Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about "Epoxidised polymerised polyene adhesives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

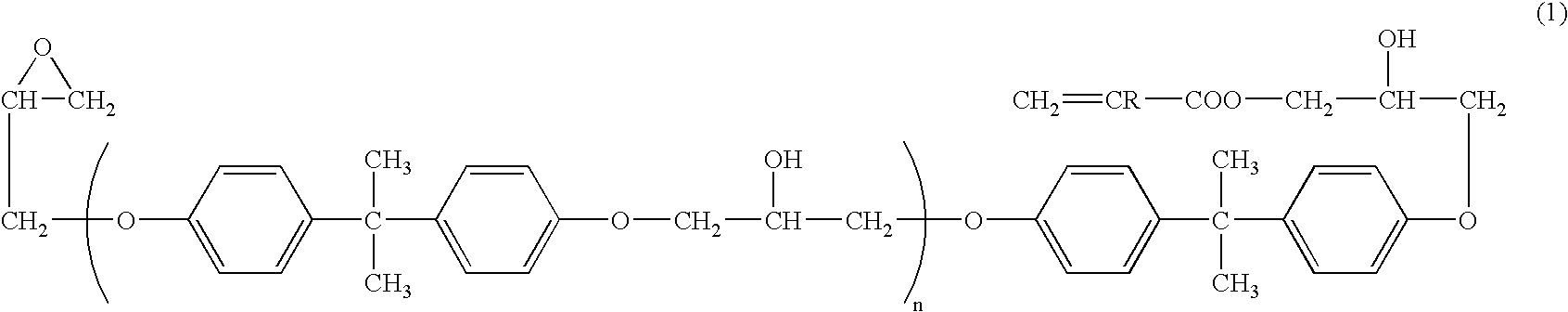

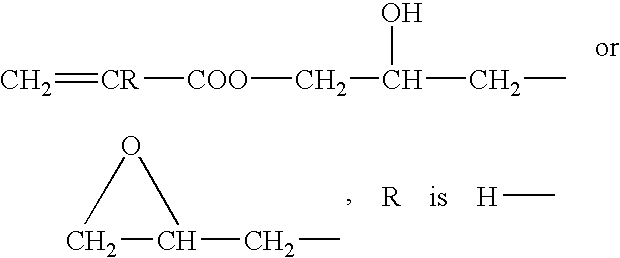

Adhesive Composition, Adhesive Sheet and Production Process for Semiconductor Device

