Environment-friendly hot-drip coating method

A hot-dip and environmental-friendly technology, applied in the hot-dip plating process, coating, metal material coating process, etc., can solve the problems of long time consumption, high cost, high energy consumption, etc., to reduce risks, avoid missing plating, adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

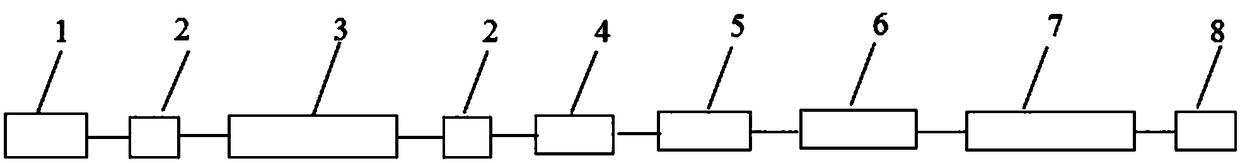

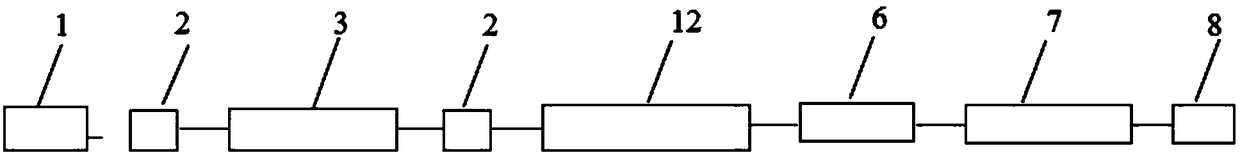

[0039] Adopt the inventive method to implement the threaded steel of product diameter 10mm, material 20MnSi, tensile strength 455Mpa, hot-dip Galfan alloy. The coating thickness is required to be 15um, and the strength drop shall not exceed 5%. Its technological process is:

[0040] Grind the threaded steel with a wire wheel to remove rust, Figure 4 The Galfan alloy was plated on the test device, and the induction heating was carried out in the quartz tube under the protection of nitrogen gas. After the rust removal treatment, it was immediately inserted into the quartz tube filled with nitrogen gas, and the heating temperature of the workpiece was measured by an infrared thermometer when it was 485 ° C. The quartz tube is directly inserted into the Galfan bath, the hot-dip time is 6 seconds, and the hot-dip temperature is 450°C. Air cooling and water cooling are proposed, thereby completing the hot-dip process without help.

[0041] In this embodiment, the diameter of the ...

Embodiment 2

[0044] Adopt the method of the present invention to implement the angle steel hot-dip galvanizing of product 30*30*3, material Q345, strength 450Mpa requires the amount of zinc 140g / m 2 , which is 20um thick, the strength drops within 5%. Its technological process is:

[0045] After the angle steel is shot blasted, the Figure 4 Galvanizing is implemented on the experimental device. In this embodiment, the inner diameter of the quartz tube matches the shape of the angle steel, and the angle steel can move up and down in the quartz tube. When induction heating is carried out in the quartz tube, an infrared thermometer is used to measure the temperature. When the surface of the angle steel is heated to 520 ° C, the hot-dip temperature is 450 ° C, inserted into the zinc solution for plating, and the hot-dip time is 8 seconds.

[0046] The three parallel hot-plated workpieces obtained by the process of this embodiment have coating thicknesses of 18 μm, 21 μm, and 23 μm, respecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com