Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about "Investigating semiconductor impurities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

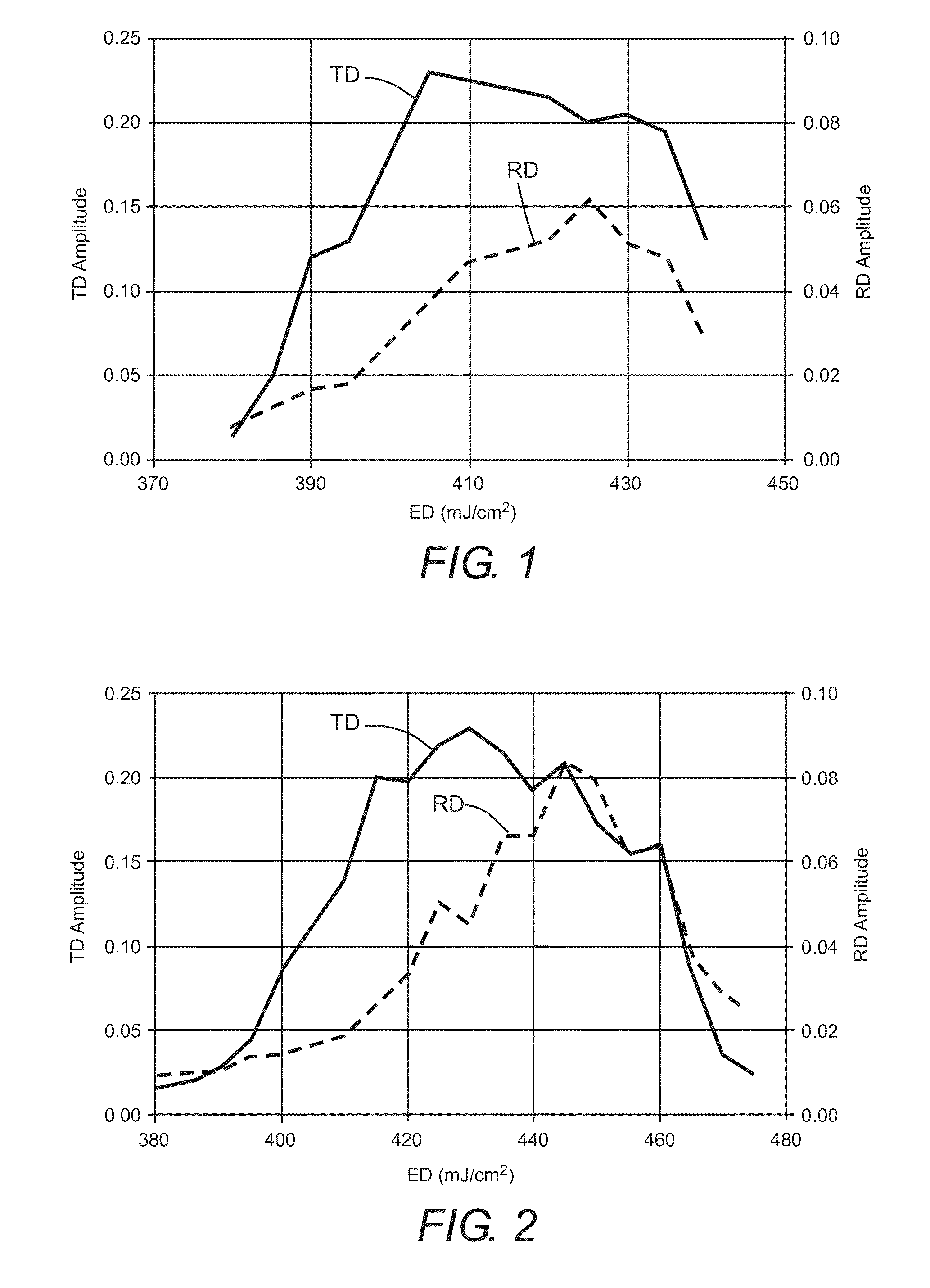

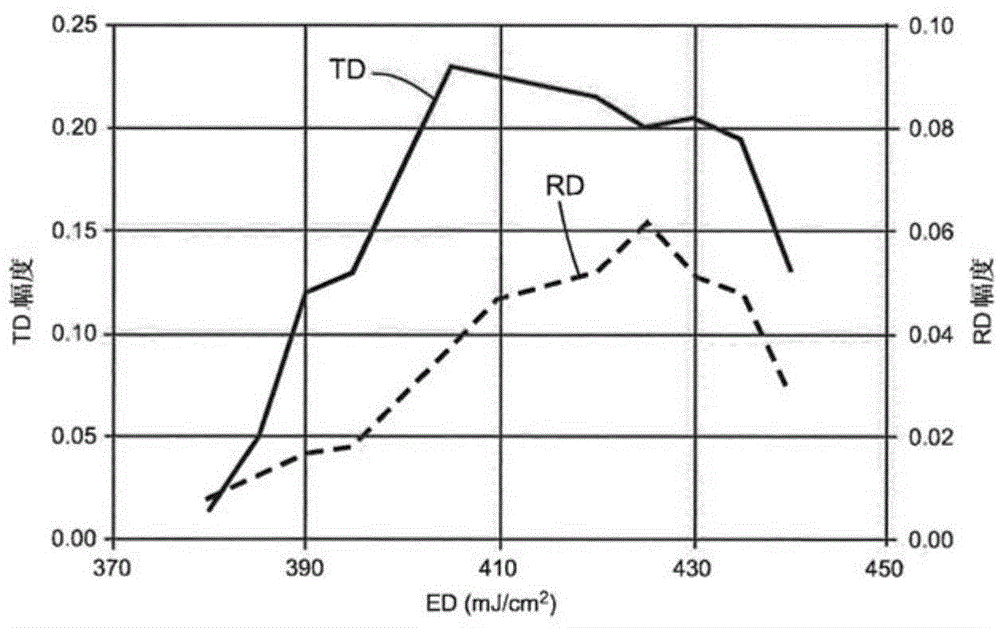

Monitoring method and apparatus for excimer laser annealing process

InactiveUS20130341310A1Investigating semiconductor impuritiesPolycrystalline material growthIrradiationMonitoring methods

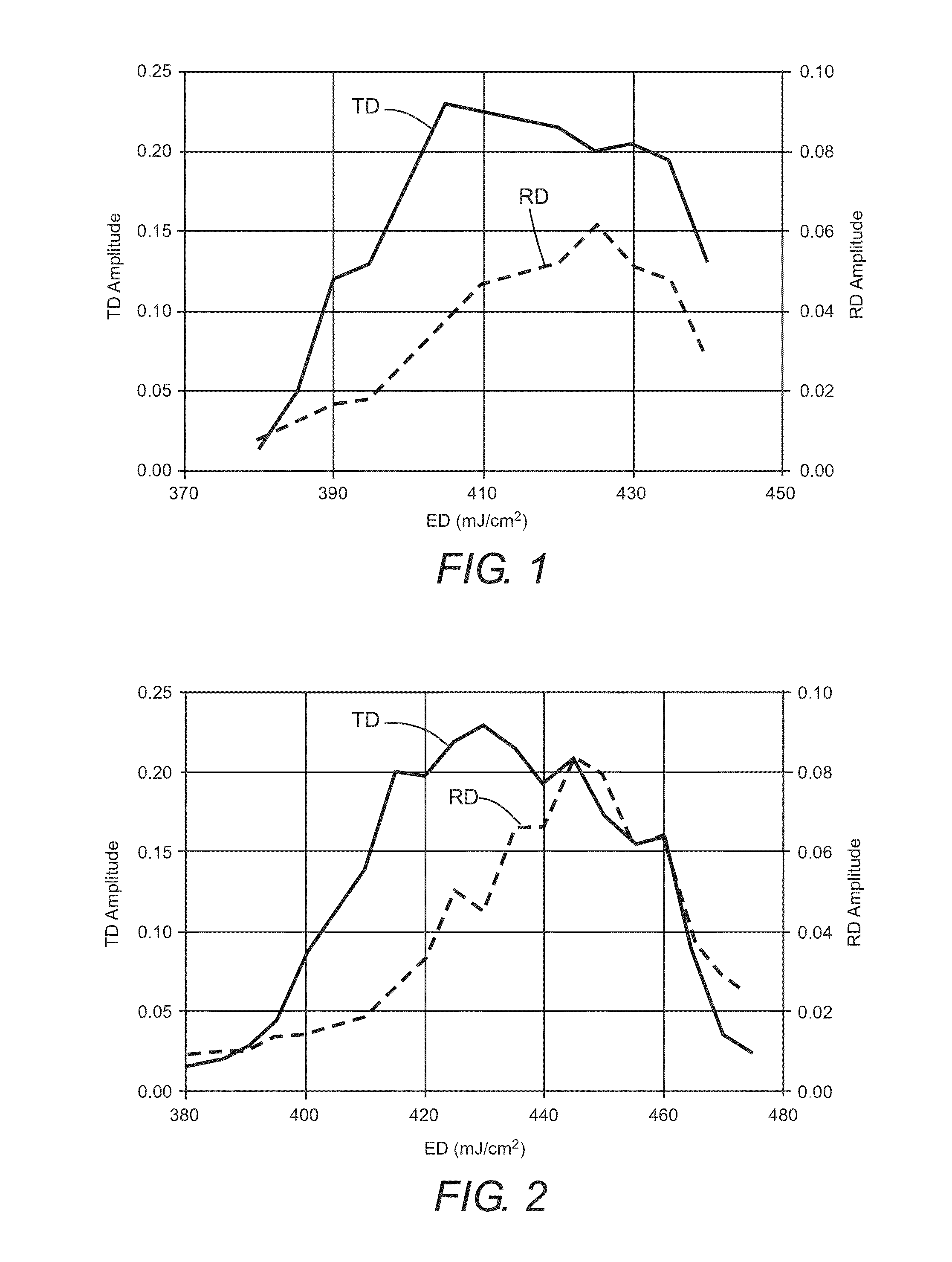

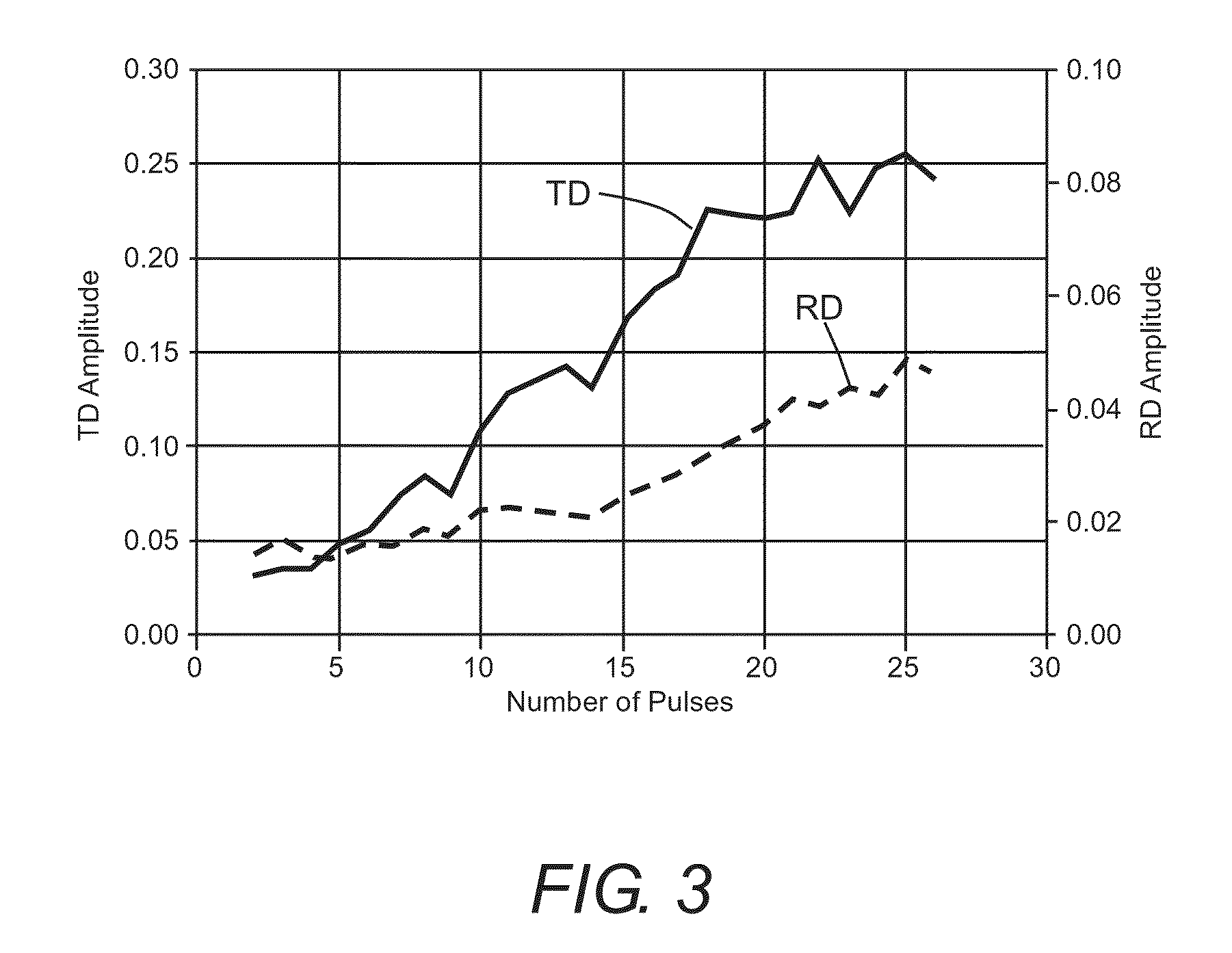

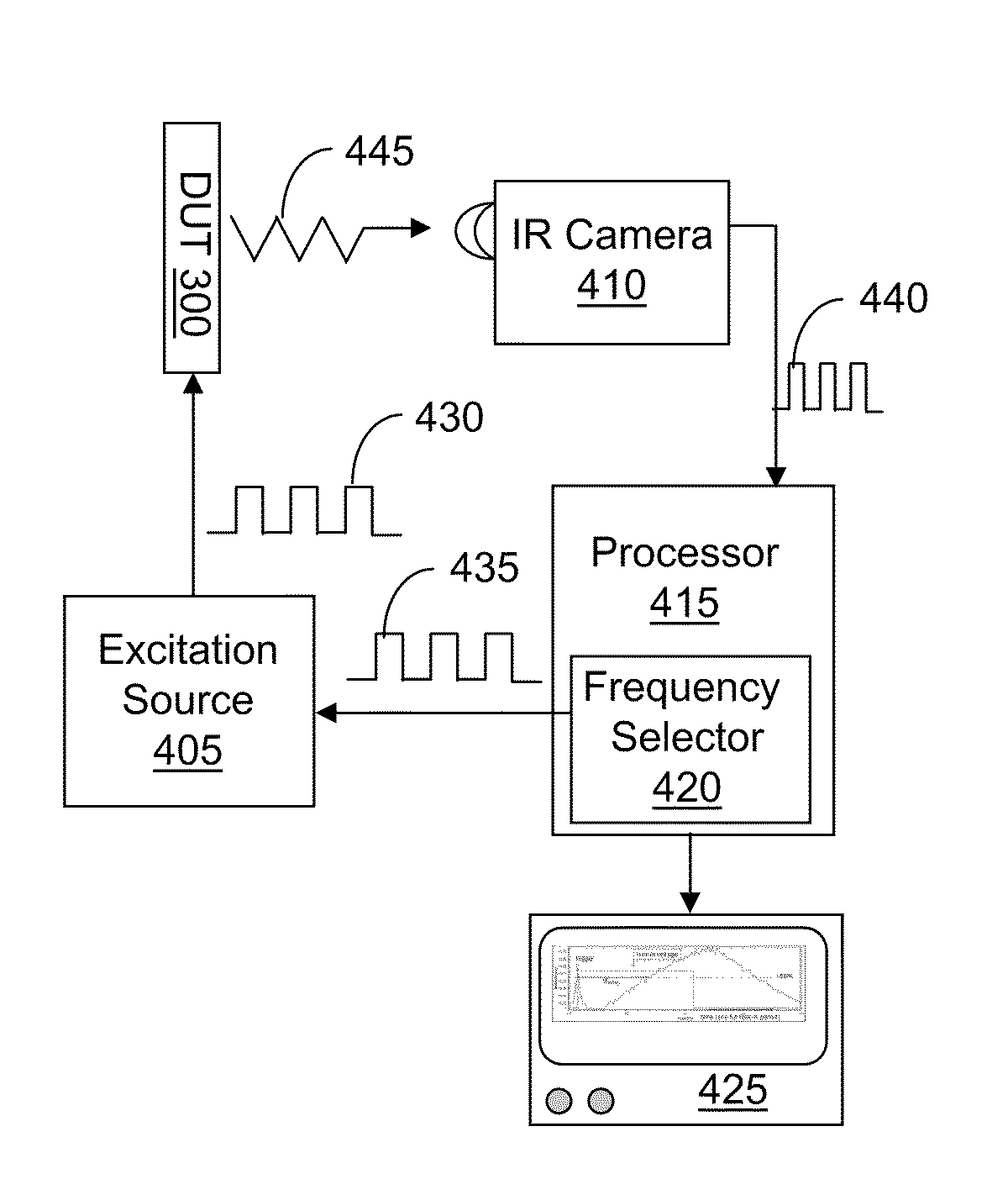

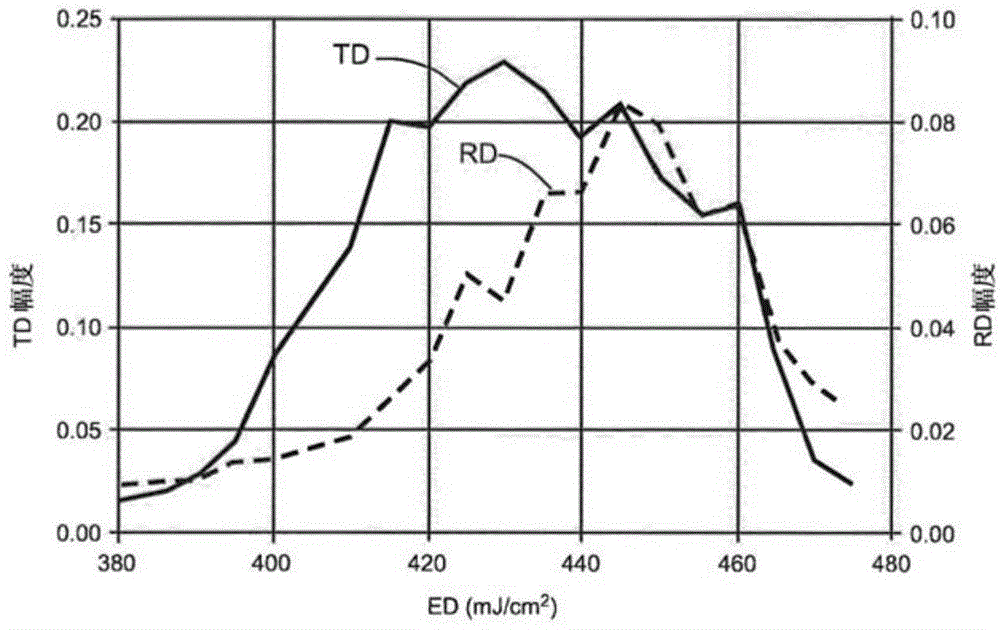

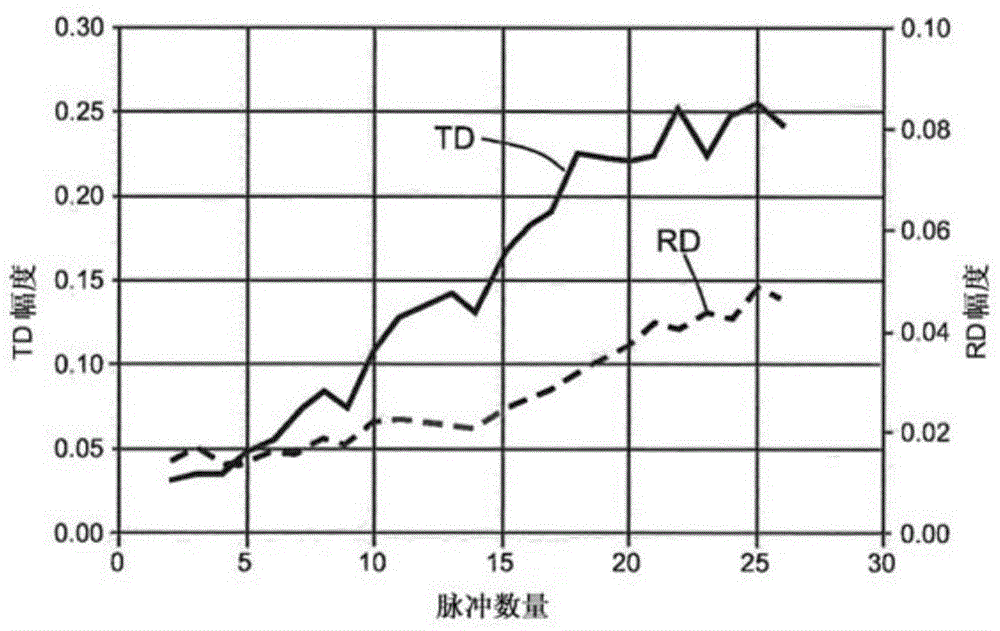

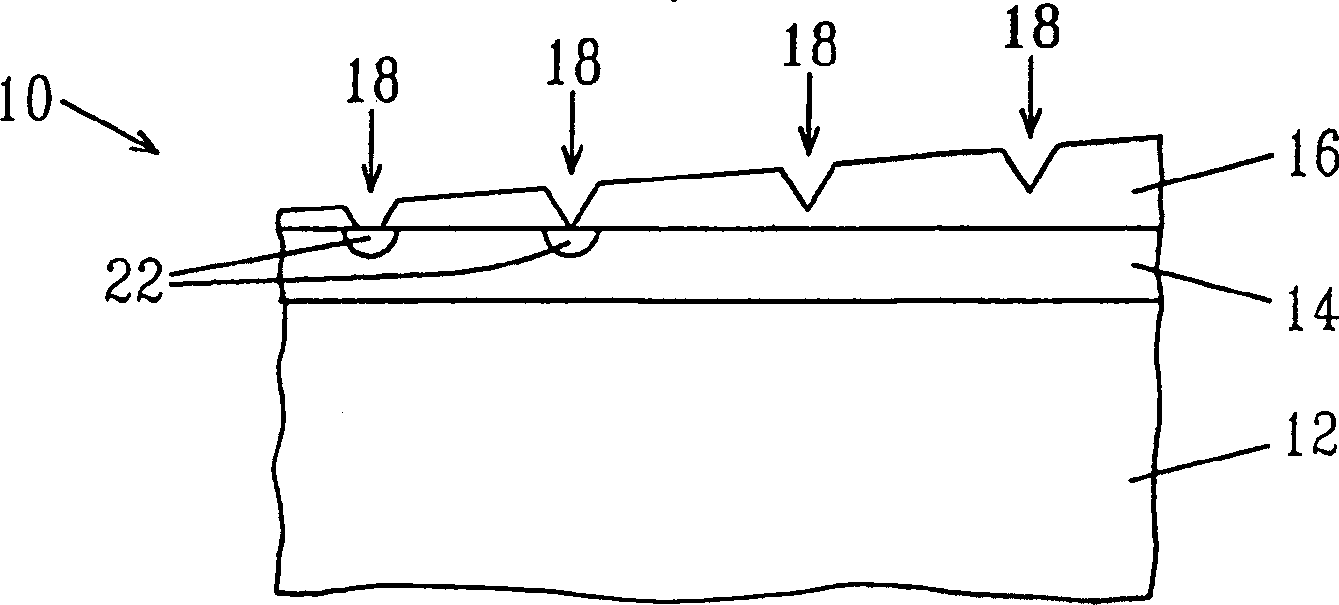

A method is disclosed evaluating a silicon layer crystallized by irradiation with pulses form an excimer-laser. The crystallization produces periodic features on the crystalized layer dependent on the number of and energy density in the pulses to which the layer has been exposed. An area of the layer is illuminated with light. A detector is arranged to detect light diffracted from the illuminated area and to determine from the detected diffracted light the energy density in the pulses to which the layer has been exposed.

