Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Avoid potential difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

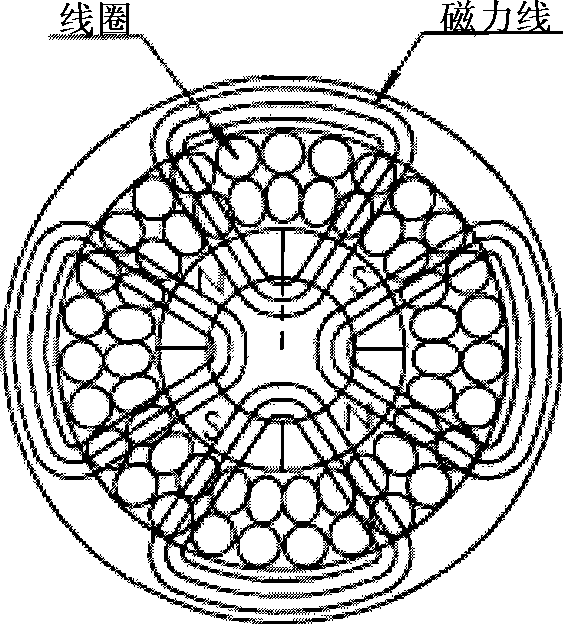

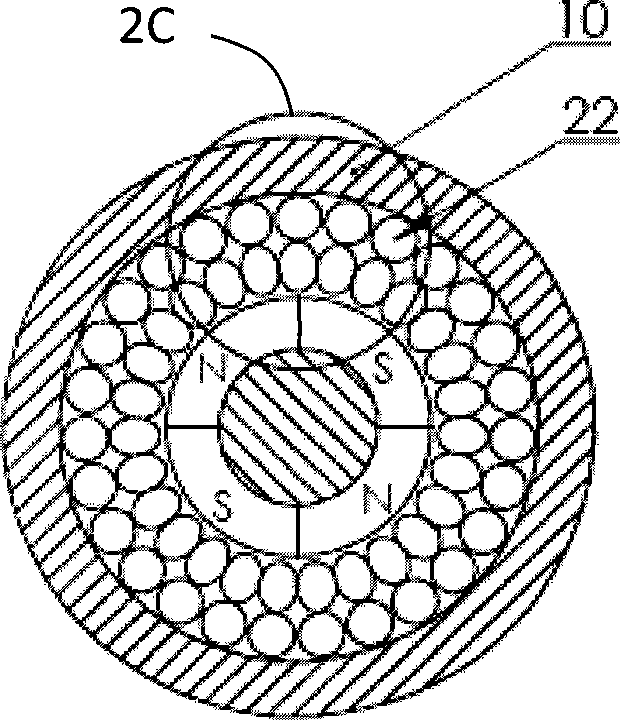

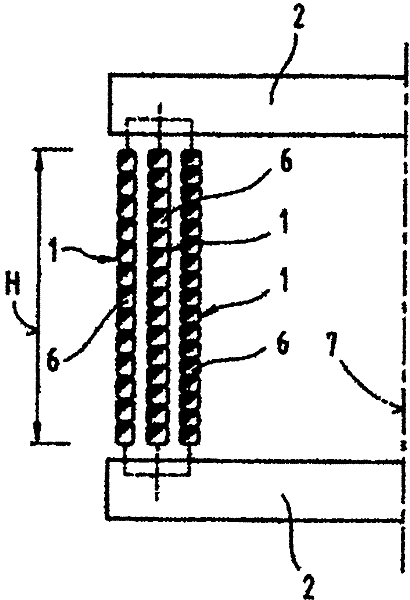

Stator winding construction and winding method for slotless motor stator winding, and stator construction with the winding construction

InactiveCN101483361AReduce eddy current lossEasy to operateManufacturing dynamo-electric machinesWindings conductor shape/form/constructionEddy currentCopper

The present invention provides a slotless motor stator winding structure, wherein the winding is winded by wire groups; the wire groups are twisted into helical shape by a plurality of paralleled insulated wires. The present invention also provides a slotless motor stator structure which comprises a stator core and windings fixed inside the iron core; the windings are mode by winding, pressing and curling a plurality of wire groups; each wire group is composed by a plurality of paralleled insulated wires and is twisted into helical shape. The slotless motor stator winding structure of the invention can effectively reduce eddy current loss that generated in the windings because the wire groups is twisted by a plurality of paralleled wires with minor diameter in application occasions of heavy current and high rotate speed. At the same time, because a plurality of wires with minor diameter are twisted into wire groups of larger diameter before winding the wires, hence convenient of following operations of wire winding and integer. In addition, a plurality of insulated wires are twisted into helical shape which is beneficial for avoiding generating electric potential difference between different wires, hence prevents bringing in circulation and increasing copper loss.

Owner:JOHNSON ELECTRIC SHENZHEN

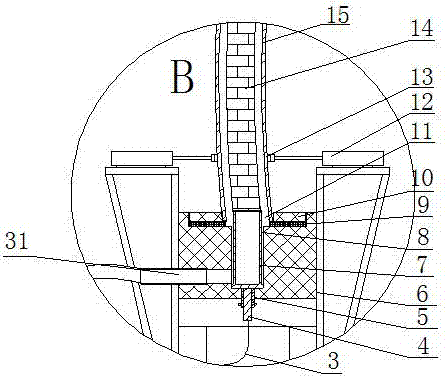

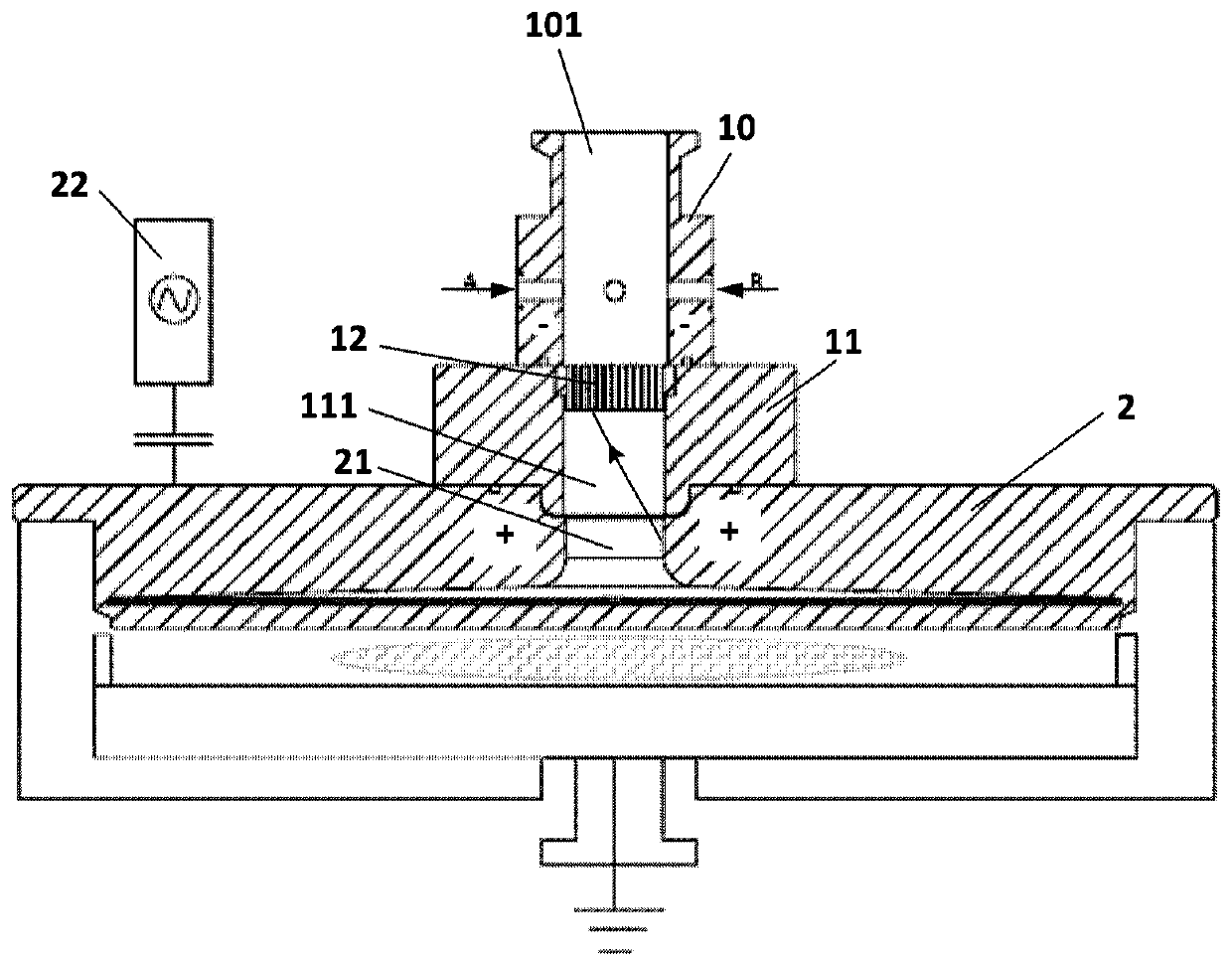

Crystallizer internal surface electroplating production line and electroplating method thereof

The invention discloses a crystallizer internal surface electroplating production line, which includes a washing section, an electroplating section, a hoisting device and an electrolyte solution circulating fluid supply system. The electroplating section is provided with a crystallizer fixed base, a tubular crystallizer and an anode titanium basket. The crystallizer fixed base is provided with an electrolyte solution feed pipe, a sealing pad and an anode lead-out device. The anode titanium basket is arranged on the base, is mounted vertically and is equipped with an upper electrode lead-out terminal and a lower electrode lead-out terminal. The crystallizer is vertically arranged on the sealing pad of the base, and is sleeved outside the anode titanium basket. The upper side of the crystallizer is provided with a seal hanging basket and a sealing pad, the seal hanging basket is equipped with a drain pipe, the seal hanging basket is provided with a mechanical compression device, the seal hanging basket is in compressed sealing connection with the crystallizer upper end through the sealing pad. An electroplating cathode is in compressed electric connection with the crystallizer. The hoisting device is equipped with a crane and a workpiece fixture. And the washing section consists of a washing liquid cleaning tank, an acid liquid cleaning tank, a clear water cleaning tank, and a pure water cleaning tank.

Owner:JILIN ANDE ELECTROCHEM TECH

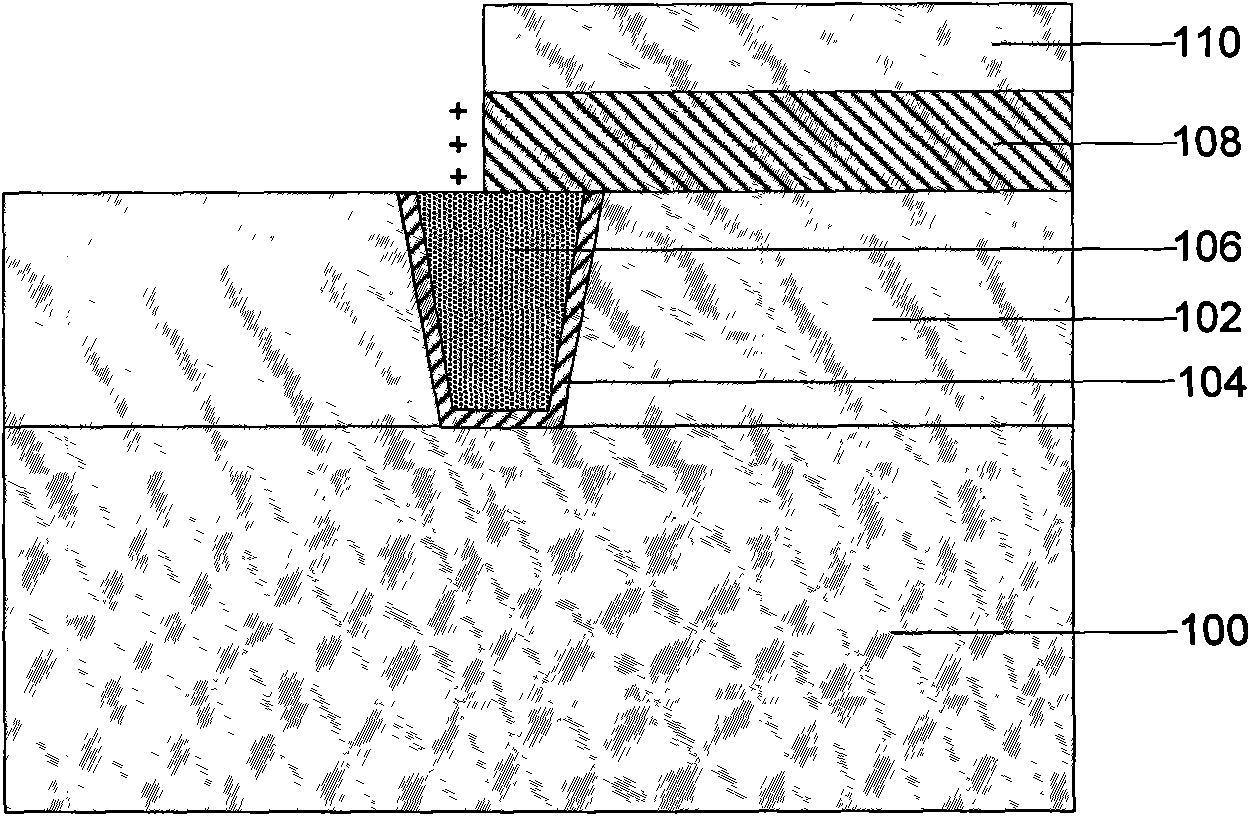

Method for preventing corrosion of tungsten plug

InactiveCN102044481AWon't hurtSimple processing methodSemiconductor/solid-state device manufacturingElectrochemical responsePotential difference

The invention relates to a method for preventing the corrosion of a tungsten plug. The method comprises the following steps of: providing a semiconductor substrate with a tungsten plug, wherein the tungsten plug is connected with a metal lead which is formed on the tungsten plug and incompletely covers the tungsten plug; and illuminating the metal lead by adopting arc light or ultraviolet light until positive charges on the metal lead are eliminated. After the method for preventing the corrosion of a tungsten plug is adopted, the positive charges on the metal lead are removed by adopting the arc light or ultraviolet light illumination method so as to avoid the potential difference between the metal lead and the tungsten plug, avoid the generation of an electrochemical reaction and avoid corroding the tungsten plug in the following cleaning process.

