Polyvinyl chloride-based composite material suitable for medium-high frequency sound absorption and preparation method thereof

A technology of polyvinyl chloride and composite materials, applied in the field of organic polymer compounds, can solve the problems of high maintenance cost, difficult construction, high density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

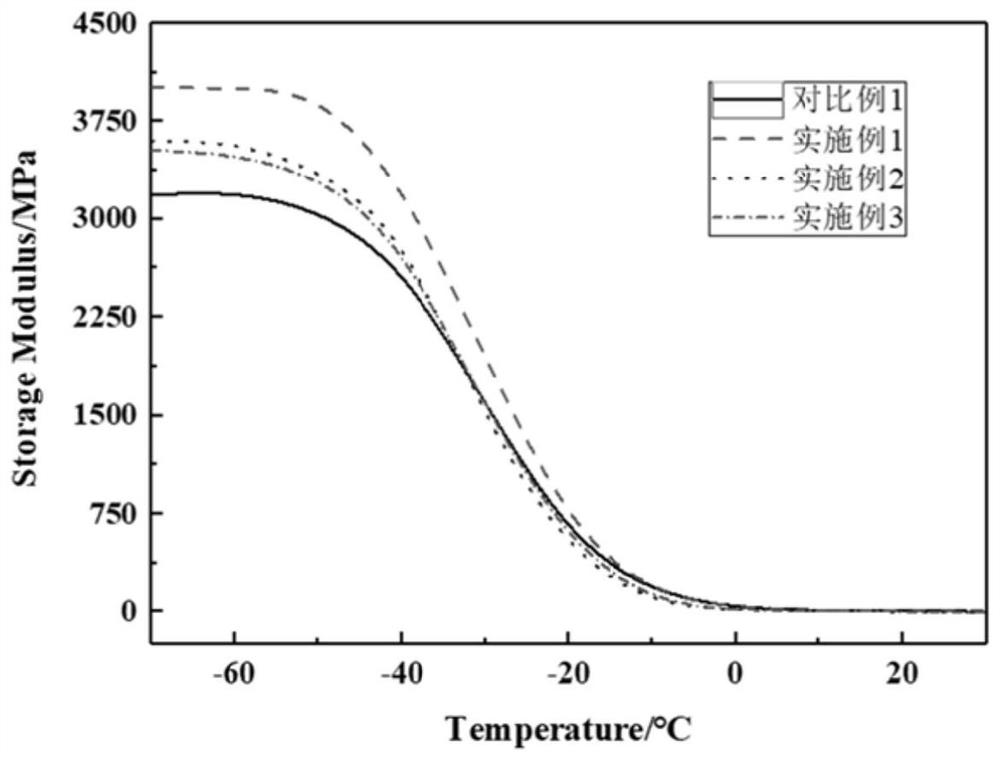

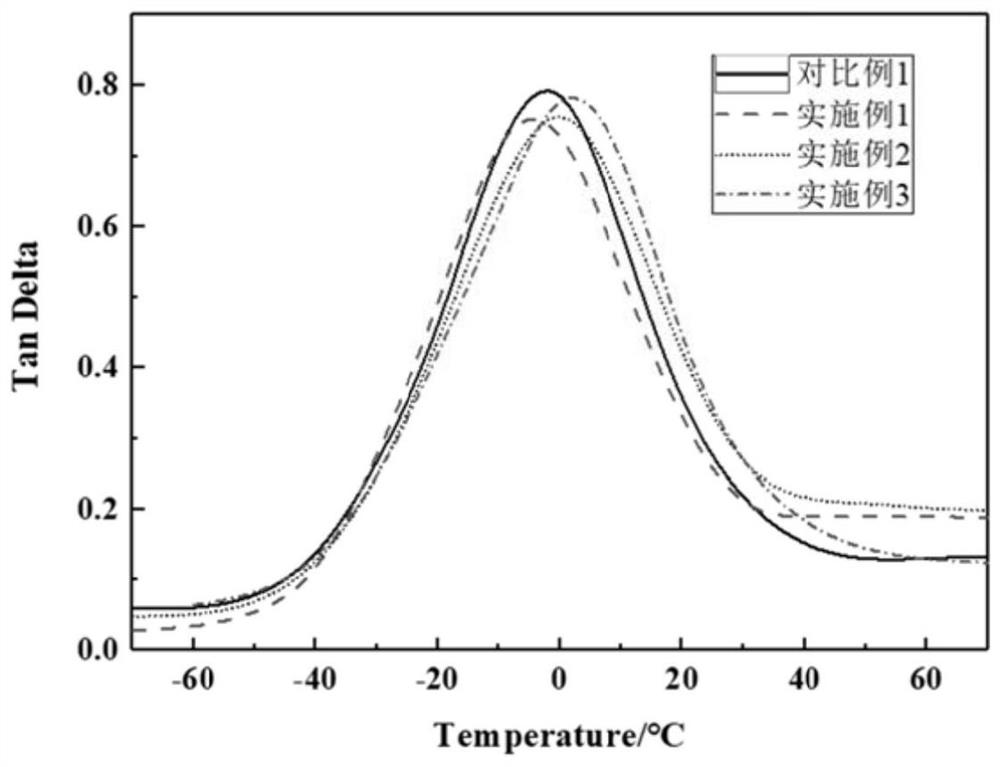

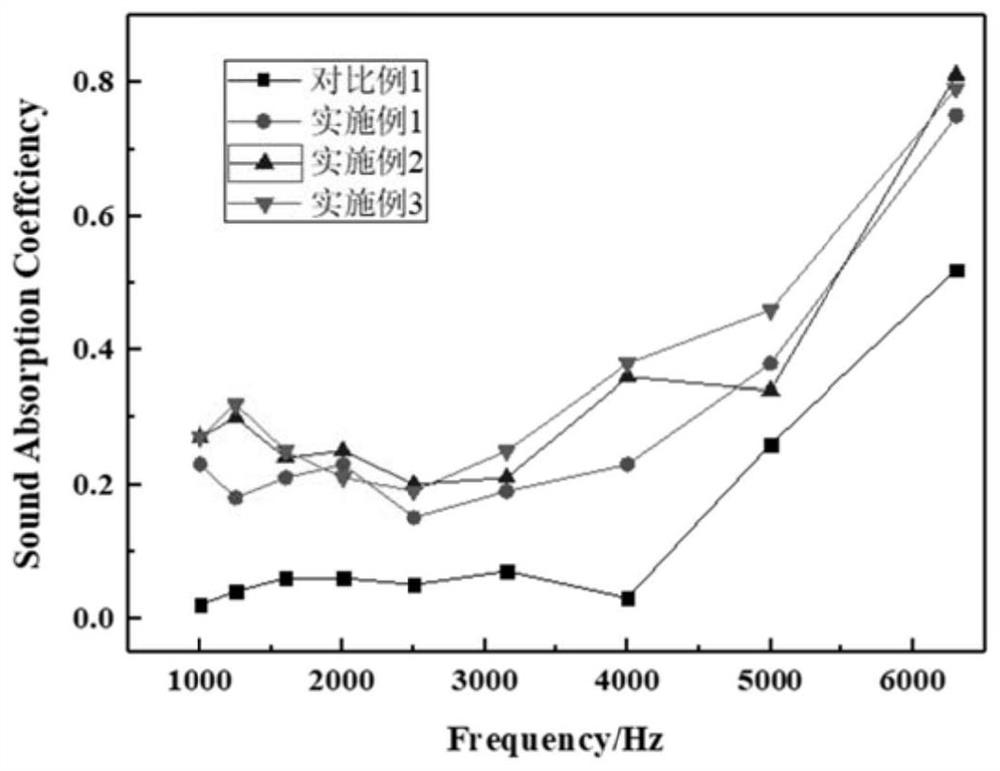

Embodiment 1

[0040] A polyvinyl chloride-based composite material suitable for medium and high-frequency sound absorption, its raw material composition and parts by weight are: 100 parts of polyvinyl chloride, 4 parts of organotin stabilizer, 130 parts of plasticizer, acrylonitrile-butadiene -26 parts of styrene terpolymers, prepared through the following steps:

[0041] (1) Weigh the raw materials in proportion, and dry the powders of polyvinyl chloride and acrylonitrile-butadiene-styrene terpolymer in a constant temperature drying oven at 60°C for subsequent use;

[0042] (2) Put the above-mentioned polyvinyl chloride, organotin stabilizer, plasticizer, and acrylonitrile-butadiene-styrene terpolymer in a high-speed mixer and stir for 5 seconds at 500 rpm / s, and stir for 3 times to obtain a uniform mixture composite powder;

[0043] (3) Put the uniformly mixed composite powder into a Harp torque rheometer for melt blending, the melting temperature is 95°C, the rotation speed is 40rpm / min...

Embodiment 2

[0046] A polyvinyl chloride-based composite material suitable for medium and high-frequency sound absorption, its raw material composition and parts by weight are: 100 parts of polyvinyl chloride, 4 parts of organotin stabilizer, 130 parts of plasticizer, acrylonitrile-butadiene - 26 parts of styrene terpolymer, 3 parts of AC blowing agent, prepared by the following steps:

[0047] (1) Weigh the raw materials in proportion, and dry the powders of polyvinyl chloride, acrylonitrile-butadiene-styrene terpolymer and AC foaming agent in a constant temperature drying oven at 60°C for subsequent use;

[0048] (2) The above-mentioned polyvinyl chloride, organotin stabilizer, plasticizer, acrylonitrile-butadiene-styrene terpolymer, and AC foaming agent are placed in a high-speed mixer and stirred for 5 s at 500 rpm / s, Stir 3 times to obtain a uniformly mixed composite powder;

[0049] (3) Put the uniformly mixed composite powder into a Harp torque rheometer for melting and blending, t...

Embodiment 3

[0053] A polyvinyl chloride-based composite material suitable for medium and high-frequency sound absorption, its raw material composition and parts by weight are: 100 parts of polyvinyl chloride, 4 parts of organotin stabilizer, 130 parts of plasticizer, acrylonitrile-butadiene - 26 parts of styrene terpolymer, 37 parts of diatomaceous earth, 3 parts of AC foaming agent, prepared by the following steps:

[0054] (1) Weigh the raw materials in proportion, and dry the powders of polyvinyl chloride, acrylonitrile-butadiene-styrene terpolymer, diatomaceous earth, and AC foaming agent in a constant temperature drying oven at 60°C spare;

[0055] (2) The above-mentioned polyvinyl chloride, organic tin stabilizer, plasticizer, acrylonitrile-butadiene-styrene terpolymer, diatomaceous earth, and AC foaming agent are placed in a high-speed mixer and stirred at 500rpm / s Stir for 5 seconds, and stir for 3 times to obtain a uniformly mixed composite powder;

[0056] (3) Put the uniforml...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com