Owner:COHERENT LASERSYST

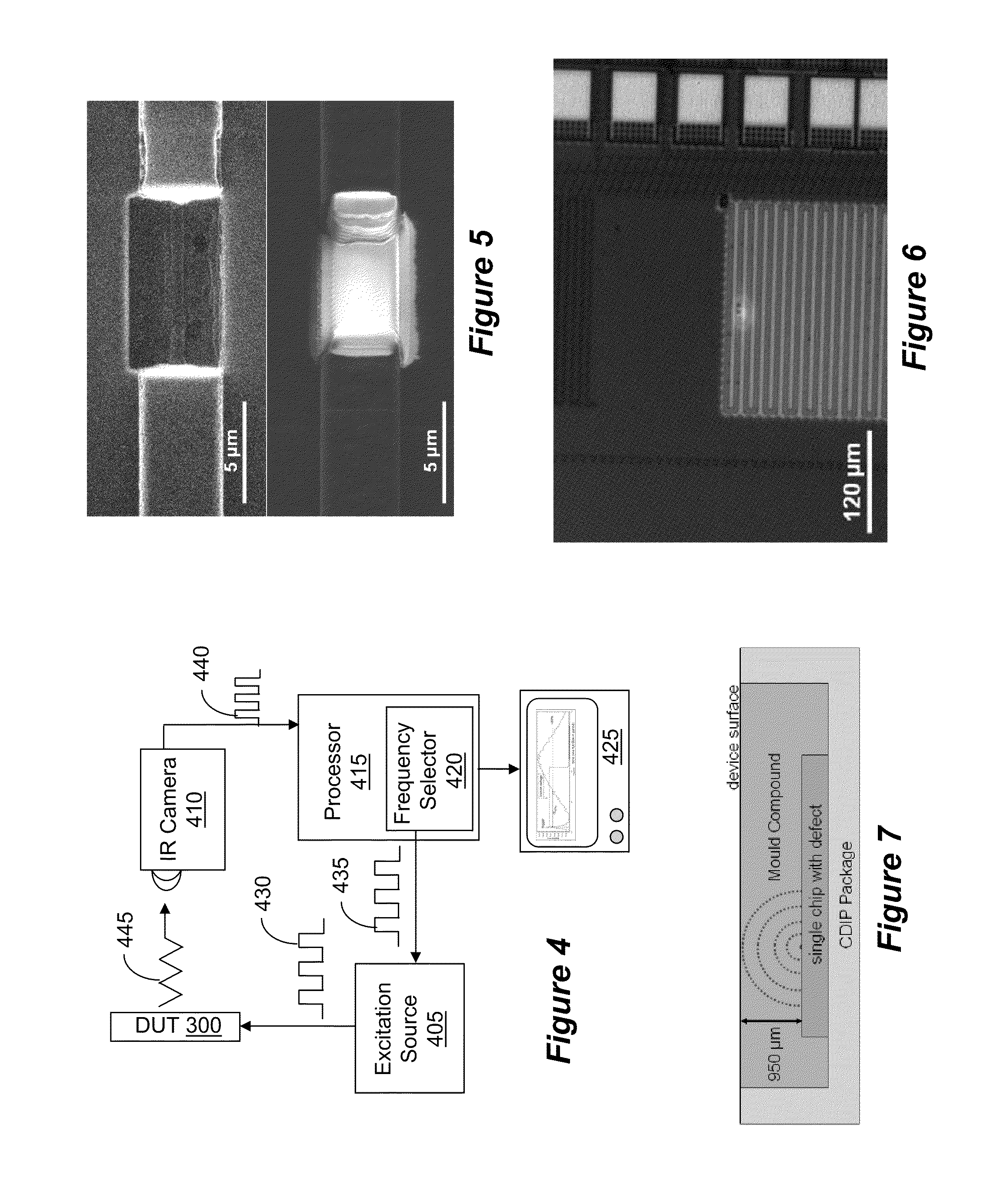

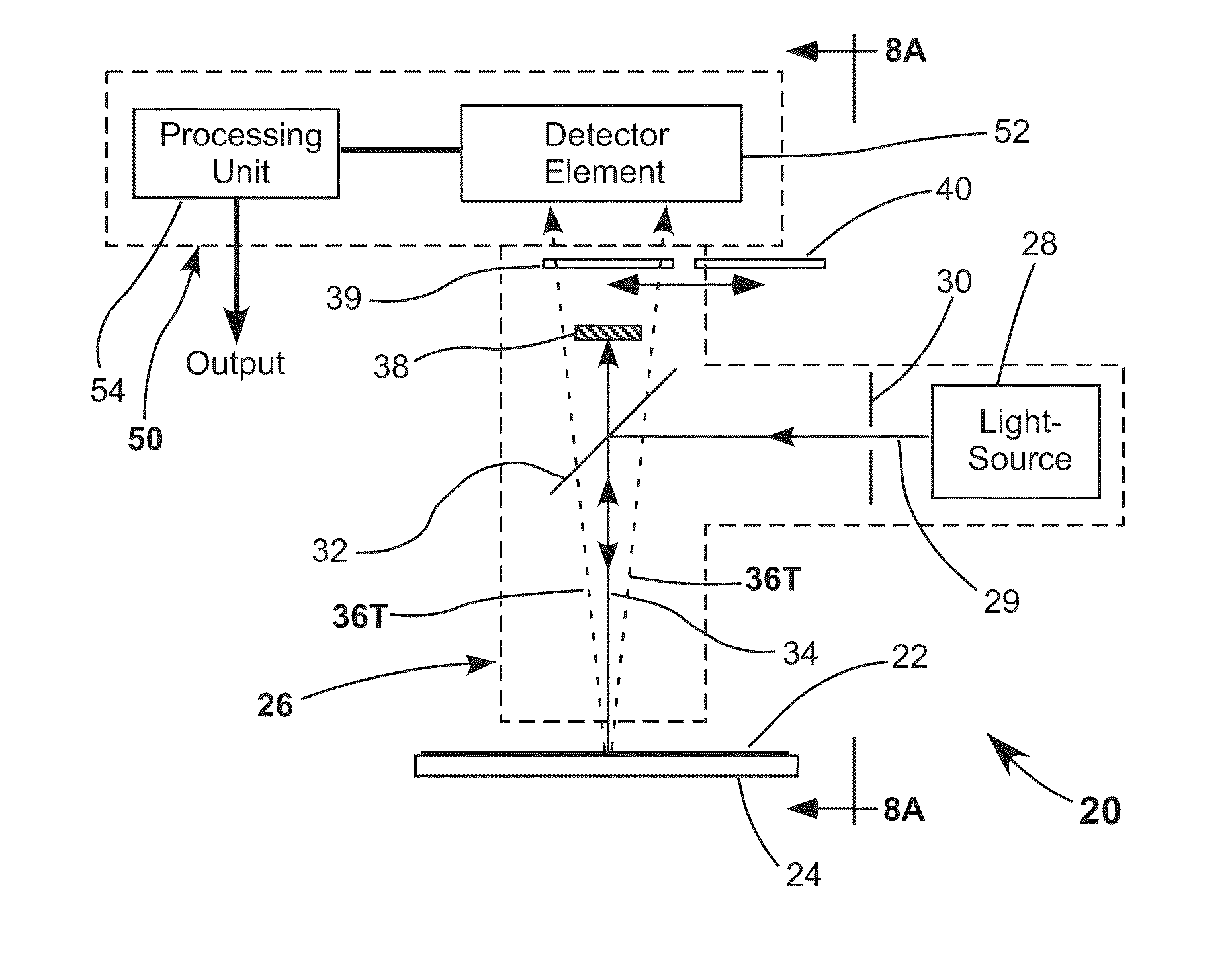

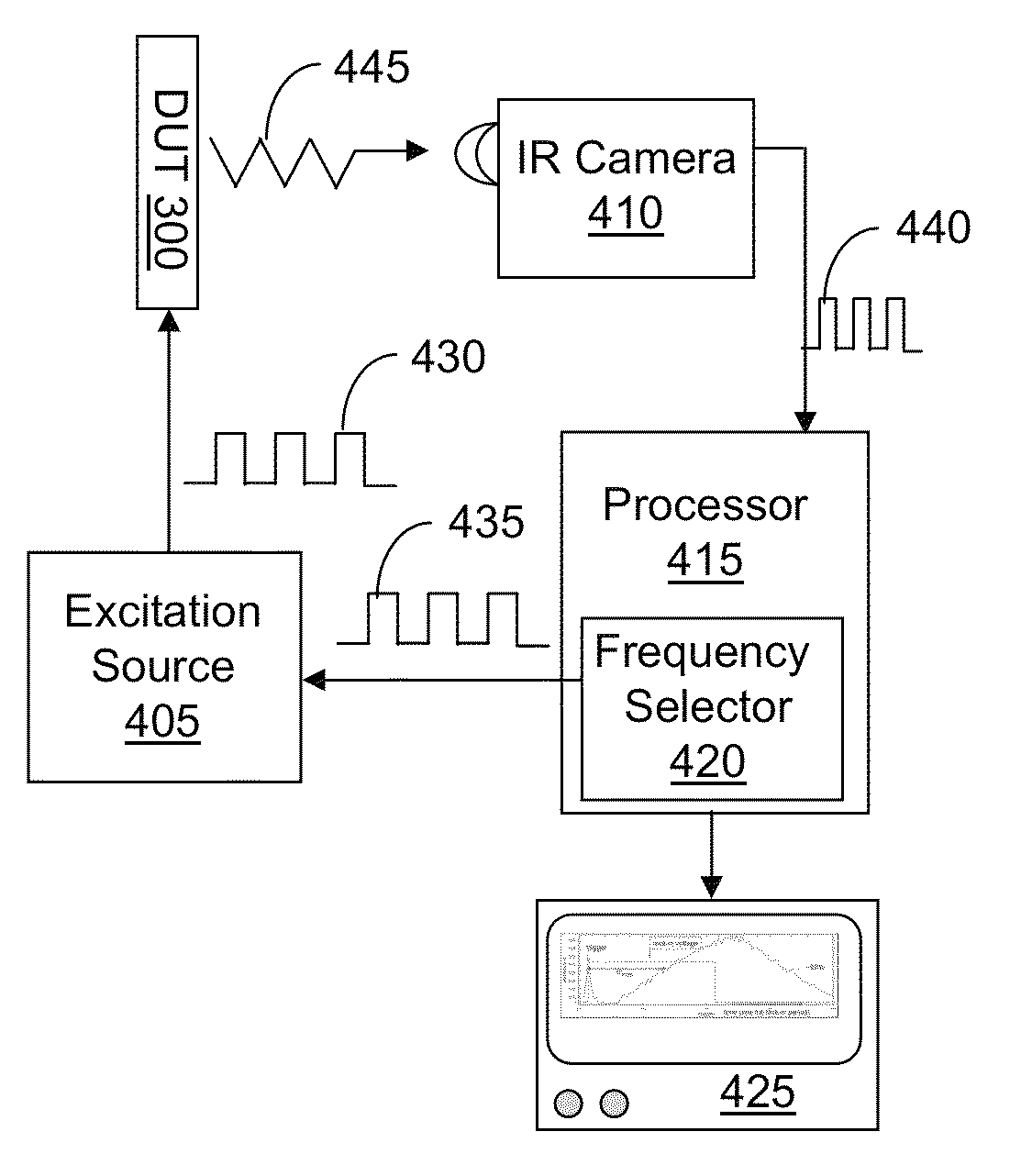

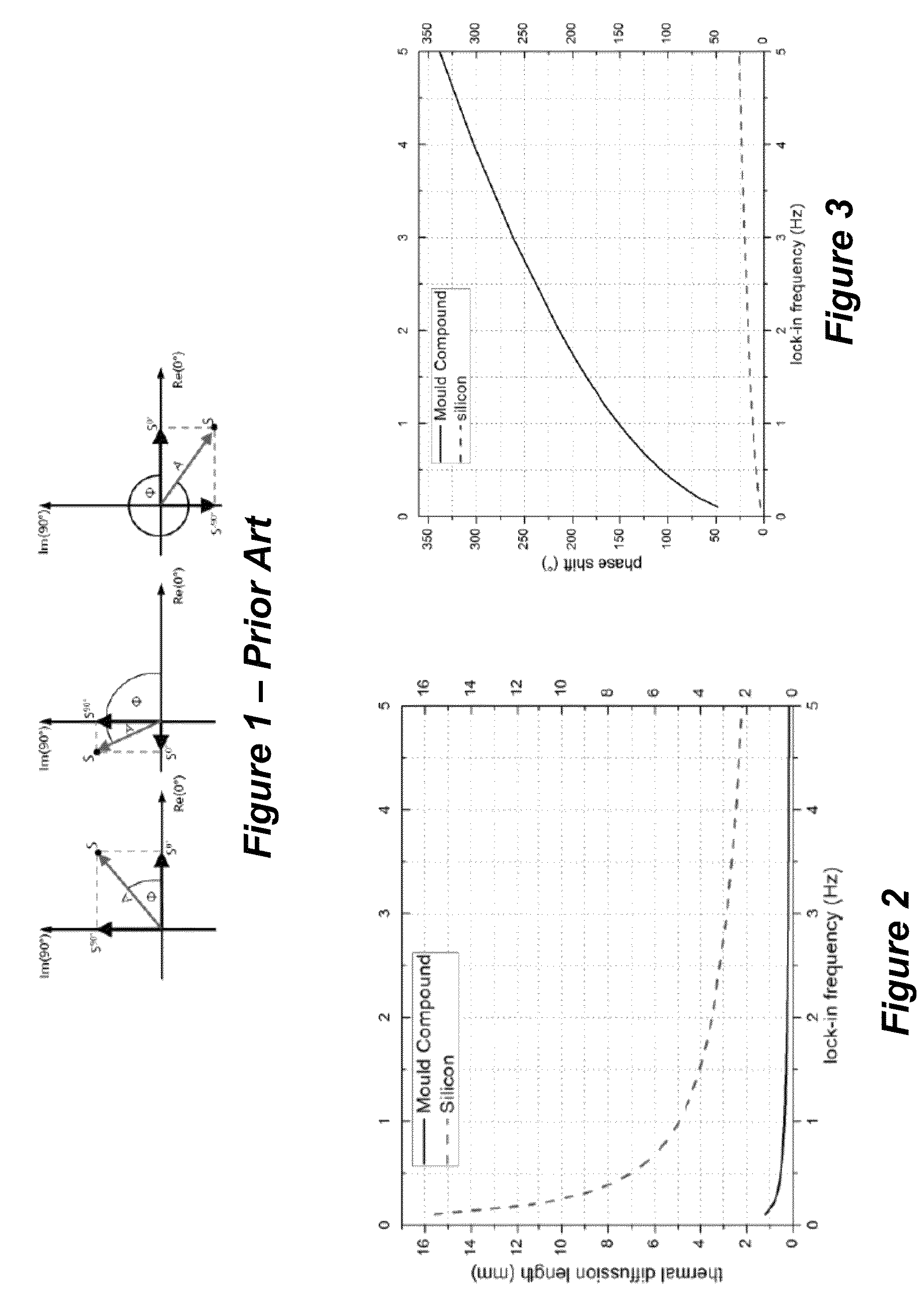

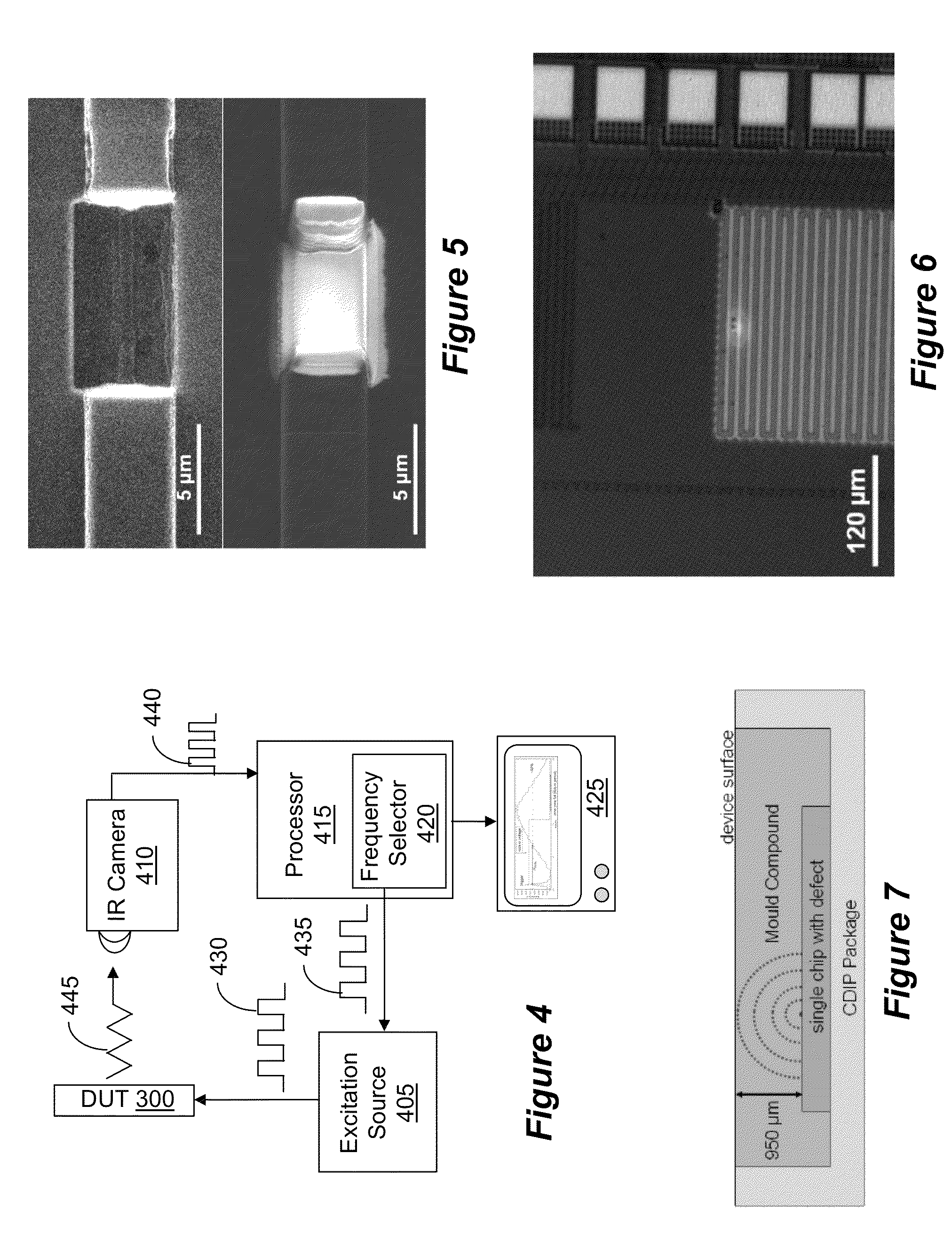

Three-dimensional hot spot localization

ActiveUS20110297829A1Improve depth resolutionImprove measurement reliabilityInvestigating semiconductor impuritiesSamplingTime delaysData acquisition

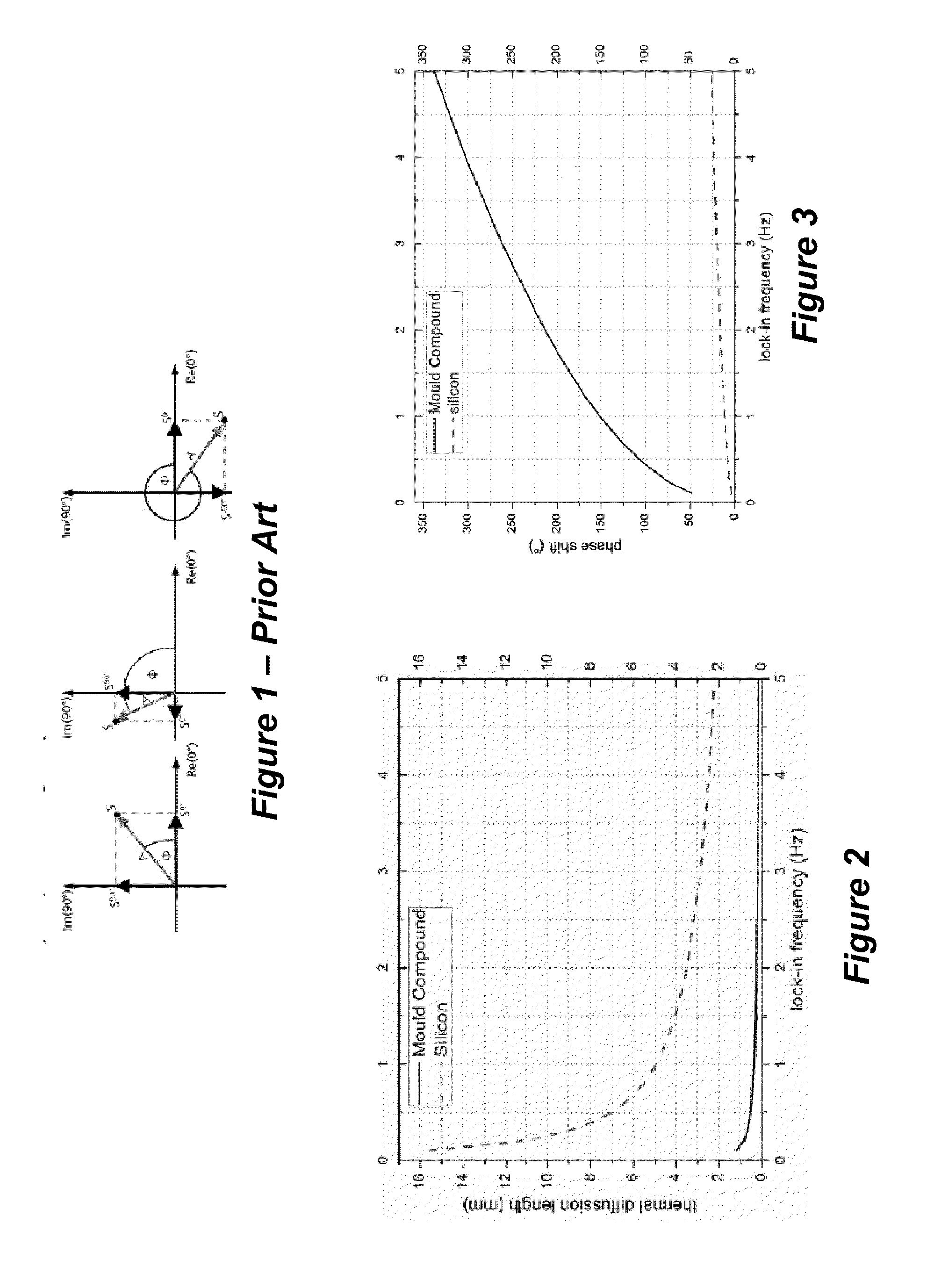

A non-destructive approach for the 3D localization of buried hot spots in electronic device architectures by use of Lock-in Thermography (LIT). The 3D analysis is based on the principles of thermal wave propagation through different material layers and the resulting phase shift / thermal time delay. With more complex multi level stacked die architectures it is necessary to acquire multiple LIT results at different excitation frequencies for precise hot spot depth localization. Additionally, the use of multiple time-resolved thermal waveforms, measured in a minimized field of view on top of the hot spot location, can be used to speed up the data acquisition. The shape of the resulting waveforms can be analyzed to further increase the detection accuracy and confidence level.

