Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Avoid miss plating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional assistant plating additive for hot dip plating process, preparation and use method thereof

ActiveCN101328568AReduce lossImprove stabilityHot-dipping/immersion processesDissolutionLiquid metal

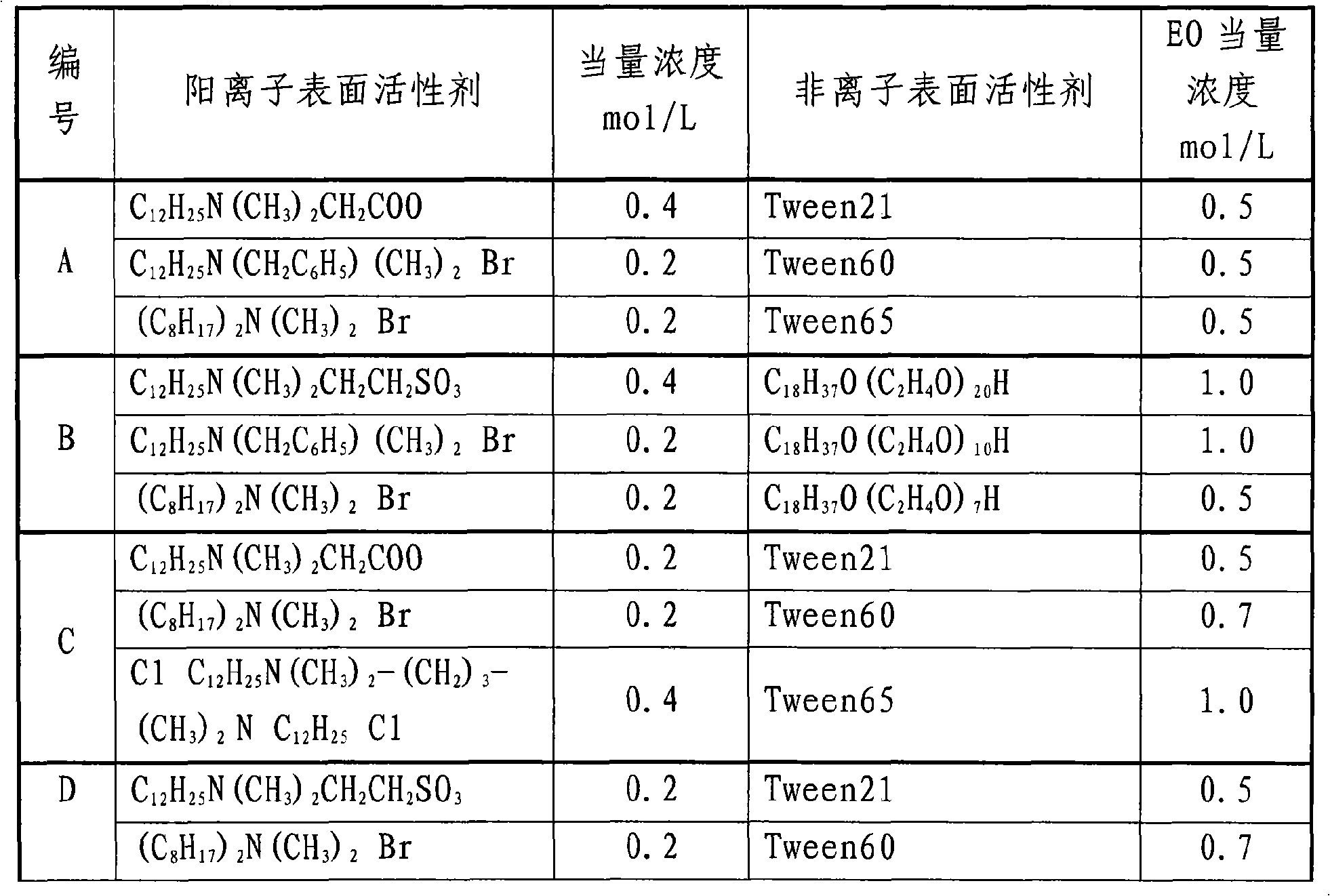

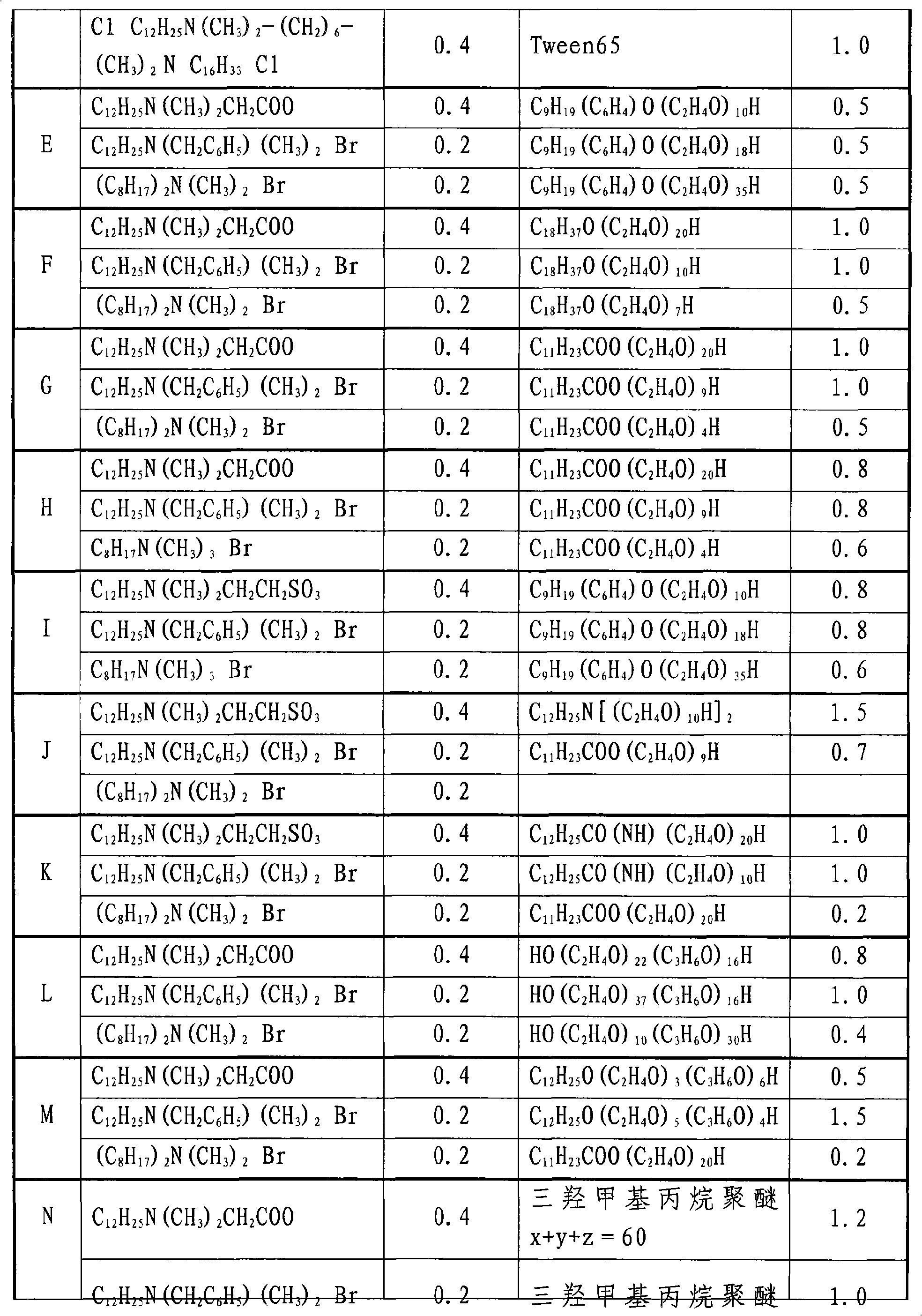

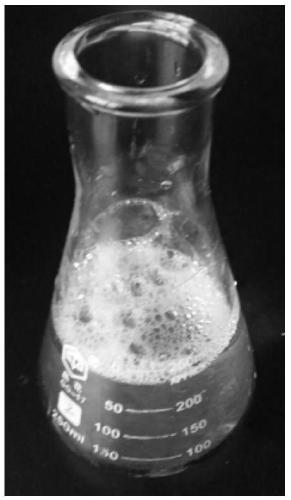

The invention relates to a multifunctional plating assisting additive for a hot dipping metallization process and a preparation and application method thereof, and belongs to the metal material anticorrosive technical field for providing multiple plating assisting efficacy. The technical proposal of the invention comprises that: a plurality of cations or an amphoteric surfactant ( an equivalent concentration of a quaternary ammonium group is between 0.1 and 2 mol / L) and nonionics (an equivalent concentration of a polyoxyethylene group is between 0.5 and 5 mol / L) are dissolved in deionized water. The method can improve the wetting quality between a liquid-state metal and a workpiece, and the adhesive uniformity and continuity of the plating assisting additive, reduces the drying time, prevents the liquid-state metal from falling and splashing, shortens the dipping and plating time, saves raw materials, improves a residue form, reduces an ash content, increases an ash discharge speed, isolates air, stops oxidation, disperses residual dirt and is suitable for a plurality of processes of hot galvanizing, hot plating zinc-aluminum alloy, hot plating aluminum, etc. The preparation steps comprise dissolution, cubage determination, cooling, keeping stand and filling; when the multifunctional plating assisting additive is used, the multifunctional plating assisting additive is directly added into a plating assisting additive solution and is evenly stirred.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

