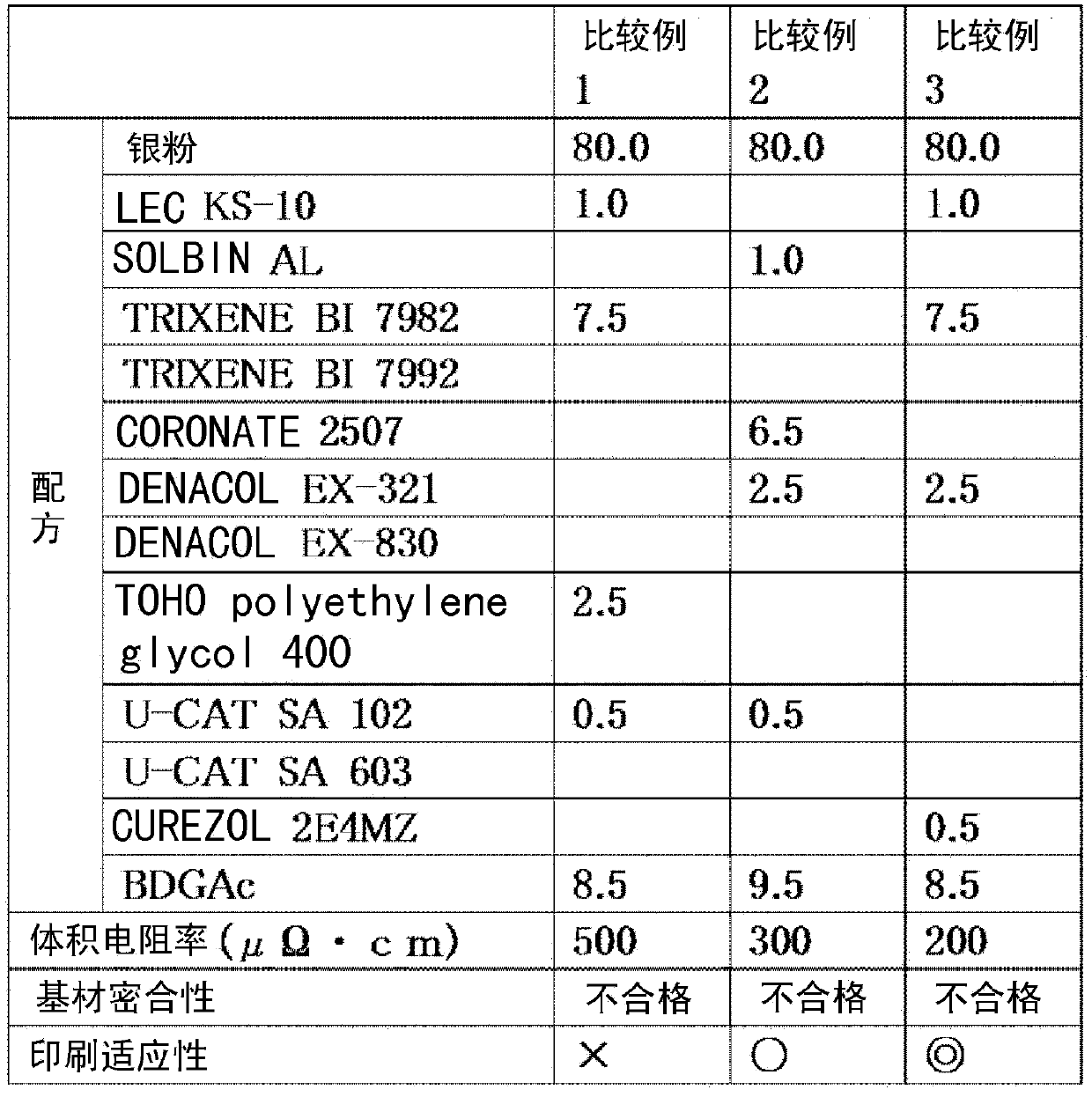

Conductive ink composition, method for producing conductive patterns, and conductive circuit

ActiveCN104204114ADoes not cause deformationImprove conductivityConductive layers on insulating-supportsConductive materialOrganic solventPhysical chemistry

Owner:DIC CORP

Stacker for plate members, method for stacking plate members, and stacked plate members

Owner:SHOWA DENKO KK

Blood vessel bracket prosthesis

ActiveCN102100587BDoes not cause deformationNo discountStentsBlood vesselsTectorial membraneProsthesis

