Steamed vermicelli roll manufacturing method and low-temperature fine rice milk grinding machine

A technology for pulping and rice rolls, applied in food preparation, cocoa, grain processing, etc., can solve problems such as high temperature, unfavorable taste of rice rolls, premature rice milk precursor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The method for preparing rice rolls of the present invention includes the steps:

[0042] Rice washing; low temperature soaking rice; low temperature grinding; adding flour; dilution; steaming; forming.

[0043] Among them, the rice soaking step is to soak the rice in the cold storage temperature, which can ensure that the rice absorbs enough moisture while ensuring its low temperature;

[0044] In the low-temperature refining step, ice and / or ice water are added to the grinding disc during the rice grinding process to achieve the cooling effect.

[0045] In the process of grinding rice with the grinding disc, a relatively high relative movement speed will occur between the grinding disc and the rice, between the grinding disc and the grinding disc, and will also produce greater friction. This friction will generate a higher temperature, which may reach 30-50 ℃, the local instantaneous temperature can exceed 70℃. The high temperature generated during the refining process will c...

Embodiment 1

[0049] Rotation speed of the grinding disc s, the distance between the grinding discs D (mm), the inclination angle of the grinding disc θ, the rice soaking time t, the current average temperature T, the rice adding rate p, the average narrow end outer diameter of the rice d;

[0050] The diameter of crushed ice is similar to that of rice grains and is in the millimeter level. In this embodiment, the size of crushed ice is usually 2 to 4 mm. The smaller size is classified as ice water, and the larger size of homing ice cubes can be compared with rice grains in the grinding process. Contact with each other to achieve the best cooling effect, the adding rate Q1 (grams per second), the ice cube cooling effect is the second, the adding rate Q2, the ice water cooling effect is the second, the cooling rate is the fastest, and the adding rate Q3.

[0051] When d <1.2 and t When <1.5h, the grinding diameter of the rice grains is small and the soaking time of the rice grains is short. At thi...

Embodiment 2

[0071] Example 2 is similar to Example 1. The difference is that in the preparation step of rice rolls, the step of refining is specifically, namely:

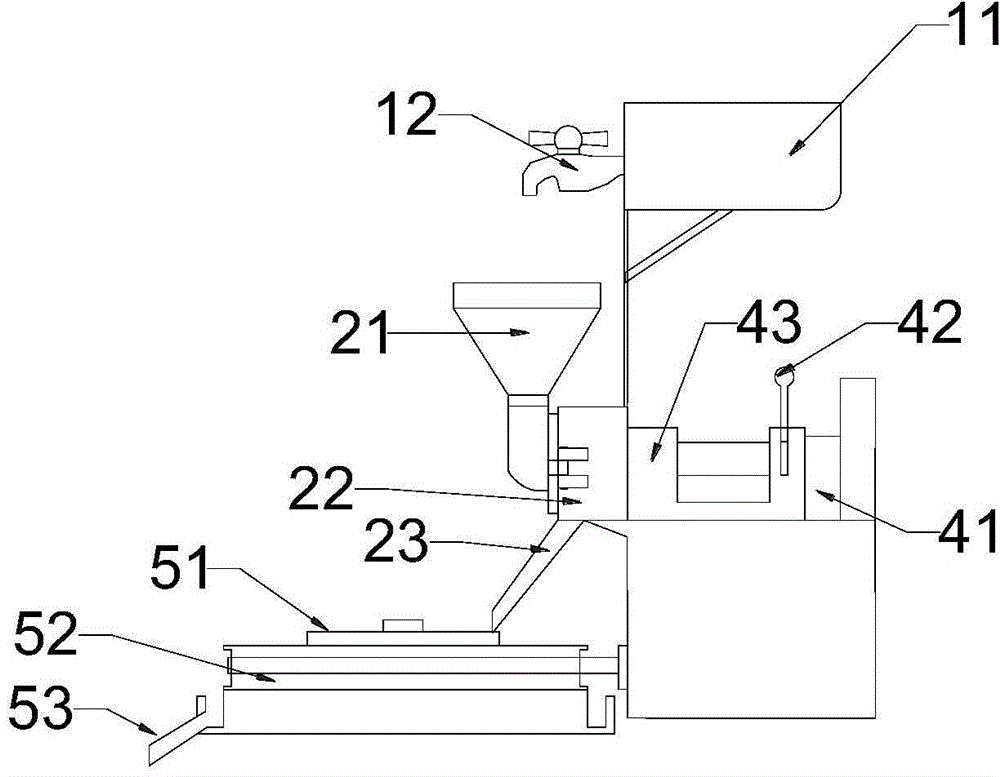

[0072] Rice washing; low-temperature soaking rice; low-temperature refining; secondary refining; adding flour; dilution; steaming; forming.

[0073] In the secondary refining in the step, a small amount of crushed ice can be added to keep the temperature low.

[0074] The setting of the secondary refining step can grind the rice slurry for the initial grinding more delicately. More preferably, if a stone mill is used as the main grinding body for the secondary grinding, the trace elements in the rice slurry can be increased.

