Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Avoid premature decomposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyglycolic Acid Resin-Based Layered Sheet and Method of Producing the Same

InactiveUS20090081396A1Improve barrier propertiesPractical moisture resistanceFlexible coversWrappersMoisture resistanceOxygen barrier

There is provided a laminate sheet which is excellent in oxygen-barrier property and moisture resistance, biodegradable as a whole and therefore suitable as a base material for packaging materials, such as food containers. The laminate sheet is formed by laminating a water-containable and biodegradable polymer substrate sheet or a precursor thereof in a water-containing state with a layer of polyglycolic acid resin having a residual monomer content below 0.5 wt. % to form a laminate, and subjecting the laminate to bonding and forming under heat and pressure.

Owner:KUREHA KAGAKU KOGYO KK

Polyglycolic Acid Resin-Based Layered Sheet and Method of Producing the Same

InactiveUS20110108185A1Improve barrier propertiesPractical moisture resistanceFlexible coversWrappersMoisture resistanceOxygen barrier

There is provided a laminate sheet which is excellent in oxygen-barrier property and moisture resistance, biodegradable as a whole and therefore suitable as a base material for packaging materials, such as food containers. The laminate sheet is formed by laminating a water-containable and biodegradable polymer substrate sheet or a precursor thereof in a water-containing state with a layer of polyglycolic acid resin having a residual monomer content below 0.5 wt. % to form a laminate, and subjecting the laminate to bonding and forming under heat and pressure.

Owner:KUREHA KAGAKU KOGYO KK

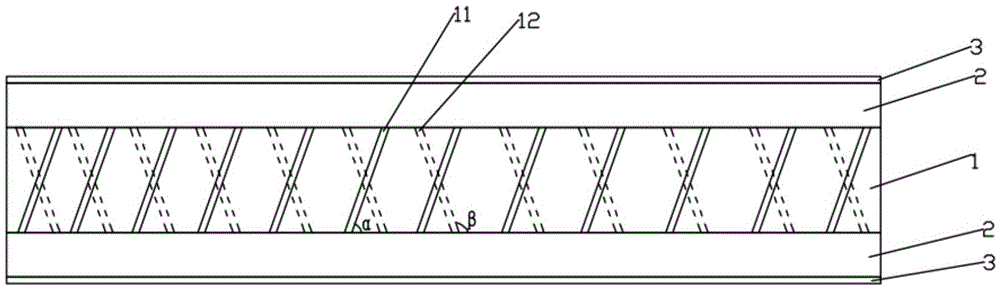

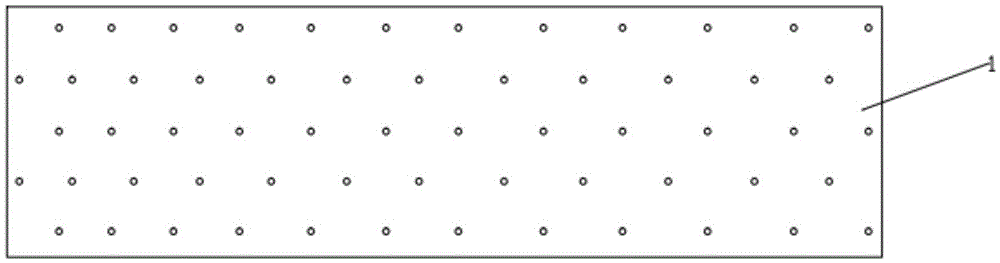

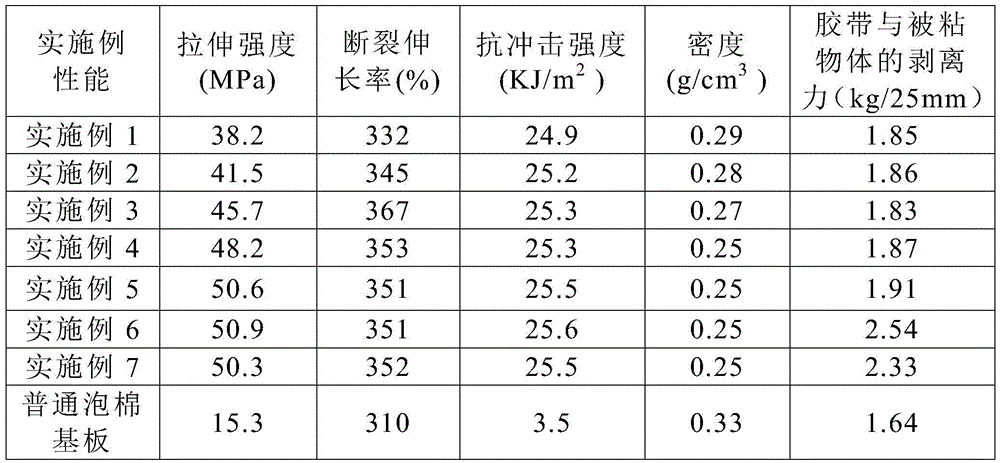

Foam two-sided adhesive tape

ActiveCN105542674AIncrease connection forceStop dislocationFilm/foil adhesivesFoaming agentShock resistance

The invention relates to a foam two-sided adhesive tape, which belongs to the technical field of an adhesive tape. The foam two-sided adhesive tape comprises a foam basal plate, an adhesive coating and a release film, wherein longitudinal through holes are formed between the upper surface and the lower surface of the foam basal plate, the foam basal plate comprises the following components in parts by weight: 100 parts of PMMA, 28 to 35 parts of polyurethane, 18 to 23 parts of fluorine rubber, 1.5 to 3.2 parts of light stabilizer, 5 to 11 parts of mesoporous nano TiO2 and 20 to 30 parts of foaming agents. The longitudinal through holes are formed in the foam basal plate, so that adhesive forms a complete lattice system, the connection performance of the adhesive tape is improved, and the connected object is more stable and reliable. The foam basal plate which is light in weight, good in shock resistance and excellent mechanical performance is adopted as the base material of the adhesive tape, so that the prepared adhesive tape is high in strength, good in flexibility, high in impact resistance and applicable to the manufacturing of more precise instruments and equipment.

Owner:NINGBO JIXIANG PLASTIC PROD CO LTD

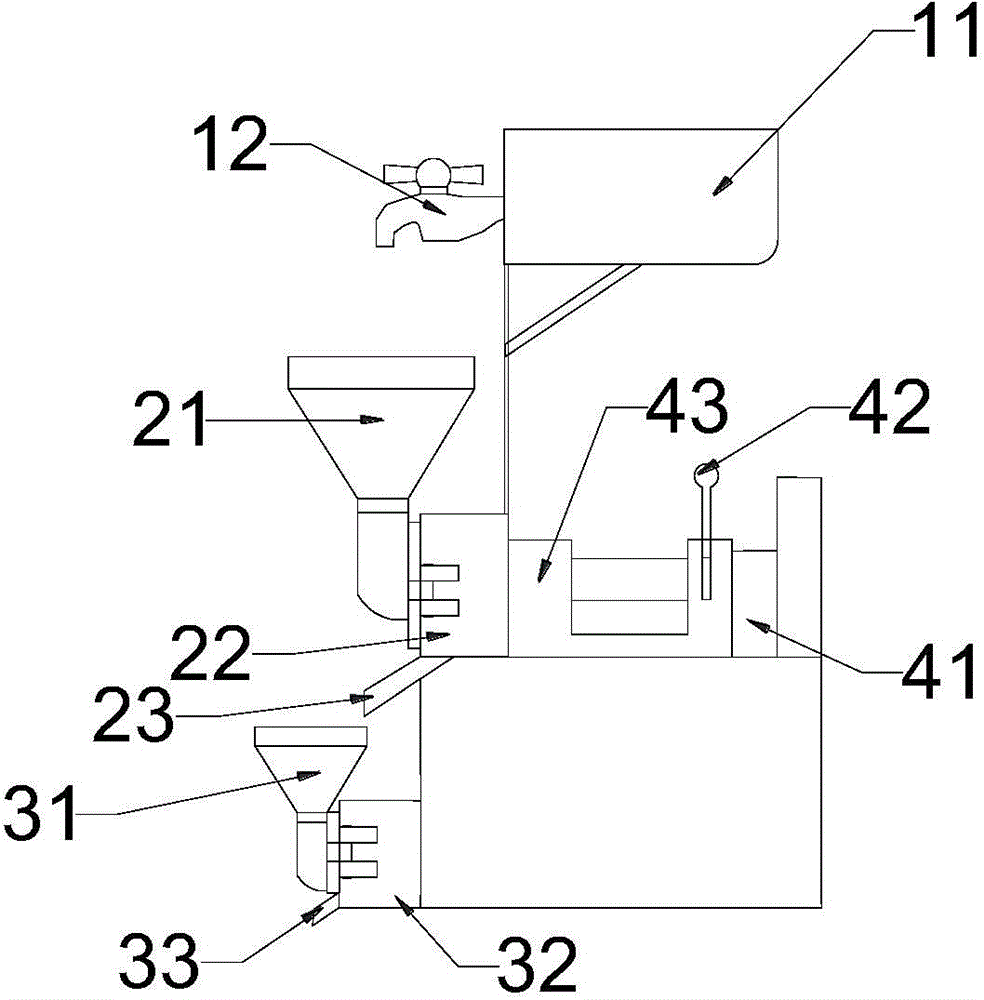

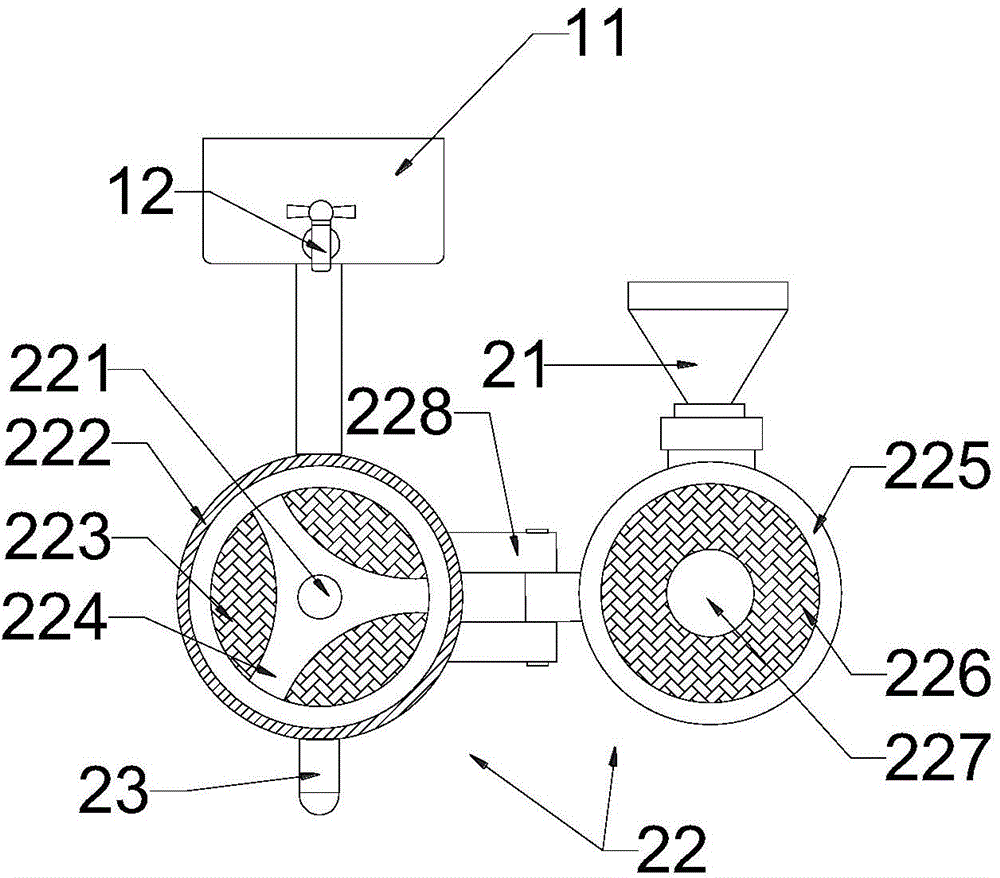

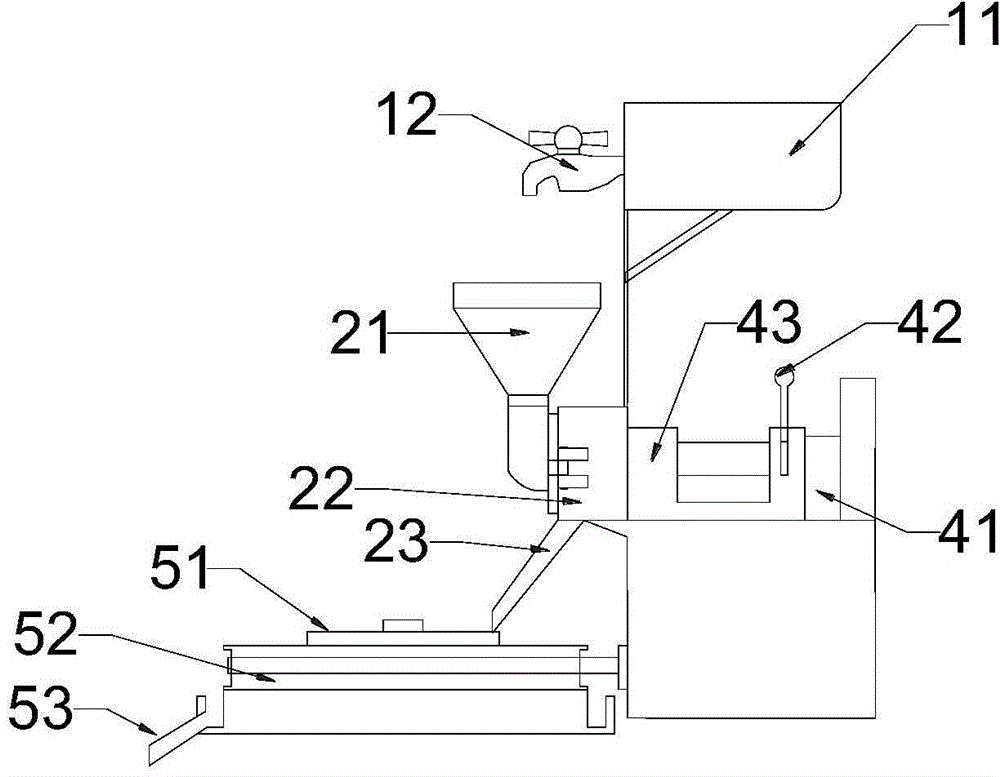

Steamed vermicelli roll manufacturing method and low-temperature fine rice milk grinding machine

The invention provides a steamed vermicelli roll manufacturing method and a low-temperature fine rice milk grinding machine. The steamed vermicelli roll manufacturing method includes the steps that rice is washed clean; the rice is soaked in a low-temperature environment; rice milk is generated through rice grinding in the low-temperature environment; starch is added into the rice milk, the starch and the rice milk are stirred to form mixed rice milk; water is added into the mixed rice milk for dilution to form pre-made rice milk; the pre-made rice milk is placed in a steamer to be heated till the rice milk is fully steamed, and steamed vermicelli rolls are formed; by means of a forming technology, the steamed vermicelli rolls are shaped into expected shapes. The method is characterized in that during rice milk grinding, crushed ice and / or ice cakes and / or ice water are / is added into a millstone. By means of the low-temperature rice milk grinding mode, the situation that temperature is too high and accordingly the rice milk is heated when the rice is ground is avoided, the situation that rice milk precursors become early steamed is prevented, and the taste of the steamed vermicelli rolls is better.

Owner:黄越通

Hollow blow-molded micro-foamed automobile air duct material and preparation method thereof

InactiveCN108892830AImprove appearance qualityGood material strengthTubular articlesPolyesterMaterials science

The invention relates to an automobile air duct and a preparation method, especially to a hollow blow-molded micro-foamed automobile air duct material and a preparation method thereof. The material ofthe invention comprises the following components, by weight: 50-80 parts of polyethylene, 0-15 parts of mineral powder, 1-30 parts of polyester, 0.2-1 part of a tackifier, 0.5-10 parts of a foaming agent, 5-15 parts of a blowing promotor, 0.2-0.5 part of a lubricant, and 0.2-0.5 part of an antioxidant. The invention also discloses the preparation method of the material. The hollow blow-molded micro-foamed automobile air duct has the characteristics of high cell density and good apparent quality. An automobile engine hood product prepared by the material has the characteristics of light weight, good heat insulation effect, good dimensional stability, high yield and the like. Under the condition that the whole weight of the product is reduced by more than 40%, the normal assembly and use ofparts are not affected, and the purpose of lightweight is achieved.