Owner:DCG SYST +1

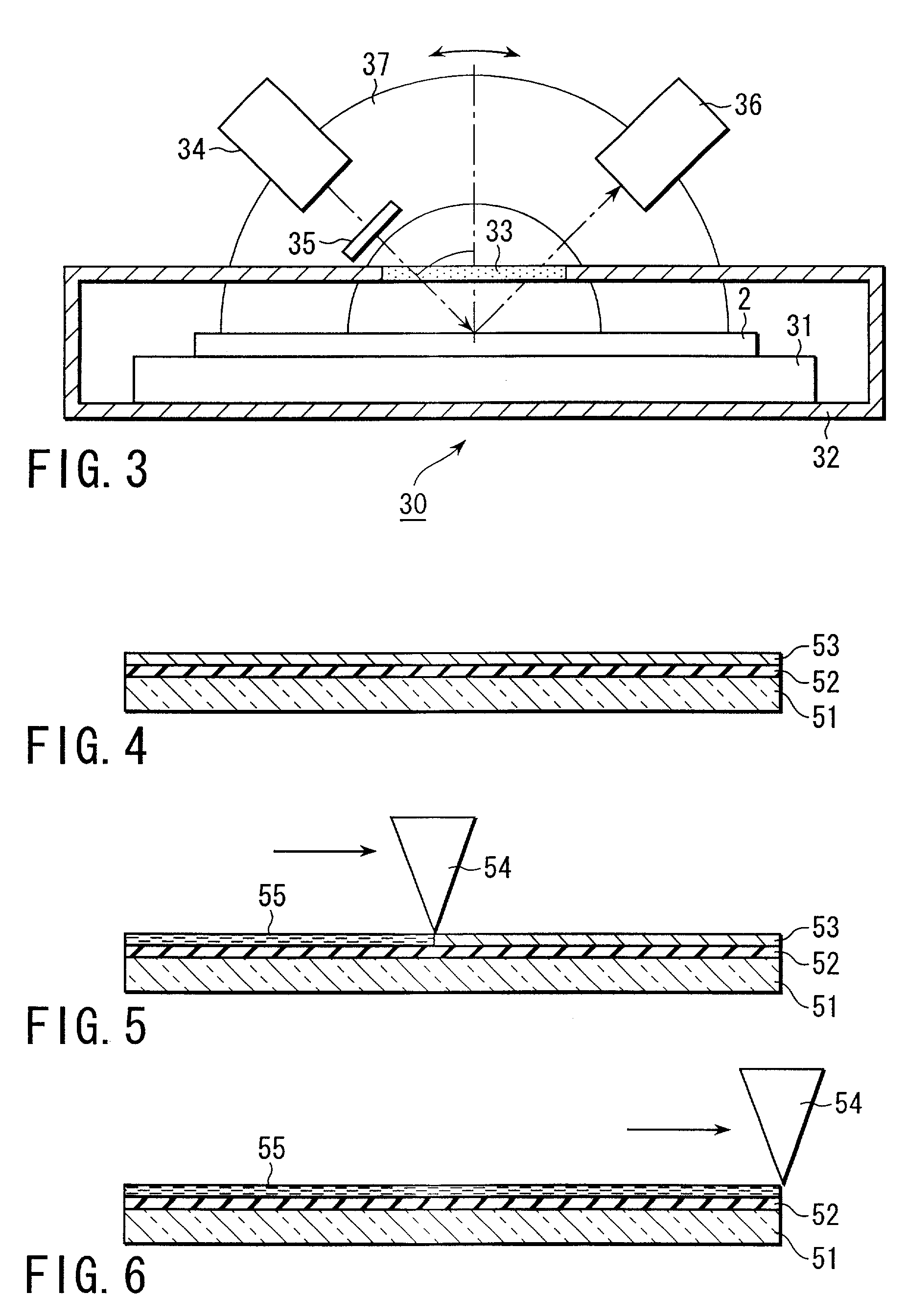

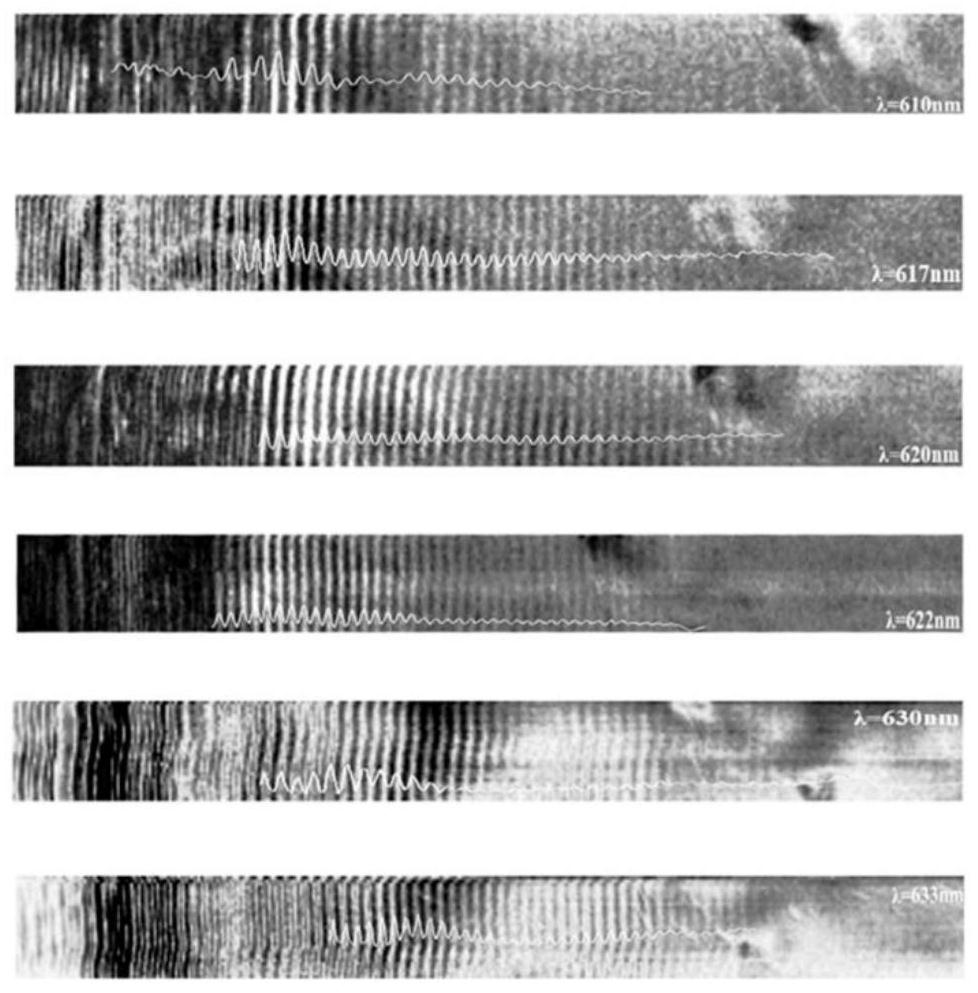

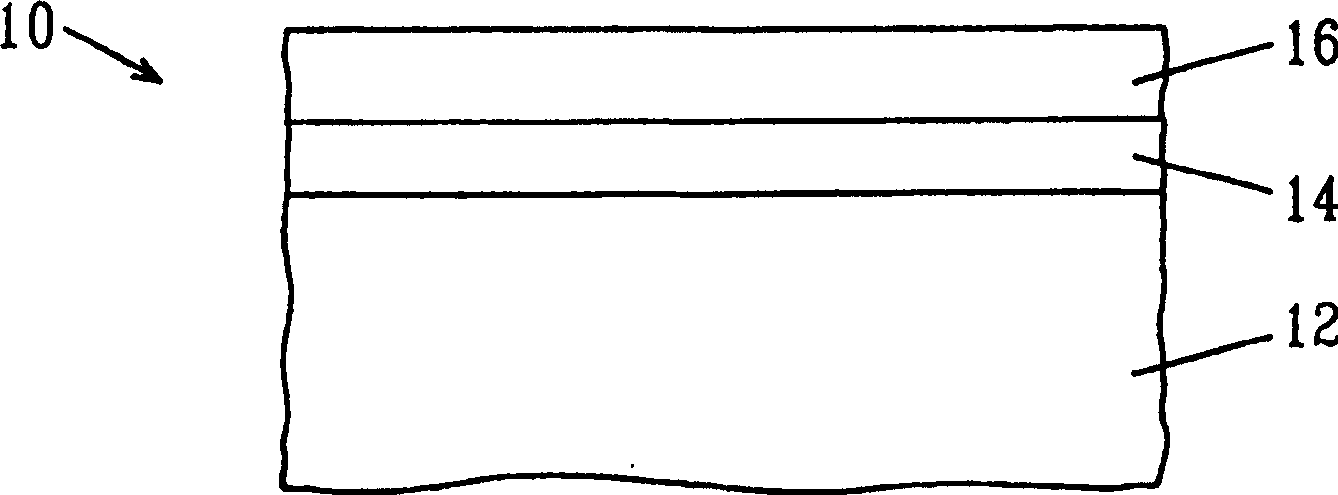

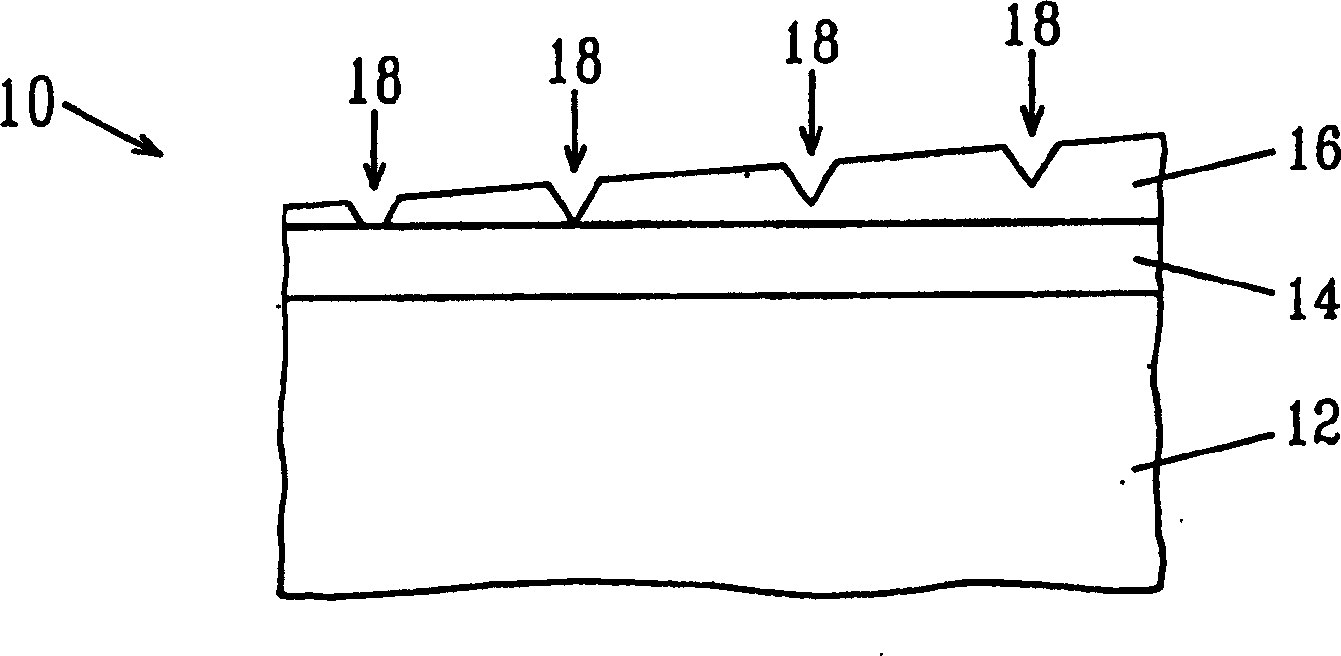

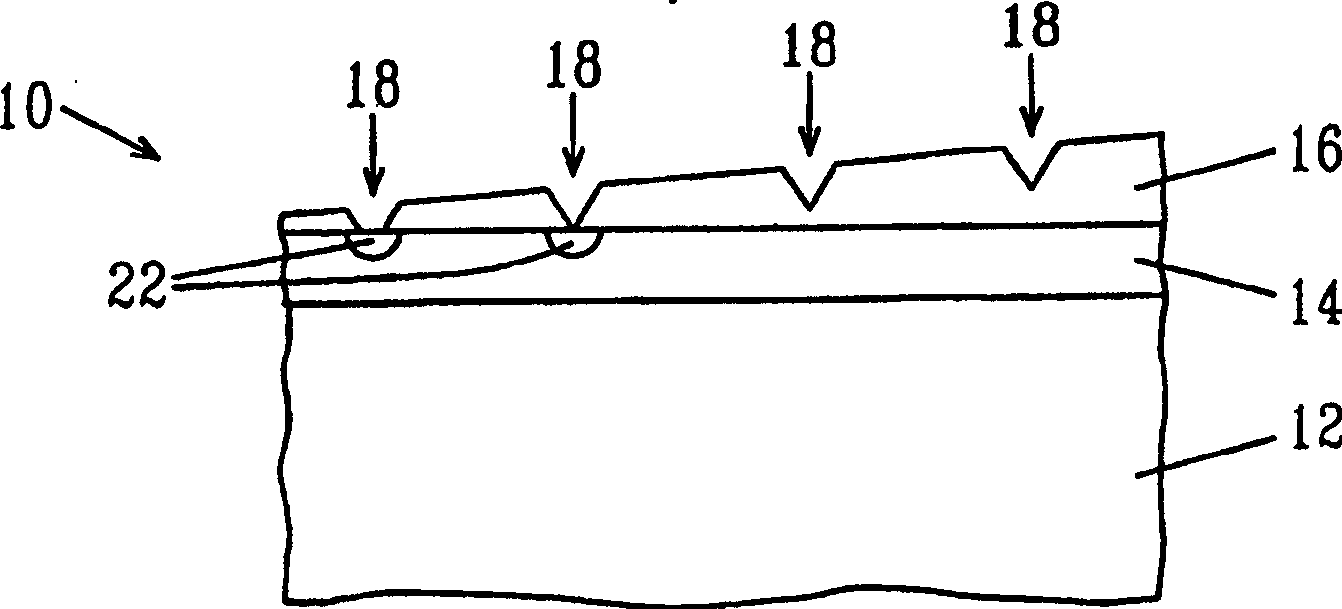

Monitoring method and apparatus for control of excimer laser annealing

ActiveUS20150247808A1Investigating semiconductor impuritiesPolycrystalline material growthIrradiationMonitoring methods

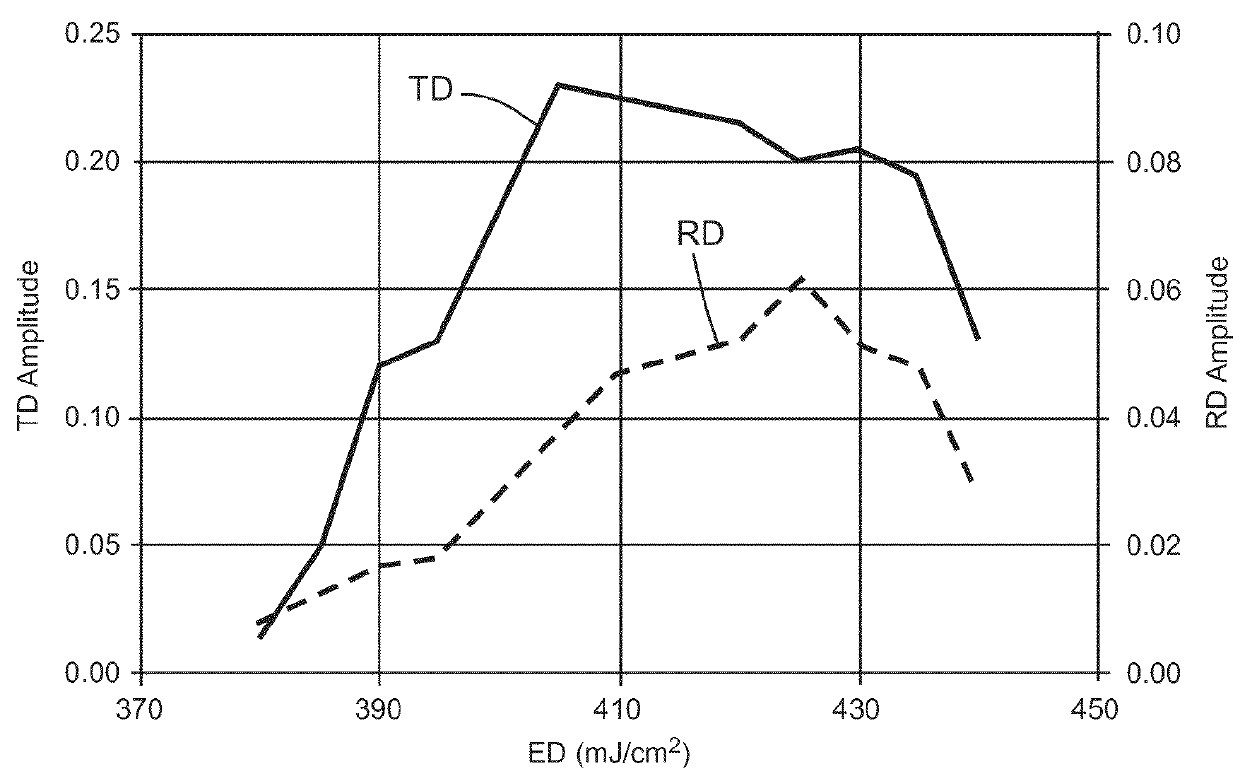

A method is disclosed evaluating a silicon layer crystallized by irradiation with pulses form an excimer-laser. The crystallization produces periodic features on the crystalized layer dependent on the number of and energy density ED in the pulses to which the layer has been exposed. An area of the layer is illuminated with light. A microscope image of the illuminated area is made from light diffracted from the illuminated are by the periodic features. The microscope image includes corresponding periodic features. The ED is determined from a measure of the contrast of the periodic features in the microscope image.

Owner:COHERENT LASERSYST

Film quality inspecting method and film quality inspecting apparatus

InactiveUS6975386B2Investigating semiconductor impuritiesScattering properties measurementsFilm baseLight beam

A film quality inspecting method comprising applying a measuring beam having a specific wavelength to an annealed silicon film formed on a substrate in a direction inclined with respect to the silicon film, measuring a reflection intensity or reflectivity of a reflection beam reflected by the silicon film as a result of the application, and inspecting a film quality of the silicon film based on a measurement value obtained by the measurement.

Owner:SHARP KK +1

Three-dimensional hot spot localization

ActiveUS8742347B2Fast and secure detectionImprove reliabilityInvestigating semiconductor impuritiesSamplingTime delaysData acquisition

A non-destructive approach for the 3D localization of buried hot spots in electronic device architectures by use of Lock-in Thermography (LIT). The 3D analysis is based on the principles of thermal wave propagation through different material layers and the resulting phase shift / thermal time delay. With more complex multi level stacked die architectures it is necessary to acquire multiple LIT results at different excitation frequencies for precise hot spot depth localization. Additionally, the use of multiple time-resolved thermal waveforms, measured in a minimized field of view on top of the hot spot location, can be used to speed up the data acquisition. The shape of the resulting waveforms can be analyzed to further increase the detection accuracy and confidence level.

Owner:DCG SYST +1

Monitoring method and apparatus for excimer laser annealing process

ActiveCN104641460AInvestigating semiconductor impuritiesPolycrystalline material growthIrradiationMonitoring methods

A method is disclosed evaluating a silicon layer crystallized by irradiation with pulses form an excimer-laser. The crystallization produces periodic features on the crystalized layer dependent on the number of and energy density in the pulses to which the layer has been exposed. An area of the layer is illuminated with light. A detector is arranged to detect light diffracted from the illuminated area and to determine from the detected diffracted light the energy density in the pulses to which the layer has been exposed.

Owner:COHERENT LASERSYST

Monitoring method and apparatus for control of excimer laser annealing

ActiveUS9335276B2Investigating semiconductor impuritiesPolycrystalline material growthIrradiationMonitoring methods

A method is disclosed evaluating a silicon layer crystallized by irradiation with pulses form an excimer-laser. The crystallization produces periodic features on the crystallized layer dependent on the number of and energy density ED in the pulses to which the layer has been exposed. An area of the layer is illuminated with light. A microscope image of the illuminated area is made from light diffracted from the illuminated are by the periodic features. The microscope image includes corresponding periodic features. The ED is determined from a measure of the contrast of the periodic features in the microscope image.

Owner:COHERENT LASERSYST

Method for identifying silicate phase in vanadium-titanium sintered ore

InactiveCN108445002AHigh strengthGuaranteed reliabilityInvestigating semiconductor impuritiesPreparing sample for investigationSolid fuelTitanium

The invention provides a method for identifying a silicate phase in vanadium-titanium sintered ore, and relates to the technical field of phase identification. According to the method, vanadium-titanium ore is pretreated and is then finely polished, so that a sheet sample is prepared; the phase in the sintered ore can be uniformly, conveniently, efficiently and accurately identified by identifyingthe color and crystal form of the sheet sample and measuring the contents of all elements of the silicate phase, so that the reliability of the measured data is ensured; after the types and structures of the main metal minerals in the vanadium-titanium sintered ore are figured out, a technical support is provided for the later evaluation of the metallurgical properties of the vanadium-titanium sintered ore, so that sintering and blast furnace production can be adjusted according to the composition, structure and embedding characteristics of the phase in the sintered ore as well as the metallurgical properties of the vanadium-titanium sintered ore; therefore, the method has important theoretical guiding significance for reducing solid fuel consumption, improving sintered ore strength and reducing blast furnace comprehensive coke ratio, and can be applied to inspection and research institutes of various laboratories and production sites.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method of measuring crystal defects in thin SI/SIGE bilayers

InactiveCN1601274AInvestigating semiconductor impuritiesSemiconductor/solid-state device testing/measurementAlloyCrystallographic defect

Described herein is a method for delineating crystalline defects in a thin Si layer over a SiGe alloy layer. The method uses a defect etchant with a high-defect selectivity in Si. The Si is etched downed to a thickness that allows the defect pits to reach the underlying SiGe layer. A second etchant, which can be the same or different from the defect etchant, is then used which attacks the SiGe layer under the pits while leaving Si intact.