Owner:SEMICON MFG INT (SHANGHAI) CORP

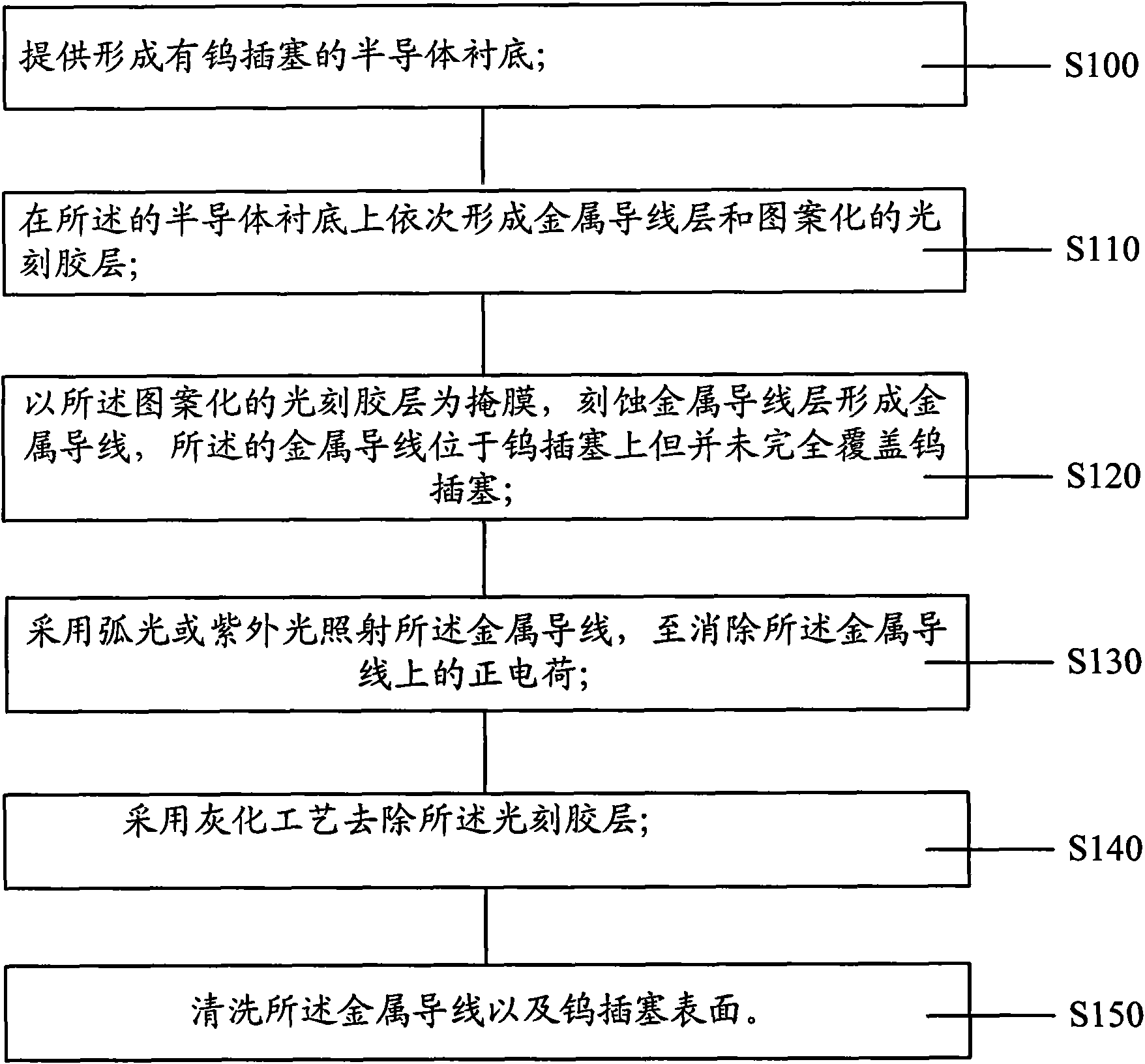

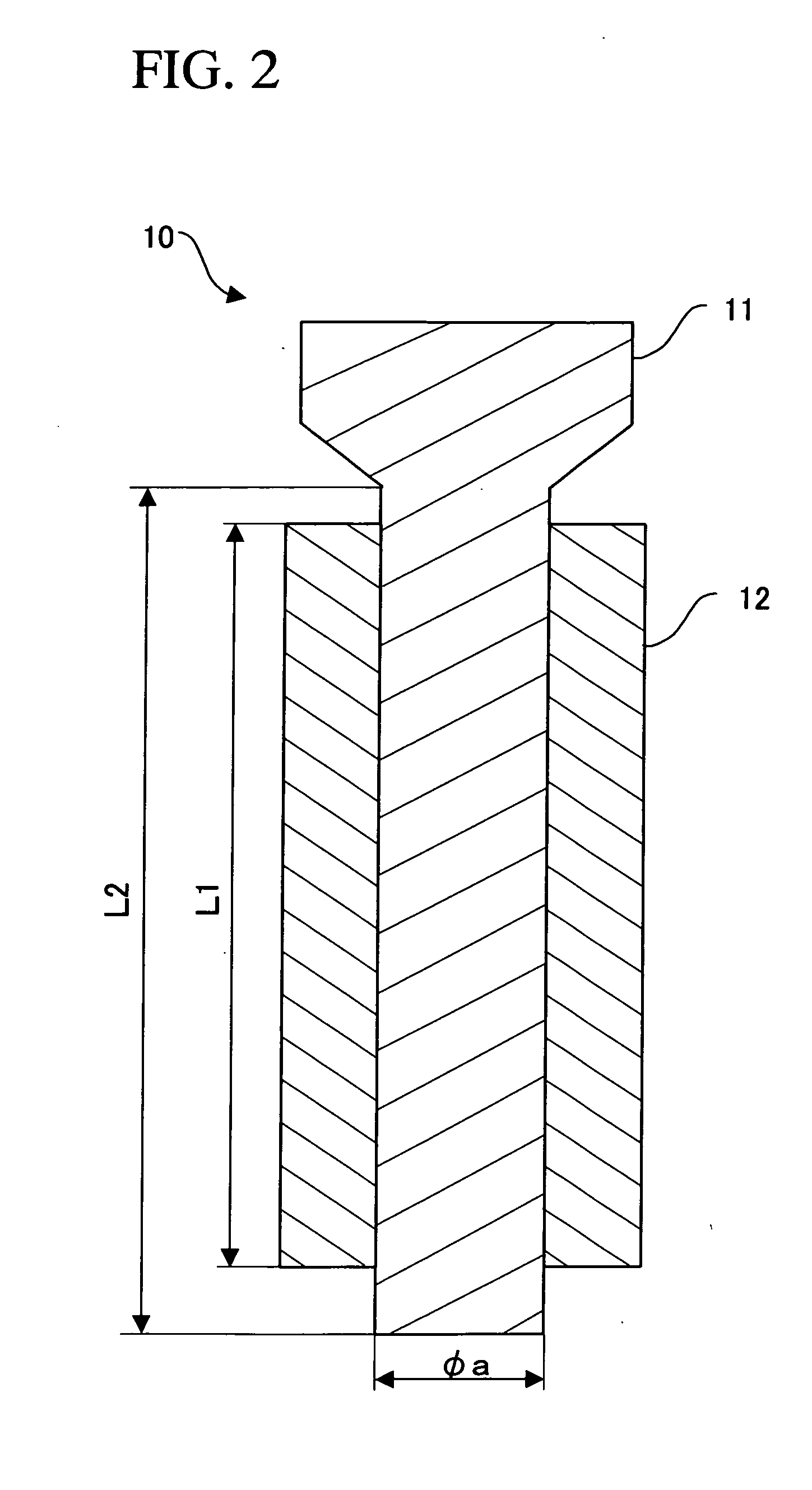

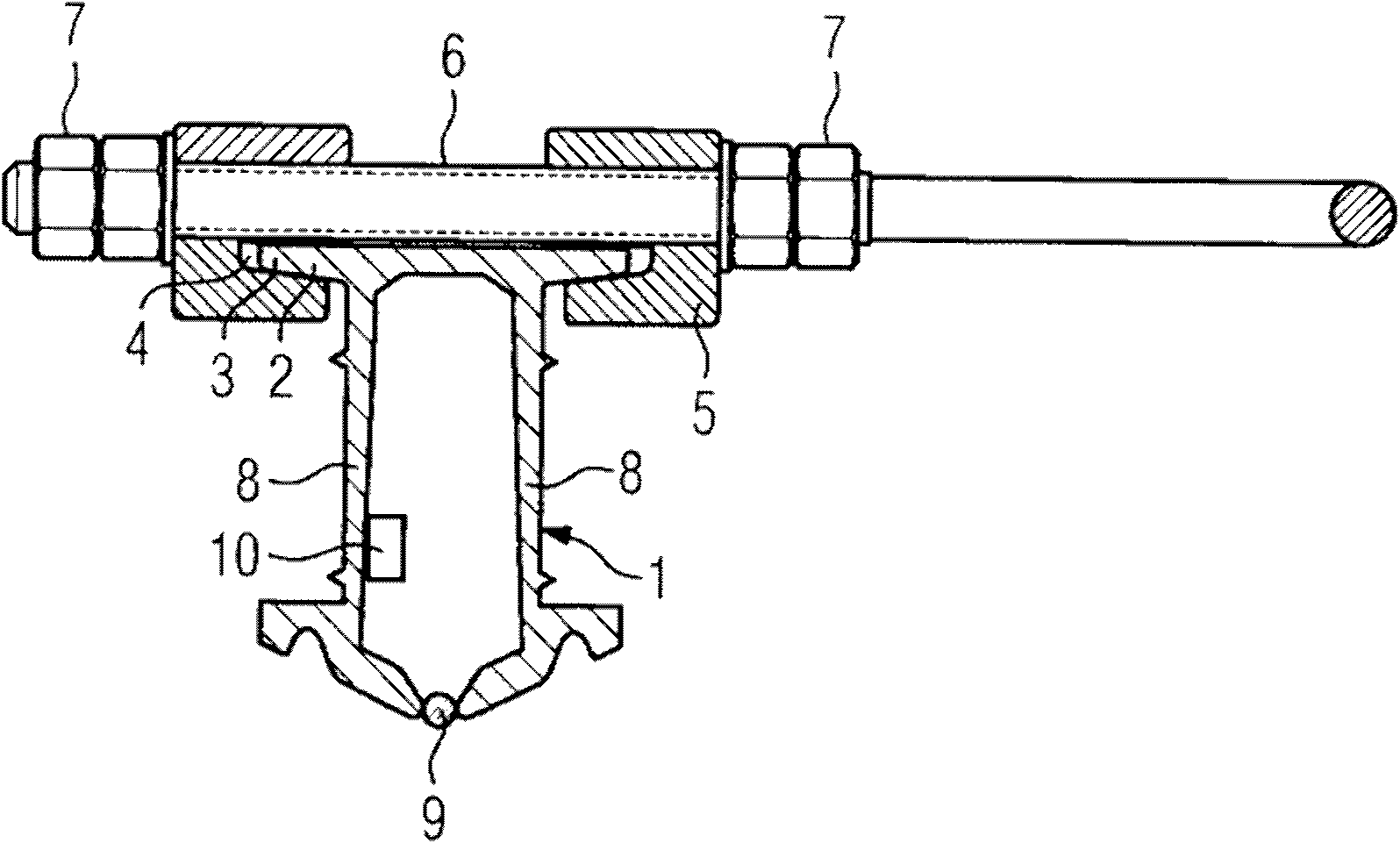

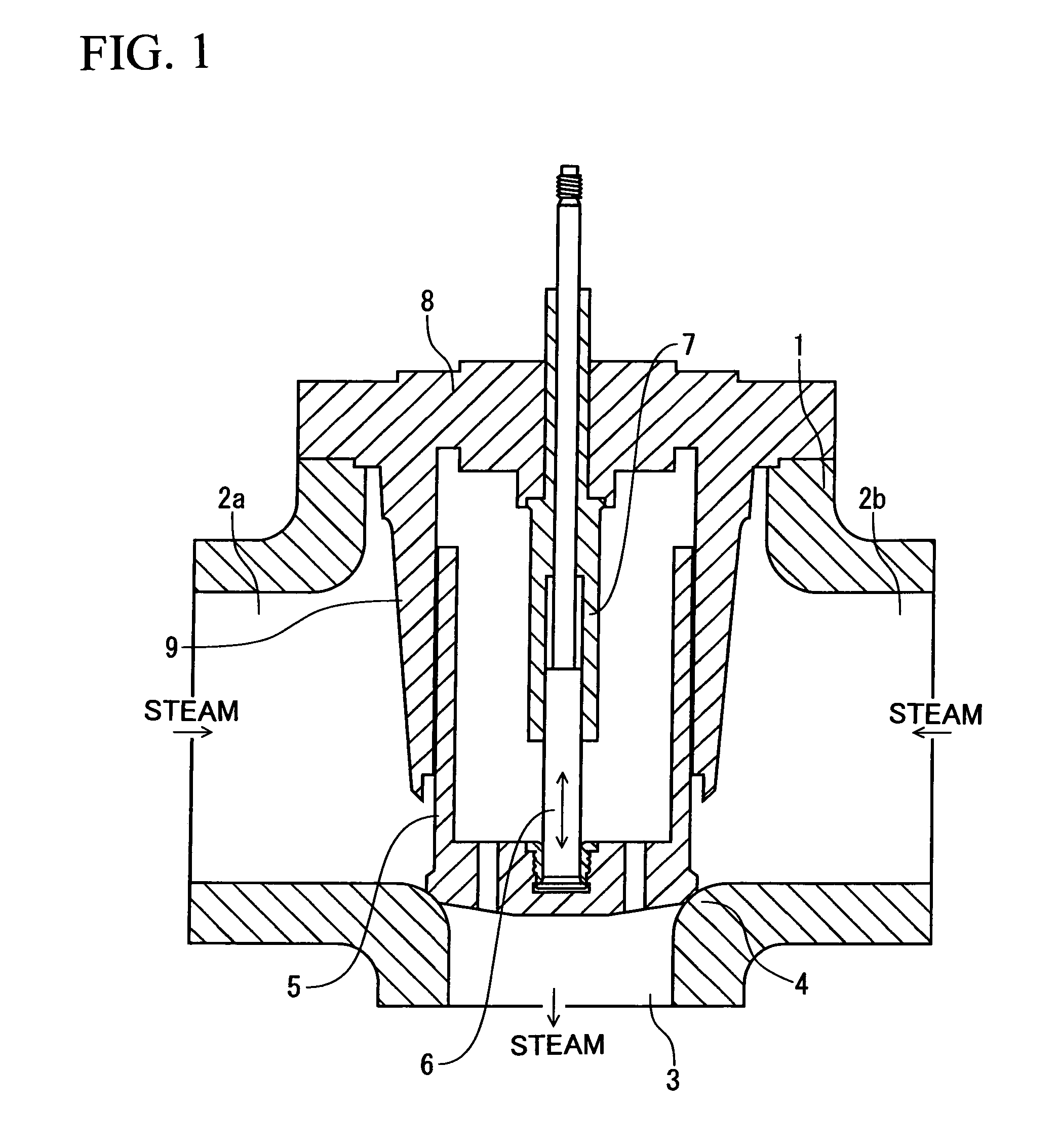

Valve Gear

ActiveUS20100032607A1Avoid it happening againReduce corrosionCheck valvesLift valvePotential differenceSurface roughness

Provided is a valve gear in which corrosion due to a potential difference does not occur and which can reduce the corrosion occurrence even when loads due to microvibrations are given. The valve gear according to the present invention comprises a valve stem 6 and a valve bush 7 that slidably supports the valve stem 6. The valve stem 6 is formed from a forged part made of a Ni-based superalloy and the valve bush 7 is formed from a cast part made of a Ni-based superalloy. The preferable surface roughness of a sliding surface of the valve stem 6 in contact with the valve bush 7 and the preferable surface roughness of a sliding surface of the valve bush 7 in contact with the valve stem 6 is 100 μm or less in units of Rz.