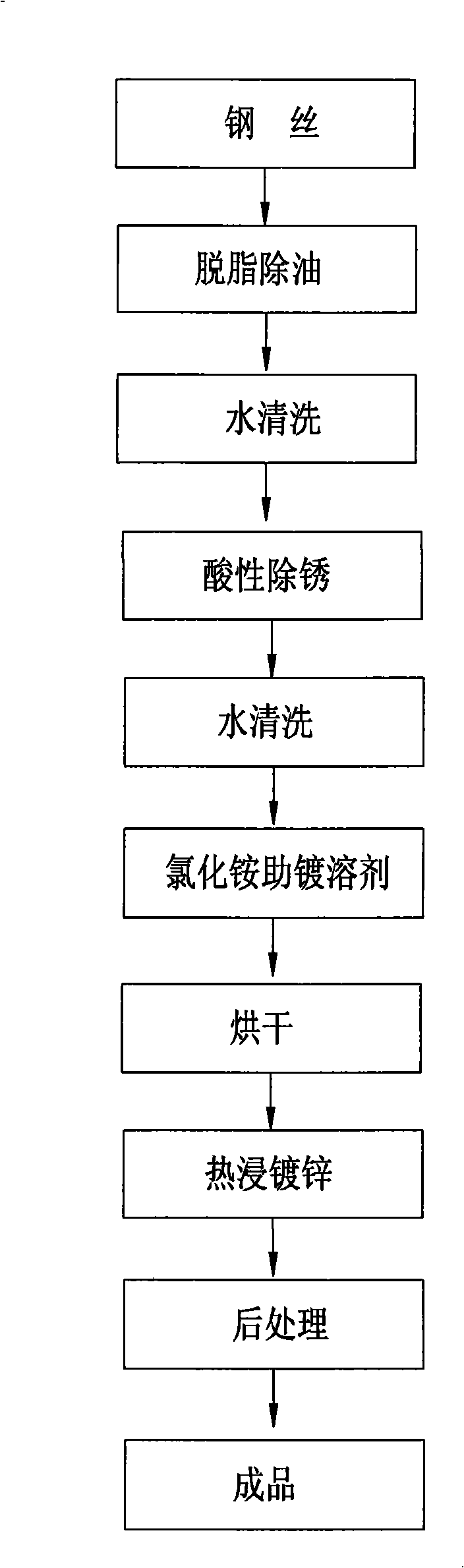

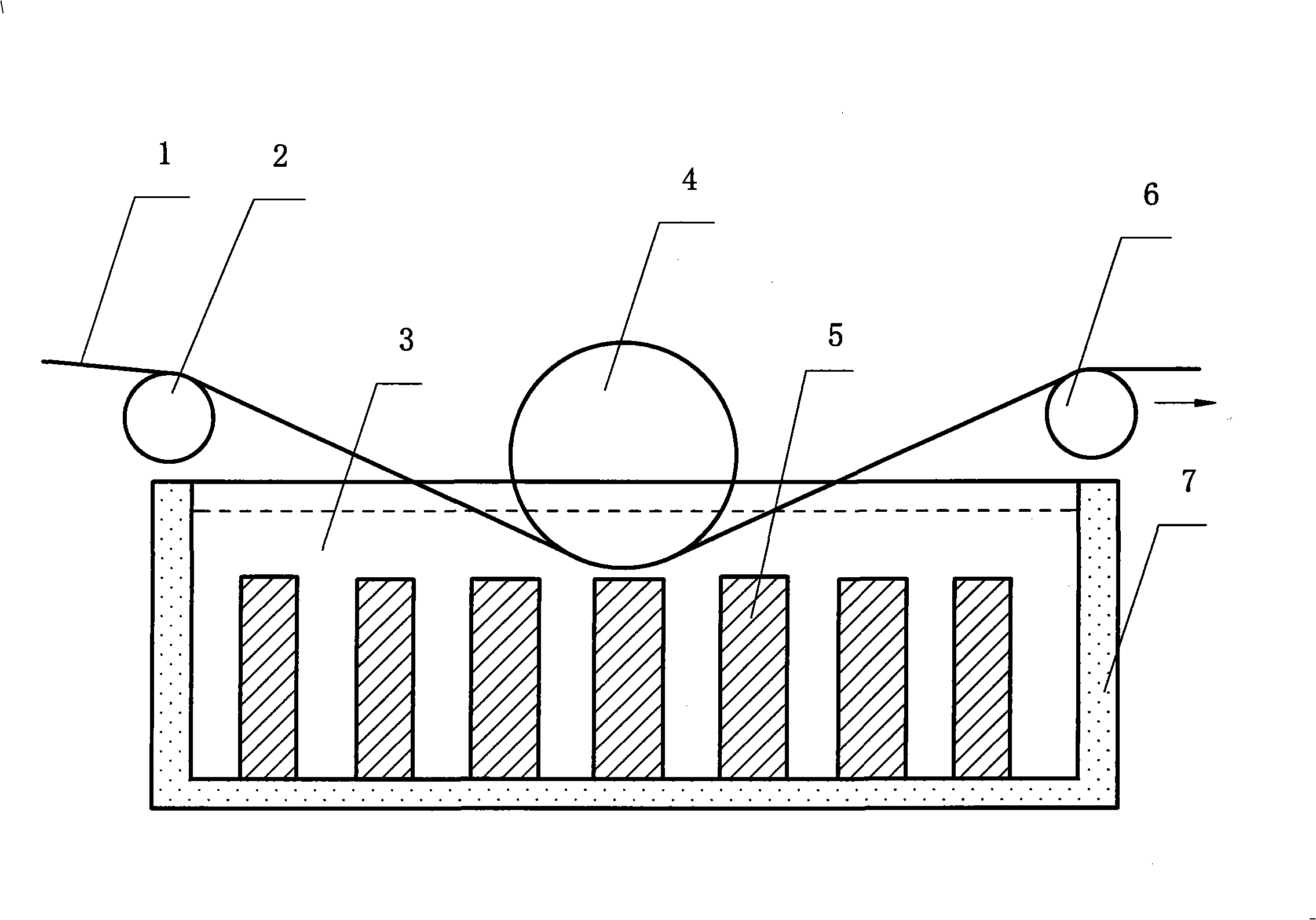

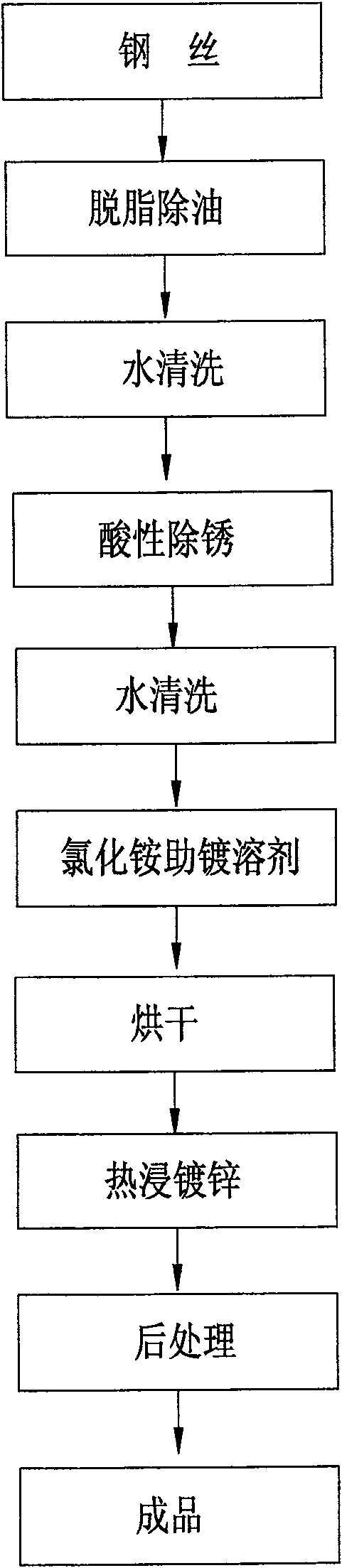

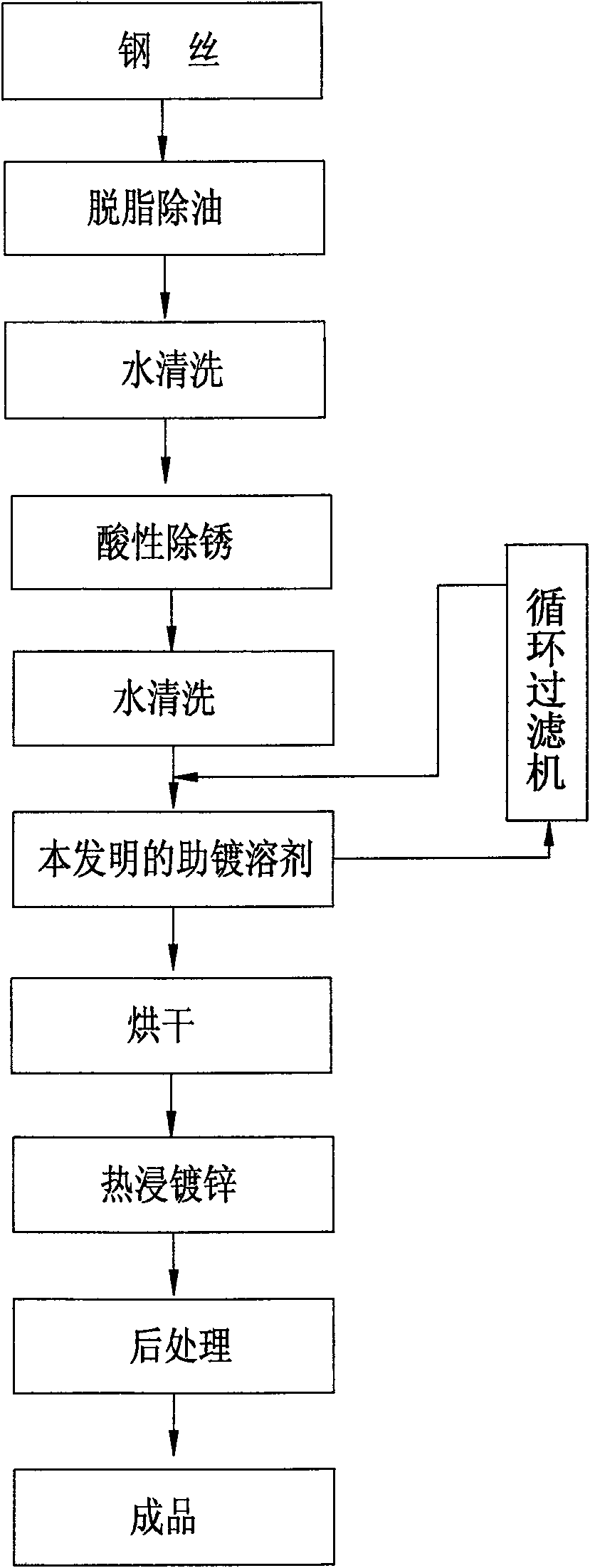

Electrolytic plating assisting method for hot dip galvanizing of steel wire and electrolytic plating assistant

InactiveCN101948990AEasy to dryImprove protectionHot-dipping/immersion processesElectrolysisEthylic acid

The invention relates to electrolytic plating assistant for hot dip galvanizing of a steel wire. Electrolytic plating assistant comprises the following components: 30-220 g / L of zinc chloride, 0-150 g / L of potassium chloride, 0-150 g / L of sodium chloride, 2-90 g / L of ammonium chloride, 0-100 g / L of boric acid, 0-70 g / L of acetic acid, 1-25 g / L of sodium fluoride, 2-50 g / L of cerium chloride, 0-50 g / L of potassium fluozirconate, 0-50 g / L of methanol, 0.5-20 g / L of hydrogen peroxide and the balance of water. The electrolytic plating assisting method comprises the following steps: washing with alkali, removing oil, washing with water, washing with acid to remove rust, washing with water, activating with weak acid, electrolyzing to assist plating, drying, and purifying the electrolytic plating assistant. The method can reduce the generation of AlCl3, prevent skip plating and reduce the generation of smoke dust. The electrolytic plating assistant has the characteristic of relatively high melting point, and thus, can increase the drying temperature and shorten the drying time. The dried plating assistant has the characteristics of low brittleness, high compatibility with electrogalvanizing, and low tendency to shedding.

Owner:NORTHEASTERN UNIV

Additive for heat zinc coating auxiliary agent

InactiveCN101126142AHigh activityIncrease profitHot-dipping/immersion processesSlagSurface-active agents