Owner:SHANGHAI MICROPORT ENDOVASCULAR MEDTECH (GRP) CO LTD

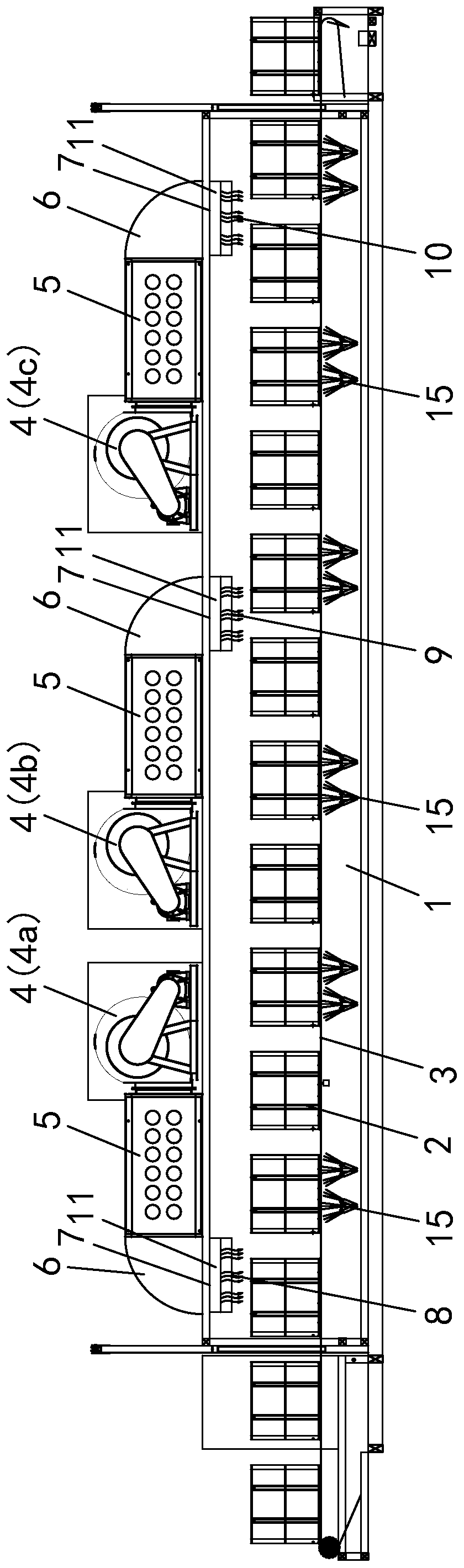

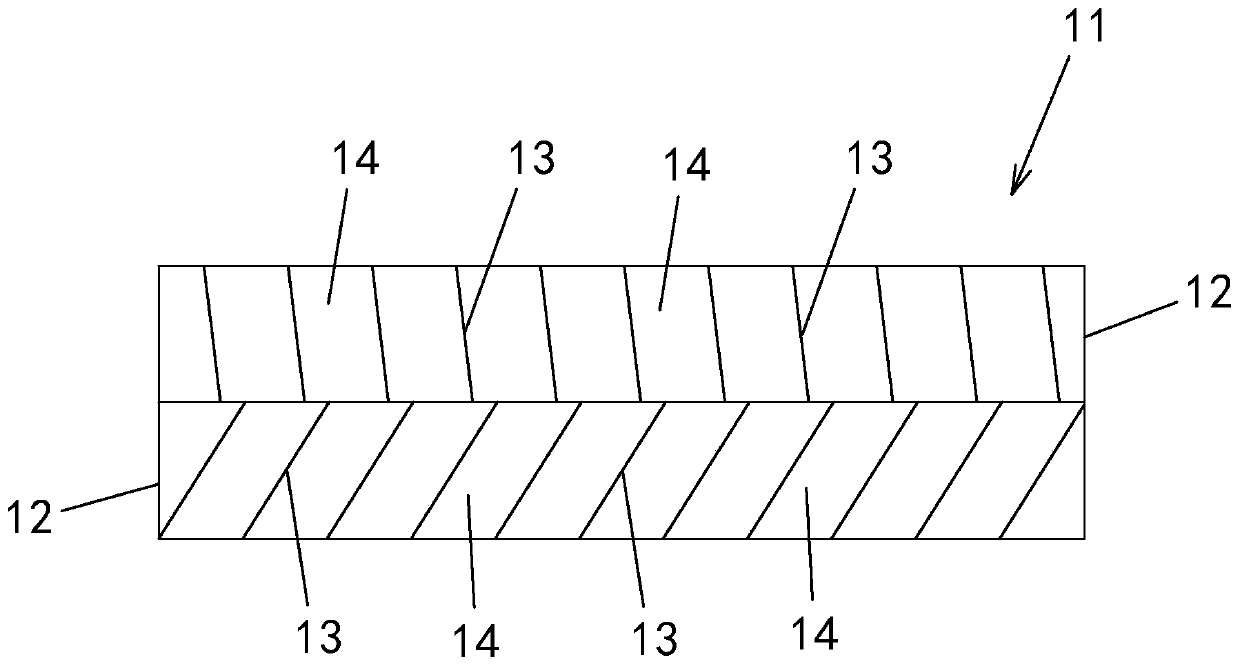

Drying equipment for metal sheet

The invention relates to drying equipment for a metal sheet. The drying equipment comprises a drying cavity. A hot air circulating motor heats blown air through a heating box body and blows the hot air into the drying cavity from top to bottom through an air outlet pipeline. A plurality of air outlets of the air outlet pipeline are uniformly formed in the upper part of the drying cavity, so that primary pre-drying air outlet, secondary drying air outlet and third dry air outlet are achieved. The drying equipment also comprises a wind direction adjusting device arranged corresponding to the airoutlets. The wind direction adjusting device comprises a wind direction adjusting plate which is composed of a plurality of guide plates which are horizontally