Owner:NANJING JULONG SCI&TECH CO LTD +1

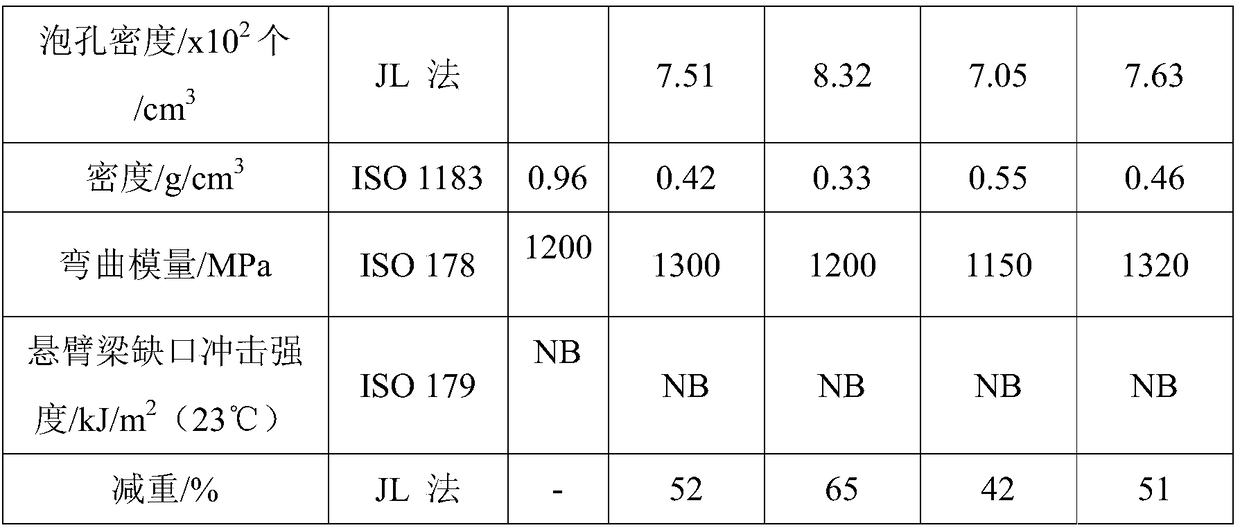

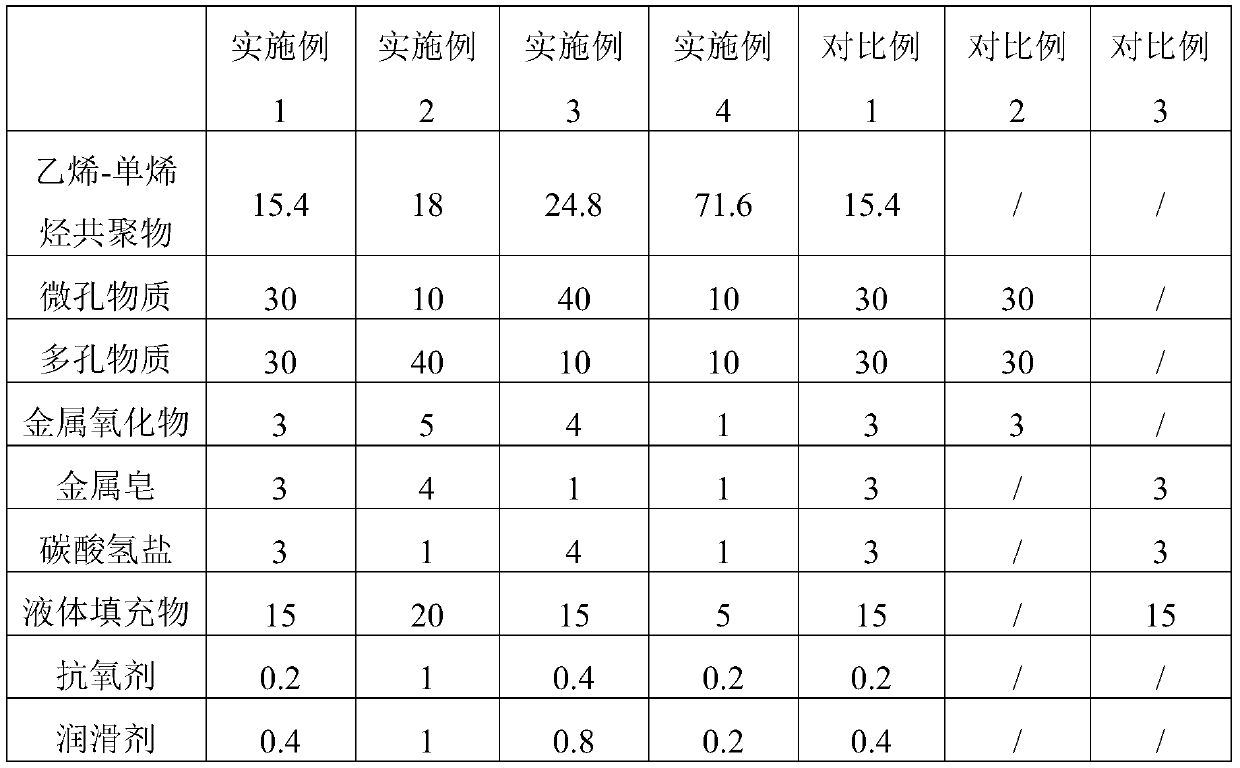

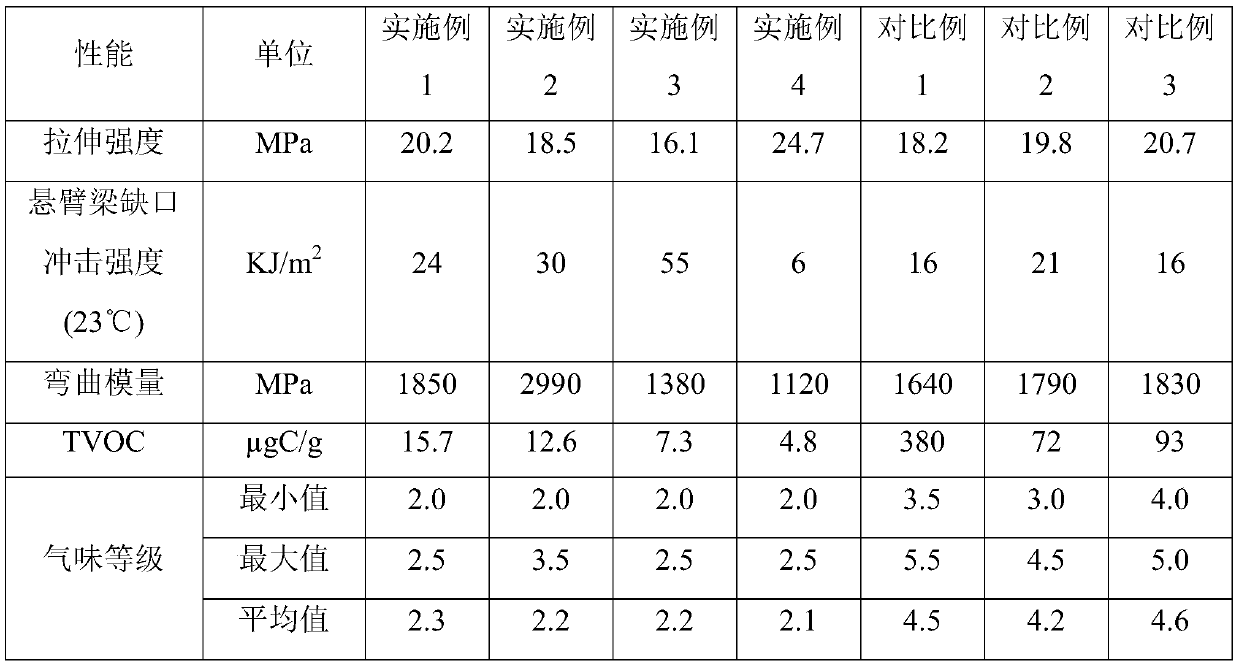

Low-odor low-TVOC polypropylene composite material and preparation method thereof

ActiveCN110964260ARemove completelyLower odor levelDispersed particle separationElastomerPolypropylene composites

The invention provides a low-odor low-TVOC polypropylene composite material and a preparation method thereof. The low-odor low-TVOC polypropylene composite material is characterized by comprising thefollowing raw materials in parts by weight: 30-99% of polypropylene, 0-30% of an elastomer; 0-40% of mineral powder; 0.5%-10% of an odor adsorbent; 0.5 to 4% of other auxiliary agents; wherein the odor adsorbent is prepared from the following raw materials in parts by weight: 10 to 75% of ethylene-monoolefine copolymer; 10-40% of a microporous substance; 10-40% of a porous substance; 1-5% of a metal oxide; 1-4% of a metallic soap; 1-4% of a bicarbonate; 5-20% of a liquid filler; 0.2 to 1.0% of an antioxidant; and 0.2 to 1.0% of a lubricant. The low-odor low-TVOC polypropylene composite material disclosed by the invention has relatively low odor and TVOC value.

Owner:TIANJIN KINGFA NEW MATERIAL

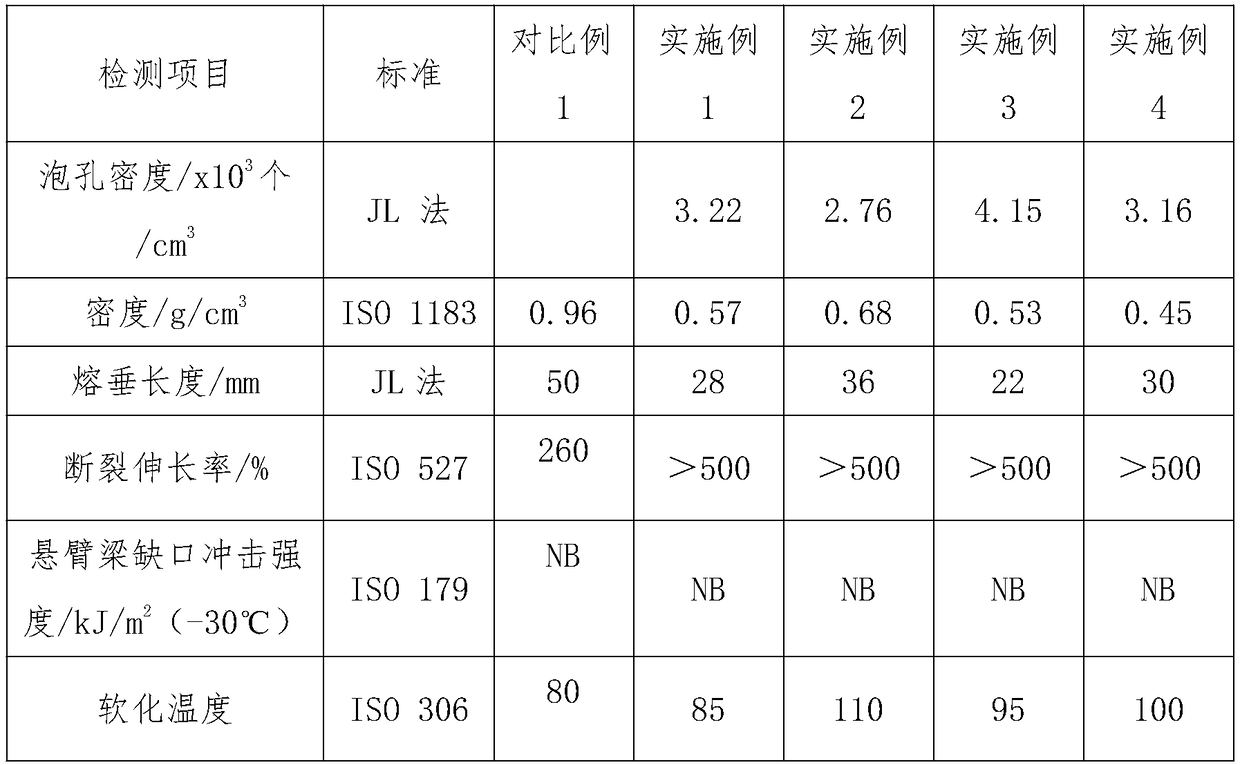

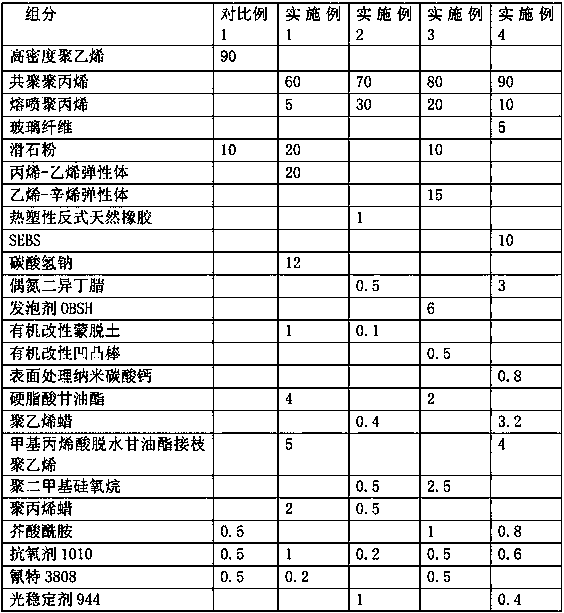

Material for hollow blow-molded micro-foamed tool box and preparation method thereof

The invention relates to a tool box and a preparation method thereof, and particularly relates to a hollow blow-molded micro-foamed tool box and a preparation method of the tool box. The material related to the invention comprises the following components in parts by weight: 60-90 parts of co-polypropylene, 5-30 parts of melt-blown polypropylene, 0-20 parts of a filler, 1-20 parts of a modifier, 0.5-12 parts of a foaming agent, 1-10 parts of a foaming auxiliary agent, 0.5-2 parts of a lubricant, 0.2-1 part of an antioxidant and 0.2-1 part of a light stabilizer. The invention discloses the preparation method of the hollow blow-molded micro-foamed tool box. According to the invention, the tool box with a fine micropore structure is obtained. The anti-sagging property and the transverse stretching performance of the polypropylene melt in a blow-molding and micro-foaming process are effectively improved, the requirements of free regulation of wall thickness distribution of the product is met, the smooth operation of the polypropylene hollow blow-molding micro-foaming process is ensured, and the product has a significant characteristic of light weight. The tool box provided by the invention also has excellent dimensional stability, anti-dropping performance and anti-shocking performance. The preparation method provided by the invention has the advantages of shorter forming period, low manufacturing cost, high product qualification rate and easy realization of industrialization.