Owner:MITSUBISHI POWER LTD

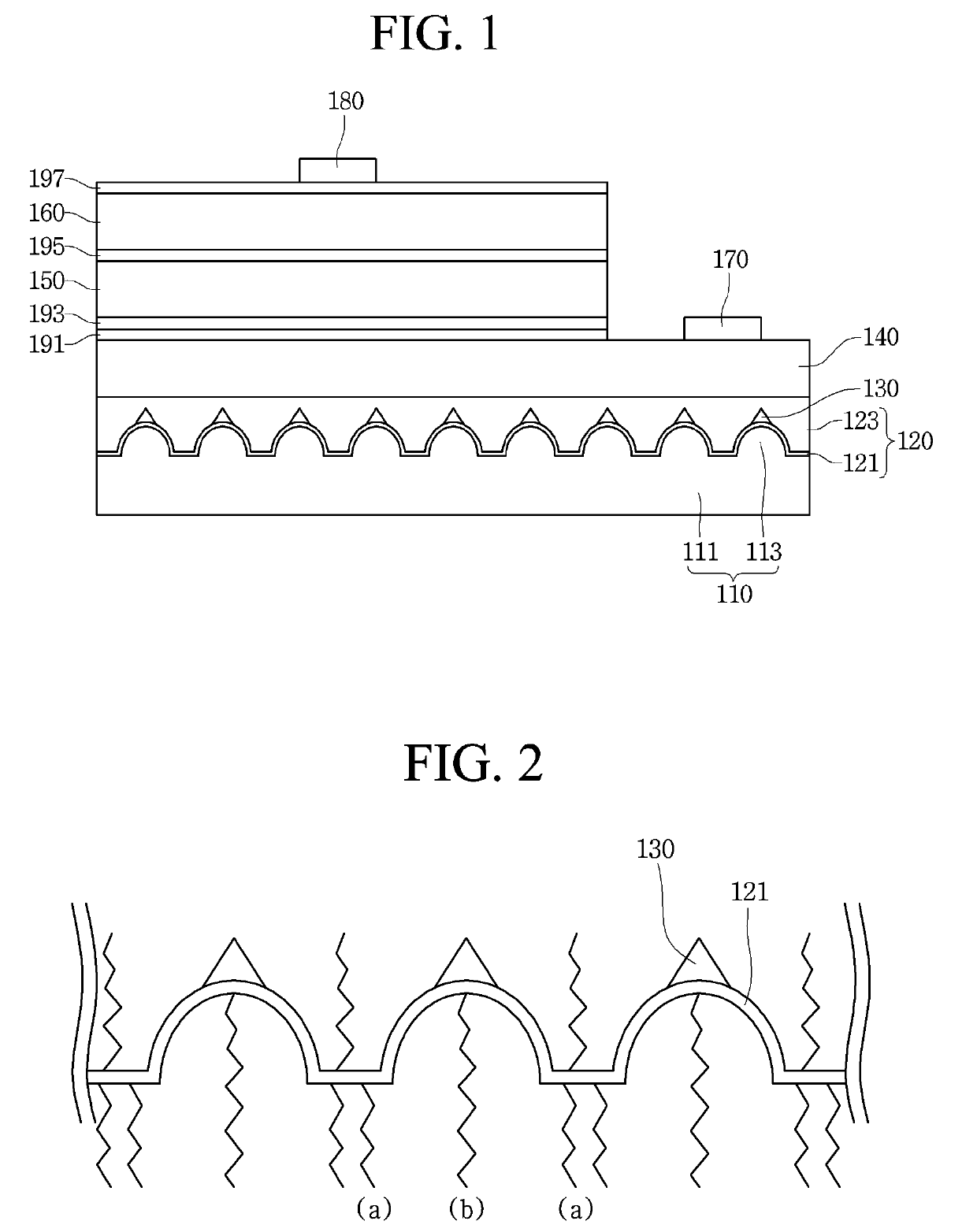

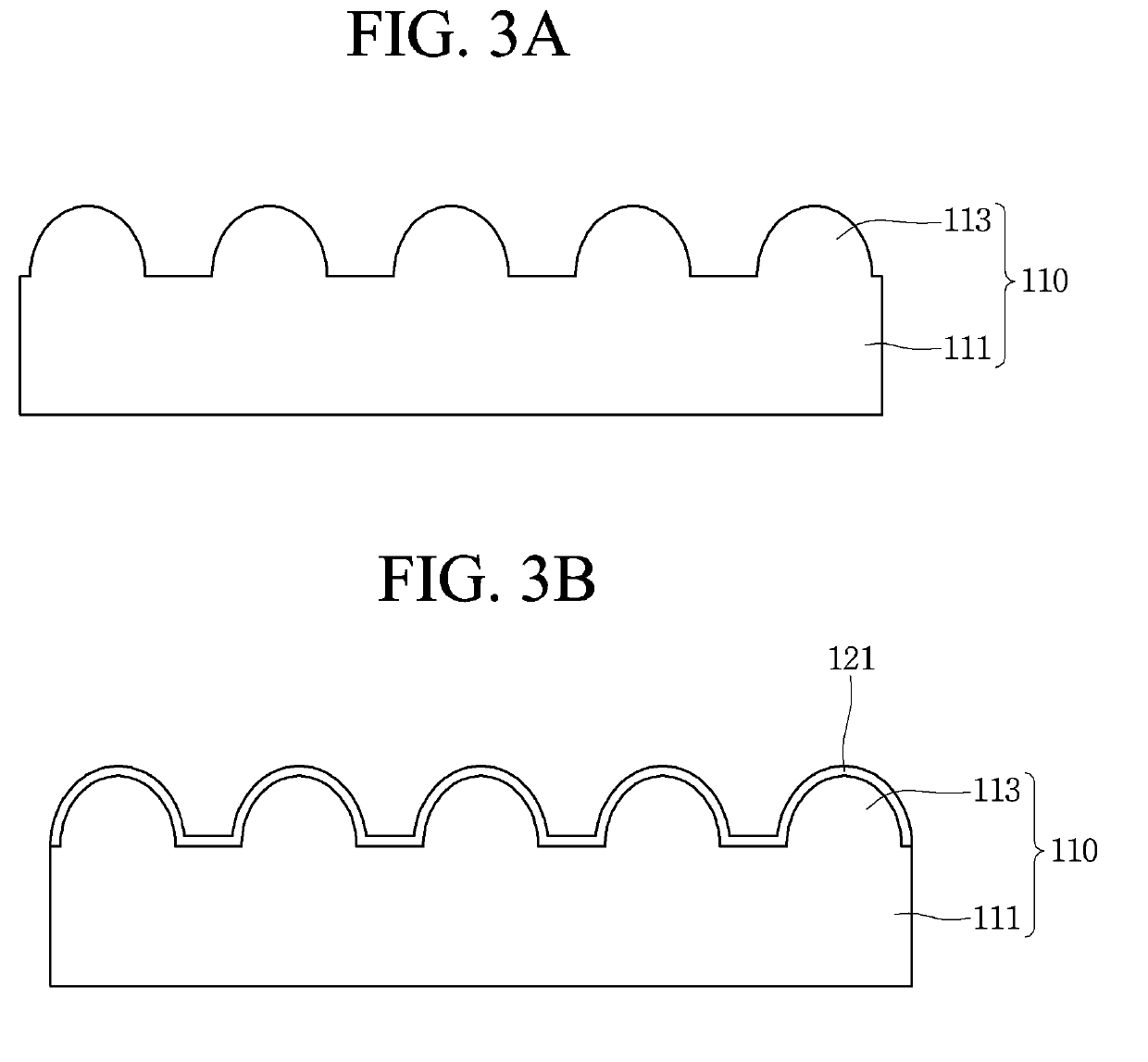

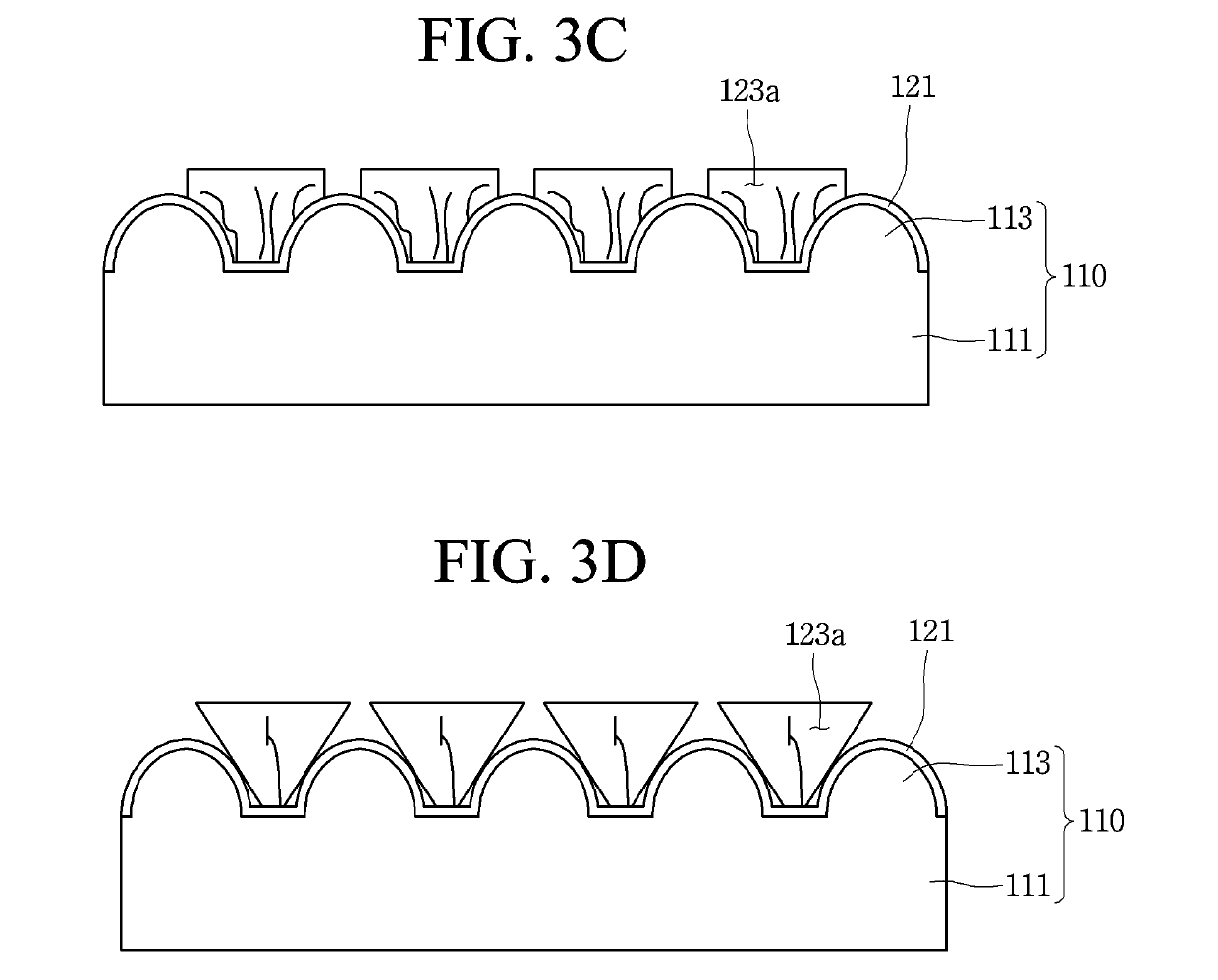

Light emitting device, method for manufacturing light emitting device and lighting system having same

ActiveUS10374124B2Avoid potential differenceDefect due to the potential difference can be more effectively blockedSemiconductor devicesPotential differenceLighting system

A light emitting device, according to one embodiment, may comprise: a substrate having a pattern part disposed on the upper surface thereof; a first buffer layer disposed on the substrate; a second buffer later disposed on the first buffer layer; a first conductive semiconductor layer disposed on the second buffer layer; an active layer disposed on the first conductive semiconductor layer; a second conductive semiconductor layer disposed on the active layer; and a void layer disposed on the first buffer layer corresponding to the pattern part of the substrate. By further forming a void on the buffer layer, the embodiment has the effect of more effectively preventing defects caused by a potential difference.

Owner:SUZHOU LEKIN SEMICON CO LTD

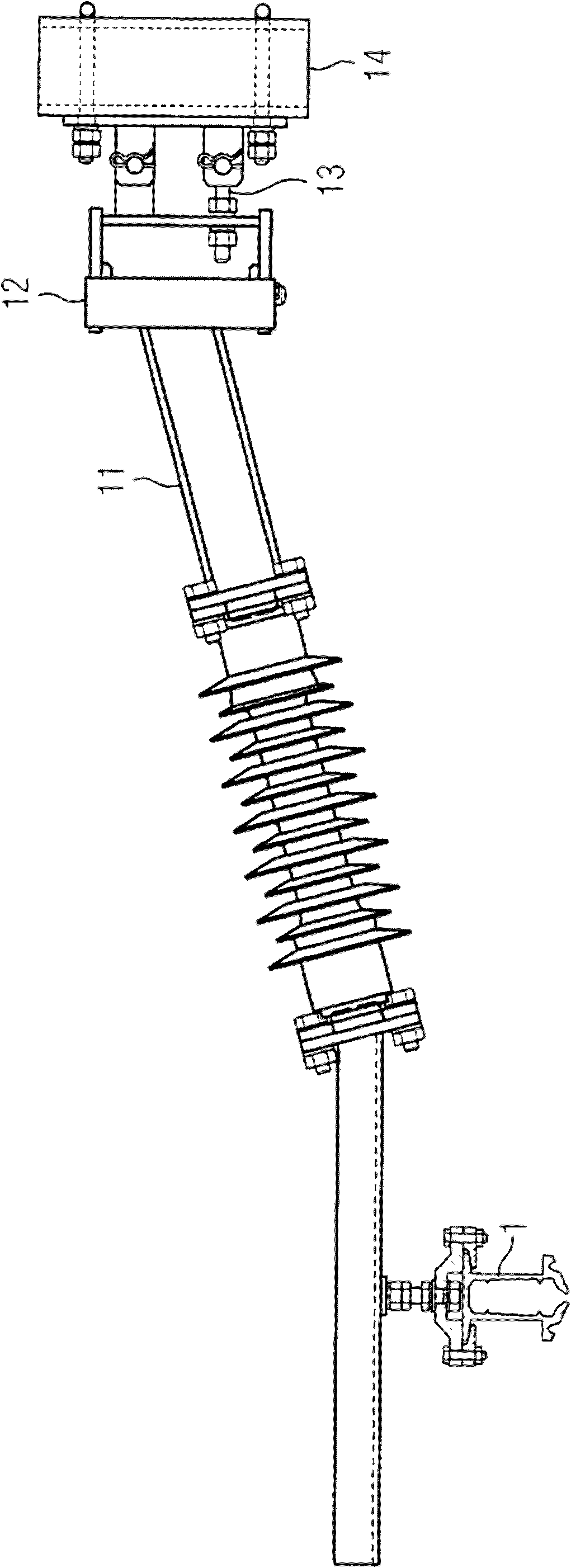

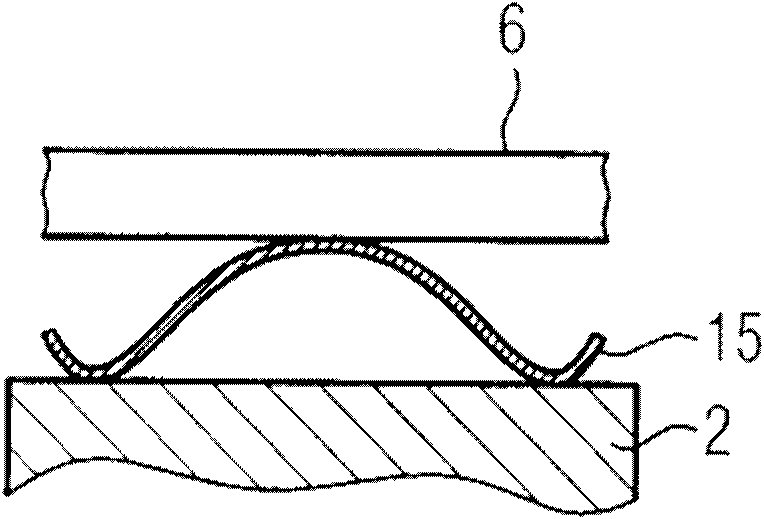

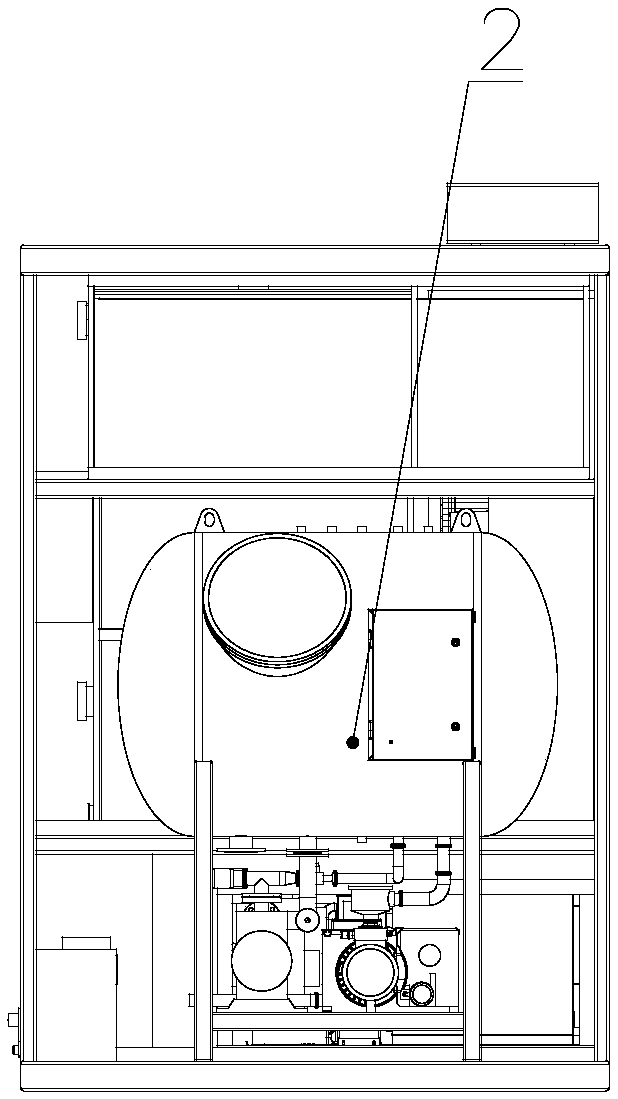

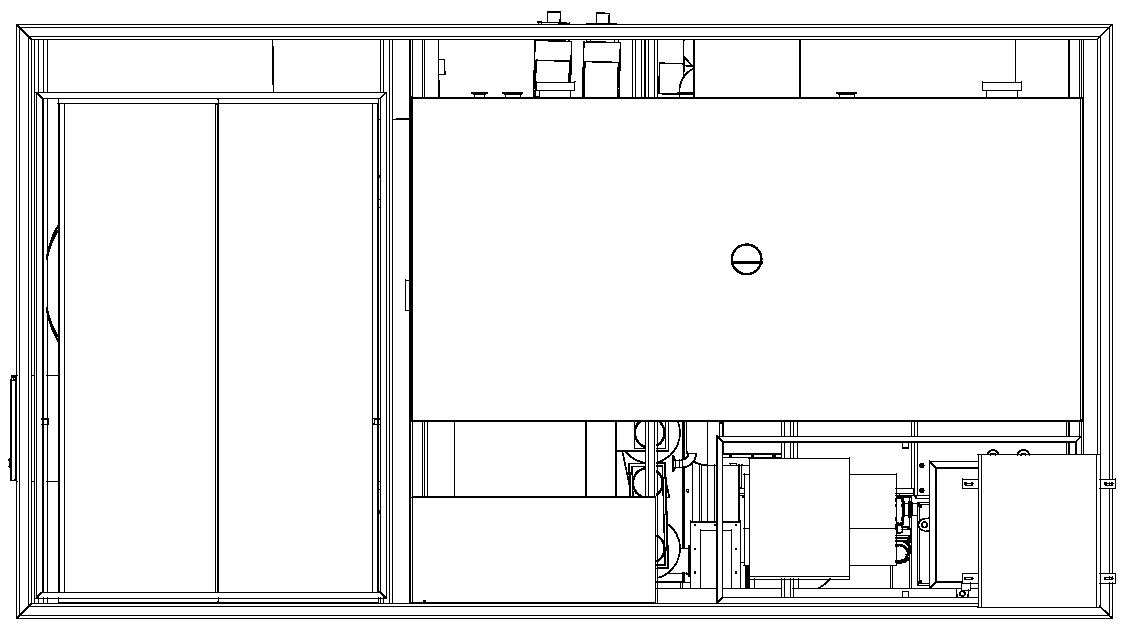

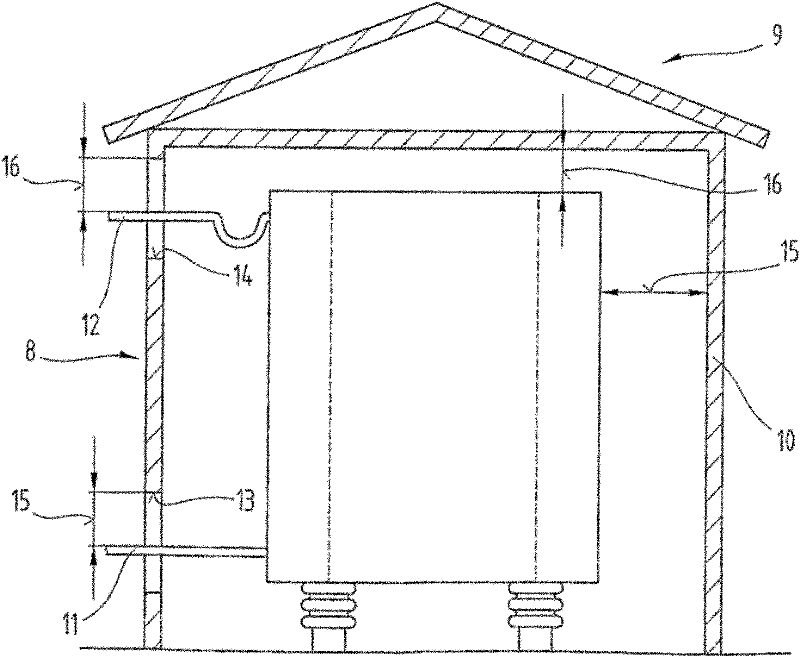

Overhead line system

InactiveCN102438855AGood clamping performanceImprove power transmissionPower railsEngineeringContact wire

The invention relates to an overhead line system comprising overhead conductor rails (1, 16), which are fixed in the center region thereof by a fixed point to a structure (14) and are otherwise connected to the structure (14) by way of moveable support point legs (11). According to the invention, at least one of the overhead conductor rails (1, 16) comprises a transverse carrier (2) at the upper side thereof, two downwardly directed tensioning arms (8) originating from said transverse carrier at connecting points for holding a contact wire (9). The transverse carrier (2) comprises conically tapered moldings (3) on both sides of the connecting points of the tensioning arms (8), which moldings can be inserted in corresponding recesses (4) of a clamping fitting (5).

