Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Avoid Cold Shut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lost foam casting coating and preparation method thereof

The invention discloses a lost foam casting coating, which comprises fire-proof powder, phenolic resin, white latex, calcium bentonite and isopropyl alcohol, wherein the fire-proof powder includes bauxite and quartz powder. The bauxite is formed by uniformly mixing the following components: 80% of particles with the granularity ranging from -280 to -310, 14% of particles with the granularity ranging from -280 mesh to -190 mesh and 6% of particles with the granularity ranging from -90 mesh to -190 mesh. The preparation method of the lost foam casting coating is as follows: calcining selected bauxite ore at the temperature of 1510-1550 DEG C; grinding calcined clinkers to acquire the granularity particles with the granularities respectively; evenly mixing the particles according to the composition proportion; and mixing the mixed bauxite with quartz powder, phenolic resin, white latex, calcium bentonite and isopropyl alcohol. According to the invention, bauxite is distributed according to particle sizes, and bauxite particles of different sizes are alternately arranged after even mixing. As a result, the compactness is changed, the air permeability is strengthened, the cold shut phenomenon occurring between liquid metal and the coating is avoided, and finally the quality of the casting produced through lost foam casting is improved.

Owner:ANYUE COUNTY JINLONG MACHINERY MFG

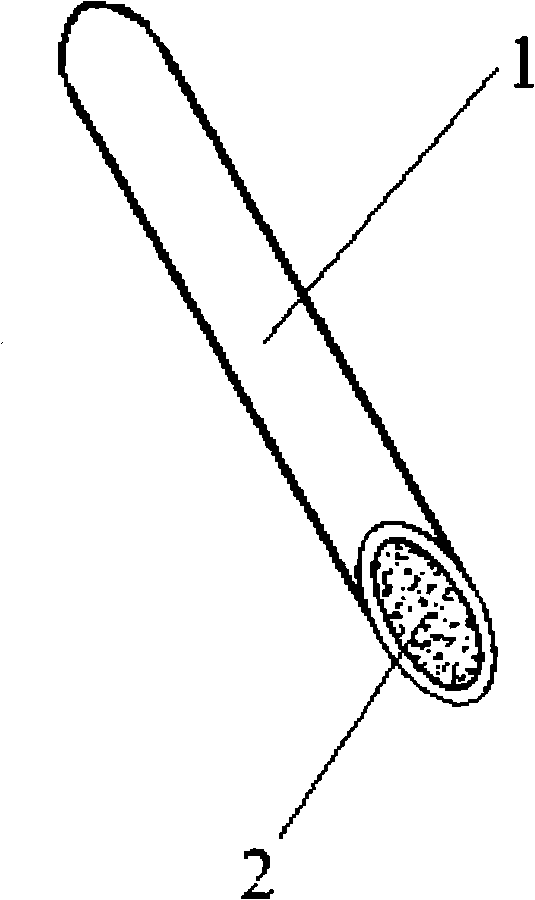

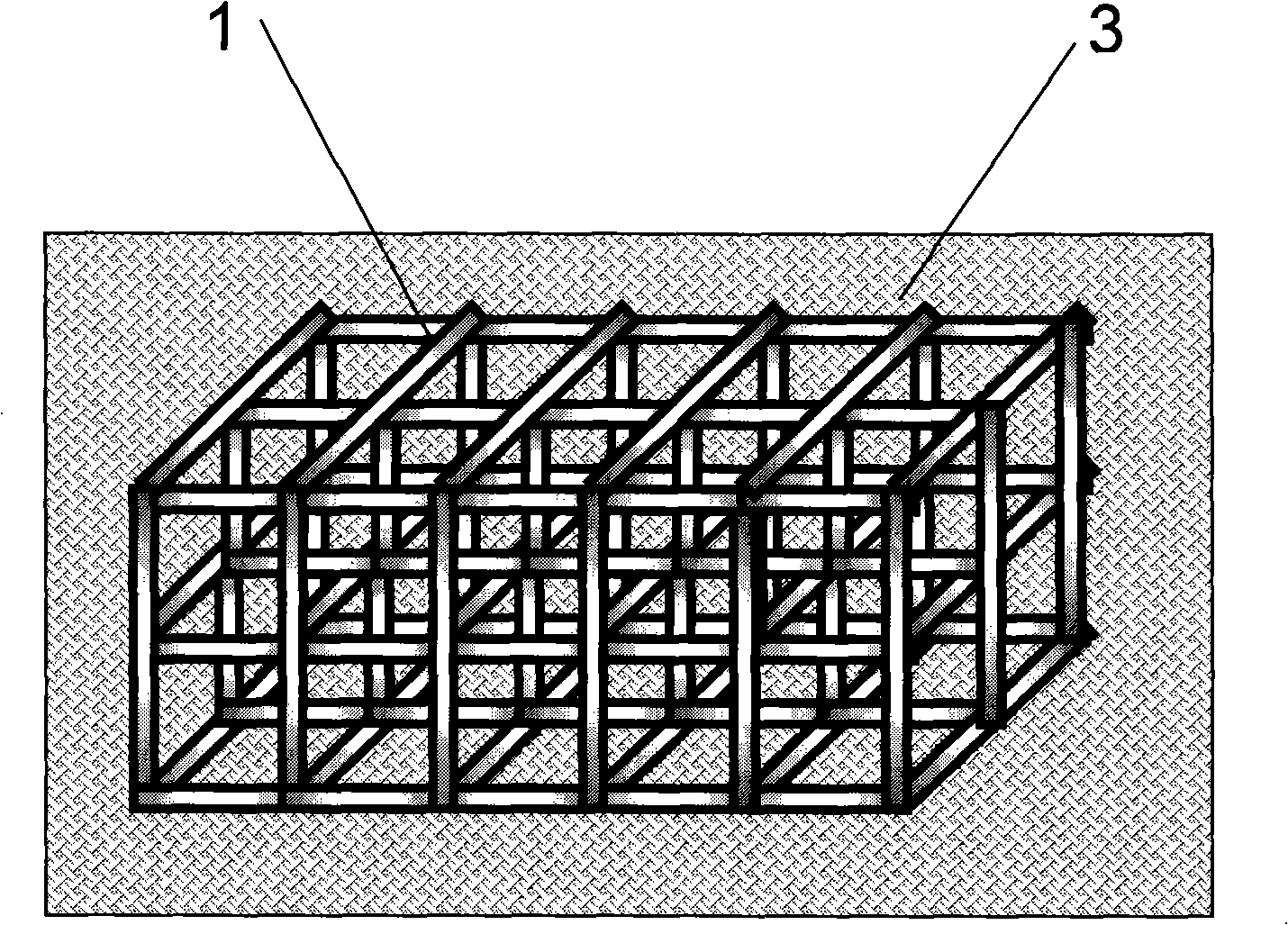

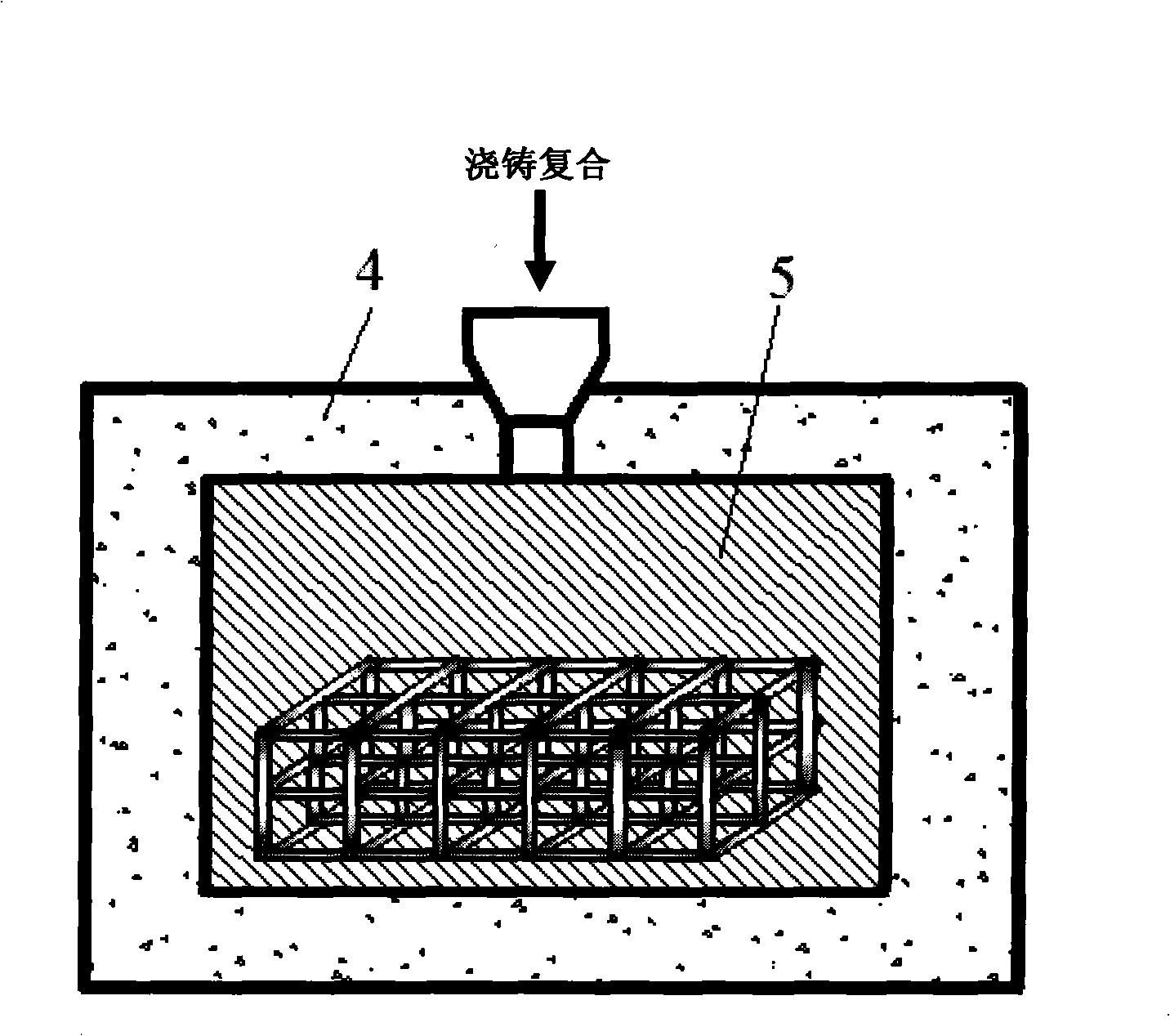

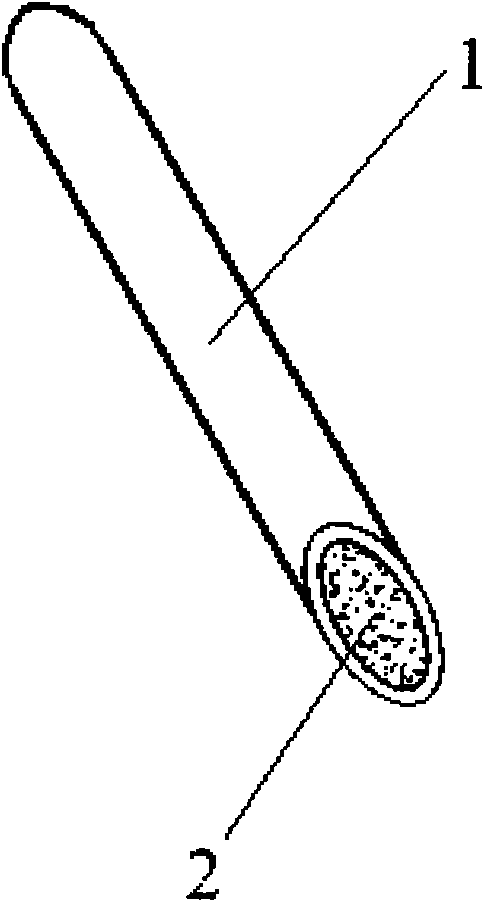

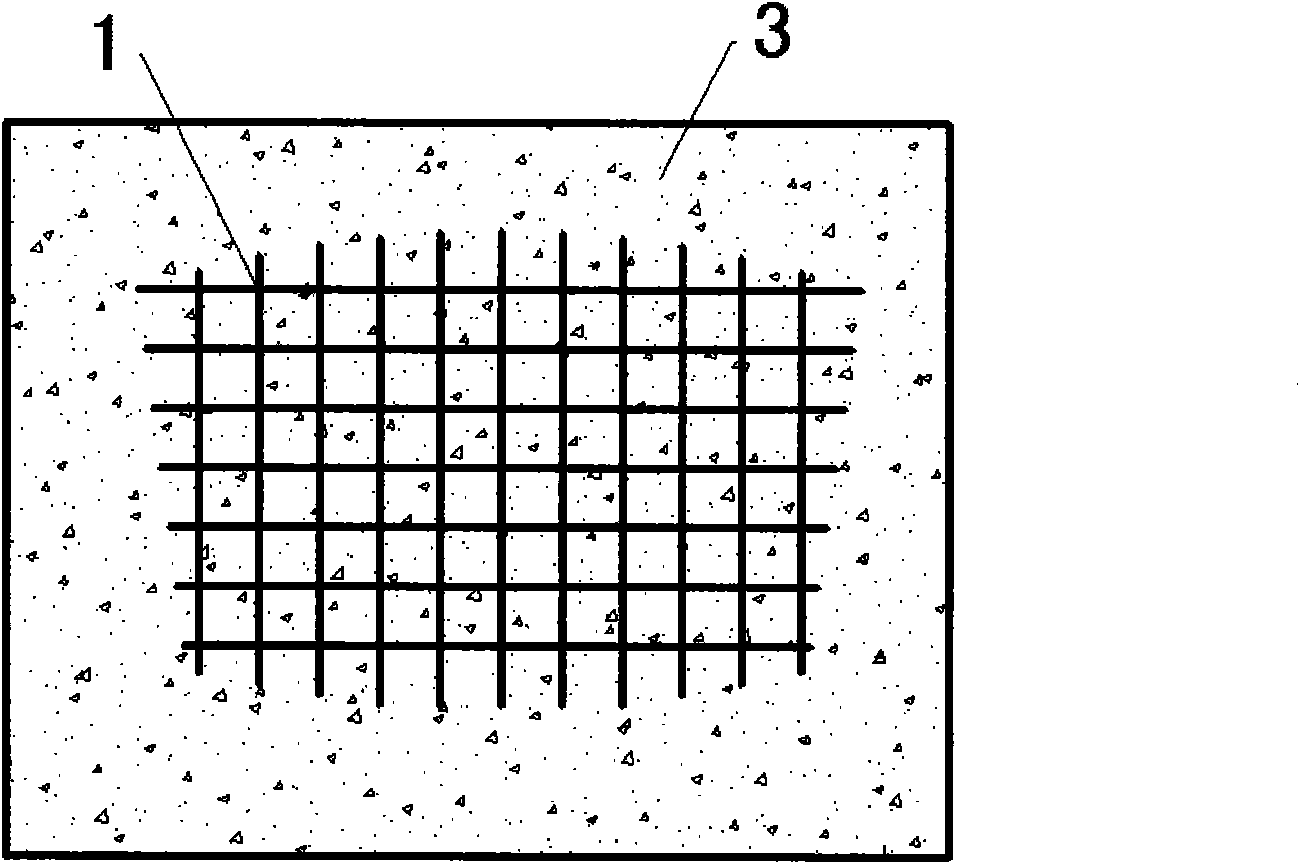

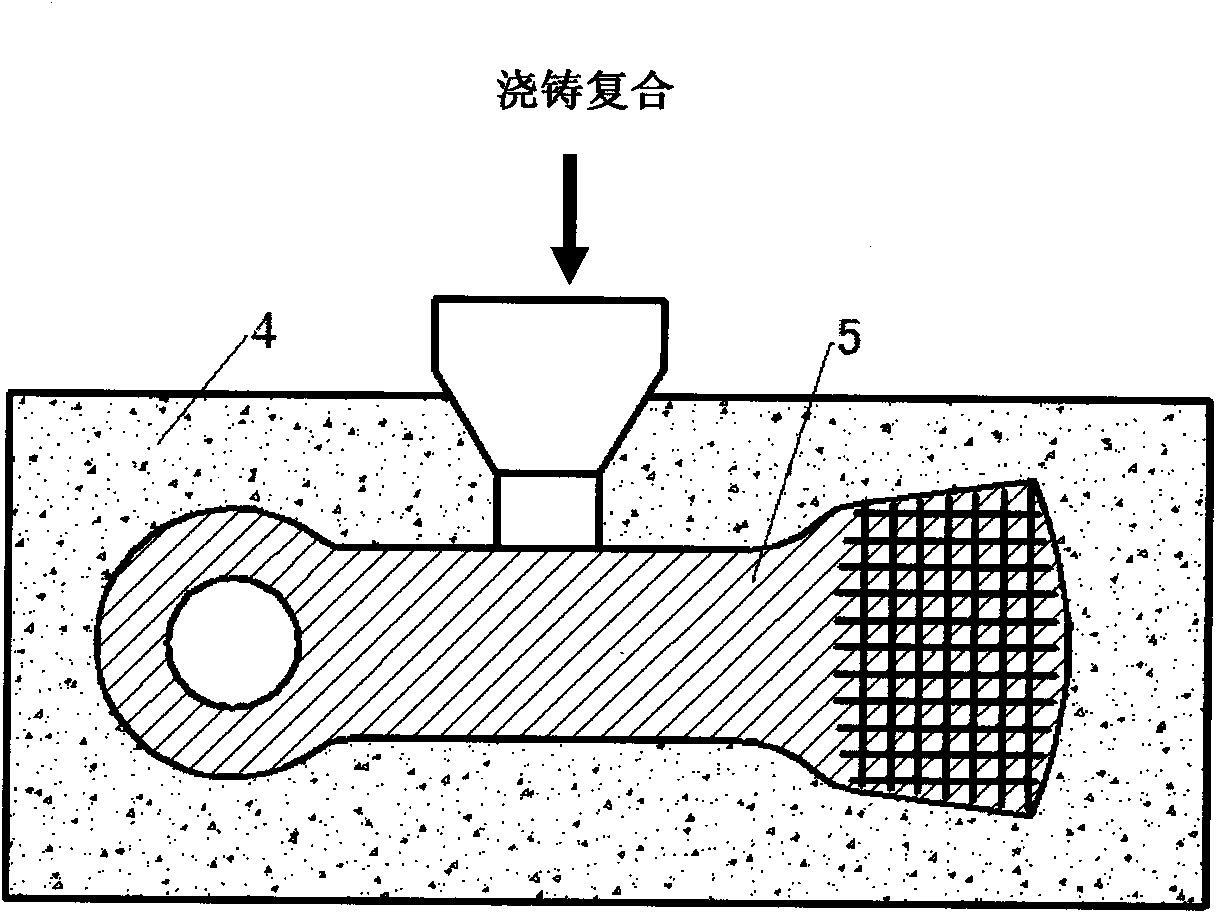

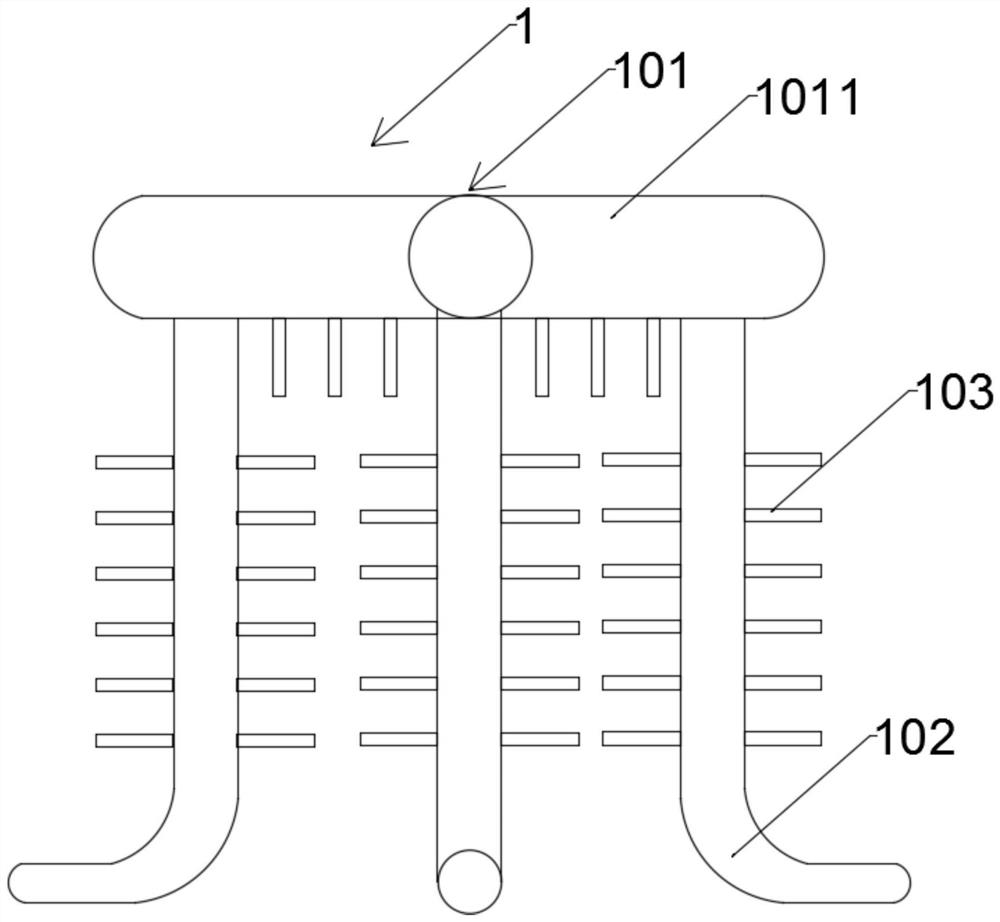

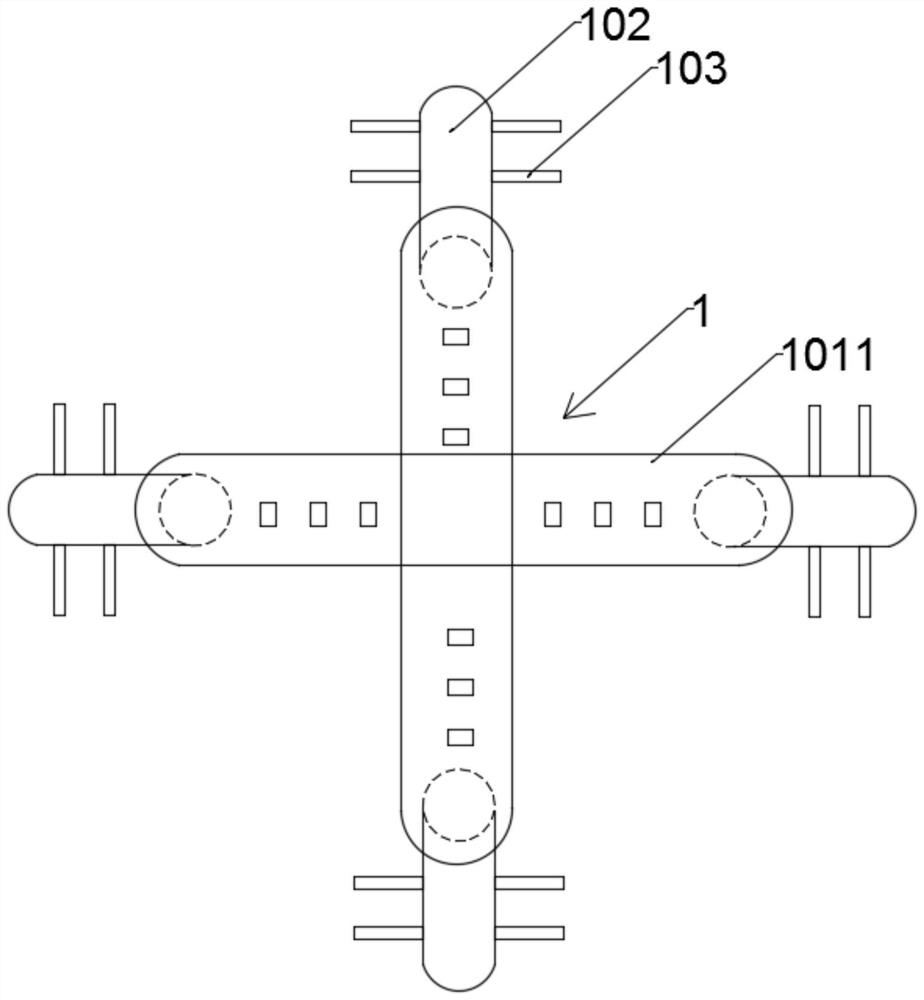

Preparation method of reinforced composite wear-resistant lining board of precast framework