Owner:NANJING JULONG SCI&TECH CO LTD

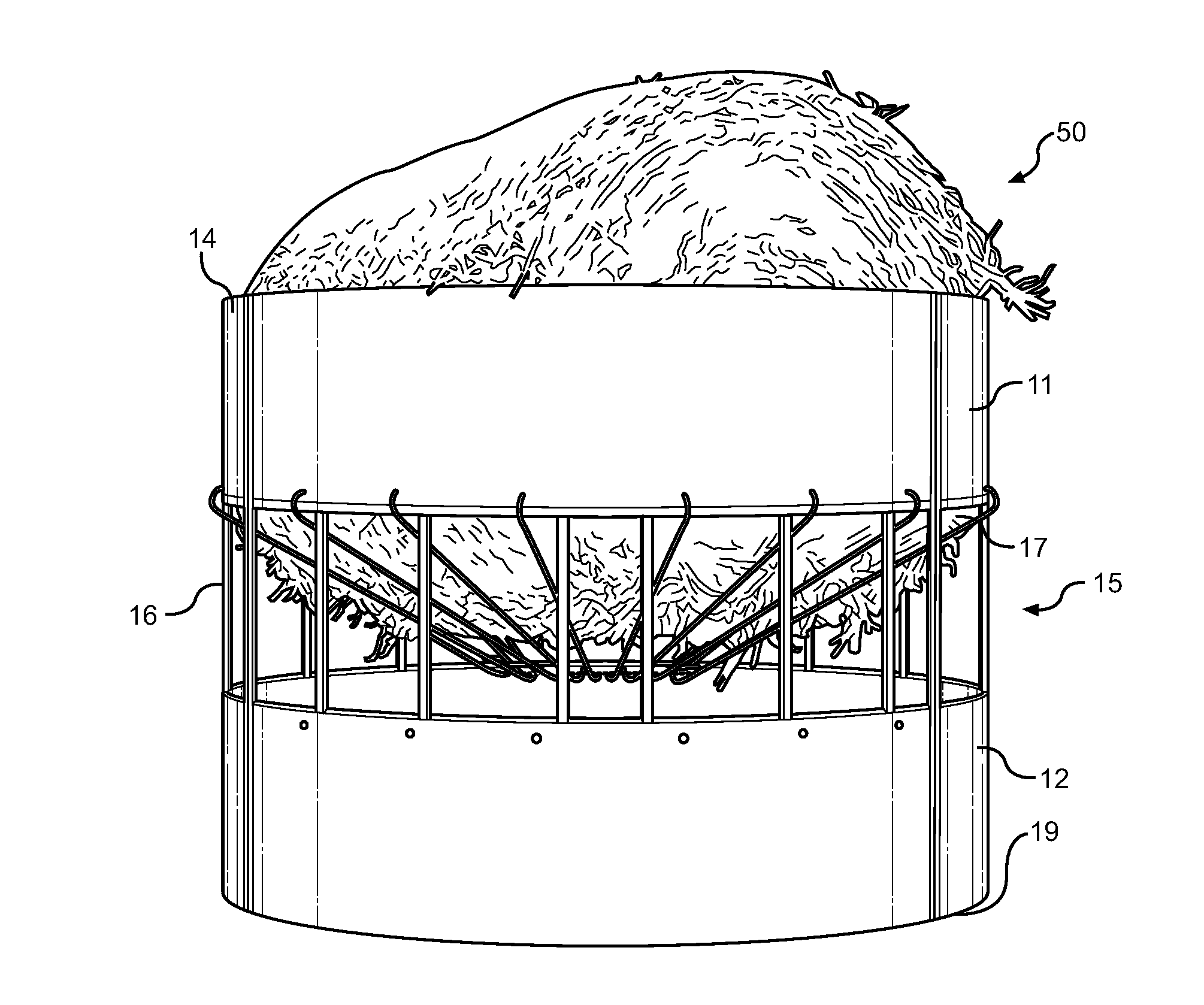

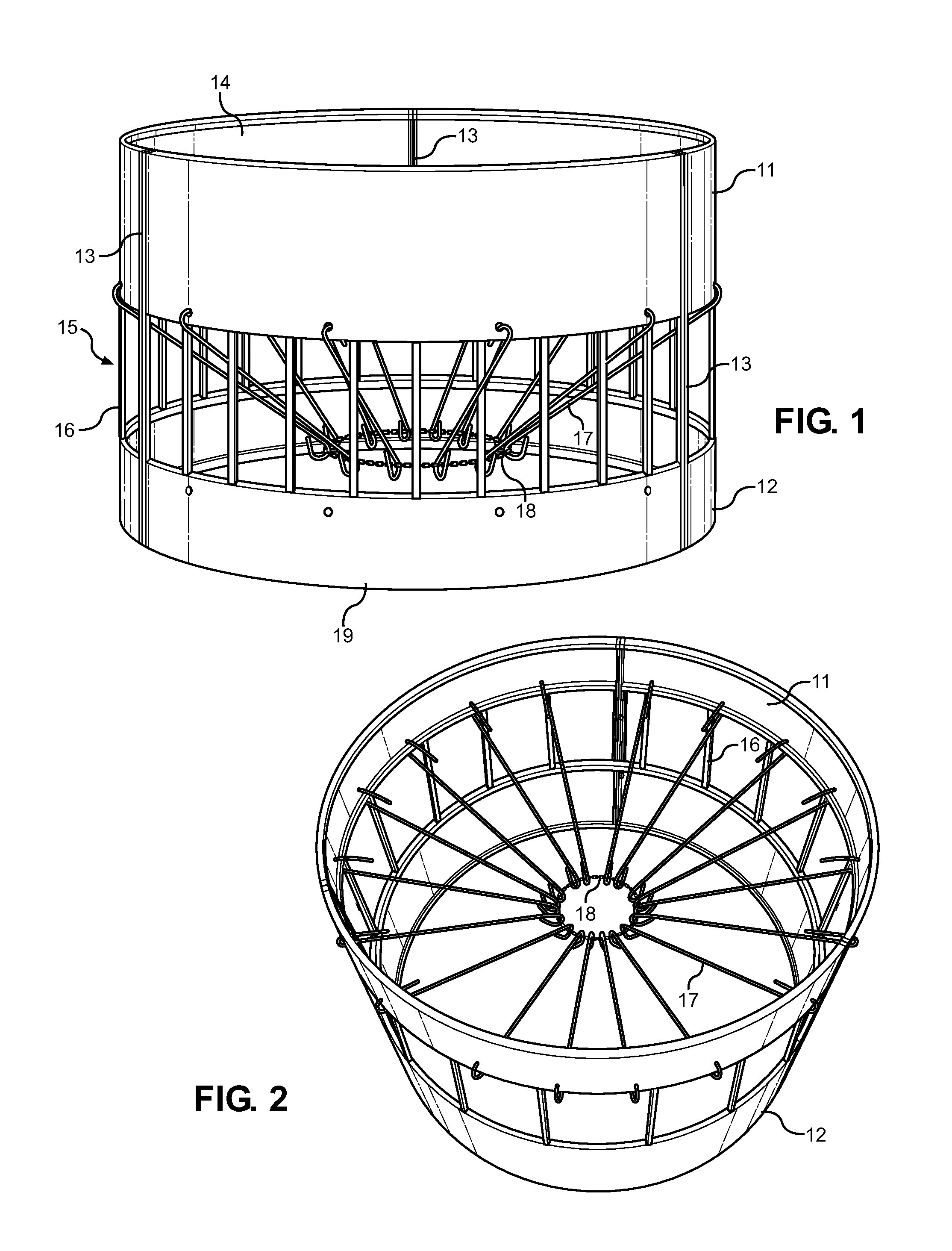

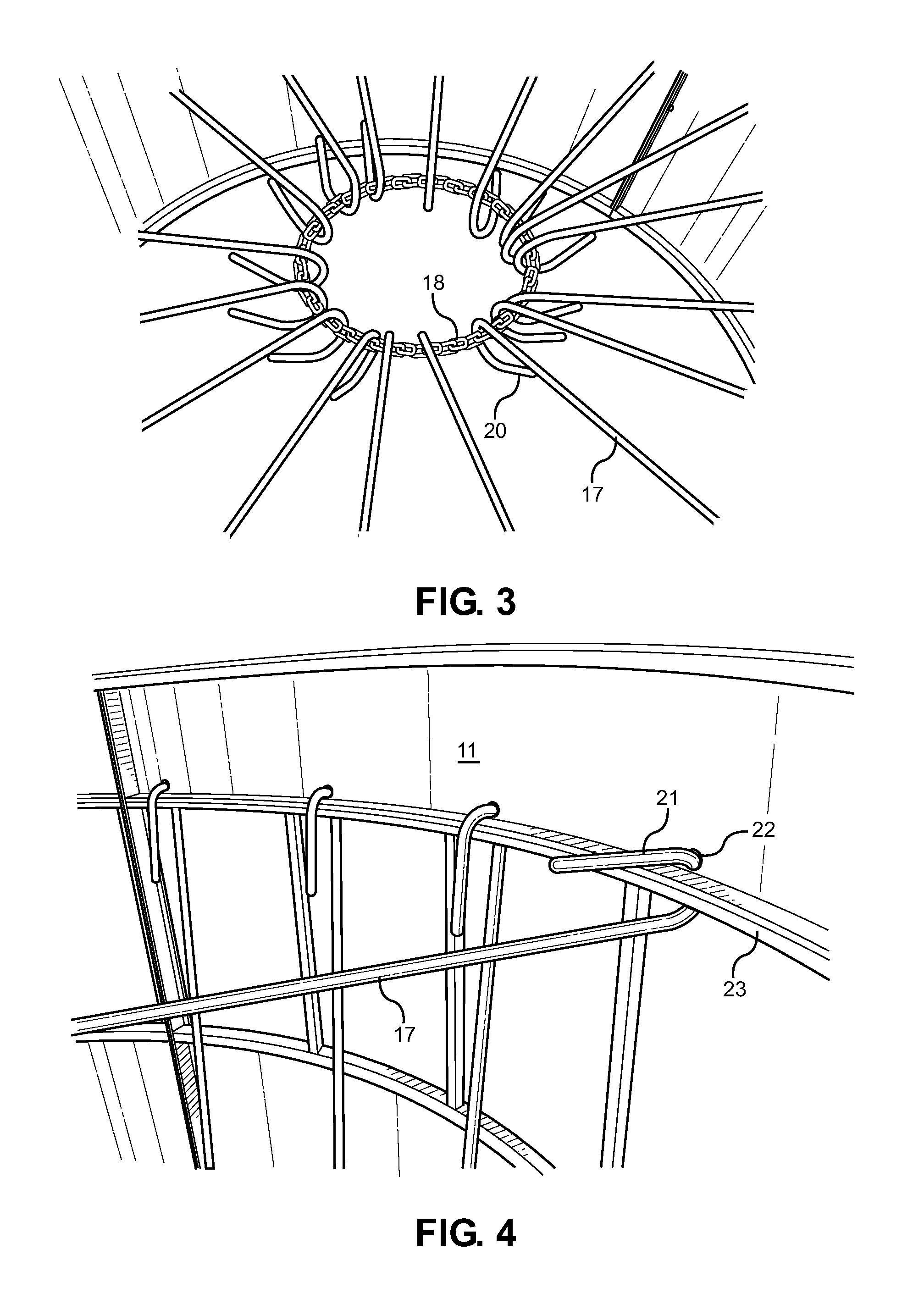

Livestock Feeder

InactiveUS20150020740A1Avoid premature decompositionConsiderable wasteAnimal feeding devicesAnimal housingEngineeringChain link

A livestock feeder assembly is provided that comprises an outer frame having an open interior, whereby the feeder is adapted to support hay bales in an elevated condition and above the ground for livestock to feed upon. Within the interior of the outer frame is a plurality of inwardly directed support bar members, wherein the members are secured together by way of a chain or tether at their inner distal ends. The support bar members support one or more bales of hay above the ground, whereby the height of the bales can be adjusted by updating the distance from the inner distal ends of the members. Overall, the assembly supports hay above the ground to reduce premature decomposition, and provides openings in the frame for livestock to access the hay for consumption. Different sizes, shapes and configurations of the outer frame are contemplated.

Owner:LACEY TED

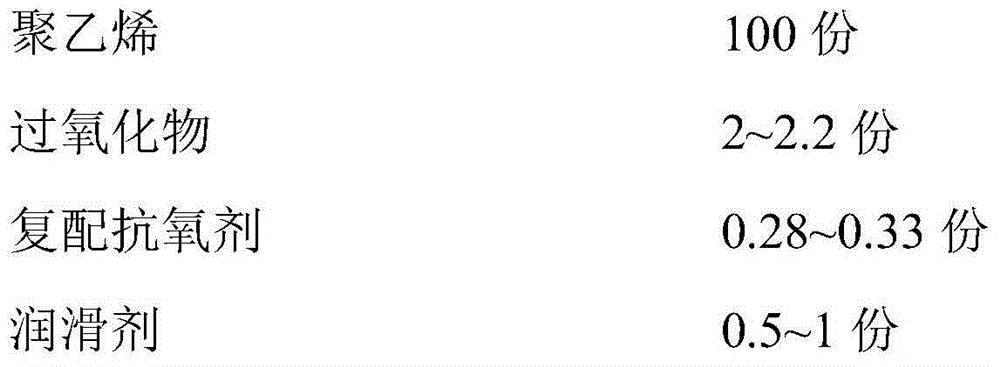

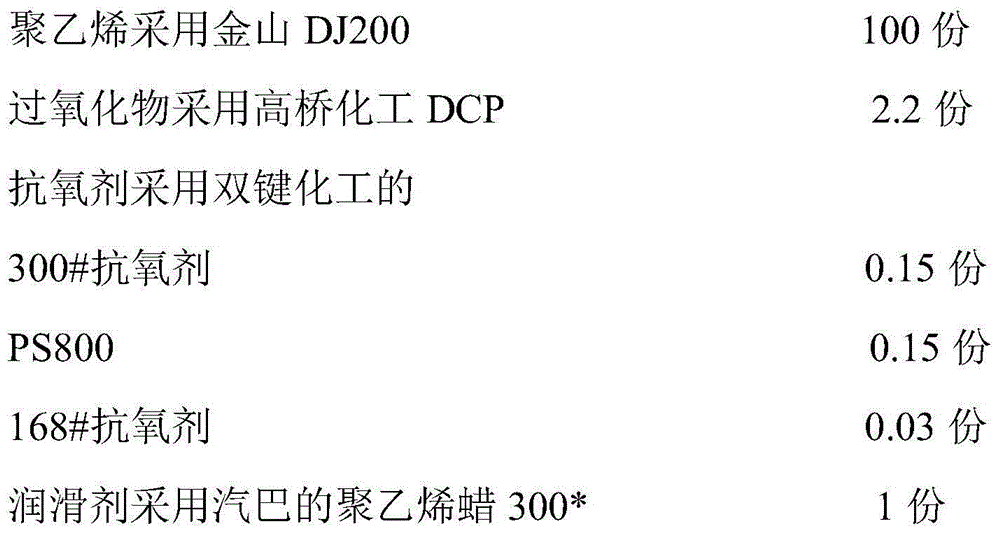

Chemical crosslinked polyethylene insulating plastic for submarine cable

InactiveCN104558759AImprove processing performanceImproves scorching resistancePlastic/resin/waxes insulatorsDecompositionAntioxidant

The invention provides a chemical crosslinked polyethylene insulating plastic for a submarine cable. The chemical crosslinked polyethylene insulating plastic comprises the following components in parts by weight: 100 parts of polyethylene, 1.0-3.0 parts of peroxide, 0.02-2 parts of a compound antioxidant and 0.1-2 parts of a lubricant. Appropriate peroxide and antioxidant system are adopted, so that advanced decomposition of the peroxide can be effectively prevented when a submarine cable material is processed into cables; no local high-temperature phenomenon in the processing process is ensured by addition of the lubricant; the processing property and the burning resistance of the material are improved in common; the applicability of a chemical crosslinked modified material is improved; the manifestation of traditional chemical crosslinked modified polyethylene in manufacturing of the submarine cable is changed; the pre-crosslinked phenomenon is inhibited from the source; and the continuous driving time of the submarine cable in the manufacturing process is prolonged.

Owner:上海新上化高分子材料有限公司

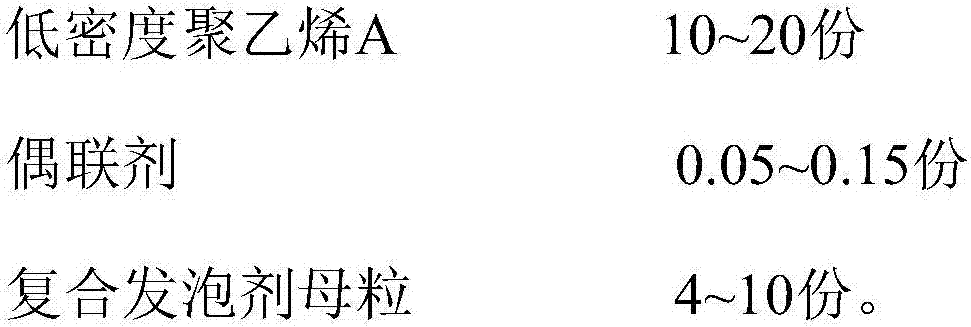

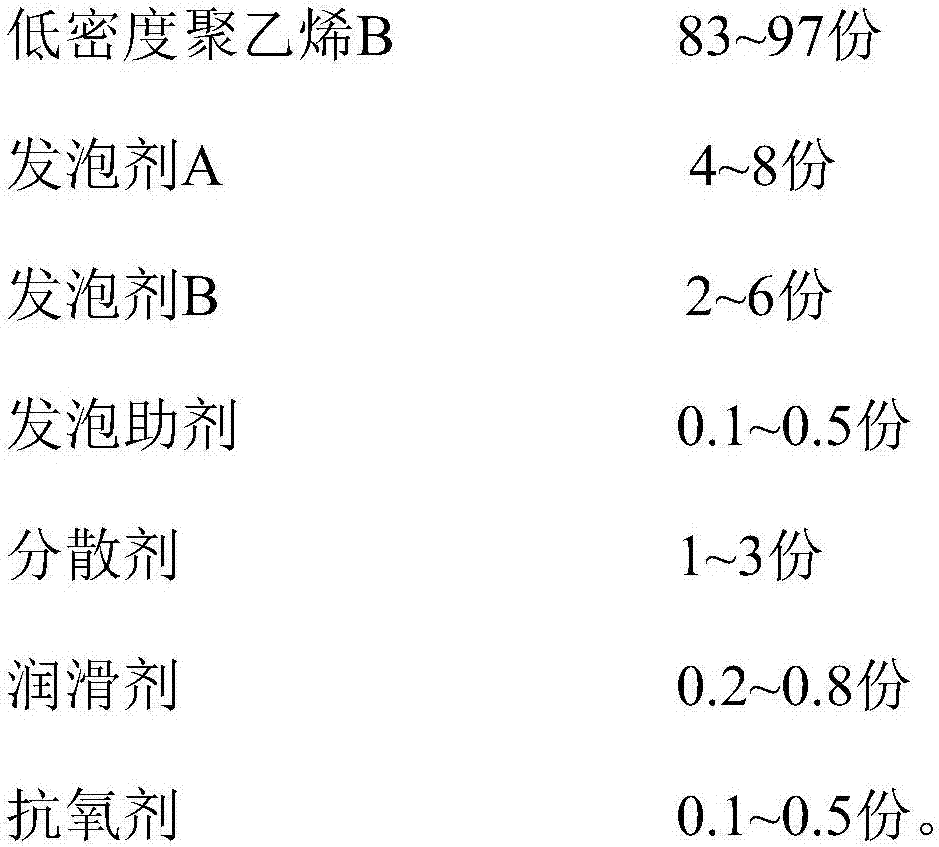

Chemical foaming polyethylene composition, preparation method and applications thereof

InactiveCN106947153AHigh foamingImprove mechanical propertiesPlastic/resin/waxes insulatorsLow-density polyethyleneFoaming agent

The present invention discloses a chemical foaming polyethylene composition, a preparation method and applications thereof, wherein the chemical foaming polyethylene composition is prepared from the following components by weight: 70-86 parts of high-density polyethylene, 10-20 parts of low-density polyethylene A, 0.05-0.15 part of a coupling agent, and 4-10 parts of composite foaming agent master batch. According to the present invention, the chemical foaming polyethylene composition retains the high foaming degree of the low-density polyethylene foaming material and the good mechanical property of the high-density polyethylene chemical foaming material so as to obtain the foaming insulation layer having the good electrical property. Another purpose of the present invention is to provide the preparation method of the chemical foaming polyethylene composition, wherein the preparation method is simple and is easy to operate. The present invention further provides uses of the chemical foaming polyethylene composition in preparation of communication cables.

Owner:广州敬信高聚物科技有限公司

Micro-foaming tool kit capable of silk printing and blow molding and preparation method of micro-foaming tool kit

The invention relates to a micro-foaming tool kit material and a preparation method thereof and in particular relates to a micro-foaming tool kit capable of silk printing and blow molding and a preparation method of the micro-foaming tool kit. The micro-foaming tool kit comprises the following components in parts by weight: 70-90 parts of polyethylene, 5-15 parts of ultrahigh-flowability polyethylene, 0-10 parts of filler, 1-10 parts of polar modifier, 1-5 parts of compatilizer, 1-15 parts of toughening agent, 1-10 parts of foaming agent, 3-15 parts of foaming auxiliary and 0.5-2 parts of other auxiliaries. In addition, the invention discloses a preparation method of the micro-foaming tool kit. The micro-foaming tool kit disclosed by the invention is fine and smooth in molding foam hole, high in foam hole density, smooth and uniform in surface, capable of uniformly smearing and spreading a paint, abundant in texture, strong in silk printing paint adhesive strength, free of dropping after being proved by adhesion force tests, capable of meeting a silk printing requirement of the tool kit and also capable of meeting silk printing of various types of printing ink and also has the characteristics such as lightweight, good buffering effect, good dimensional stability, short molding period and high finished product qualified rate.

Owner:NANJING JULONG SCI&TECH CO LTD

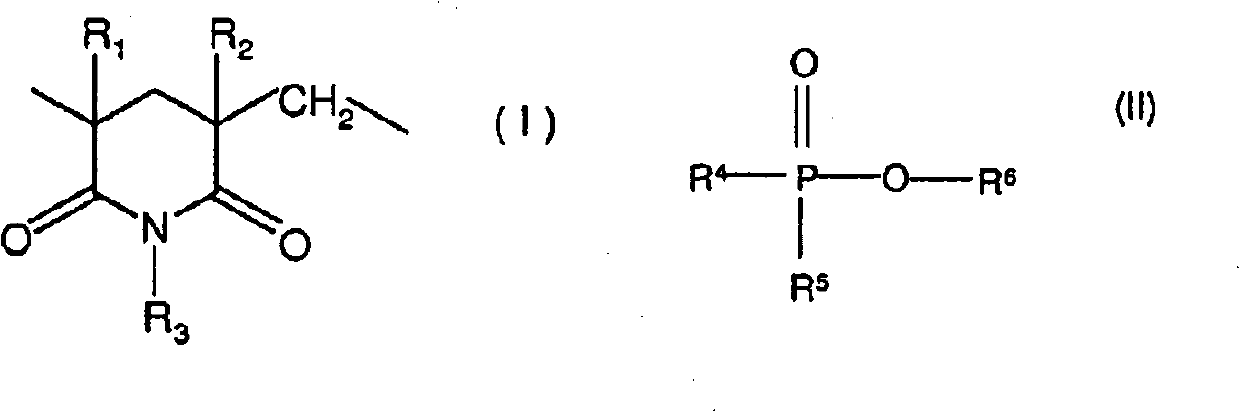

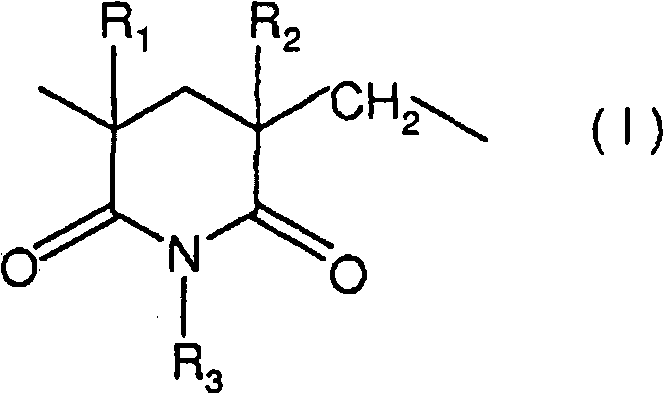

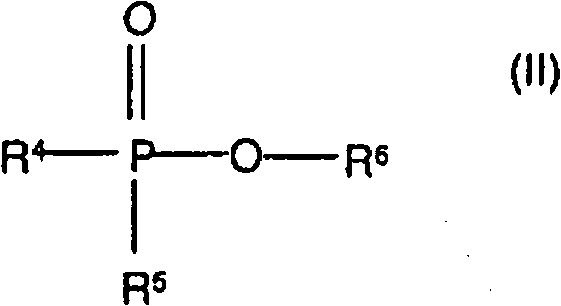

Poly(meth)acrylaimide having improved optical and color properties, particularly under thermal load

The invention relates to a method for the production of molding compounds FM having improved optical and color properties, comprising a polymer PM, which includes units of the formula (I), where R1 and R2 are hydrogen and methyl, and R3 is hydrogen, C1-C18-alkyl, C5-C8-cycloalkyl, C6-C10-aryl, and C6-C10-aryl-C1-C4-alkyl, said groups being substitutable by up to three times with groups selected from the group consisting of C1-C4-alkoxy and halogen, produced in a generally known imidization reaction in a reaction extruder, an amount of one or more phosphorous compounds P having a reducing effect, which amount is effective for color stabilization, being added to the polymer PM after conclusion of the imidization reaction, characterized in that the phosphorous compounds are organic phosphorous compounds OP, selected from the group consisting of the compounds of formula (II), where R4 and R5 are hydrogen or an aromatic 6-member ring independent of each other, which may be substituted up to 5 times with a C1-C4-alkyl and / or C5-C8-cycloalkyl group. Molded bodies obtained according to the method, particularly optical fibers, have a low tendency toward yellowing under thermal load, together with low haze (cloudiness) and stable and high transparency.

