WSe2 sheet with controllable growth and preparation method and application thereof

A flake, wse2 technology, applied in crystal growth, single crystal growth, single crystal growth and other directions, can solve the problems of unresearched performance, lack of controllability and repeatability of growth conditions and overlapping layers, single shape of WSe2, etc. Greater controllability and repeatability, broadening the effect of shape studies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

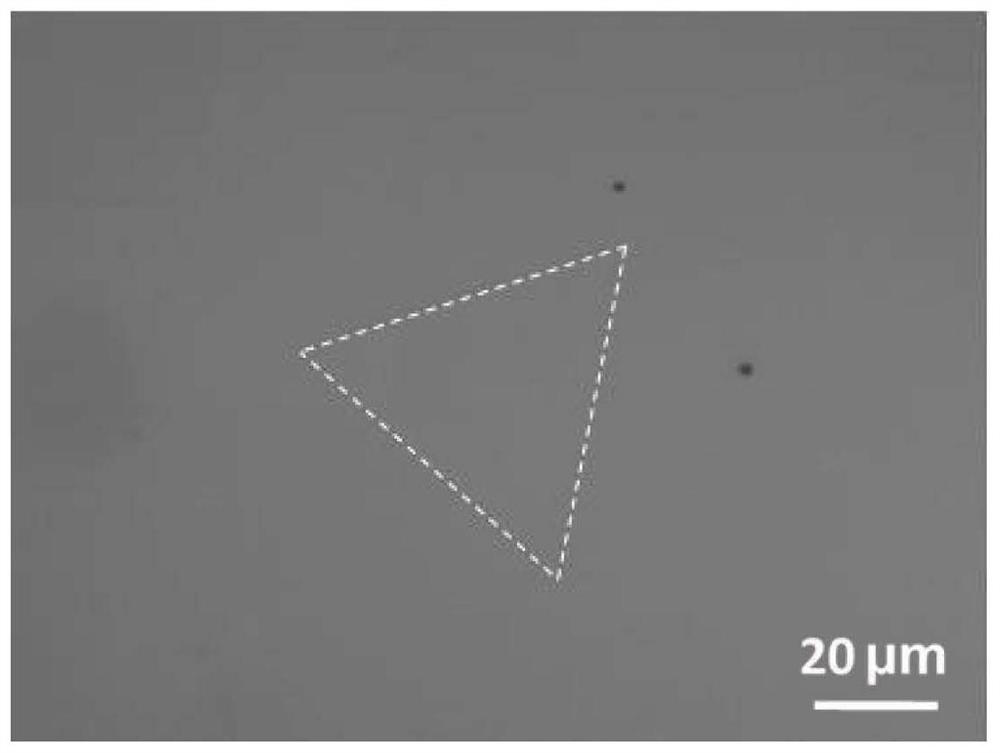

[0034] A kind of WSe with 1T crystal phase monolayer 2 flakes, such as figure 1 shown, the WSe 2 The flakes have an equilateral triangle of 1T crystal phase, which are the substrate 1 and the 1T crystal phase layer 2 in order from bottom to top. Its preparation includes the following steps:

[0035] 1. The 300nm SiO 2 / Si wafers were split into substrates with a size of 1cm×1cm, and then the substrates were ultrasonically cleaned with acetone, anhydrous ethanol, and deionized water for 5 min respectively, then soaked and rinsed with deionized water, and finally blown with a nitrogen gun. Dry storage.

[0036] 2. Put 1.5~2.0g of WSe 2 The powder (purity 99.99%) is placed in a clean quartz boat A, and the quartz boat A is placed in the middle of the hot zone of the tube furnace; The quartz boat B is placed at a downstream position of the airflow 13 cm from the middle of the hot temperature zone.

[0037] 3. Change the airflow direction from forward ventilation (WSe 2 The...

Embodiment 2

[0041] A kind of WSe with 1T crystal phase monolayer 2 flakes, such as figure 1 As shown, the substrate 1 and the 1T crystal phase layer 2 are sequentially included from bottom to top. The 1T crystal phase monolayer of WSe 2 The preparation of the flakes includes the following steps:

[0042] 1. The 300nm SiO 2 / Si wafers were split into substrates with a size of 1cm×1cm, and then the substrates were ultrasonically cleaned with acetone, anhydrous ethanol, and deionized water for 5 min respectively, then soaked and rinsed with deionized water, and finally blown with a nitrogen gun. Dry storage.

[0043] 2. Put 1.5~2.0g of WSe 2 The powder is placed in a clean quartz boat, and the quartz boat is placed in the middle of the hot temperature zone of the tube furnace; then the substrate is placed up and flat in another clean quartz boat, and the quartz boat is placed at a distance 14cm downstream of the airflow in the middle of the hot temperature zone.

[0044] 3. Change the...

Embodiment 3

[0048] A bilayer overlapped WSe with 1T crystal phase 2 flakes, such as Figure 4 shown, the WSe 2 The flakes have two overlapping equilateral triangles of 1T crystal phase, but different sizes, which are substrate 1, 1T crystal phase layer 2 and 1T crystal phase layer 3 in order from bottom to top. Its preparation includes the following steps:

[0049] 1. The 300nm SiO 2 / Si wafers were split into substrates with a size of 1cm×1cm, and then the substrates were ultrasonically cleaned with acetone, anhydrous ethanol, and deionized water for 5 min respectively, then soaked and rinsed with deionized water, and finally blown with a nitrogen gun. Dry storage.

[0050] 2. Put 1.5~2.0g of WSe 2 The powder is placed in a clean quartz boat A, and the quartz boat A is placed in the middle of the hot temperature zone of the tube furnace; then the substrate is placed in a clean quartz boat B, and the quartz boat B is placed The downstream position of the airflow 13cm from the middle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com