High thermal adhesive strength and high barrier aluminum laminated film and production method thereof

A high-strength, aluminized film technology, applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problem of barrier performance, heat sealing performance reduction, unsafe use, and reduced shelf life of contents and other issues, to achieve the effects of enhanced tensile properties, uniform and dense aluminum plating process, and minimum cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

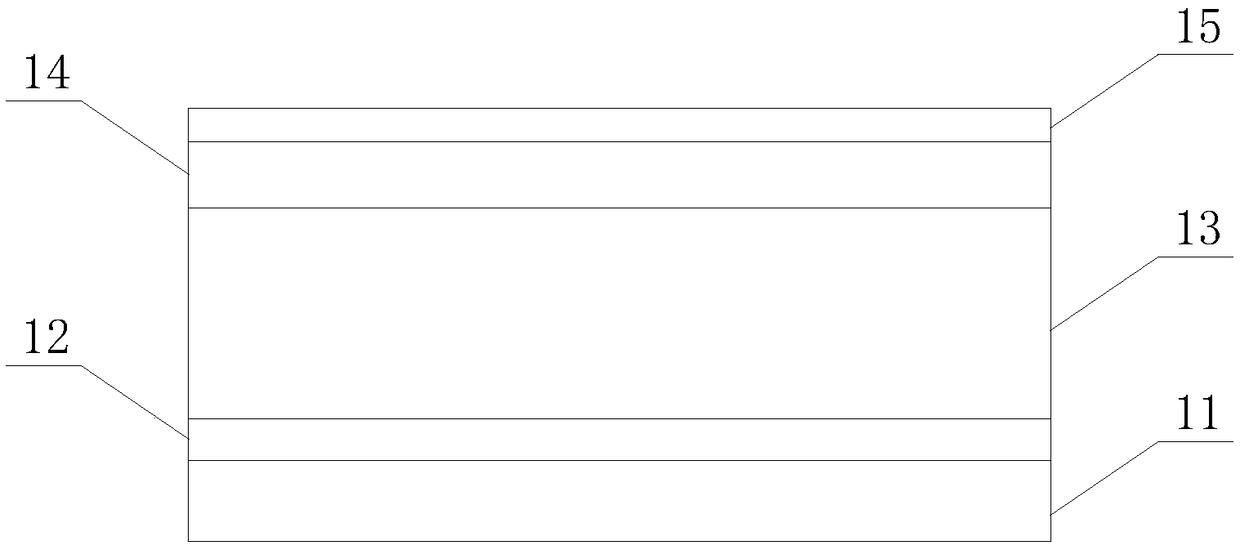

[0035] In the heat-sealing layer, the mass ratio of the ternary copolymerized PP and the blocking agent is 95:2, the second core layer includes homopolymerized PP, the first core layer includes random copolymerized PP, and the corona layer includes: The mass ratio of binary copolymerized PP, cycloolefin copolymer, and high viscoelastic body is 68:16:12, and the melt index of the high viscoelastic body is 6.5g / 10min; the thickness of the heat-sealing layer is 15 μm, and the The thickness of the second core layer is 50 μm, the thickness of the first core layer is 10 μm, and the thickness of the corona layer is 25 μm.

Embodiment 2

[0037] In the heat-sealing layer, the mass ratio of the ternary copolymerized PP and the blocking agent is 97:3, the second core layer includes homopolymerized PP, the first core layer includes random copolymerized PP, and the corona layer includes: The mass ratio of binary copolymerized PP, cycloolefin copolymer, and high viscoelastic body is 70:17:13, and the melt index of the high viscoelastic body is 7g / 10min; the thickness of the heat-sealing layer is 16 μm, and the first The thickness of the second core layer is 51 μm, the thickness of the first core layer is 9 μm, and the thickness of the corona layer is 24 μm.

Embodiment 3

[0039] In the heat-sealing layer, the mass ratio of the ternary copolymerized PP and the blocking agent is 99:4, the second core layer includes homopolymerized PP, the first core layer includes random copolymerized PP, and the corona layer includes: The mass ratio of binary copolymerized PP, cycloolefin copolymer and high viscoelastic body is 72:18:14, and the melt index of the high viscoelastic body is 7.5g / 10min; the thickness of the heat-sealing layer is 17 μm, and the The thickness of the second core layer is 52 μm, the thickness of the first core layer is 8 μm, and the thickness of the corona layer is 23 μm.

[0040] The following table 2 is the physical and mechanical properties and barrier performance test comparison results of the barrier properties of the high thermal adhesive strength and high barrier aluminized film base material obtained in the present invention and the traditional barrier film base material and the high barrier VMCPP film disclosed in Patent No. CN...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Financial index | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com