The invention provides an additive used in hot-dip galvanizing assistant plating agent, belonging to the technical field of metal material plating. The invention is used for solving the problem of assistant plating efficiency. The technical proposal of the invention is that the additive is a de-ionized water solution; the water solution contains cation surface active agent and organic solvent of the long chain alkyl; the content of the long chain alkyl cation surface active agent is 100 to 800 gram per liter; the organic solvent can be ethanol, isopropyl alcohol, acetone or one of nickel and N-dimethyl formamide, with adding content of 30 to 160 gram per liter. The invention has the advantages that the assistant plating agent is made and the made element have a plating face with excellent wettability and compatibility, which can increase the activity and the utilization rate, improve the assistant plating efficiency, prevent plated element from escaping, prevent the plated element which is assistant plated from being secondarily oxidized in air, reduce zinc slag, prevent the zinc liquid from splashing and increase the surface quality of the made element. Furthermore, the invention can be directly added into the assistant agent, and then is evenly mixed, with the character of easy operation. The invention is not limited by the temperature of the assistant plating agent so that the invention can be used under room temperature.

Owner:陈冬

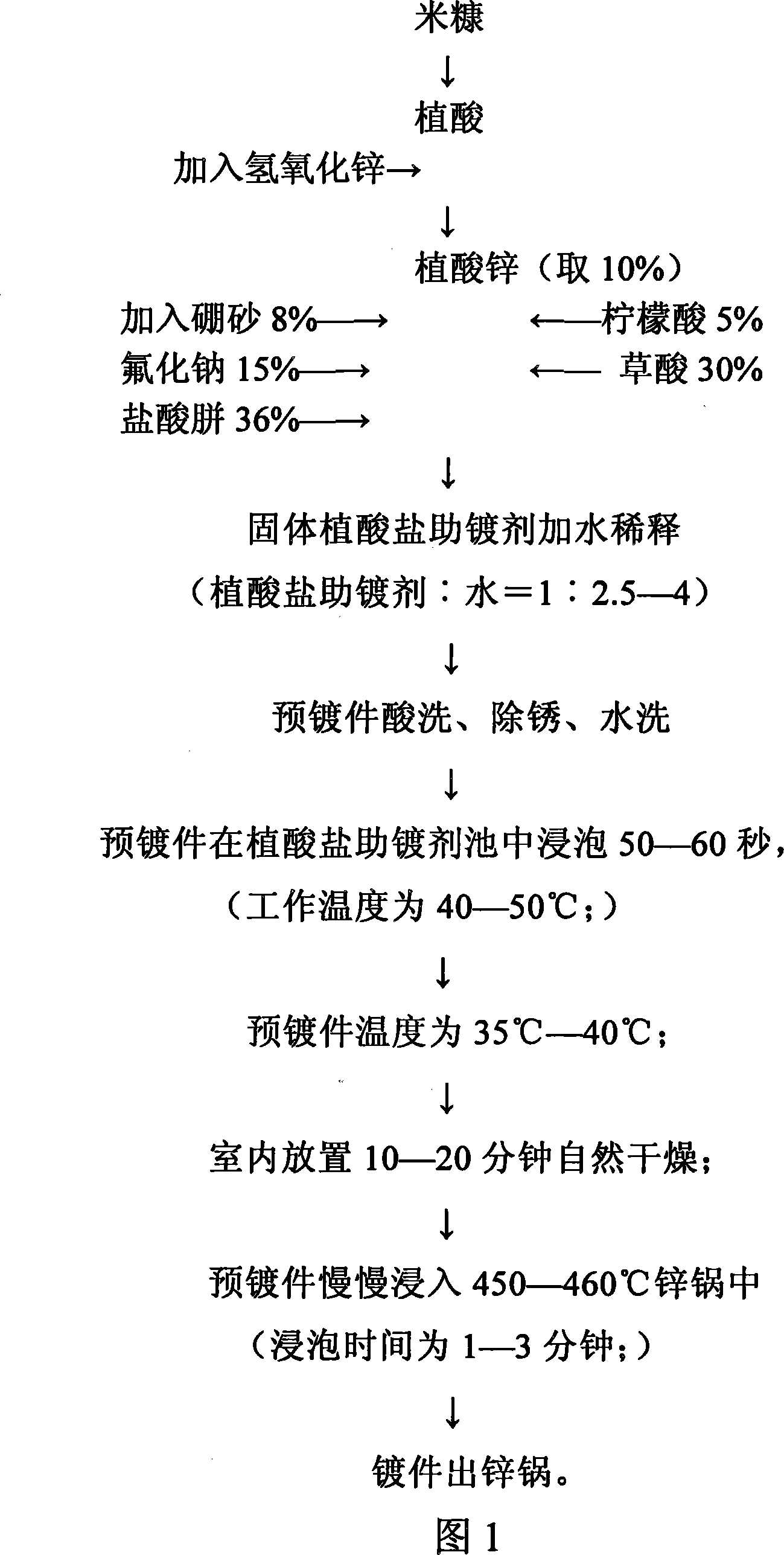

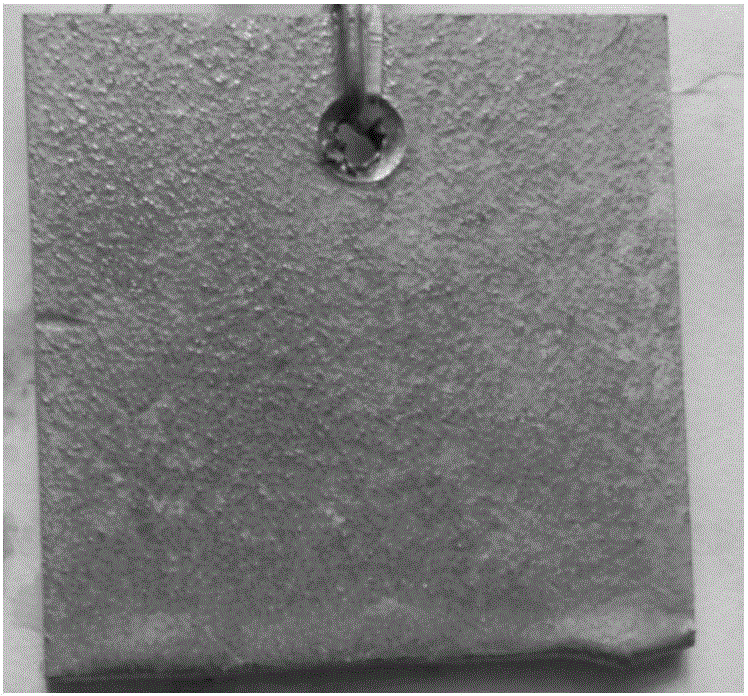

Phytate plating resisting agent for heat zinc coating

InactiveCN101122000ASimple production processAvoid it happening againHot-dipping/immersion processesHuman healthEnergy conservation