Owner:GLOBALFOUNDRIES INC

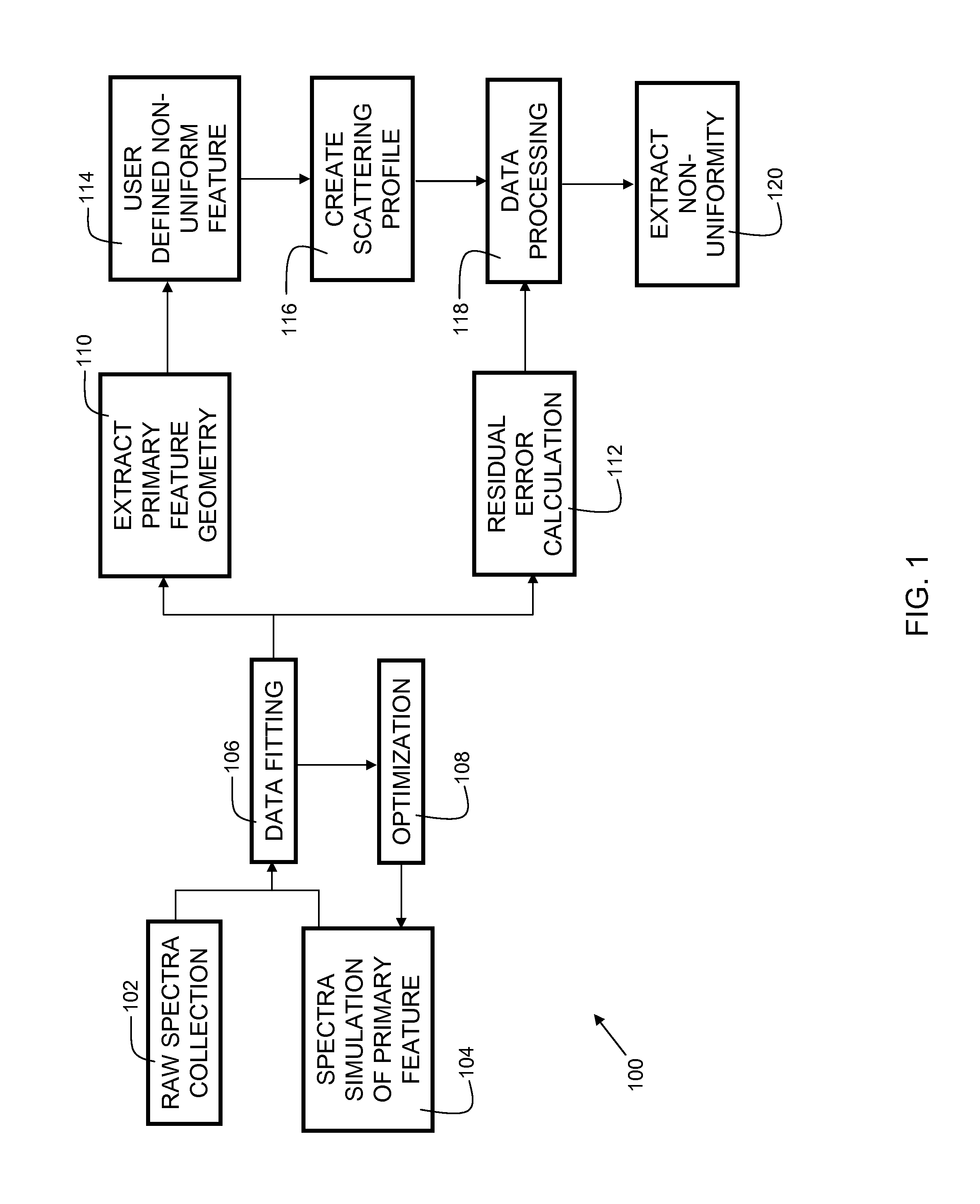

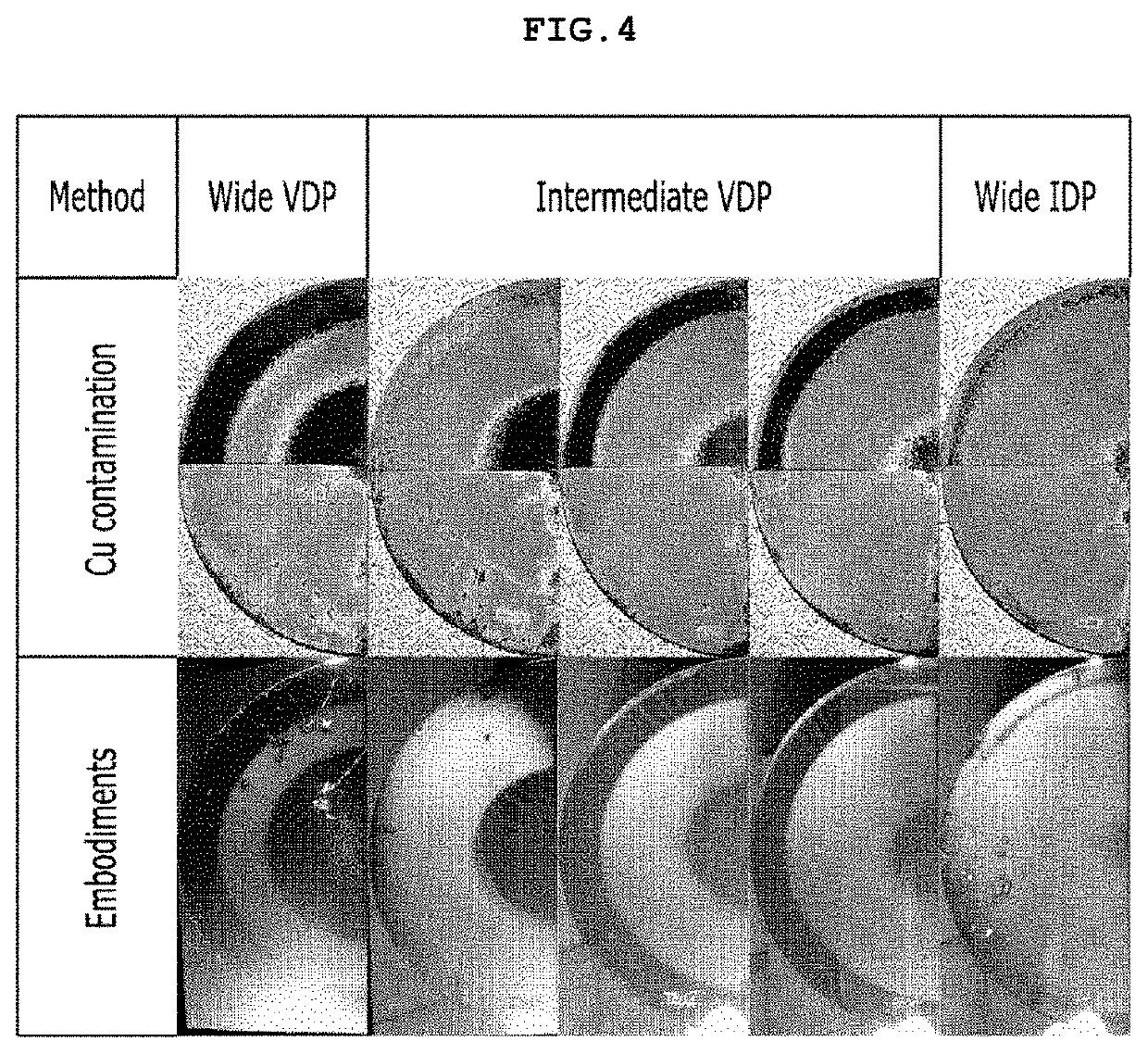

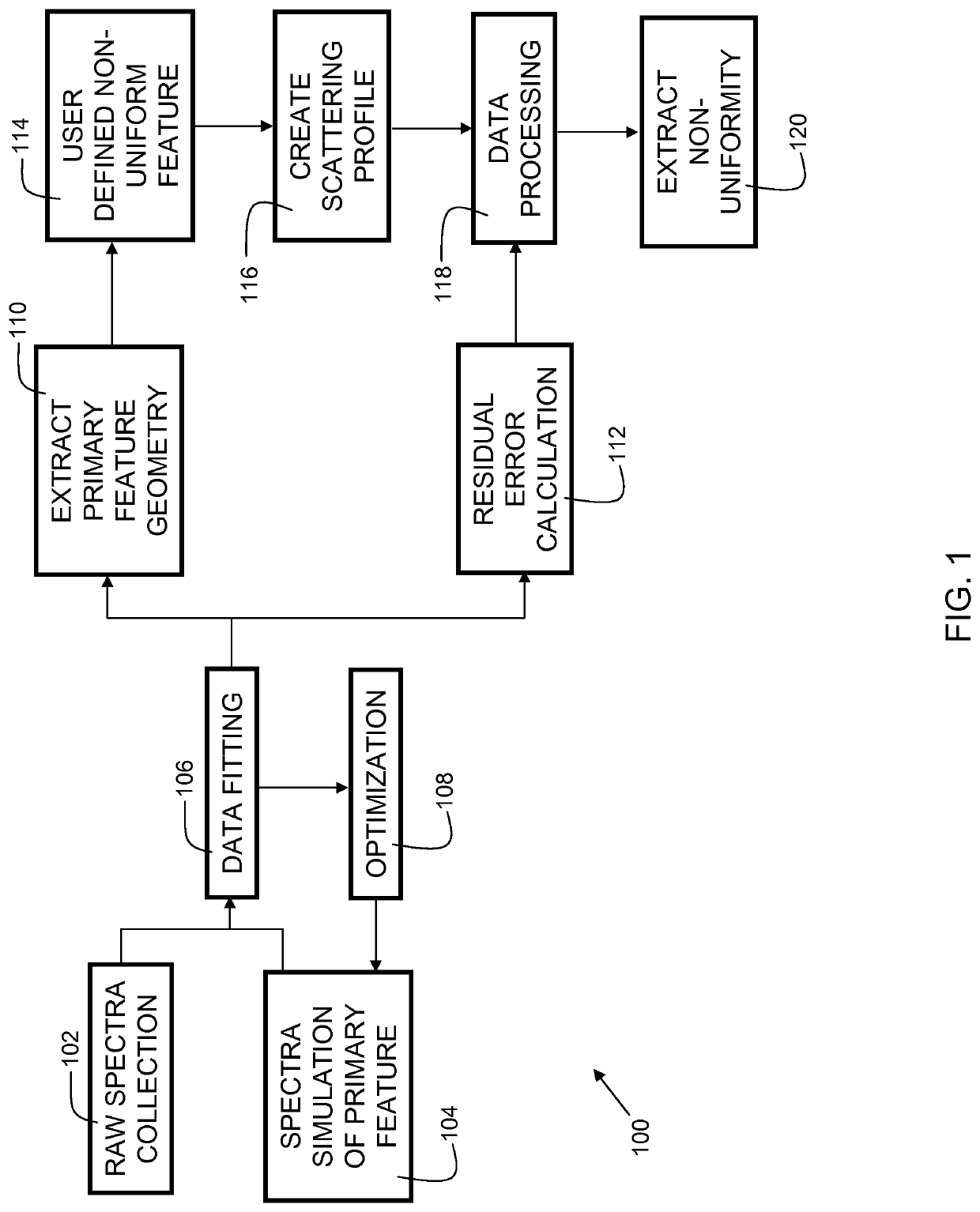

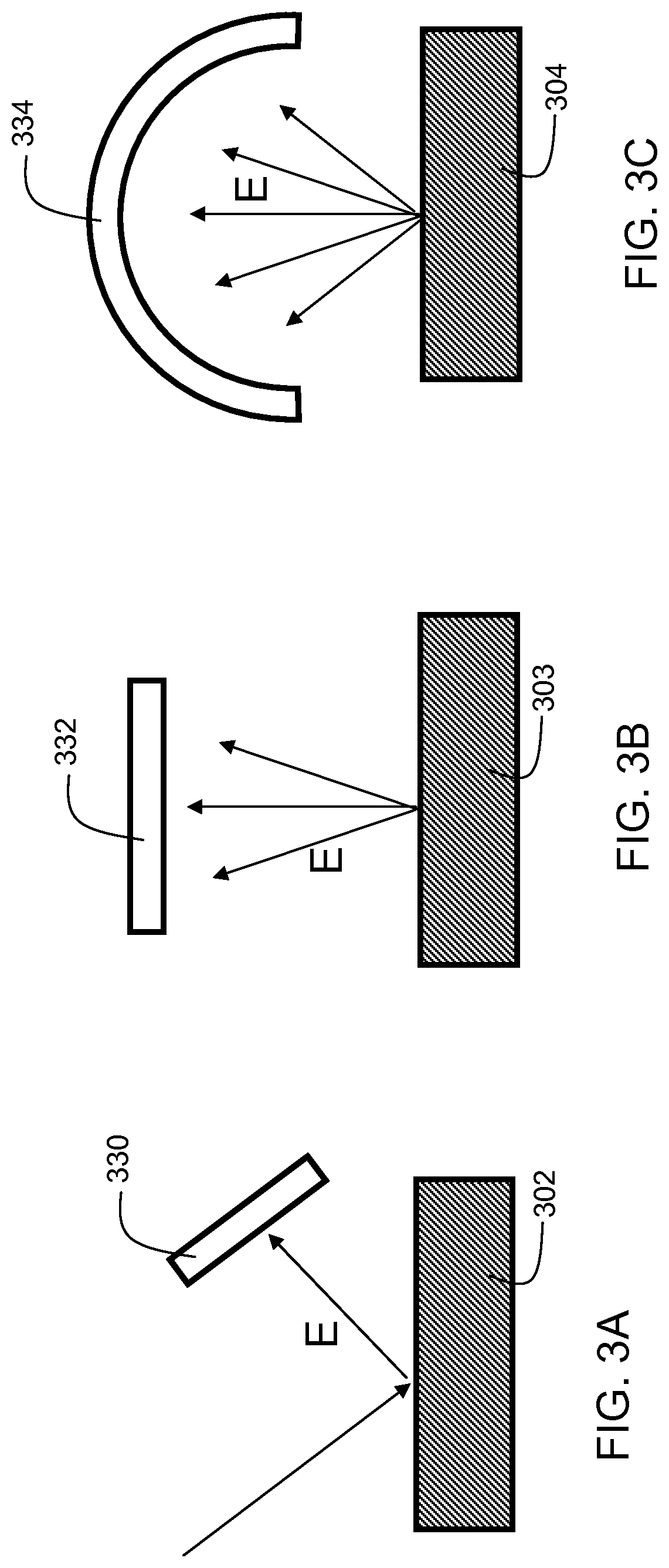

Method for quantification of process non-uniformity using model-based metrology

ActiveUS20150134286A1Investigating semiconductor impuritiesOptically investigating flaws/contaminationMetrologySemiconductor structure

Embodiments of the present invention provide an improved method and system for assessing non-uniformity of features in the measurement area (within the beam spot) on a semiconductor structure, (e.g. wafer), such as a non-uniform film thickness. The scattering from non-uniform features is modeled. Post-processing the residual of theoretical and collected spectra is performed to assess a measure of non-uniformity from within an incident spot beam of a spectrum acquisition tool.