The invention discloses a preparation method of a reinforced composite wear-resistant lining board of a precast framework. The prepared reinforced composite wear-resistant lining board is formed by compounding a framework reinforced body containing hard phases and base body metal. The preparation method comprises the following steps: adopting a framework precast body made of tube wires filled with hard materials, performing the vacuum high-temperature sintering, forming the framework reinforced body containing hard phases, and leading the framework reinforced body to perform the metal casting composite molding with the base body metal, so as to form the lining board formed by compounding the framework reinforced body containing hard phases and the base body metal. The framework reinforced body is performed by the vacuum high-temperature sintering to form a complete metallurgical texture structure, which has order arrangement, uniform distribution, stable performance and strong integrity, can always keep complete framework structure after compounding with the base body metal, thereby developing the high wear-resistance of the hard phases in the framework reinforced body, and keeping better flexibility of the base body metal. The reinforced composite wear-resistant lining board can be compounded locally or gradiently, or integrally, and can be widely applied to wear-resistant fields of mine, electricity, metallurgy, coal, building materials, and the like.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

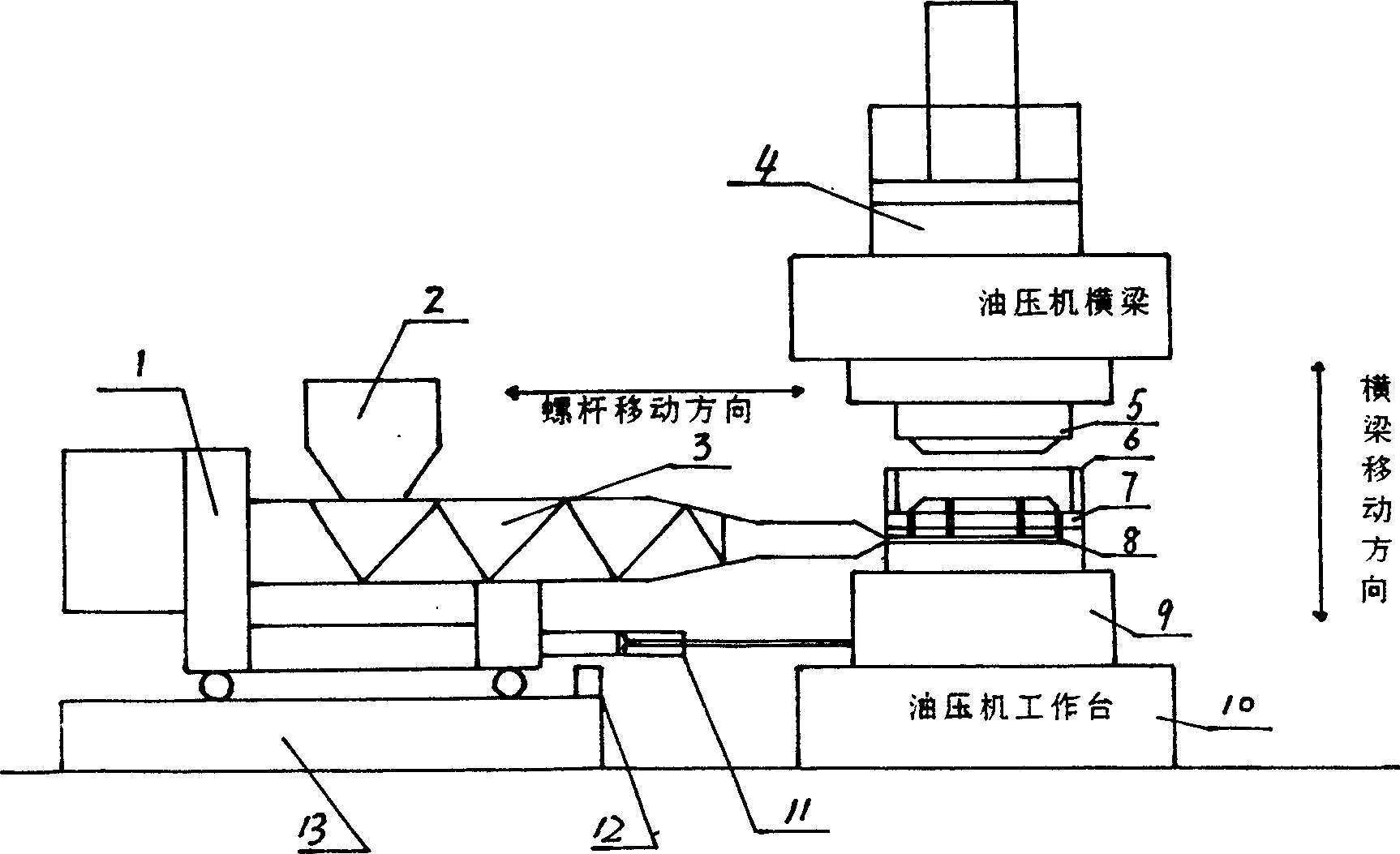

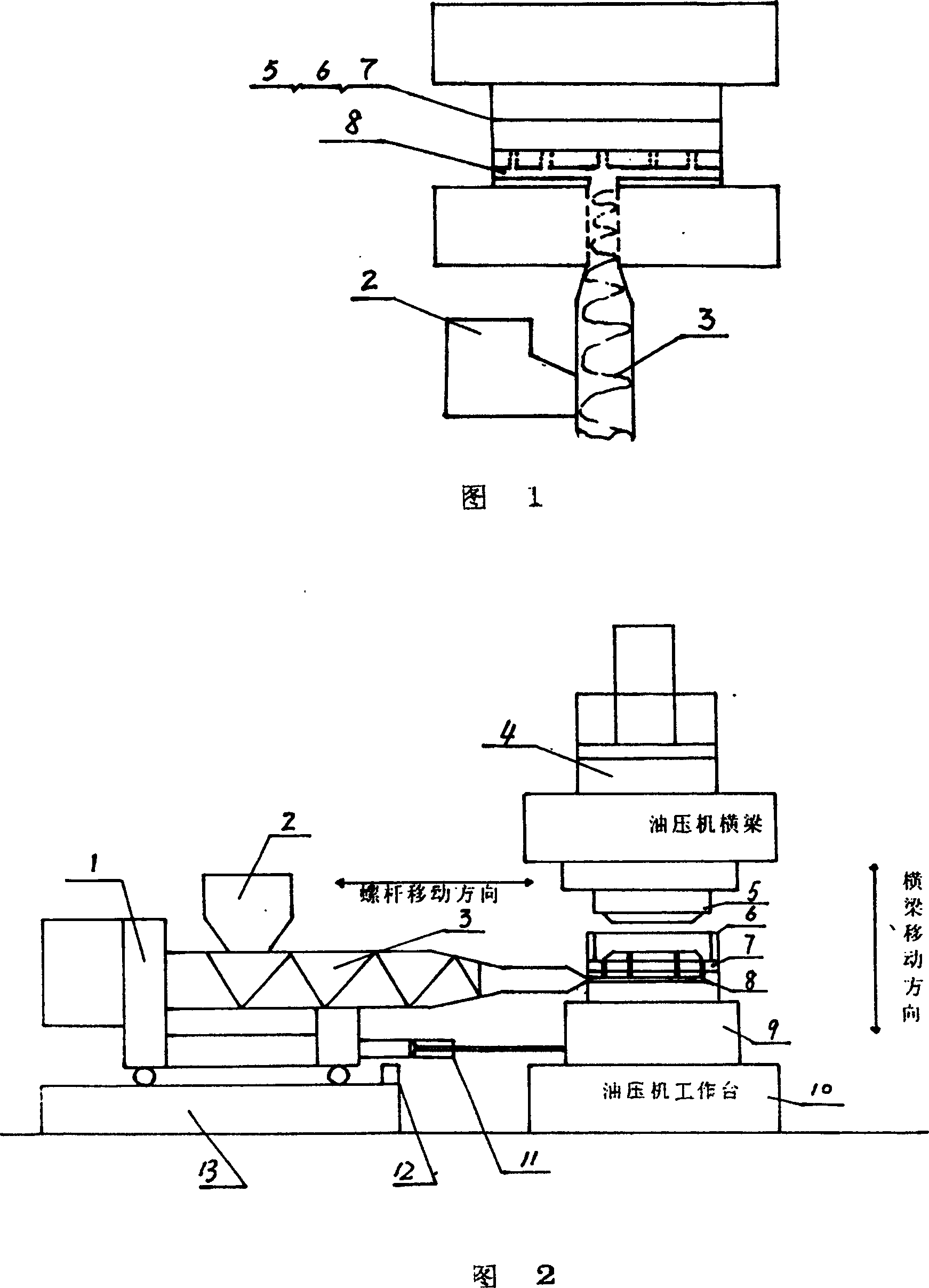

Plastic filtering board or board forming process

A process for preparing the plastic filter plate or plastic plate features that its mould is controlled by hydraulic press, its heat channel is positioned at the bottom of lower mould and communicated with said lower mould, and the plasticized plastics is injected in said mould via heat channel.

Owner:ZHEJIANG LONGYUAN ENVIRONMENTAL TECH CO LTD

Preparation method of framework reinforcement compound hammerhead

InactiveCN101658917AImprove wear resistanceImprove toughnessGrain treatmentsCompound aWear resistance

The invention discloses a preparation method of a framework reinforcement compound hammerhead. The made compound hammerhead is formed by compounding a framework reinforcement containing hard phase anda base metal. The method comprises the following processes: making a framework prefabricated part by utilizing a pipe thread filled with hard materials; carrying out vacuum high temperature metallurgy sintering on the framework perform so as to make the framework reinforcement containing the hard phase; and compounding the framework reinforcement with the base metal for molding to form the hammerhead formed by compounding the framework reinforcement containing the hard phase and the base metal. The framework reinforcement forms a sufficient metallurgical structure through vacuum high temperature metallurgy sintering, has orderly arrangement, uniform distribution, stable performance and strong integrity, and can keep complete framework structure when being compounded with the base metal. The invention not only exerts the highly wearable property of the hard phase in the framework reinforcement, but also keeps good toughness of the base metal, and can carry out local compound, graded compound or overall compound, thereby achieving the best use effect and obviously enhancing the comprehensive property.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

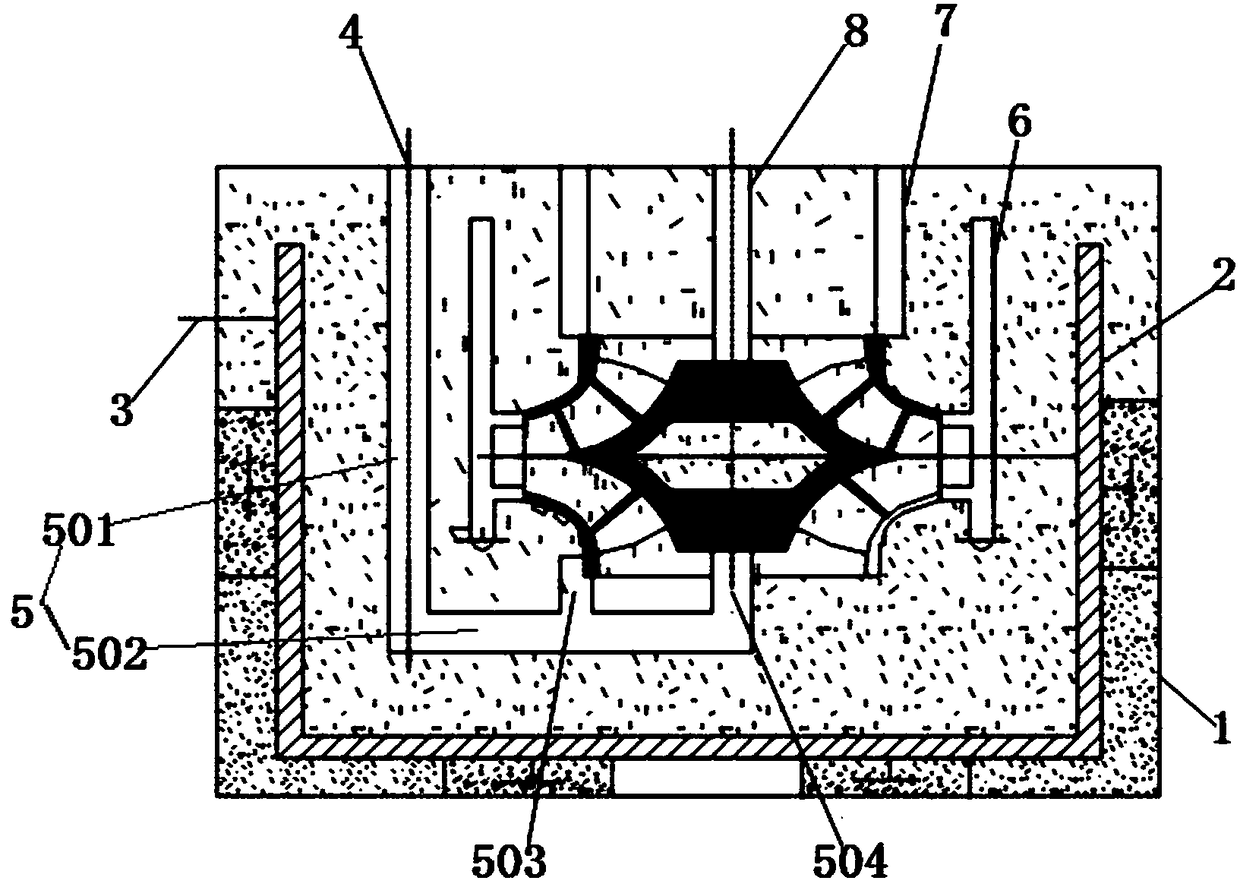

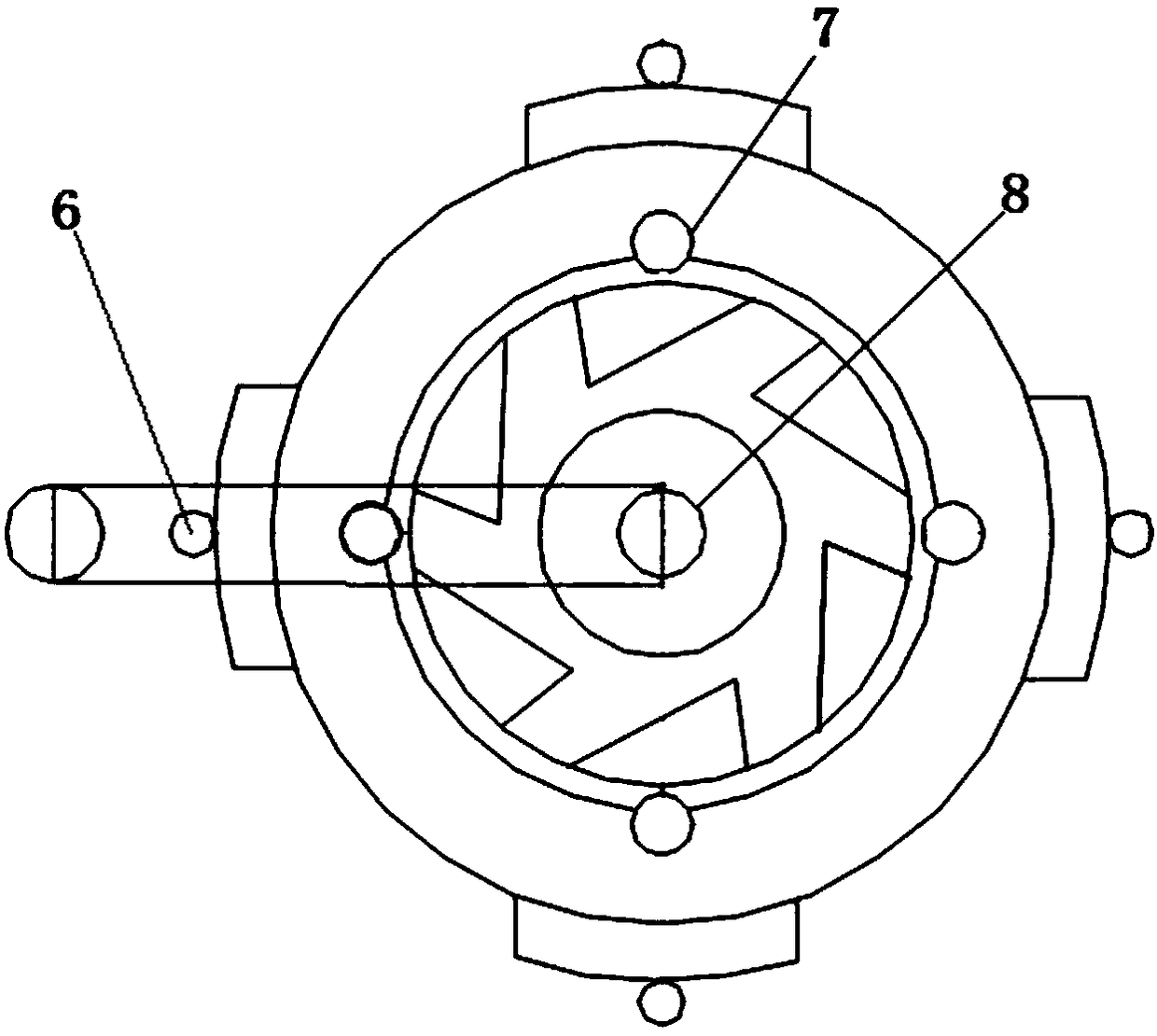

Die for cast copper impeller casting

InactiveCN108580811AIncrease temperatureSmall temperature differenceFoundry mouldsFoundry coresBrickHeat sensitive

The invention discloses a die for cast copper impeller casting. The die for cast copper impeller casting comprises a pouring die, wherein the pouring die comprises a casting box, a thermistor is further installed around the inner side of the casting box, and the thermistor is fixed into the casting box through a heat-resistant brick; and the thermistor is connected with an external power supply through a conductive wire. According to the die for cast copper impeller casting, before pouring, casting sand is heated through the heating of the thermistor, so that the effects of steam removal and moisture removal are achieved; meanwhile, the temperature of the casting sand is increased, and the temperature difference between molten copper and the casting sand is reduced, so that the phenomenonof cold shut caused by the temperature drop difference due to the non-uniform thickness of a casting is prevented; with the adoption of the casting die and the casting process thereof, the thicknessesof a hub, a front cover plate, a rear cover plate and blades of the cast bronze double-suction impeller manufactured by the casting die and the casting process are uniform and little in difference, and the shapes are regular and level; and moreover, the problem of high pouring rejection rate caused due to the inconsistency of the melting points and oxidability of copper, aluminum and iron can beavoided.