The invention relates to a phytate fluxing agent for hot-dip galvanizing, which contains the following ingredients in weight percent: 8%-12% of zinc phytate, 2%-6% of borax, 13%-17% of sodium fluoride, citric acid 2%-7%. Oxalic acid 35%-25%, hydrazine hydrochloride 40%-33%. When hot-dip galvanizing with phytate flux: pre-coated parts are pickled, washed with water after rust removal; the solid phytate flux with the above components is diluted with water, and the ratio is phytate flux: water = 1: 2.5-4, put it in the pool; soak the pre-coated parts in the pool for 50-60 seconds, the working temperature is 40-50 °C; the temperature of the pre-coated parts is 35 °C-40 °C; place it indoors for 10-20 minutes dry. Its advantages: the production process of the flux is simple, the passivation film formed on the pre-plated parts is thin, it can be dried naturally, saves energy, avoids a large amount of dense smoke, splashing and missing plating, protects the environment, and is beneficial to human health. High quality and low cost.

Owner:王玉强

Method for preparing plating aid for preventing omission of heat dip galvanization

ActiveCN101338407AReduce ammonium chloride contentTo solve the need to regularly add ammonium chloride to ammonium chloride aqueous solutionHot-dipping/immersion processesChemical reactionSlag

The invention relates to a preparation method for a plating assistant agent which prevents the hot-galvanized leakage on the surface of a steel wire. The method includes: dipping the steel wire after being washed by muriatic acid and bathed into a water solvent slot; fishing out the slag of zinc from the bottom part of a steel wire hot-galvanized smelted zinc boiler; putting into an ammonium chloride water solvent slot after being cooled; heating the water solvent containing the ammonium chloride and maintaining the temperature between 70 to 75 DEG C; wherein, the initial content of the ammonium chloride is 30 to 45g / L; the initial pH value is 2 to 3; a method for utilizing the muriatic acid brought in by the steel wire after being washed by the muriatic acid to generate a chemical reaction with the slag of zinc to generate zinc chloride is used to form the mixed water solvent of the zinc chloride and the ammonium chloride which meets the quality demand for producing a galvanized layer by the hot-galvanized steel wire. The method has the advantages of simple technique, low production cost, stable quality, being capable of industrial production, etc. The consumption for the ammonium chloride for producing each ton of steel wire can be saved by 40 to 50 percent; the generating amount of the slag of zinc (FeZn13) is reduced; the zinc consumption is reduced; the zinc can be saved by 10 to 15 percent.

Owner:巩义市恒星金属制品有限公司

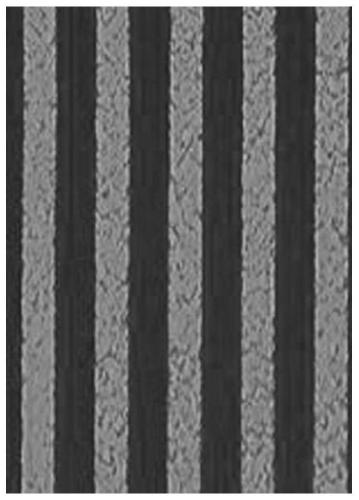

Plating assistant agent additive for preventing plating leakage of steel wire hot galvanizing

ActiveCN101597732AGood interface wettabilityGood compatibilityHot-dipping/immersion processesAlcoholEther

The invention discloses a plating assistant agent additive for preventing plating leakage of steel wire hot galvanizing which comprises the following components in percentage by weight: 20-25% of fatty alcohol-polyoxyethylene ether, 20-26% of dodecyl phenyl polyoxyethyleneether, 8-14% of polyoxyethylene octylphenol ether, 3-6% of triethanolamine, 0.8-1.5% of carbamide and 30-36% of methyl alcohol. The method comprises the following steps: weighing the raw materials according to the proportioning of the additive, mixing and stirring the raw materials evenly to form the additive of the invention, adding the stock solution of the plating assistant agent additive of the invention into a slot according to a proportion that the amount of the added stock solution of the plating assistant agent additive accounts for 0.1-0.2% of the plating assistant agent bath solution, stirring evenly, and being able to use at the temperature of 70-75 DEG C. By adding the additive of the invention into the plating assistant agent, the wettability and the infiltrative of the plating assistant agent can be effectively enhanced, the plating effect on the surface of the steel wire is improved, and the plating leakage of the steel wire zinc plating is avoided.

Owner:巩义市恒星金属制品有限公司

Plating assistant agent for zinc-aluminum-nickel-rare earth-alloy hot-dip plating and technological method

InactiveCN105908113AHigh activityIncrease profitHot-dipping/immersion processesHexamethylenetetramineActive agent

The invention provides a plating assistant agent for zinc-aluminum-nickel-rare earth-alloy hot-dip plating and a technological method. The plating assistant agent comprises the following components of an A solution containing zinc chloride, ammonium chloride, stannous chloride and urotropin and a B solution containing ethyl alcohol, a nonionic surfactant and a cationic surfactant, wherein the plating assistant agent is obtained by mixing the A solution and the B solution. By using the plating assistant agent, skip plating can be effectively avoided; and the surface quality of a plating layer is obviously improved; the yield of a plated article is improved; and the corrosion-resistance of the plating layer can be obviously improved. The plating assistant agent does not contain fluorinion which is harmful to the environment, and requirement of environment protection is met.

Owner:CHANGAN UNIV

Environment-friendly hot-drip coating method

ActiveCN108265252AOvercome the disadvantages of high cost and inconvenient industrial useLow costHot-dipping/immersion processesDip-coatingZinc

The invention relates to an environment-friendly hot-drip coating method. According to the method, an environment-friendly rust removing method is adopted to conduct rust removing treatment on the surface of steel, and a preparing surface before coating is obtained; then fast heating is conducted in a protective atmosphere, then a to-be-processed workpiece directly enters a plating solution in a closed system for executing hot-dip coating, the fast heating temperature is higher than the hot-dip coating temperature, and a coating layer is formed on the metal surface; and finally, aftertreatmentis performed to obtain a finished product, and the hot-dip coating technology is completed. According to the environment-friendly hot-drip coating method, the advantages of a solvent method and the advantages of a reduction method are combined, the defects of the solvent method and the defects of the reduction method are abandoned, a mechanical derusting method or a modern environment-friendly rust remover is used for replacing seriously-polluted acid pickling, no plating-assistant agent is used, the workpiece subjected to environment-friendly rust removing is quickly heated and plated underthe inert gas shielding action, and accordingly environment-friendly hot-dip coating without acid pickling and plating assisting can be well achieved. The method not only can be used for hot-dip galvanizing but also can be used for hot-dip coating of other kinds of zinc-aluminum alloy, and the application range is wide.