Owner:IBM CORP

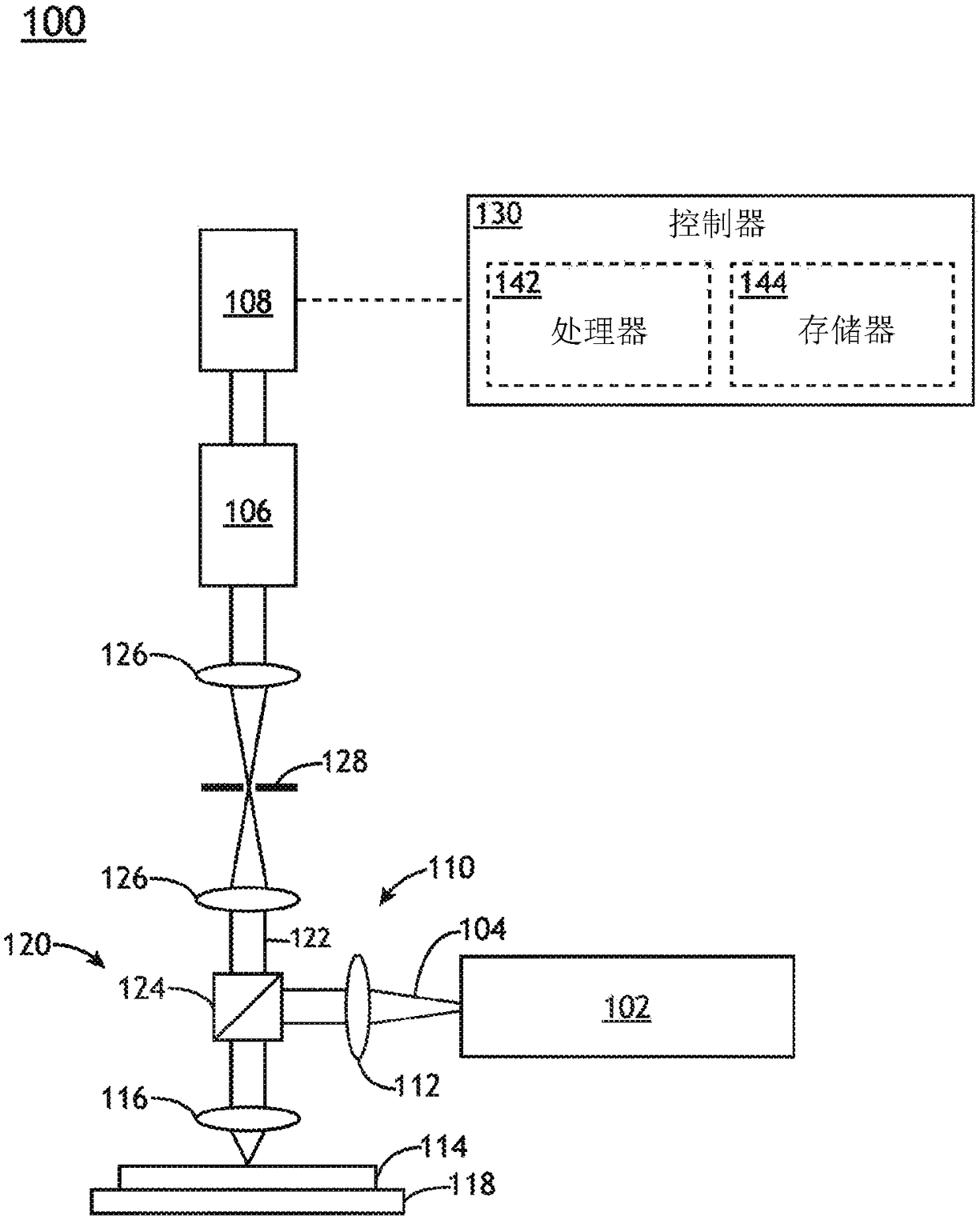

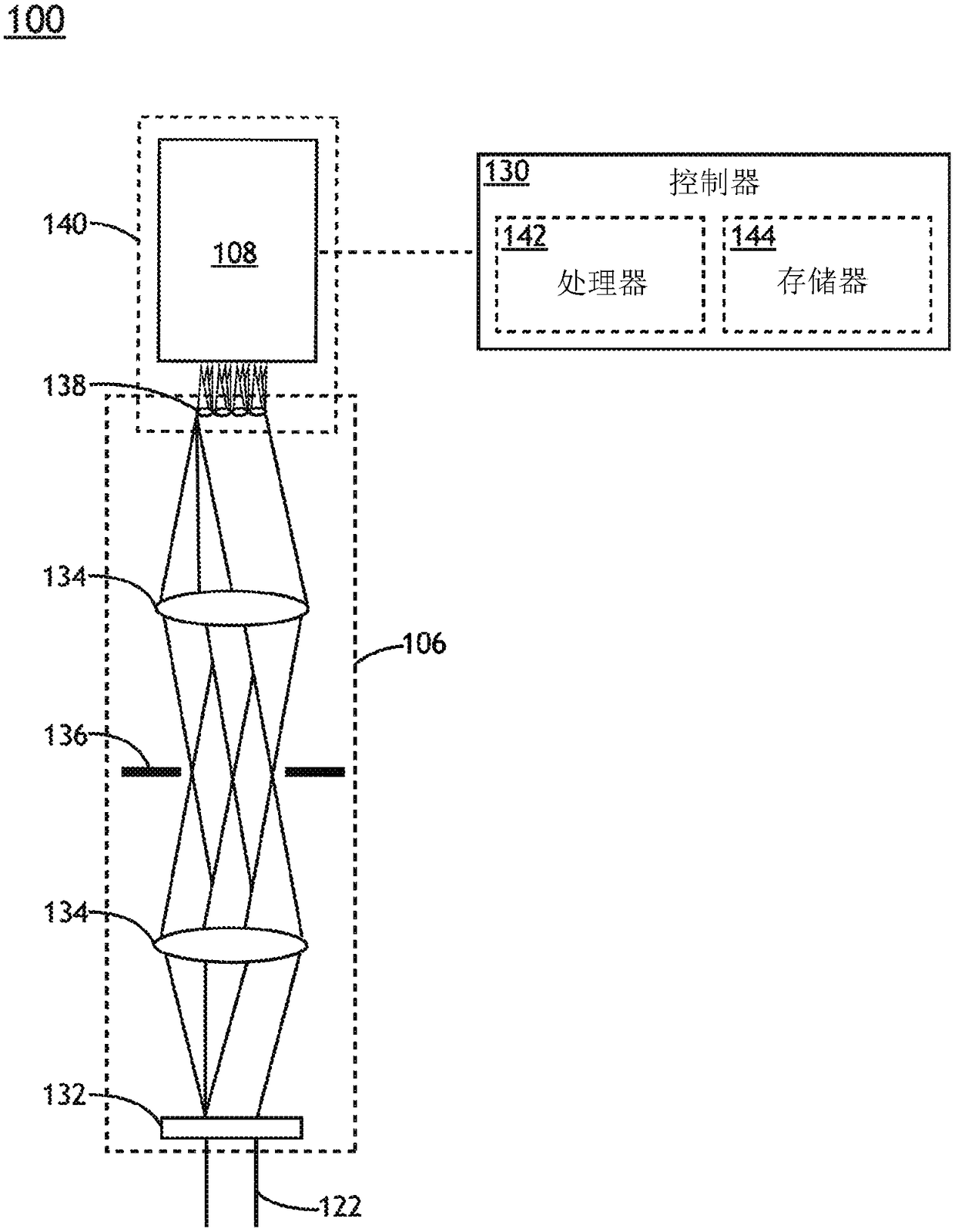

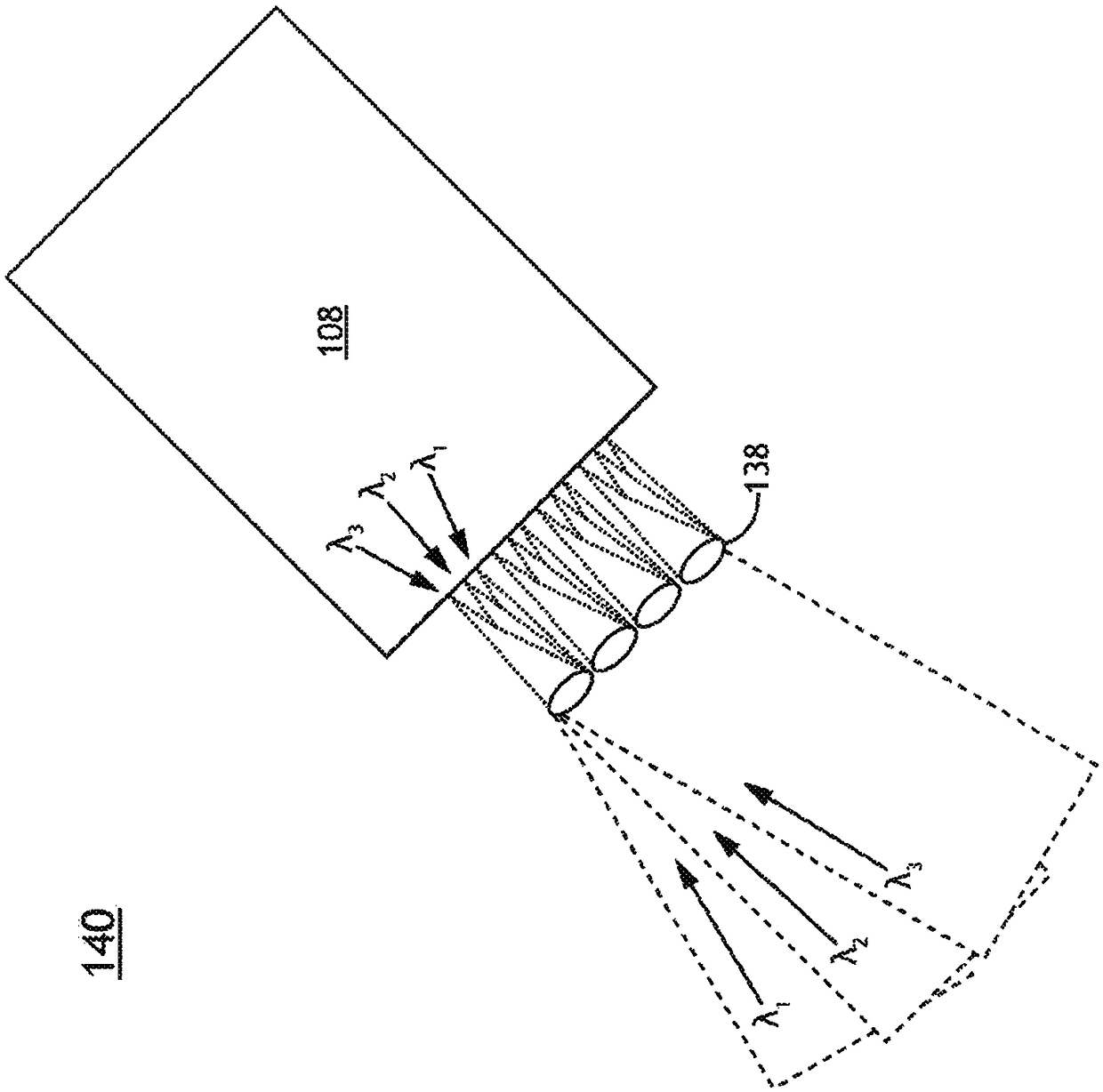

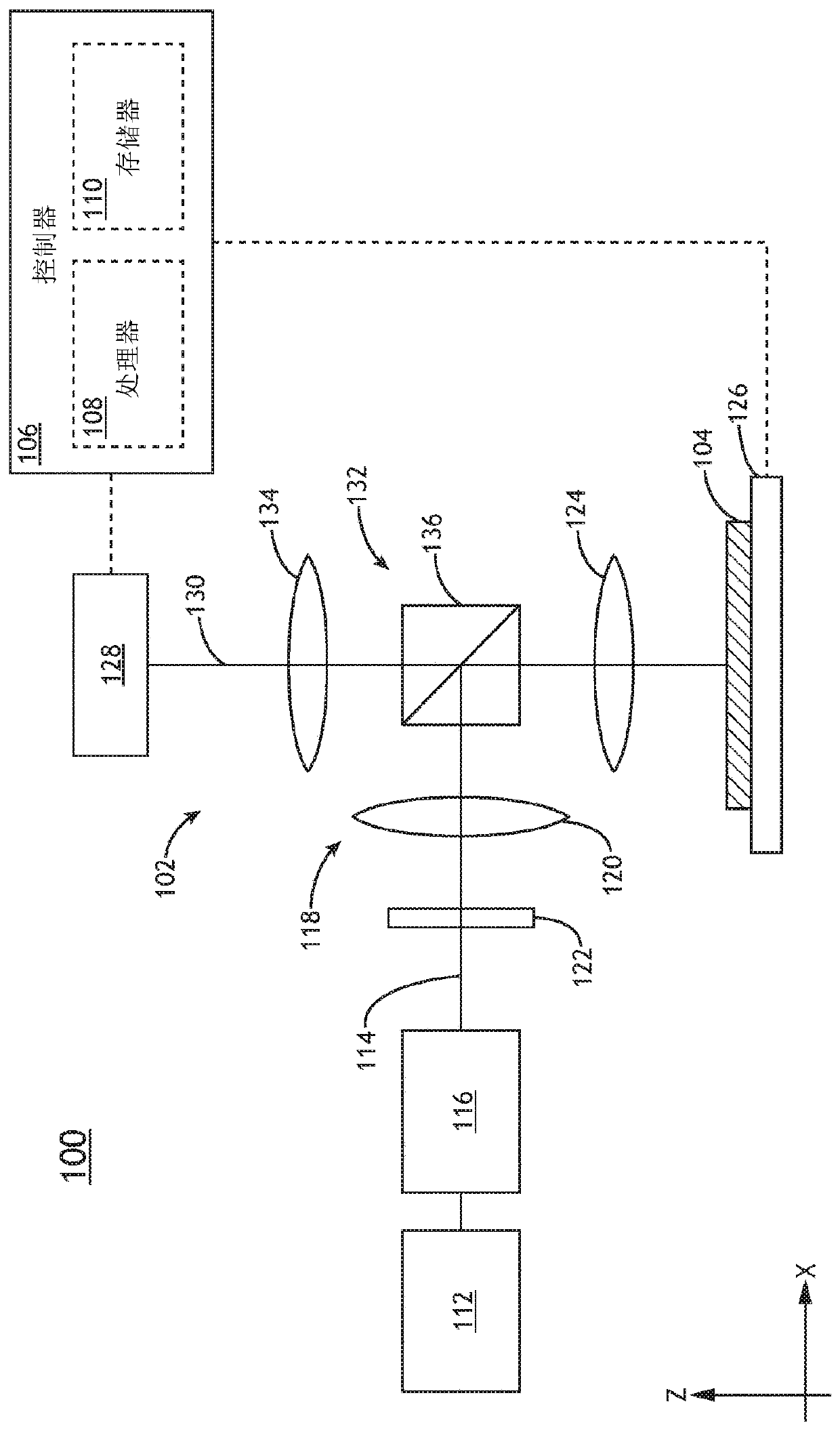

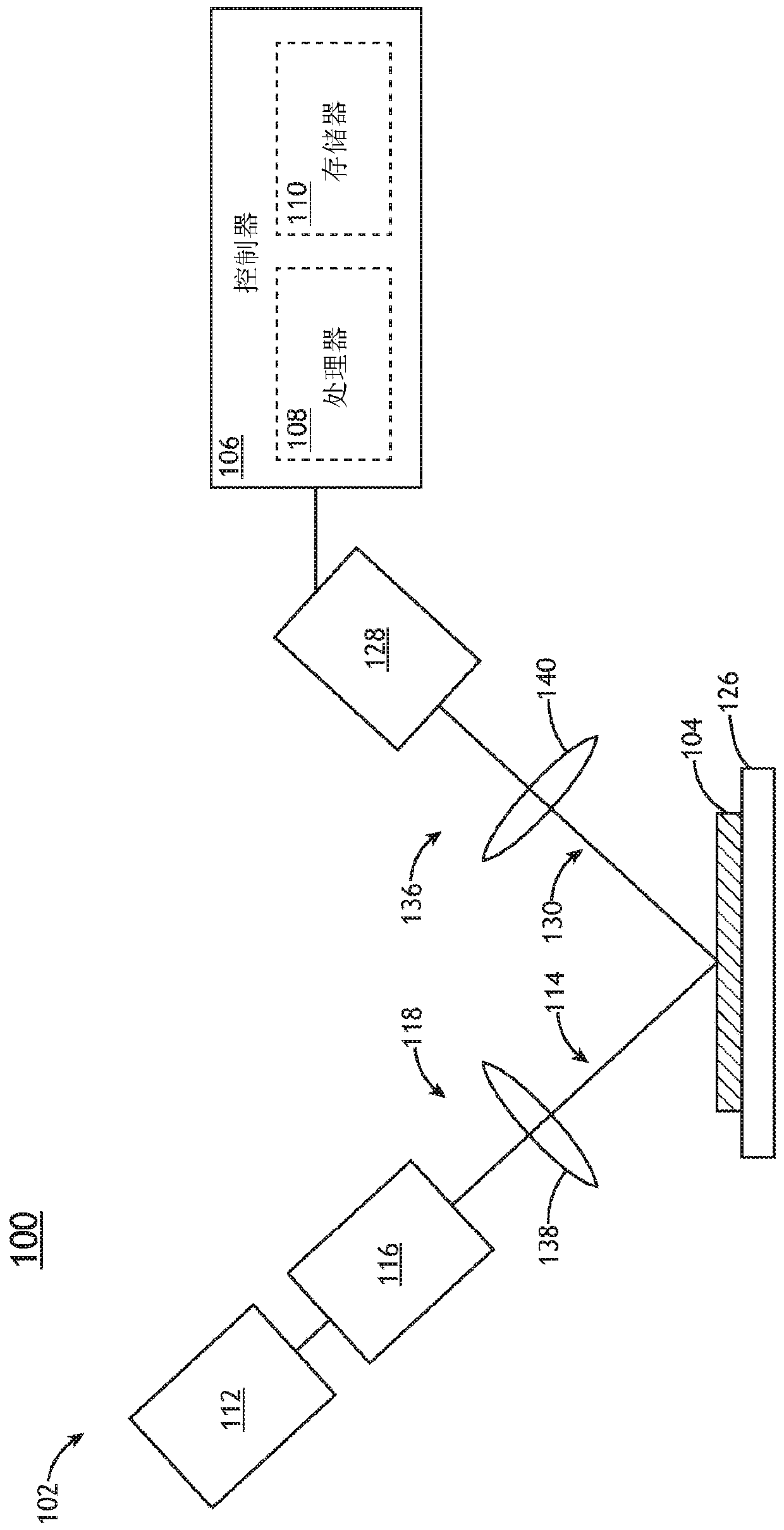

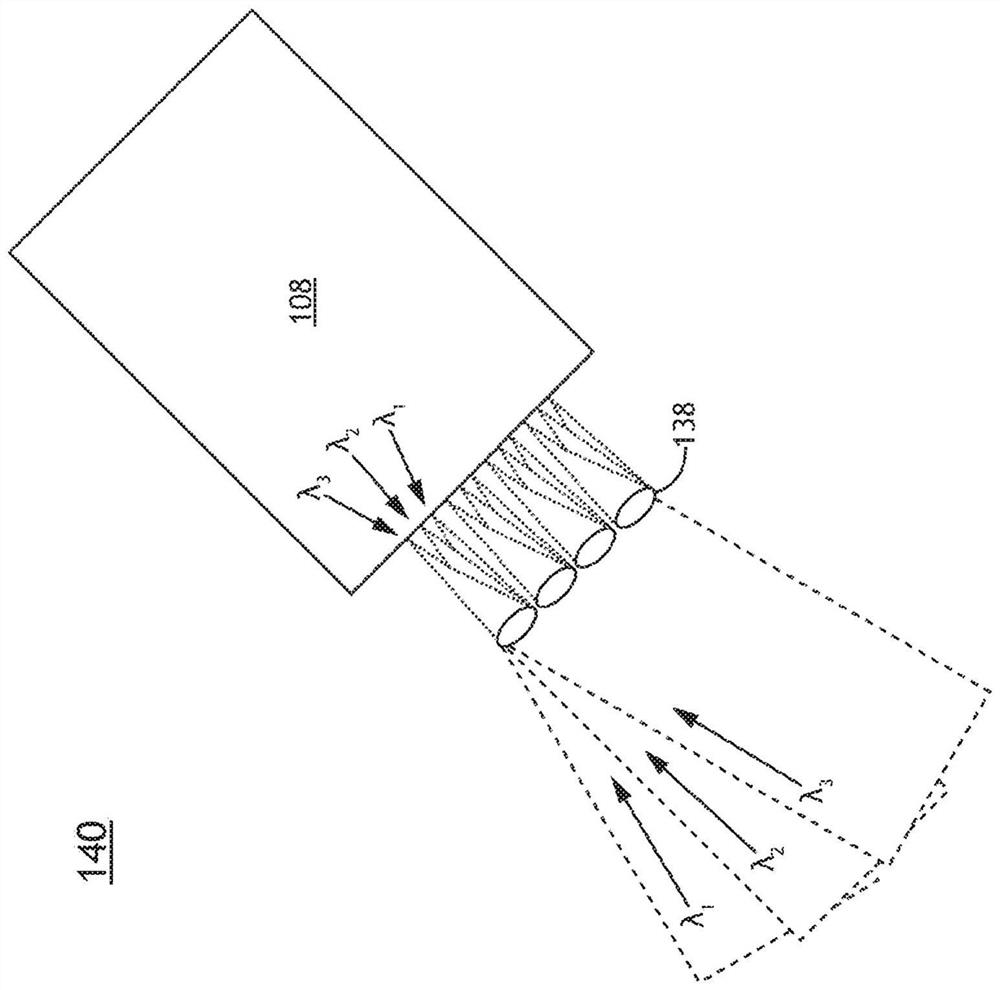

System and method for hyperspectral imaging metrology

A metrology system includes an illumination source configured to generate an illumination beam, one or more illumination optics configured to direct the illumination beam to a sample, one or more collection optics configured to collect illumination emanating from the sample, a detector, and a hyperspectral imaging sub-system. The hyperspectral imaging sub-system includes a dispersive element positioned at a pupil plane of the set of collection optics configured to spectrally disperse the collected illumination, a lens array including an array of focusing elements, and one or more imaging optics. The one or more imaging optics combine the spectrally-dispersed collected illumination to form an image of the pupil plane on the lens array. The focusing elements of the lens array distribute thecollected illumination on the detector in an arrayed pattern.

Owner:KLA TENCOR TECH CORP

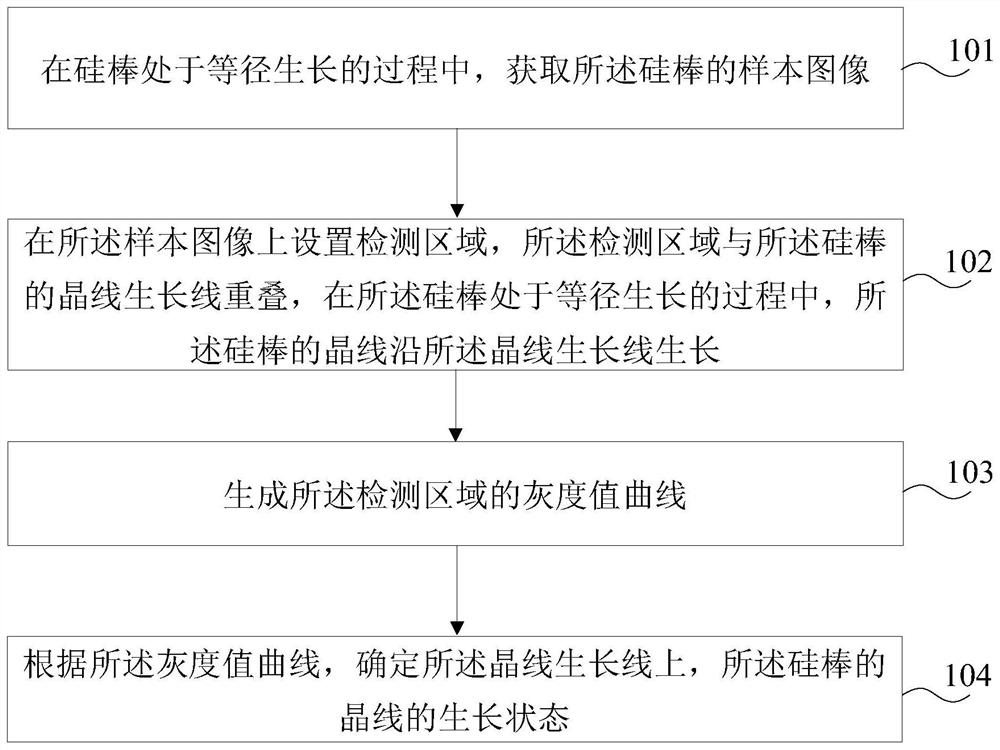

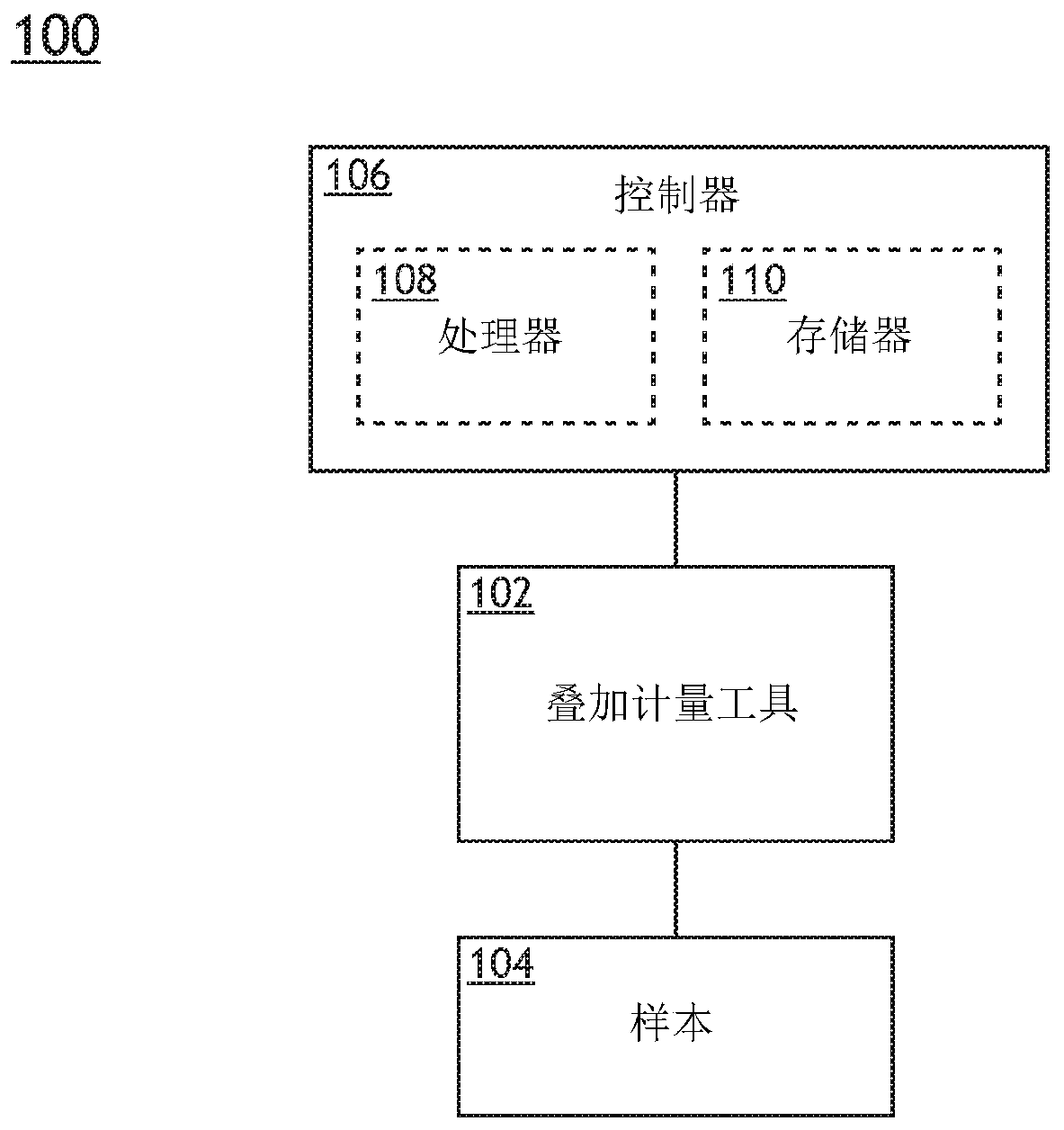

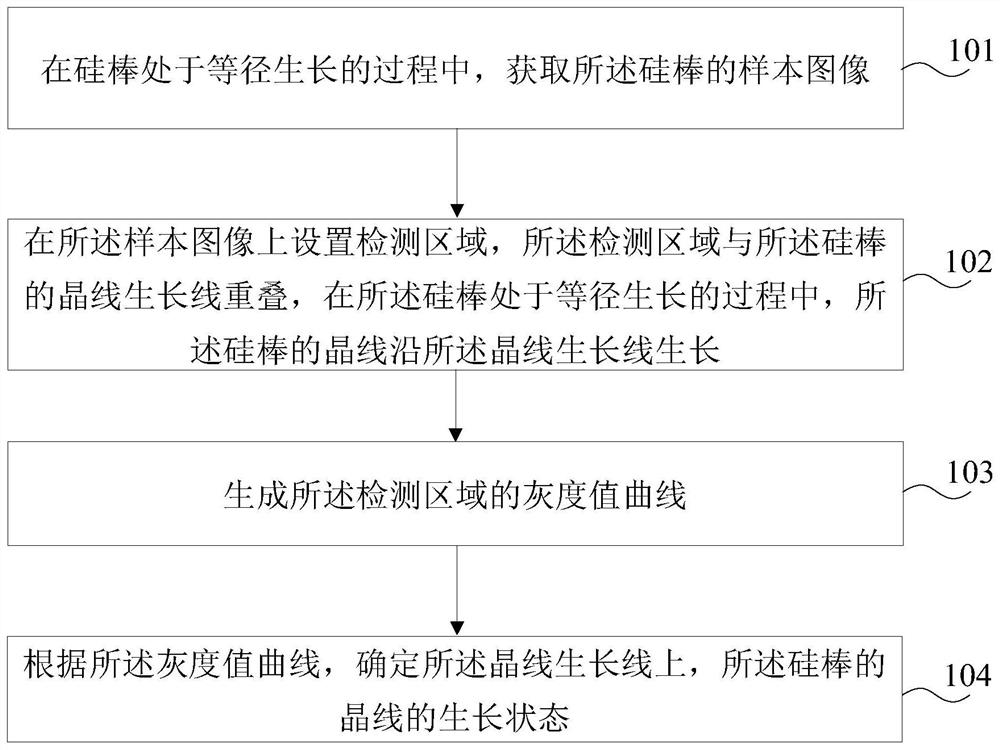

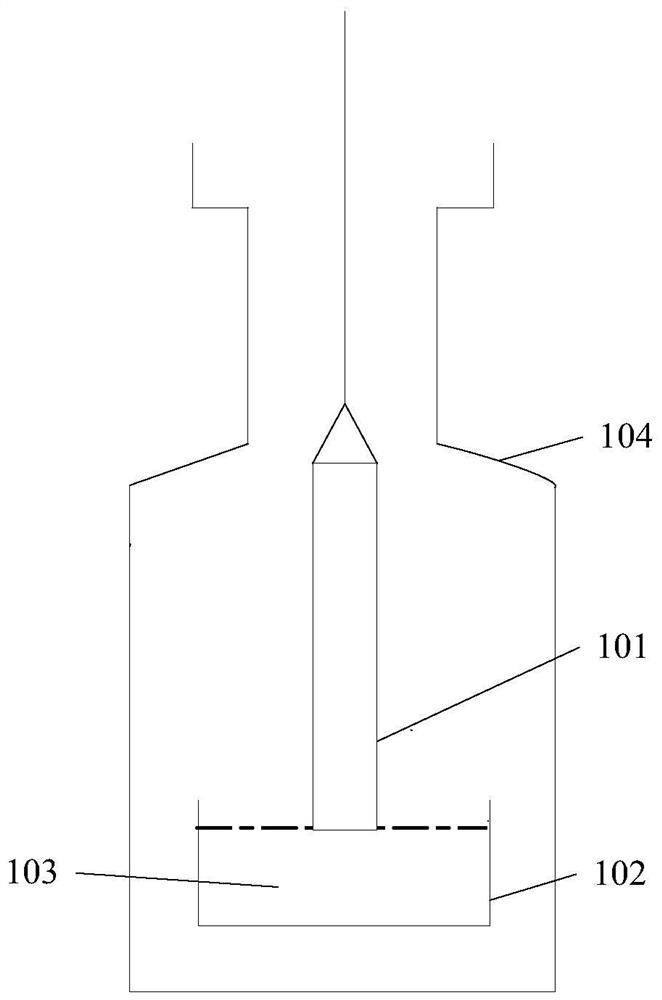

Silicon rod crystal line growth state detection method, device and equipment

ActiveCN112444516AImprove detection accuracyImprove detection efficiencyInvestigating semiconductor impuritiesImage enhancementSample imageMaterials science