Owner:ANHUI LINE ELECTRIC PUMP

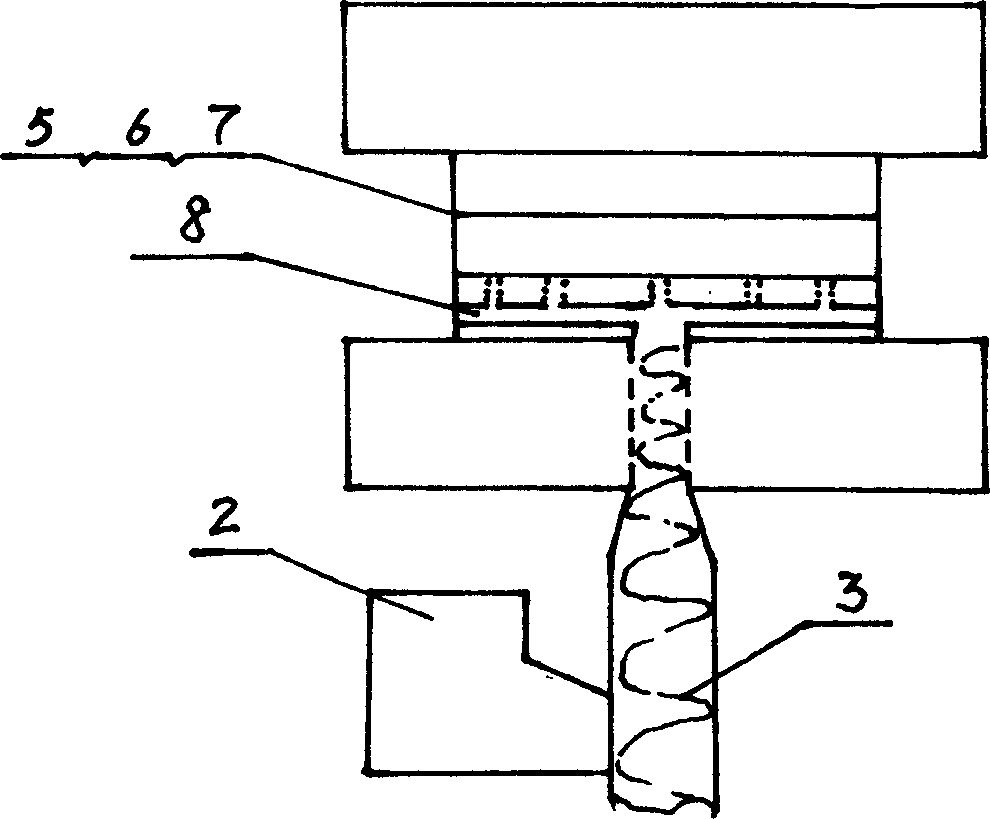

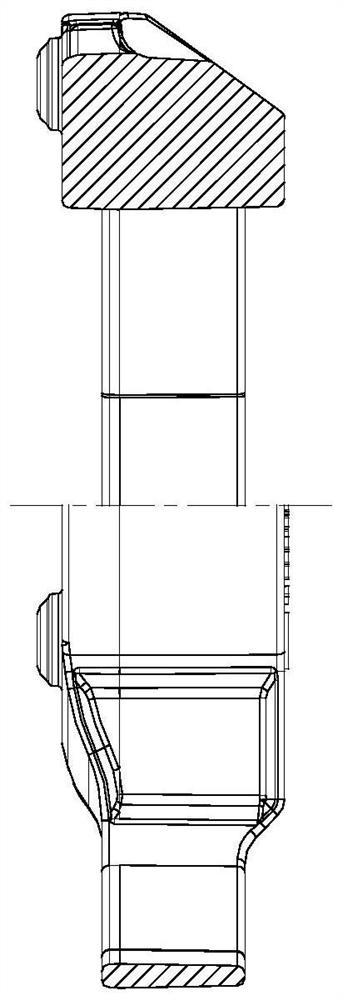

Runner device and mold filling method of centrifugal casting thin-wall cartridge receiver casting

The invention relates to a runner device and mold filling method of a centrifugal casting thin-wall cartridge receiver casting. The runner device comprises a disc-shaped transverse runner, a straightrunner vertically adheres to the transverse runner, and an annular inner runner and an annular outer runner further adhere to the transverse runner; the inner runner and the outer runner surround thearea beyond the straight runner; and the inner runner and the outer runner are connected through a plurality of lap joint runners. The mold filling method comprises the steps that after the runner device is prepared, molten metal is poured through the straight runner, the inner runner and the outer runner, so that the molten metal reaches the joint of the inner runner and the transverse runner atthe same time and is gathered. By means of the technical scheme, the cross section area of the lap joint runners is limited, so that the pressure head flowing through the molten metal is increased, and a foundation is laid for enabling the molten metal to reach the junction of the inner runner and the transverse runner at the same time and to be gathered, the purpose of avoiding cold separation defects of the casting is achieved, welding repairing and repairing processes for the casting in the later period are avoided, the casting technology is simplified, and the product quality is improved.

Owner:GUIZHOU ANJI AVIATION PRECISION CASTING

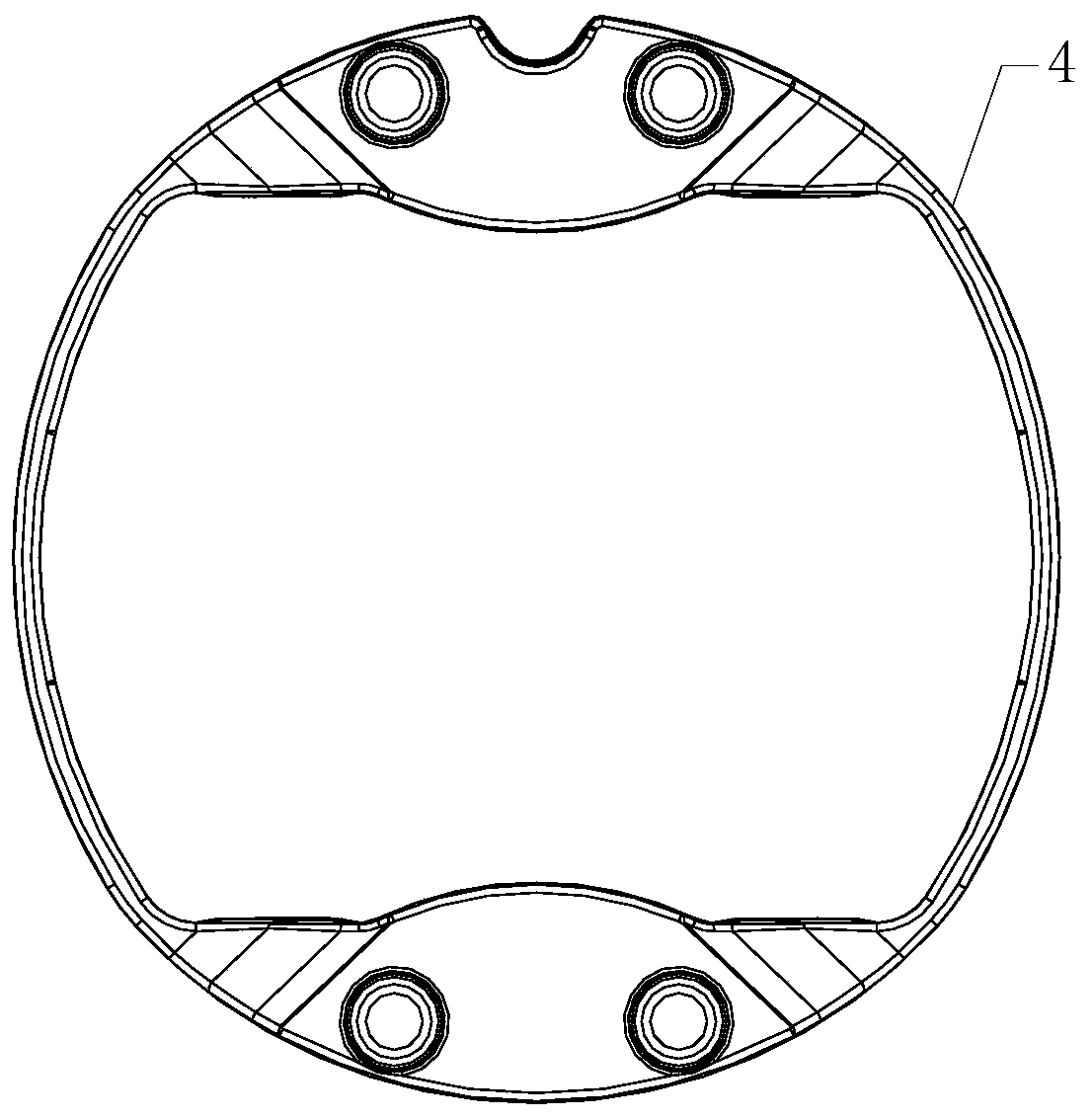

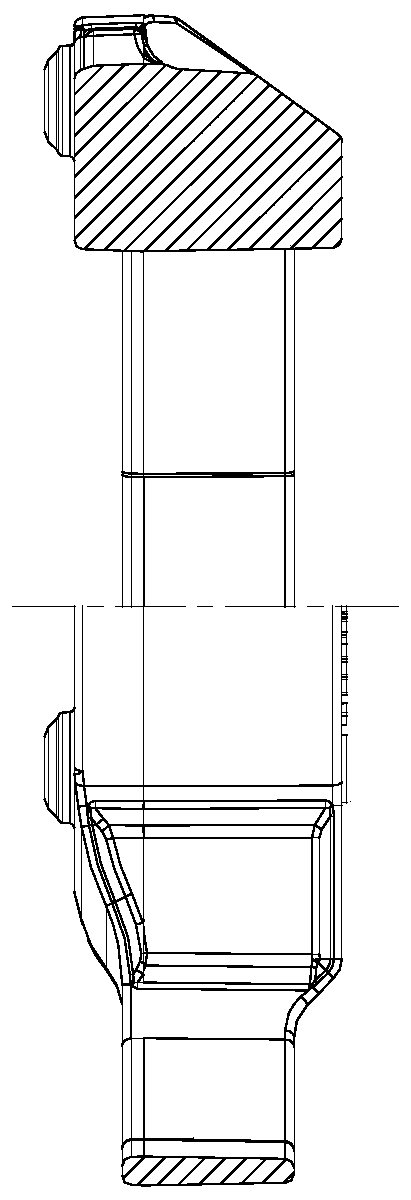

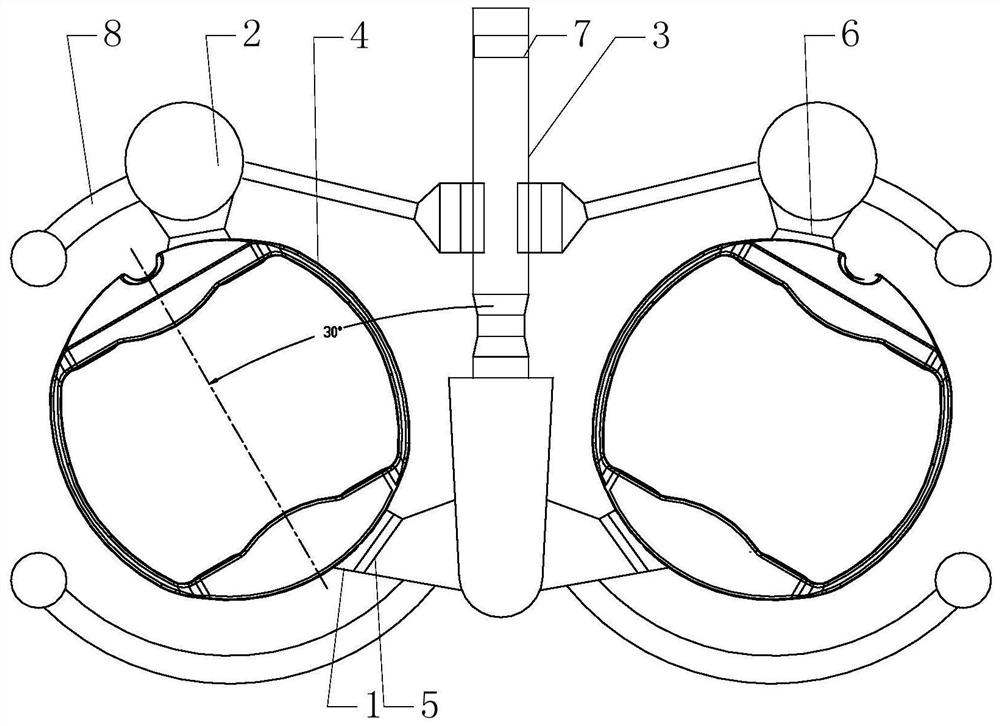

Casting method for turbine shell

The invention provides a casting method for a turbine shell. The turbine shell is internally provided with a partition plate. The casting process comprises the following steps that S1, a riser (6) is placed at the edge of a mold core of the turbine shell, and the riser (6) is made to be connected with the mold core of the turbine shell; S2, a transverse pouring gate and a flow resistant channel (4) are arranged in a mold, the transverse pouring gate is provided with a plurality of water inlets (7) which are connected to the periphery of the mold core of the turbine shell at intervals, one end of the flow resistant channel (4) is connected with the transverse pouring gate, and the other end of the flow resistant channel (4) is connected with the riser (6); S3, pouring liquid is injected into the sand mold and is filtered; and S4, the filtered pouring liquid enters a cavity of the turbine shell through the multiple water inlets (7) and the flow resistant channel (4), pouring is completed, and the turbine shell is obtained. According to the casting method for the turbine shell, cold shut of the partition plate of the turbine shell and the casting surface slag hole defect can be eliminated, and the internal quality and the yield of the turbine shell are improved.