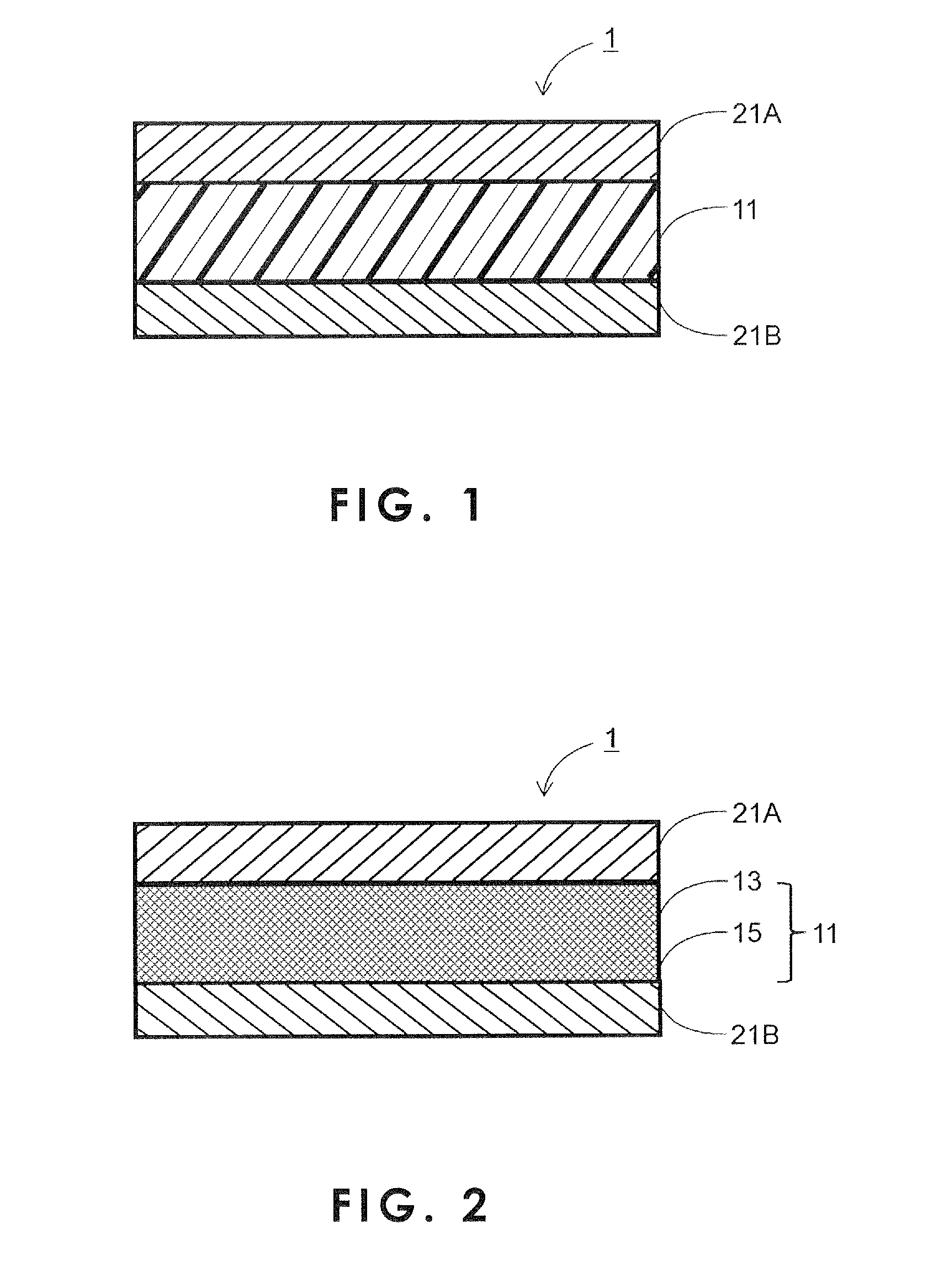

ActiveUS20080124839A1High package reliabilityImprove reliabilityLayered productsSemiconductor/solid-state device detailsUnsaturated hydrocarbonSemiconductor chip

An adhesive composition is characterized by including an acrylic polymer, an epoxy thermosetting resin having an unsaturated hydrocarbon group and a thermosetting agent. The adhesive composition achieves high reliability in a package in which a semiconductor chip of reduced thickness is mounted even when exposed to severe reflow conditions. An adhesive sheet having an adhesive layer comprising the above adhesive composition and a production process for a semiconductor device using the above adhesive sheet are also provided.