The invention provides a silicon rod crystal line growth state detection method, device and equipment, and relates to the technical field of monocrystalline silicon, and the method comprises the steps: obtaining a sample image of a silicon rod in an equal-diameter growth process of the silicon rod; setting a detection area on the sample image, wherein the detection area is overlapped with the crystal line growth line of the silicon rod; generating a gray value curve of the detection area; and determining the growth state of the crystal line of the silicon rod on the crystal line growth line according to the gray value curve of the detection area. According to the method, the sample image of the silicon rod in the growth process is collected in real time, the detection area is arranged on the sample image, and the growth state of the crystal line of the silicon rod can be determined according to the gray value curve of the detection area so that whether the silicon rod is a monocrystalline silicon rod or not is judged; by adopting the method, the influence of the fluctuation of the diameter of the silicon rod and the unobvious characteristics of the crystal wire on the detection process of the crystal wire is reduced so that the detection precision and the detection efficiency of the crystal wire are improved, and the operation is simple.

Owner:LONGI GREEN ENERGY TECH CO LTD

Overlay metrology using multiple parameter configurations

ActiveCN111095509AInvestigating semiconductor impuritiesSemiconductor/solid-state device testing/measurementSoftware engineeringLight beam

An overlay metrology system includes an overlay metrology tool configurable to generate overlay signals with a plurality of recipes and further directs an illumination beam to an overlay target and collects radiation emanating from the overlay target in response to the at least a portion of the illumination beam to generate the overlay signal with the particular recipe. The overlay metrology system further acquires two or more overlay signals for a first overlay target using two or more unique recipes, subsequently acquires two or more overlay signals for a second overlay target using the twoor more unique recipes, determines candidate overlays for the first and second overlay targets based on the two or more overlay signals for each target, and determines output overlays for the first and second overlay targets based on the two or more candidate overlays for each target.

Owner:KLA TENCOR TECH CORP

EVALUATION METHOD AND MANUFACTURING METHOD OF SiC EPITAXIAL WAFER

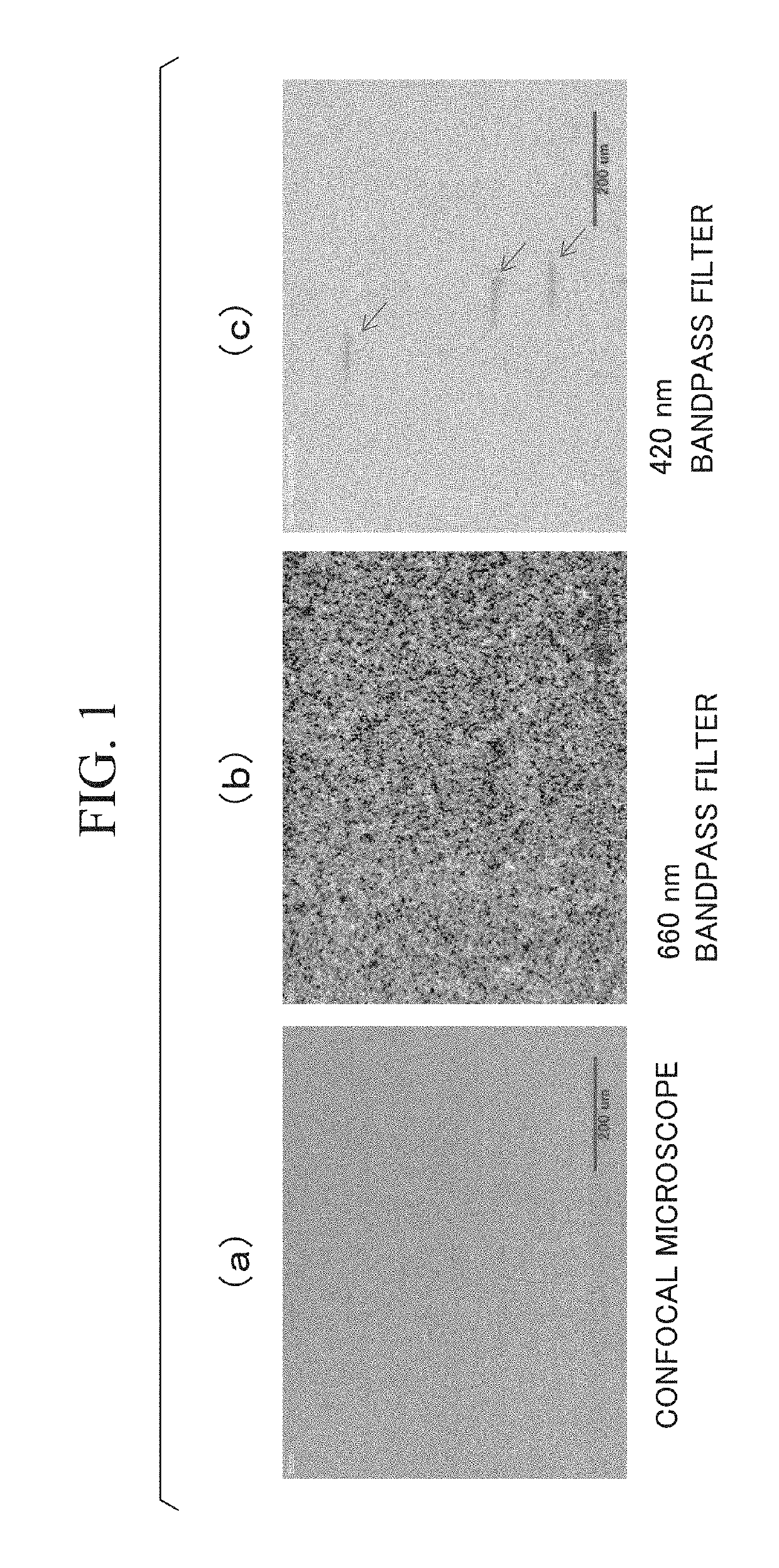

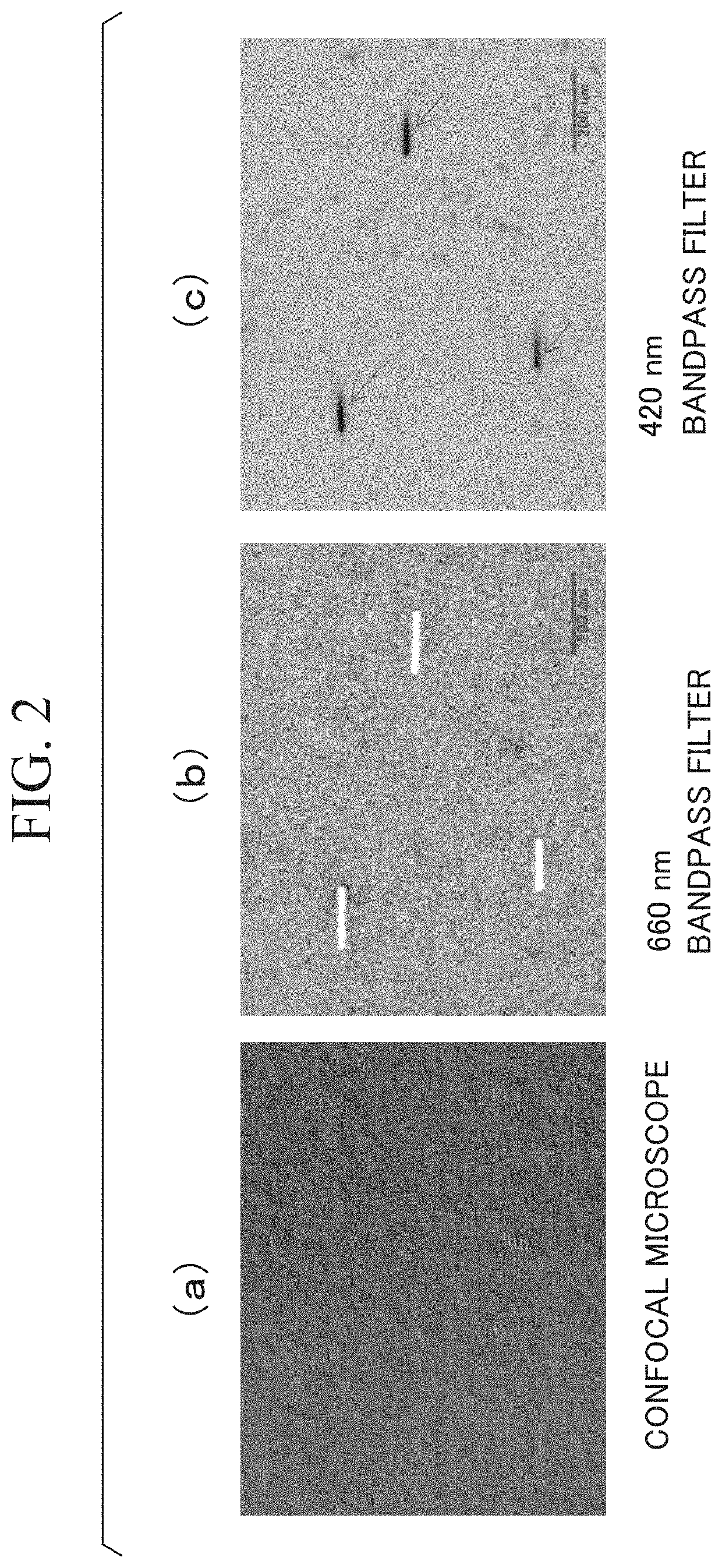

ActiveUS20190172758A1Investigating semiconductor impuritiesPolycrystalline material growthHigh concentrationBand-pass filter

An evaluation method of a SiC epitaxial wafer includes: a first observation step of preparing a SiC epitaxial wafer having a high-concentration epitaxial layer having an impurity concentration of 1×1018 cm−3 or more, irradiating a surface of the high-concentration epitaxial layer having an impurity concentration of 1×1018 cm−3 or more with excitation light, and observing a surface irradiated with the excitation light via a band-pass filter having a wavelength band of 430 nm or less.

Owner:RESONAC CORP

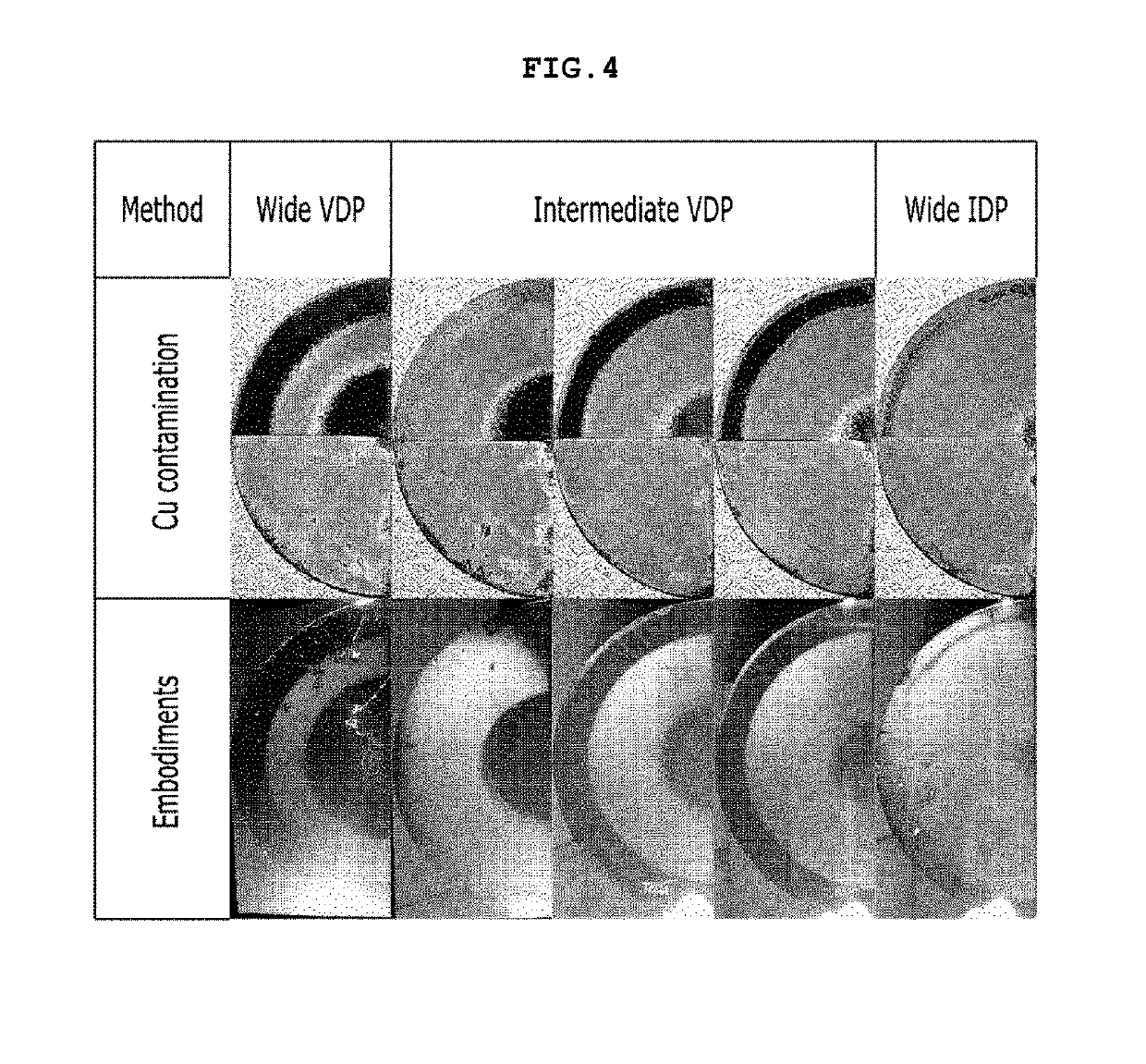

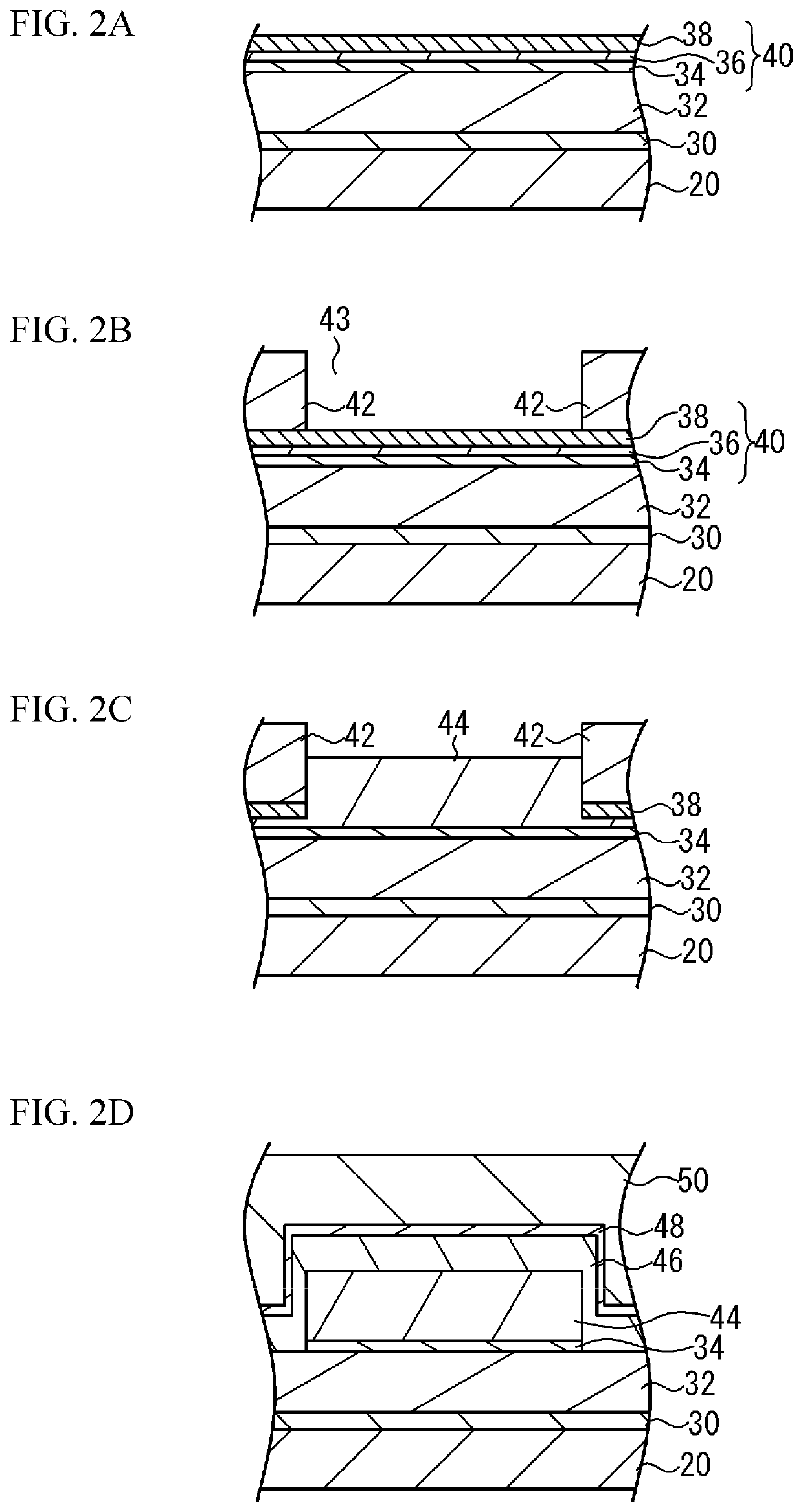

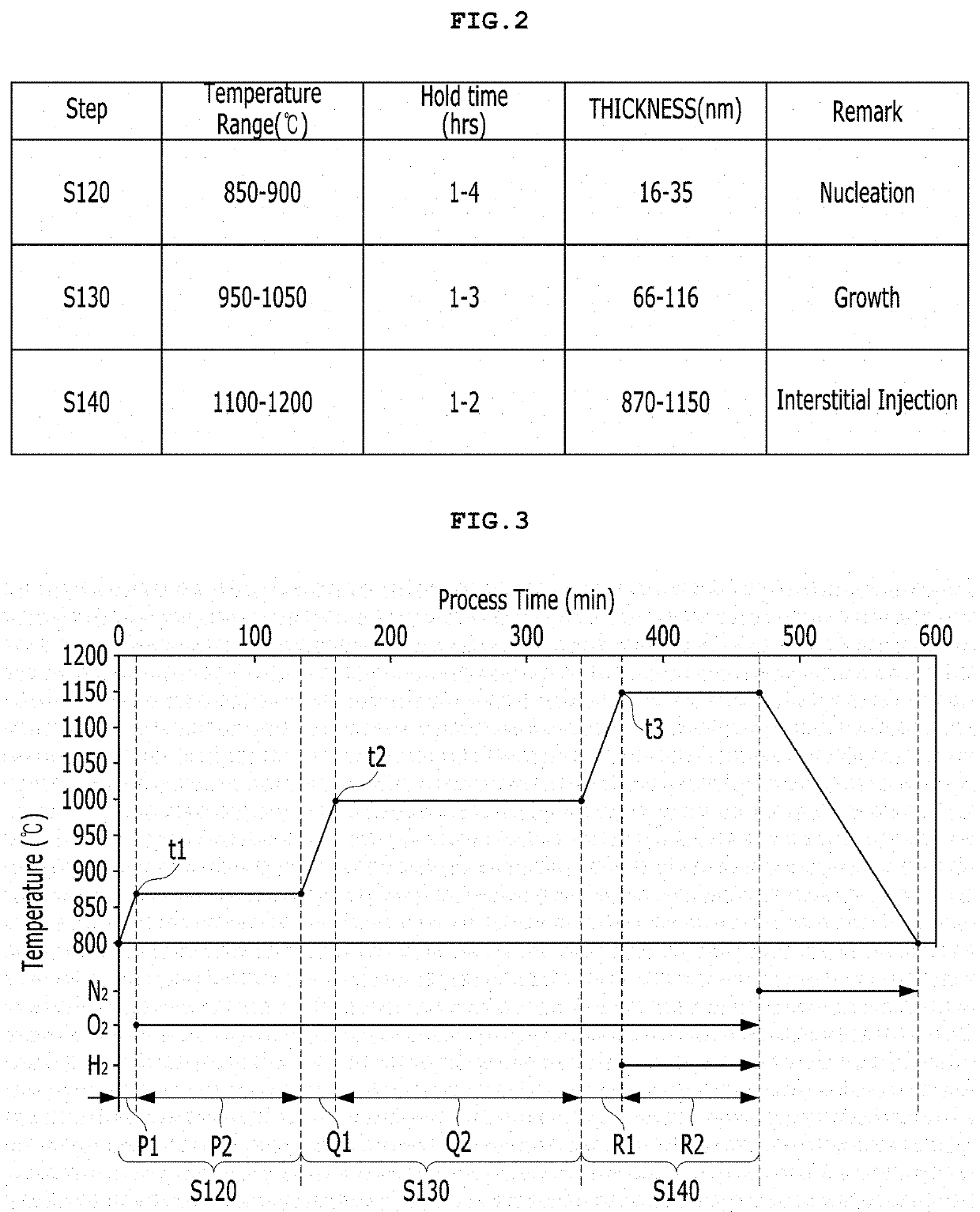

Method of identifying defect regions in wafer

ActiveUS20190170661A1Investigating semiconductor impuritiesSemiconductor/solid-state device testing/measurementAnalytical chemistryHaze

A method of identifying a wafer defect region is disclosed. The method includes preparing a sample wafer, forming a primary oxide film on the sample wafer at a temperature of 800° C. to 1000° C., forming a secondary oxide film on the primary oxide film at a temperature of 1000° C. to 1100° C., forming a tertiary oxide film on the secondary oxide film at a temperature of 1100° C. to 1200° C., removing the primary to tertiary oxide films, etching one surface of the sample wafer from which the primary to tertiary oxide films are removed to form haze on one surface of the sample wafer, and identifying a defect region of the sample wafer based on the haze.