Owner:CRRC CHANGZHOU AUTO PARTS CO LTD +1

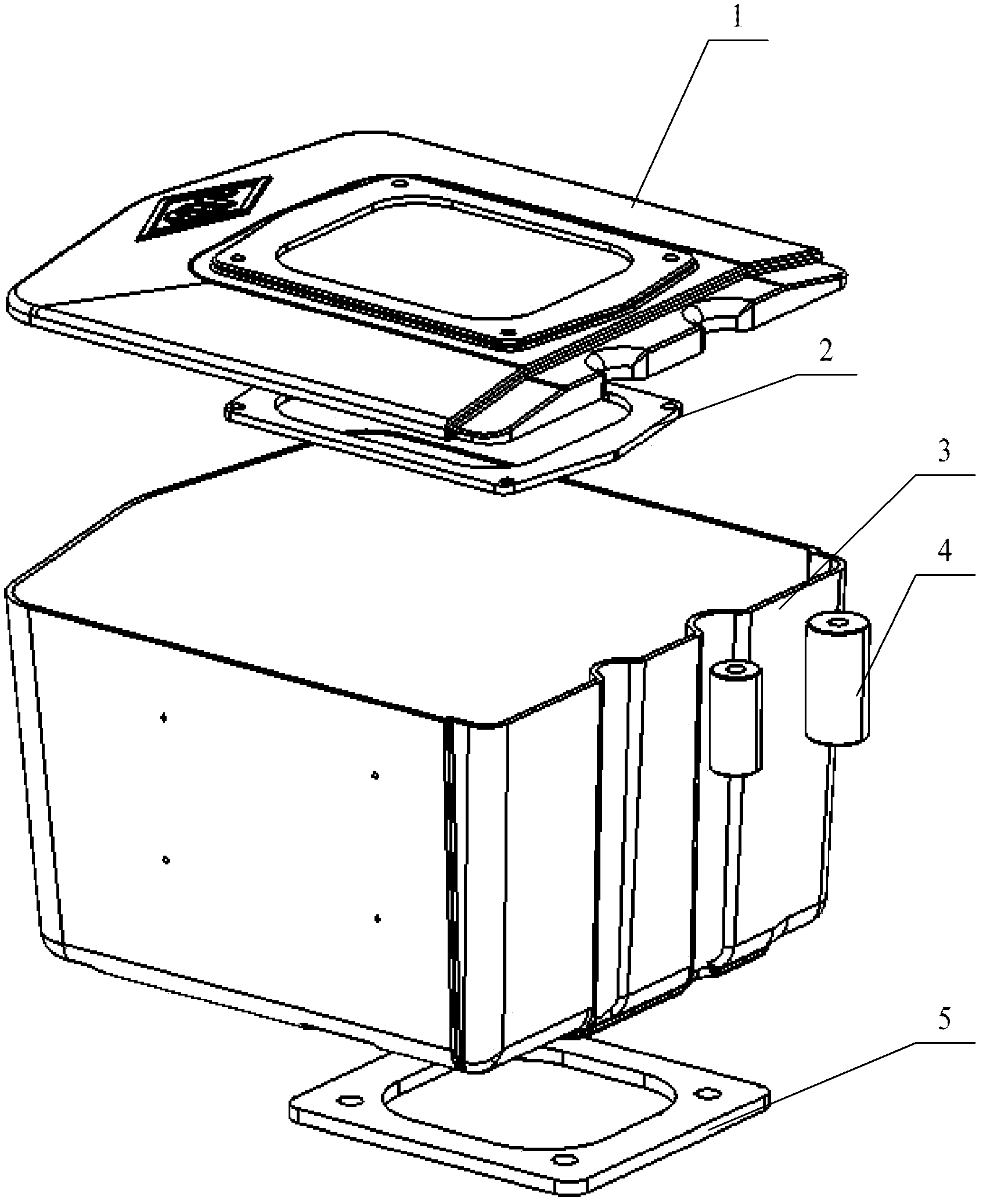

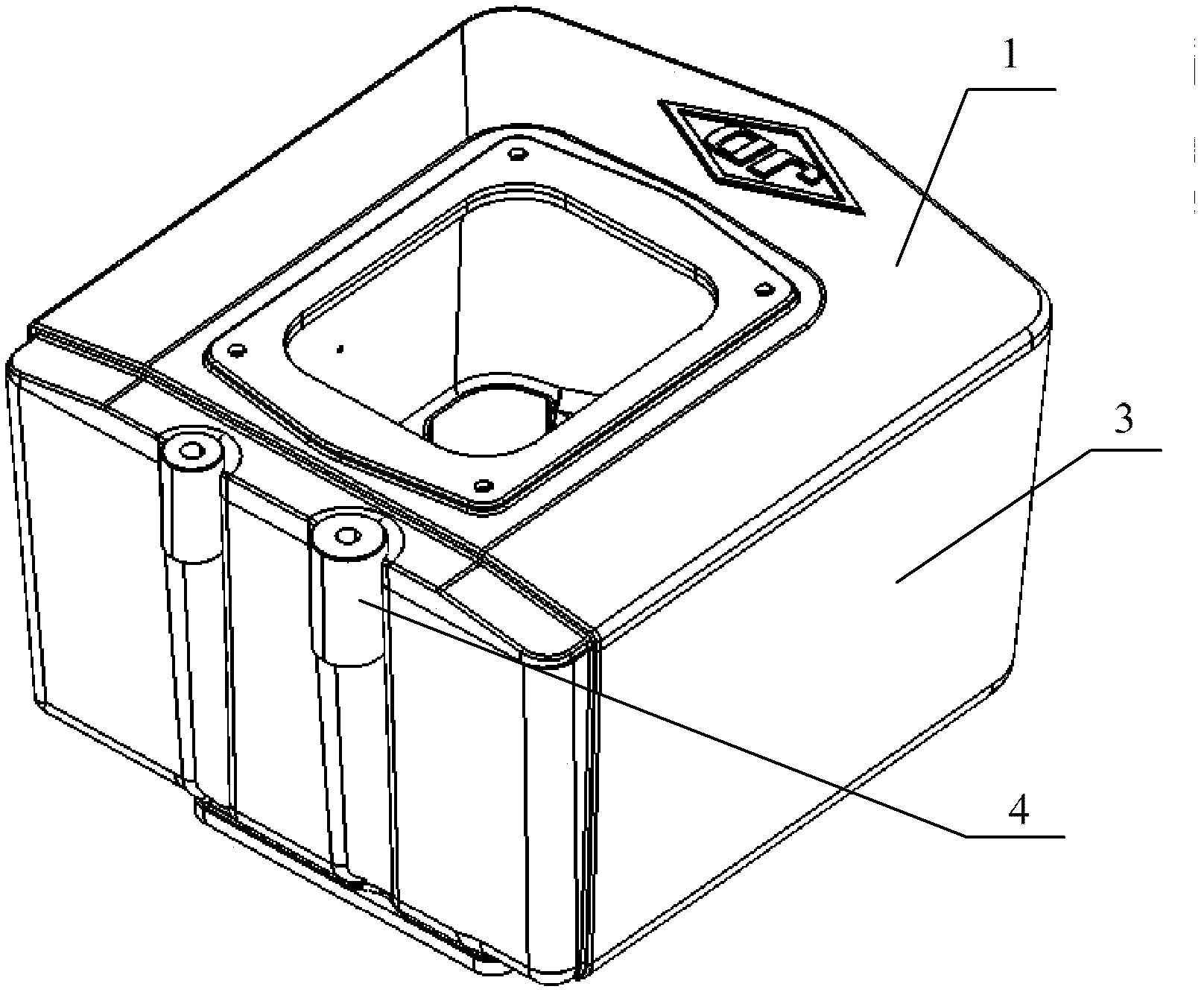

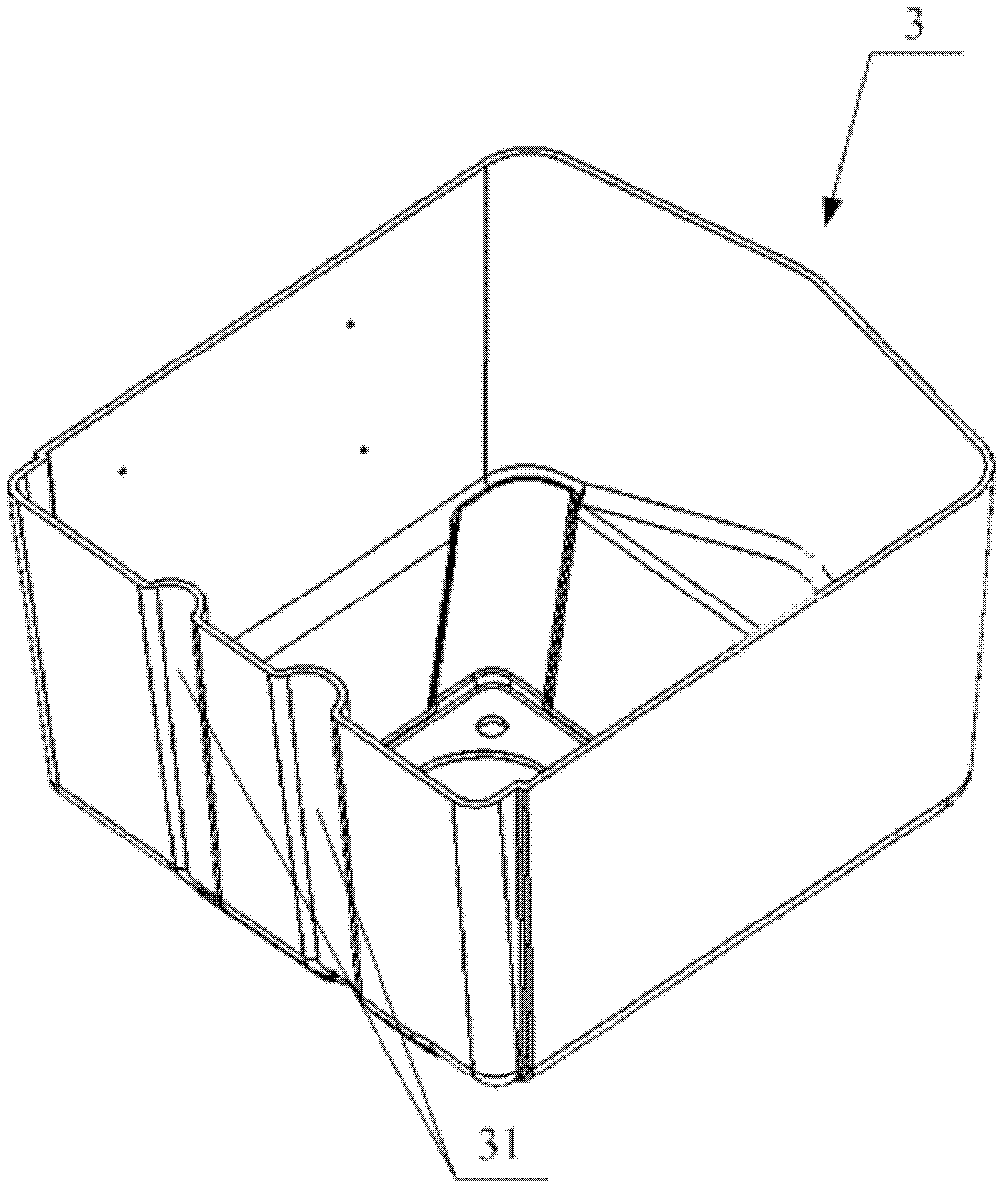

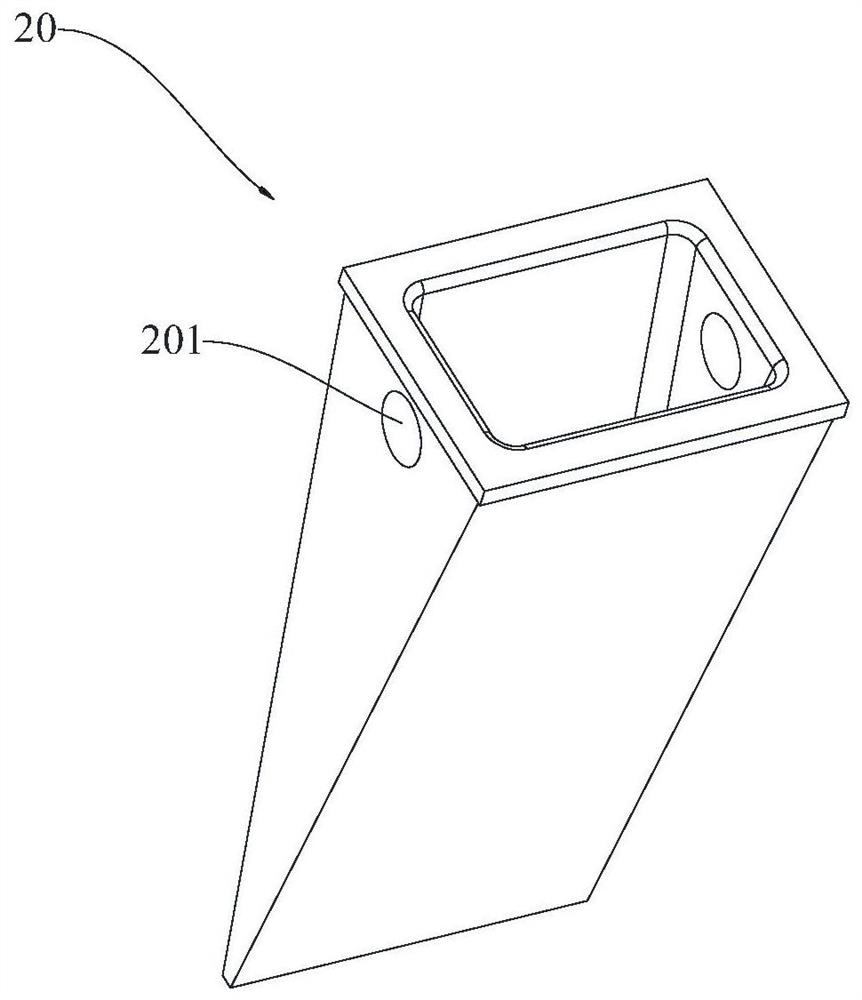

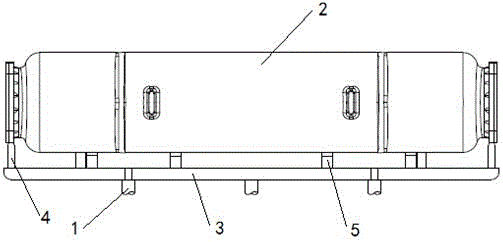

Water tank of diesel engine

InactiveCN102400769ANo leakageAvoid Cold ShutMachines/enginesEngine cooling apparatusAgricultural engineeringUltimate tensile strength

The invention discloses a water tank of a diesel engine. The water tank of the diesel engine comprises a connecting stud, and a water tank upper cover, a water tank middle body and an upper welding plate which are subjected to drawing and stamping forming, wherein the water tank upper cover is welded at the opening of the upper end of the water tank middle body; the upper welding plate is welded on the water tank upper cover; and the connecting stud is welded on one side of the water tank upper cover and the water tank middle body. In the water tank of the diesel engine, the water tank upper cover, the water tank middle body and the upper welding plate have the drawing and stamping forming structure, and the stud, the water tank upper cover, the water tank middle body and the upper welding plate are welded together to form the water tank of the diesel engine. The water tank of the diesel engine are divided into a plurality of parts which are subjected to drawing forming sequentially, so the defects of cold shut, sand burning, uneven outer surface and the like caused by casting are overcome. The water tank of the diesel engine has a bright and clean surface, does not have sand hole leakage, does not require procedures of sanding, polishing and the like, saves materials, and has high production efficiency and shock strength higher than that of products produced by a casting process.

Owner:JIANGSU NONGHUA WISDOM AGRICULTURAL SCIENCE AND TECHNOLOGY CO LTD

Casting process of aluminum alloy ingots for ships and warships

The invention discloses a casting process of aluminum alloy ingots for ships and warships. The process comprises the following steps that A, alloys are smelted to obtain aluminum alloy melts; B, the aluminum alloy melts are subjected to counter gravity casting, and the aluminum alloy ingots are obtained; and C, the obtained aluminum alloy ingots are sequentially subjected to homogenization, solidsolution treatment and aging treatment, and the aluminum alloy ingots for the ships and warships are obtained. The process can obtain the aluminum alloys with the excellent comprehensive properties like tensile strength, yield strength, ductility and exfoliating corrosion resistance, solves the problems that when existing aluminum alloys are applied on ships, the aluminum alloys are poor in corrosion resistance and low in intensity, and accordingly prolonging the service life of the ships in complex and atrocious environments of the ocean.

Owner:CENT SOUTH UNIV

Plastic filtering board or board forming process

ActiveCN100360296CIncrease clamping pressureRealize automated productionDomestic articlesHot runnerFilter press

A process for preparing the plastic filter plate or plastic plate features that its mould is controlled by hydraulic press, its heat channel is positioned at the bottom of lower mould and communicated with said lower mould, and the plasticized plastics is injected in said mould via heat channel.

Owner:ZHEJIANG LONGYUAN ENVIRONMENTAL TECH CO LTD

Machining method of cast-state nodular cast iron well lid

The invention discloses a machining method of a cast-state nodular cast iron well lid. The machining method is characterized by the cold barrier is prevented through adjusting a pouring system, improving the friction conditions and reducing the flowing resistance; and the inoculation is strengthened through controlling the discharge temperature of molten iron and purifying the molten iron. The product quality and the yield of the nodular cast iron well lid are improved; and the cost is reduced.