Owner:LINTEC CORP

Curable resin composition

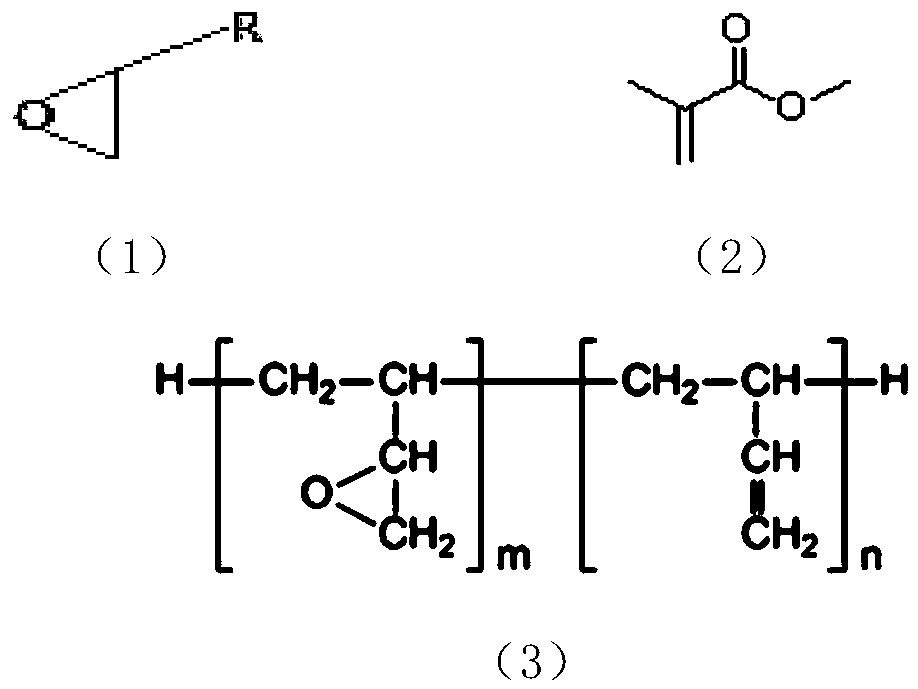

InactiveUS20060074199A1High elongationGood rubber elasticityPhotomechanical apparatusEpoxidised polymerised polyene adhesivesAdhesiveIsoprene

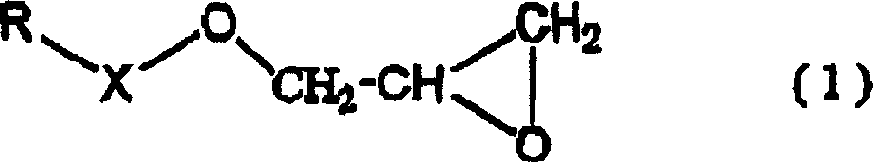

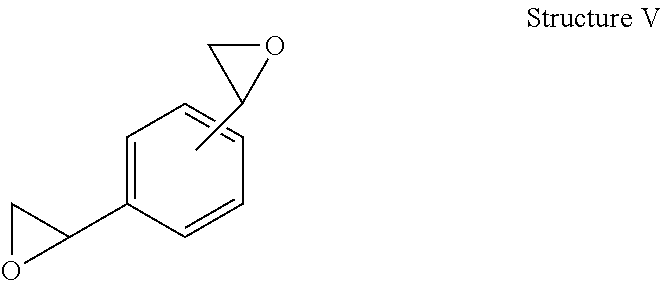

A curable resin composition includes (A) a cationically polymerizable-compound, (B) a cationic photopolymerization initiator, and (C) an epoxidized polyisoprene containing an epoxy group at 0.15 to 2.5 meq / g in the molecule and having a number-average molecular weight of 15000 to 200000. The curable resin composition shows excellent elongation properties and high break elongation even in a cured state and can give a cured product having superior compatibility, transparency, flexibility and waterproofness. Accordingly, the composition is suitable for use as adhesives, coating agents, encapsulating materials, inks, sealing materials and the like.