Owner:TIANJIN GONGDA GALVANIZING EQUIP CO LTD

Electrolytic plating assisting method for hot dip galvanizing of steel wire and electrolytic plating assistant

InactiveCN101948990BAvoid secondary oxidationEasy to dryHot-dipping/immersion processesElectrolysisEthylic acid

Owner:NORTHEASTERN UNIV LIAONING

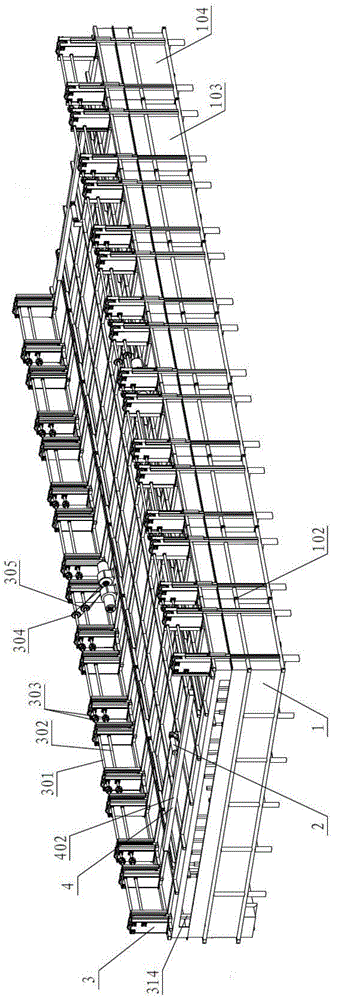

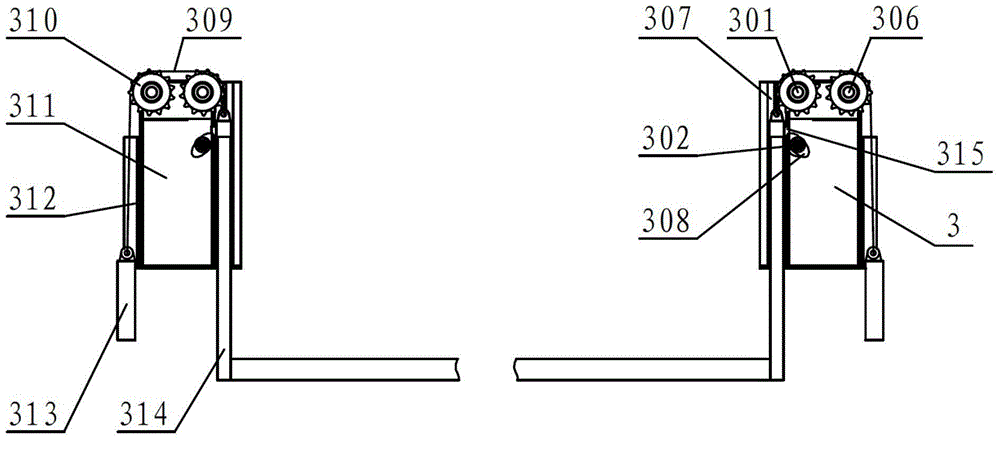

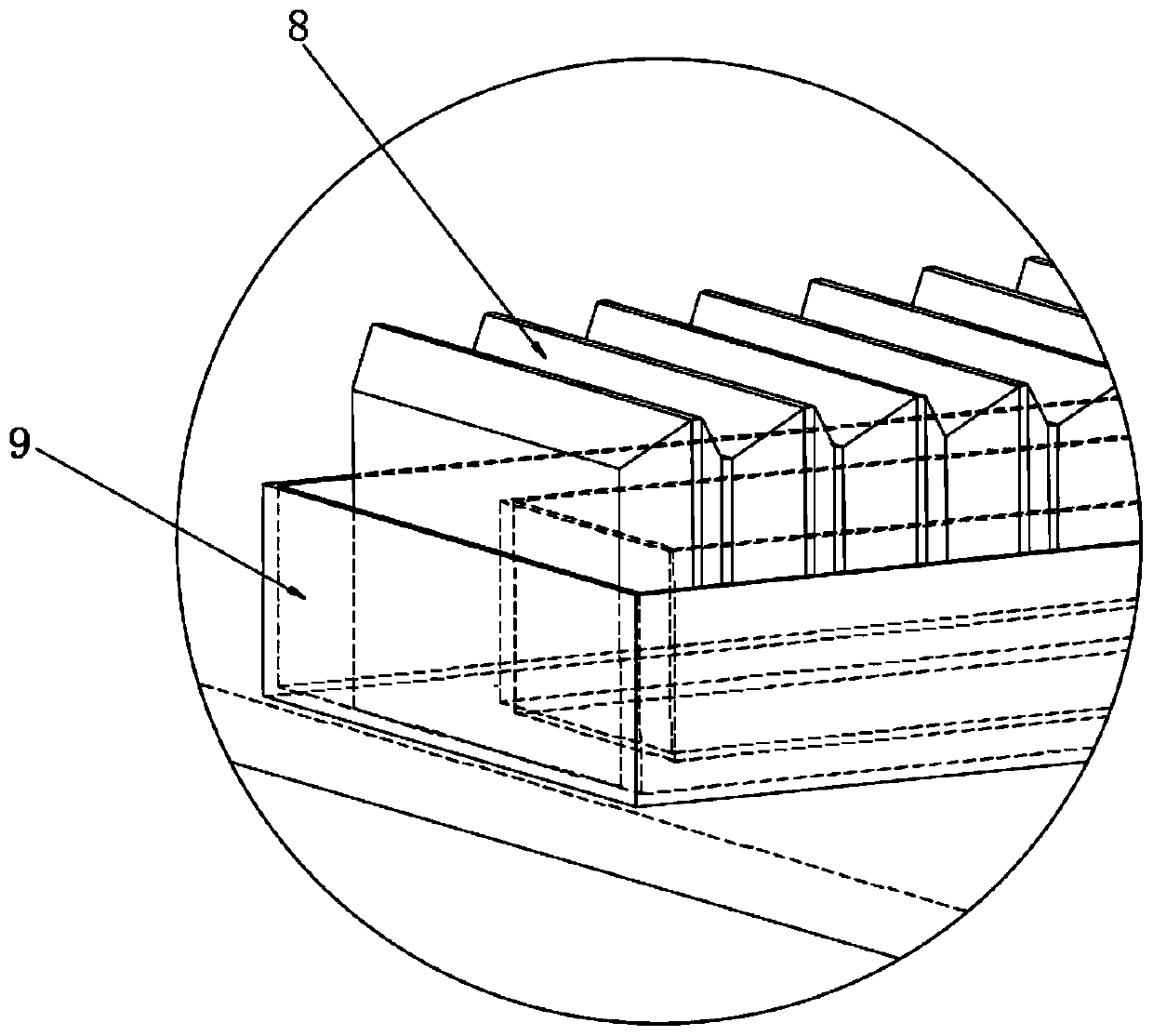

Pickling system and pickling method

InactiveCN105002513AAvoid miss platingQuality improvementHot-dipping/immersion processesEngineeringPickling Agents

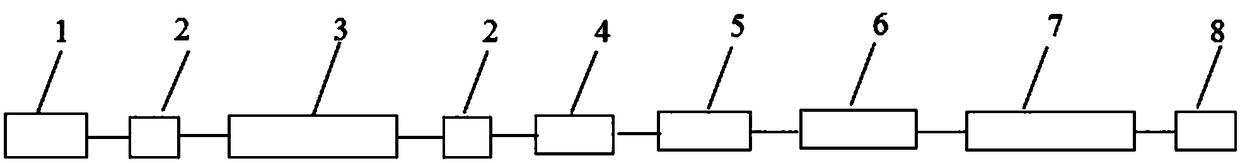

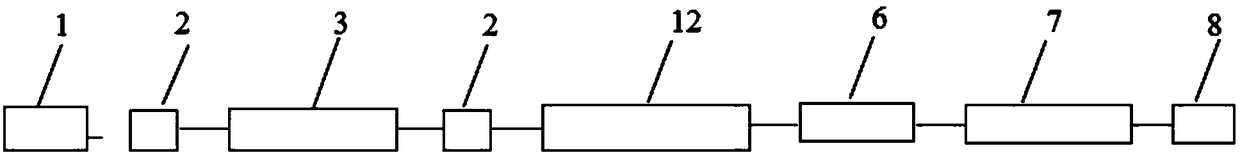

The invention relates to the plating field and discloses a pickling system and a pickling method. The pickling system comprises a pickling bath group (1) which comprises a plurality of pickling baths (101) that are arranged between a feeding end and a discharging end in the length direction of the pickling system, and parts to be pickled can be sequentially pickled in the pickling baths (101). Through step-by-step pickling of the parts to be pickled in the pickling baths, not only can the pickling quality be improved and the parts to be pickled be prevented from mis-plating, but also a pickling agent in one of the pickling baths can be transferred to the upper stage step by step, a pickling solution, of which the concentration is reduced and impurities are increased, in the first-stage pickling bath can be discharged and disposed, the dilution speed of the pickling agent in the multiple stages of the pickling baths is reduced, accordingly, the utilization ratio of the pickling agent is improved, and the production cost is lowered.

Owner:北京钢研新冶环科科技有限公司

Chemical immersion tin plating solution and preparation method thereof

InactiveCN109055921AUniform and dense coatingGood solderability of the coatingLiquid/solution decomposition chemical coatingEnvironmental chemistryCompound (substance)

The invention relates to a chemical immersion tin plating solution and a preparation method thereof. The chemical immersion tin plating solution is composed of tin salt, an accelerant, a wetting agentand a stabilizer, wherein the mass concentration of the tin salt is 5-20 g / L, the mass concentration of the accelerant is 30-200 g / L, the mass concentration of the wetting agent is 0.1-0.5 g / L, the mass concentration of the stabilizer is 50-170 g / L. Under reasonable concentration proportioning and the synergistic effect of all the components, the chemical immersion tin plating solution is very stable, the plating layer is uniform, compact and semi-bright, moreover, the used working temperature is not high, the temperature is 35-45 DEG C, plating is carried out for 10-15 minutes, the thicknessof the plating layer can reach about 1.5-2 microns, and the plating layer is good in weldability.