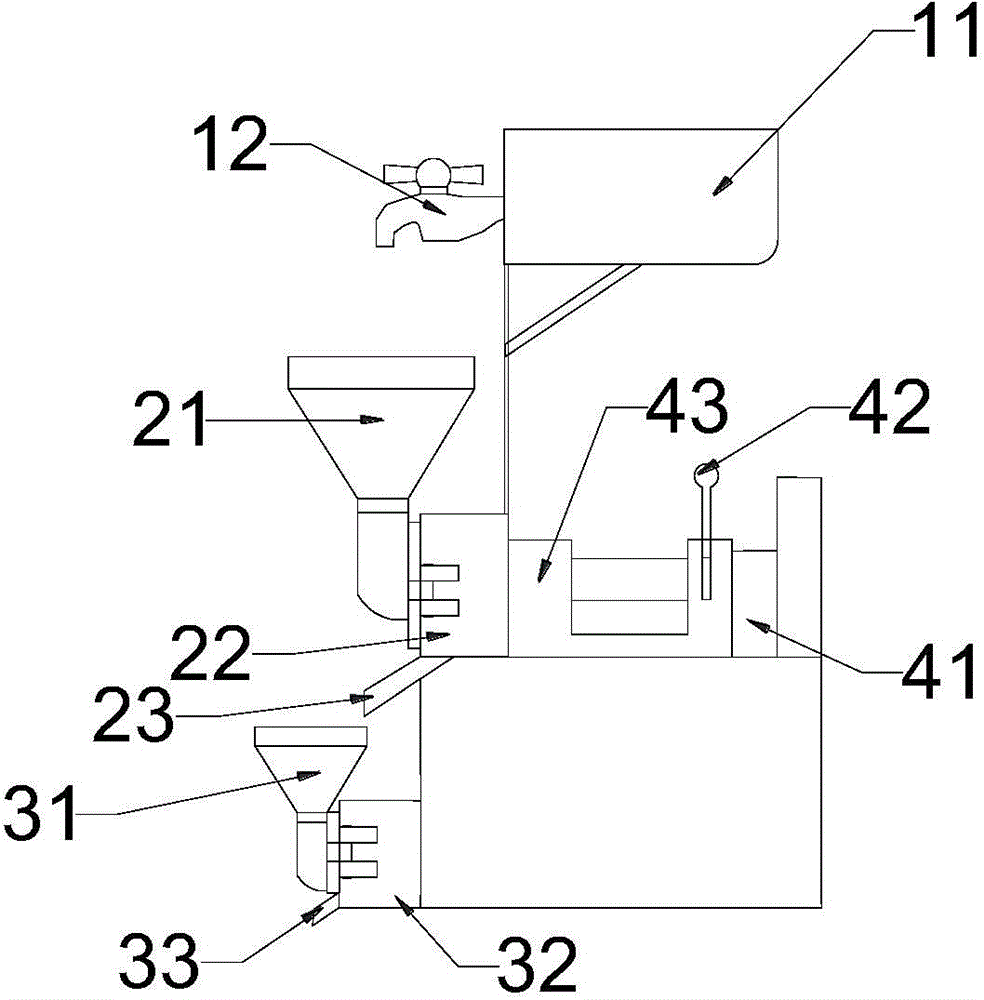

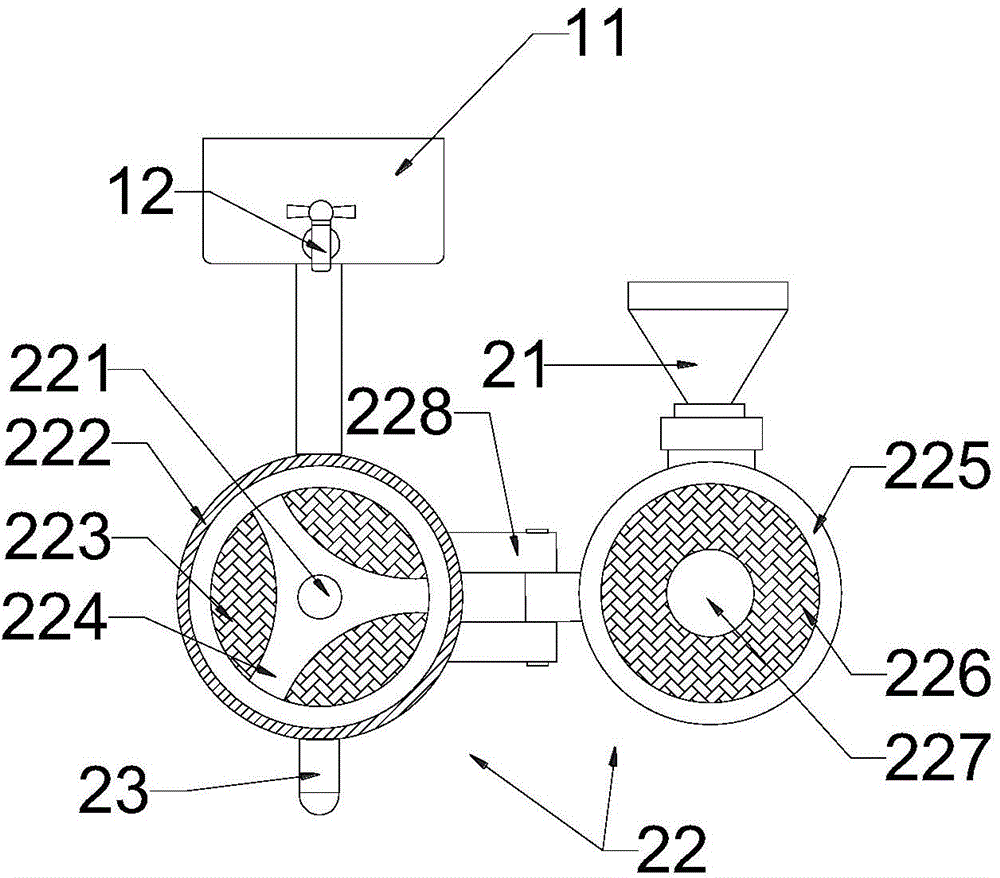

[0075] A device for refining the steps described in the second embodiment of the above-mentioned intestine powder preparation method, that is, a low-temperature fine refiner, includes a water adding structure, a first refining structure, a second refining structure, and a power structure.

[0076] The water adding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com