Owner:SIEMENS AG

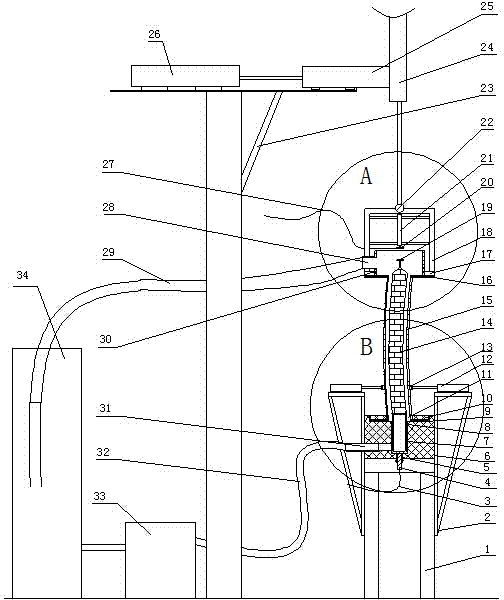

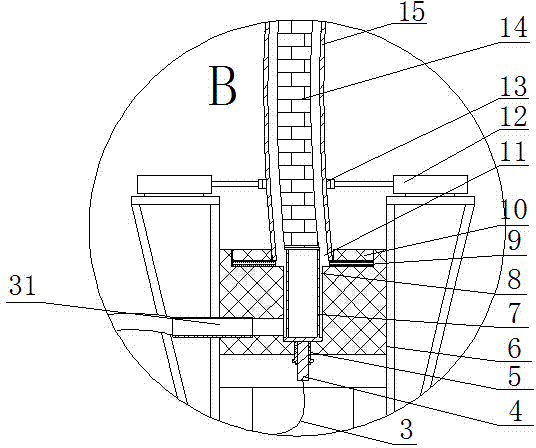

Sewage treatment method based on sewage treatment equipment

InactiveCN108975618ACompact distributionReduce liquidityWater/sewage treatment by centrifugal separationWater treatment parameter controlSlagThree stage

The invention discloses a sewage treatment method based on sewage treatment equipment. The sewage treatment equipment for the sewage treatment method comprises a system framework, a vacuum collectingmechanism, a scraping slag precipitating mechanism, a super-gravity drying mechanism, a precipitate electrolyzing mechanism and an electric control cabinet, wherein the scraping slag precipitating mechanism is provided with an area A, an area B, an area C and an area D; the super-gravity drying mechanism comprises a centrifugal system, a heating system, a deodorizing system, a separating system, and a cooling system; the mechanisms and the systems are respectively cooperated in working. The sewage treatment method has the advantage that the three stages of precipitating and filtering and the three stages of treatment can be performed on the sewage, so as to obtain the treated water with high cleanliness.

Owner:张家港市欧微自动化研发有限公司

Inductance coil for electric power grids having reduced sound emission

ActiveCN102203888AEliminates the risk of arcingReduce noiseTransformers/inductances coils/windings/connectionsFixed inductances without magnetic coreElectricityPower grid

The invention relates to an inductance coil, particularly an inductance coil without iron core for use in electric power grids, comprising at least two cylindrical winding layers (1), which are disposed concentrically with respect to a coil center line (7) and are connected electrically in parallel. The inductance coil comprises at least one means for reducing or minimizing sound emissions developing during operation of the inductance coil. At least the outermost winding layer (1) is designed as a current-conducting, acoustic shield winding (18) with respect to the winding layer (1) adjoining in the direction of the center line (7), wherein the shield winding (18) is dimensioned electrically such that it is designed for the transmission of a current intensity which is between the 0.1% to the maximum 50% of the current intensity transmitted by the adjacent winding layer (1) towards to the direction of the coil center line (7). The invention further relates to a clamp-like retaining element disposed on at least one face end of the inductance coil for reducing sound emissions.

Owner:COIL HLDG

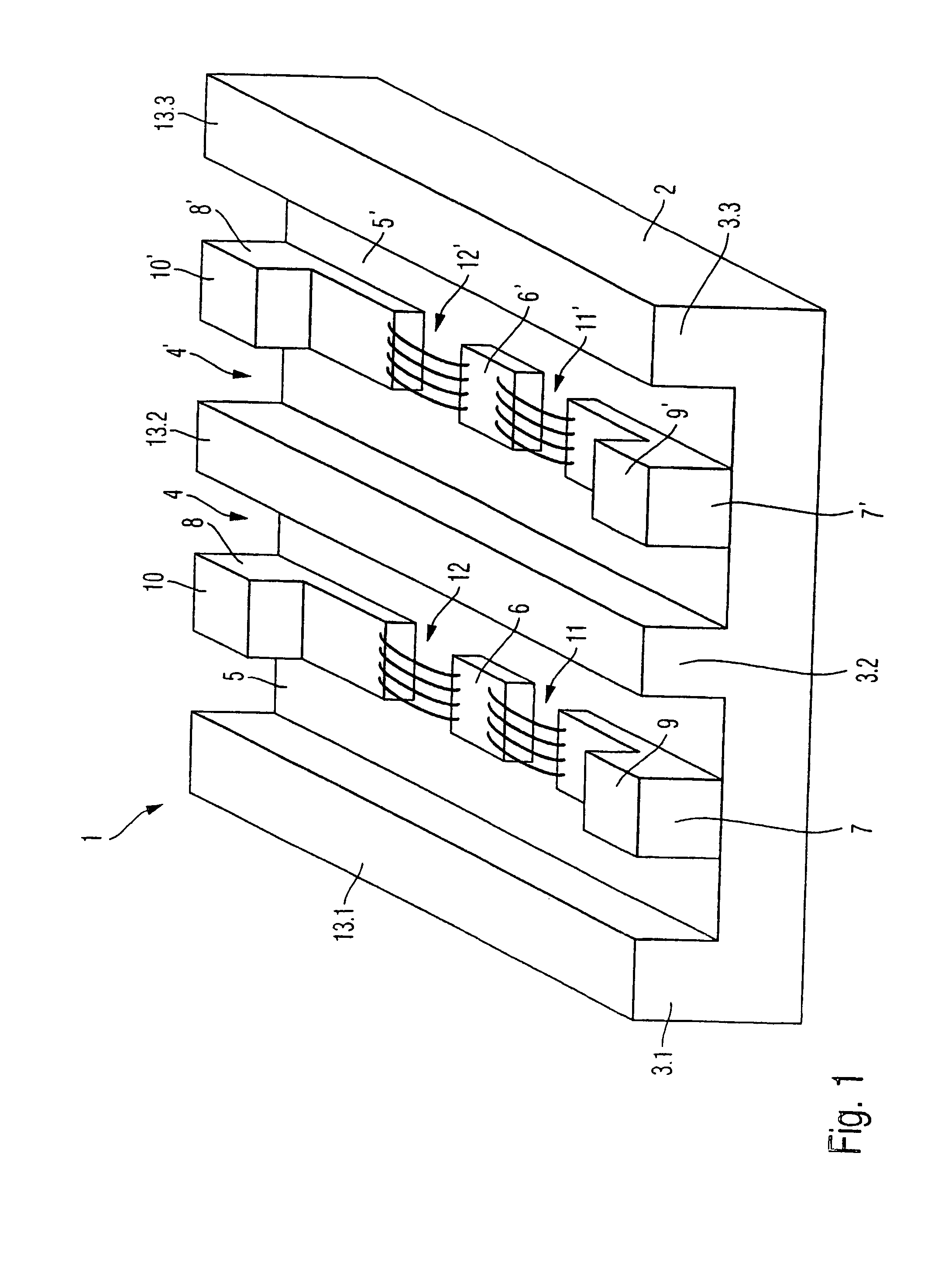

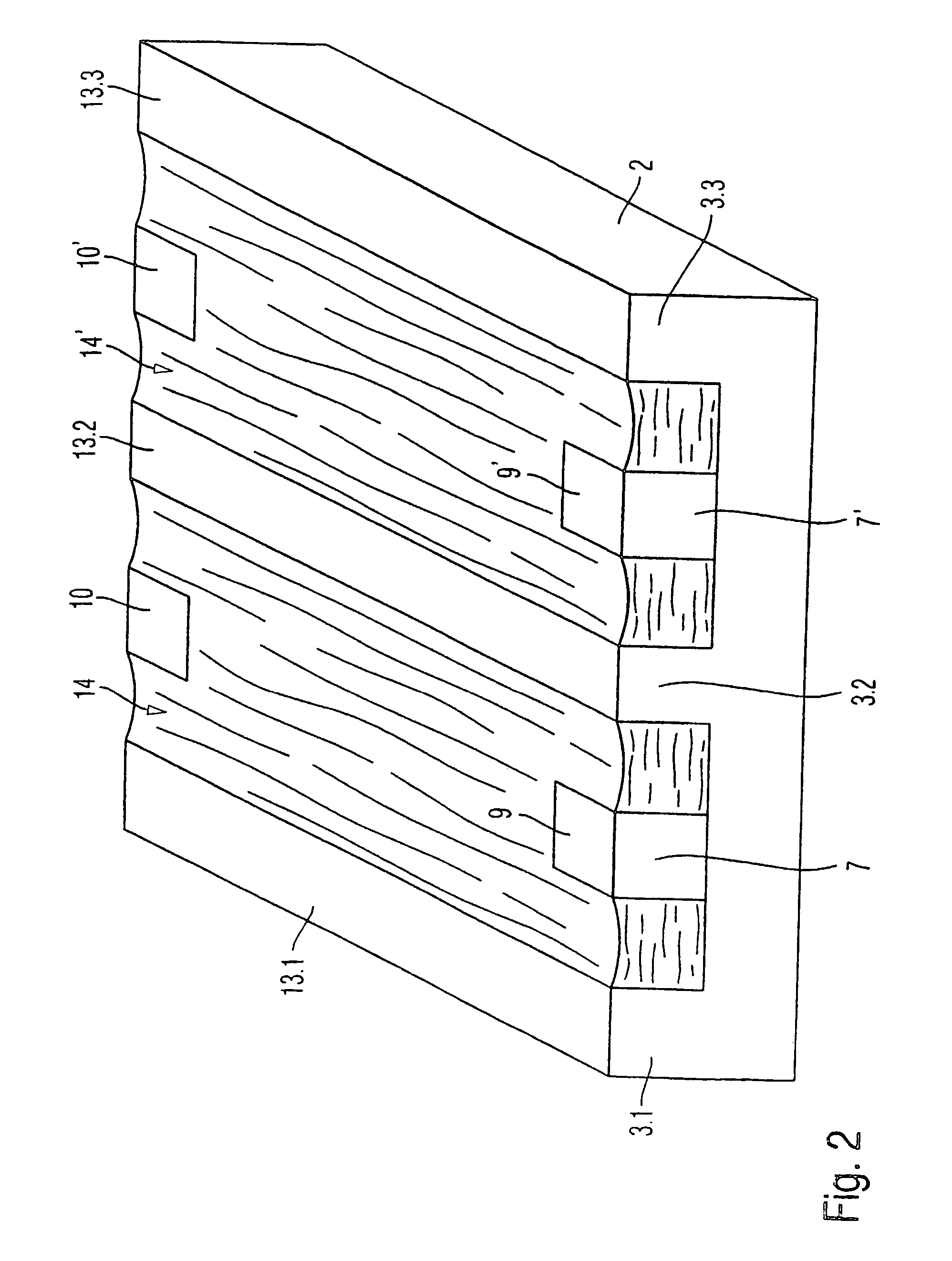

Electronic component comprising a cooling surface

InactiveUS7633158B2Cool arrangement be simplifyParasitic inductivity and capacity be avoidSemiconductor/solid-state device detailsSolid-state devicesPrinted circuit boardEngineering

An electronic component comprising at least two connection elements (2,7,8), each provided with at least one contact surface (13.1, 13.2, 13.3, 9, 10) which is used to fix the electronic component (1) to a surface of a printed circuit board. An at least partially plane cooling surface is formed on the first connection element (2), for placing on a cooling body that is oriented in the direction of the side of the electronic component (1) opposing the printed circuit board. The first connection element (2) has at least one raised area (3.1, 3.2, 3.3) on the side thereof facing the printed circuit board, on which the contact surface (13.1, 13.2, 13.1) of the first connection element (2) is formed. Said first connection element (2) also has at least one recessed area (4, 4′) in which the at least one other connection element (7, 7′; 8, 8′) is arranged.

Owner:ROHDE & SCHWARZ GMBH & CO KG

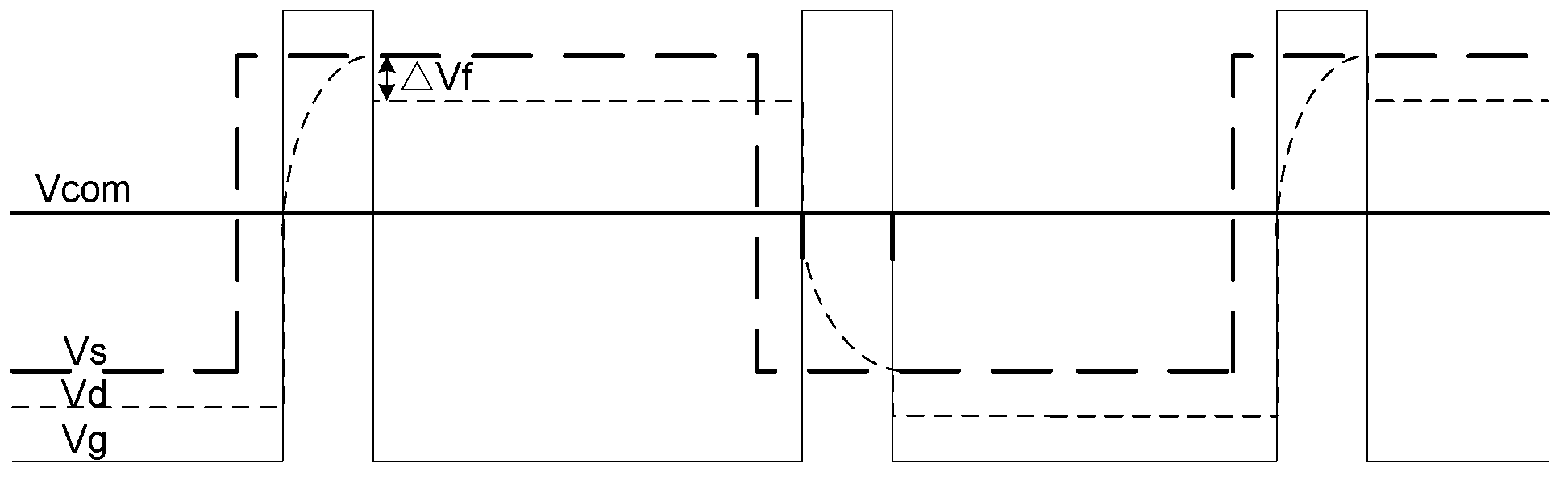

Display driving circuit, display unit and driving method thereof

InactiveCN103226933AAvoid potential differenceImprove display qualityStatic indicating devicesElectricityPotential difference

The embodiment of the invention provides a display driving circuit, a display unit and a driving method thereof, relates to the technical field of displaying, can prevent the feed-through effect from influencing the potential differences between pixel electrodes and a common electrode, and can improve the displaying quality of a picture. The display driving circuit comprises a gate driving unit, a source driving unit and a circuit unit, wherein, the gate driving unit is used for controlling a TFT (Thin Film Transistor) to be switched on; the source driving unit is used for outputting signals to a source electrode of the TFT; the circuit unit is used for supplying electricity to the common electrode; when the TFT is switched on, the circuit unit outputs a first voltage to the common electrode; when the TFT is switched off, the circuit unit outputs a second voltage to the common electrode; and in addition, the first voltage is different from the second voltage.