Owner:CHONGQING LIDAO SURFACE TECH

Electroplating method of smart card package frame

The invention provides an electroplating method of a smart card package frame and belongs to the technical field of electronic information. The electroplating method is characterized by comprising the following steps of: electroplating a nickel layer which is 1.8-2.2 microns thick on the contact layer of the frame after performing pretreatment on the molded frame, and then electroplating a phosphorus-nickel alloy layer which is 0.4-0.8 microns thick on the basis of the nickel layer, and further electroplating a gold layer which is 0.009-0.05 microns thick outside the phosphorus-nickel alloy layer of the contact surface of the frame. The electroplating method provided by the invention can be used for improving the wearability and corrosion resistance of the contact surface of the product. Besides, the electroplating method is also capable of reducing the thickness of the hard metal, omitting the application of posttreatment and greatly saving the cost.

Owner:新恒汇电子股份有限公司

Chemical palladium solution applied to PCB chemical gold palladium clad layer

ActiveCN110318047AExtended service lifeControl deposition rateLiquid/solution decomposition chemical coatingPrinted circuit manufactureWire widthPh buffering

The invention discloses a chemical palladium solution applied to a PCB chemical gold palladium clad layer. Main salt, a coordination agent, a reducing agent, a stabilizer, a pH buffering agent and a surface active agent are included. The mass concentration serves as the unit, the components include, by proportion, 0.4-0.6 g / L of the palladium in the main salt according to the concentration, 0.1-30g / L of the coordination agent, 0.1-25 g / L of the reducing agent, 1-150 mg / L of the stabilizer, 1-25 g / l of the pH buffering agent, 0.1-10 mg / L of the surface active agent and the balance pure water.A palladium layer prepared through the palladium solution can meet good welding and bonding requirements, and meanwhile the chemical palladium solution is applicable to surface treatment of a circuitwith the wire width / wire distance being 0.5 mil or below or even smaller.

Owner:深圳市溢诚电子科技有限公司

Plating assistant agent additive for preventing plating leakage of steel wire hot galvanizing

ActiveCN101597732BGood interface wettabilityGood compatibilityHot-dipping/immersion processesAlcoholAlkylphenol

Owner:巩义市恒星金属制品有限公司

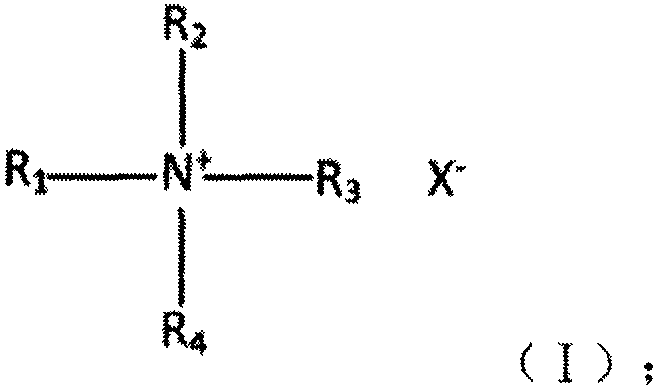

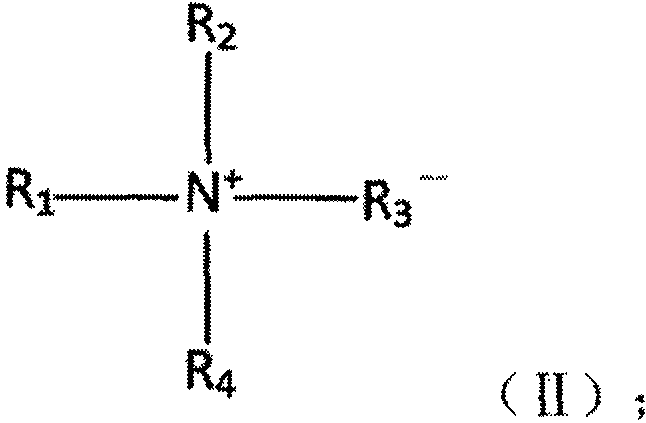

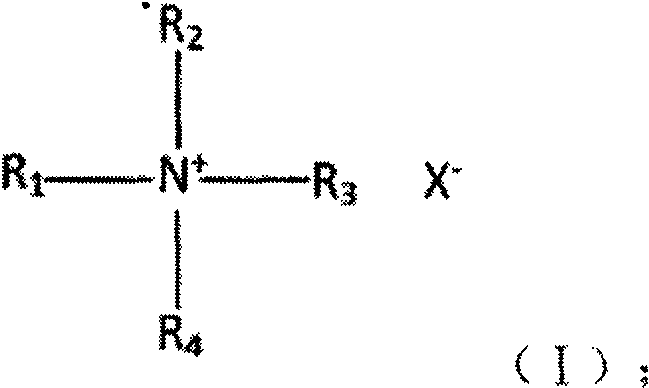

Additive for plating assisting, plating assisting solution and hot-dip plating method

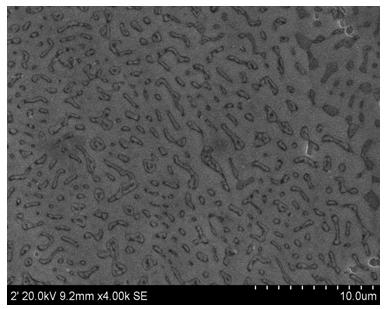

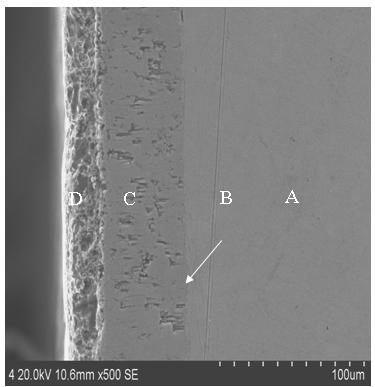

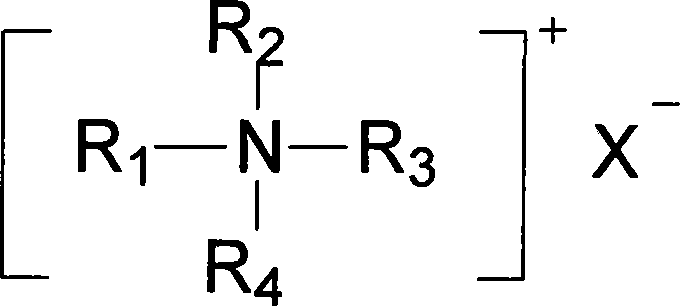

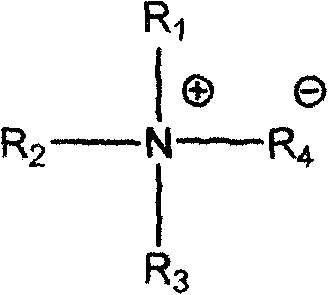

ActiveCN107699833AReduce the amount of adhesionGood interface wettabilityHot-dipping/immersion processesOrganic chemistryMaterial consumptionMethyl group

The invention relates to an additive for plating assisting, a plating assisting solution and a hot-dip plating method in the technical field of chemical engineering. The additive for plating assistingcomprises a chemical compound which is as shown in the formula I (Please see the formula I in the specification.), wherein R1 represents C12-16 alkyl radical, R2 represents methyl or hydroxypropyl, R3 represents one of hydroxyethyl, hydroxypropyl and dihydroxy propyl, R4 represents one of methyl, hydroxyethyl and dihydroxy propyl, and X represents one of Cl, Br and I. According to the additive, better interface wettability between molten coated metal and workpieces can be achieved, and skip plating is prevented; and meanwhile, the adhesion amount of a plating assisting agent is reduced, the drying process is accelerated, the risk of accidents such as scalds is reduced, the dip plating time is shortened, and material consumption is reduced.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

Method for producing zinc-aluminum-magnesium alloy coated steel products with good corrosion resistance and zinc-aluminum-magnesium alloy coated steel products

ActiveCN100363526CImprove bindingImprove wettabilityHot-dipping/immersion processesRare earthSolvent

The present invention discloses a process for preparing zincium aluminum-magnesium alloy plating steel products and zincium aluminum-magnesium alloy plating steel products. A solvent method and a gas fluid reduction method are adopted, wherein the chemical components of the plating solution is 2.5-20% of AL, 1.5-4.5% of Mg, 0.01-0.3% of RE, with the rest being Zn and unavoidable impurities; right amount of Si and V are added into the plating solution, wherein the solvent is aqueous solution with a chemical composition of 200-1000g / L ZnCl2, 0-200g / L NH4Cl, 0-100g / L KCl, 0-100g / L NaCl and 0-100g / L rare earth chloride, with the pH being 3-4; the temperature of the plating solution is controlled at 450-580 DEG C, and the plating time is 2-300s. The present invention improves the moisturising capacity for steel products, restrains the reaction of aluminum and chlorides solvents, and then avoids plating leakage occurring and improves the bonding force of plating layers, not only can produce sheet materials but also can produce plating steel products such as sectional materials, pipes and wire rods, and have wide extending and applying foreground.

Owner:ANSC TKS GALVANIZING

Preparation method for fire pump guide vane with coating

InactiveCN106179908AImprove product qualityAvoid miss platingPump componentsPretreated surfacesPulp and paper industryImpurity

The invention discloses a preparation method for a fire pump guide vane with a coating. The preparation method comprises the following steps of preprocessing to remove oil stain, iron and scale impurities on the surface of the guide vane; spraying the fire pump guide vane with a dyclonine solution or dipping the fire pump guide vane in the dyclonine solution, then removing the redundant treating solution through centrifuge dripping, natural vertical flowing and brushing; and baking in a circulating hot air baking oven during the process of converting the dyclonine treating solution on a guide vane matrix into a film, then cleaning and polishing the guide vane.