Owner:安徽大来机械制造有限公司

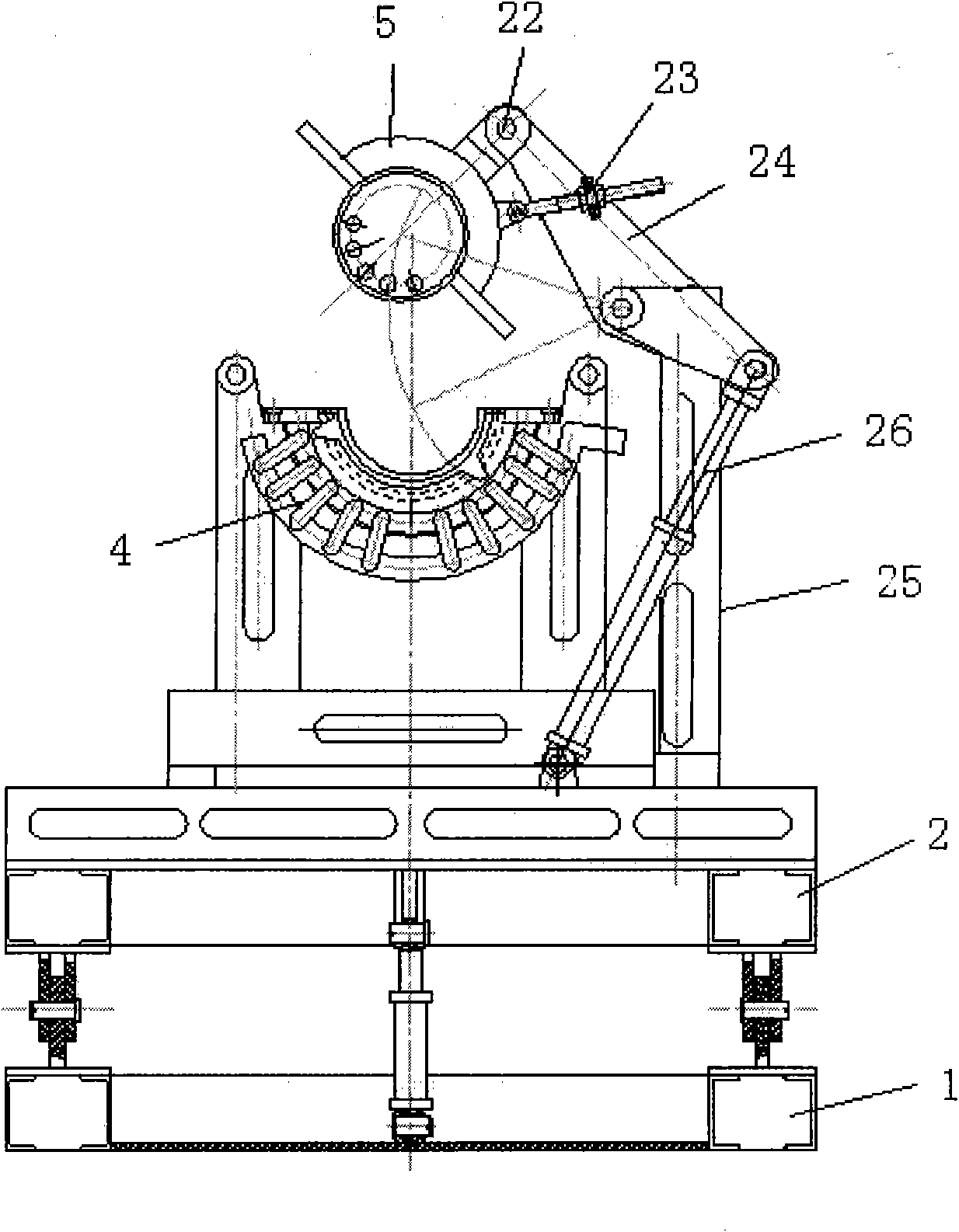

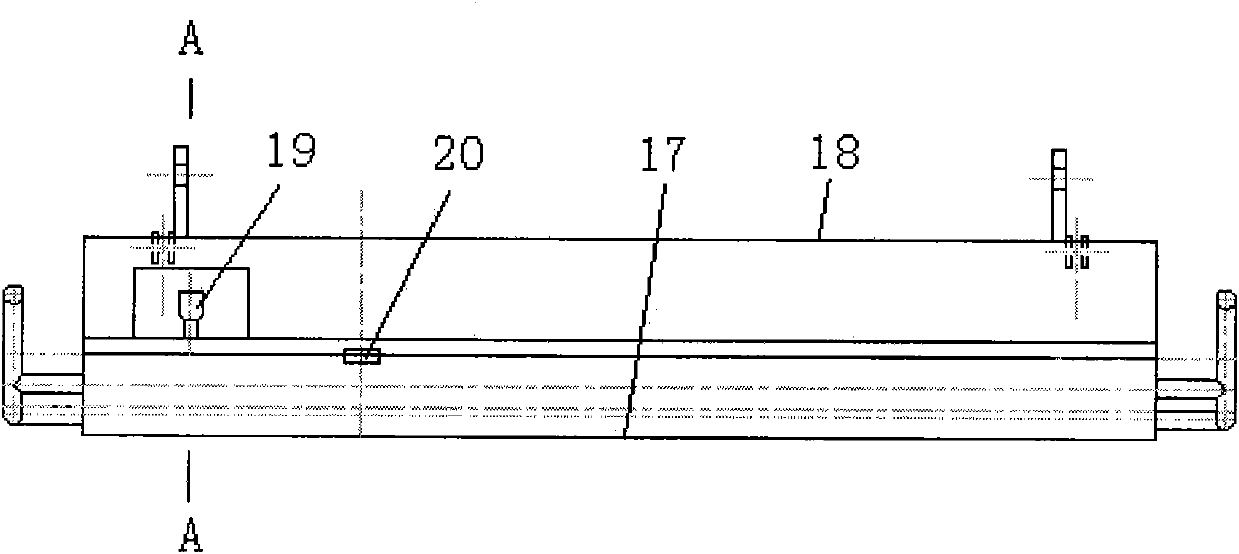

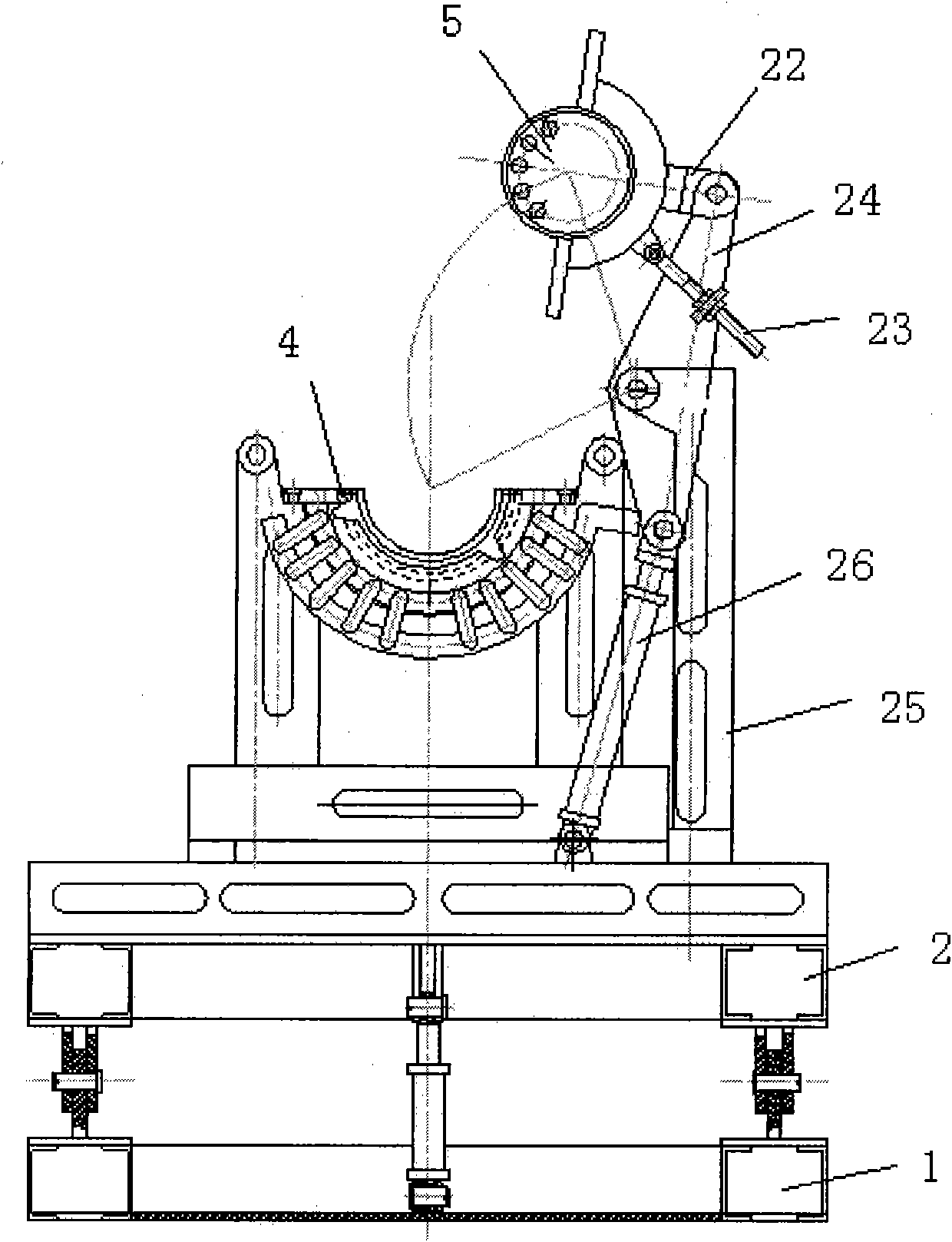

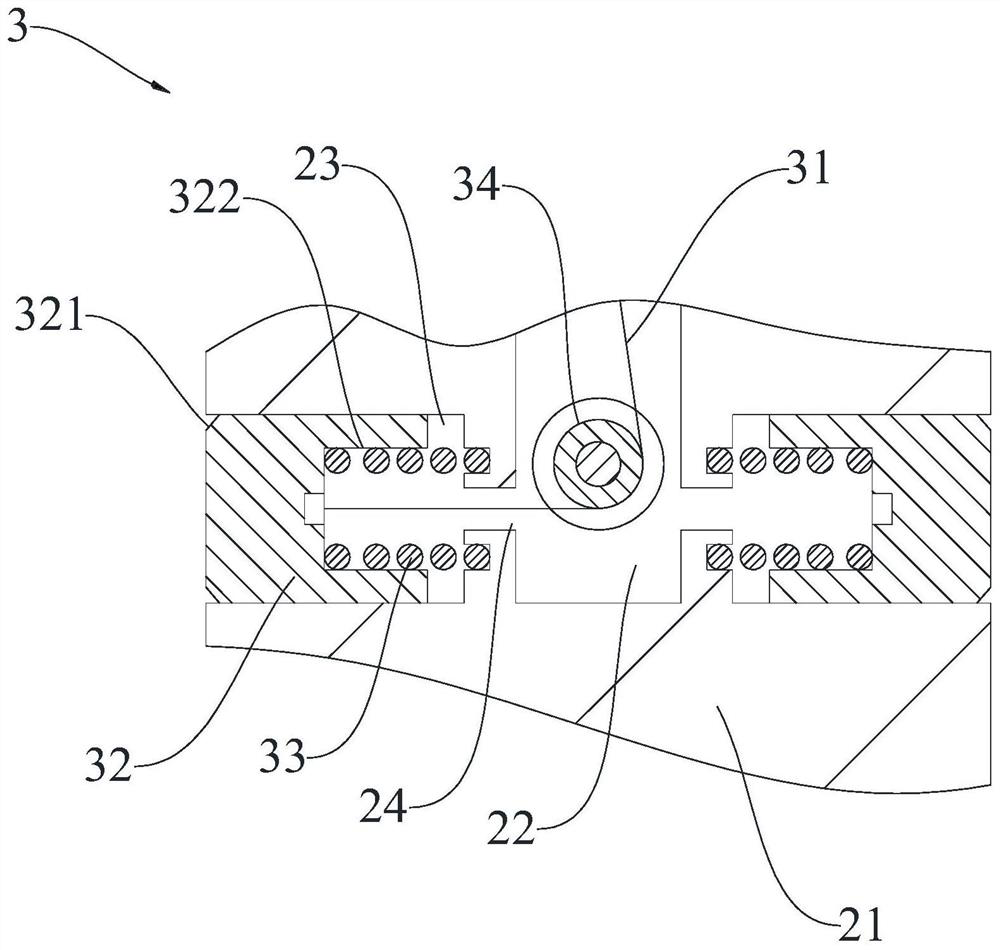

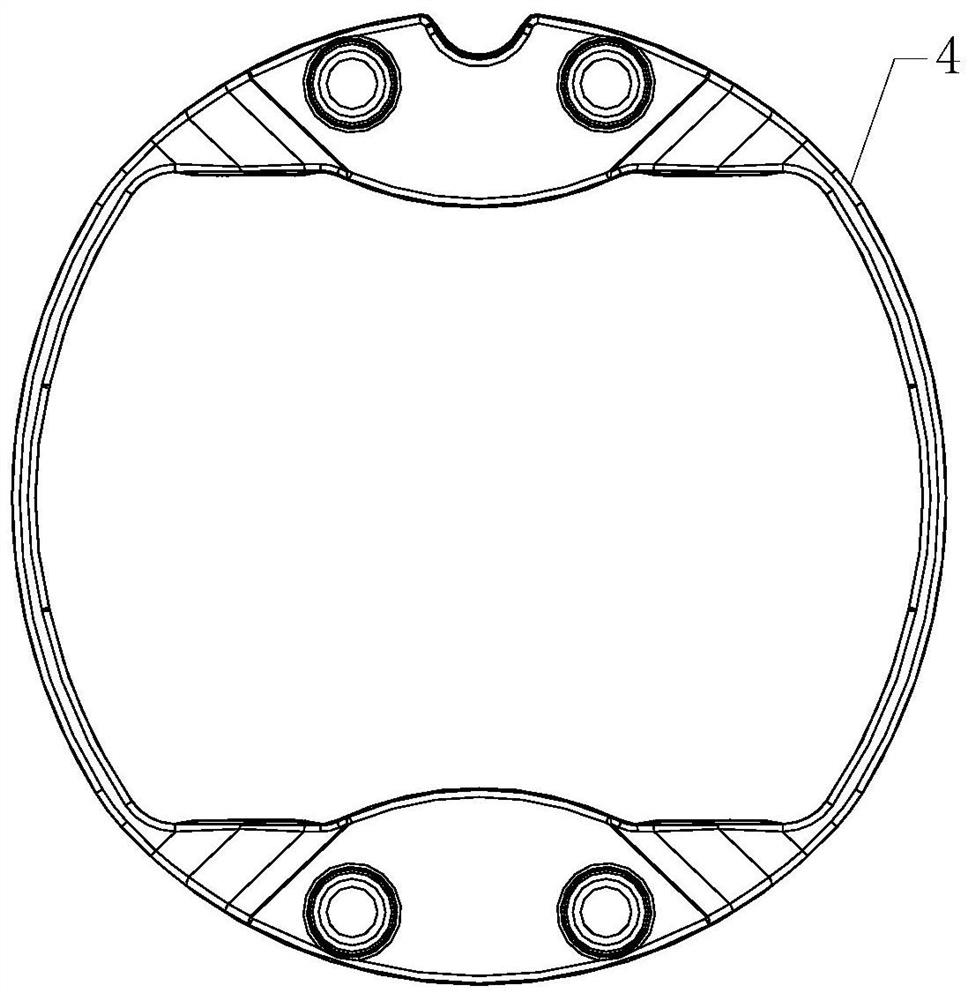

Casting mold for vortex-induced vibration suppression device

The invention discloses a casting mold for a vortex-induced vibration suppression device. The casting mold comprises an underframe, a rotating tilt stand, a female die, a female die support, a male die, a male die support, a rotating mechanism, a pressing mechanism, a hydraulic station, a heating device and the like; the female die consists of a semicircular female mold with a spiral groove, and a built-in heating coil; the male die consists of a semicircular male mold; the rotating mechanism and the pressing mechanism are hydraulic power mechanisms to control the rotating tilt stand and the male mold to oscillate; the mold comprises two sets to realize the casting of two parts of the vortex-induced vibration suppression device; and finally the two half parts are assembled into a molded product of the vortex-induced vibration suppression device.

Owner:CHINA NAT OFFSHORE OIL CORP +1

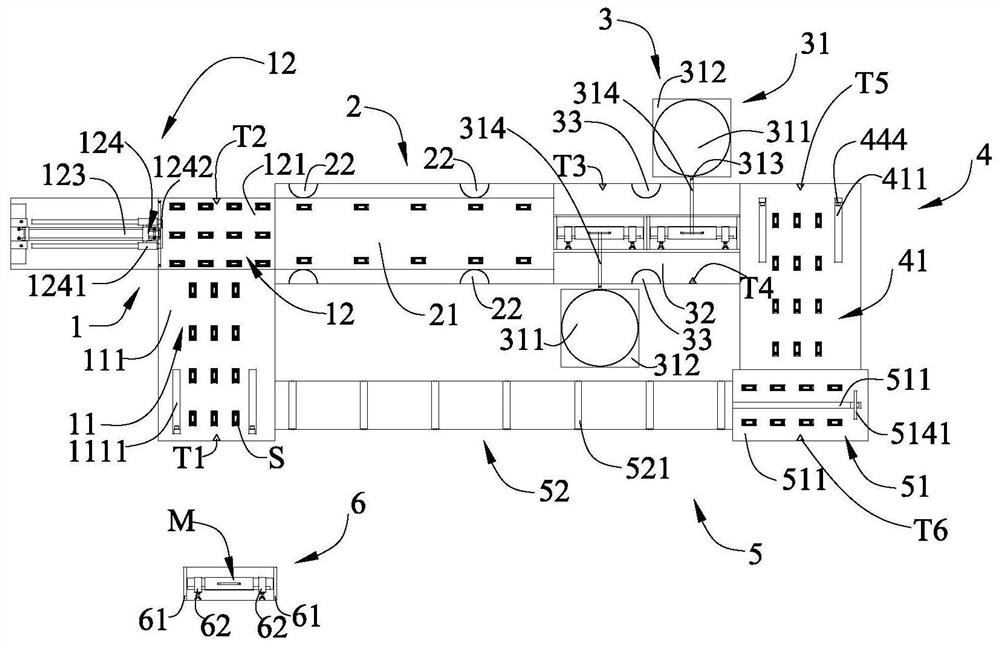

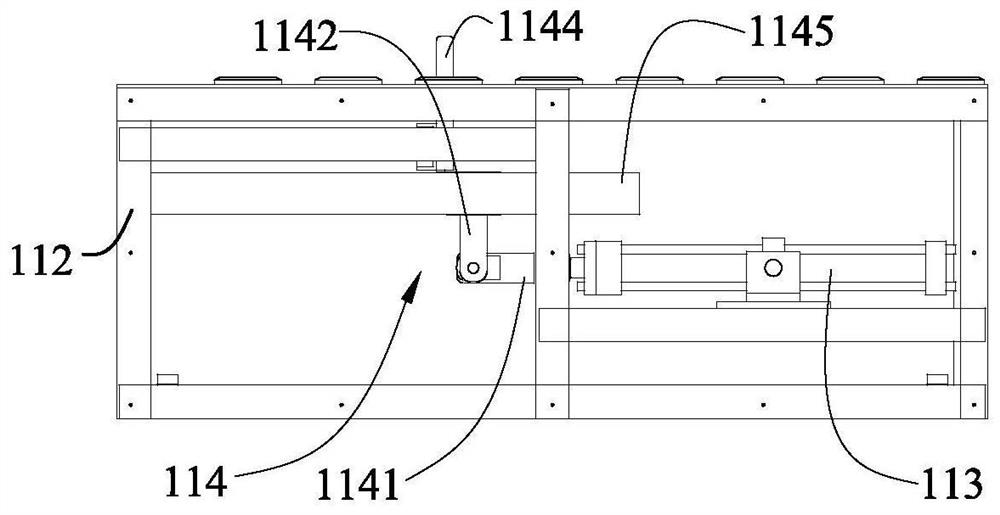

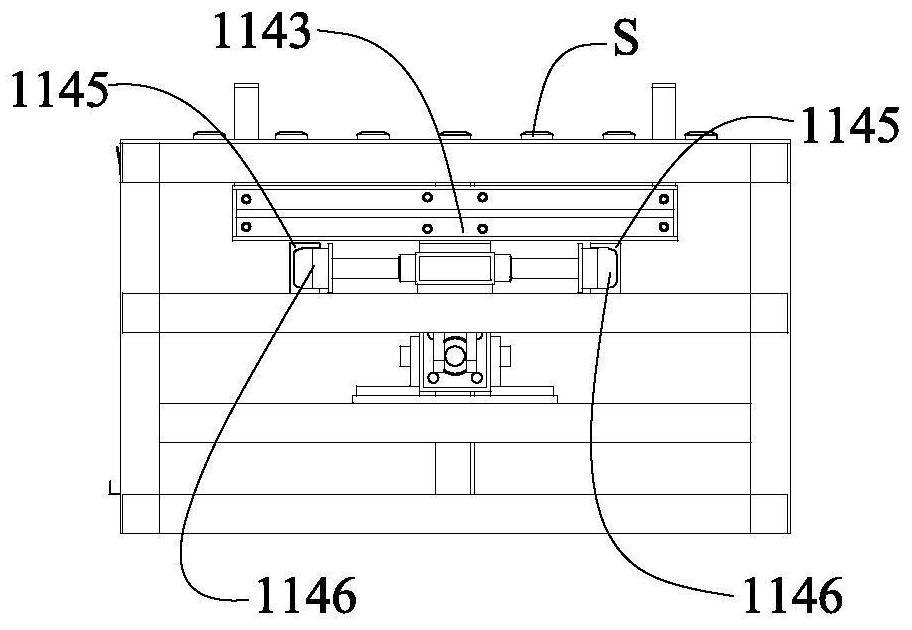

Automatic metal pouring production line

InactiveCN112191838AAvoid Cold ShutIncrease productivityCasting plantsMould handling equipmentsProduction lineThermodynamics

The invention provides an automatic metal pouring production line which comprises a preparation area, a mold heating area, a pouring area, a cooling area and a demolding area. The preparation area isused for fixing and automatically conveying a mold. The mold heating area is of a tunnel structure, is connected to the preparation area and is used for automatically preheating and heating the mold.The pouring area is connected to the mold heating area, and automatic pouring devices are arranged on the two side walls, parallel to the conveying direction, of the pouring area respectively. The cooling area is connected to the pouring area and used for cooling and automatically conveying poured products. The demolding area is connected to the cooling area and the preparation area and used for product demolding. According to the automatic metal pouring production line, preheating, heating and conveying of the mold can be automatically conducted, molten metal is automatically poured into thepreheated and heated mold, and conveying and demolding of the poured products are automatically conducted. On one hand, the mold is preheated before pouring, and the cold shut phenomenon is effectively avoided; and on the other hand, the whole pouring production process is automatically completed, and the production efficiency and the controllability of the product quality are improved.

Owner:FIRST RARE MATERIALS CO LTD

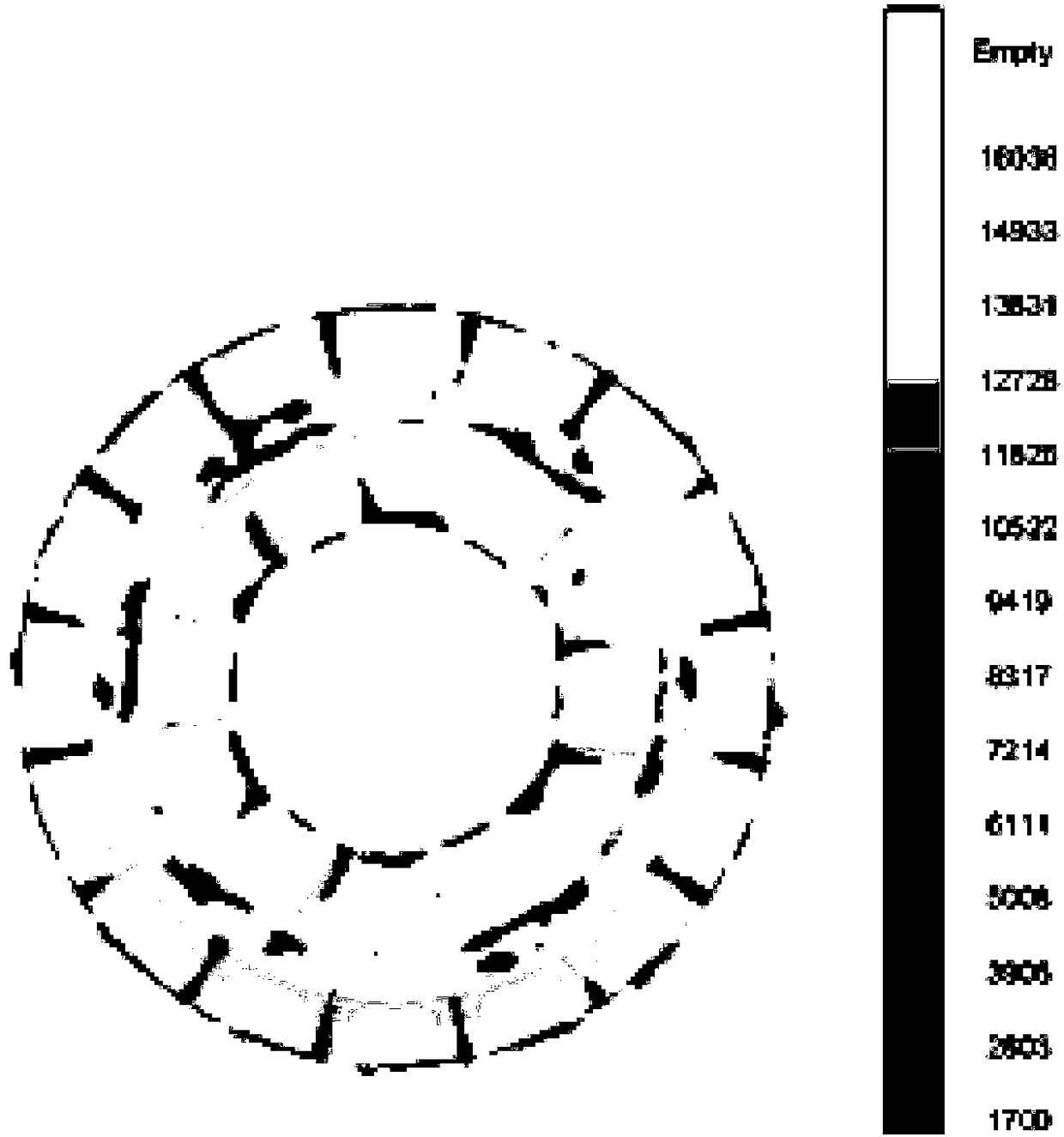

Casting mold and casting method for large-size disc type complicated-structure part

The invention discloses a casting mold for a large-size disc type complicated-structure part. The casting mold comprises a casting mold body; the casting mold body is provided with a disc-like part cavity, a plurality of riser cavities, a plurality of air outlets and a grouting system; the grouting system comprises at least two iron inlets, at least two liquid iron main flow channels, a central flow dividing chamber, a plurality of liquid iron branch flow channels and a plurality of filters; the liquid iron main flow channels and the liquid iron branch flow channels are arranged at the bottomof the casting mold body; and the central flow dividing chamber is arranged at the central position of the bottom of the casting mold body. The grouting system is reasonably distributed, so the grouting time can be greatly shortened, and stable iron feeding is guaranteed. The riser cavities and the air outlets are arranged in a targeted manner in order to guarantee the air generation quantity of the cavities and shrinkage compensation of the riser. The invention also discloses a casting method, and the casting method adopts the casting mold which is combined with graphite chill iron and mold weight, thereby effectively solving the casting problems such as shrinkage, loosening, slag inclusion, cold shut and deformation which are easily generated in a casting process.

Owner:JIANGSU JIXIN WIND ENERGY TECH

Process for producing ductile iron piece mold with large wall thickness difference through vertical line

ActiveCN110899623AEfficient productionPrevent shrinkageFoundry mouldsFoundry coresPhysicsThin walled

The invention discloses a process for producing a ductile iron piece mold with large wall thickness difference through a vertical line. The process comprises a pouring device. The pouring device comprises a pouring gate assembly, a riser assembly and a vertically-arranged pouring gate. The pouring gate assembly and the riser assembly are both inclined upwards relative to the pouring gate and are both communicated with the pouring gate, the riser assembly is arranged above the pouring gate assembly, and outlets of the riser assembly and the pouring gate assembly correspond to the thick and large positions of the ductile iron part, wherein a necking neck is arranged at the outlet of the pouring gate assembly, a riser neck is arranged at the outlet of the riser assembly, and an intercepting block is arranged on the pouring gate and located above the pouring gate assembly. With application of the process for producing the ductile iron piece mold with the large wall thickness difference through the vertical line, efficient production of ductile iron pieces with the large wall thickness difference is realized and shrinkage cavities in the thick and large positions and cold shut in the thin wall positions can be avoided.

Owner:BAODING DONGLI MASCH MFG CO LTD

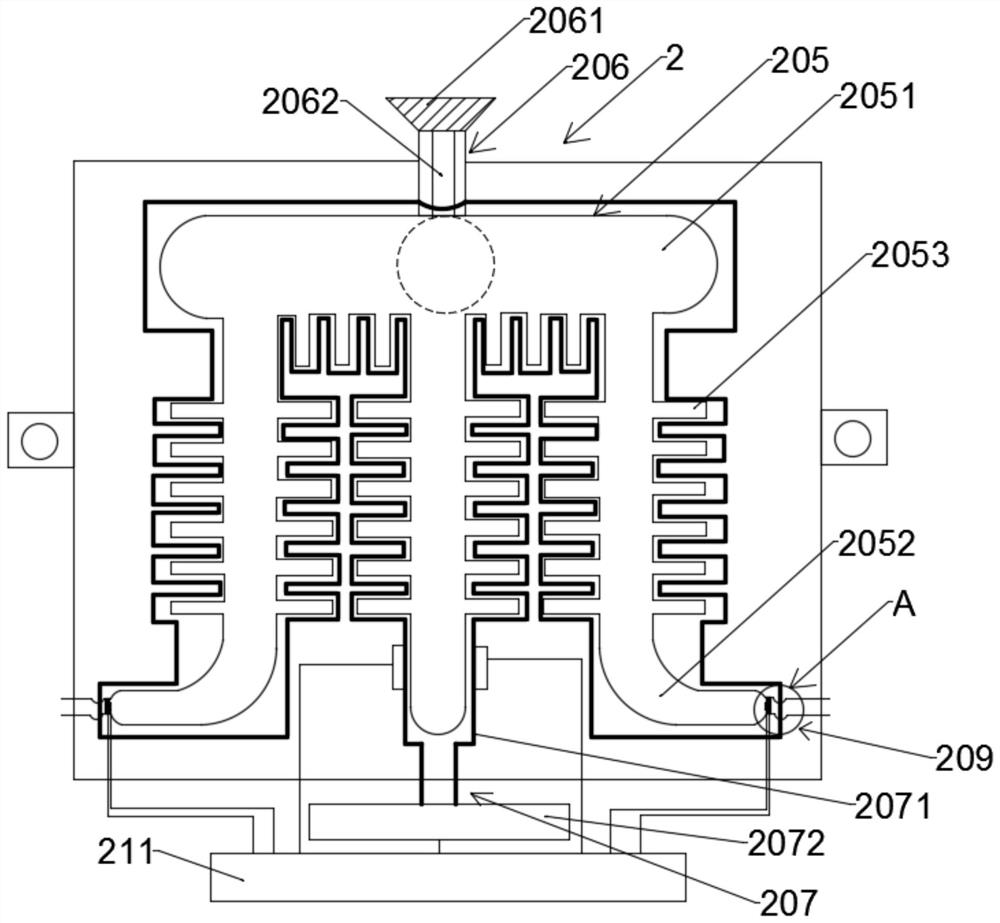

Pre-embedded fastener of green building fabricated type steel structure and forming method

ActiveCN113136964AImprove mechanical propertiesImprove bearing capacityFoundry mouldsBuilding constructionsRebarGas release

The invention discloses a pre-embedded fastener of a green building fabricated type steel structure. The pre-embedded fastener comprises a pre-embedded fastener body and a forming device used for manufacturing the pre-embedded fastener body, the pre-embedded fastener body comprises a connecting base and a pre-embedded foot fixed to the connecting base, and the pre-embedded foot is formed by extending outwards from the bottom of the connecting base. According to the pre-embedded fastener, building base materials are subjected to primary reinforcement and secondary reinforcement through the pre-embedded foot and an auxiliary bar respectively, so that the pre-embedded fastener good in mechanical property and high in bearing capacity is obtained; meanwhile, the pre-embedded fastener is machined in an integrated pouring mode, the bending and deviation adjustment process of steel bars is avoided, and the machining efficiency is improved; and a mold temperature mechanism and an exhaust mechanism are arranged on a forming device for machining the pre-embedded fastener, so that the liquidity of molten steel in the pouring process is maintained, the defects of cold shut and under-casting at a hook-shaped structure of the pre-embedded fastener are avoided, gas in a cavity is released through the exhaust mechanism, meanwhile, ejection defect of the molten steel is avoided, and the machining precision of the pre-embedded fastener is jointly improved.

