A car sector bracket

A fan-shaped, automotive technology, applied in mechanical equipment, fixtures, etc., can solve the problems of local density drop of products, poor filling at joints, and great difference in wall thickness, so as to avoid cold insulation, strengthen strength, and improve strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

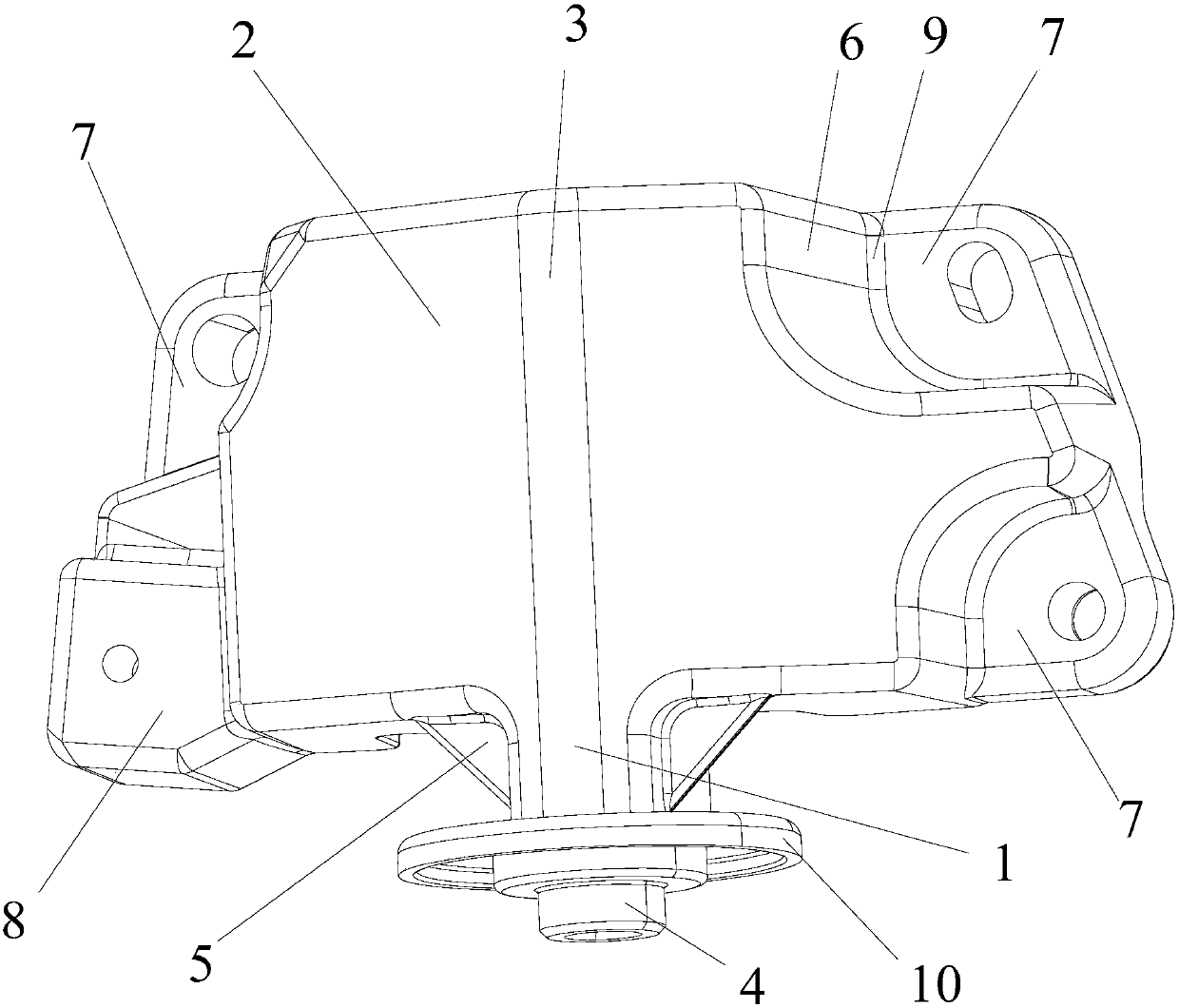

[0012] Such as figure 1 Shown, a kind of automobile fan support, it comprises support handle 1 and the support fan wing 2 that is integrally connected with support handle 1; The center of described support fan wing 2 is provided with intermediate beam 3; The end of described support handle 1 is provided with Insertion shaft 4; a reinforcement plate 5 is provided between the end of the bracket fan 2 and the end of the bracket handle 1; the three corners of the bracket fan 2 are respectively provided with extension pieces 6; the bracket fan 2 The fourth corner is set as a connecting plate 8; the edge of the extension sheet 6 is connected to the positioning plate 7; a rounded transition area 9 is provided between the extension sheet 6 and the positioning plate 7; hole; the connection plate 8 is provided with a connection hole; the upper end of the insertion shaft 4 is located on the bracket handle 1 and a round cover 10 is also provided.

[0013] The fan-shaped bracket for autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com