spaced and arranged obliquely. Guide air ducts are formed between adjacent guide plates. As the air outlet pressure and temperature are relatively low, the metal sheet is not deformed, and meanwhile, as many air outlet directions are available and blow air is uniform, parts of the metal sheet can be fully dried. The drying equipment has the advantages of being high in drying efficiency and good in drying effect.

Owner:CHIA CHANG TECHNOLOGY (SUZHOU) CO LTD

Chip packaging outer lead wire molding die

InactiveCN101312112AGood coplanarityWill not deformSolid-state devicesSemiconductor/solid-state device manufacturingForming processesMinimum distance

Owner:SEMICON MFG INT (SHANGHAI) CORP

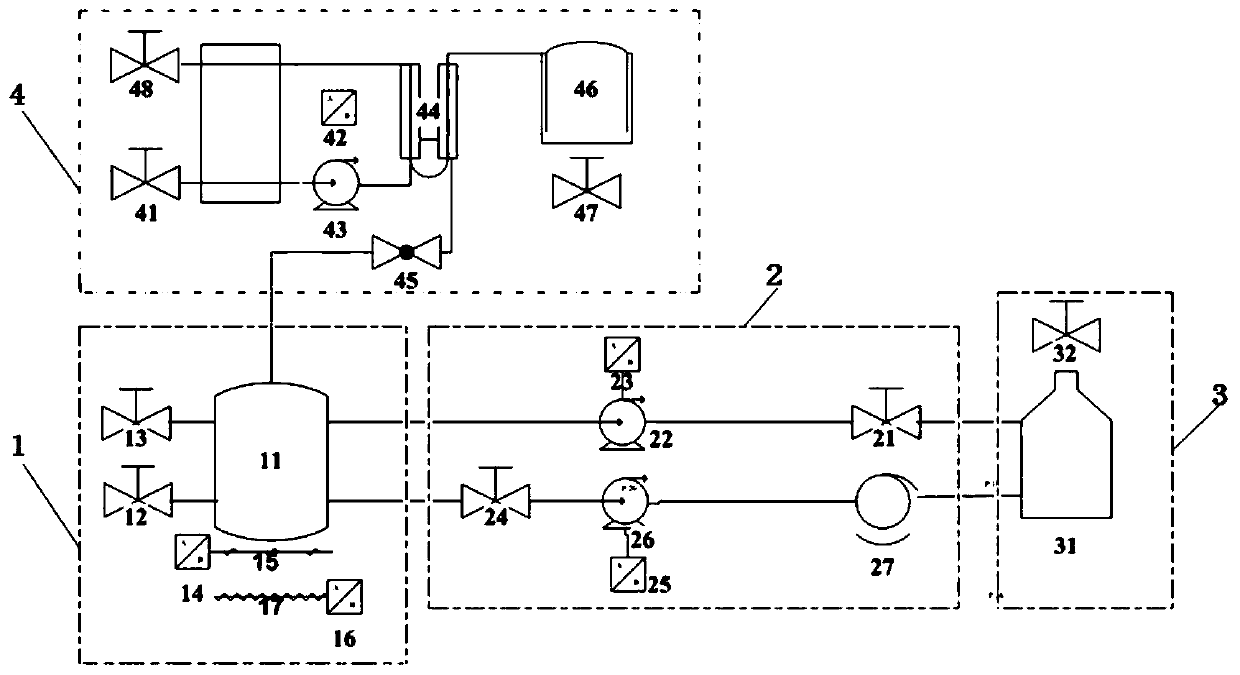

Deacidification system for paper record files and using method thereof

PendingCN110241652AGood deacidification effectExtend shelf lifeOld paper after-treatmentMaterial resourcesLiquid storage tank

