Radial polarizer for particle detection

A polarizer and detector technology, applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as inability to achieve sensitive image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Reference will now be made in detail to the disclosed subject matter illustrated in the accompanying drawings. The invention has been particularly shown and described with respect to particular embodiments and its particular features. The embodiments set forth herein are to be regarded as illustrative and not restrictive. As used herein, directional terms (e.g., "left," "right," "top," "bottom," "above," "below," "up," "upward," "down," "downward") and "downward") are intended to provide relative positions for descriptive purposes, and do not wish to specify an absolute frame of reference. It will be readily apparent to those skilled in the art that various changes and modifications in form and details can be made without departing from the spirit and scope of the invention.

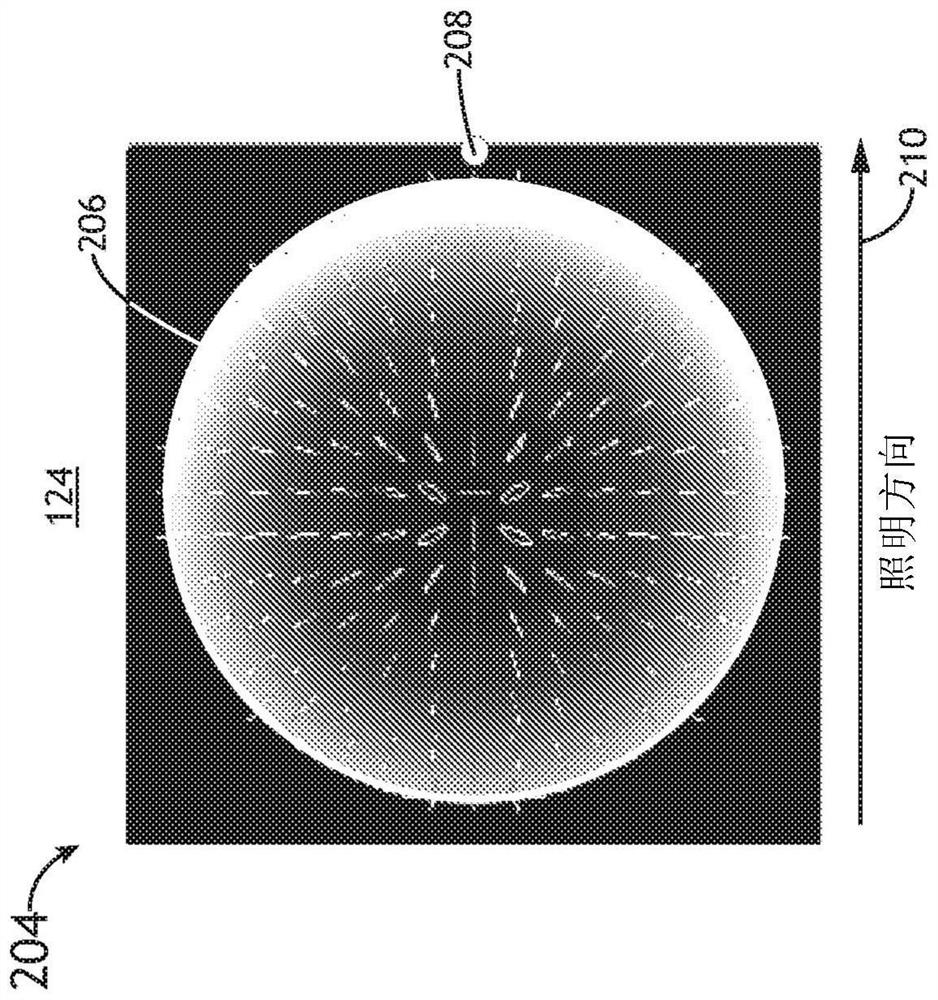

[0026] Embodiments of the invention relate to dark field imaging for selective filtering of surface scatter (e.g., surface haze) based on utilizing a haze-repelling polarizer in the pupil plane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com