Owner:ROHM G M B H

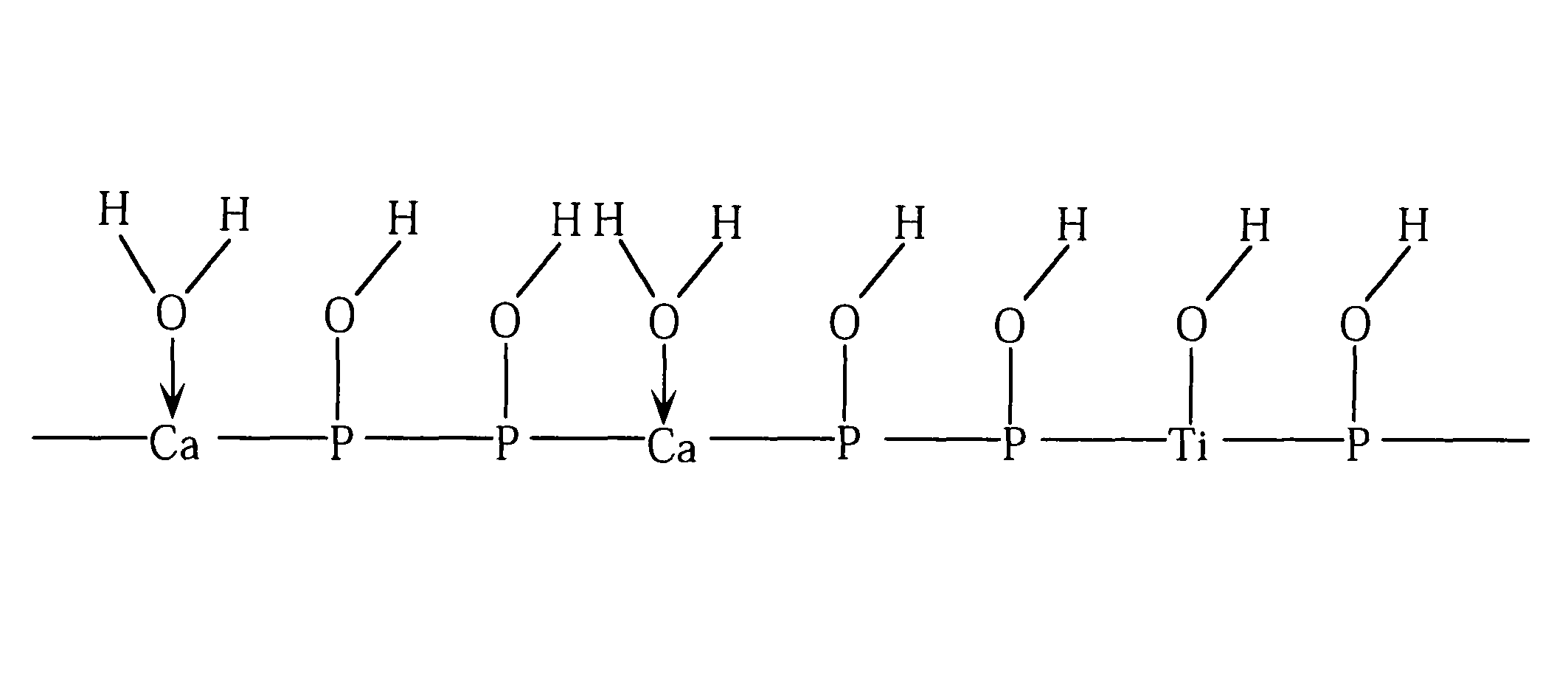

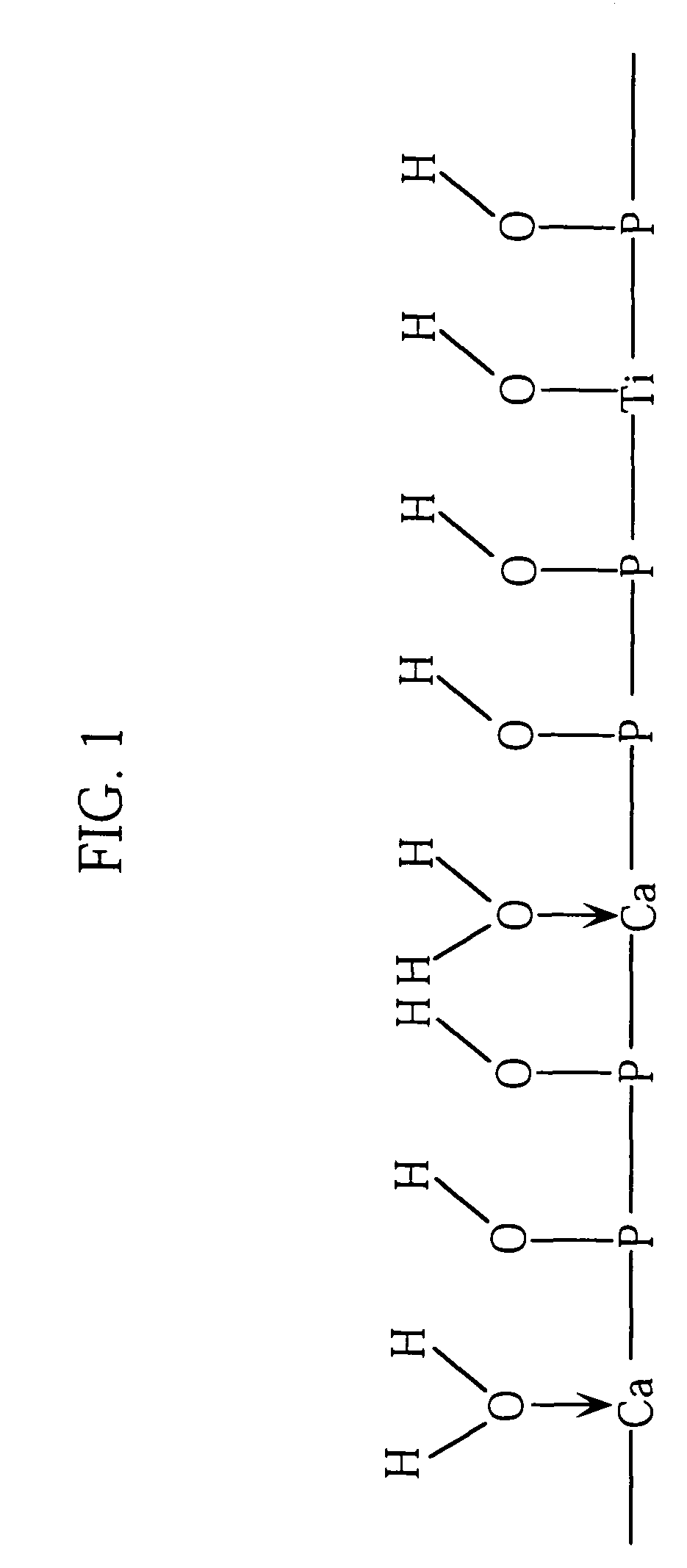

Agricultural chemical component and decomposer for residual agricultural chemical

ActiveUS20050159317A1Reduce residual agricultural chemicalResidue reductionBiocideOther chemical processesDecomposerChemistry

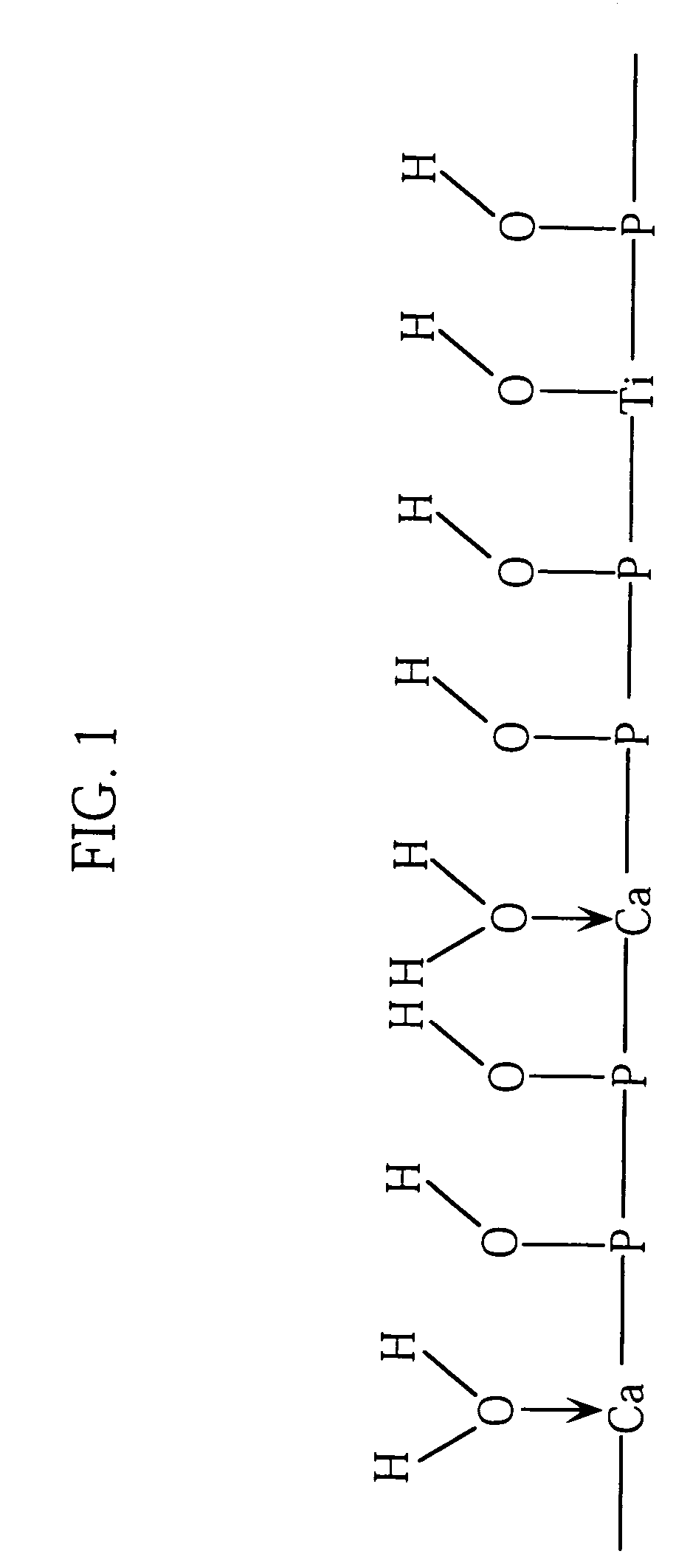

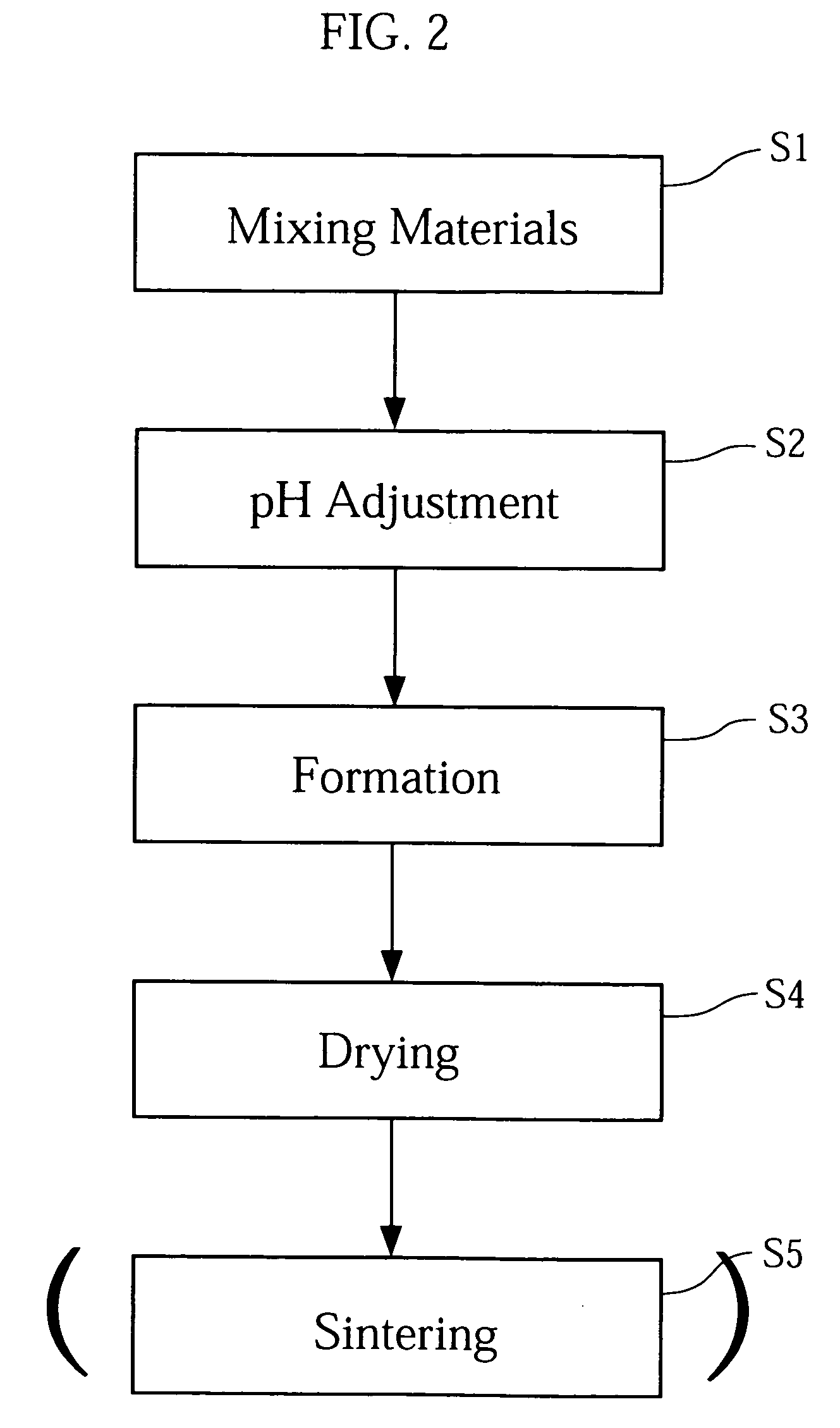

An agricultural chemical component includes an active agricultural chemical ingredient and a powder metal-modified apatite which has part of metal atoms in its apatite crystal structure provided by an optically catalytic metal. Preferably, the metal-modified apatite is coated with an organic film.

Owner:FUJITSU LTD

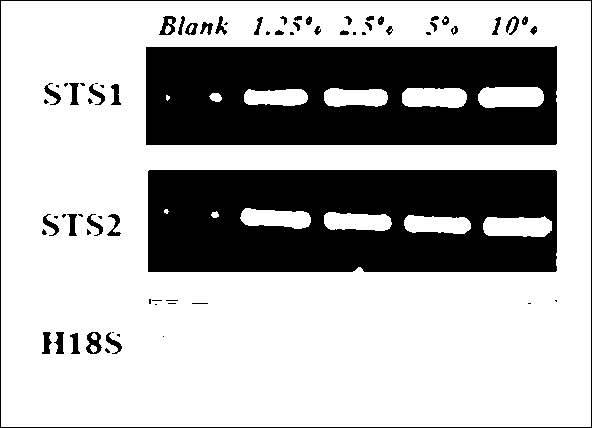

Method for inducing accumulation of stilbenes in grapes

InactiveCN102835263AInduction effect is not goodSolve effective useHorticulture methodsBiotechnologyPathogenic bacteria

The invention relates to a method for inducing the accumulation of stilbenes resveratrol, polydatin and pterostilbene in grape leaves, grape stems and grape fruits. The method comprises related methods for preparation of a hydrogen peroxide inducer, spraying treatment of in-vivo and in-vitro materials of grapes and impregnation treatment of the in-vitro materials of the grapes. According to the technical scheme, increase of stilbene content of the materials can be effectively, specifically and comprehensively induced, and the method has the characteristics of safety and convenience for large-scale application to township enterprises with rich grape resources, and is easy to operate. The quality of the grapes can be improved, grape planting waste can be comprehensively utilized, and grape trees can resist pathogenic bacteria to a certain extent to reduce loss caused by diseases.