Owner:SK SILTRON CO LTD

Evaluation method and manufacturing method of SiC epitaxial wafer

ActiveUS11315839B2Investigating semiconductor impuritiesPolycrystalline material growthHigh concentrationBand-pass filter

Owner:RESONAC CORPORATION

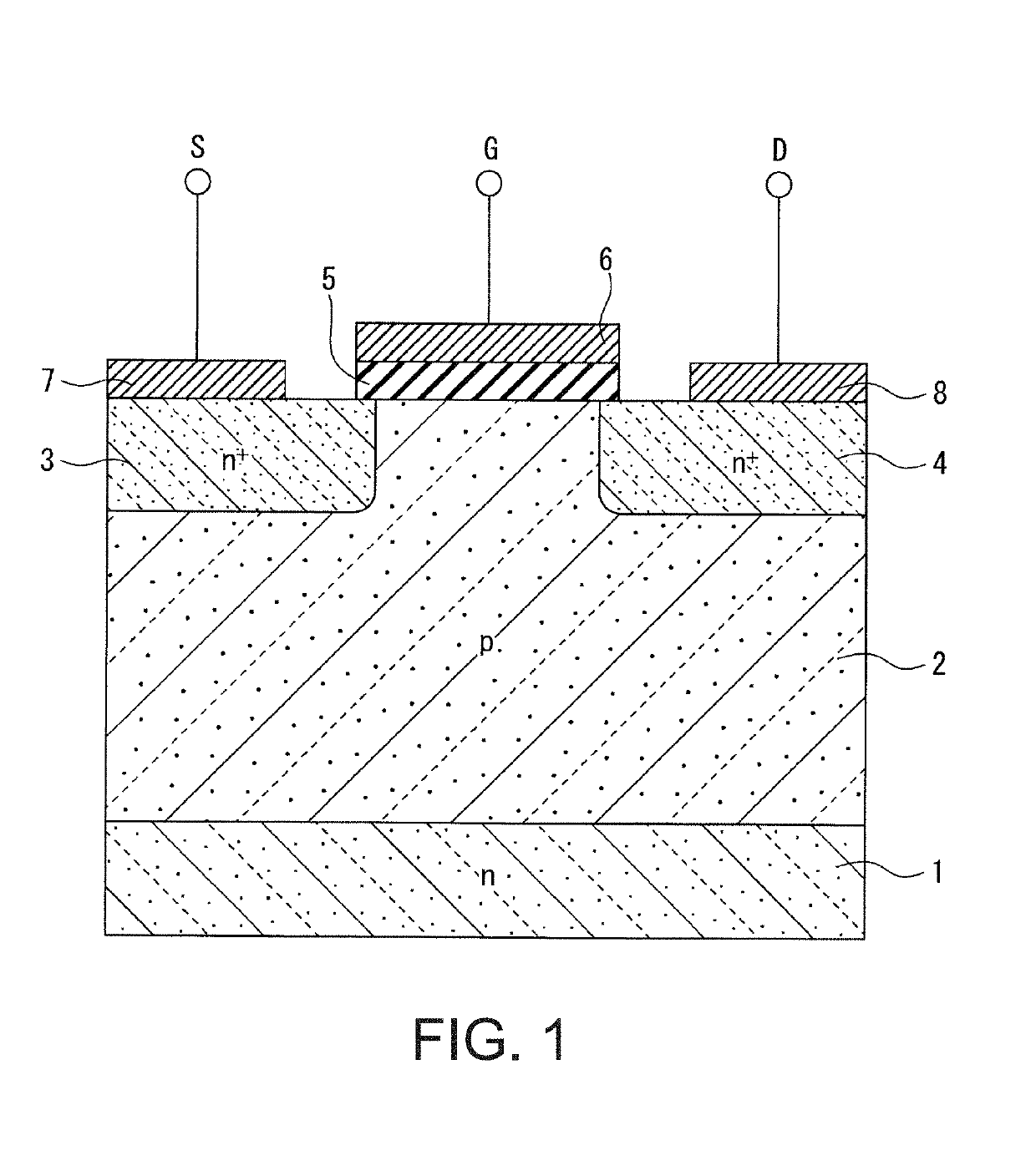

Method of evaluating insulated-gate semiconductor device

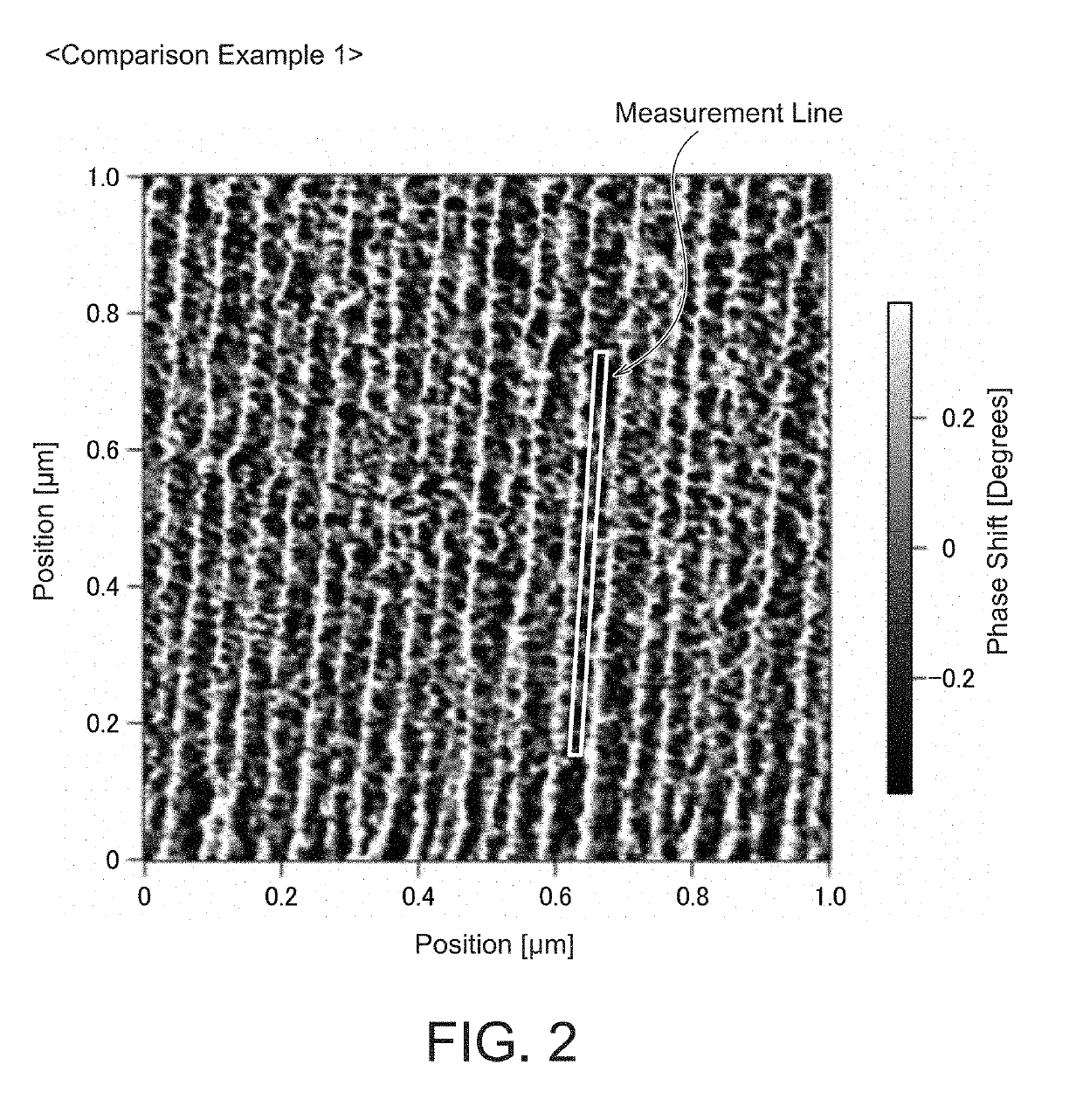

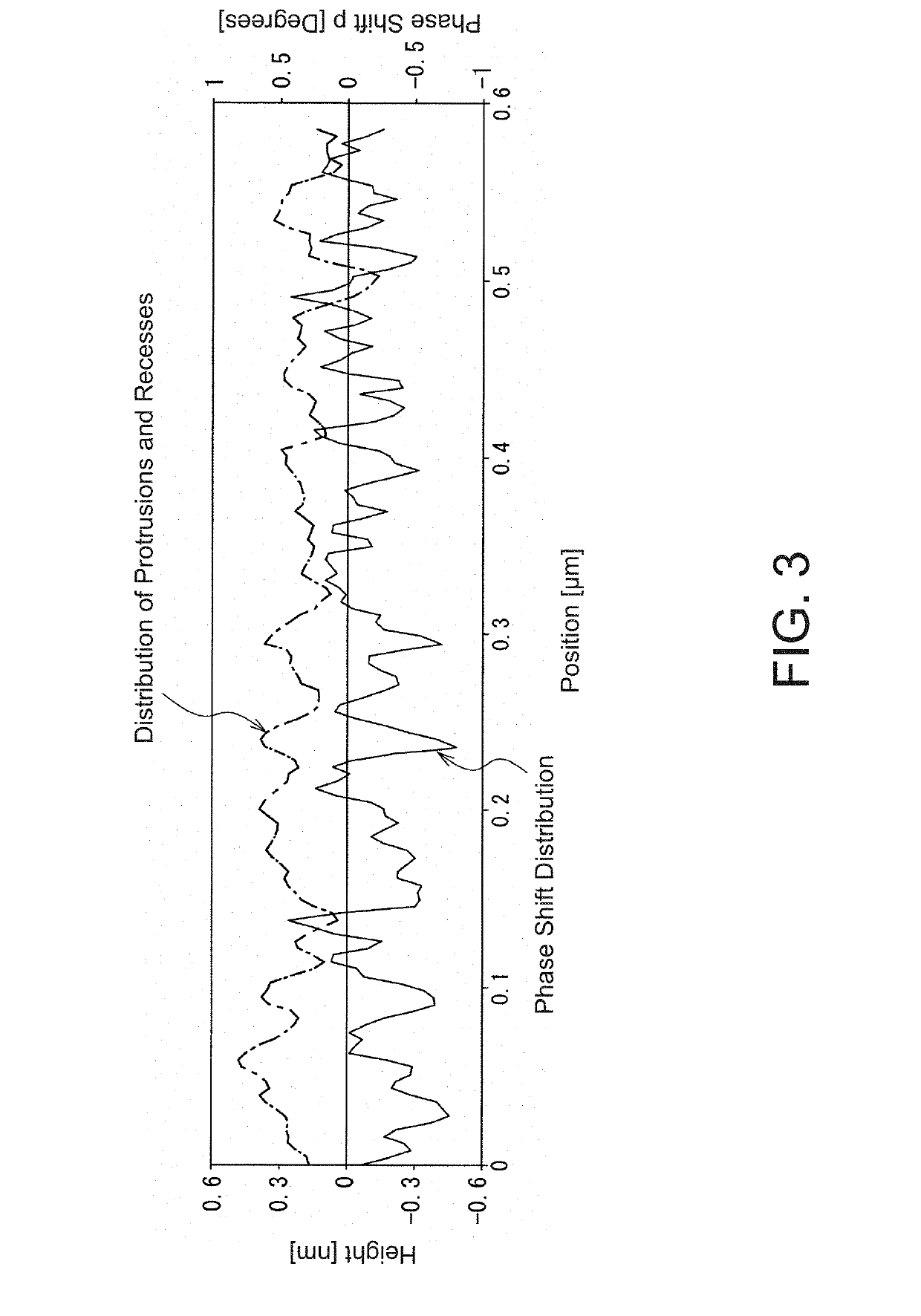

ActiveUS20190172912A1High field-effect mobilityHigh densityInvestigating semiconductor impuritiesSemiconductor/solid-state device testing/measurementPhase shiftedEngineering

A method of evaluating an insulated-gate semiconductor device having an insulated-gate structure including a channel formation layer made of a wide-bandgap semiconductor and a gate insulating film formed contacting the channel formation layer includes removing the gate insulating film in order to expose a surface of the channel formation layer; taking a phase image of the exposed surface of the channel formation layer using a phase mode of an atomic force microscope; evaluating a surface condition of the exposed surface of the channel formation layer by calculating an evaluation metric from phase shift values in the phase image and by determining whether the evaluation metric satisfies a prescribed condition; and determining that the insulated-gate semiconductor device is acceptable when the evaluation metric satisfied the prescribed condition.

Owner:FUJI ELECTRIC CO LTD

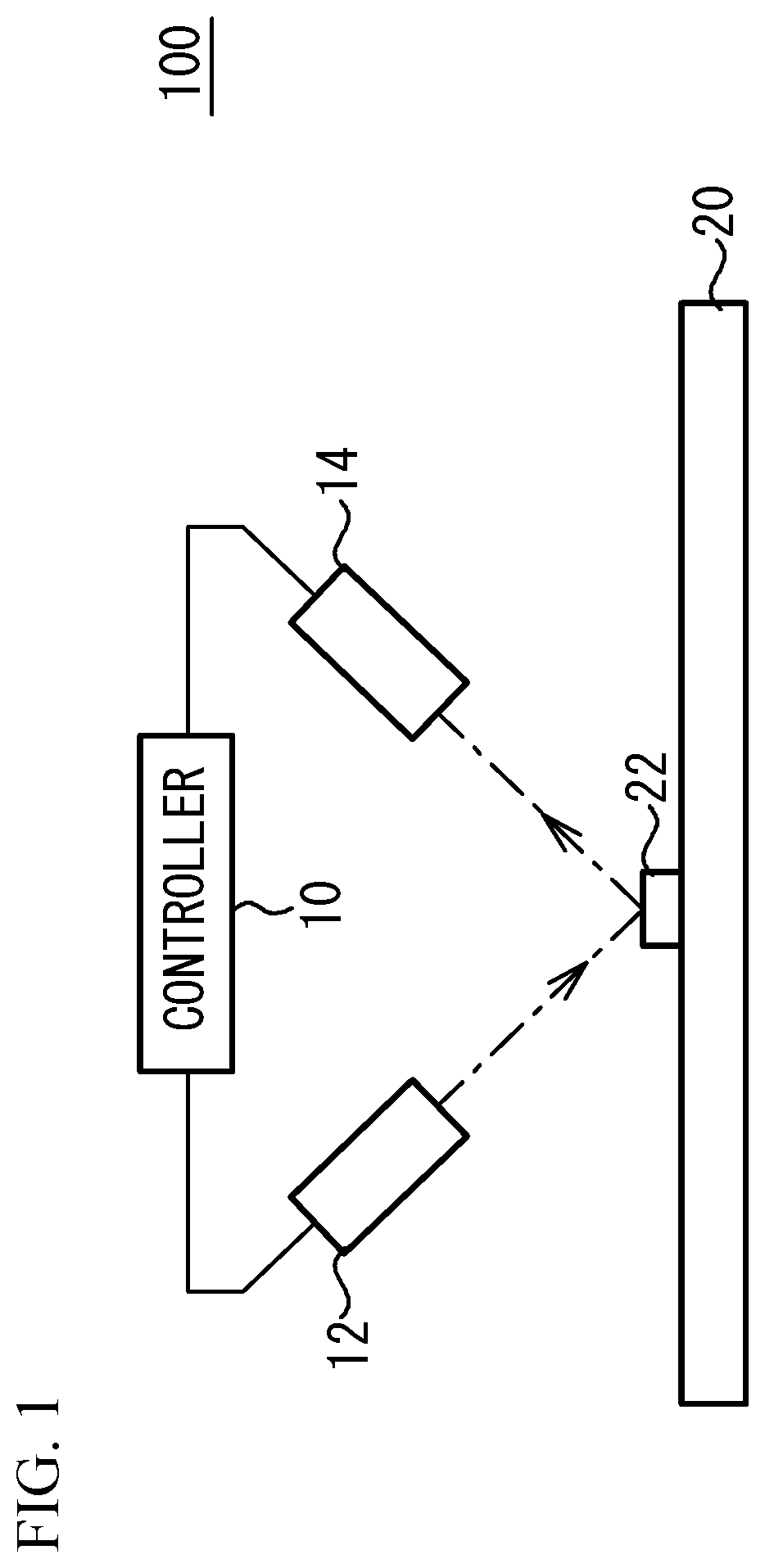

Method for inspecting surface of wafer, device for inspecting surface of wafer, and manufacturing method of electronic component

ActiveUS20200400587A1Quick fixInvestigating semiconductor impuritiesSemiconductor/solid-state device testing/measurementForeign matterWafering

A method for inspecting a surface of a wafer, includes steps of: irradiating a surface of the wafer with a laser beam having three or more distinct wavelengths; detecting a reflected light from the surface of the wafer when the surface of the wafer is irradiated with the laser beam; and determining whether a foreign matter exists on the surface of the wafer based on reflectances of the surface of the wafer with respect to the laser beam having the three or more distinct wavelengths, wherein the step of determining whether the foreign matter exists includes a step of determining whether the foreign matter is a metal or a non-metal.

Owner:SUMITOMO ELECTRIC DEVICE INNOVATIONS

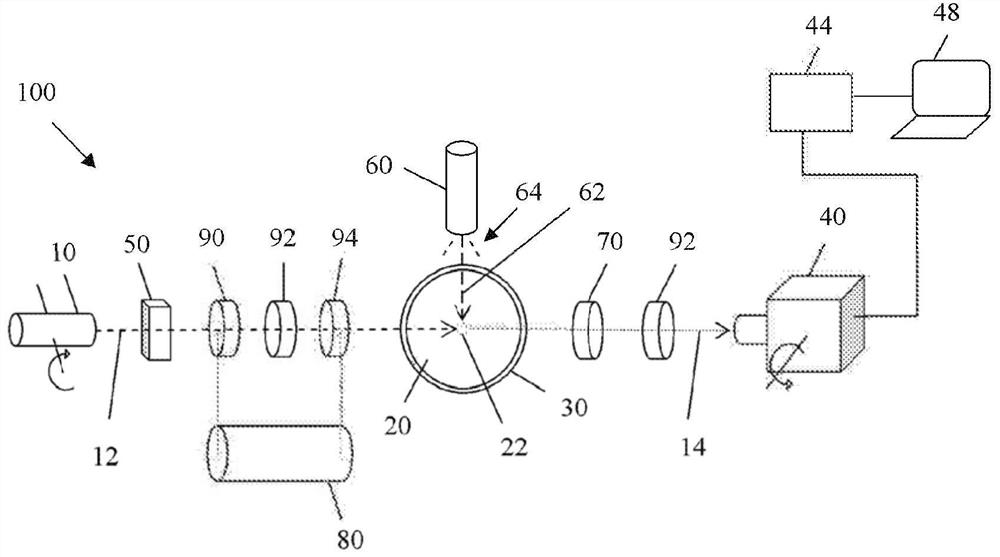

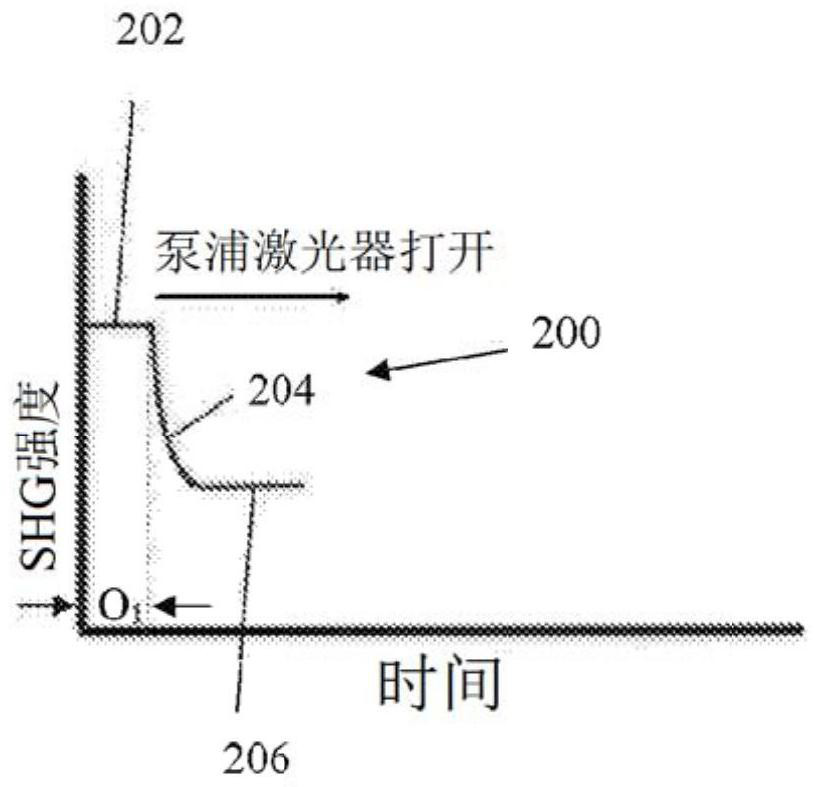

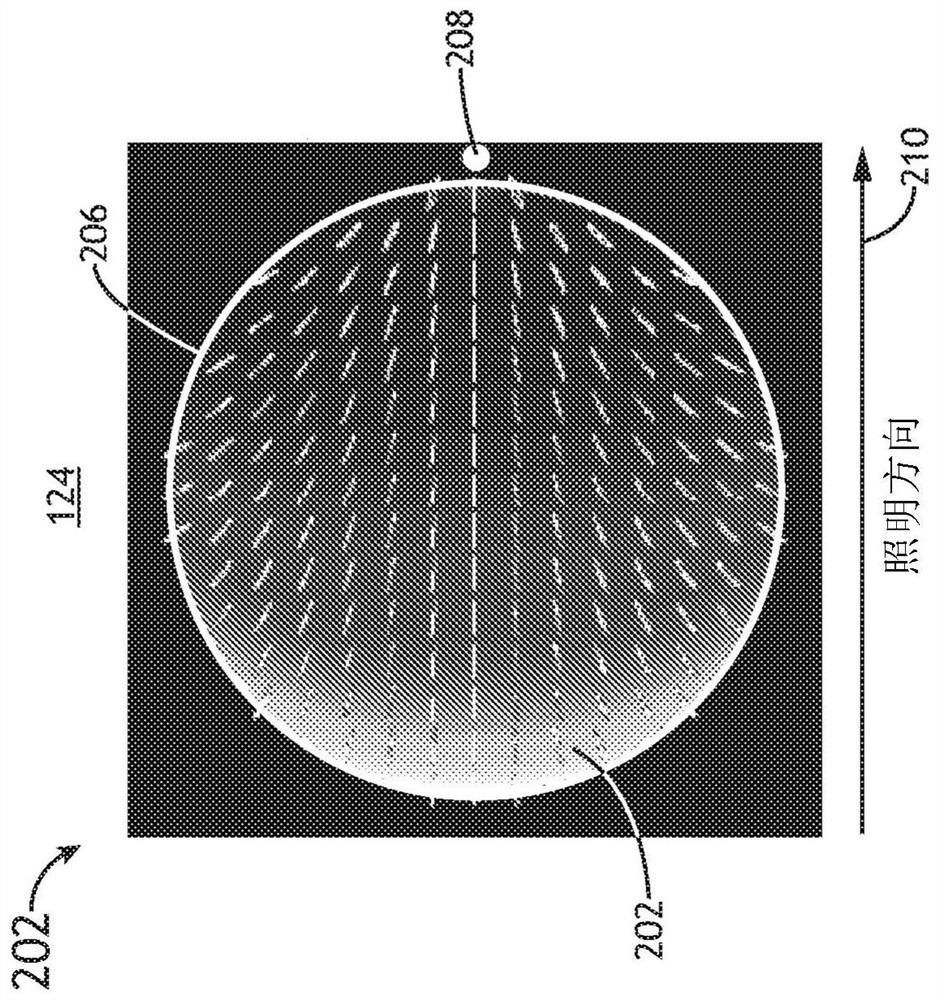

Systems and methods for determining characteristics of semiconductor devices

PendingCN113056814AReduced Risk of Optical DamageLight in massInvestigating semiconductor impuritiesSemiconductor/solid-state device testing/measurementWaferingSemiconductor structure

Second Harmonic Generation (SHG) can be used to interrogate a surface such as a surface of a layered semiconductor structure on a semiconductor wafer. In some instances, SHG is used to evaluate an interfacial region such as between metal and oxide. Various parameters such as input polarization, output polarization, and azimuthal angle of incident beam, may affect the SHG signal. Accordingly, such parameters are varied for different types of patterns on the wafer. SHG metrology on various test structures may also assist in characterizing a sample.