Owner:BOE TECH GRP CO LTD +1

Valve gear having a valve stem and a valve bush

ActiveUS8235357B2Reduce generationAvoid potential differenceCheck valvesLift valvePotential differenceSurface roughness

Owner:MITSUBISHI POWER LTD

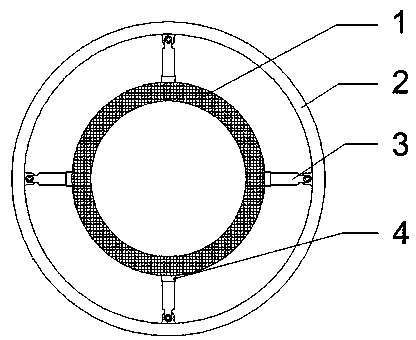

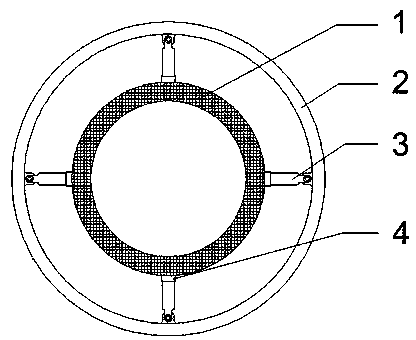

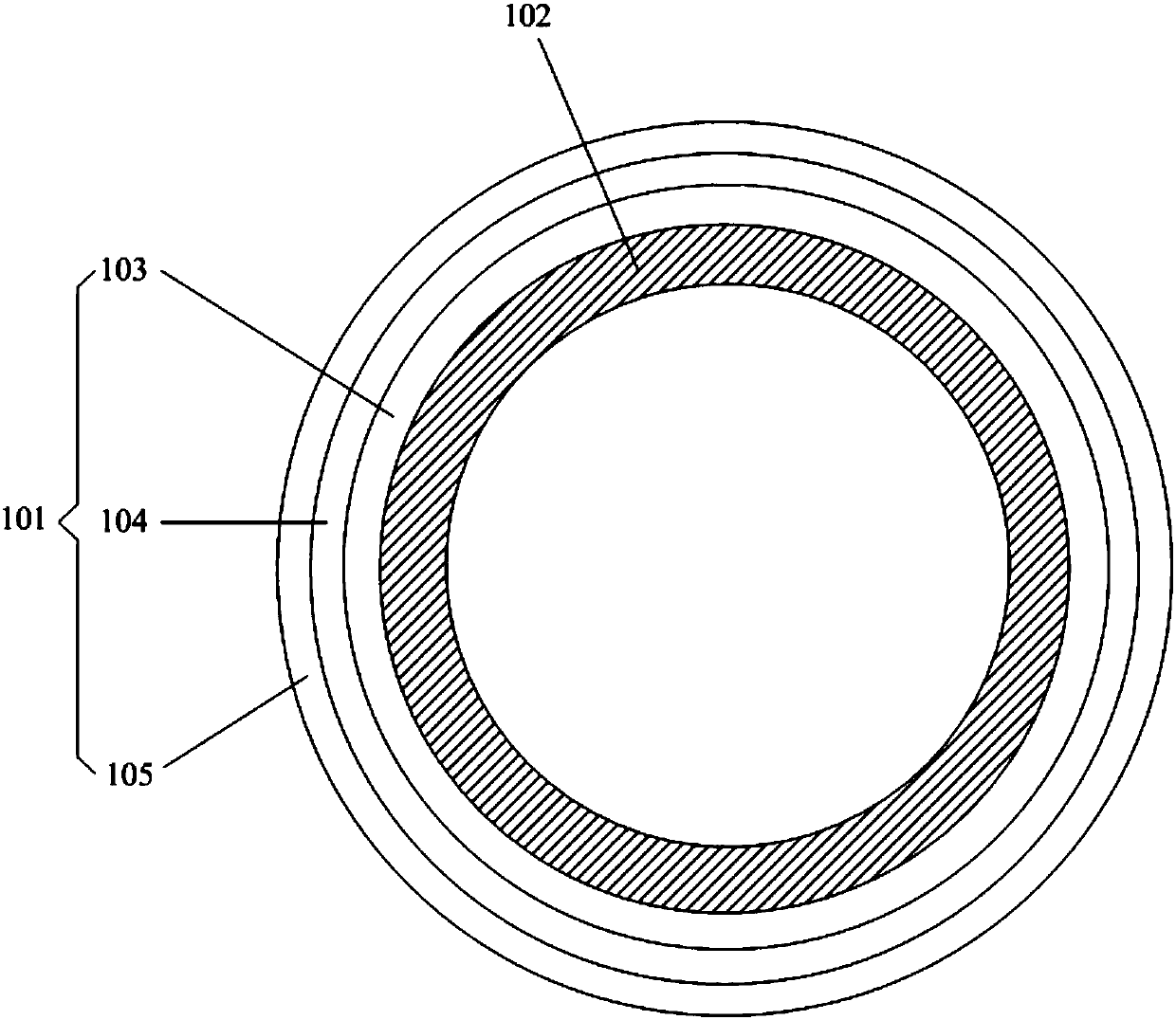

Super-high voltage grading ring and production process thereof

InactiveCN110010314ANot easy to breakdown failureImprove conductivityVacuum evaporation coatingSputtering coatingSemiconductor materialsPotential difference

The invention provides a super-high voltage grading ring and a production process thereof, aiming at the problems that the existing grading ring material is easy to cause potential difference and failure of the grading ring under the super-high voltage. The super-high voltage grading ring comprises an annular grading ring body which is made of semiconductor materials, the outer portion of the grading ring body is coaxially provided with an aluminum ring, a plurality of connection rods are uniformly distributed in an annular interval between the grading ring body and the aluminum ring, and theextension lines of the connection rods pass through the centers of circles of the grading ring body and the aluminum ring. By using the semiconductor material, the produced grading ring has an electric field under the super-high voltage to fundamentally avoid the potential difference problem, and the grading ring is not easy to cause breakdown of a device when the voltage generates voltage jump soas to obviously improve the whole reliability of the device.

Owner:平顶山正植科技有限公司

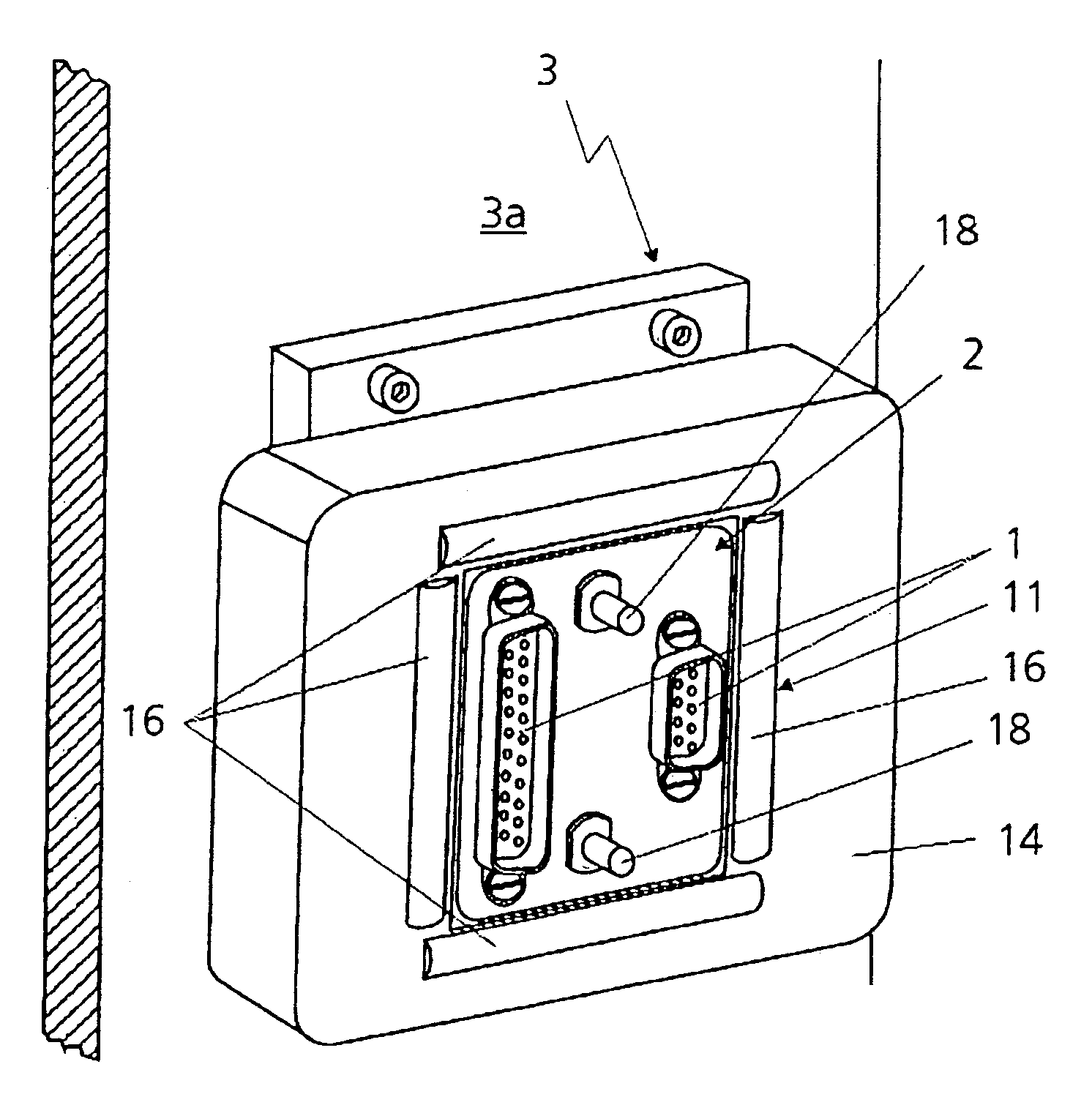

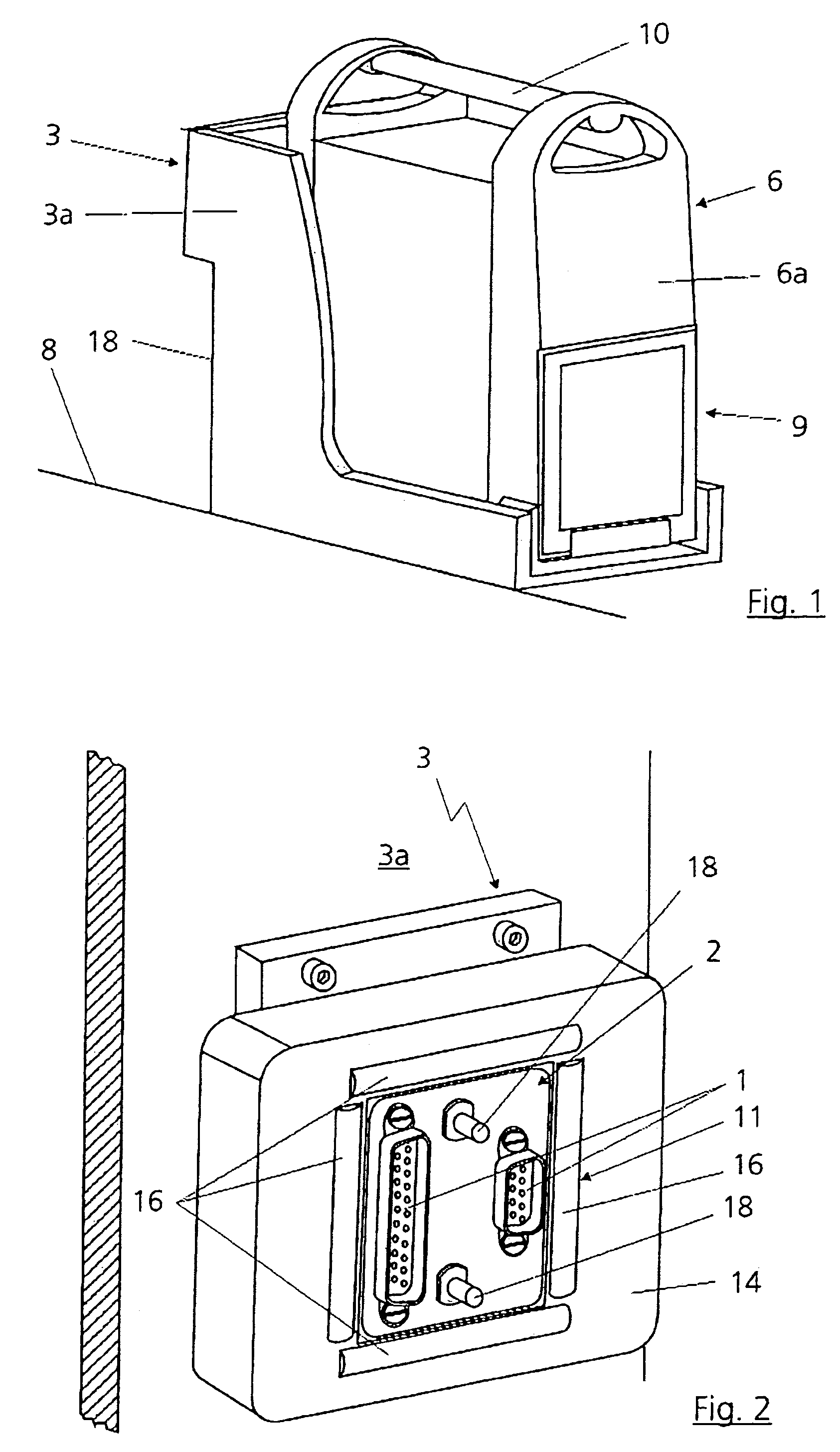

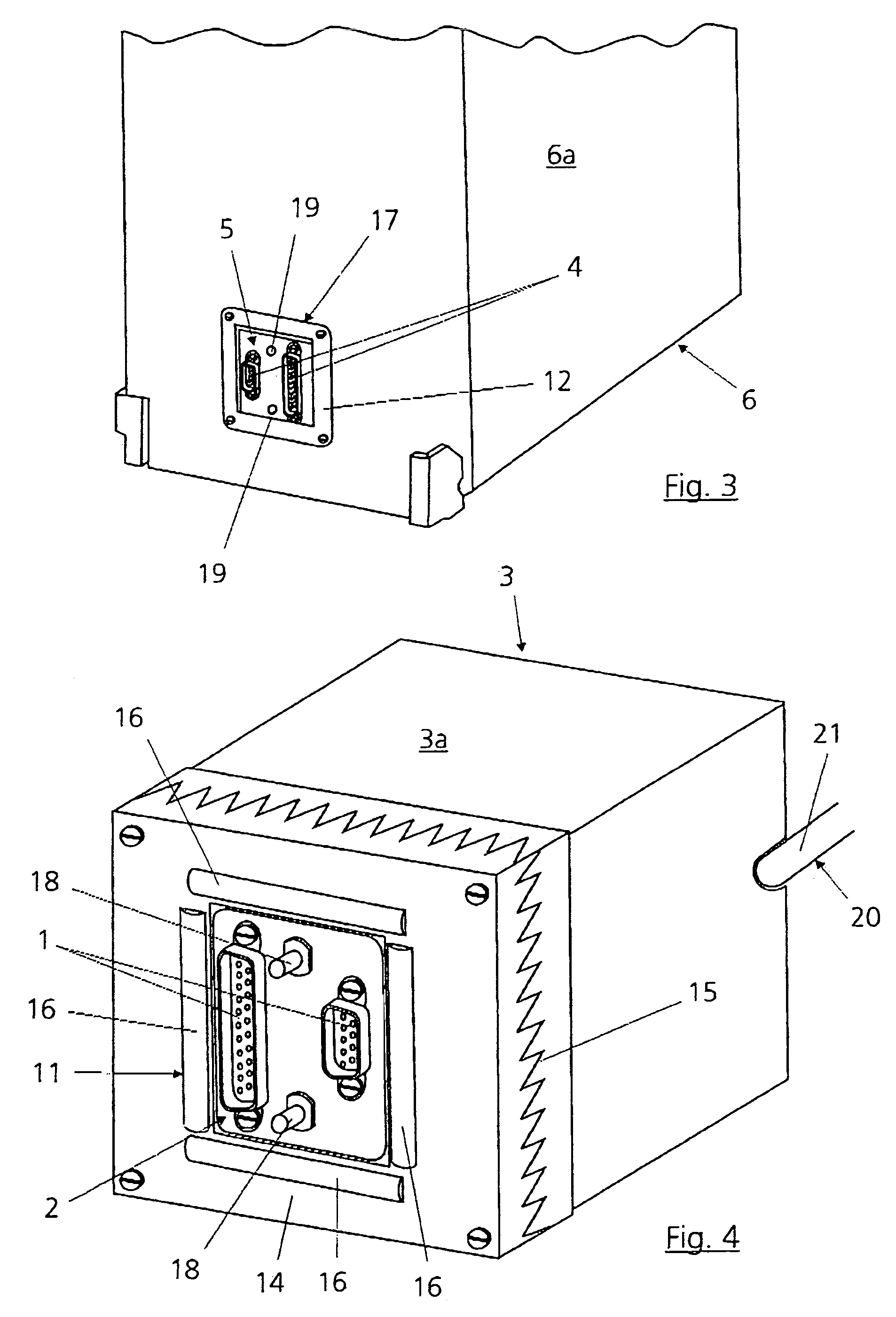

Apparatus for production of an electromagnetically shielded connection

ActiveUS7147511B2Reliable shieldingEasy to implementMagnetic/electric field screeningCoupling parts mountingEngineeringElectromagnetic shielding