Owner:张波 +1

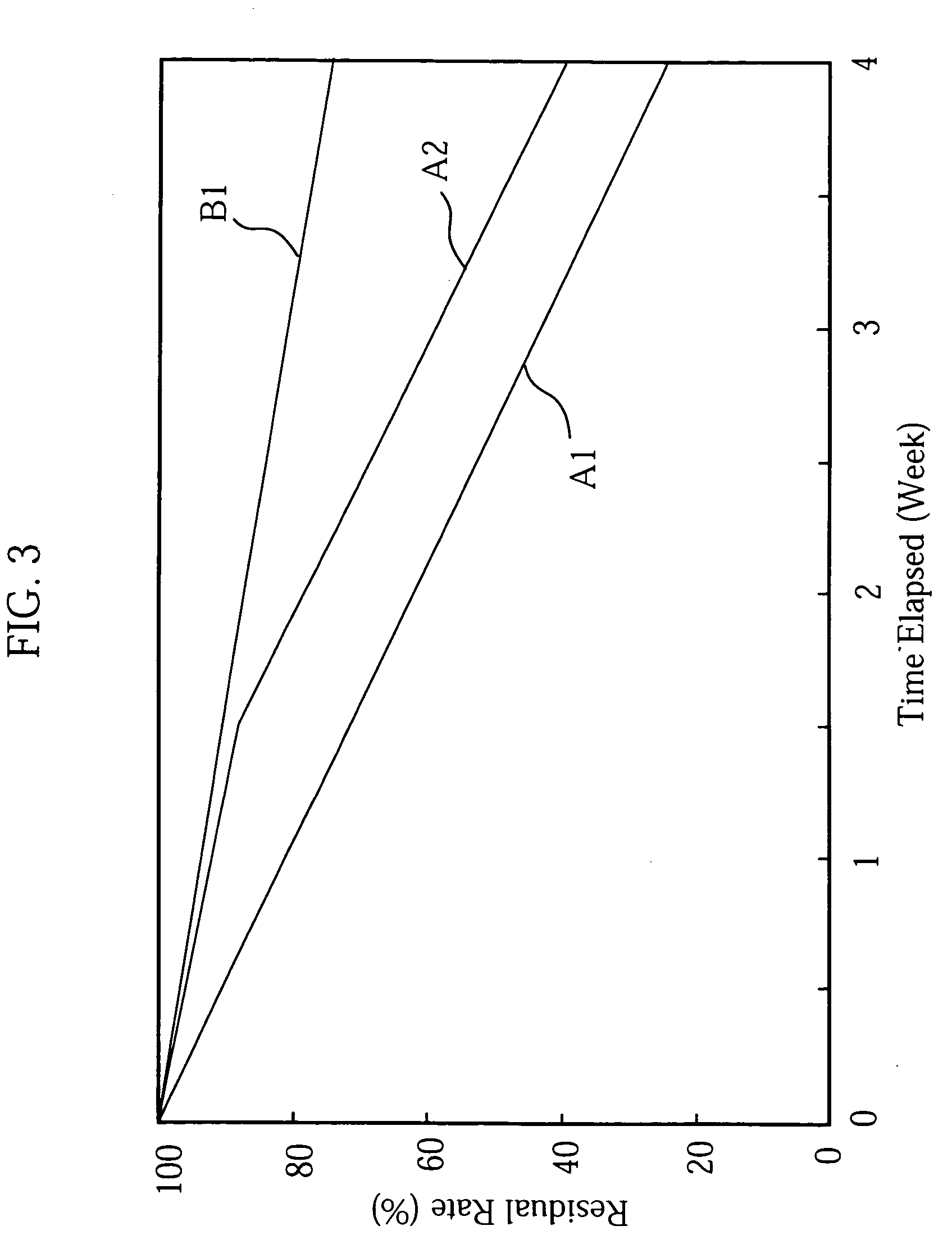

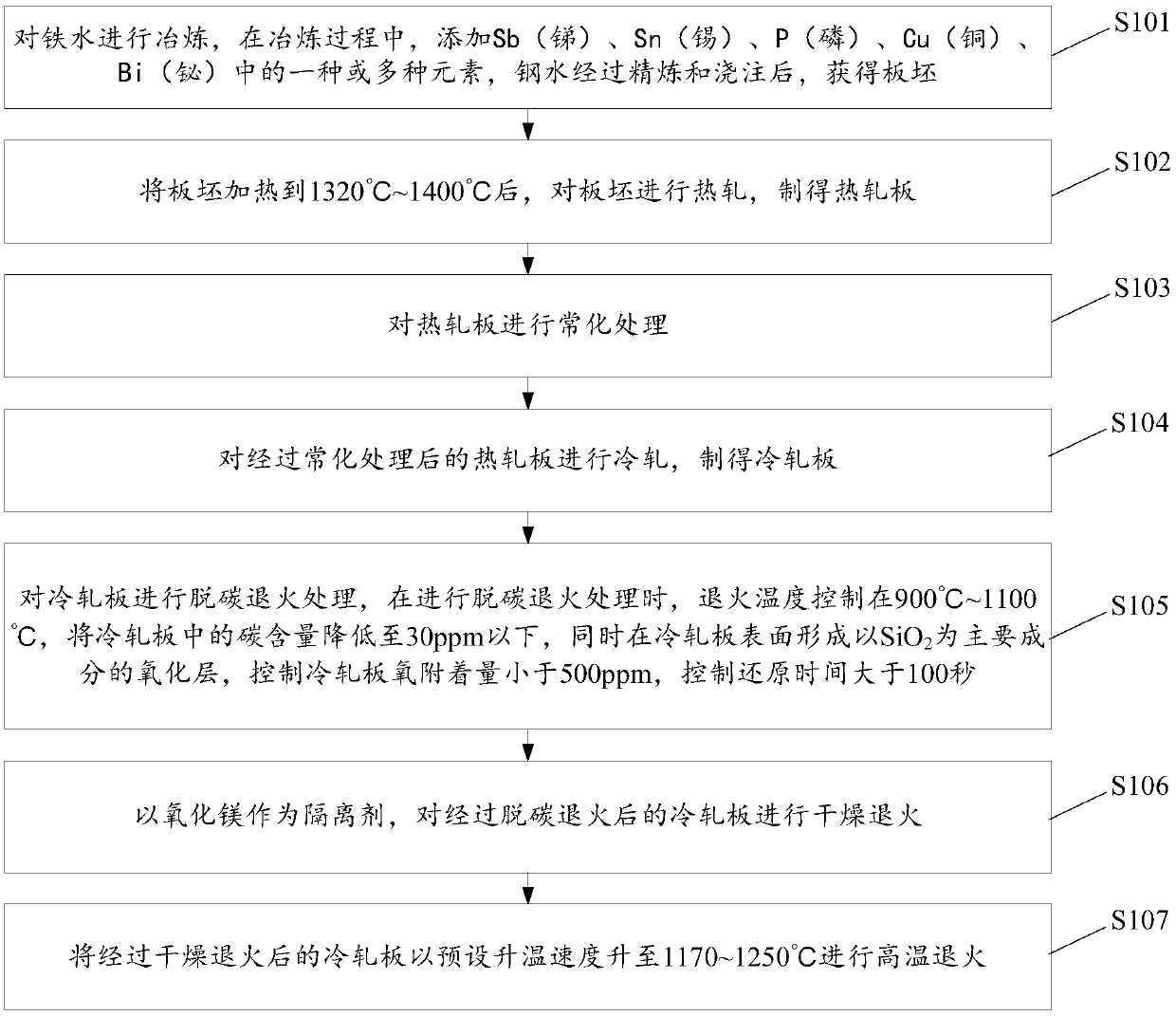

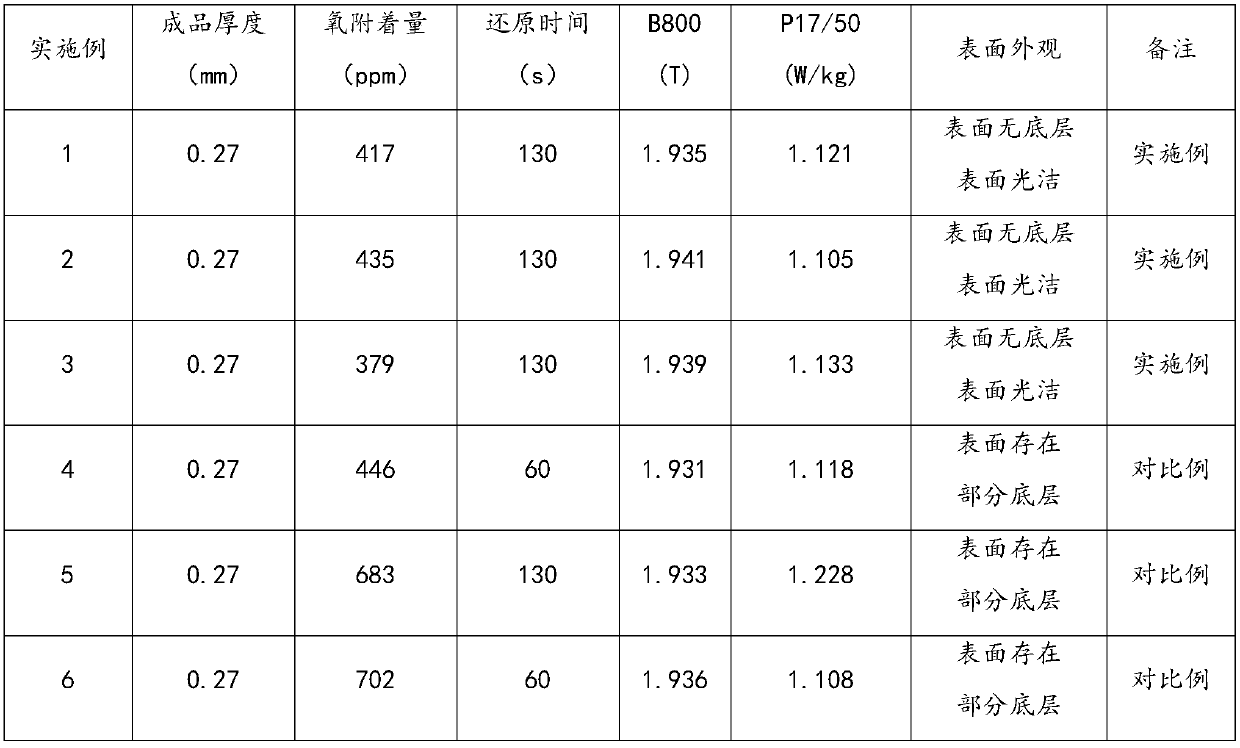

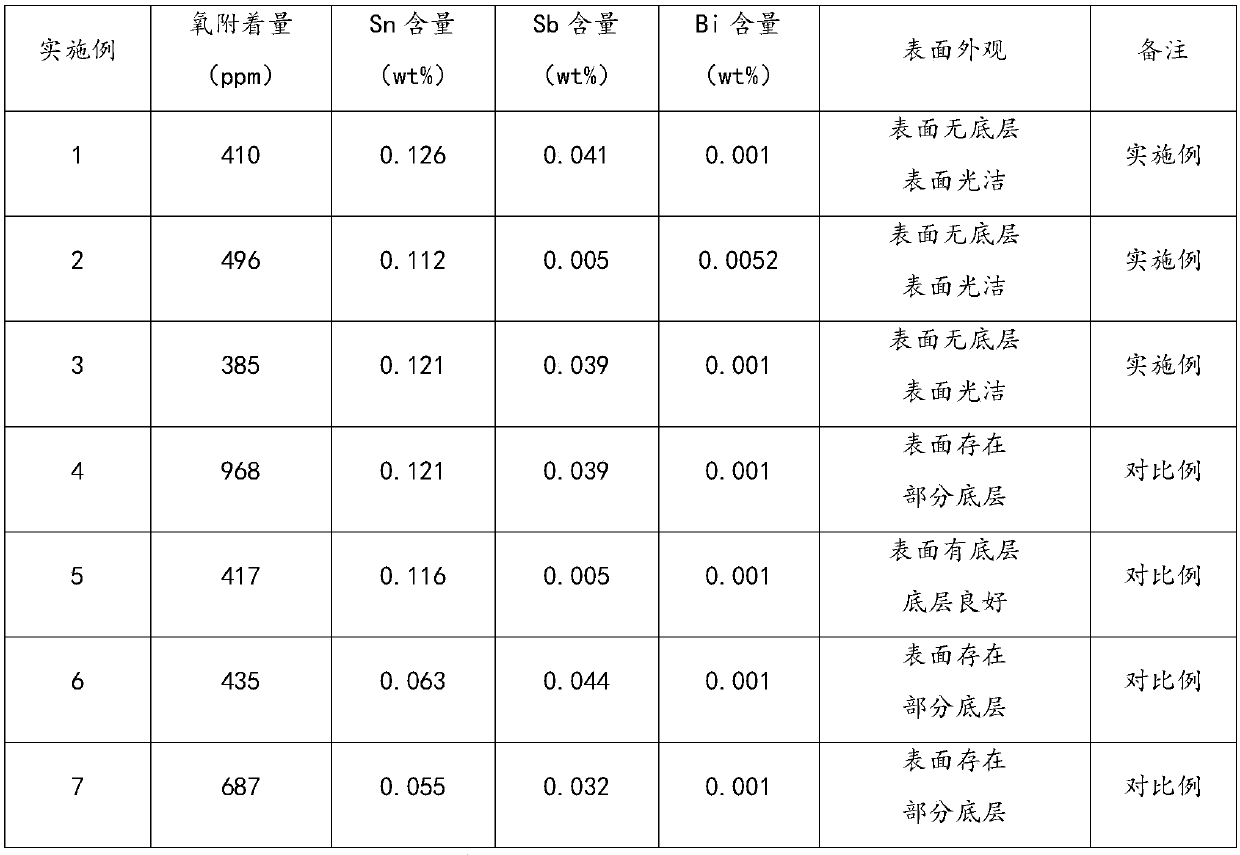

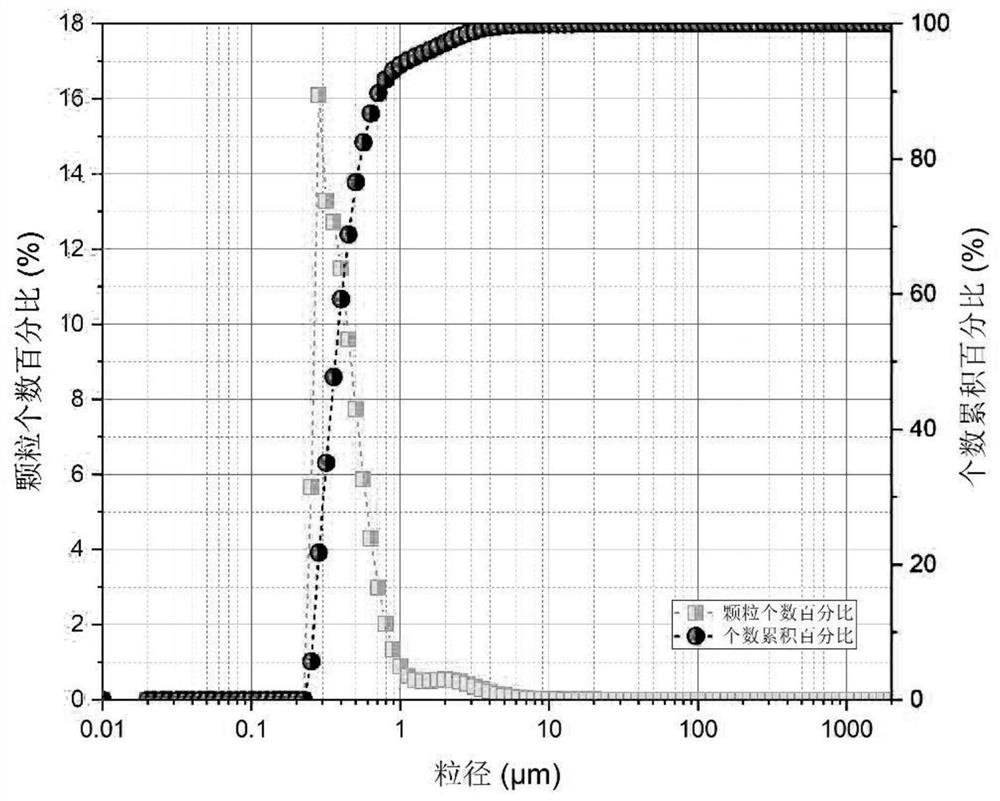

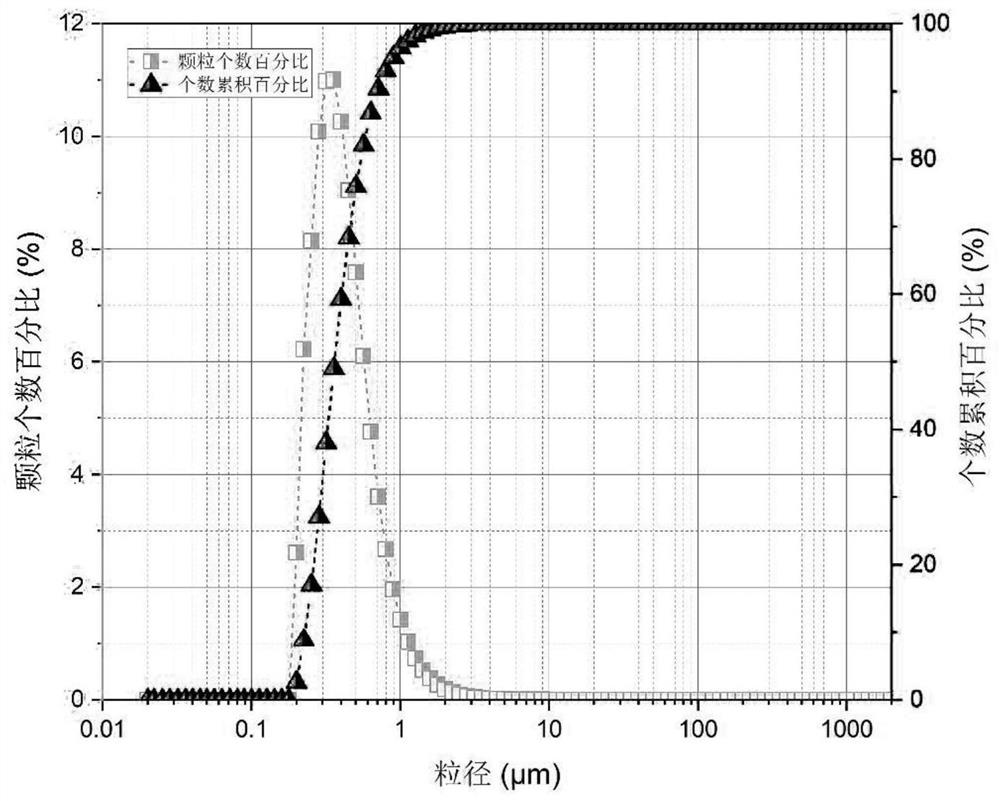

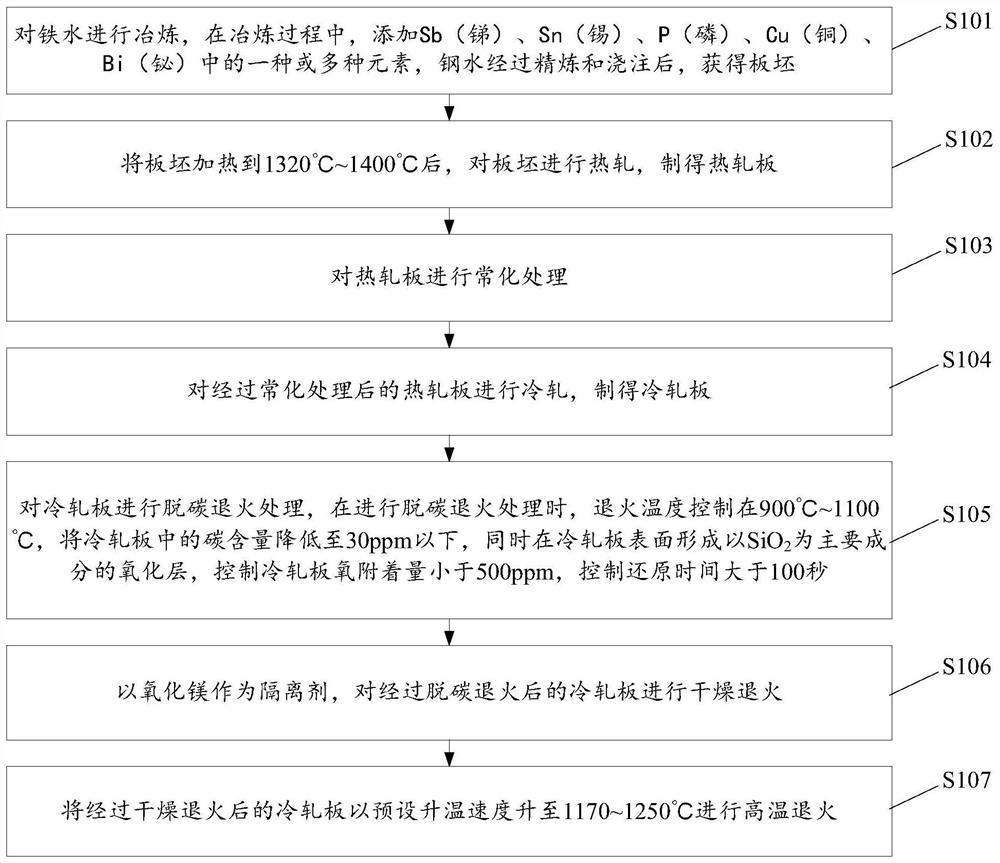

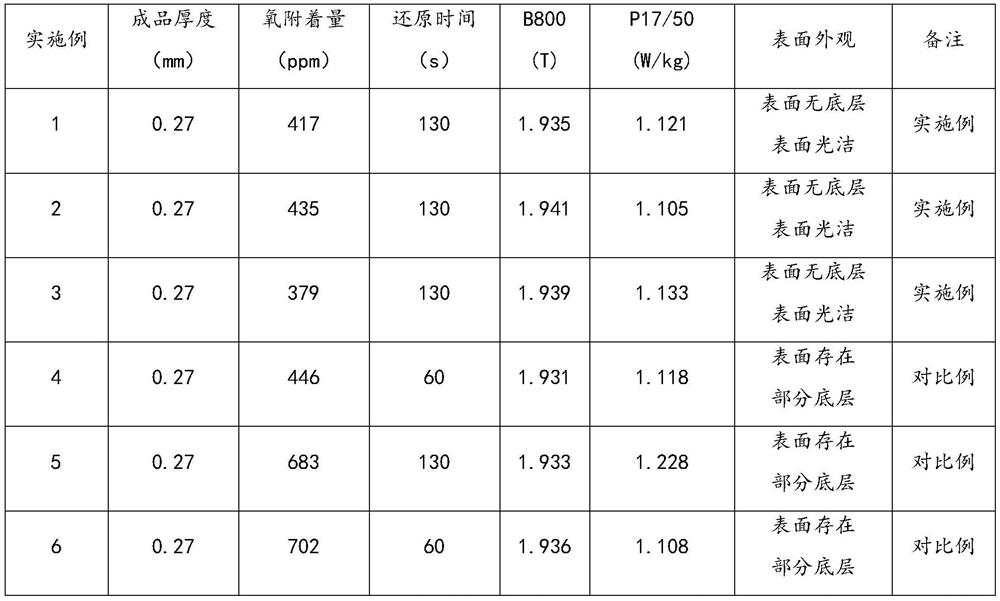

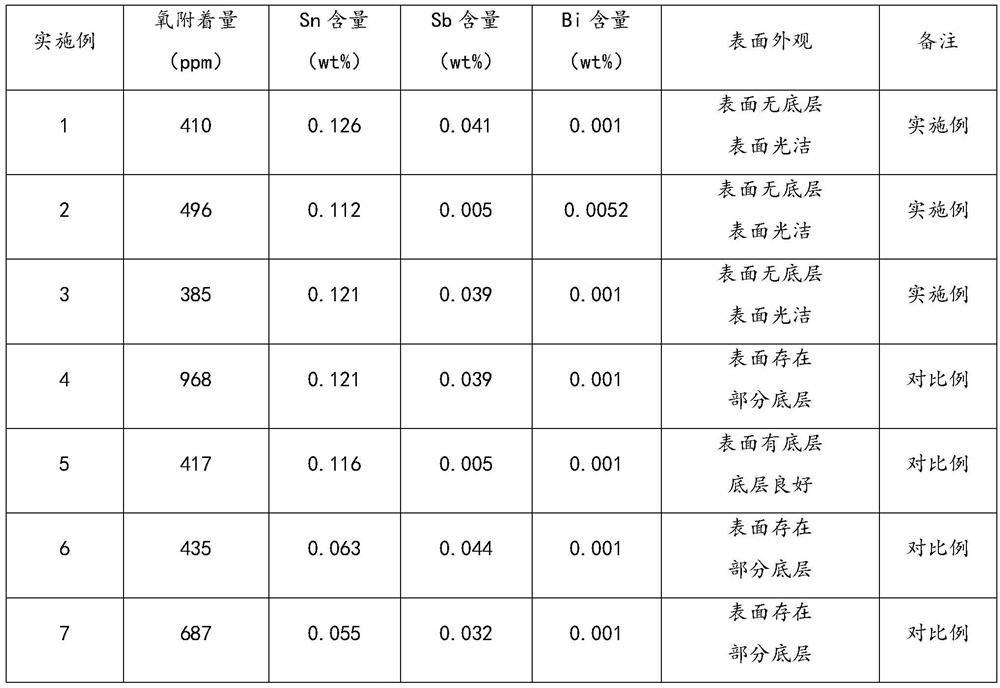

Manufacturing method of mirror oriented silicon steel

The invention discloses a manufacturing method of mirror oriented silicon steel. The manufacturing method of the mirror oriented silicon steel comprises the steps that molten iron is smelted, one or more elements of Sb, Sn, P, Cu and Bi are added in the smelting process, and after the molten steel is refined and poured, a plate blank is obtained; after the plate blank is heated to 1320 DEG C-1400DEG C, the plate blank is hot-rolled, and a hot-rolled plate is prepared; the hot-rolled plate is normalized; the hot-rolled plate after being normalized is cold-rolled, and a cold-rolled plate is obtained; the cold-rolled plate is decarburized and annealed, during decarburizing and annealing, the carbon content in the cold-rolled plate is reduced to below 30ppm, meanwhile, a SiO2 oxide layer is formed on the surface of the cold-rolled plate, the oxygen adhering amount of the cold-rolled plate is controlled to be less than 500ppm, and the reduction time is controlled to be greater than 100 seconds; the decarburized and annealed cold-rolled plate is dried and annealed with magnesium oxide as an isolating agent; and the dried and annealed cold-rolled plate is heated to 1170-1250 DEG C at a preset heating rate for high temperature annealing.

Owner:武汉钢铁有限公司

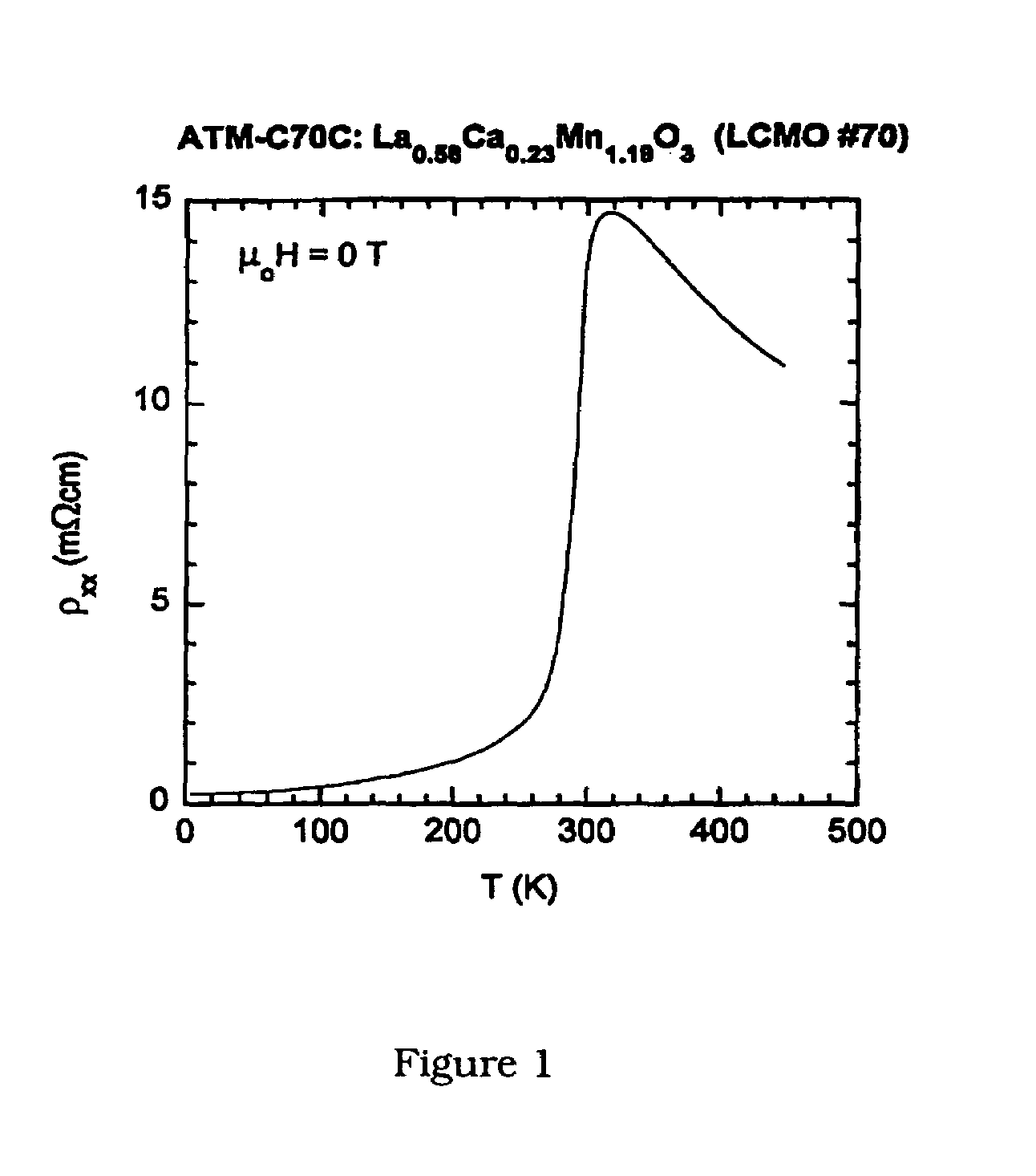

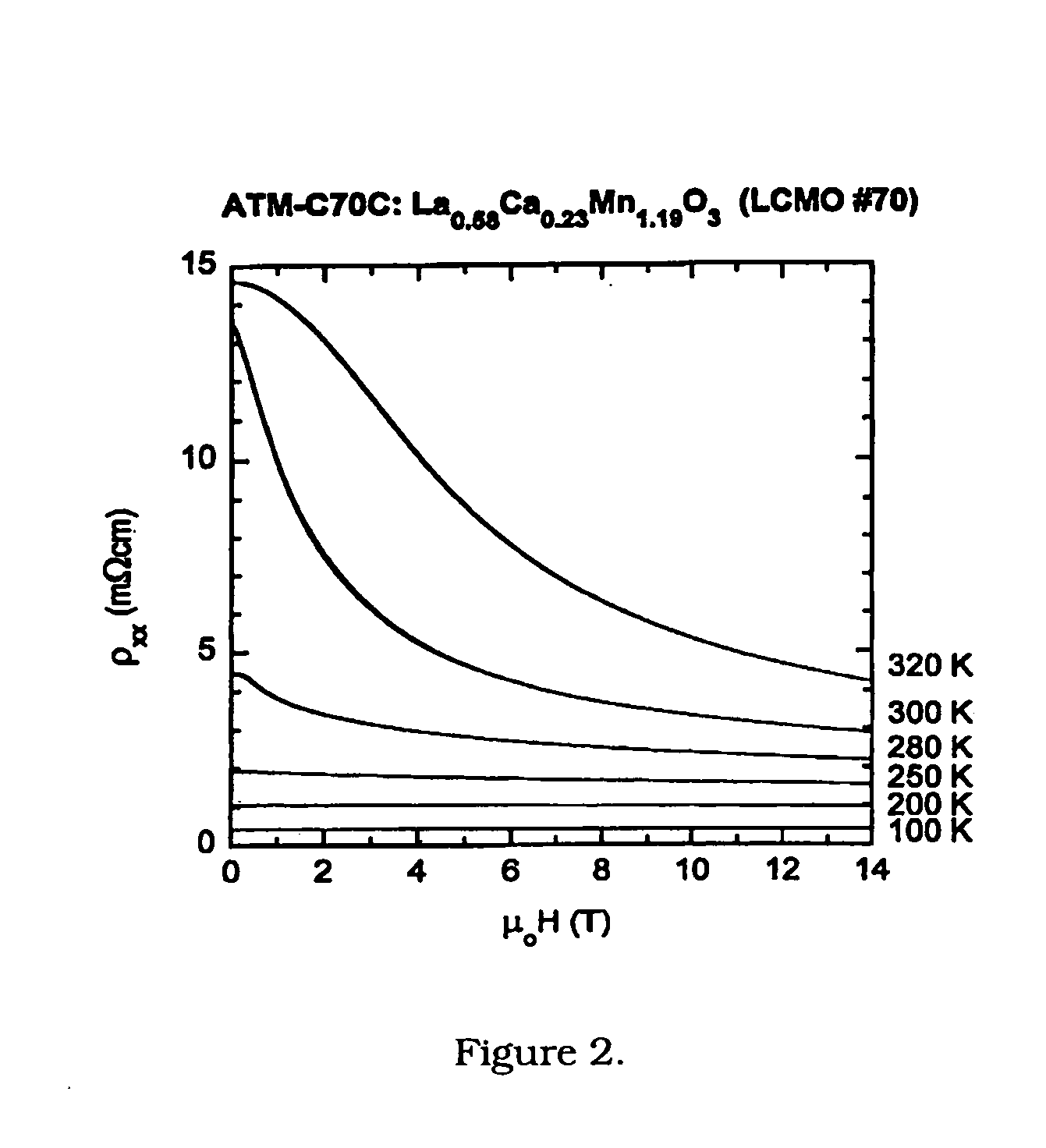

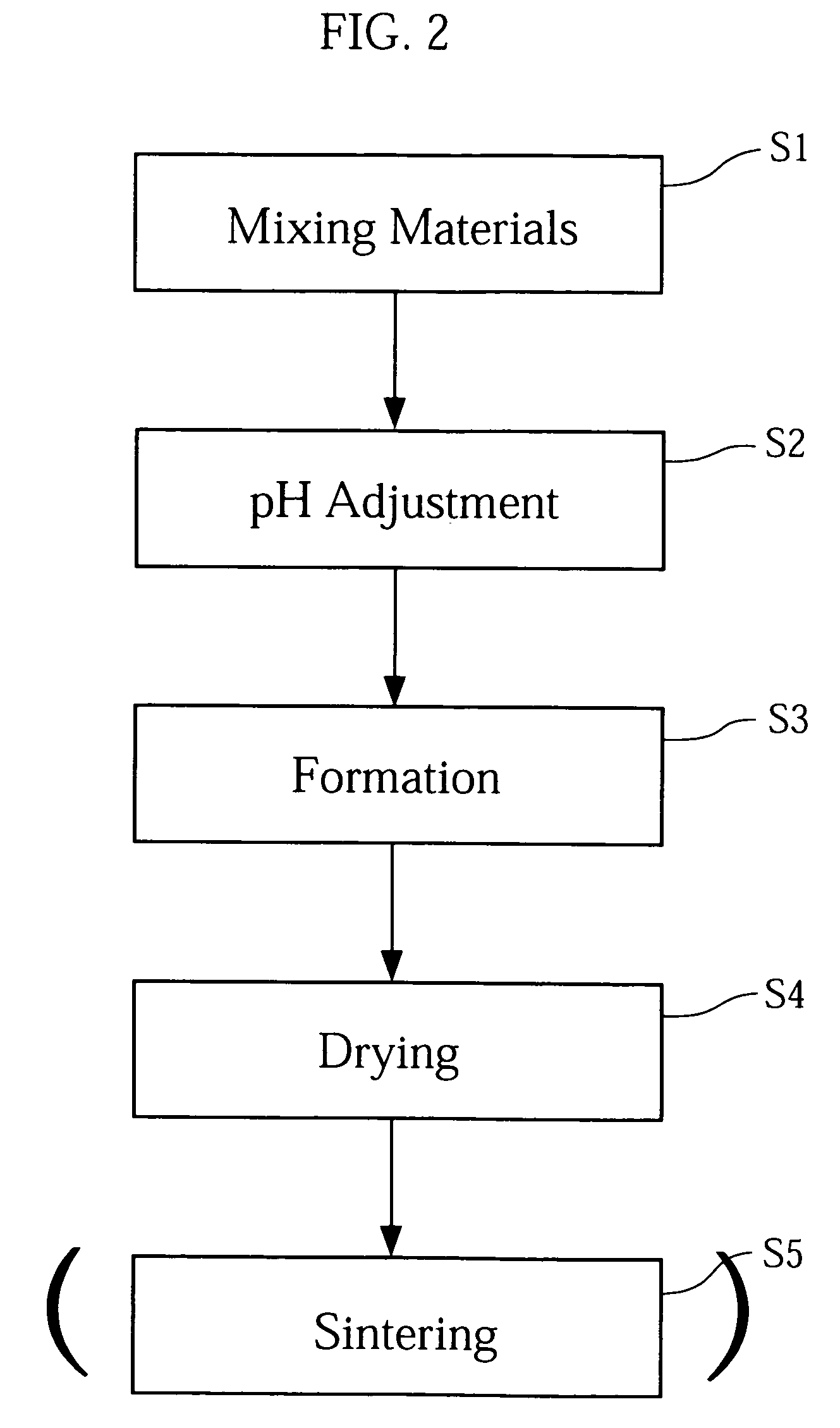

Composition and method for forming doped A-site deficient thin-film manganate layers on a substrate

InactiveUS7029724B1Precise control of ingredientsPreventing unwanted premature decompositionPretreated surfacesSpecial surfacesManganateManganese