The invention relates to a deacidification system for paper record files and a using method thereof. The method comprises the following steps of: connecting dozens of bound paper record files in series through a special clamping bracket, soaking the bound paper record files in a soaking tank in a whole, performing ultrasonic deacidification treatment, condensing a waste gas escaping from the top of the soaking tank, storing the waste gas in a recovery tank, pumping deacidified deacidification liquid to a filter to filter impurities, and then returning the deacidification liquid to a liquid storage tank for reuse. The deacidification system can process dozens or hundreds of files in batch at one time, shows good deacidification effect and greatly saves manpower and material resources.

Owner:HUBEI TAIDEANXIN INFORMATION TECH CO LTD

Cloth clamping air frame of embroidery equipment

The invention discloses a cloth clamping air frame of embroidery equipment, which comprises a rectangular frame arranged on a rack; two opposite sides of the rectangular frame are respectively provided with cloth pressing mechanisms; other two opposite sides of the rectangular frame are respectively fitted with side cloth clamping strips, and the two cloth pressing mechanisms and the side cloth clamping strips form an embroidery area by enclosing; each side cloth clamping strip is provided with a side cloth clamping area and a narrow channel whereby the side cloth clamping area and the embroidery area are communicated with each other, the length of the side cloth clamping area is equal to that of the embroidery area, and the two ends of the side cloth clamping area are provided with openings for the edge of the embroidery cloth to enter and exit; at least one side clamping cloth strip is in sliding connection with the rectangular frame, and a tensioning mechanism for driving the side clamping cloth strip away from or close to the other side clamping cloth strip is further arranged on the rectangular frame. The side cloth clamping area can provide integral clamping for the edge of the embroidery cloth, the stress at each position of the edge of the embroidery cloth is uniform, deformation cannot occur, and the final embroidery result is ensured; the tensioning mechanism can adjust a distance between the two side clamping cloth strips and can adjust the tensioning state of the embroidery cloth in the clamping process.

Owner:赵海

Ultrasonic sensor having a deflecting element

ActiveCN105518450ADoes not cause deformationMaterial analysis using sonic/ultrasonic/infrasonic wavesMachines/enginesPropagation timeEngineering

The invention relates to an ultrasonic sensor for performing a propagation-time measurement in a liquid, comprising an ultrasound transmitter and a deflecting element made of plastic, into which deflecting element the ultrasound pulses emitted by the ultrasound transmitter are conducted, which ultrasound pulses are deflected on a boundary surface within the deflecting element by reflection. A hermetically sealed air bag is arranged inside the deflecting element. A wall of said air bag forms the plastic / air boundary surface for reflecting the ultrasound pulses. Such an ultrasonic sensor ensures especially good functional capability of the deflecting element over a long time period, while said ultrasonic sensor is economically produced.

Owner:VTESCO TECH GMBH

A kind of manufacturing technology of anti-counterfeit metal cover and anti-counterfeit metal cover

InactiveCN102275676AAdvanced technologyExcellent product effectClosure with auxillary devicesSynthetic resin layered productsStamping processCost savings

The invention relates to a manufacturing process of an anti-counterfeit metal cover, in particular to a process of transferring information patterns to a metal surface by using a film as a carrier and stamping to form an anti-counterfeit metal cover, and the anti-counterfeit metal cover produced by the process. A manufacturing process of an anti-counterfeiting metal cover according to the present invention, the process is characterized in that it also includes the following steps: a composite process: further coating and curing an adhesive layer on the information protection layer, and compounding the film and the metal surface to position the film Adhere to the metal surface; peel off the film; stamping: In the stamping machine, the metal in the above steps is positioned and stamped to form an anti-counterfeiting metal cover. The invention uses the film as the carrier to transfer the information pattern, and the product effect is more superior; the precise positioning of the information pattern on the metal surface is realized; the film can be peeled off after compounding, so that the subsequent processing of the metal will not be affected, and it can be punched out according to the demand. A metal cover of a specific shape. And the stripped film is recycled, which greatly saves the cost.

Owner:陈炜玲

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com