Die for cast copper impeller casting

An impeller and mold technology, used in manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of inconsistent melting point, high casting rejection rate, inconsistent oxidation, etc., to achieve little difference, uniform thickness, and prevent uneven thickness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

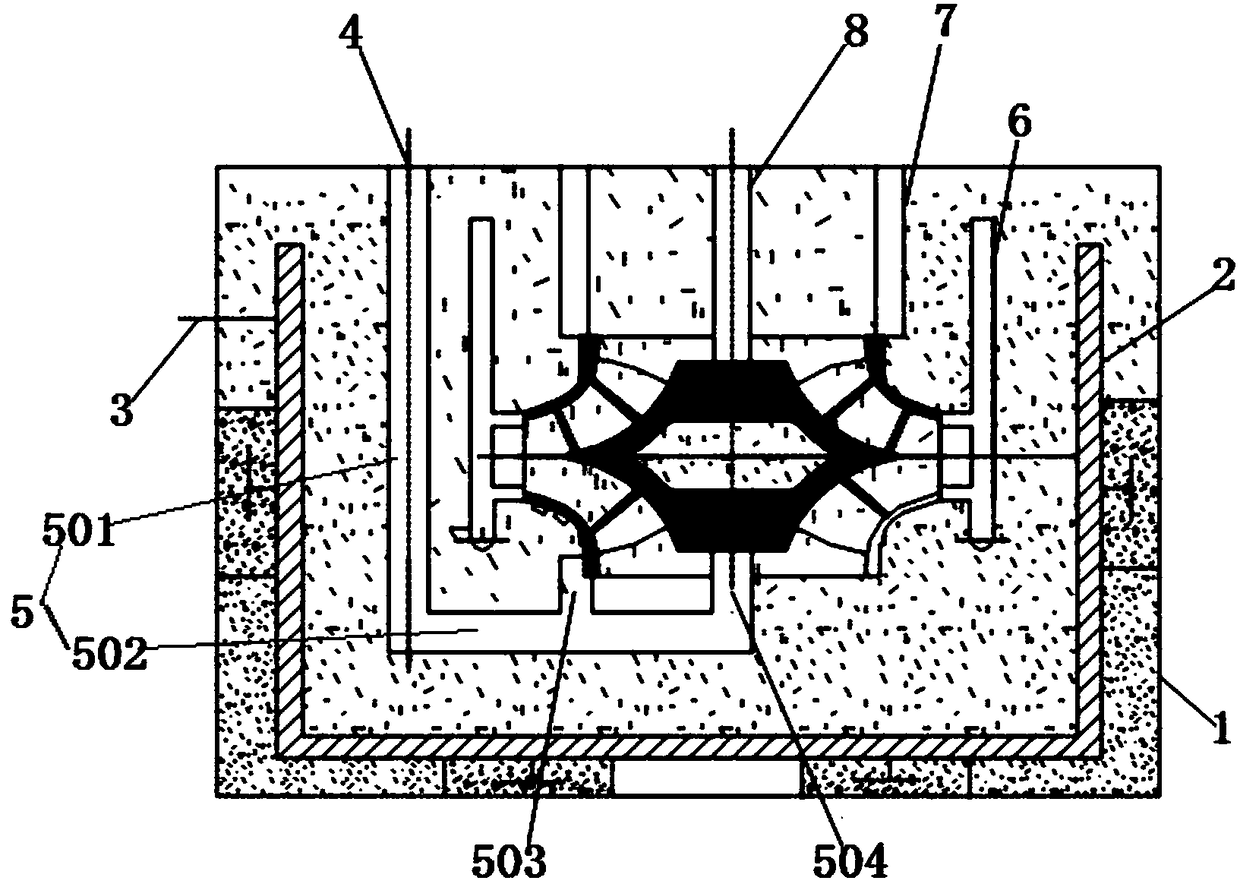

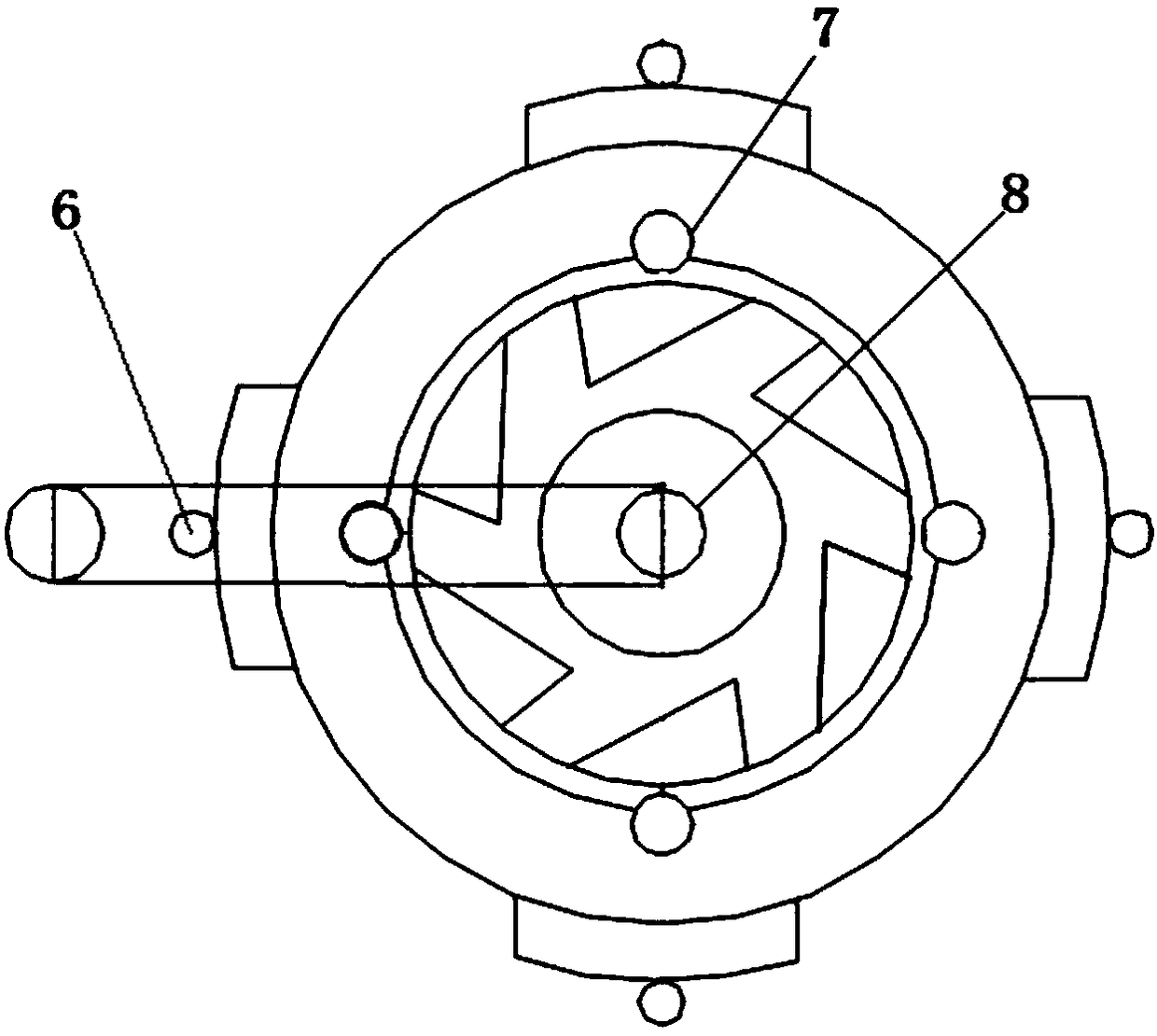

[0022] Such as Figure 1-2 As shown, a mold for casting a copper impeller includes a casting mold, and the casting mold includes a mold box 1, and a thermistor 2 is installed around the inner side of the mold box 1, and the thermistor 2 is passed through a heat-resistant brick. fixed inside the mold box 1; the thermistor 2 is connected to an external power supply through a wire 3;

[0023] The upper end of the molding box 1 is also provided with a main gate 4, and the inside of the molding box 1 is also provided with a copper sprue 5, and the copper sprue 5 includes a main sprue 501, and the main sprue 501 is formed by the molded box 1. The main gate 4 at the upper end of the box 1 is vertically downward to the bottom of the impeller mud core, and the lower end of the main runner 501 is also connected with the horizontal runner 502; the upper end of the horizontal runner 502 is also connected with the first runner 503 and the second runner respectively. Runner 504; the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com