A method of forming an A site deficient thin film manganate material on a substrate from corresponding precursor(s), comprising liquid delivery and flash vaporization thereof to yield a precursor vapor, and transporting the precursor vapor to a chemical vapor deposition reactor for formation of an A site deficient manganate thin film on a substrate. The invention also contemplates a device comprising an A site deficient manganate thin film, wherein the manganate layer is formed on the substrate by such a process and is of the formula LaxMyMnO3, where M=Mg, Ca, Sr, or Ba, and (x+y)<1.0, and preferably from about 0.5 to about 0.99.

Owner:ADVANCED TECH MATERIALS INC

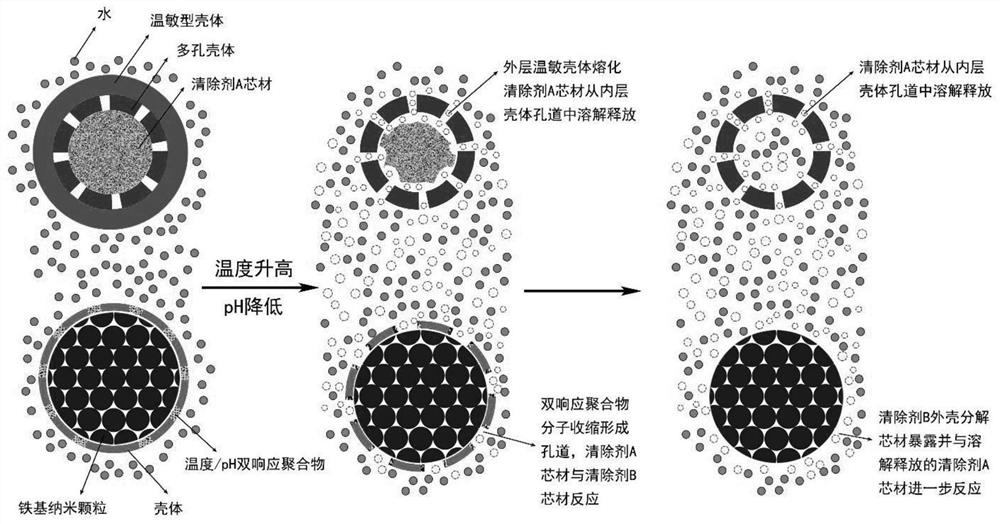

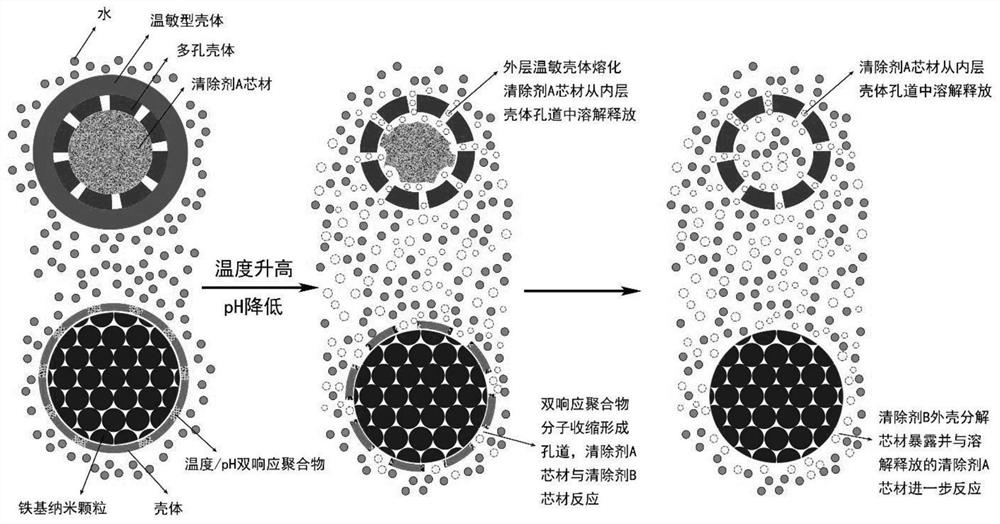

Environmental response type well cementation filter cake removing liquid

ActiveCN113004880AEnvironmentally responsiveAvoid premature decompositionDrilling compositionActive agentWell cementing

The invention discloses an environmental response type well cementation filter cake removing liquid which comprises the following components in parts by weight: 5-20 parts of an environmental response type scavenger A, 0.2-5 parts of an environmental response type scavenger B, 0.5-3 parts of a surfactant I, 0.3-2.5 parts of a suspending agent, 0.5-3 parts of a stabilizer and 100 parts of water with the pH value of 8-10. Components of the scavengers can start to react under the conditions of certain underground temperature and pH, through the synergistic activation effect of the environment response type scavenger B-formation heat on the environment response type scavenger A, the decomposition efficiency and rate of a polymer treating agent are improved, rapid decomposition within a short time is achieved, solid-phase particles are easy to remove after a filter cake is damaged, and in addition, advanced decomposition of the scavengers in the links of liquid preparation, transportation and the like is avoided, and the characteristics and requirements of well cementation operation are met.