Owner:LEICA GEOSYSTEMS AG +1

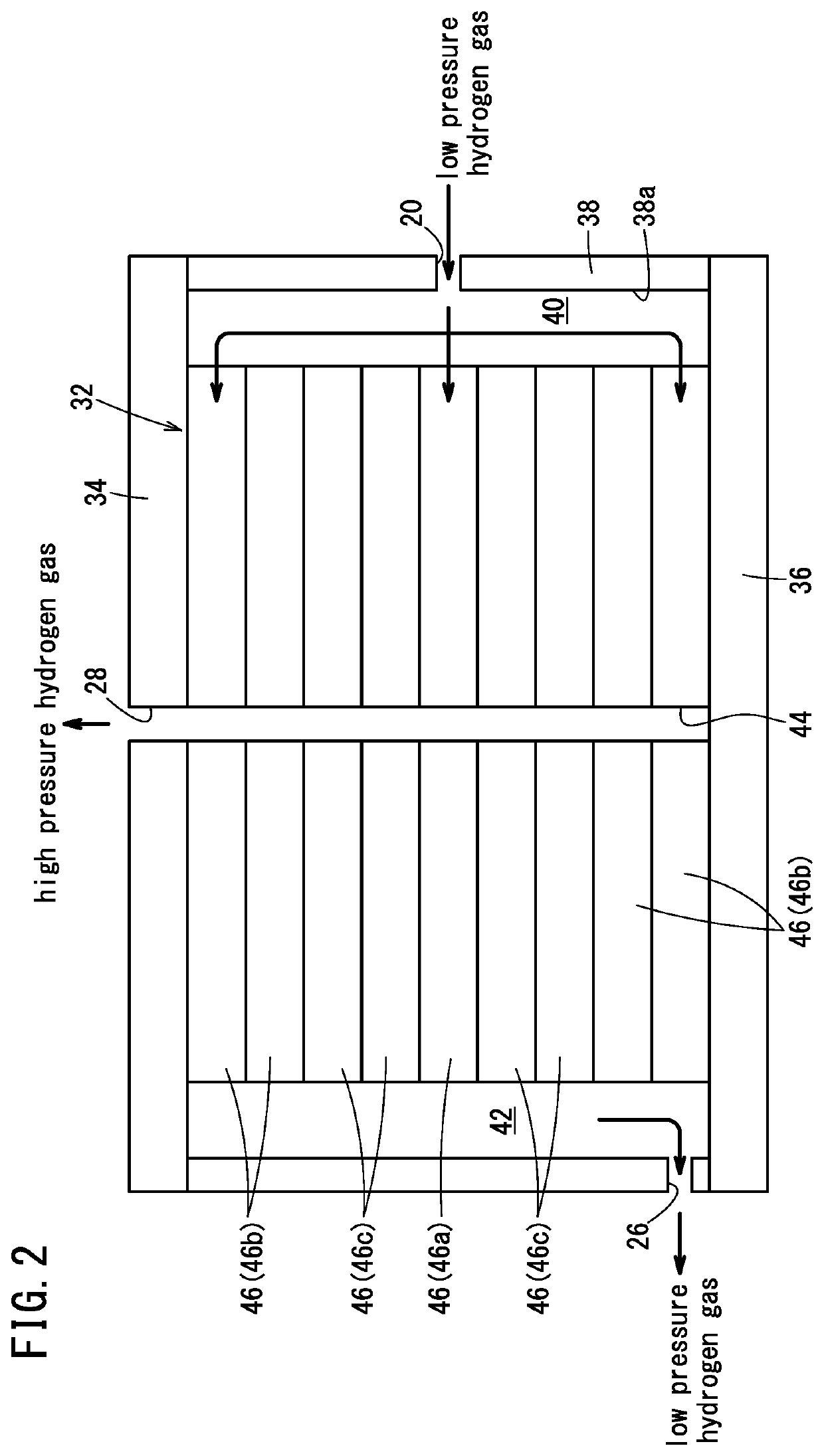

Electrochemical hydrogen compressor

PendingUS20220298656A1Inhibit wearAvoid cloggingCellsPositive displacement pump componentsChemical physicsConductive materials

An electrochemical hydrogen compressor comprises a unit cell that includes: an electrolyte membrane having hydrogen ion conductivity; an anode current collector stacked on one main surface side of the electrolyte membrane, a support member (for example, a flow field member or an anode separator) arranged so as to face the anode current collector; and a cathode current collector stacked on another main surface side of the electrolyte membrane, wherein the anode current collector is formed of a hydrophilic conductive material having a plurality of vent holes and has a surface facing the support member, the surface being subjected to a water-repellent treatment.

Owner:HONDA MOTOR CO LTD

Pipeline anticorrosion coating and anticorrosion pipeline

PendingCN110296298AAvoid concentrated damageImprove anti-corrosion performanceCorrosion preventionPipe protection against corrosion/incrustationEngineeringAnti-corrosion

The invention provides a pipeline anticorrosion coating and an anticorrosion pipeline, wherein the pipeline anticorrosion coating is tubular and is used for wrapping a pipe body; the pipeline anticorrosion coating comprises an inner insulating layer, a semi-conductive bonding layer and an outer insulating layer, and the inner insulating layer, the semi-conductive bonding layer and the outer insulating layer are sequentially arranged from inside to outside in the radial direction of the pipeline anticorrosion coating; the semi-conductive bonding layer is a uniform mixture of an adhesive and semi-conductive particles; and the semi-conductive bonding layer is bonded with the inner insulating layer and the outer insulating layer. The pipeline anticorrosion coating can improve the anti-corrosion effect of the pipeline, and particularly can resist the damage of stray current to the pipeline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment process for preventing membrane corrosive pitting and perforating on surface of steel and iron base

InactiveCN111321366APrevents galvanic corrosion phenomenaImprove uniformityMolten spray coatingAnti-corrosive paintsThermal sprayingElectrochemical corrosion

The invention provides a treatment process for preventing membrane corrosive pitting and perforating on the surface of a steel and iron base. The treatment process comprises the following steps that (1) an oxidation layer on the surface of a steel and iron base material is polished and removed; (2) a thermal spraying layer is formed on the surface of the steel and iron base material obtained in the first step through a thermal spraying technology; and (3) membrane laminating is conducted on the surface of the thermal spraying layer obtained in the second step. According to the treatment process, a compact particle surface layer can be formed on the surface of the steel and iron base by adoption of the thermal spraying layer, the homogeneity is good and no lattice defect exists; and potential equalization of the steel and iron base material covered with the surface membrane in a high-temperature state is achieved within the high-temperature range of 280-420 DEG C, the potential difference is avoided and the phenomenon of electrochemical corrosion causing breakdown of the surface membrane is prevented.

Owner:PINGDINGSHAN MEIYI METAL PROD

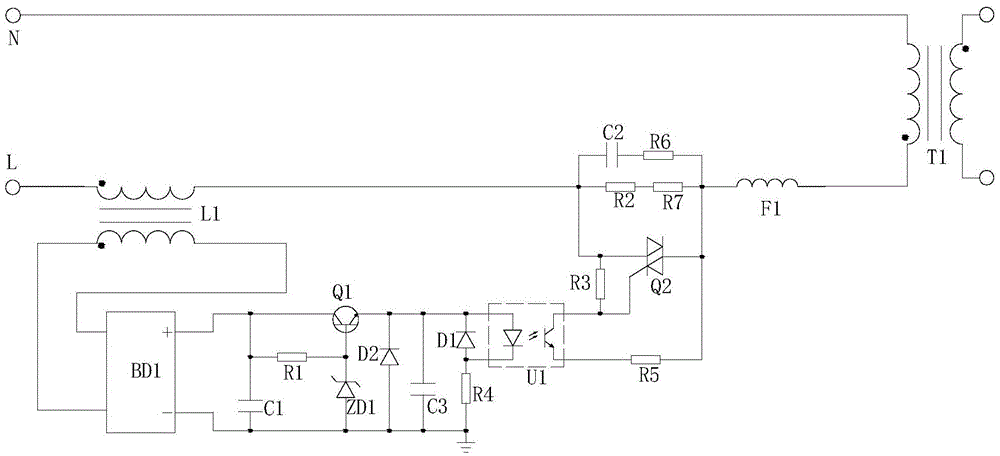

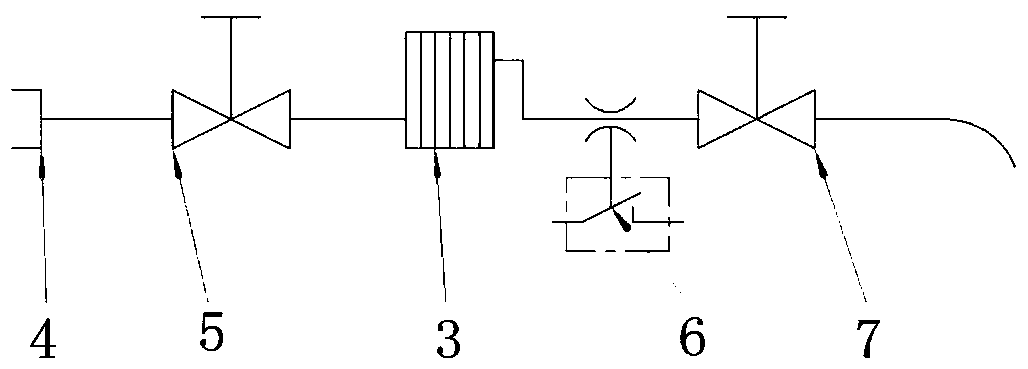

Industrial frequency transformer impact current suppression circuit, industrial frequency transformer and intrinsically safe power supply

ActiveCN103872891ALow failure rateAvoid high costEmergency protective arrangements for limiting excess voltage/currentPower conversion systemsBurning outVariable-frequency transformer

The invention provides an industrial frequency transformer impact current suppression circuit. The industrial frequency transformer impact current suppression circuit comprises an energy taking unit arranged on a fire wire of a transformer, a rectification unit electrically connected with the output end of the energy taking unit, a constant voltage unit electrically connected with the rectification unit and a current suppression unit electrically connected with the output end of the constant voltage unit, and the current suppression unit is arranged on the fire wire of the transformer and electrically connected with a fuse F1 of the transformer. Most input voltages can be loaded on a current limiting resistor in the power-on process, all the voltages loaded on the current limiting resistor are loaded at the two input ends of the transformer after the power-on process, therefore, large impact currents cannot be generated by the transformer at the starting-up moment, meanwhile, potential differences are prevented from being generated on the current limiting resistor, the fuse can be effectively prevented from being burnt out by the impacts of the large currents, and the fault rate of the fuse of the industrial frequency transformer is lowered. In addition, high cost caused by transformer power increase through the mode of increasing rated currents of the fuse can be avoided.

Owner:CHINA COAL TECH ENG GRP CHONGQING RES INST

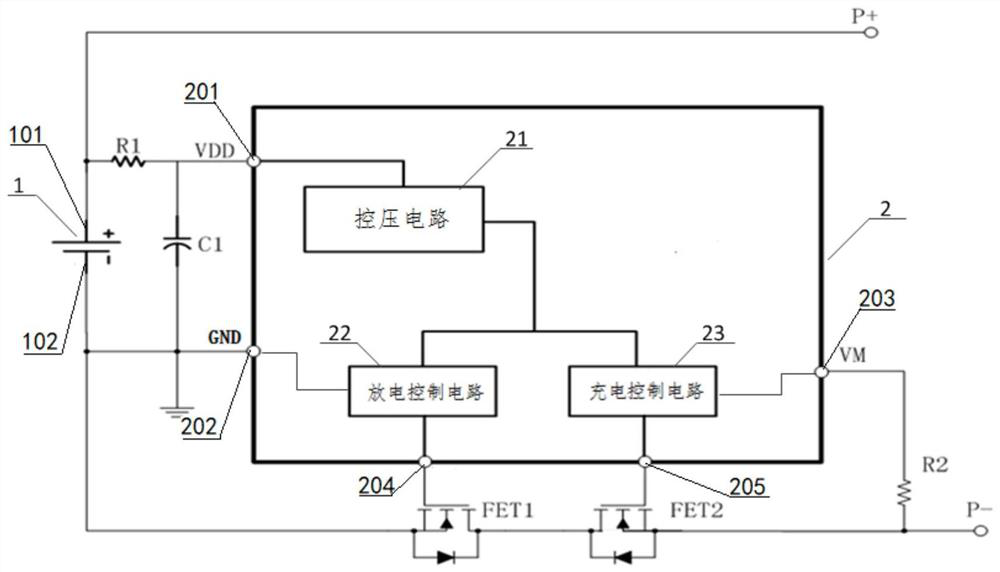

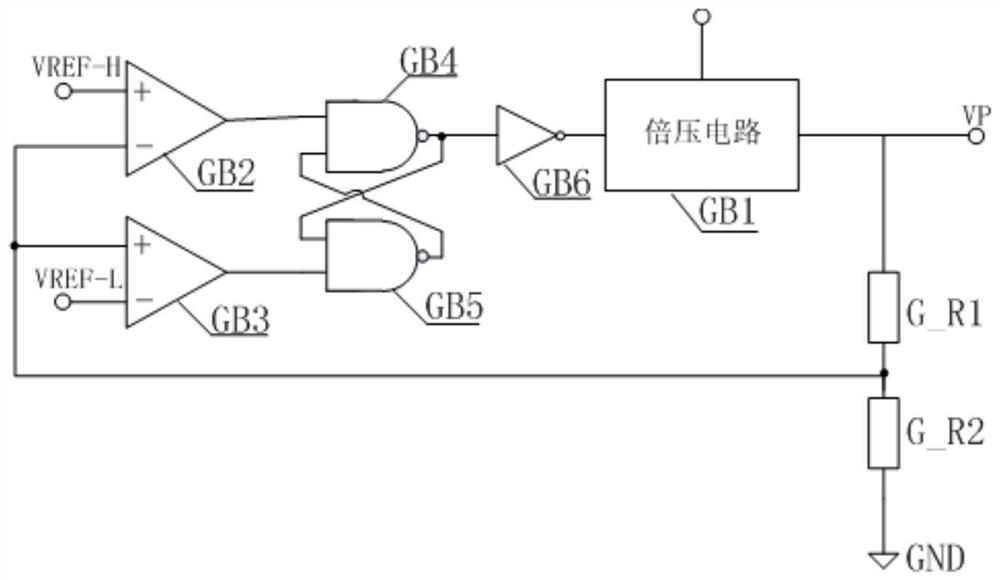

Battery assembly, battery protection chip and electronic product

ActiveCN112635857AAvoid potential differenceControl voltage stabilityCells structural combinationElectric powerElectrical batteryPotential difference

The invention discloses a battery assembly, a battery protection chip and an electronic product, wherein the battery protection chip comprises a power supply pin, a grounding pin, a current detection pin, a discharge control pin and a charge control pin, and also comprises a voltage control circuit, a discharge control circuit and a charge control circuit internally. The discharge control pin and the charge control pin of the battery protection chip are respectively used for controlling a first NMOS tube electrically connected with the negative electrode end of the battery and a second NMOS tube electrically connected with the negative electrode end of an external power supply, and the voltage control circuit generates stable control voltage, so that the conduction state of the two NMOS tubes is not influenced by the voltage drop of the battery. And the potential difference caused by no common ground inside and outside due to disconnection of the battery negative electrode end inside and outside the battery is effectively avoided.