Owner:KURARAY CO LTD

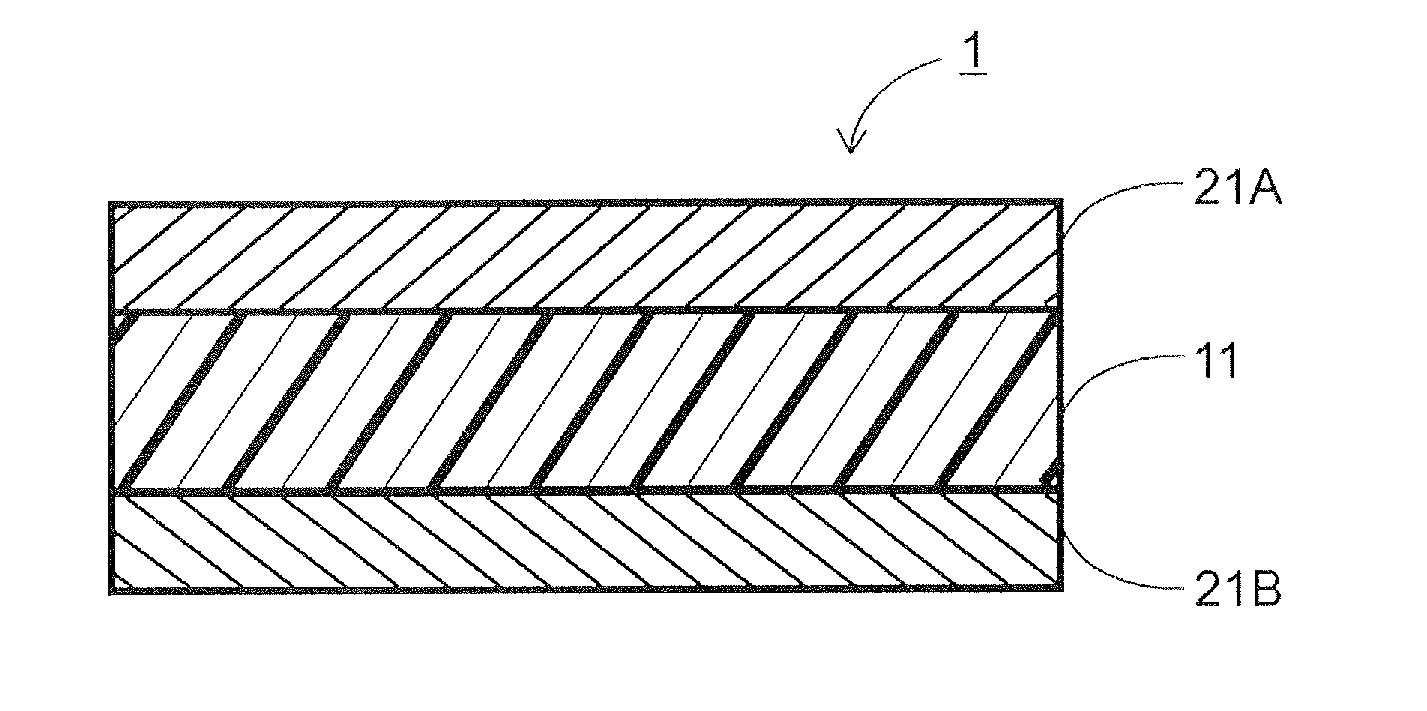

Adhesive sheet and bonding method using the same

ActiveUS20120288659A1Improve adhesion strengthAdhesive bondAdhesive processesLamination ancillary operationsEpoxyAcrylic resin

There is provided an adhesive sheet that has initial adhesiveness, can realize bonding between metals, between a metal and an organic material, and between organic materials, and can retain an excellent adhesion strength without undergoing a temperature change. The adhesive sheet comprises a first release paper, an adhesive layer, and a second release paper stacked in that order, the adhesive layer containing an adhesive, the adhesive containing at least an acrylic resin, an epoxy resin, and a curing agent, the content of the epoxy resin being 175 to 300 parts by weight per 100 parts by weight of the acrylic resin.