Owner:SOUTHWEST PETROLEUM UNIV

Polyethylene wax with inner and outer lubrication performances

InactiveCN107022156AImprove mechanical propertiesIncrease the number of copiesZinc compoundsPolymer science

The invention discloses polyethylene wax with inner and outer lubrication performances. The polyethylene wax is prepared from the following raw materials: 95kg to 105kg of polyvinyl chloride, 3kg to 4.5kg of a calcium-zinc compound stabilizer, 1.5kg to 2.5kg of an acrylate copolymer, 3.5kg to 4.5kg of chlorinated polyethylene, 0.2kg to 0.5kg of a lubricant and 1.5kg to 2.5kg of titanium dioxide. The polyethylene wax is prepared through the following steps: after mixing all the raw materials, stirring and heating at temperature of 50 DEG C to 120 DEG C for 50min to 200min to obtain the polyethylene wax. Or the polyethylene wax is prepared through the following steps: uniformly mixing and stirring all the raw materials, cooling and keeping heat; pressurizing and heating and stirring and keeping warm; cooling to room temperature to obtain the polyethylene wax. The product provided by the invention pays attention to mechanical properties and surface brightness of a polyvinyl chloride hard product and is especially suitable for a high-calcium system formula. According to the polyethylene wax disclosed by the invention, the mechanical properties of a polyvinyl chloride product can be enhanced and the utilization portion of filling materials can be correspondingly increased due to an excellent coupling capability so that the surface glossiness of the polyvinyl chloride is increased. The polyethylene wax has a softening point of 102 DEG C and the viscosity of 45cps and has the inner and outer lubrication performances.

Owner:青岛赛诺新材料有限公司

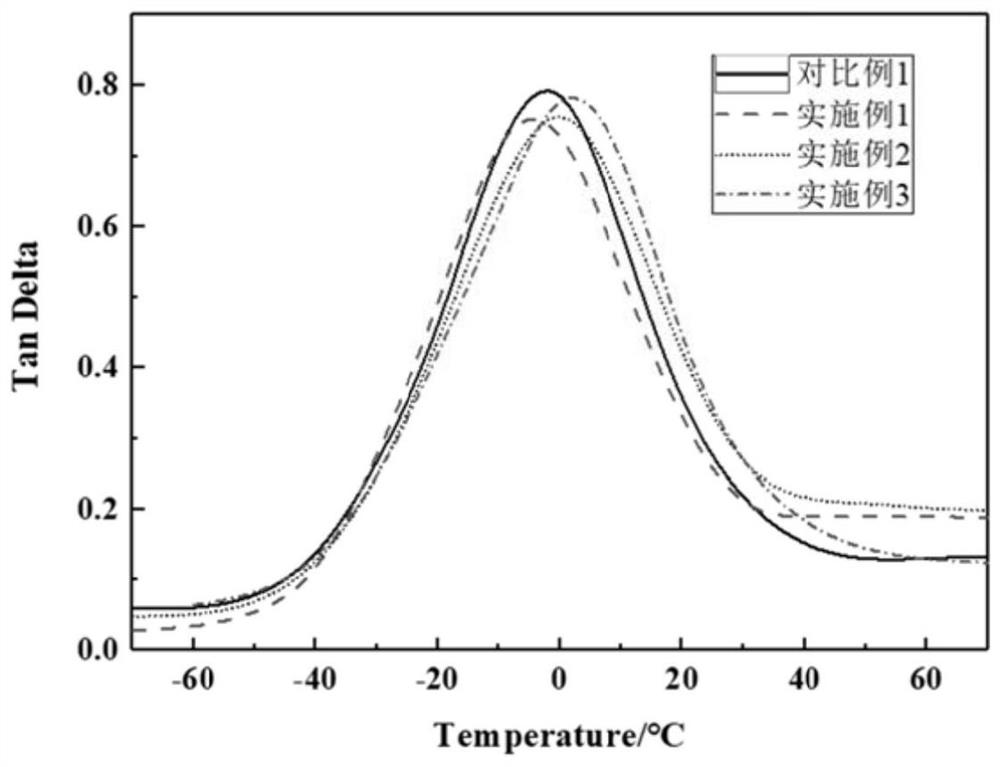

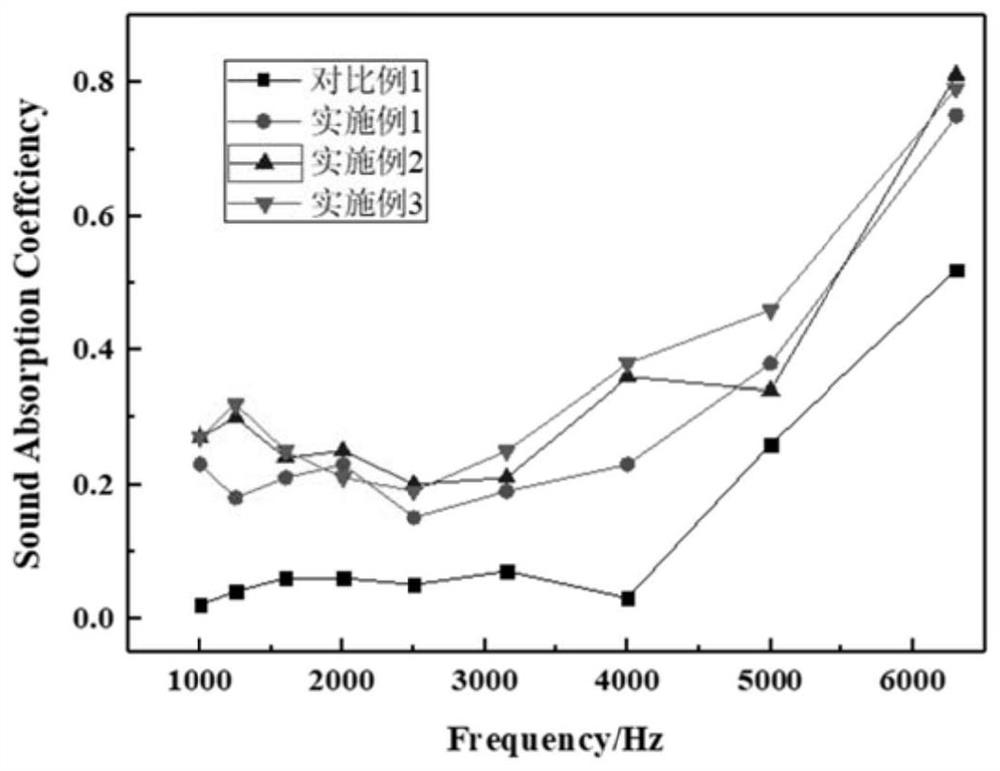

Polyvinyl chloride-based composite material suitable for medium-high frequency sound absorption and preparation method thereof

PendingCN112694691AAvoid premature decompositionEnsure successful sample preparationButadiene DioxideFoaming agent

The invention provides a polyvinyl chloride-based composite material suitable for medium-high frequency sound absorption and a preparation method thereof. The polyvinyl chloride-based composite material comprises the following raw material components by mass: 100 parts of polyvinyl chloride, 3-5 parts of an organic tin stabilizer, 100-130 parts of a plasticizer, 25-30 parts of an acrylonitrile-butadiene-styrene terpolymer, 0-50 parts of diatomite and 0-4 parts of an AC foaming agent. The polyvinyl chloride-based composite material provided by the invention has excellent sound absorption performance, the average sound absorption coefficient within 1000-6300Hz is 0.2-0.35, and the polyvinyl chloride-based composite material is suitable for medium-high frequency sound absorption materials.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

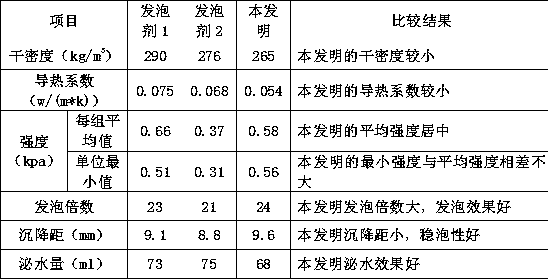

Preparation method for compound type foaming agent

The invention discloses a preparation method for a compound type foaming agent, relates to a preparation method for an additive for a building, in particular to a preparation method for a foaming agent added into concrete. The compound type foaming agent is compounded from an initial product, N,N'-dinitrosopentamethylamine (DPT), diglycol and lauryl alcohol. The compound type foaming agent is prepared on the basis of the original foaming agent, substances with excellent foaming properties are added into the foaming agent, and other additives are added to achieve the effects of increasing foams, stabilizing foams and regulating. The compound type foaming agent prepared by the preparation method is verified in practical production, and has the outstanding characteristics of being great in foaming amount, small in foam loss, small in strength effect and the like. The preparation method is simple to operate, is easy to control and is relatively high in yield.

Owner:云南森博混凝土外加剂有限公司

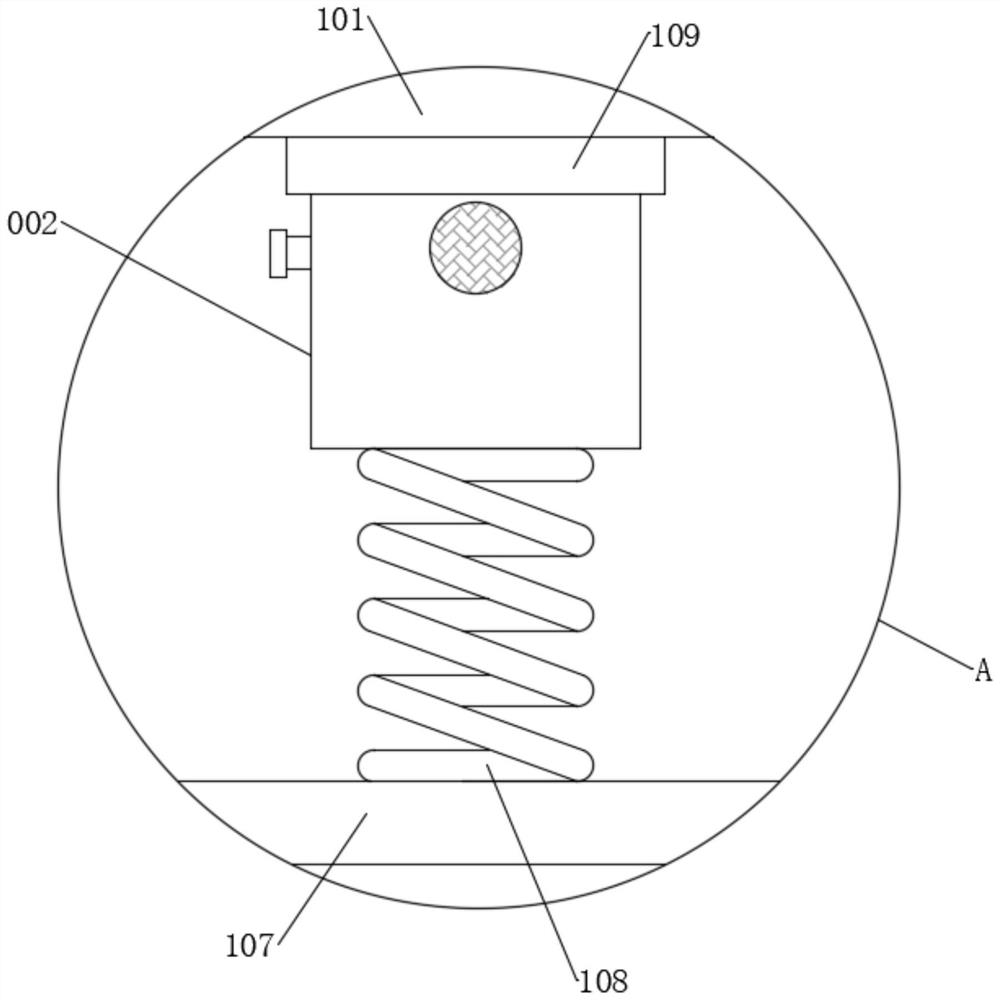

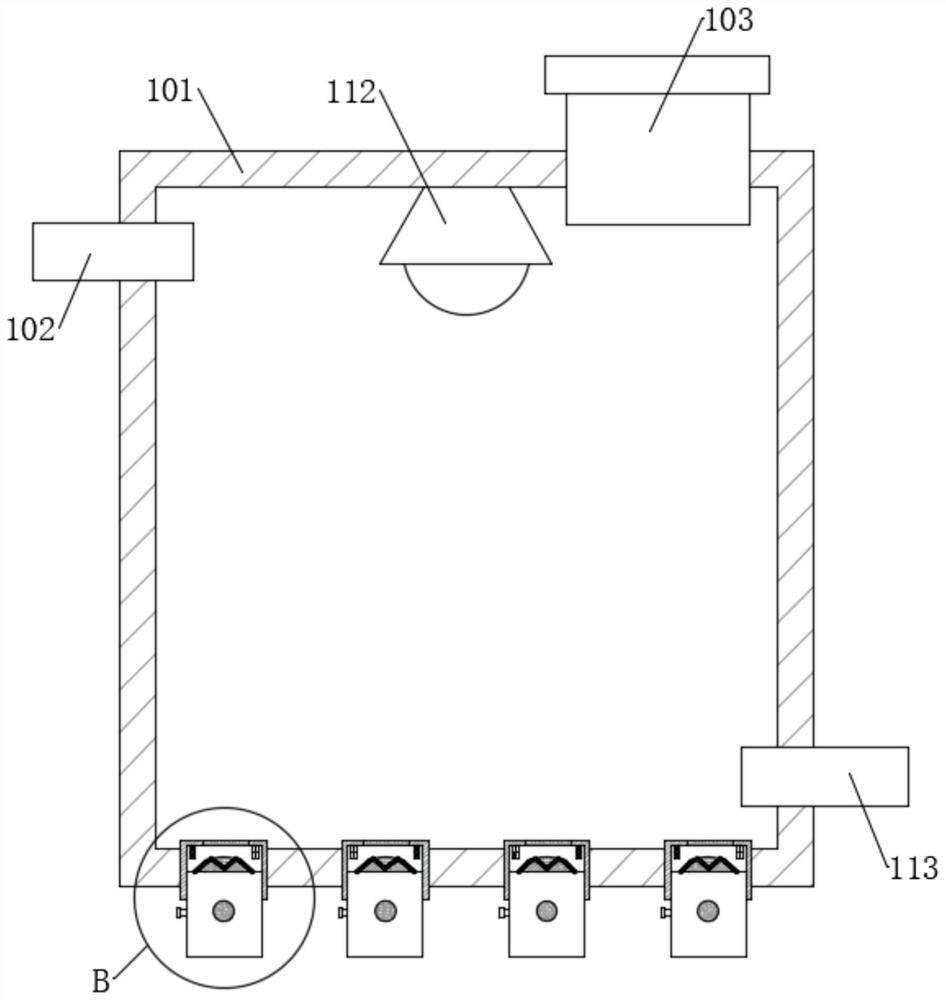

Secondary water supply water storage tank with sludge detection function

ActiveCN113833058AThe detection method is simpleEfficient detection methodUsing optical meansWater supply tanksWater useWater storage tank

The invention discloses a secondary water supply water storage tank with a sludge detection function, and belongs to the technical field of secondary water supply. Through the arrangement of a photosensitive detection cylinder part, the sludge accumulation condition can be detected only by turning on a light supply lamp, if the sludge accumulation at a certain position is relatively thick, a result judgment film in the photosensitive detection cylinder part does not change, otherwise, if a certain position has no sludge or less sludge, the result judgment film in the photosensitive detection cylinder part protrudes outwards and deforms, so that a worker can complete the detection of the sludge accumulation condition without entering a stainless steel box body, and the detection of the sludge accumulation condition can be completed. The detection method is simple, efficient and accurate and is high in practicability, a worker can roughly judge the sludge accumulation condition at the bottom end of the stainless steel box body according to the change condition of a plurality of photosensitive detection cylinder parts, then the cleaning work can be reasonably arranged according to the accumulation condition of the sludge, so that unnecessary cleaning can be avoided, and the water safety problem caused by excessive sludge can be prevented.

Owner:海口金福宝水塔太阳能有限公司

A method for dispersing ceramic particles in the process of composite plating on the surface of metal materials

ActiveCN106676613BEvenly dispersedSuspension stabilityElectrolytic coatingsLiquid/solution decomposition chemical coatingMetallic materialsMetal

The invention discloses a dispersion method for ceramic particles in the process of metal material surface composite plating and belongs to the technical field of metal surface treatment. According to the dispersion method for the ceramic particles in the process of metal material surface composite plating, an ammonium type compound is added during preparation of a ceramic particle slurry to be used as a dispersion agent; through the combination of NH4+ and the ceramic particles, the ceramic particles can be evenly distributed in a plating solution and stably suspend, plating of the ceramic particles is reduced or avoided, the bearing capacity of the plating solution is not influenced, the situation that because the ceramic particles are added to the plating solution, the plating solution is decomposed in advance is avoided, the service life of the plating solution is prolonged, and the plating cost is reduced; and meanwhile, the generated NH4+ structure is one of metal ion complexing components in the plating solution, the improvement on the stability of heavy metal ions in the plating solution is facilitated, the performance of a plating layer is prevented from being influenced, and the improvement on the performance of the plating layer is facilitated.

Owner:有研金属复材技术有限公司

Agricultural chemical component and decomposer for residual agricultural chemical

ActiveUS8030245B2Residue reductionExhibit some effectBiocideOther chemical processesOrganic filmChemical composition

An agricultural chemical component includes an active agricultural chemical ingredient and a powder metal-modified apatite which has part of metal atoms in its apatite crystal structure provided by an optically catalytic metal. Preferably, the metal-modified apatite is coated with an organic film.