Owner:XI AN WENXIAN SEMICON TECH CO LTD

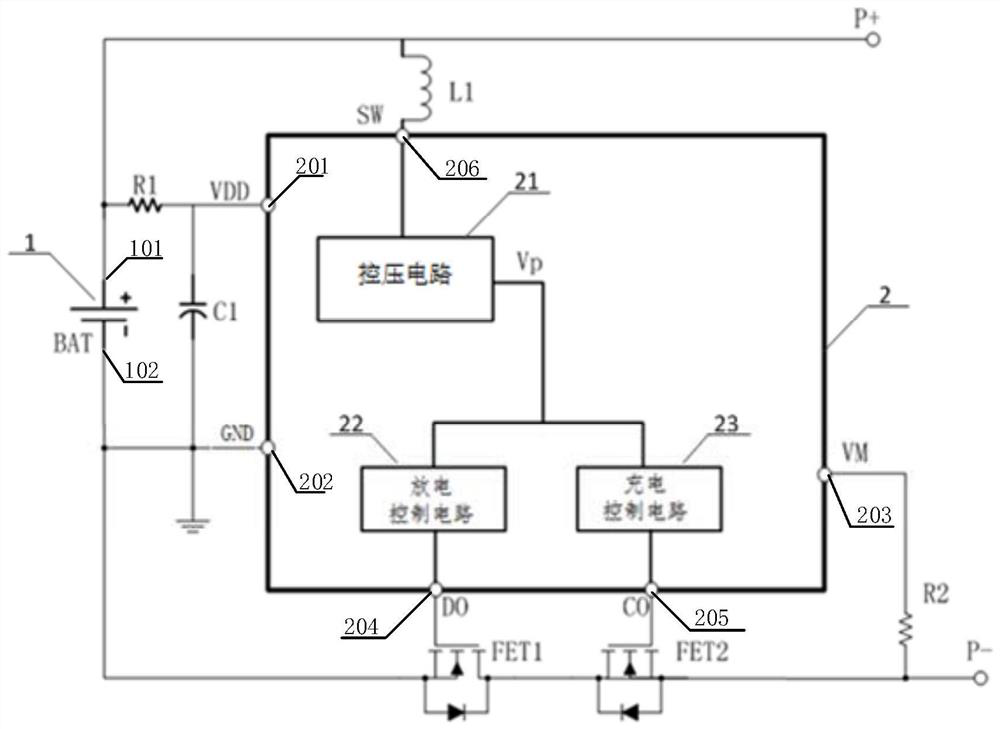

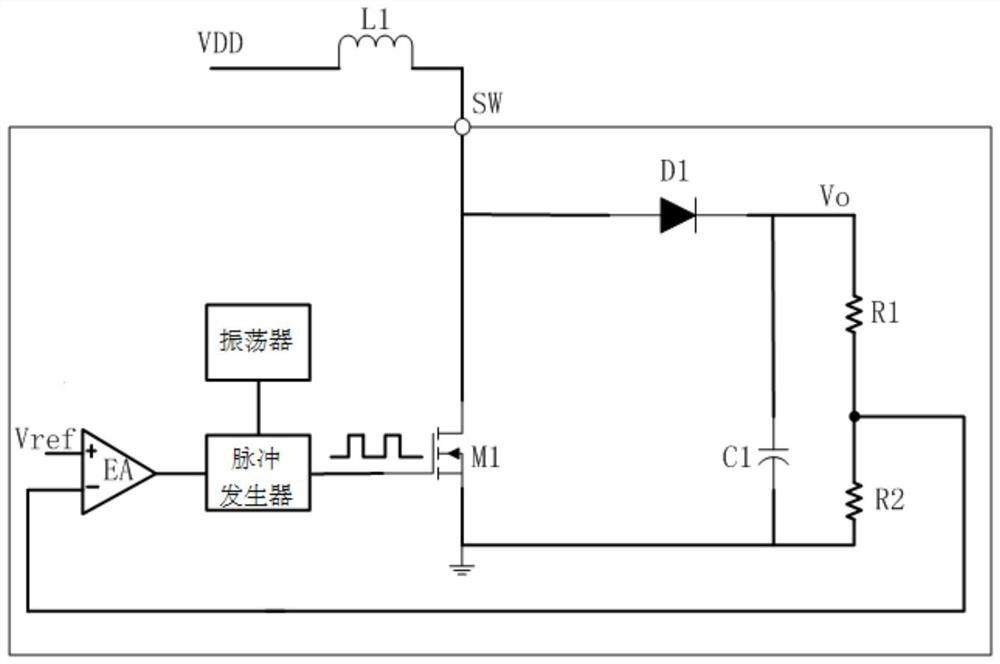

A battery assembly, battery protection chip and electronic product

ActiveCN112583078BAvoid potential differenceControl voltage stabilityElectric powerBattery overcharge protectionElectrical batteryElectrical connection

The invention discloses a battery component, a battery protection chip and an electronic product, wherein the battery protection chip includes a power supply pin, a ground pin, an inductance access pin, a current detection pin, a discharge control pin and a charge control pin , the chip also includes a voltage control circuit, a discharge control circuit and a charge control circuit. One end of the inductor is connected to the input end of the voltage control circuit, and the other end is electrically connected to the positive terminal of the battery. The discharge control pin and charge control pin of the battery protection chip They are respectively used to control the first NMOS tube electrically connected to the negative terminal of the battery, and the second NMOS tube electrically connected to the negative terminal of the external power supply. The voltage control circuit generates a stable control voltage, so that the conduction state of the two NMOS tubes is not affected by the battery voltage. The impact of the drop, and effectively avoid the potential difference between the inside and outside of the battery due to the disconnection of the negative terminal of the battery.

Owner:XI AN WENXIAN SEMICON TECH CO LTD

Lead storage battery production method, lead storage battery, electrolyte production method and electrolyte

ActiveCN108493498ASmall number of molecular clustersImprove solubilityFinal product manufactureLead-acid accumulators constructionChemistryExothermic reaction

The invention relates to a lead storage battery production method, a lead storage battery, an electrolyte production method and an electrolyte. The lead storage battery production method comprises anelectrolyte production process, wherein during the electrolyte production process, distilled water is treated into small-molecular-group distilled water through water electrifying equipment and is then mixed with pure sulfuric acid. The electrolyte prepared by adopting the method is small in moleculer group number, and after the electrolyte is mixed with the sulfuric acid, a sulfuric acid solutionis more uniform. If the sulfuric acid and the water are mixed more uniformly, the current density distribution of a pole plate is more uniformly when the pole plate is charged and discharged, the potential difference of different parts of the battery is avoided, the polarization of the battery is reduced, meanwhile, the resistance of the pole plate can be reduced, the exothermic reaction of the battery during charging is reduced, and active substances can more favorably participate in charging and discharging, so that the charging acceptability of the storage battery is improved. In addition,a method for increasing the specific energy of the battery through only replacing the electrolyte not only can be accomplished at the design production stage of the battery, but also can be used on amature product and a recycled product.

Owner:北京君禾科技有限公司

Ultra-UHV pressure equalizing ring and its production process

InactiveCN110010314BNot easy to breakdown failureImprove conductivityVacuum evaporation coatingSputtering coatingSemiconductor materialsPotential difference

The invention provides a super-high voltage grading ring and a production process thereof, aiming at the problems that the existing grading ring material is easy to cause potential difference and failure of the grading ring under the super-high voltage. The super-high voltage grading ring comprises an annular grading ring body which is made of semiconductor materials, the outer portion of the grading ring body is coaxially provided with an aluminum ring, a plurality of connection rods are uniformly distributed in an annular interval between the grading ring body and the aluminum ring, and theextension lines of the connection rods pass through the centers of circles of the grading ring body and the aluminum ring. By using the semiconductor material, the produced grading ring has an electric field under the super-high voltage to fundamentally avoid the potential difference problem, and the grading ring is not easy to cause breakdown of a device when the voltage generates voltage jump soas to obviously improve the whole reliability of the device.

Owner:平顶山正植科技有限公司

Mold inner surface electroplating production line and electroplating method

Owner:JILIN ANDE ELECTROCHEM TECH

Power frequency transformer surge current suppression circuit, power frequency transformer and its intrinsically safe power supply

ActiveCN103872891BIncrease powerAvoid burnsEmergency protective arrangements for limiting excess voltage/currentPower conversion systemsElectricityElectrical resistance and conductance

The invention provides an industrial frequency transformer impact current suppression circuit. The industrial frequency transformer impact current suppression circuit comprises an energy taking unit arranged on a fire wire of a transformer, a rectification unit electrically connected with the output end of the energy taking unit, a constant voltage unit electrically connected with the rectification unit and a current suppression unit electrically connected with the output end of the constant voltage unit, and the current suppression unit is arranged on the fire wire of the transformer and electrically connected with a fuse F1 of the transformer. Most input voltages can be loaded on a current limiting resistor in the power-on process, all the voltages loaded on the current limiting resistor are loaded at the two input ends of the transformer after the power-on process, therefore, large impact currents cannot be generated by the transformer at the starting-up moment, meanwhile, potential differences are prevented from being generated on the current limiting resistor, the fuse can be effectively prevented from being burnt out by the impacts of the large currents, and the fault rate of the fuse of the industrial frequency transformer is lowered. In addition, high cost caused by transformer power increase through the mode of increasing rated currents of the fuse can be avoided.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

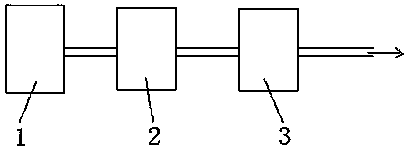

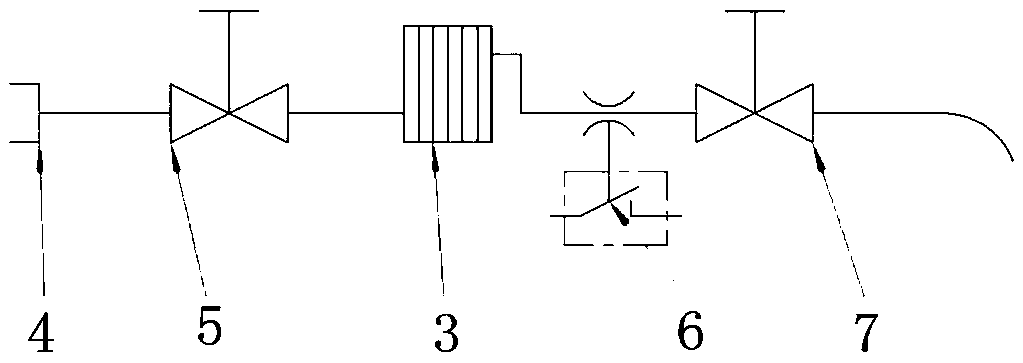

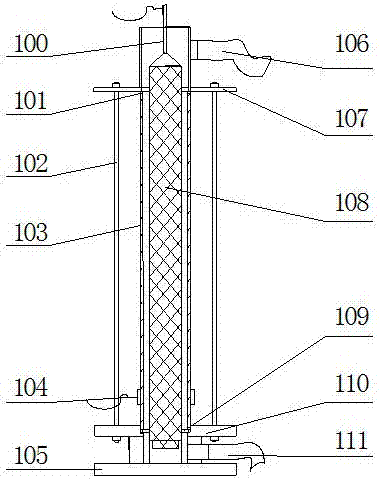

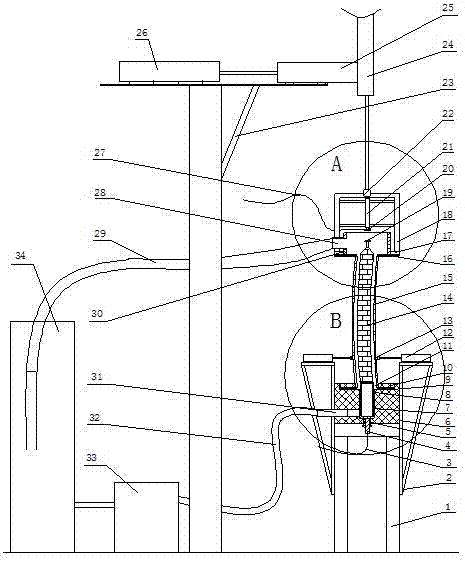

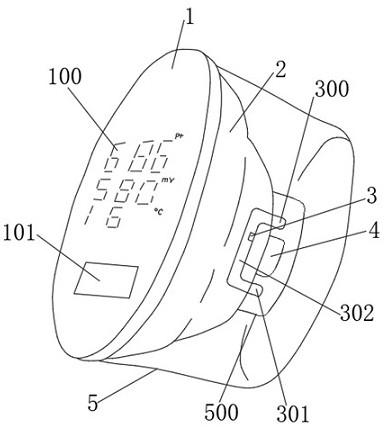

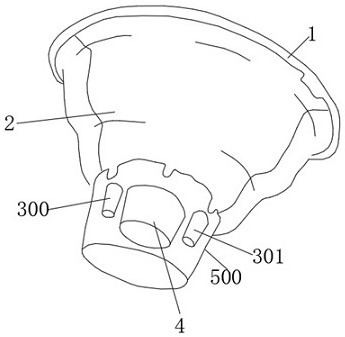

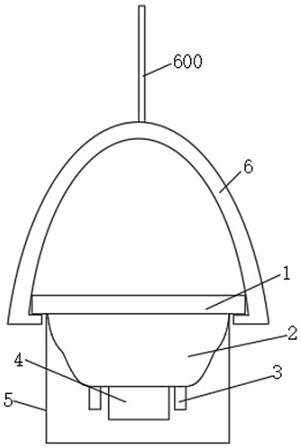

A rapid test device for oxidation-reduction potential value of aqueous solution with water pump

ActiveCN113340953BFlow fastAvoid potential differenceMaterial electrochemical variablesAqueous solutionRapid testing

The invention provides a rapid test device for the oxidation-reduction potential value of an aqueous solution with a water pump, comprising a main body of the test device, an auxiliary stirring mechanism, a water inlet pipe and a water outlet pipe are arranged on the main body of the test device, and the water inlet pipe and the The outlet pipe is connected through a pipe, and electrodes are arranged in the pipe, and the auxiliary stirring mechanism is a water pump, and the water pump is used to stir the measured aqueous solution to promote the rapid flow of the measured aqueous solution, and accelerate the aqueous solution to enter the pipe through the water inlet pipe. Through the process of flowing out of the water outlet pipe, the ions in the aqueous solution are quickly captured by the electrodes, and at the same time, the deionized aqueous solution can be stirred to promote the rapid removal of the aqueous solution ions on the electrodes, reducing the use time interval of the test device . The invention can solve the technical problem of low testing efficiency of existing devices for testing the oxidation-reduction potential value of aqueous solution.

Owner:深圳科瑞德健康科技有限公司

Lead storage battery production method and lead storage battery, electrolyte production method and electrolyte solution

ActiveCN108493498BSmall number of molecular clustersImprove solubilityFinal product manufactureLead-acid accumulators constructionElectrolytic agentElectrical battery