Owner:菲拓梅里克斯公司

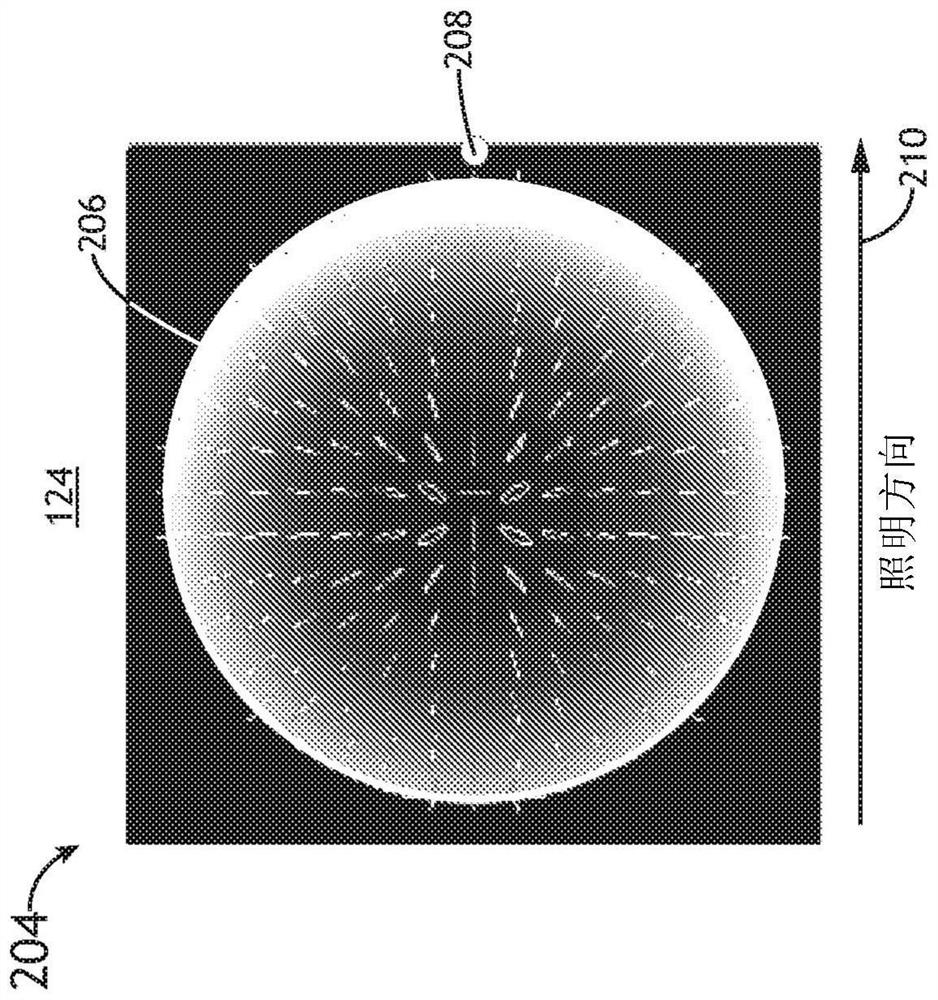

Systems and methods for particle detection

ActiveCN112969910BInvestigating semiconductor impuritiesSemiconductor/solid-state device testing/measurementLight beamPolarizer

The present invention discloses a dark field inspection system, which may include: an illumination source for generating an illumination beam; one or more illumination optics for directing the illumination beam along an illumination direction at an off-axis angle to a sample; a detector; one or more collection optics for producing a dark field image of the sample on the detector based on light collected from the sample in response to the illumination beam; and radial polarization a polarizer positioned at a pupil plane of the one or more collection optics, wherein the radial polarizer repels specular reflections from the sample in the pupil plane corresponding to the illumination beam The reference point has radially polarized light.

Owner:KLA CORP

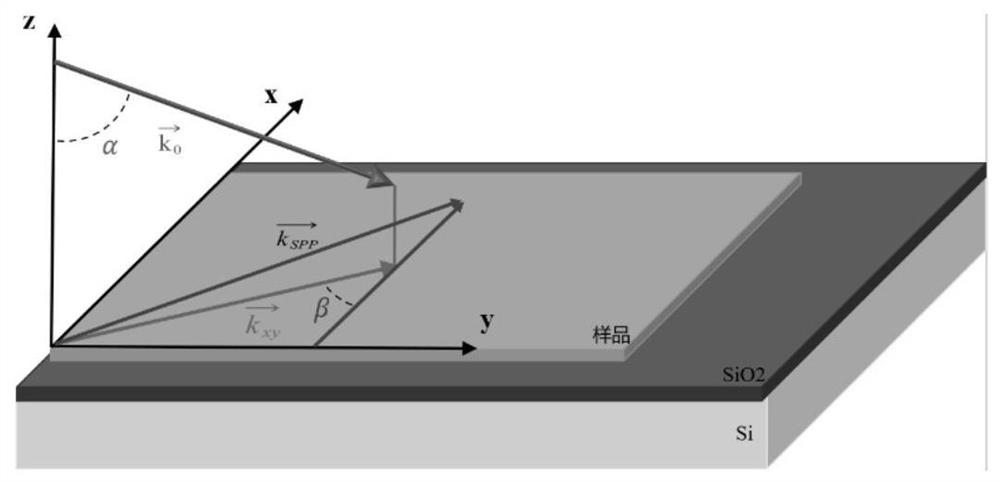

Method for representing real space characteristics of two-dimensional polariton

PendingCN114594097ASize limitOvercoming the drawbacks of measurement complexityInvestigating semiconductor impuritiesScanning probe microscopyLaser lightSpatial image

The invention provides a method for representing real space characteristics of two-dimensional polaritons, which comprises the following steps of: S1, placing a sample to be tested on a SiO2 / Si substrate, and enabling one edge of the sample to be tested and the edge of a cantilever arm of a scattering type near-field optical microscope to form an angle of 45 degrees; s2, enabling the needle point of the scattering type near-field optical microscope to scan along the edge vertical to the tested sample, sequentially changing the wavelength of the excitation laser light source, and scanning by the scattering type near-field optical microscope to obtain a near-field real space image; s3, Fourier transform processing is carried out on the near-field real space images obtained in the step 2 one by one, and a wave vector real part k'p and a propagation length Lp of a hybrid polariton mode are obtained respectively; and S4, obtaining wave vectors k'p and Lp of the hybrid polaritons under each wavelength according to a formula. The diffraction limit is broken through through the scattering type near-field optical microscope, the physical phenomenon of interaction between light and substances in a near-field area is explored, and the real space characteristics of two-dimensional polaritons are presented.

Owner:NANJING UNIV

Method of measuring crystal defects in thin SI/SIGE bilayers

InactiveCN1258214CInvestigating semiconductor impuritiesSemiconductor/solid-state device testing/measurementAlloyCrystallographic defect

Owner:GLOBALFOUNDRIES INC

System and method for hyperspectral imaging metrology

ActiveCN108603789BInvestigating semiconductor impuritiesRaman/scattering spectroscopyLight beamEngineering

Owner:KLA CORP

Method, device and equipment for detecting crystal line growth state of silicon rod

ActiveCN112444516BImprove detection accuracyImprove detection efficiencyInvestigating semiconductor impuritiesImage enhancementSample imageRegion detection

The present invention provides a method, device and equipment for detecting the crystal line growth state of a silicon rod, which relate to the technical field of single crystal silicon, including: obtaining a sample image of a silicon rod during the growth process of a silicon rod; A detection area is set on the image, and the detection area overlaps with the crystal line growth line of the silicon rod; a gray value curve of the detection area is generated; according to the gray value curve of the detection area, the crystal line of the silicon rod on the crystal line growth line is determined growth status. In the present invention, by collecting the sample image of the silicon rod in the growth process in real time, and setting a detection area on the sample image, according to the gray value curve of the detection area, the growth state of the crystal wire of the silicon rod can be determined, thereby Judging whether the silicon rod is a single crystal silicon rod, this method reduces the influence of the fluctuation of the diameter of the silicon rod and the unobvious characteristics of the crystal wire on the detection process of the crystal wire, thereby improving the detection accuracy and efficiency of the crystal wire, and the operation Simple.

Owner:LONGI GREEN ENERGY TECH CO LTD

Radial polarizer for particle detection

ActiveCN112969910AInvestigating semiconductor impuritiesSemiconductor/solid-state device testing/measurementLight beamEngineering

A dark field inspection system may include an illumination source to generate an illumination beam; one or more illumination optics to direct the illumination beam to a sample at an off-axis angle along an illumination direction; a detector; one or more collection optics to generate a dark-field image of the sample on the detector based on light collected from the sample in response to the illumination beam; and a radial polarizer located at a pupil plane of the one or more collection optics, where the radial polarizer rejects light with radial polarization with respect to a reference point in the pupil plane corresponding to specular reflection of the illumination beam from the sample.

Owner:KLA TENCOR CORP

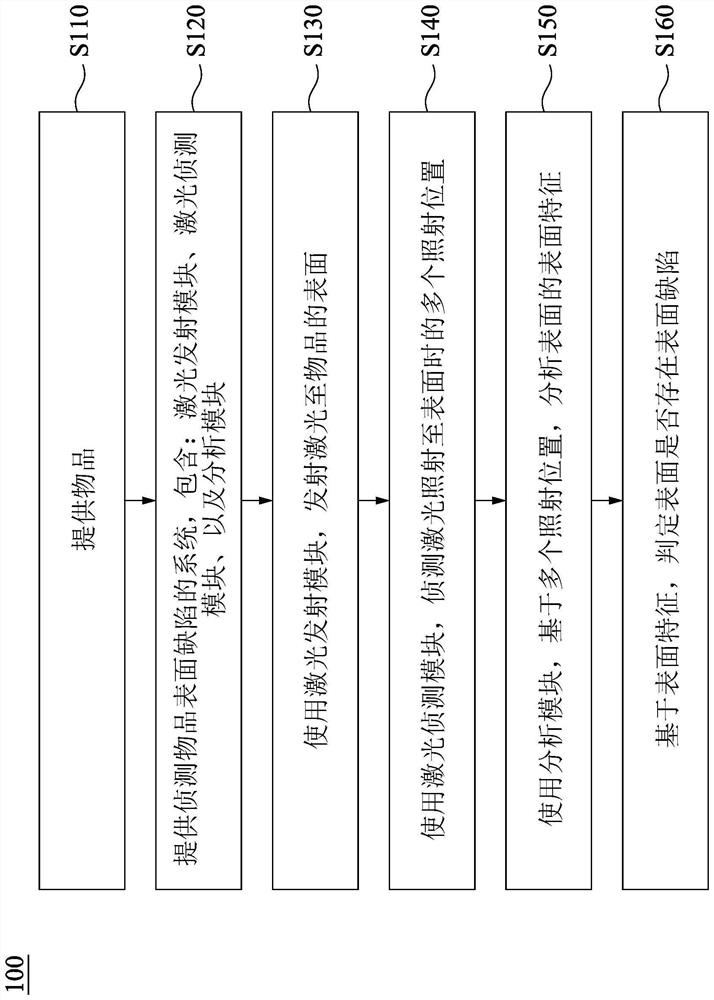

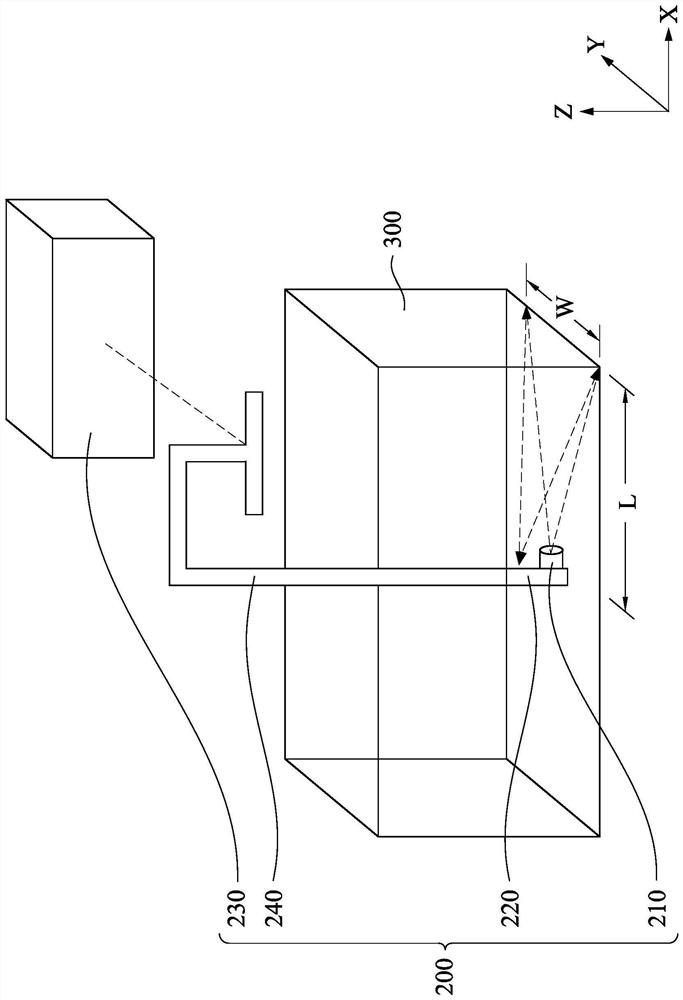

Method and system for detecting surface defects of article

PendingCN114252393AImprove resolutionSubtle surface defectsInvestigating semiconductor impuritiesLaser detectionLightness

The invention discloses a method and a system for detecting surface defects of an article. The method for detecting the surface defects of the article comprises the following steps of: providing the article; the system for detecting the surface defects of the object comprises a laser emission module, a laser detection module and an analysis module, the laser detection module is electrically connected with the laser emission module, and the analysis module is electrically connected with the laser detection module; emitting laser to the surface of the object by using a laser emitting module; using a laser detection module to detect a plurality of irradiation positions when the laser irradiates the surface; analyzing, using an analysis module, a surface feature of the surface based on the plurality of illumination locations; and determining whether the surface has surface defects based on the surface features. The invention also provides a system for detecting the surface defects of the article, compared with a known automatic optical detection system or human eye identification, the detection resolution is not influenced by the illumination brightness or the shooting angle, the resolution is better, and finer surface defects can be distinguished.

Owner:NAN YA TECH

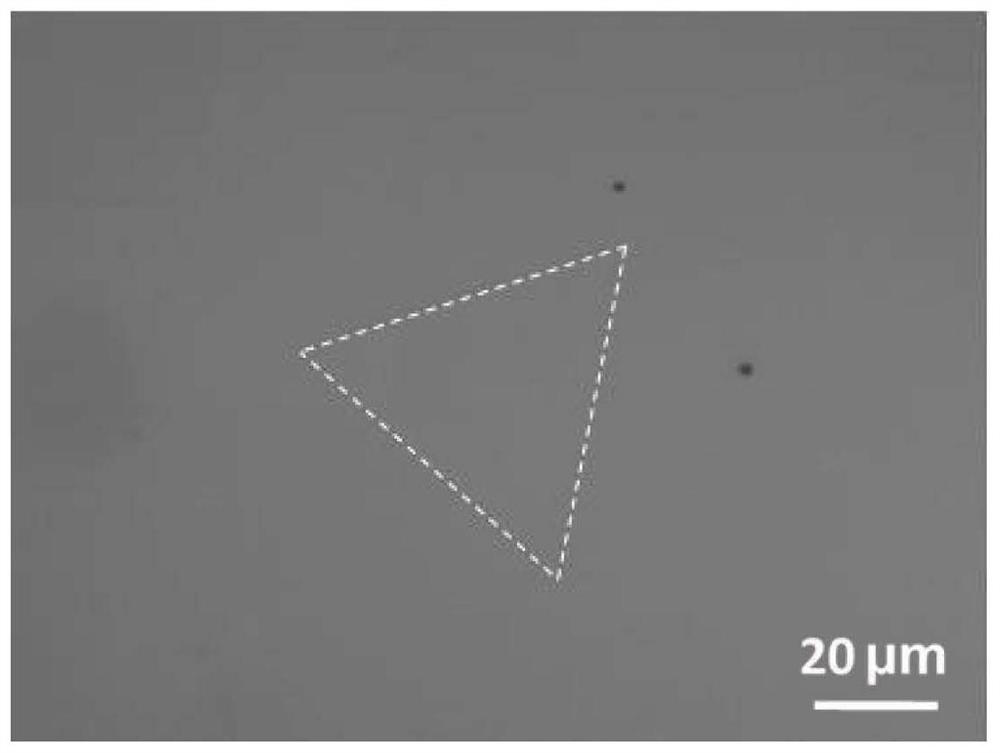

WSe2 sheet with controllable growth and preparation method and application thereof

ActiveCN114717650AAbundant growth shapeBroaden the shape studyInvestigating semiconductor impuritiesPolycrystalline material growthPhotovoltaic detectorsThin sheet

The invention belongs to the technical field of transition metal chalcogenide two-dimensional materials, and discloses a growth-controllable WSe2 sheet and a preparation method and application thereof. The method comprises the following steps: enabling argon flow to flow to the direction of WSe2 powder from a SiO2 / Si substrate, adjusting the pressure, reducing the speed of the argon flow to 30-50sccm, simultaneously raising the temperature to 1100-1130 DEG C, reducing the speed of the argon flow to 0sccm, changing the direction of the argon flow to flow to the SiO2 / Si substrate from the WSe2 powder, raising the speed of the argon flow to 100-130sccm, growing for 8-15 minutes at the temperature of 1100-1130 DEG C, and cooling to the room temperature under the condition of ventilation to obtain the WSe2 sheet with controllable growth. Controllable growth of the WSe2 sheet is realized by controlling the reaction time and the gas flow rate, so that the WSe2 has different crystal phases and layer numbers, and possibility is provided for preparing a novel photoelectric detector.

Owner:GUANGDONG UNIV OF TECH

Method of identifying defect regions in wafer

ActiveUS10634622B2Investigating semiconductor impuritiesSemiconductor/solid-state device testing/measurementWaferingNanotechnology

A method of identifying a wafer defect region is disclosed. The method includes preparing a sample wafer, forming a primary oxide film on the sample wafer at a temperature of 800° C. to 1000° C., forming a secondary oxide film on the primary oxide film at a temperature of 1000° C. to 1100° C., forming a tertiary oxide film on the secondary oxide film at a temperature of 1100° C. to 1200° C., removing the primary to tertiary oxide films, etching one surface of the sample wafer from which the primary to tertiary oxide films are removed to form haze on one surface of the sample wafer, and identifying a defect region of the sample wafer based on the haze.

Owner:SK SILTRON CO LTD

Method for detecting back-surface soft damage density of silicon wafer

ActiveCN110618132AGuarantee product qualityInvestigating semiconductor impuritiesSemiconductor/solid-state device testing/measurementSilicon chipCorrosion

The invention provides a method for detecting back-surface soft damage density of a silicon wafer. The method comprises the following steps of S1, thermal-oxidization processing; S2, corrosion, in which the silicon wafer obtained in the step S1 is placed in hydrofluoric acid for immersion; S3, dying, in which a chromium oxide solution is prepared, the silicon wafer obtained in the step S2 is immersed in the prepared chromium oxide solution for reaction; S4, washing with clean water; and S5, calculation. Fault is induced to be generated by thermal oxidization, an oxide layer is removed by corrosion, the fault is dyed by the chromium oxide solution, the fault occurring in an ultramicro damage layer is intuitively displayed under microscope, the method has the advantages of stability, reliability, high efficiency and convenience, a technical department can be helped to optimize a sand-blasting process or a special sand-blasting process is selected according to a client demand, daily production of a product also can be monitored, and the product quality is ensured.

Owner:TIANJIN ZHONGHUAN ADVANCED MATERIAL TECH

Method for quantification of process non uniformity using model-based metrology

ActiveUS10955359B2Investigating semiconductor impuritiesOptically investigating flaws/contaminationWaferingSemiconductor structure

Embodiments of the present invention provide an improved method and system for assessing non-uniformity of features in the measurement area (within the beam spot) on a semiconductor structure, (e.g. wafer), such as a non-uniform film thickness. The scattering from non-uniform features is modeled. Post-processing the residual of theoretical and collected spectra is performed to assess a measure of non-uniformity from within an incident spot beam of a spectrum acquisition tool.

Owner:IBM CORP

Popular searches

Investigating crystals By zone-melting liquids Semiconductor/solid-state device manufacturing Laser beam welding apparatus Single crystal growth details Solid-state devices Material flaws investigation Color/spectral properties measurements Pyrometry for hot spots detection Pyrometry for temperature profile

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com