Owner:FUJITSU LTD

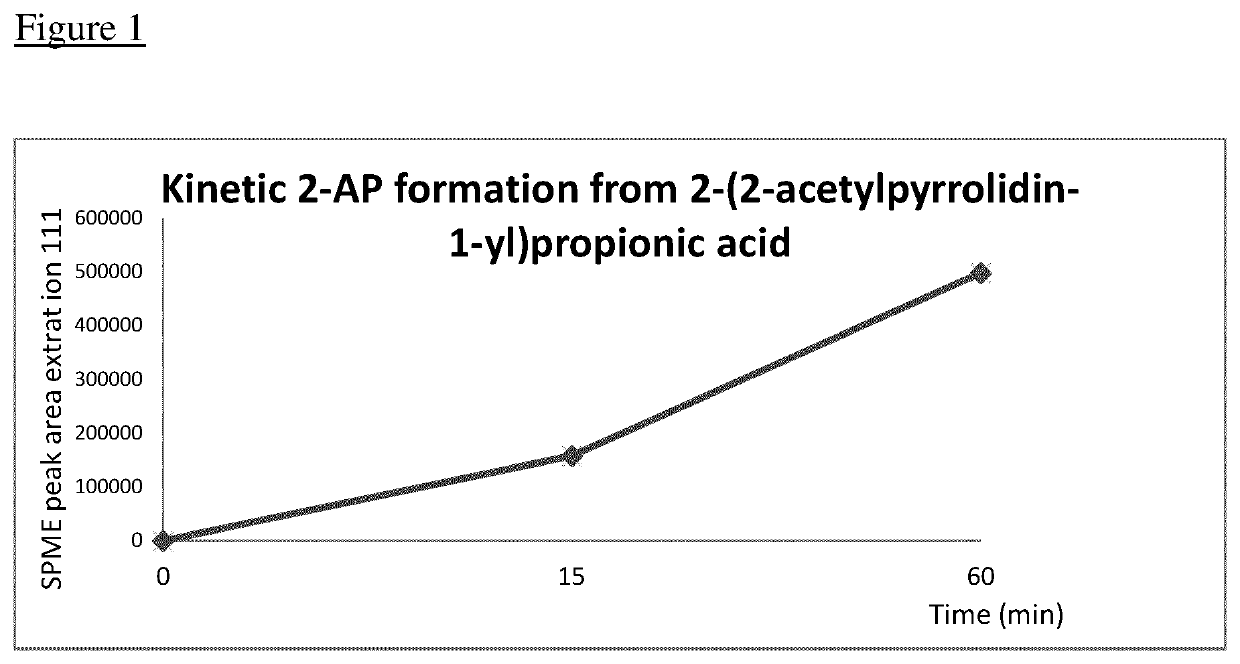

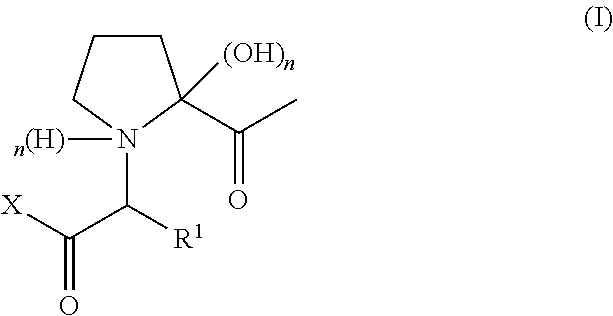

2-acetylpyrroline precursor

PendingUS20220361542A1Improve the organoleptic impact of 2-acetyl-1-pyrrolineAvoid premature decompositionOrganic chemistryFood scienceHydrocarbonAceglatone

Described herein is a precursor compound of formula (I) releasing 2-acetyl-1-pyrroline and a method to release 2-acetyl-1-pyrroline from the precursor compound of formula (I)in the form of any one of its stereoisomers, tautomers, salts or as a mixture thereof, where R1 represents a hydrogen atom or a C1 to C10 hydrocarbon group optionally including one to three heteroatoms; X represents an amino acid, a peptide or a OR2 wherein R2 represents a hydrogen atom or a C1 to C20 hydrocarbon group optionally including one to three heteroatoms and n is 0 when the dotted line represents a single bond or n is 1 when the dotted line represents no bond.

Owner:FIRMENICH SA

Fusion graft process for modified polypropylene/acrylic acid polyester ether

The present invention relates to an improved melting grafting method of polypropylene and polyether acrylate, which comprises the following process steps: a) adding polyether acrylate monomers, peroxidation initiators and antioxidants into a high-speed disperser at normal temperature Mix uniformly in the middle to form a mixed solution of grafted monomer and initiator; b) the twin-screw extruder is heated up to the reaction temperature, and the polypropylene resin is passed through the feeder of the twin-screw extruder, with a fixed feeding frequency Add from the feed port; c) at the feed port of the twin-screw extruder mixing section, continuously add the mixed solution of the graft monomer and the initiator by the liquid pump to make the peroxidation initiator, polyether acrylate monomer and react with polypropylene melt in the mixing section of the twin-screw extruder; d) Turn on the vacuum pump at the end of the screw to remove low-molecular matter, and the extruded melt is cooled and pelletized to obtain the final polypropylene / Acrylic polyether ester grafted product. The invention avoids the problem of material slipping at the feeding port of the twin-screw extruder, is beneficial to the grafting reaction, and improves the grafting efficiency.

Owner:江苏创源科技新材料有限公司 +1

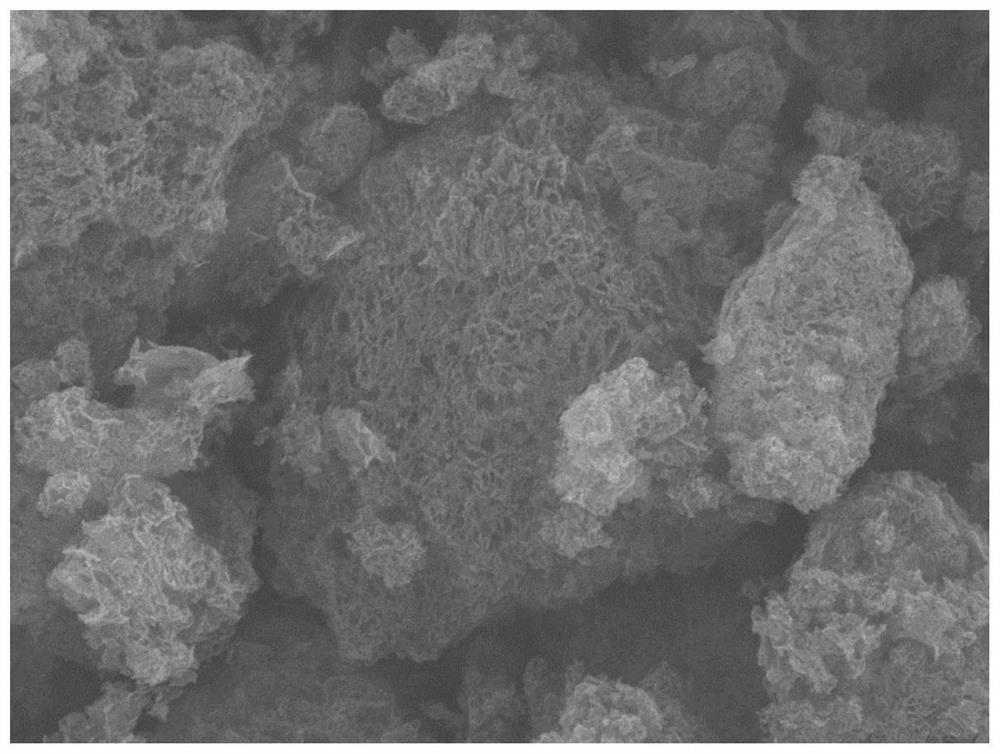

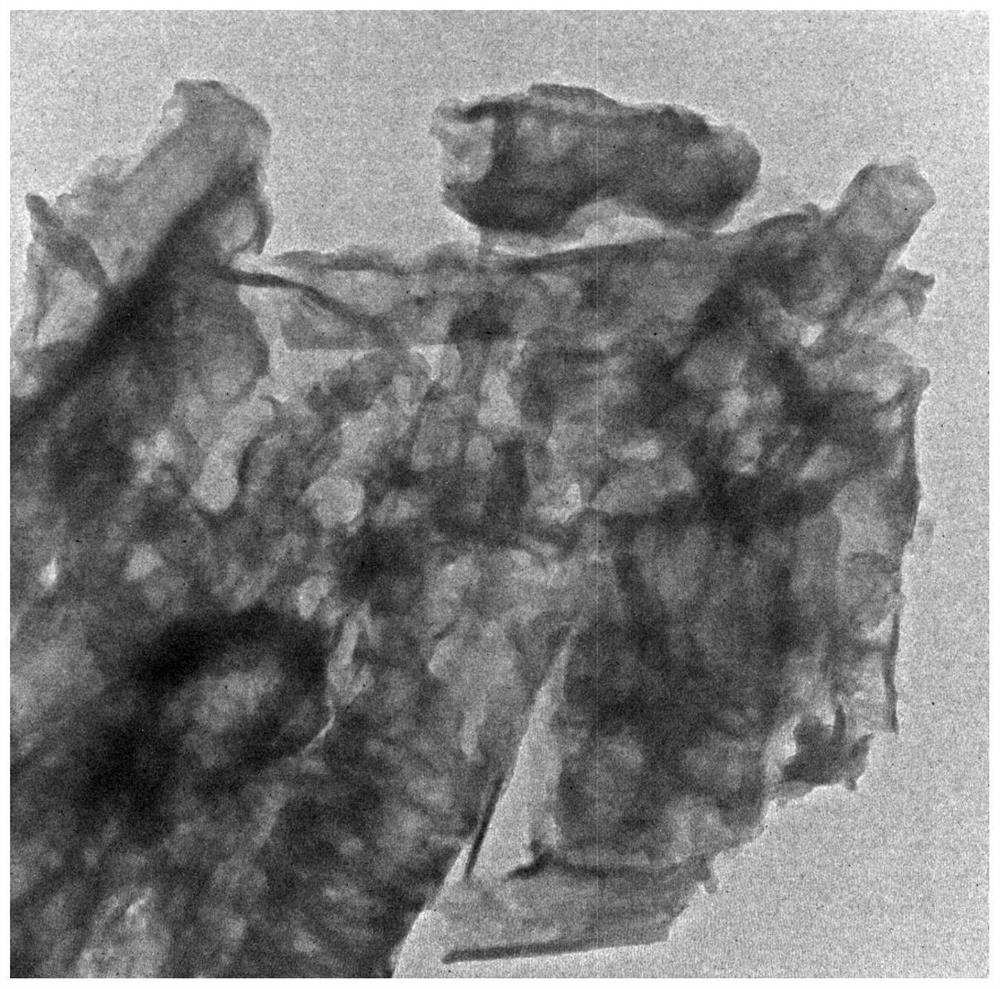

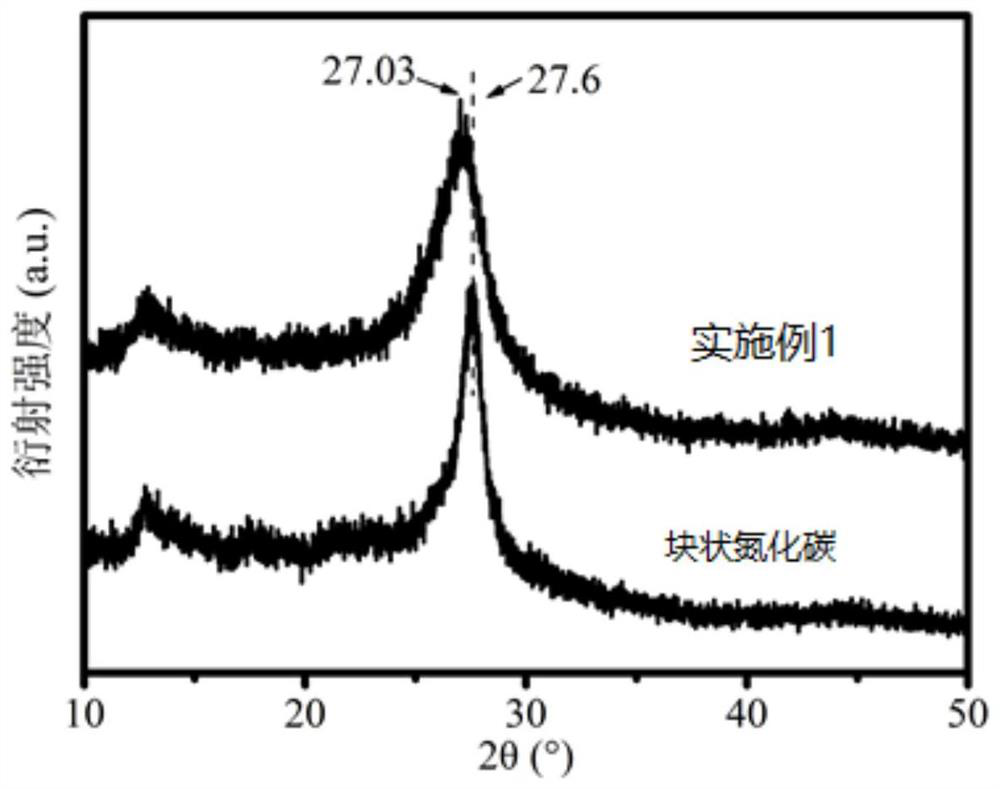

Carbon nitride-graphene composite material as well as preparation method and application thereof

ActiveCN113593924AHigh specific surface areaHigh reactivityHybrid capacitor electrodesHybrid/EDL manufacturePolythiocyanogenThiocyanic acid

The invention provides a carbon nitride-graphene composite material as well as a preparation method and application thereof. The preparation method of the carbon nitride-graphene composite material comprises the following steps: (1) mixing and stirring trithiocyanuric acid, thiourea and water, then conducting drying to obtain a block, crushing the block, carrying out heating and preserving heat to obtain sulfur-doped porous honeycomb carbon nitride; and (2) dispersing the sulfur-doped porous honeycomb carbon nitride obtained in the step (1) to obtain a carbon nitride solution, and mixing and stirring the carbon nitride solution with a graphene-HCl dispersion liquid to obtain the carbon nitride-graphene composite material. The carbon nitride-graphene composite material provided by the invention is high in specific capacity, high in surface reaction activity and strong in conductivity.

Owner:哈尔滨万鑫石墨谷科技有限公司 +1

An environmental responsive cementing filter cake removal fluid

ActiveCN113004880BEnvironmentally responsiveAvoid premature decompositionDrilling compositionActive agentPhysical chemistry

The invention discloses an environment-responsive cementing filter cake removal liquid, which comprises the following components in parts by weight: 5-20 parts of environment-responsive scavenger A, 0.2-5 parts of environment-responsive scavenger B. 0.5-3 parts of surfactant 1. 0.3-2.5 parts of suspending agent, 0.5-3 parts of stabilizer and 100 parts of water with a pH of 8-10. The scavenger component of the present invention can only start to react under certain temperature and pH conditions downhole, and through the synergistic activation of the environment-responsive scavenger B-formation heat on the environmental-responsive scavenger A, the decomposition of the polymer treatment agent is improved Efficiency and speed, to achieve rapid decomposition in a short period of time, the solid phase particles are easy to be removed after the filter cake is destroyed, and avoid the early decomposition of the scavenger caused by liquid preparation, transportation and other links, and adapt to the characteristics and requirements of cementing operations.

Owner:SOUTHWEST PETROLEUM UNIV

A kind of manufacturing method of mirror-oriented silicon steel

The invention discloses a manufacturing method of mirror oriented silicon steel. The manufacturing method of the mirror oriented silicon steel comprises the steps that molten iron is smelted, one or more elements of Sb, Sn, P, Cu and Bi are added in the smelting process, and after the molten steel is refined and poured, a plate blank is obtained; after the plate blank is heated to 1320 DEG C-1400DEG C, the plate blank is hot-rolled, and a hot-rolled plate is prepared; the hot-rolled plate is normalized; the hot-rolled plate after being normalized is cold-rolled, and a cold-rolled plate is obtained; the cold-rolled plate is decarburized and annealed, during decarburizing and annealing, the carbon content in the cold-rolled plate is reduced to below 30ppm, meanwhile, a SiO2 oxide layer is formed on the surface of the cold-rolled plate, the oxygen adhering amount of the cold-rolled plate is controlled to be less than 500ppm, and the reduction time is controlled to be greater than 100 seconds; the decarburized and annealed cold-rolled plate is dried and annealed with magnesium oxide as an isolating agent; and the dried and annealed cold-rolled plate is heated to 1170-1250 DEG C at a preset heating rate for high temperature annealing.

Owner:武汉钢铁有限公司

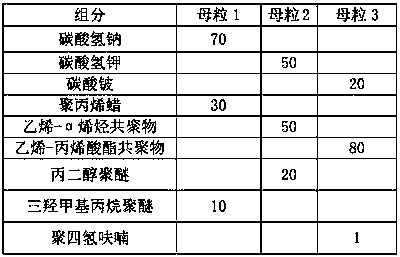

Low-odor high-dispersion foaming master batch, and preparation method and application thereof

The invention discloses a low-odor high-dispersion foaming master batch and application of the same to a modified polymer material, belonging to the technical field of materials. The foaming materialcomprises the following components in parts by weight: 20-70 parts of a foaming agent, 1-20 parts of polyether polyol, 30-80 parts of carrier resin, 1-10 parts of an odor improver, 0.5-5 parts of a dispersing agent, 1-10 parts of an interface improver and 0.5-2.0 parts of an auxiliary agent. The invention also discloses a preparation method of the low-odor high-dispersion foaming master batch. Anodor removing agent in the low-odor high-dispersion foaming master batch interacts with volatile components generating odor in a modified plastic material during processing of the modified plastic material, and a mixture is extracted out of a modified polymer melt by utilizing the vacuum negative pressure effect of the vacuum port of an extruder, so the content of harmful volatile components suchas odor molecules of the modified plastic material is effectively reduced, and the increasingly high requirements for no toxicity, no odor and no harm of modified plastic products are met.

Owner:NANJING JULONG SCI&TECH CO LTD

Manufacturing process of chemical foaming fluorine material

InactiveCN111187442AOmit the compression processReduce pollutionLow-density polyethyleneDecomposition

The invention discloses a manufacturing process of a chemical foaming fluorine material. The manufacturing process comprises the following steps: 1, selecting a fluorine material with good physical properties and chemical properties, and weighing for later use; 2, selecting foaming powder suitable for chemical foaming production, and weighing for later use; 3, performing master batch treatment onthe foaming powder by using molding equipment, taking EVA or low-density polyethylene as a carrier, preparing 5-10% of foaming master batch, and performing extrusion treatment at a decomposition temperature; 4, adding the foaming master batch into the fluorine material according to 0.3-3% of the addition amount of the foaming powder, and fully stirring and mixing by using stirring equipment to obtain a mixture I; and 5, aging the mixture I at 95-100 DEG C for 6-12 hours, and directly extruding the mixture I by using the molding equipment to prepare the chemical foaming fluorine material. By improving the fluorine material and the production process, the production efficiency of the foaming fluorine material is improved while various properties of the fluorine material are retained.

Owner:广州敬信高聚物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com