Owner:DAI NIPPON PRINTING CO LTD

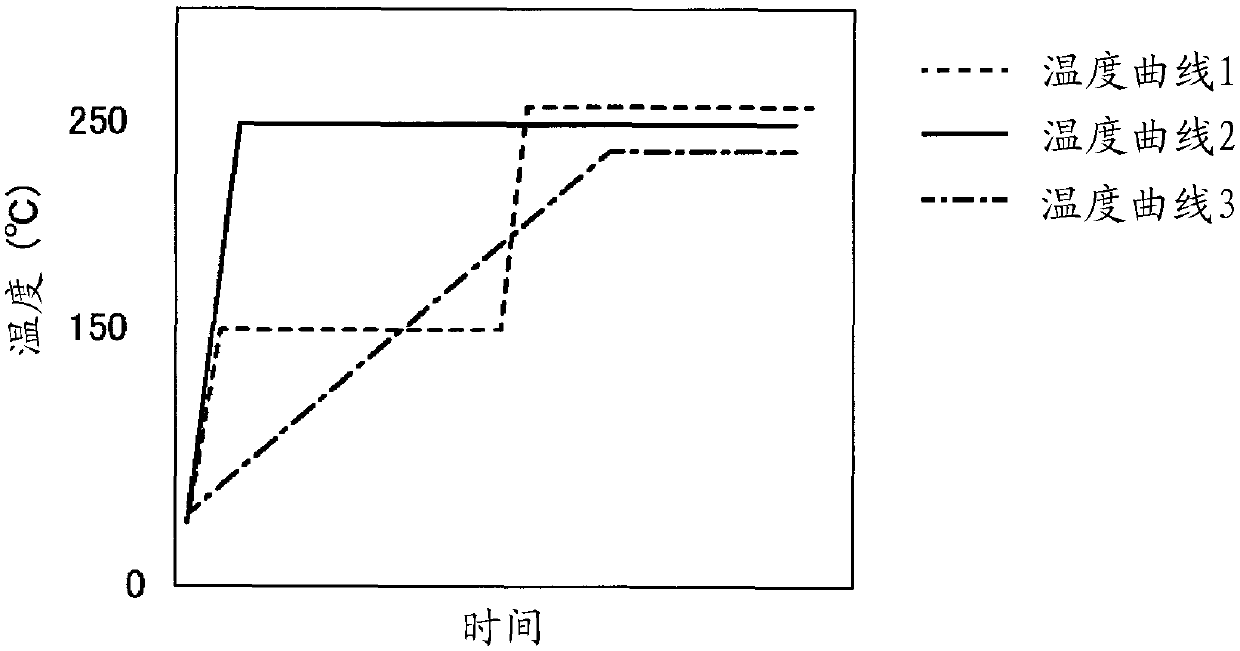

Method for preparing flexible heat conducting insulating adhesive film used in LED heat radiation substrate

InactiveCN102676109AGood flexibilityImprove insulation performanceNon-macromolecular adhesive additivesLaminationAdhesive cementTemperature control

A method for preparing flexible heat conducting insulating adhesive film used in an LED heat radiation substrate comprises the preparation of a flexible heat conducting insulating adhesive and that of the flexible heat conducting insulating adhesive film, wherein the flexible heat conducting insulating adhesive comprises liquid epoxy resin, solid epoxy resin, flexibilizer, curing agent, high-heat conductivity inorganic packing, organic solvent, coupling agent, dispersing agent and flatting agent. The method for preparing the flexible heat conducting insulating adhesive film comprises the following steps: coating the flexible heat conducting insulating adhesive on a release film through a coating machine; baking through a temperature control baking channel to obtain an flexible heat conducting insulating adhesive layer used in the LED heat radiation substrate; coating the release film on the adhesive surface in a compounding manner; and rolling and forming to obtain the flexible heat conducting insulating adhesive film used in the LED heat radiation substrate. The adhesive film used in the LED heat radiation substrate has the characteristics of high heat dissipation, insulation, heat resistance and peel strength, flexibility and the like.

