Casting mold for vortex-induced vibration suppression device

A suppression device and vortex-induced vibration technology, applied in the field of casting molds, can solve the problems of difficult mechanization and batch production, difficult mechanization production, complex manufacturing process, etc., to achieve uniform temperature, improve surface quality, and smooth circulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the drawings and embodiments.

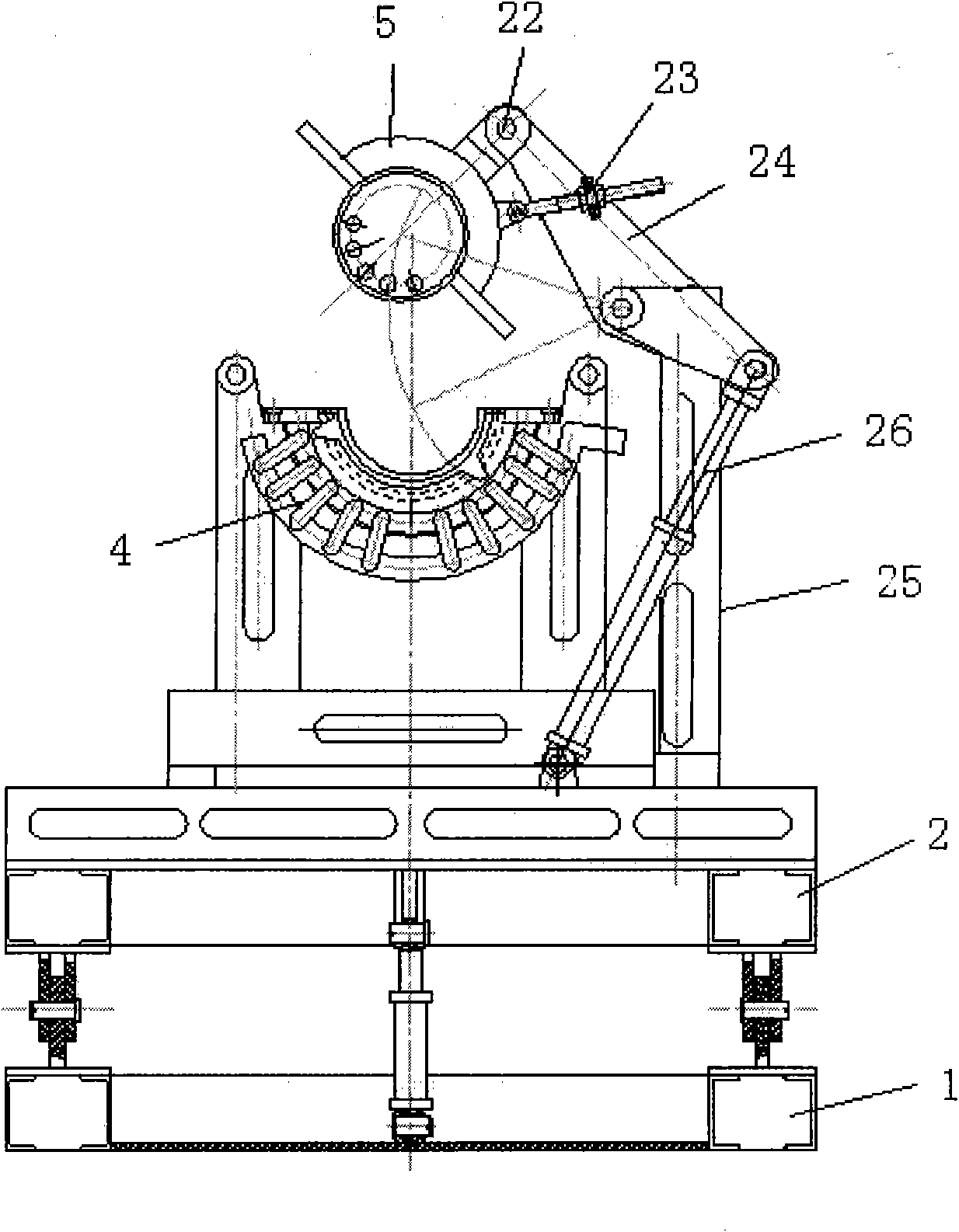

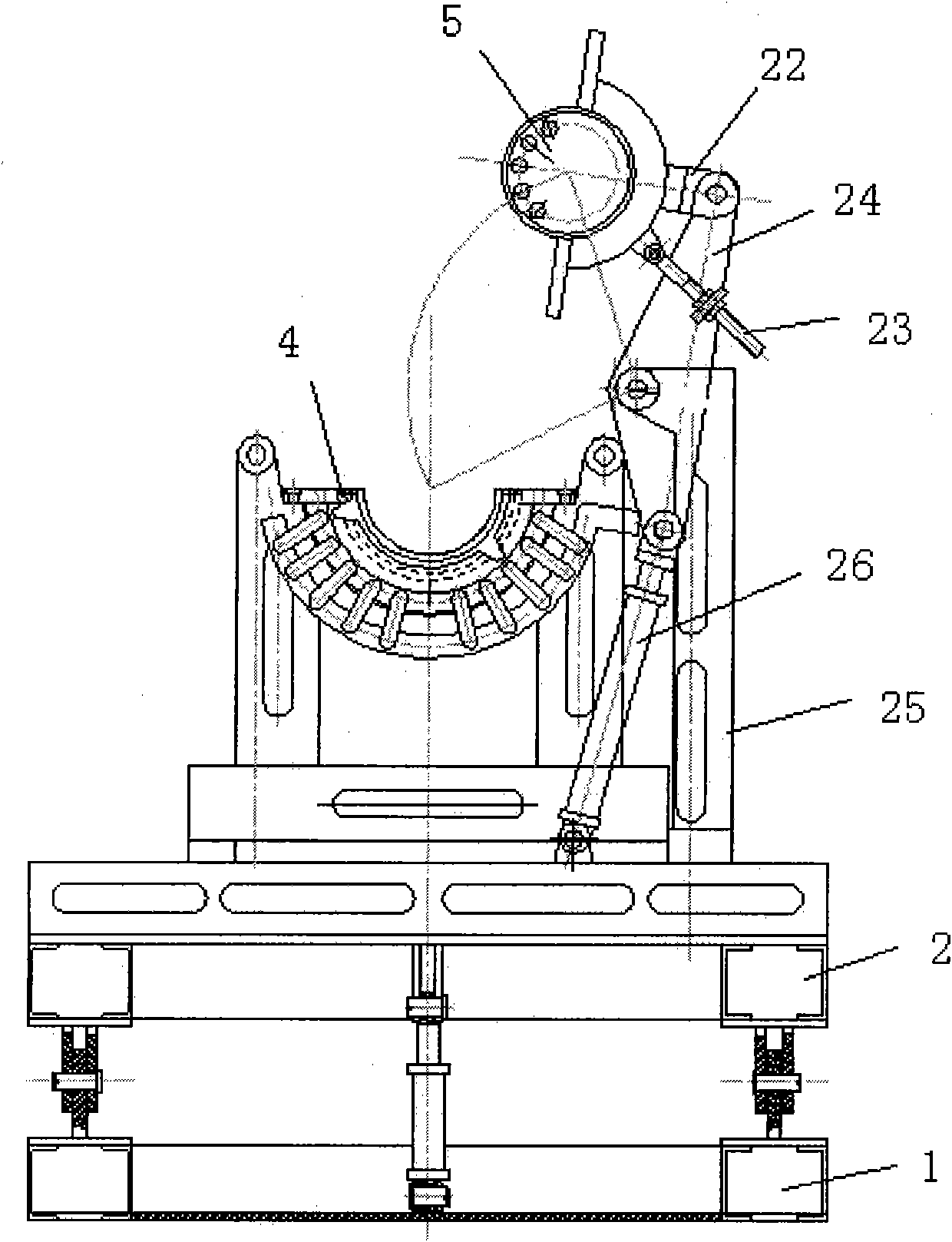

[0030] Such as figure 1 , figure 2 As shown, the marine riser vortex-induced vibration suppression device 100 is a tubular protection device that surrounds the outer surface of the marine riser that is vulnerable to the impact of ocean currents. It is generally made of corrosion-resistant and erosion-resistant polyurethane elastic material. Its appearance generally has spiral fins 101, and its head and tail ends have socket protrusions 102 and socket grooves 103. In the actual engineering application process, it is difficult to put a complete vortex-induced vibration suppression device directly onto the pipe from one end of the ocean riser, but it is necessary to pre-make the vortex-induced vibration suppression device into the upper part 104 and the lower part 105 The two halves are then fastened to the marine riser 107 with a steel band 106.

[0031] Therefore, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com