Anisotropic rubber material and preparation method thereof

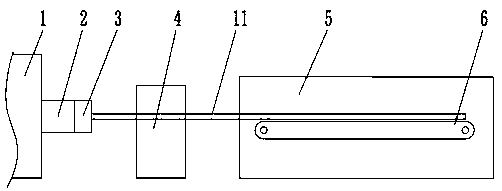

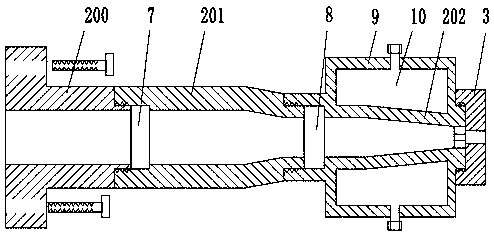

A rubber material and anisotropic technology, applied in the field of anisotropic rubber material and its preparation, can solve the problems of tensile deformation, affecting water vapor sealing, shielding effect, etc. heterosexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

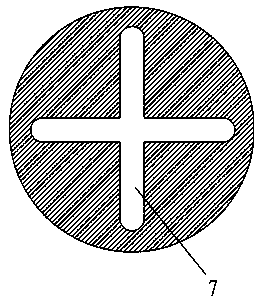

[0036] The anisotropic rubber strip of present embodiment and preparation method are as follows:

[0037] 1) Mix aminopropyltriethoxysilane and purified water at a ratio of 1:10, stir for 10 minutes to fully hydrolyze the coupling agent, and add glass fibers with a ratio of 1:1 to purified water, with a diameter of about 3 μm and a long diameter The ratio is about 100. After stirring for 10 minutes and standing still for 20 minutes, put it into an oven for drying treatment. The drying condition is 120°C for 4 hours. After drying, it is cooled, and the cooled short fiber material is put into an ultrasonic disperser for ultrasonic dispersion treatment. After the dispersion is completed, it is ready for use; 2) Put 100 parts of methyl vinyl silicone rubber (vinyl mole fraction 0.15%) raw rubber into the kneader, masticate at 30 ° C for 10 minutes, and then add 15 parts of gas phase method Silica (with a specific surface area of 200m 2 / g), 3 parts of hydroxyl silicone oil, af...

Embodiment 2

[0039] The anisotropic rubber strip of present embodiment and preparation method are as follows:

[0040]1) Mix 3-(3,4-epoxycyclohexyl)ethyltrialkoxysilane and purified water at a ratio of 1.5:10, stir for 10 minutes to fully hydrolyze the coupling agent, add 1 / 2 amount of pure water Lun nanofiber with a diameter of about 60nm and an aspect ratio of about 120, then add 1 / 2 glass fiber of pure water with a diameter of about 5μm and an aspect ratio of about 150, stir for 15 minutes, let it stand for 20 minutes, and then put it in an oven Carry out drying treatment, the drying condition is 120°C, 4h. After drying, it is cooled, and the cooled short fiber material is put into an ultrasonic disperser for ultrasonic dispersion treatment. After the dispersion is completed, it is ready for use; 2) Put 100 parts of methyl vinyl silicone rubber (vinyl mole fraction 0.15%) raw rubber into the kneader, masticate at 30°C for 10 minutes, and then add 10 parts of gas phase method Silica (w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com