Transmission and tension control system and control method thereof

A technology of tension control and tension, which is applied in the direction of thin material processing, sending objects, transportation and packaging, etc., can solve the problems of great influence of the tension state, damage of low tension substrate, unstable operation of equipment, etc., without reducing equipment Function, reduce product quality, solve the effect of uneven texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

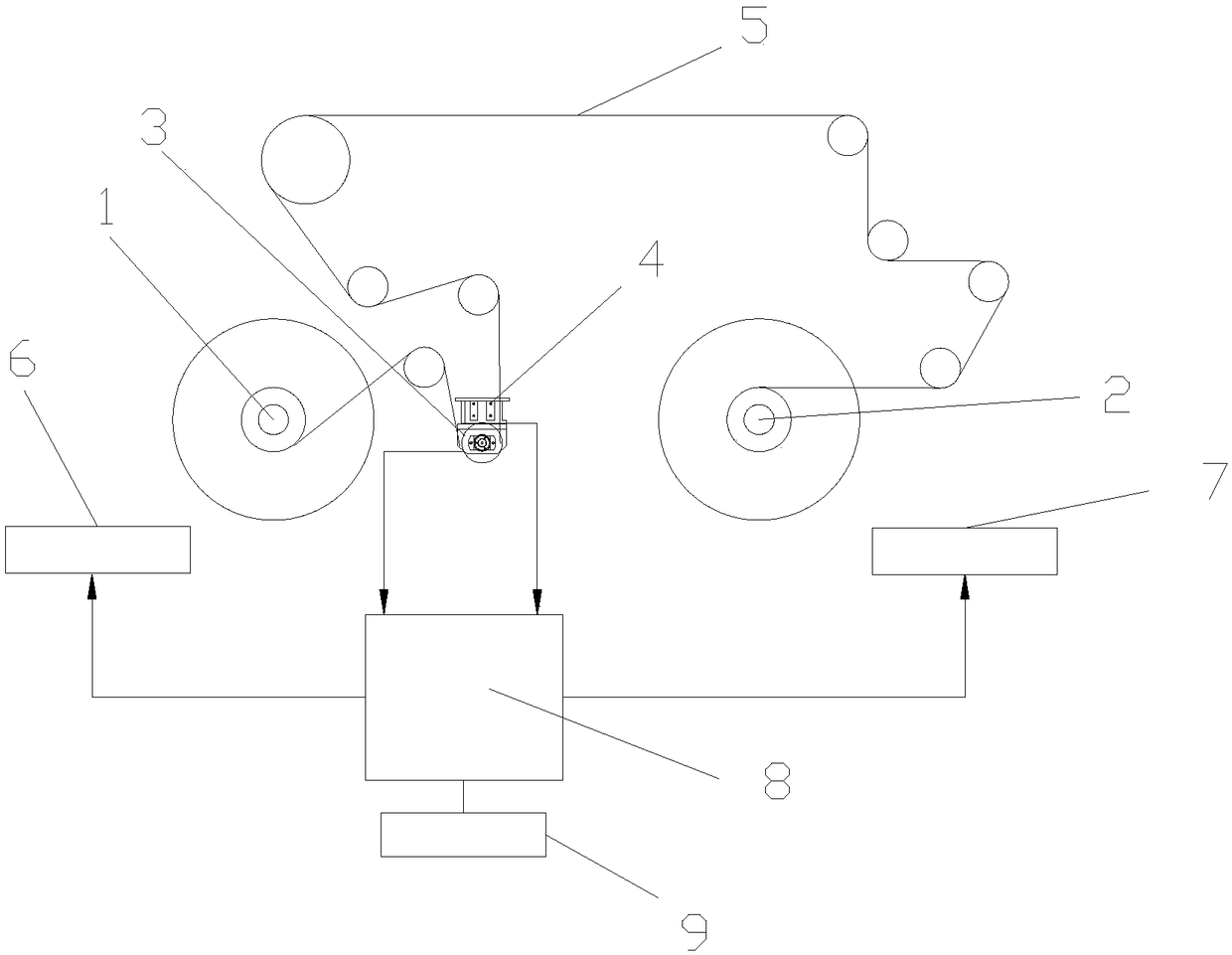

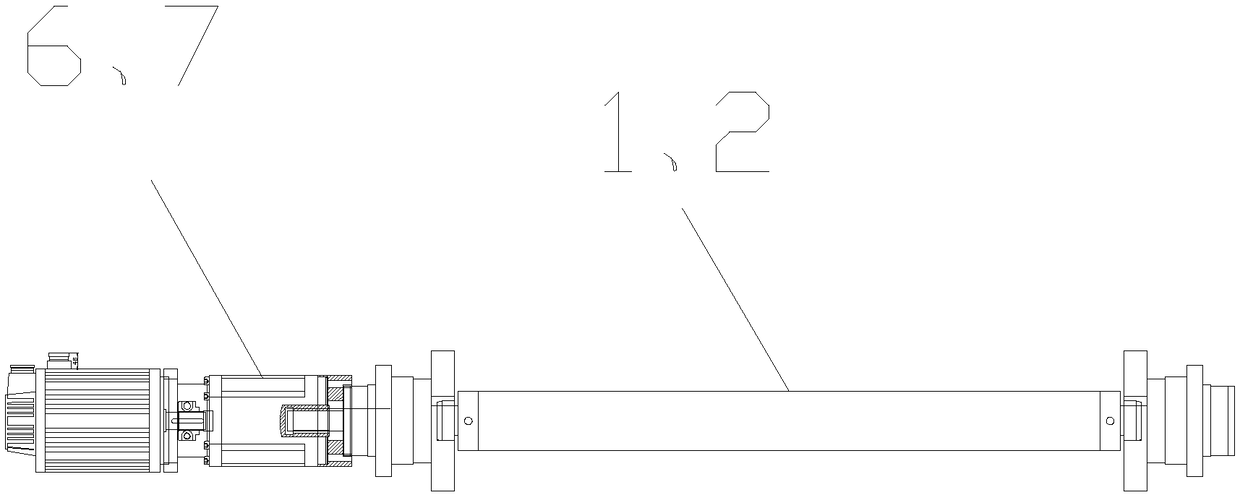

[0021] Embodiment 1 A kind of transmission and tension control system proposed by the present invention comprises a speed measuring sensor 3, a tension sensor 4 and a control device 8, and the speed measuring sensor 3 is arranged on the film belt between the unwinding reel 1 and the rewinding reel 2 to measure The speed of the film belt 5, the speed sensor 3 is connected with the control device 8 and transmits data; the tension sensor 4 measures the tension of the film belt 5, and is connected with the control device 8 and transmits data, and the control device 8 controls the rotation speed of the unwinding and rewinding shafts 1 and 2.

[0022] A transmission and tension control system, the speed measuring sensor 3 is arranged between the unwinding shaft 1 and the winding shaft 2, and the speed measuring sensor 3 is used to measure the transmission speed of the film belt 5, and the data signal is transmitted to the control device 8, the control device 8 Determine the radius of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com