Owner:HAISO TECH

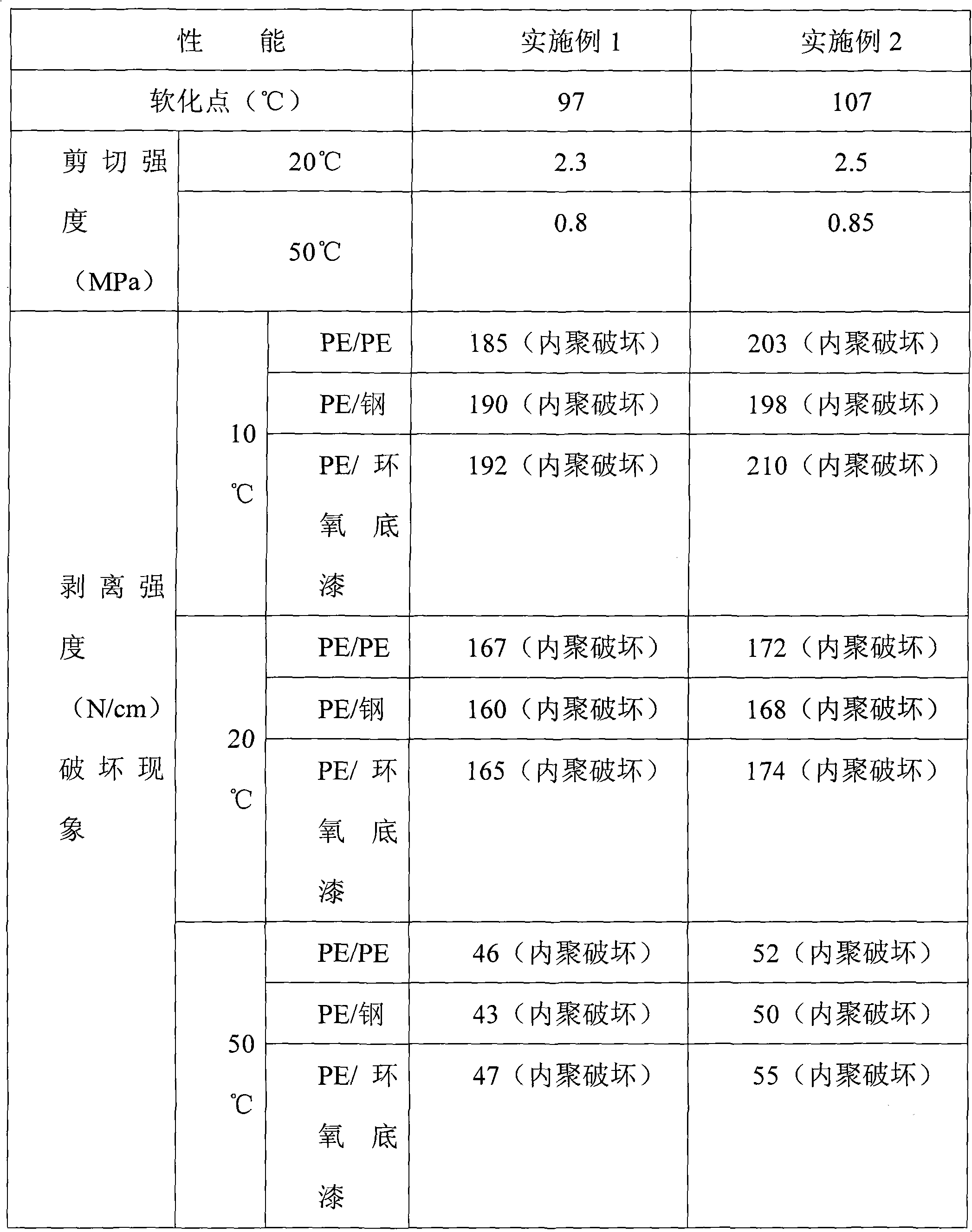

Hot-melt adhesive for preventing corrosion of repaired mouth of pipeline

InactiveCN102250574AHigh peel strengthImprove toughnessMineral oil hydrocarbon copolymer adhesivesEpoxidised polymerised polyene adhesivesElastomerBond properties

The invention relates to the technical field of corrosion of repaired mouths of engineering and petroleum pipelines, in particular to a hot-melt adhesive for preventing the corrosion of a repaired mouth of a pipeline. The hot-melt adhesive comprises the following components in percentage by weight: 30 to 70 percent of epoxidized SBS (styrene-butadiene-styrene) resin, 5 to 40 percent of vinyl copolymer, 5 to 40 percent of rubber elastomer, 5 to 40 percent of tackifying resin, 5 to 20 percent of inorganic filler and 1 to 8 percent of aid; and the hot-melt adhesive is prepared by performing melt blending on the components by using an intensive shear banbury, and performing extrusion granulation by using a twin-screw extruder. The hot-melt adhesive for preventing the corrosion of the repaired mouth of the pipeline, which is prepared from the epoxidized SBS resin serving as a base material, solves the problem that the conventional hot-melt adhesive has insufficient toughness and brittle failure at low temperature and low peel strength at high temperature. The hot-melt adhesive has high toughness at low temperature and high peel strength at high temperature, hardly falls off or allows water to enter the pipeline in the long-term running process, is convenient to construct in field, has excellent bonding property and ensures reliable bonding.