Owner:GUANGXI ANXUN TECH INVESTMENT CO LTD

Method for preparing plating aid for preventing omission of heat dip galvanization

ActiveCN100594252CReduce ammonium chloride contentLess smokeHot-dipping/immersion processesChemical reactionSlag

The invention relates to a preparation method for a plating assistant agent which prevents the hot-galvanized leakage on the surface of a steel wire. The method includes: dipping the steel wire afterbeing washed by muriatic acid and bathed into a water solvent slot; fishing out the slag of zinc from the bottom part of a steel wire hot-galvanized smelted zinc boiler; putting into an ammonium chloride water solvent slot after being cooled; heating the water solvent containing the ammonium chloride and maintaining the temperature between 70 to 75 DEG C; wherein, the initial content of the ammonium chloride is 30 to 45g / L; the initial pH value is 2 to 3; a method for utilizing the muriatic acid brought in by the steel wire after being washed by the muriatic acid to generate a chemical reaction with the slag of zinc to generate zinc chloride is used to form the mixed water solvent of the zinc chloride and the ammonium chloride which meets the quality demand for producing a galvanized layerby the hot-galvanized steel wire. The method has the advantages of simple technique, low production cost, stable quality, being capable of industrial production, etc. The consumption for the ammoniumchloride for producing each ton of steel wire can be saved by 40 to 50 percent; the generating amount of the slag of zinc (FeZn13) is reduced; the zinc consumption is reduced; the zinc can be saved by 10 to 15 percent.

Owner:巩义市恒星金属制品有限公司

Production method of small harvester squeezing roller with coating

InactiveCN106191850AGood corrosion resistanceAvoid missing plating on steel pipesMetallic material coating processesOxideCoating

The invention discloses a production method of a small harvester squeezing roller with a coating. The production method is characterized by comprising the following steps: carrying out pretreatment by removing impurities including oil stains, iron and oxide scales on the surface of a part squeezing roller; carrying out coating treatment by spraying or dipping the part squeezing roller by using a Dacromet solution, then removing redundant Dacromet treatment solution by centrifuge dripping, naturally vertically flowing and / or brushing; carrying out roasting treatment by a process of transforming the Dacromet treatment solution on the squeezing roller body into a film layer in a mesh-belt type circulation hot air roasting oven, dividing the whole process into a preheating area and a solidifying area, preheating the part in the preheating area at the temperature of 60-180 DEG C, then solidifying the part for 25-30 minutes at the temperature of 280-330 DEG C after the part enters the solidifying area; and washing and grinding the squeezing roller.

Owner:柳州名品科技有限公司

Hot galvanizing antiknock agent and preparation method thereof

ActiveCN112962042AReduce surface tensionIncrease coverageHot-dipping/immersion processesOrganic solventActive agent

The invention discloses a hot galvanizing antiknock agent and a preparation method thereof. The hot galvanizing antiknock agent comprises the following raw materials of, in percentage by weight, 20%-35% of ionic liquid, 1%-20% of a nonionic surfactant, 1%-3.5% of a diamide compound, 35%-50% of an organic solvent and 1%-10% of deionized water, in a hot galvanizing process, the antiknock agent is directly added into a plating assisting agent solution, and the mixture is uniformly stirred and used at 60-75 DEG C. The antiknock agent is suitable for plating assisting treatment of various processes such as hot galvanizing, hot galvanizing aluminum alloy, hot galvanizing aluminum and the like, the surface tension between the plating assisting agent and a workpiece can be effectively reduced, the plating assisting effect is improved, the surface quality of a galvanized layer is improved, the zinc immersion time is shortened, the surface glossiness of the galvanized layer is improved, liquid metal splashing caused by residual liquid on the surface of the workpiece in the immersion plating process is prevented, the usage amount of a plating assisting agent is reduced, the adhesion amount of the plating assisting agent on the surface of the workpiece is reduced, zinc slag is reduced, solvent smoke and solvent ash are reduced, and the environment is improved.

Owner:JIANGXI SCI & TECH NORMAL UNIV

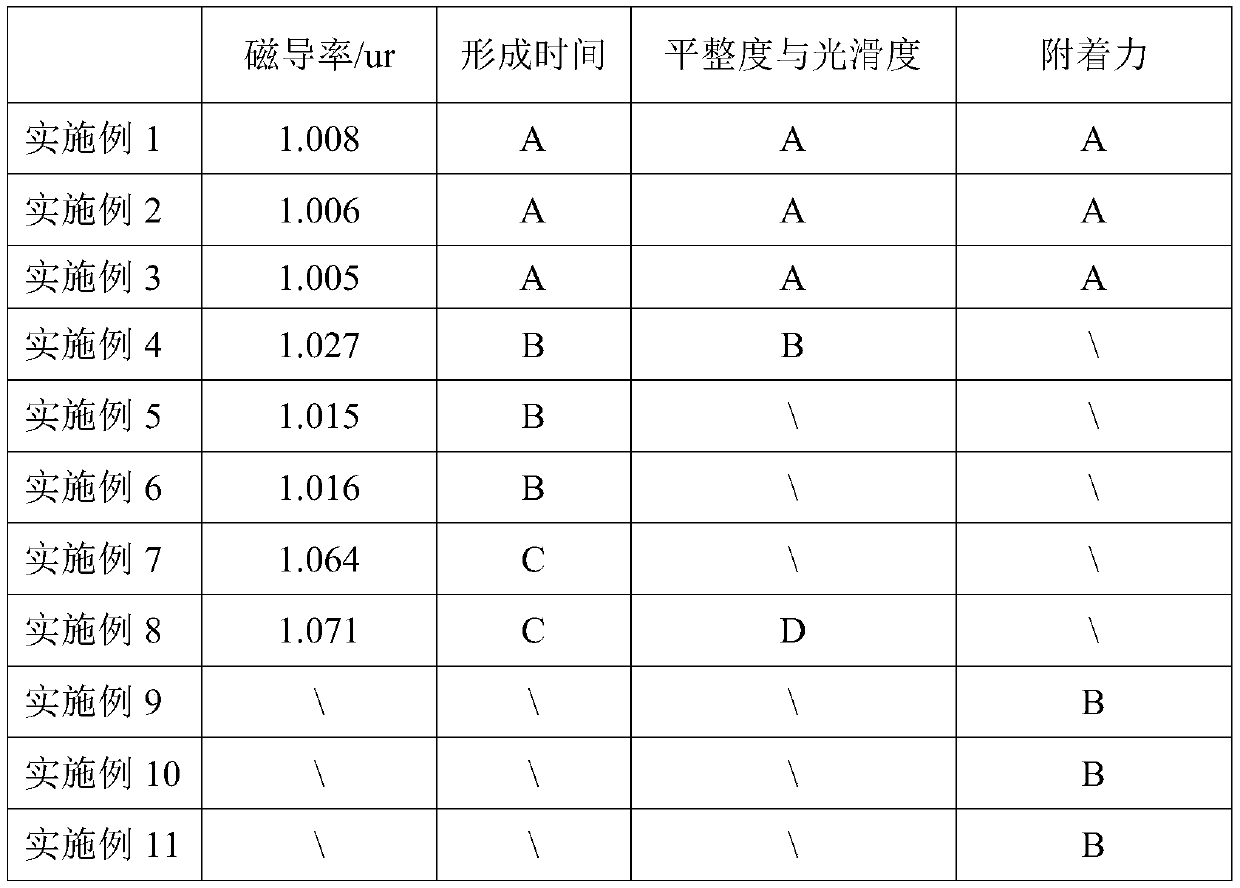

Nickel plating process for surface of aluminum alloy

ActiveCN111334784AImprove bindingInhibit sheddingLiquid/solution decomposition chemical coatingSiliconAluminium alloy

The invention relates to the relevant field of nickel plating methods, in particular to a nickel plating process for a surface of an aluminum alloy. In the first aspect, the nickel plating process forthe surface of the aluminum alloy is provided, and sequentially comprises the steps: oil removal, silicon removal, first-time deposition of zinc and nickel, second-time deposition of the zinc and thenickel, alkaline nickel plating, acid nickel plating, hole sealing and drying. Through the method that the zinc and the nickel are deposited twice, then alkaline and acid nickel plating is conducted,and finally hole sealing and drying are conducted, nickel plating is conducted on the surface of the aluminum alloy, in the process of the plating process, binding force between a plated layer and analuminum material is increased, the good protection effect on zinc-nickel plating is achieved, an adopted reagent is prevented from corroding the plated layer, meanwhile skip plating of fine sand holes can be prevented, plated layers of local positions can also be prevented from falling off, then the magnetic conductivity is reduced through a specific acid nickel plating solution, and the flatness and smoothness of the plated layer are improved.