Owner:山东天成钢结构有限公司

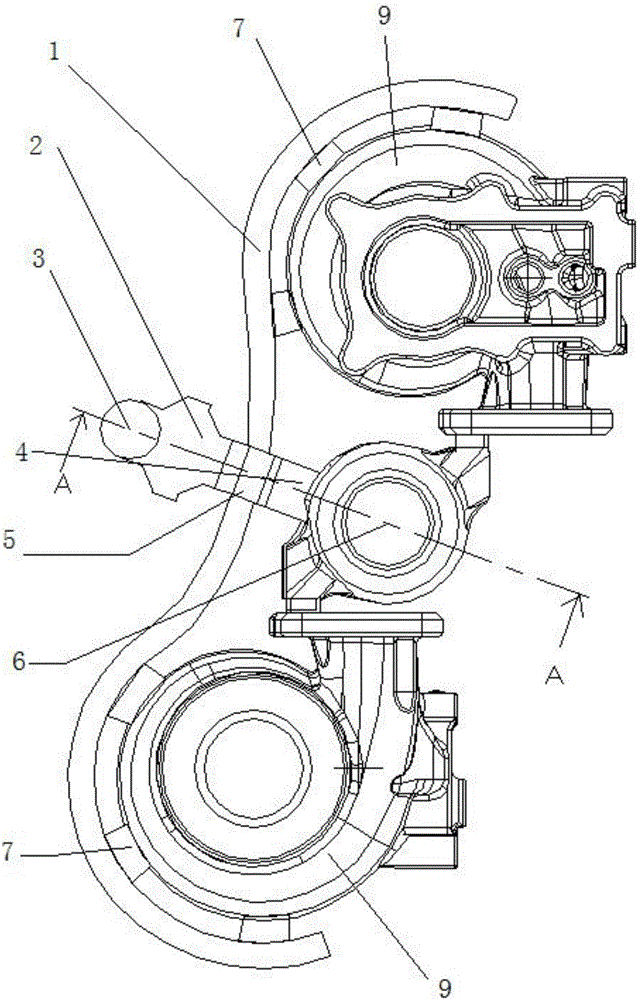

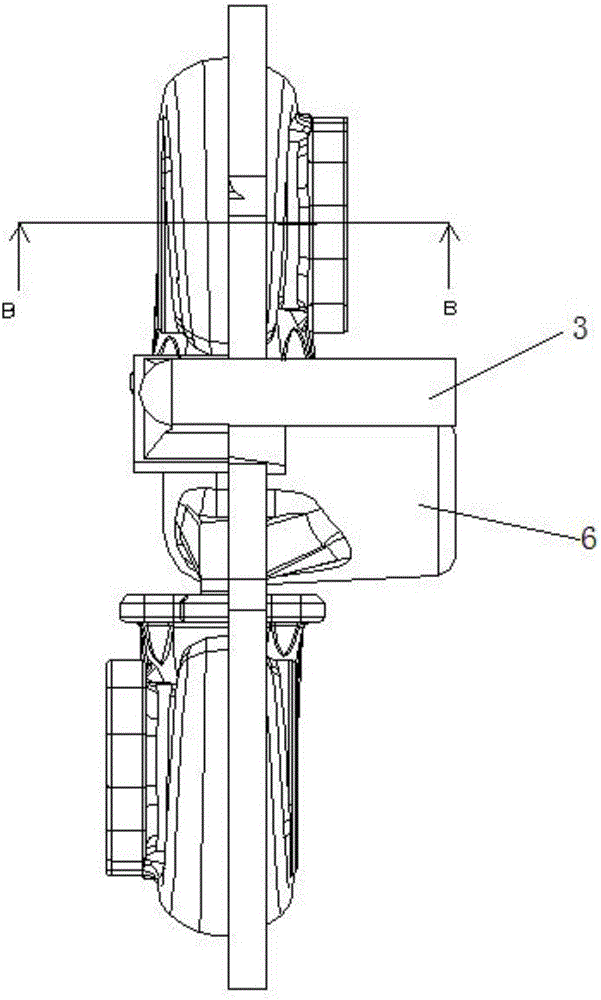

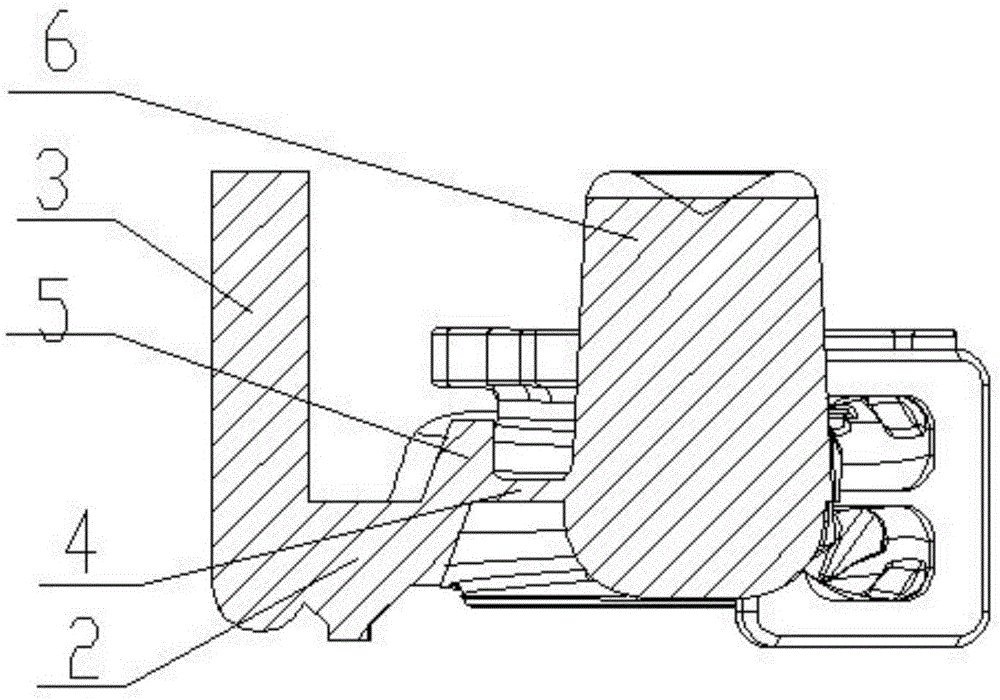

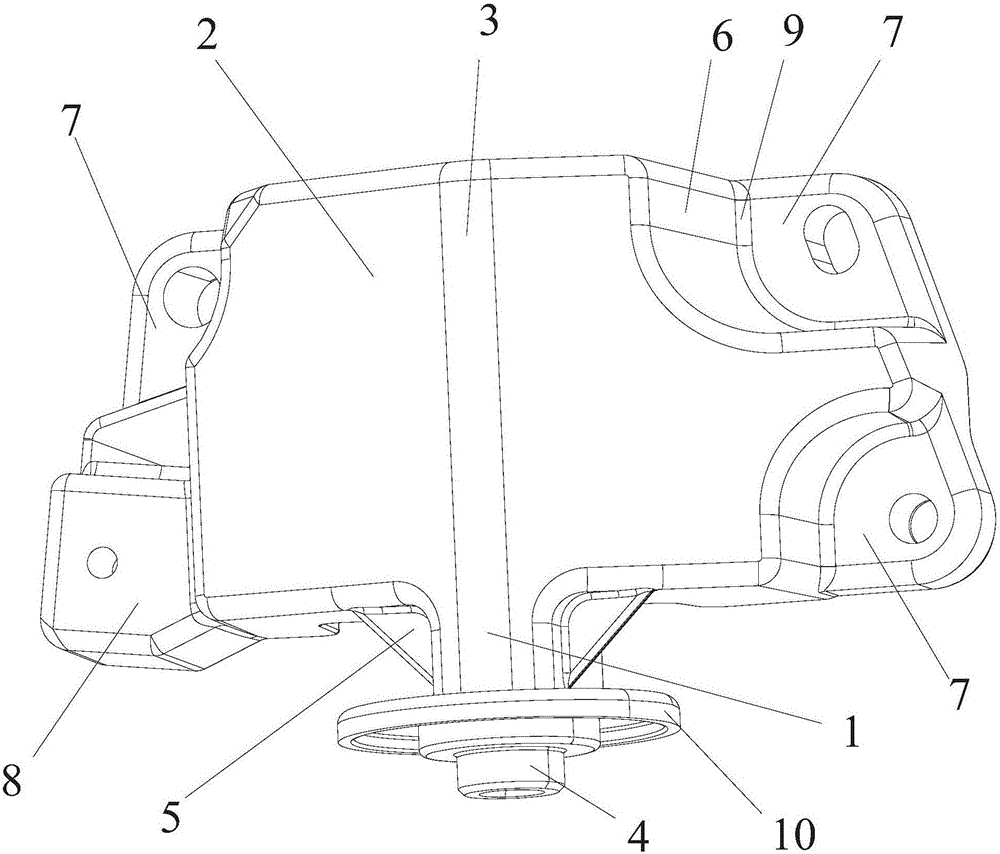

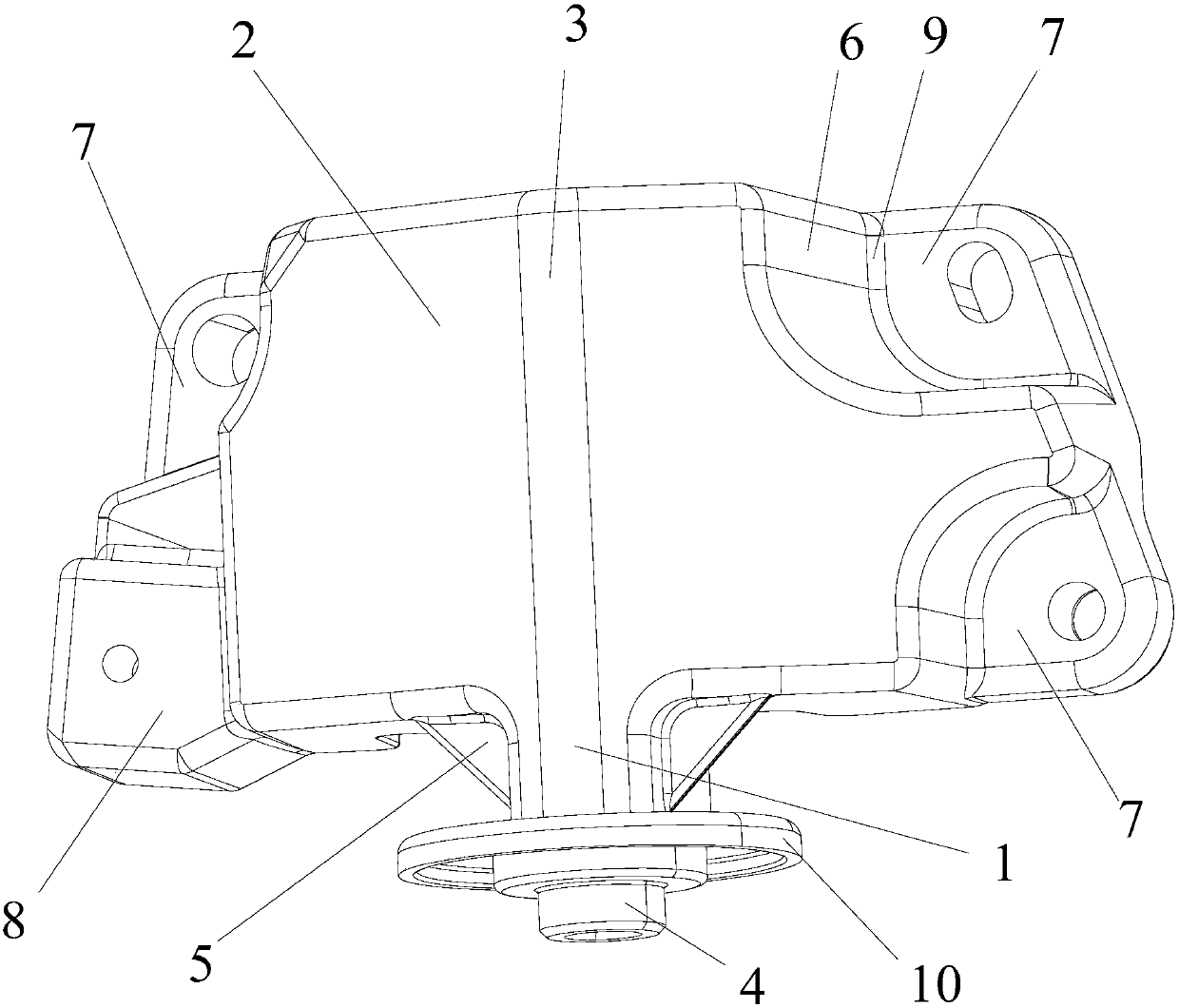

Automobile sector-shaped supporting frame

The invention relates to an automobile sector-shaped supporting frame. The automobile sector-shaped supporting frame comprises a supporting frame handle and a supporting frame fan wing which is integrally connected with the supporting frame handle. A middle beam is arranged in the middle of the supporting frame fan wing. An inserting shaft is arranged at the end of the supporting frame handle. Stiffening plates are arranged between the end of the supporting frame fan wing and the end of the supporting frame handle. Extending panels are arranged at three corners of the supporting frame fan wing separately and a connecting plate is arranged at the forth corner of the supporting frame fan wing. The edges of the extending panels are connected with locating plates and rounded corner transition areas are arranged between the extending panels and the locating plates.By means of the automobile sector-shaped supporting frame, the strength of the whole supporting frame is greatly improved by using the middle beam, the stiffening plates and the rounded corner transition areas. Furthermore, molten aluminum can flow and fill well between the thin extending panels and the thick locating plates because of the arrangement of the rounded corner transition areas when a mould cavity is filled with the molten aluminum, so that the cold shut phenomenon can be avoided, the overall density of the products can be uniform, the strength of the products can be strengthened and the requirements can be met better.

Owner:昆山博而准精密机械有限公司

Forging bucket tooth casting, forging and quenching integrated production process

ActiveCN112170774APromote ruptureImprove toughnessMetal-working apparatusFurnace typesTemperingMechanical engineering

The invention discloses a forging bucket tooth casting, forging and quenching integrated production process. The forging bucket tooth casting, forging and quenching integrated production process comprises a casting step, a water toughening step, a material adding step, a forging step, a trimming step and a quenching step. After a trimmed casting is washed clean, low-temperature tempering and quenching are conducted, and therefore a bucket tooth is obtained. According to the forging bucket tooth casting, forging and quenching integrated production process, casting and forging are combined, thenumber of air holes of the bucket tooth is reduced, the toughness, impact resistance, abrasion resistance and other mechanical properties of the bucket tooth are improved, and meanwhile the productioncost can be saved.

Owner:浙江继望锻造科技有限公司

Alum ore tailing alcohol-based casting paint and manufacturing method thereof

InactiveCN104399867AImprove breathabilityAvoid Cold ShutFoundry mouldsFoundry coresFiberSodium Bentonite

The invention discloses an alum ore tailing alcohol-based casting paint, which is characterized by being composed of the following raw materials in parts by weight: 65 to 80 parts of lightly-calcined magnesite, 25 to 30 parts of perlite powder, 30 to 50 parts of alum ore tailing, 2 to 4 parts of bentonite, 0.1 to 0.4 part of EFKA-2035 defoaming agent, 0.4 to 0.7 part of carbon fiber, 0.2 to 0.6 part of antioxidant 1212, 0.4 to 0.8 part of calcium stearate, 0.7 to 2.1 parts of dodecyl trimethyl ammonium sulfate, 14 to 18 parts of pine wood bran, 1 to 3 parts of sodium carboxymethyl starch, 5 to 8 parts of ethyl silicate, 45 to 60 parts of ethanol, and 3 to 6 auxiliary agents. The alum ore tailing is modified, the compactness of the alum ore tailing is changed, the modified alum ore tailing is added into the raw materials to enhance the breathability of the paint so as to avoid the phenomenon of cold shut between the liquid metal and the coating during the casting process, and thus the obtained casting member quality is improved finally.

Owner:WUHU HONGKUN AUTO PARTS

Low-pressure precision casting method for magnesium alloy thin-wall shell part

PendingCN114273638AEnsure dimensional accuracyEnsure surface roughnessFoundry mouldsFoundry coresNonferrous metalMold filling

The invention discloses a low-pressure precision casting method for a magnesium alloy thin-wall shell part, and belongs to the field of non-ferrous metal part casting methods. According to the method, through wax mold manufacturing, sand hanging and sintering, a mold shell with a high surface quality, high size precision and an internal complex structure is obtained, a magnesium melt is prevented from reacting and oxidizing with the mold shell by internally brushing a coating, and the surface quality is guaranteed; then, a pouring scheme is designed, and key process parameters such as low-pressure casting mold filling time and crystallization pressure are reasonably controlled in combination with a mold shell heat preservation measure, an anti-oxidation measure and a filtering device, so that stable flowing and anti-oxidation of a melt in the rising and mold filling process, in-place mold filling under the pressure condition and feeding in the solidification process are ensured; the internal metallurgical quality of the casting is guaranteed, a complex thin-wall structure is achieved, and meanwhile good surface quality and dimensional accuracy are achieved. By adopting the casting method, not only are the metallurgical quality and the yield of the magnesium alloy casting improved, but also materials are saved, the process yield of the casting is improved, and economic benefits are improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A car sector bracket

The invention relates to an automobile sector-shaped supporting frame. The automobile sector-shaped supporting frame comprises a supporting frame handle and a supporting frame fan wing which is integrally connected with the supporting frame handle. A middle beam is arranged in the middle of the supporting frame fan wing. An inserting shaft is arranged at the end of the supporting frame handle. Stiffening plates are arranged between the end of the supporting frame fan wing and the end of the supporting frame handle. Extending panels are arranged at three corners of the supporting frame fan wing separately and a connecting plate is arranged at the forth corner of the supporting frame fan wing. The edges of the extending panels are connected with locating plates and rounded corner transition areas are arranged between the extending panels and the locating plates.By means of the automobile sector-shaped supporting frame, the strength of the whole supporting frame is greatly improved by using the middle beam, the stiffening plates and the rounded corner transition areas. Furthermore, molten aluminum can flow and fill well between the thin extending panels and the thick locating plates because of the arrangement of the rounded corner transition areas when a mould cavity is filled with the molten aluminum, so that the cold shut phenomenon can be avoided, the overall density of the products can be uniform, the strength of the products can be strengthened and the requirements can be met better.

Owner:昆山博而准精密机械有限公司

Method for producing flap valve cover by adopting resin sand

InactiveCN107774869AAvoid Cold ShutAvoid deformation defects such as warpingFoundry mouldsMoulding machinesIntermediate frequencyWater transport

The invention discloses a method for producing a flap valve cover by using resin sand. Firstly, a mold and a sand box are made. The mold has an integrated structure, and the sand box is integrally cast with nodular iron; the original sand and the curing agent are evenly mixed, and furan is added in proportion Mix the resin evenly; fill the sand box with resin sand until the sand box is full and scrape it flat, then place it on the vibration table and shake it mechanically; prepare the coating, and apply the coating on the surface of the formed resin sand. Coating method: After the coating is dry, bake the surface of the coated resin sand with a blowtorch; hoist the sand box to the pouring table and then close the box; add the raw materials to the intermediate frequency furnace for melting according to the conventional nodular iron ratio. The spheroidization is carried out according to the conventional method; the molten iron after spheroidization is transported to the pouring table for pouring, and the box clamp is released after pouring for heat preservation; the temperature is lowered to below 200 degrees and then the sand is shaken; the casting is cleaned.

Owner:QINGDAO TIANDI CASTING CO LTD

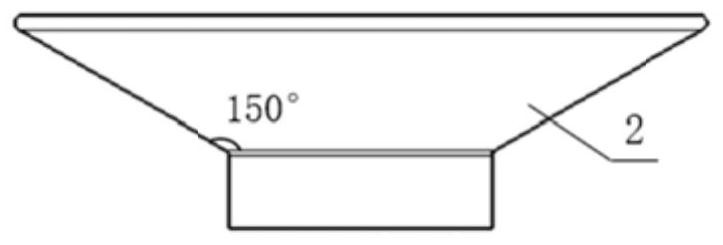

Side casting system

InactiveCN103722129APrevent splashAvoid Cold ShutFoundry mouldsFoundry coresMaterials scienceCasting

The invention discloses a side casting system. The side casting system comprises a die shell body, a cavity comprising a casting molding portion and a riser portion is in the die shell body, the side casting system also comprises a side casting apparatus connected to the side portion of the die shell body, a channel is in the side casting apparatus, one end of the channel is an outer sprue open to the outside, and the other end of the channel is at least one feeding port open to the cavity. The side casting system allowing a casting liquid to be injected from the side portion can effectively avoid the splashing and cold shut phenomena of the casting liquid.

Owner:SHANGHAI ZHONGZHOU SPECIAL ALLOY MATERIALS

An integrated production process of forging bucket teeth with casting, forging and quenching

ActiveCN112170774BAvoid inhalationAvoid excessive oxidationMetal-working apparatusFurnace typesProcess engineeringIndustrial engineering

The application discloses an integrated production process of forging bucket teeth with casting, forging and quenching, which includes a casting step, a water toughening treatment step, a feeding step, a forging step, a trimming step and a quenching step. After the trimmed casting is rinsed, it is tempered at a low temperature and quenched to obtain bucket teeth. This forged bucket tooth casting, forging and quenching integrated production process reduces the number of pores in the bucket teeth by combining casting and forging, and improves the mechanical properties of the bucket teeth such as toughness, impact resistance and wear resistance. Conducive to saving production costs.

Owner:浙江继望锻造科技有限公司

Multi-furnace and multi-liquid-rise-pipe molten aluminum mold filling method structure for sand mold low-pressure cast gas-tight thin-walled shells

The invention discloses a multi-furnace and multi-liquid-rise-pipe molten aluminum mold filling method structure for sand mold low-pressure cast gas-tight thin-walled shells. The multi-furnace and multi-liquid-rise-pipe molten aluminum mold filling method structure comprises liquid rise pipes and a thin-walled aluminum alloy casting, and is characterized in that a liquid flow tank is arranged above the liquid rise pipes in the horizontal direction; the two ends of the liquid flow tank and positions capable of being used for arrangement are fixedly connected with the thin-walled aluminum alloy casting through sprue gates; and the number of the liquid rise pipes and the number of the sprue gates are each at least two. The multi-furnace and multi-liquid-rise-pipe molten aluminum mold filling method structure is low in cost, convenient to install, stable and reliable, molten aluminum is injected into the liquid flow tank from the liquid rise pipes and cannot enter the thin-walled aluminum alloy casting through the sprue gates until the liquid flow tank is filled with the molten aluminum, in this way, it can be ensured that turbulent flow is controllable before the molten aluminum pouring, and therefore cold shut and gas inclusions are eradicated.

