Cloth clamping air frame of embroidery equipment

An embroidery and cloth clamping technology, which is applied in the field of embroidery equipment, can solve problems such as easy deformation of embroidery cloth, influence on embroidery effect, and difficulty in ensuring uniform and flat state of embroidery cloth, so as to achieve the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

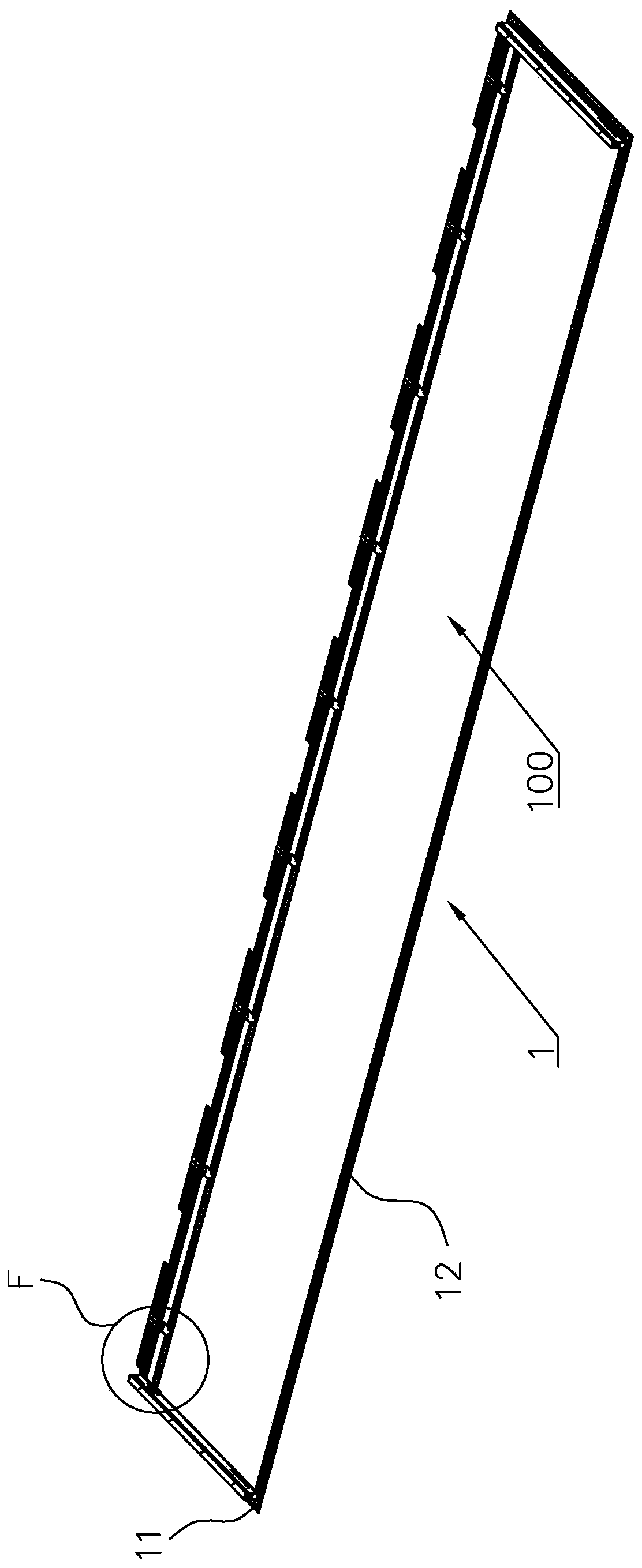

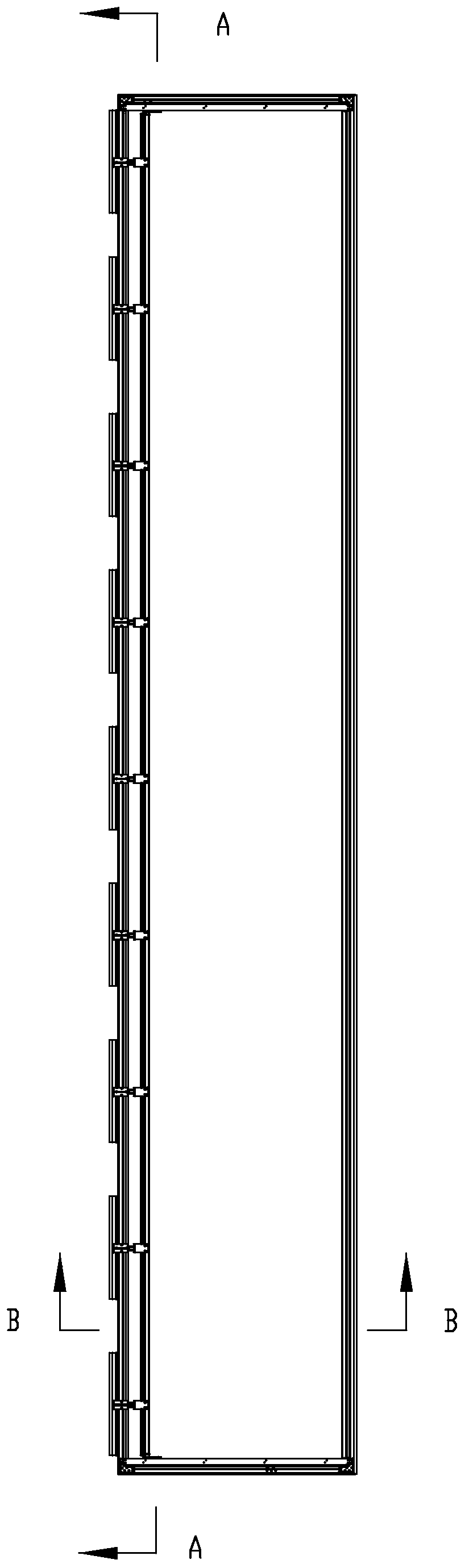

[0043] Such as figure 1 and image 3 As shown, the air frame for clamping cloth of embroidery equipment in this embodiment includes a rectangular frame 1 arranged on the frame, two wide sides 11 of the rectangular frame 1 are respectively provided with a cloth pressing mechanism 2, and two cloth pressing