Owner:SHENZHEN XINMAOXIN IND CO LTD

Pickling system and pickling method

InactiveCN105002513BAvoid miss platingQuality improvementHot-dipping/immersion processesPickling AgentsEngineering

The invention relates to the plating field and discloses a pickling system and a pickling method. The pickling system comprises a pickling bath group (1) which comprises a plurality of pickling baths (101) that are arranged between a feeding end and a discharging end in the length direction of the pickling system, and parts to be pickled can be sequentially pickled in the pickling baths (101). Through step-by-step pickling of the parts to be pickled in the pickling baths, not only can the pickling quality be improved and the parts to be pickled be prevented from mis-plating, but also a pickling agent in one of the pickling baths can be transferred to the upper stage step by step, a pickling solution, of which the concentration is reduced and impurities are increased, in the first-stage pickling bath can be discharged and disposed, the dilution speed of the pickling agent in the multiple stages of the pickling baths is reduced, accordingly, the utilization ratio of the pickling agent is improved, and the production cost is lowered.

Owner:北京钢研新冶环科科技有限公司

A kind of corrosion-resistant zinc-aluminum-magnesium rare earth alloy coating and its preparation and hot-dip coating method

InactiveCN104711502BReduce consumptionReduce thicknessHot-dipping/immersion processesCeriumAlloy coating

The invention discloses a corrosion-resistant Zn-Al-Mg rare earth alloy coating, a preparation and a hot dipping method thereof. The corrosion-resistant Zn-Al-Mg rare earth alloy coating comprises the following raw materials by ratio: 3-9wt% of Al, 0.03-0.09wt% of Mg, 0.01-0.15wt% of rare earth and the balance of zinc, wherein rare earth is lanthanum, cerium or praseodymium. Various raw materials are mixed and prepared through an alloy fusion step to fusion alloy, the plating liquid has good fluidity and has good wellability on steel base; steel with pretreated surface enables hot dipping on the prepared fusion alloy, the corrosion-resistant Zn-Al-Mg rare earth alloy coating is plated on the surface, the coating has smooth surface and has good anticorrosion performance.

Owner:中国电建集团华中电力设计研究院有限公司

Preparation method for small harvester cutting tool with coating

InactiveCN106216211APollution-freeImprove corrosion resistancePretreated surfacesCoatingsEngineeringMechanical engineering

The invention discloses a preparation method for a small harvester cutting tool with a coating. The method comprises the steps that during pre-processing, oil stains, iron and oxidation skin sundries on the surface of parts and the cutting tool are removed; during coating, a Dacromet solution is used for spraying or dipping of the parts and the cutting tool, and the residual Dacromet treating fluid is removed through centrifugal dripping, natural vertical flowing and / or brushing; during baking, the Dacromet treating fluid on the base body of the cutting tool is converted into a film layer in a mesh-belt circulating hot wind baking furnace; and then, the cutting tool is cleaned and polished.

Owner:柳州名品科技有限公司

A kind of aluminum alloy surface nickel plating process

ActiveCN111334784BImprove bindingInhibit sheddingLiquid/solution decomposition chemical coatingNickel depositionSilicon

The present invention relates to the related field of nickel plating methods, and more particularly, the present invention provides a nickel plating process on the surface of an aluminum alloy. A first aspect of the present invention provides a nickel plating process on the surface of an aluminum alloy, which sequentially includes the steps of: oil removal, silicon removal, first zinc-nickel deposition, second zinc-nickel deposition, alkaline nickel plating, acid nickel plating, Sealing and drying. The present invention adopts the method of twice immersing zinc nickel, then performing alkaline acid nickel plating, and finally performing sealing and drying to realize the nickel plating on the surface of the aluminum alloy. The bonding force has a good protective effect on zinc-nickel plating. The reagents used in placement can cause corrosion to the plating layer. At the same time, it can prevent small sand holes from leaking plating, and can also prevent local plating from falling off. The specific acid nickel plating solution is used to reduce the magnetic field. Conductivity, improve the flatness and smoothness of the coating.

Owner:SHENZHEN XINMAOXIN IND CO LTD

A kind of hot-dip galvanizing flux and method

ActiveCN106244963BAvoid miss platingQuality improvementHot-dipping/immersion processesHydrogenSURFACTANT BLEND

The invention provides a hot dip galvanizing assistant and a hot dip galvanizing method. The assistant comprises compounded salts, 70-90 g of ZnCl2, 20-80 g of NH4Cl, 120-150 mL of anhydrous ethanol, 0.5-5 g of a carbon hydrogen surfactant, 2-10 mL of a silane coupling agent and 500 g of deionized water, the compounded salts are selected from SnCl2.2H2O, KCl, AlCl3.6H2O and other chlorine salts, and the use amount of every compounded salt is 10-40 g. The hot dip galvanizing assistant has good component stability, can effectively prevent plating leakage of the surface of a plated member and substantially improve the corrosion resistance of the plated member when used in plating assisting treatment, and allows the yield of the plated member obtained by using the hot dip galvanizing assistant to reach up to 98% or above.

Owner:CHANGAN UNIV

Method and device for environment-friendly batch high-performance alloy hot-dip plating

ActiveCN111118428AAvoid pollutionQuality improvementHot-dipping/immersion processesZinc based alloyMaterials science

The invention belongs to the technical field of hot dip galvanizing, and discloses a method and device for environment-friendly batch high-performance alloy hot-dip plating. The device comprises a transfer waiting area, a heating area, an after-plating turnover area, a zinc pot and a conveying device, wherein a first closed space is arranged in the transfer waiting area, and the first closed spacecan be filled with inert gas; the heating area is arranged on the down stream of the transfer waiting area, and a second closed space capable of being filled with inert gas is arranged in the heatingarea, the second closed space can be selectively communicated with the first closed space, and a heating device is arranged in the second closed space; the after-plating turnover area is arranged onthe down stream of the heating area, a third closed space is arranged in the after-plating turnover area, and the third closed area can be selectively communicated with the second closed space; the zinc pot is arranged in the heating area and used for zinc or zinc-based alloy hot-dip plating of a to-be-processed workpiece; the conveying device is configured to convey the to-be-processed workpieceinto the transfer waiting area, the heating area, the zinc pot and the after-plating turnover area in sequence in a sealed state. On the basis without a plating assistant agent, the workpiece is subjected to zinc or zinc-based alloy hot-dip plating, and batch zinc or zinc-based alloy hot-dip plating can be achieved.

Owner:TIANJIN GONGDA GALVANIZING EQUIP CO LTD

Preparation method of straw feed particle machine feeding barrel

InactiveCN106036963AImprove corrosion resistanceImprove permeabilityFeeding-stuffElectric furnaceMelting furnaceScrap

The present invention discloses a preparation method of a straw feed particle machine feeding barrel. The preparation method is characterized by comprising the following steps: an electric furnace is used as a primary melting furnace to melt scrap steels and alloy materials to produce stainless steel primary smelting steel water, then the primary smelting steel water is subjected to refining in different refining furnaces to prepare qualified stainless steel water, the refining furnaces are divided into refining at normal pressure and vacuum conditions, thus an EAF furnace converting two-step process and an EAF-vacuum oxygen blowing two-step process are formed.

Owner:柳州名品科技有限公司

Additive for flux plating, flux solution and hot-dip plating method

ActiveCN107699833BReduce the amount of adhesionGood interface wettabilityHot-dipping/immersion processesOrganic chemistryMetallurgyPhysical chemistry

The present invention relates to an additive for plating flux, a plating flux solution and a hot-dip plating method in the field of chemical industry. The additive for plating flux contains a compound of the following formula I: (I); wherein R1 is C12- 16 alkyl; R2 is methyl or hydroxypropyl; R3 is one of hydroxyethyl, hydroxypropyl, and dihydroxypropyl; R4 is one of methyl, hydroxyethyl, and dihydroxypropyl , X is one of Cl, Br, I. The additive of the present invention can make the interface wettability better between the molten coating metal and the workpiece, reduce the amount of plating flux adhesion while preventing the occurrence of missing plating, accelerate the drying process, reduce the risk of accidents such as burns, and shorten the immersion plating time , reduce material consumption.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

Multifunctional assistant plating additive for hot dip plating process, preparation and use method thereof

ActiveCN101328568BReduce lossImprove stabilityHot-dipping/immersion processesDissolutionLiquid metal

The invention relates to a multifunctional plating assisting additive for a hot dipping metallization process and a preparation and application method thereof, and belongs to the metal material anticorrosive technical field for providing multiple plating assisting efficacy. The technical proposal of the invention comprises that: a plurality of cations or an amphoteric surfactant ( an equivalent concentration of a quaternary ammonium group is between 0.1 and 2 mol / L) and nonionics (an equivalent concentration of a polyoxyethylene group is between 0.5 and 5 mol / L) are dissolved in deionized water. The method can improve the wetting quality between a liquid-state metal and a workpiece, and the adhesive uniformity and continuity of the plating assisting additive, reduces the drying time, prevents the liquid-state metal from falling and splashing, shortens the dipping and plating time, saves raw materials, improves a residue form, reduces an ash content, increases an ash discharge speed,isolates air, stops oxidation, disperses residual dirt and is suitable for a plurality of processes of hot galvanizing, hot plating zinc-aluminum alloy, hot plating aluminum, etc. The preparation steps comprise dissolution, cubage determination, cooling, keeping stand and filling; when the multifunctional plating assisting additive is used, the multifunctional plating assisting additive is directly added into a plating assisting additive solution and is evenly stirred.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com