Owner:NANTONG L S LIGHT METAL FORMING

A Vertical Line Production Process for Ductile Iron Molds with Large Differences in Wall Thickness

ActiveCN110899623BEfficient productionPrevent shrinkageFoundry mouldsFoundry coresEngineeringDuctile iron

The invention discloses a process for producing a ductile iron piece mold with large wall thickness difference through a vertical line. The process comprises a pouring device. The pouring device comprises a pouring gate assembly, a riser assembly and a vertically-arranged pouring gate. The pouring gate assembly and the riser assembly are both inclined upwards relative to the pouring gate and are both communicated with the pouring gate, the riser assembly is arranged above the pouring gate assembly, and outlets of the riser assembly and the pouring gate assembly correspond to the thick and large positions of the ductile iron part, wherein a necking neck is arranged at the outlet of the pouring gate assembly, a riser neck is arranged at the outlet of the riser assembly, and an intercepting block is arranged on the pouring gate and located above the pouring gate assembly. With application of the process for producing the ductile iron piece mold with the large wall thickness difference through the vertical line, efficient production of ductile iron pieces with the large wall thickness difference is realized and shrinkage cavities in the thick and large positions and cold shut in the thin wall positions can be avoided.

Owner:BAODING DONGLI MASCH MFG CO LTD

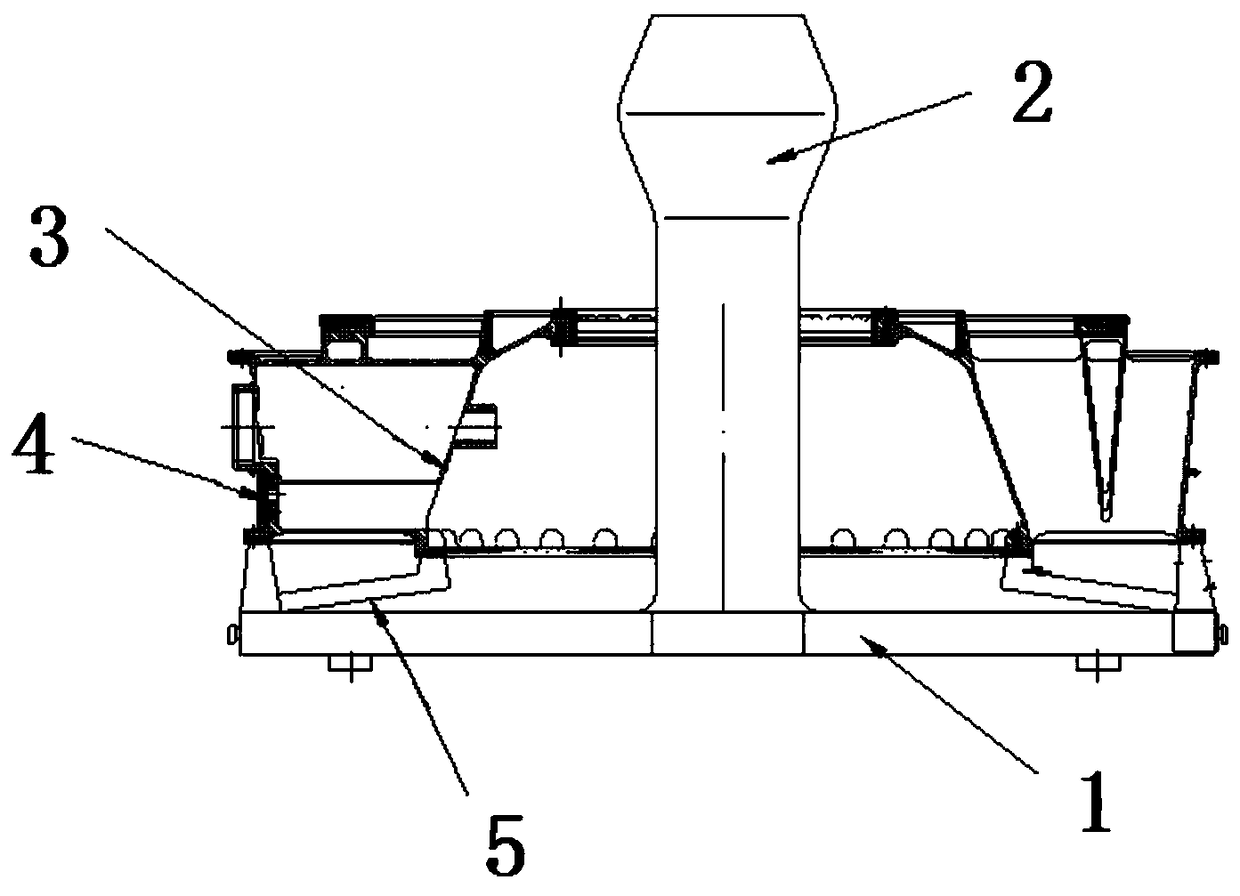

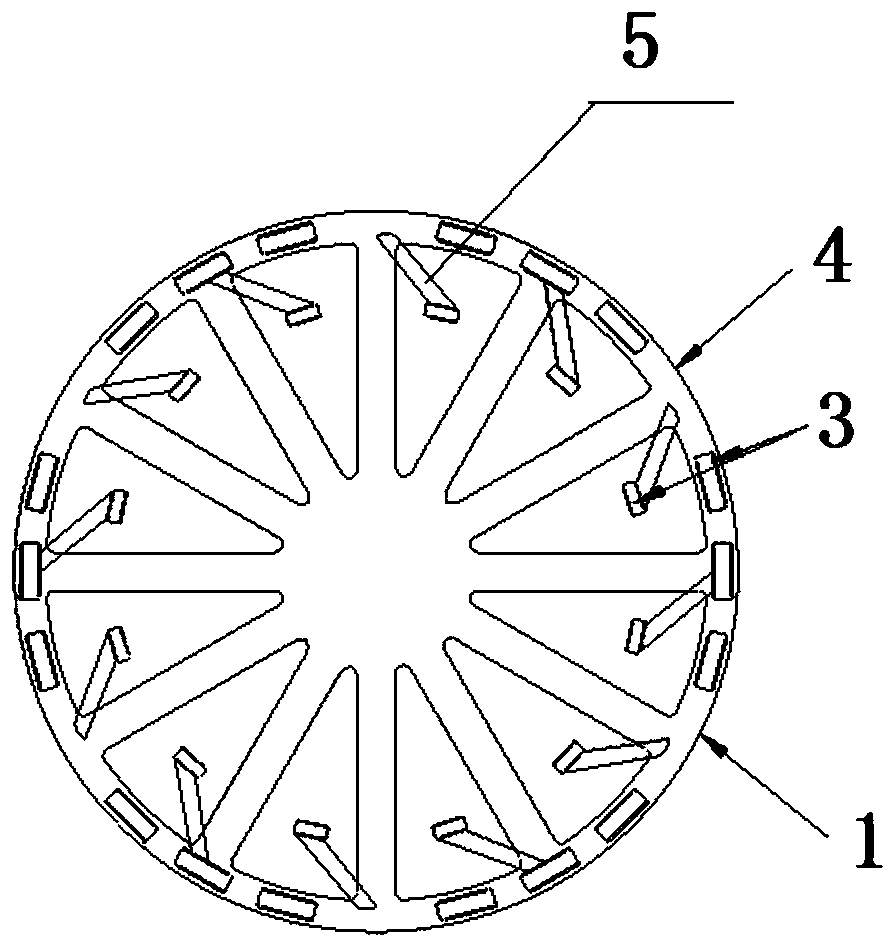

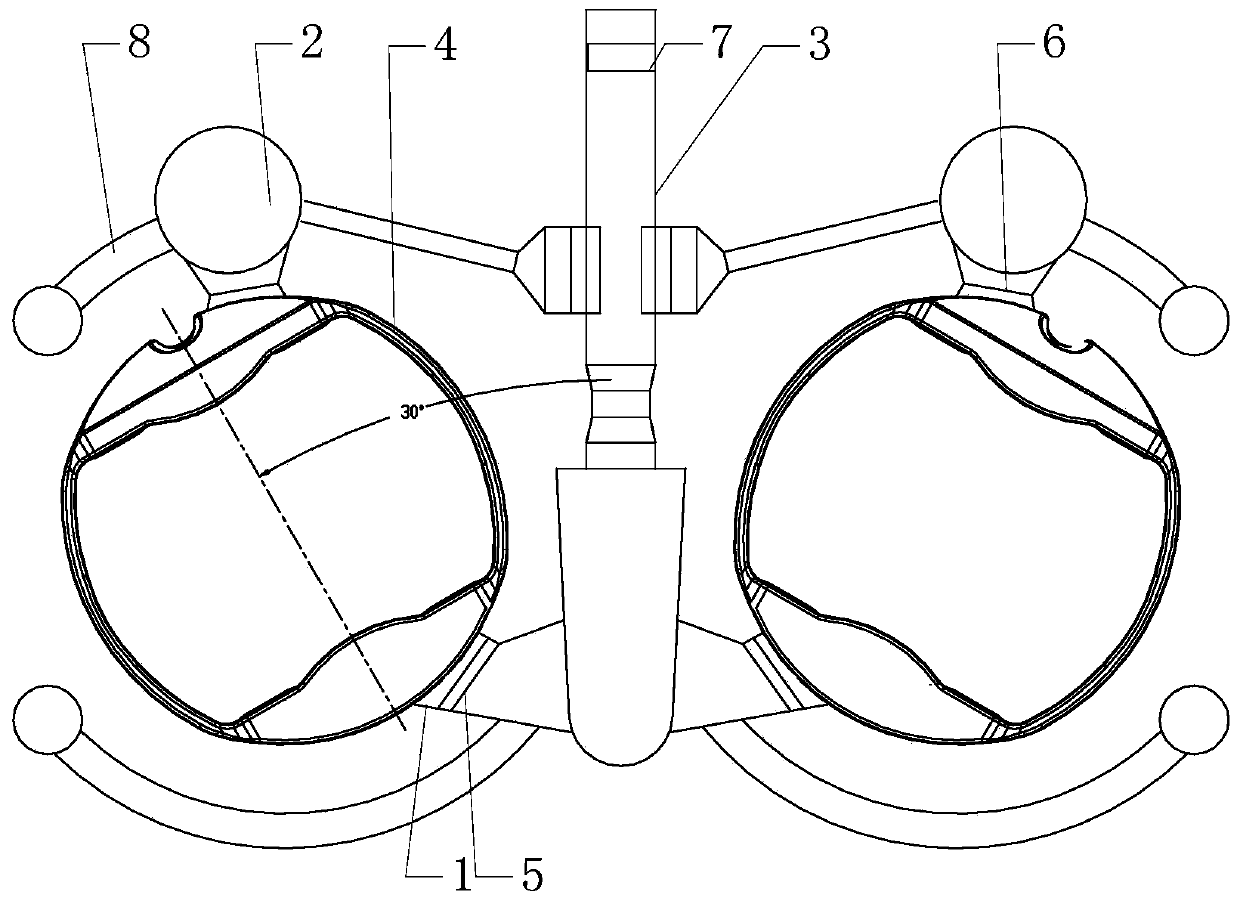

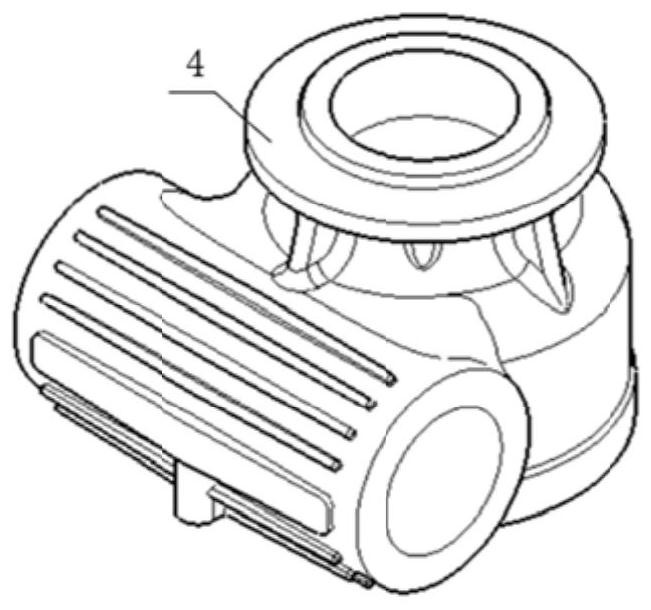

Claw-shaped circumferential equal-division type pouring system for aluminum alloy shell and pouring method of claw-shaped circumferential equal-division type pouring system

An aluminum alloy shell claw-shaped circumferential equant pouring system and a pouring method thereof are characterized in that the shapes and sizes of a riser tube, a cross gate and an ingate are reasonably set, impact of molten aluminum and a cavity wall is reduced, it is guaranteed that the casting mold filling process is stable and effective, solidification feeding is facilitated, and therefore the shrinkage porosity and shrinkage cavity defects in the casting production process are reduced, and the casting quality is improved. And the casting blank rejection rate is reduced. And the solidification time is greatly shortened by reducing the contact area of the flow gate and the bottom of the casting. The casting mold has high practicability, and the forming quality and production efficiency of castings can be effectively improved. And the device is simple in structure and easy to popularize.

Owner:NANJING UNIV OF TECH

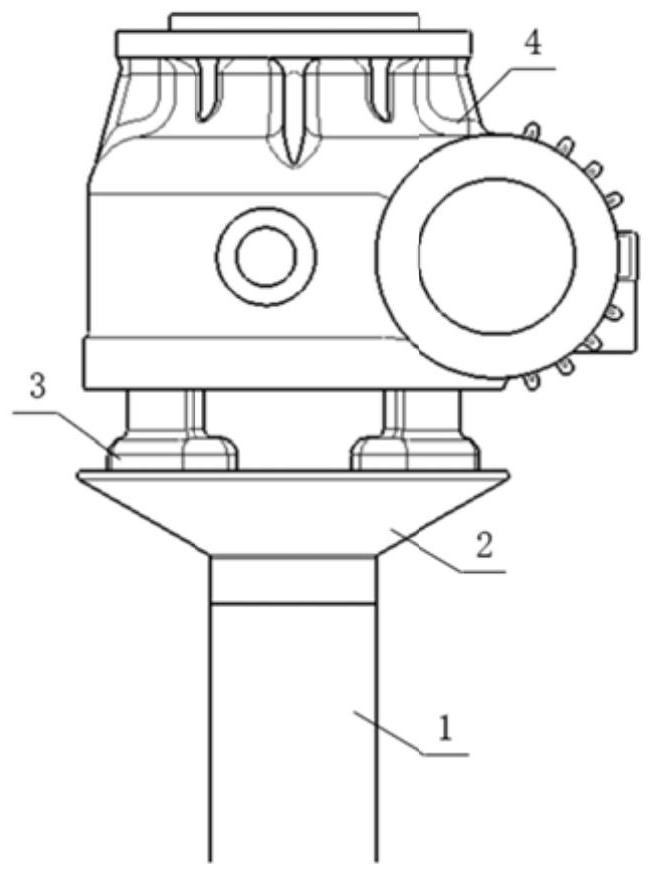

A casting process for the injection head of an injection molding machine

ActiveCN104084544BAvoid Cold ShutReduce liquid contractionFoundry mouldsFoundry coresThick wallCasting mold

The invention discloses a casting technology of an injection head of an injection molding machine. The casting technology of the injection head of the injection molding machine is characterized by comprising the following technical steps:1, arranging an ingate of a mold cavity in the thin wall of a casting, adjusting the temperature distribution after casting from an integral casting mold at a part far away from the thick wall, so that not only is the liquid shrinkage at the thick wall reduced, but also cold shut at the thin wall is prevented when low-temperature casting is adopted; 2, arranging a chilling block at the lower end of a relatively thick part of a casting in the mold cavity, accelerating the cooling of the thick wall part, and when an integral injection head is formed, condensing or condensing from bottom to top; and 3, arranging a dead head at the relatively thick part of the casting so as to perform compensation shrinkage on the relatively thick part of the casting and reduce defects. The shrinkage defect of the injection head casting can be reduced effectively and the quality of the injection head casting is improved by adopting the technological improvement.

Owner:GUANGDONG HENGCHENG TECH

Lost foam casting coating and preparation method thereof

The invention discloses a lost foam casting coating, which comprises fire-proof powder, phenolic resin, white latex, calcium bentonite and isopropyl alcohol, wherein the fire-proof powder includes bauxite and quartz powder. The bauxite is formed by uniformly mixing the following components: 80% of particles with the granularity ranging from -280 to -310, 14% of particles with the granularity ranging from -280 mesh to -190 mesh and 6% of particles with the granularity ranging from -90 mesh to -190 mesh. The preparation method of the lost foam casting coating is as follows: calcining selected bauxite ore at the temperature of 1510-1550 DEG C; grinding calcined clinkers to acquire the granularity particles with the granularities respectively; evenly mixing the particles according to the composition proportion; and mixing the mixed bauxite with quartz powder, phenolic resin, white latex, calcium bentonite and isopropyl alcohol. According to the invention, bauxite is distributed according to particle sizes, and bauxite particles of different sizes are alternately arranged after even mixing. As a result, the compactness is changed, the air permeability is strengthened, the cold shut phenomenon occurring between liquid metal and the coating is avoided, and finally the quality of the casting produced through lost foam casting is improved.