mechanisms 2 They are respectively used to compress the head end and tail end of the embroidery cloth to be embroidered; along the long side 12 of the rectangular frame 1, two side clamping cloth strips 3 are relatively arranged on the inner side of the rectangular frame 1, and the side clamping cloth strips 3 are used For clamping and fixing the two opposite edges of the embroidered cloth, the two cloth pressing mechanisms 2 and the cloth clamping strips 3 on both sides enclose an embroidery area 100 .

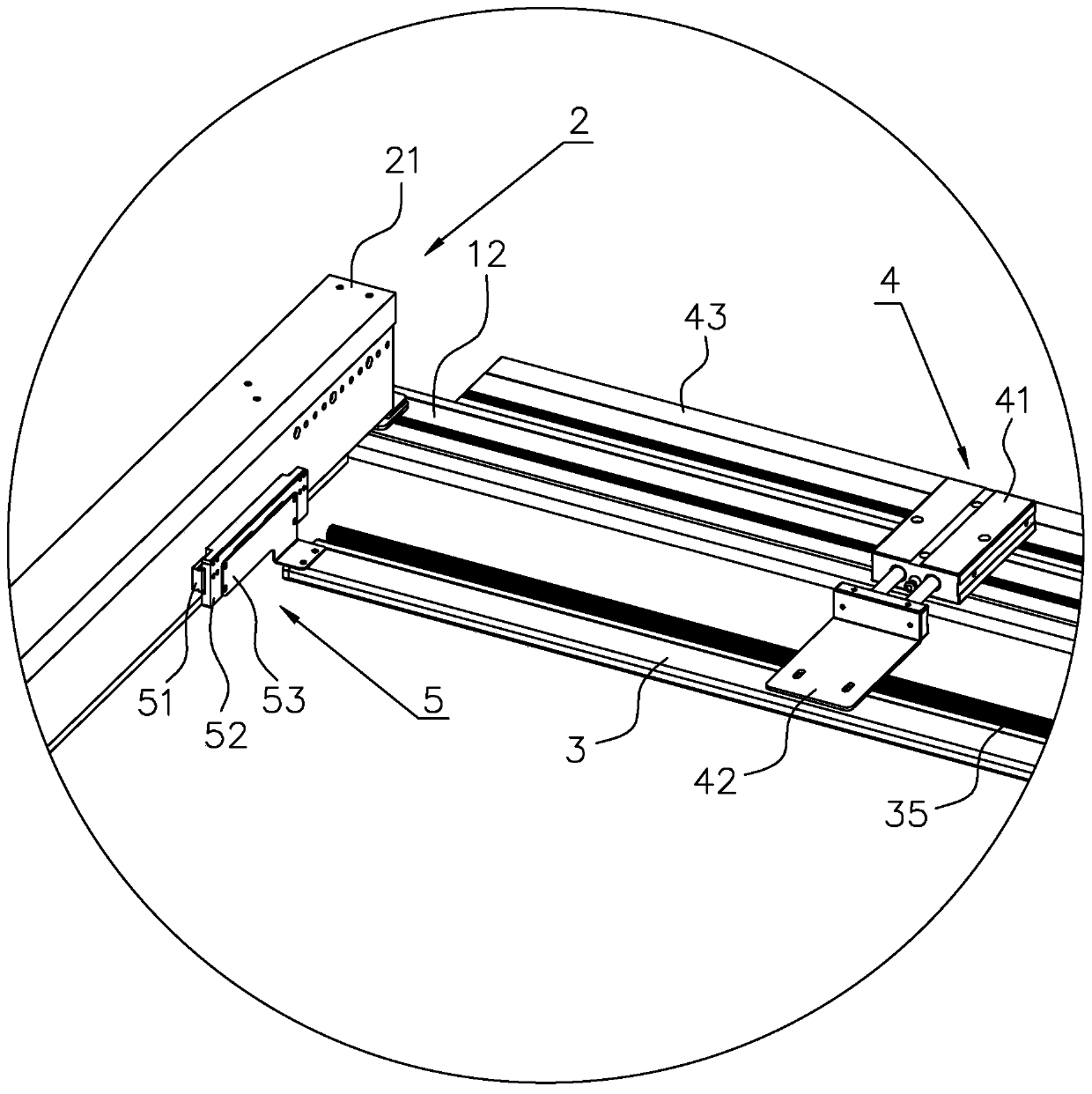

[0044] Such as figure 2 and Figure 6 As shown, in this embodiment, the cloth pressing mechanism 2 includes a section bar 21 fixedly installed on the rectangular frame 1, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com