Owner:北京君禾科技有限公司

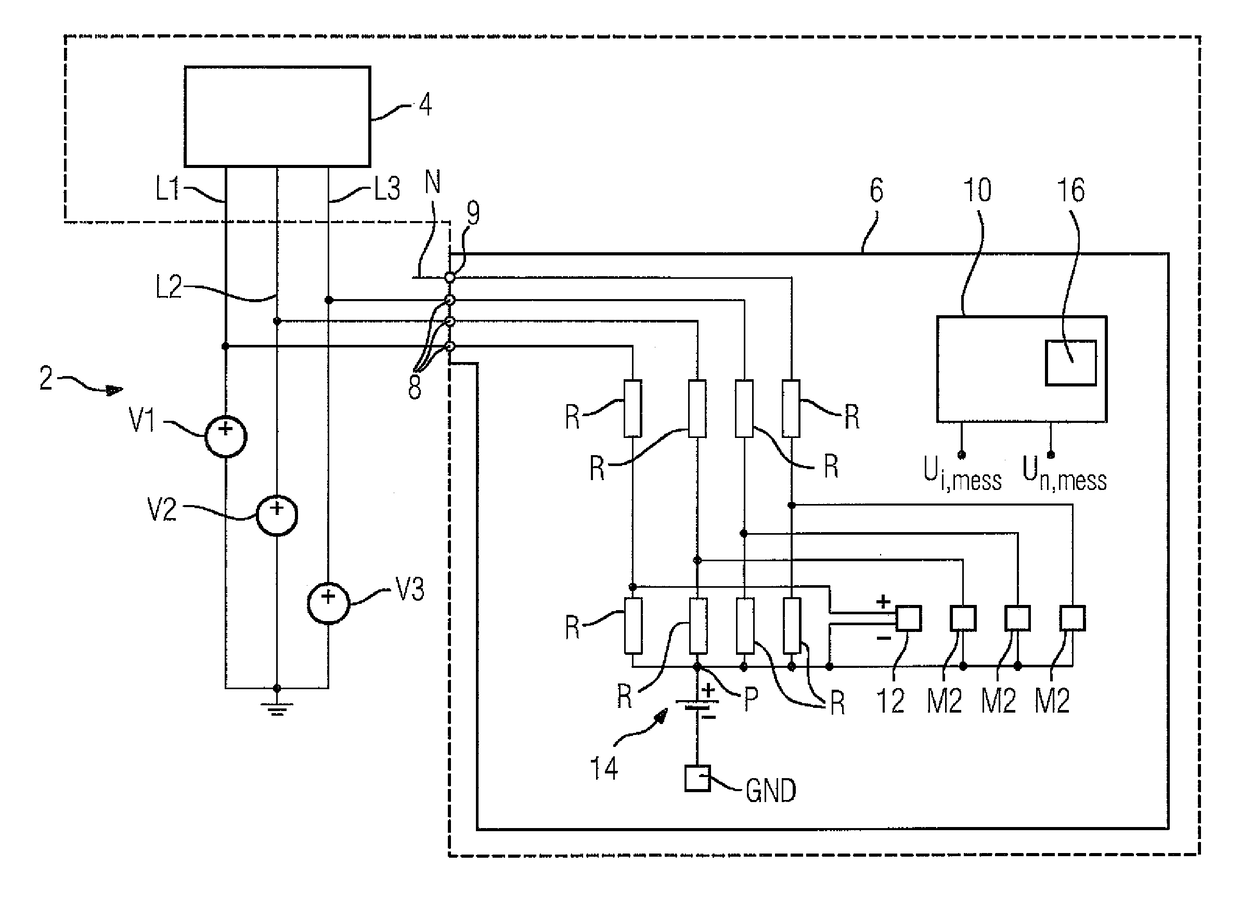

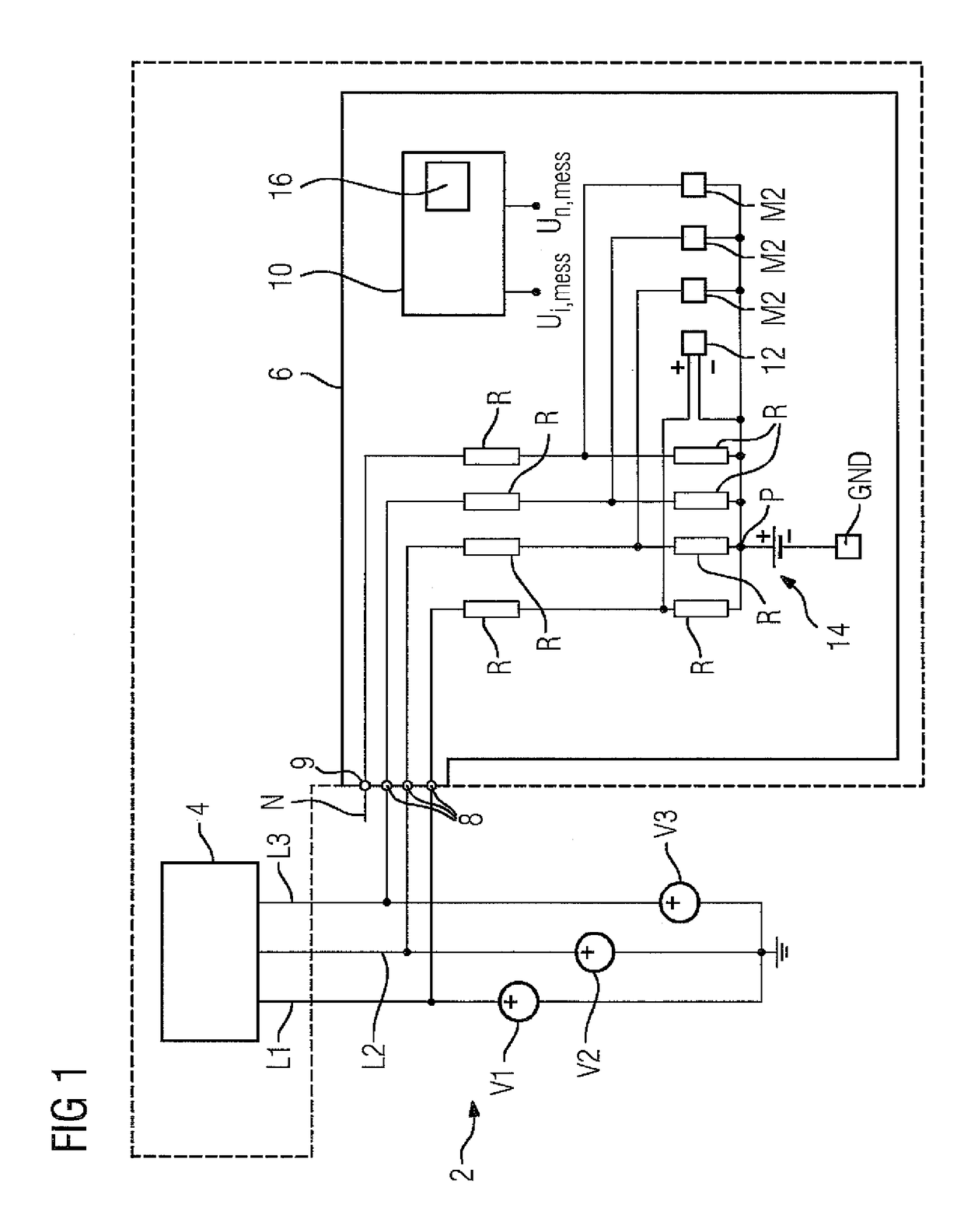

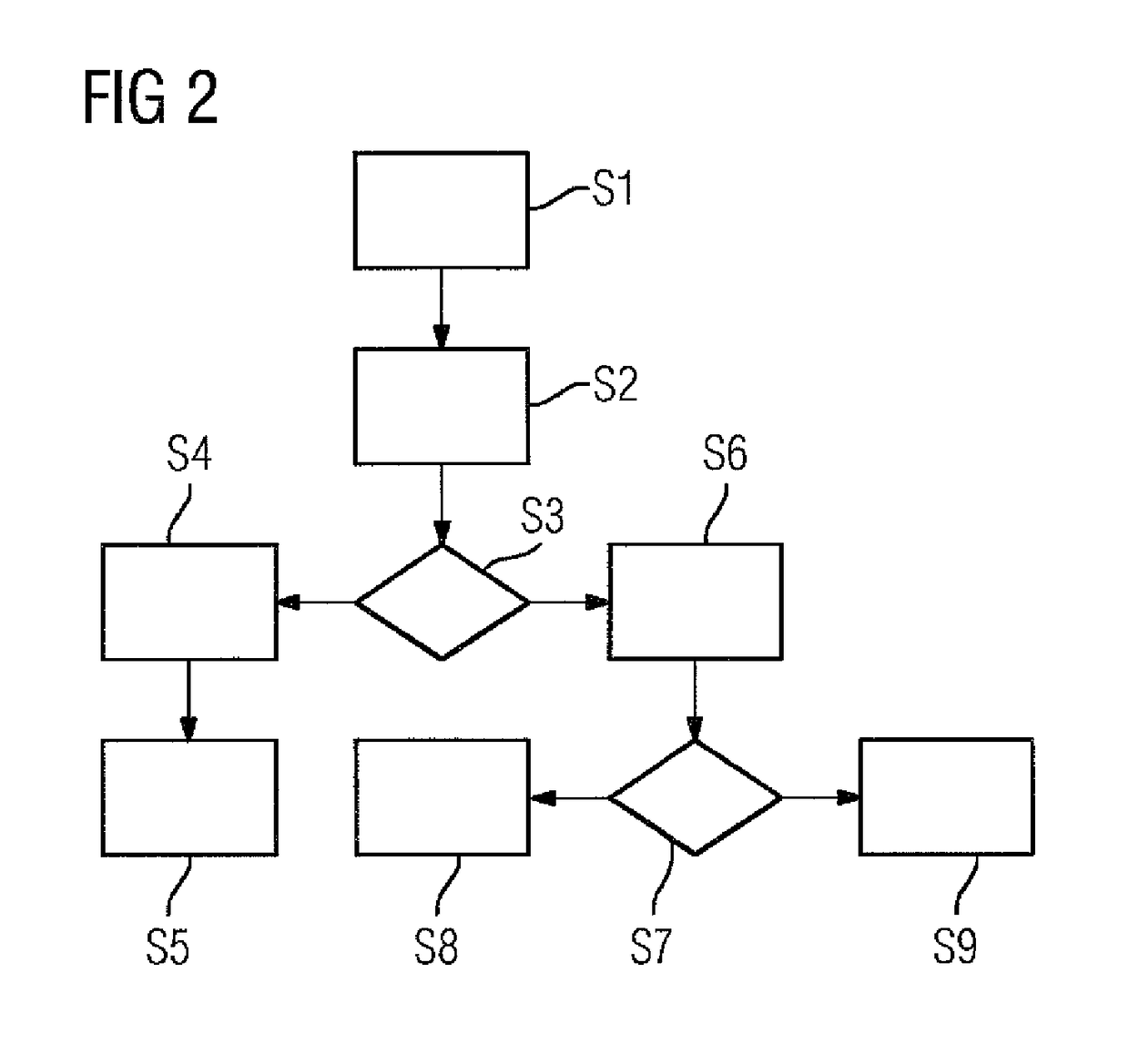

Method for determining the supply voltages of a load, and load

ActiveUS9885741B2Avoid potential differenceLow hardware costVoltage/current isolationVoltage measurements onlyThree-phaseTransformer

In order to reliably determine the supply voltages (Ui) of the individual phases (L1, L2, L3) of a load (4) in a multiphase supply network (2), in particular a three-phase supply network, a measuring module (6) is provided and is used to determine the supply voltages (Ui) from measuring voltages (Ui,mess) with the aid of a matrix operation. The matrix operation is used, in particular, to compensate for potential differences or potential shifts between the measuring system and the supply network (2) without the need for hardware measures, for example a voltage transformer.

Owner:SIEMENS AG

Method for solving skip plating of fixed position of PCB (Printed Circuit Board) caused by battery effect

PendingCN114828436AFast heatingSolve skip plating problemPrinted circuit manufactureComposite materialPrinted circuit board

The invention discloses a method for solving skip plating of a fixed position of a PCB (Printed Circuit Board) caused by a battery effect, which comprises the following steps of: providing a production board, arranging a solder resist windowing position to be subjected to nickel-gold immersion treatment and antioxidant treatment on the production board so as to expose a PAD, and arranging a non-plated-through hole and a plated-through hole on the production board; the PAD comprises a first PAD connected with the non-plated-through hole, a second PAD connected with the plated-through hole and / or a third PAD not connected with the hole; wherein the first PAD is subjected to nickel-gold deposition treatment, the second PAD connected with the plated-through hole and the plated-through hole are subjected to nickel-gold deposition treatment or anti-oxidation treatment at the same time, and the third PAD with the distance smaller than 20 mil s from the plated-through hole and the plated-through hole are subjected to nickel-gold deposition treatment at the same time; after a film is pasted on the production board, windowing is conducted on the positions corresponding to the non-plated-through holes and the positions to be subjected to nickel and gold immersion treatment; carrying out chemical nickel and gold immersion treatment on the production board; and after the film is removed, the production board is subjected to anti-oxidation treatment. The method effectively solves the problem of skip plating of the PAD in the prior art.

Owner:江西景旺精密电路有限公司

Pipeline anti-corrosion layer and anti-corrosion pipeline

PendingCN110296299AAvoid concentrated damageImprove anti-corrosion performanceCorrosion preventionPipe protection against corrosion/incrustationEngineeringMixture formation

The invention provides a pipeline anti-corrosion layer and an anti-corrosion pipeline. The pipeline anti-corrosion layer comprises an inner semi-conductive bonding layer, an insulating layer and an outer semi-conductive bonding layer which are sequentially arranged from inside to outside in the radial direction, wherein the inner semi-conductive bonding layer and the outer semi-conductive bondinglayer are formed by a uniform mixture of an adhesive and semi-conductive particles. According to the pipeline anti-corrosion layer and the anti-corrosion pipeline, the anti-corrosion effect of the pipeline can be improved, and particularly, the pipeline anti-corrosion layer and the anti-corrosion pipeline can well protect the pipeline against the damage from stray current.

Owner:CHINA PETROLEUM & CHEM CORP +1

Upper electrode assembly, reaction chamber and atomic layer deposition equipment

ActiveCN108807127BAvoid potential differenceAvoid sparkingElectric discharge tubesFinal product manufactureMechanical engineeringAtomic layer deposition

The disclosure provides an upper electrode assembly, a reaction chamber, and atomic layer deposition equipment. The upper electrode assembly includes an air intake structure and an upper electrode plate. The upper electrode plate is provided with a main pipeline. The air intake structure is used to process The gas is introduced into the reaction chamber from the main pipeline, and the gas inlet structure includes: an insulating component placed on the upper electrode plate; an gas inlet component placed on the insulating component and provided with a first gas inlet pipeline , the first air intake pipeline communicates with the main pipeline through the insulating component, and the inner wall of the first air intake pipeline is electrically isolated from the inner wall of the main pipeline through the insulating component.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

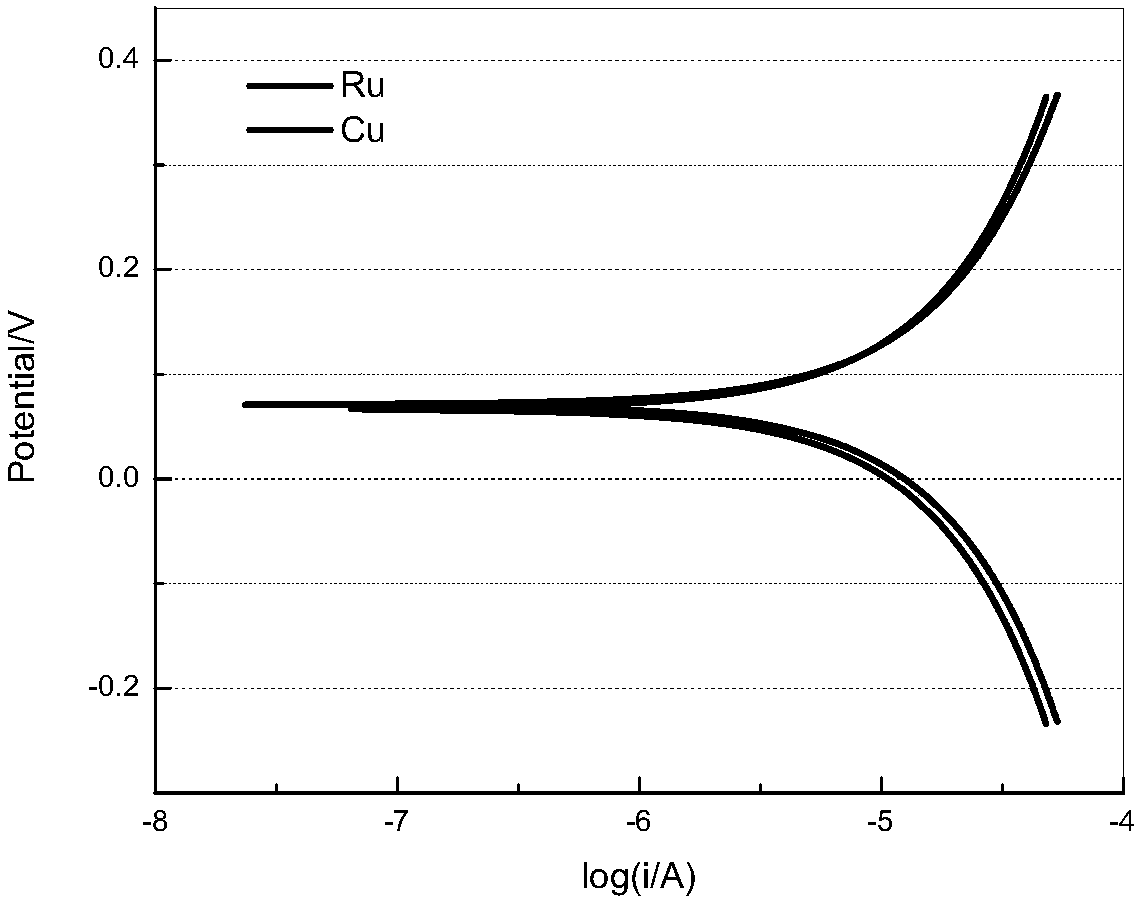

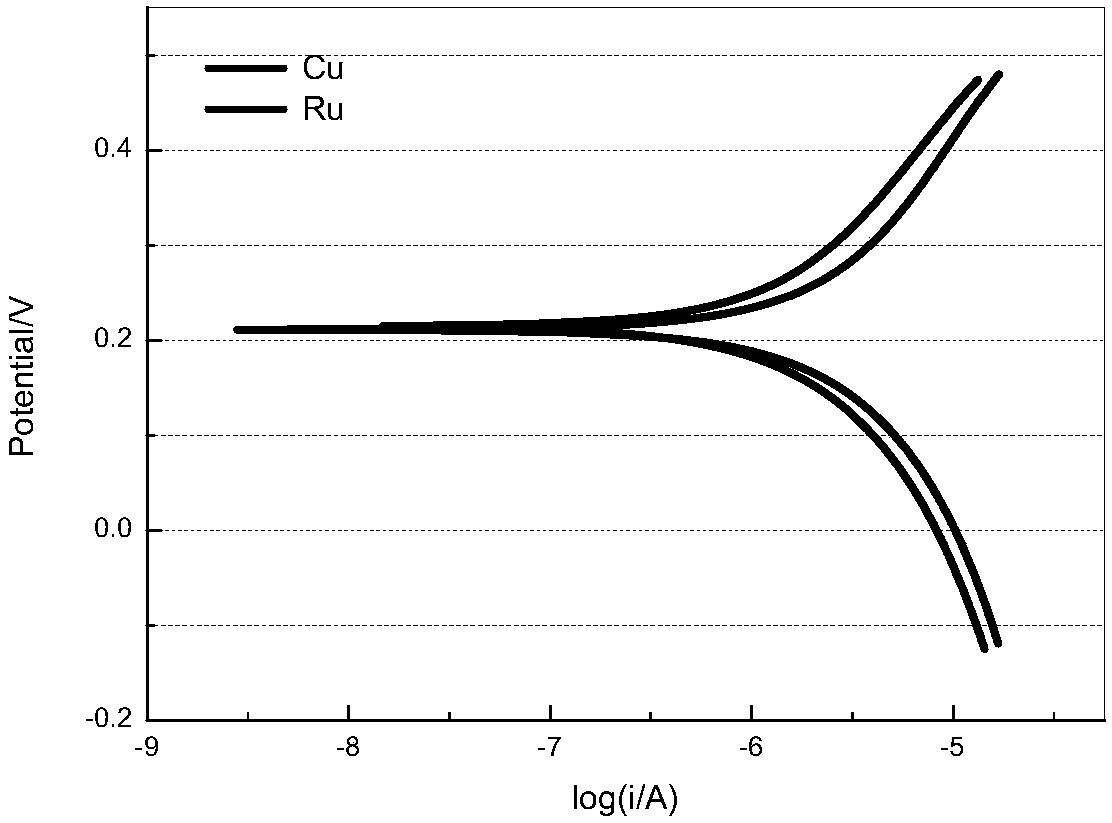

Alkaline polishing solution for inhibiting galvanic corrosion of copper-ruthenium barrier layer and preparation method thereof

ActiveCN106118495BAvoid potential differenceReduce current densityPolishing compositionsPotential differenceRuthenium

The invention relates to alkaline polishing liquid for inhibiting galvanic corrosion of a copper-ruthenium barrier layer and a preparation method of the alkaline polishing liquid. The polishing liquid is prepared from the following components in percentage by weight: 0.3 percent of H2O2, 0.5 percent to 5 percent of beta-hydroxyethylenediamine, 0.1 percent to 0.3 percent of ethylenediaminetetraacetic acid-tetra-tetrahydroxyethylethylenediamine, 0.1 percent to 5 percent of an FA / O type surfactant, 0.8 percent to 1.5 percent of a pH inorganic acid regulator and the balance being de-ionized water; the pH value of the alkaline polishing liquid is 9 to 10; the alkaline polishing liquid is obtained through a mixing manner and an inhibitor does not need to be added; the alkaline polishing liquid is easy to wash and the potential difference between Ru and Cu is effectively overcome; the current density of the galvanic corrosion is reduced and a serious galvanic corrosion problem between the Ru and the Cu is solved; the galvanic corrosion between the Ru and the Cu is inhibited very well.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com