Owner:ANYUE COUNTY JINLONG MACHINERY MFG

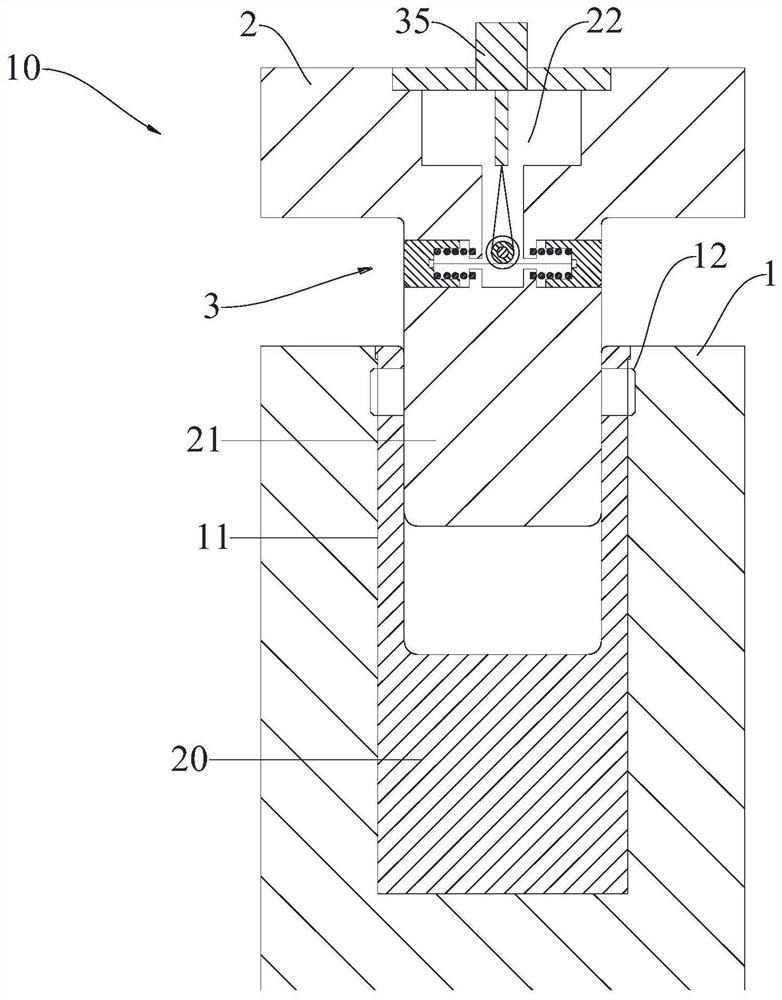

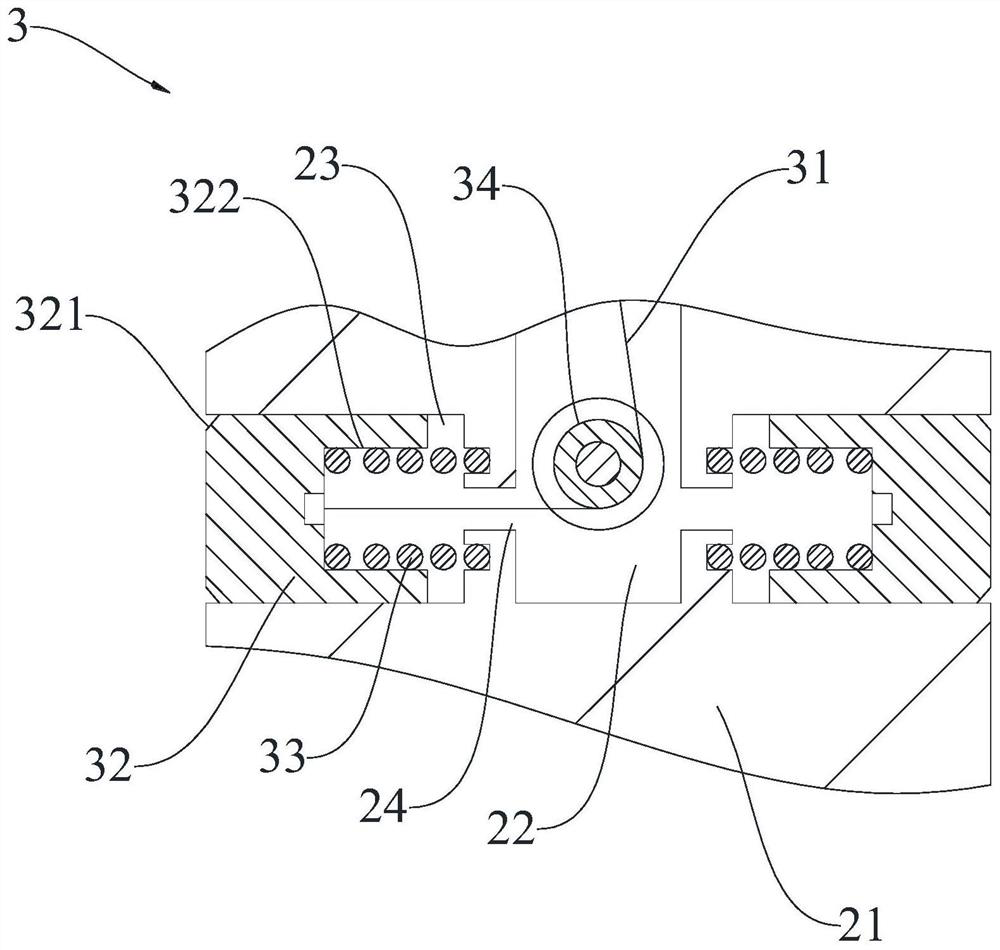

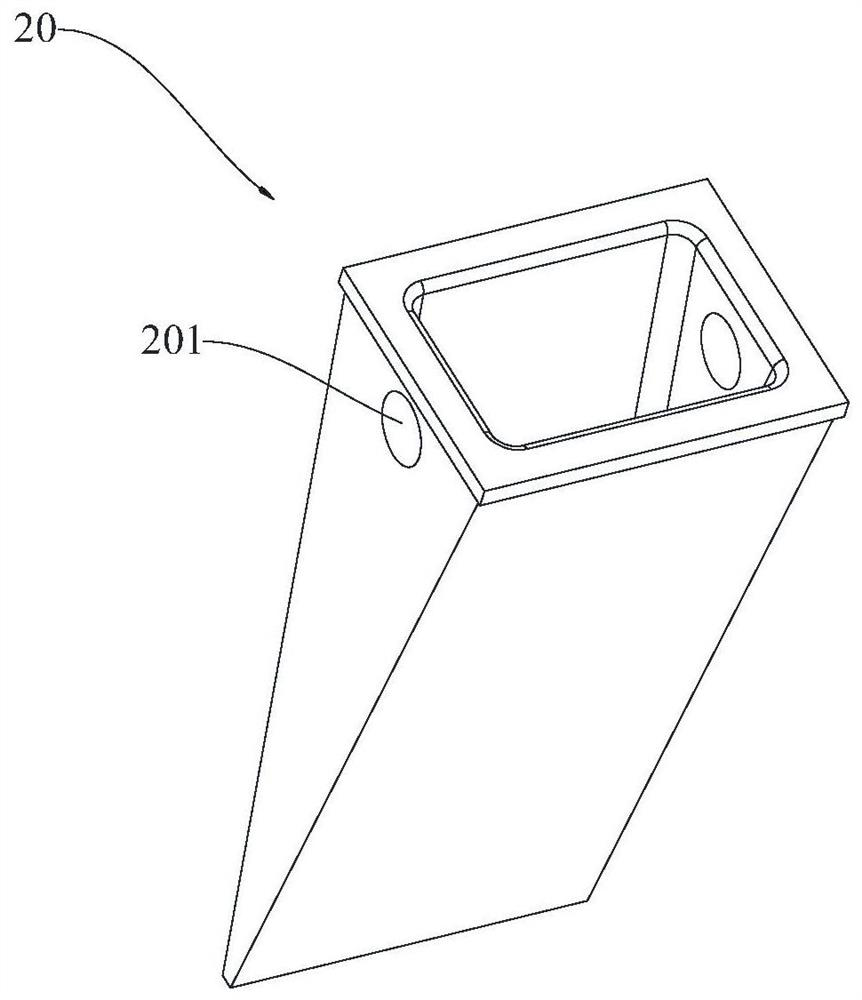

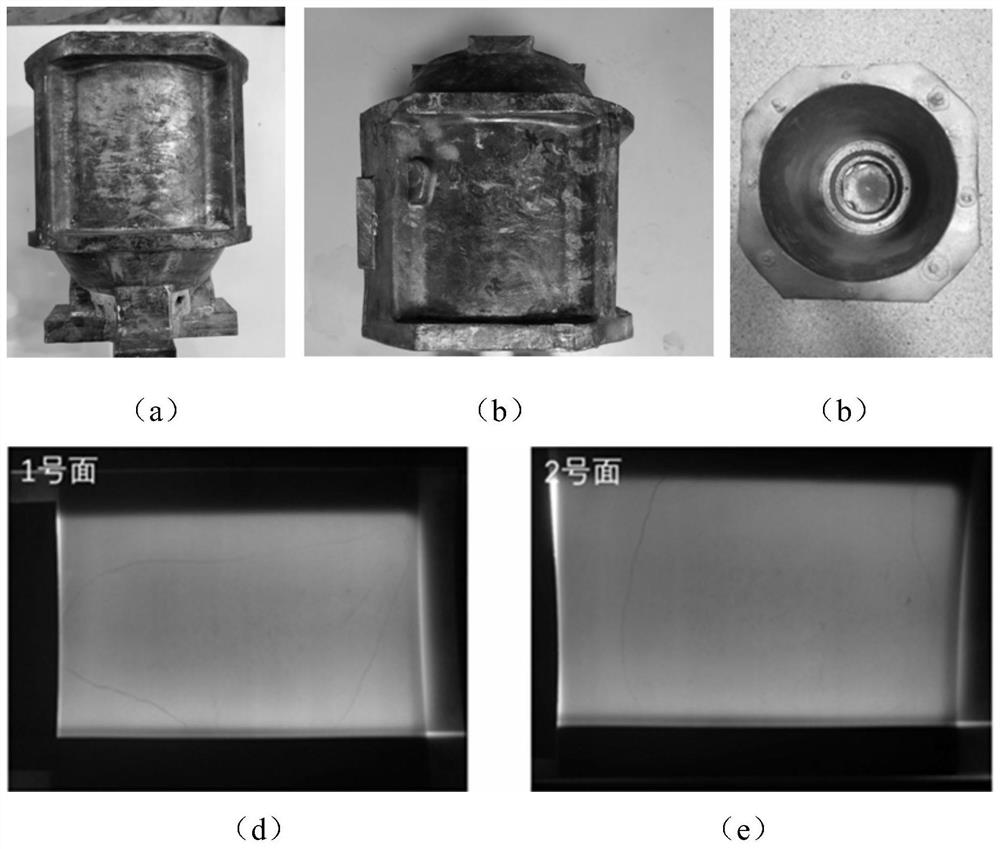

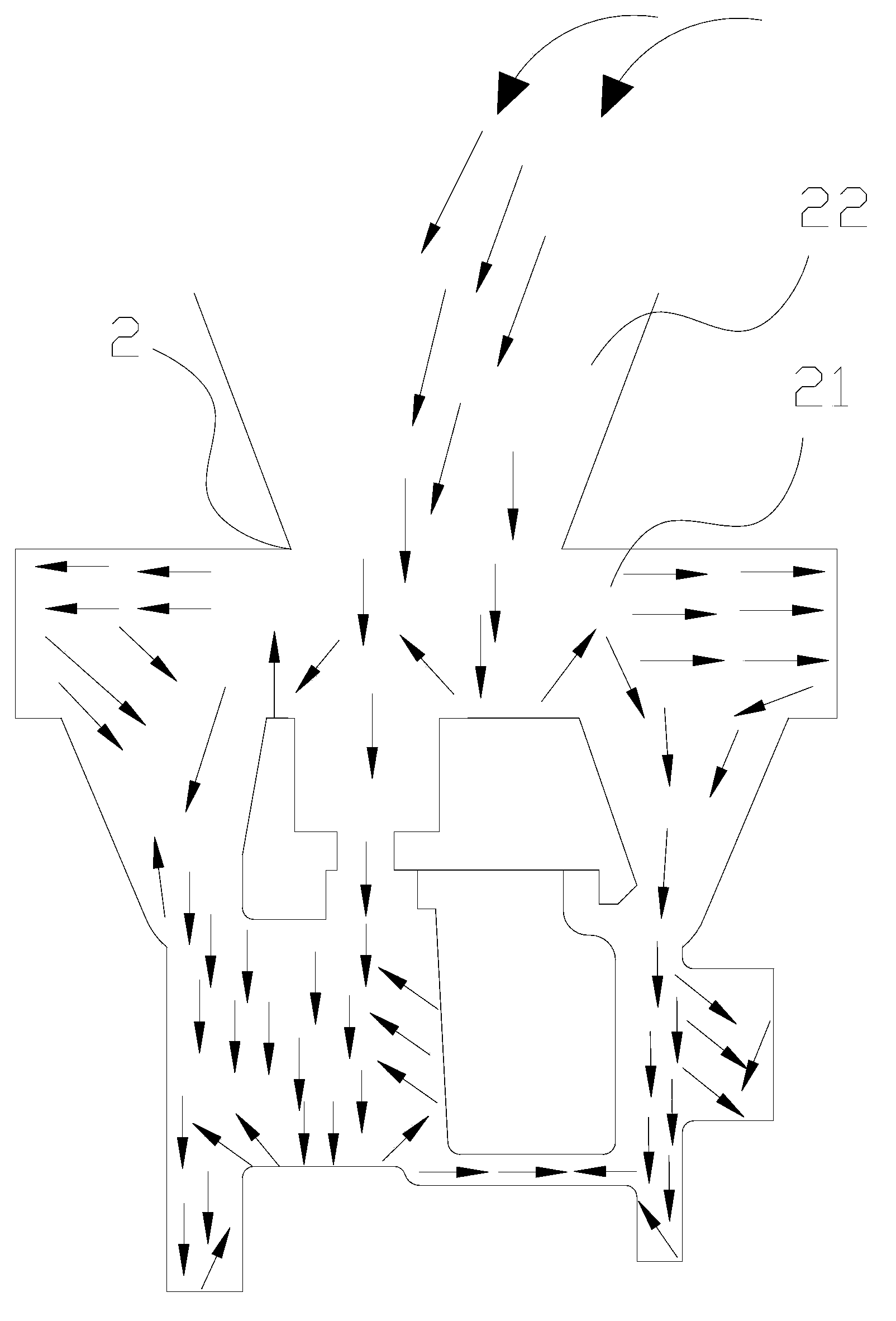

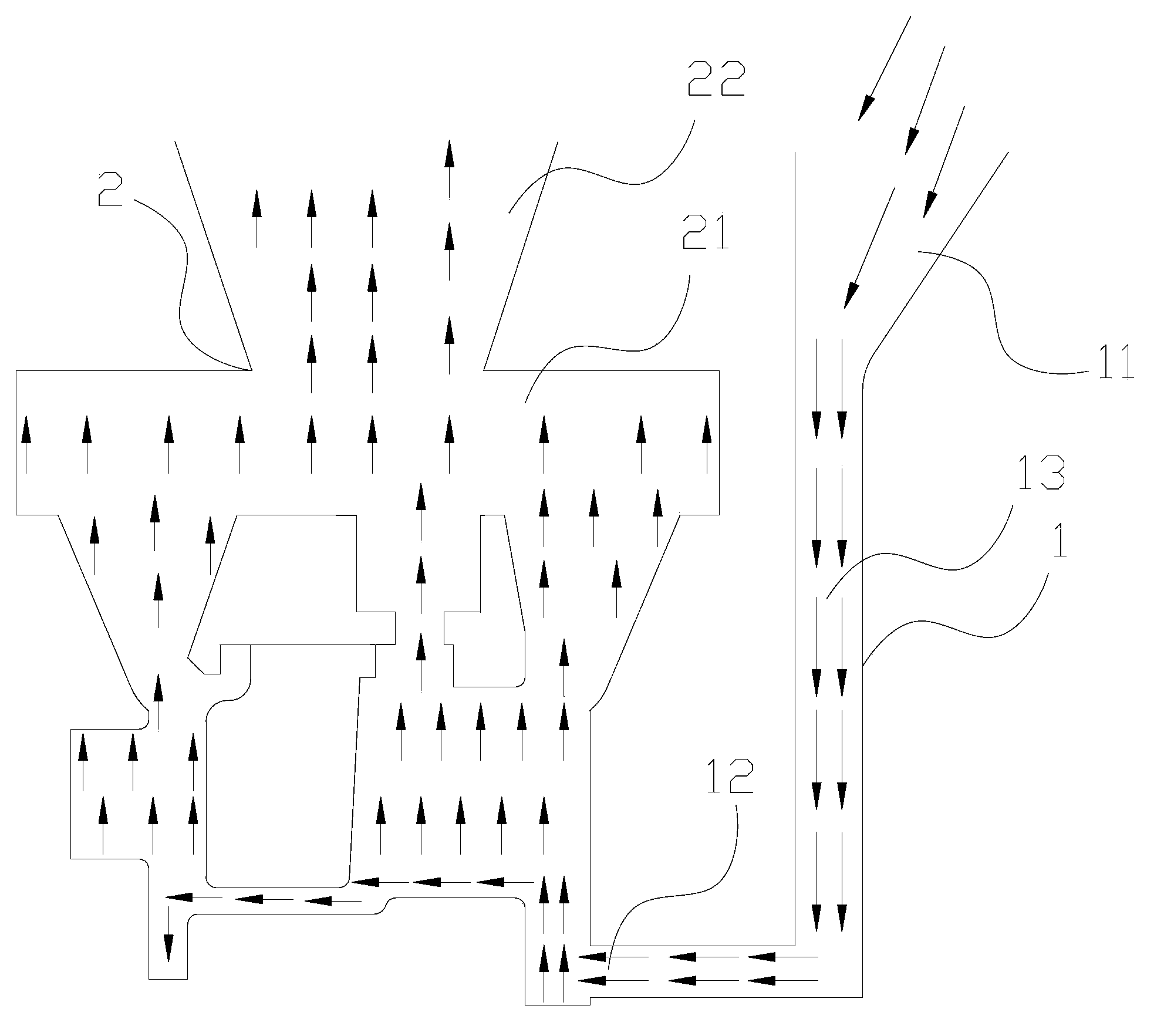

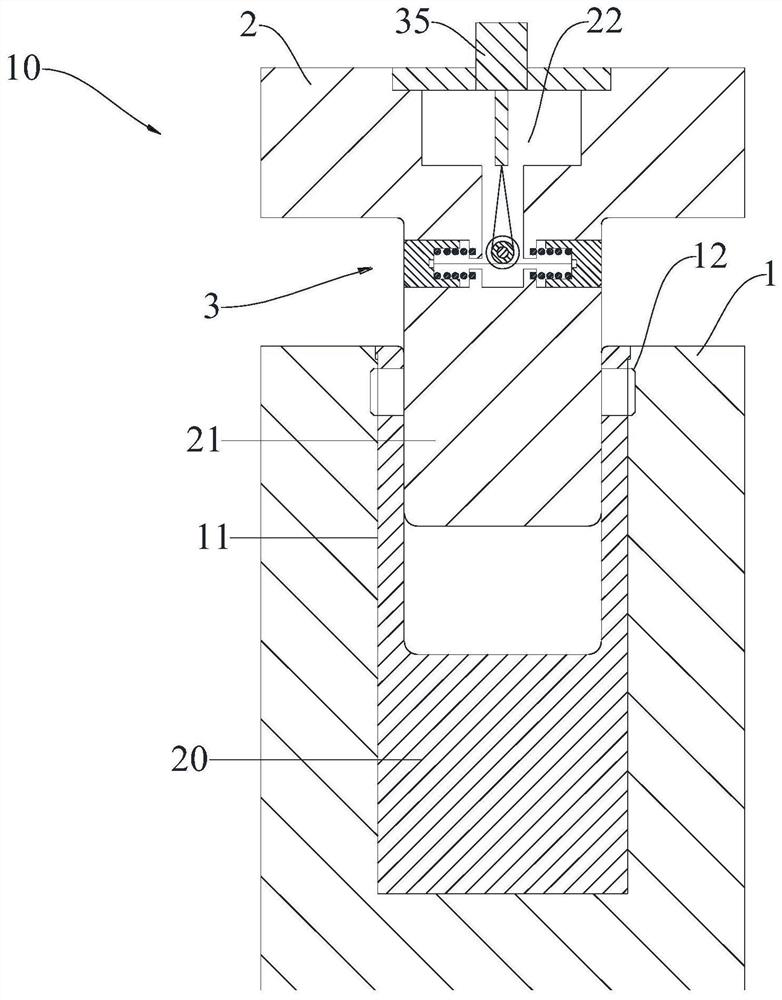

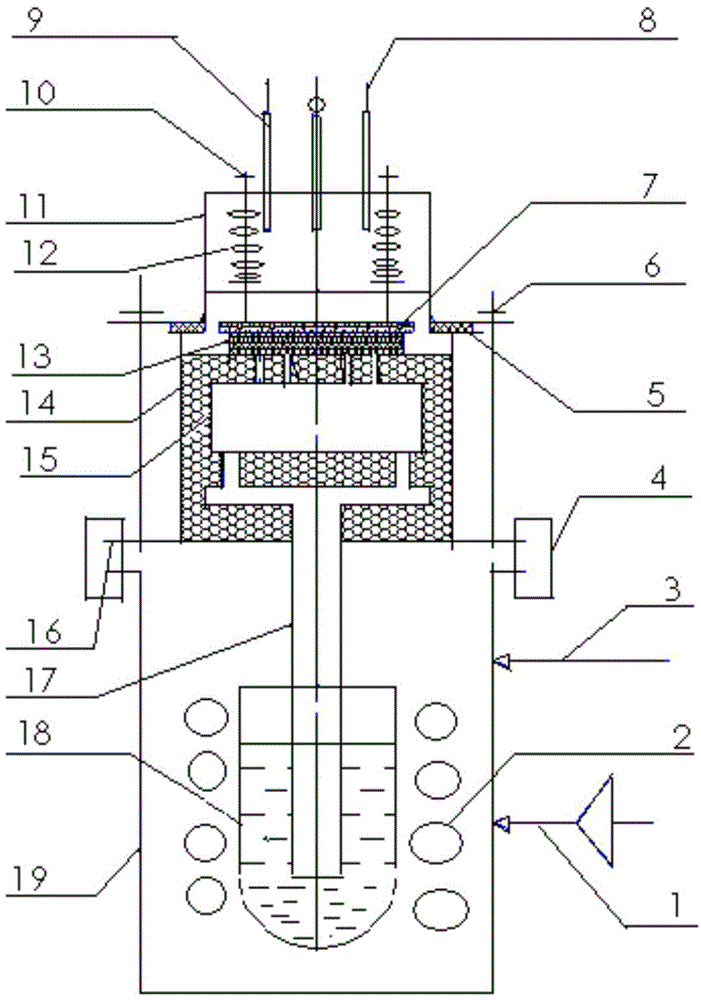

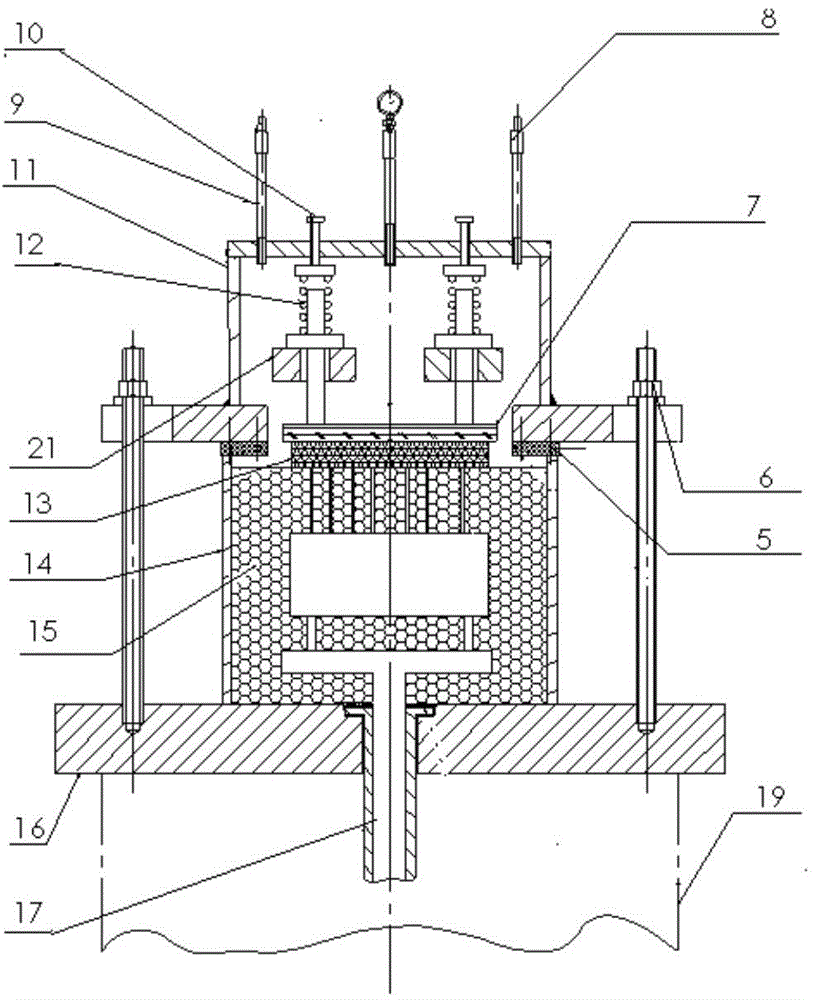

A kind of magnesium alloy anti-gravity casting device and method thereof

The invention discloses a magnesium alloy counter-gravity casting device. A melting furnace 2 and a crucible 18 are arranged in a lower tank 19; the upper part of the lower tank 19 is isolated from outside through a sealing cover plate 16; the lower tank 19 is connected to a first protective gas pipeline 3 between the melting furnace 2 and the sealing cover plate 16; the middle lower part of the lower tank 19 is connected to a pressing device 1; a negative pressure gas protection box 11 is connected to a second protective gas pipeline 8 and a negative pressure pipeline 9. The invention also discloses a method for casting with the device. Through the magnesium alloy counter-gravity casting device, large, complex and thin-wall magnesium alloy castings can be produced; the castings are high in surface quality and safety, and the production requirement can be met; the magnesium alloy counter-gravity casting device is simple to manufacture, applicable to scale production of magnesium alloys and high in production efficiency.

Owner:HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com