Owner:四川久远科技股份有限公司

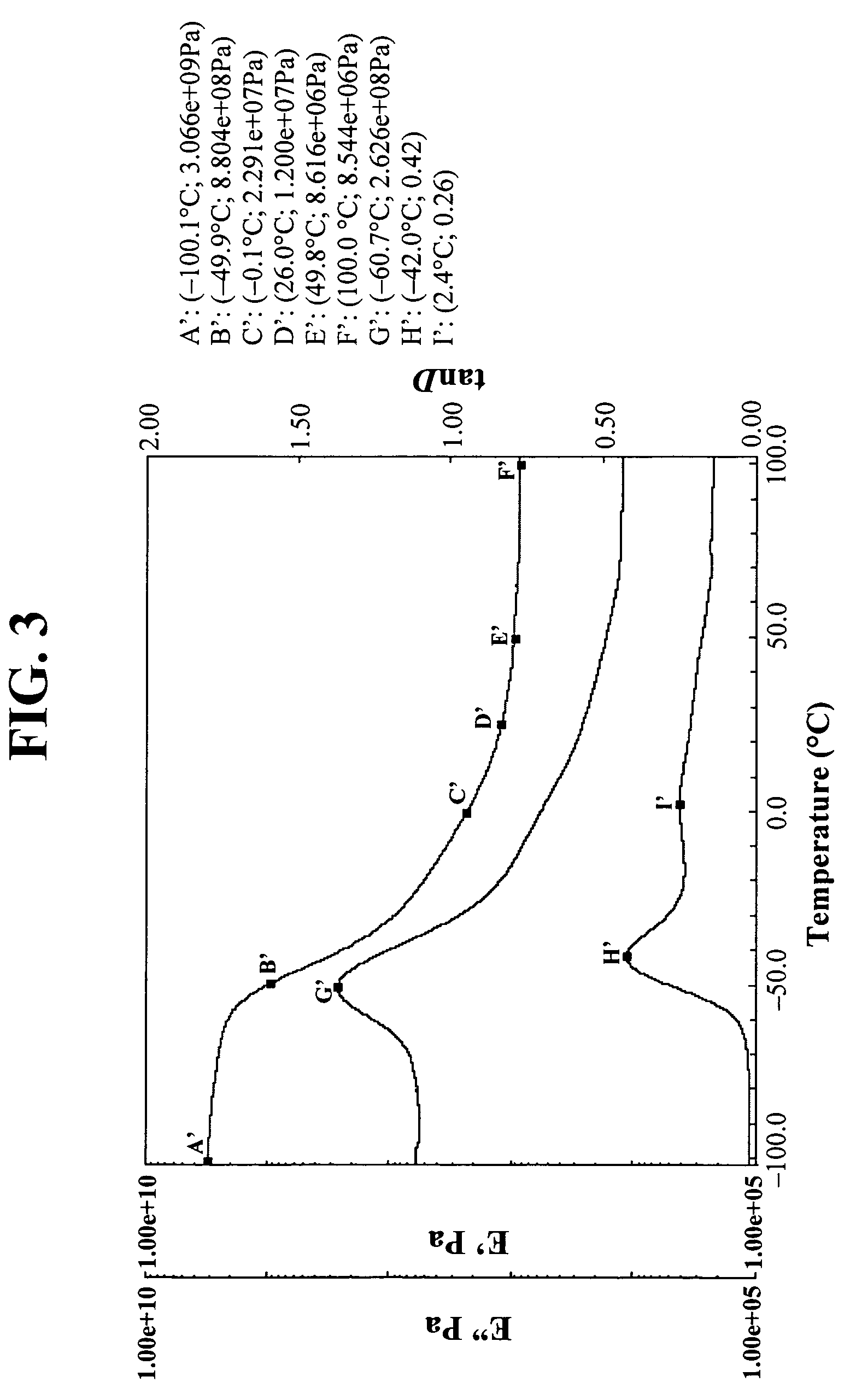

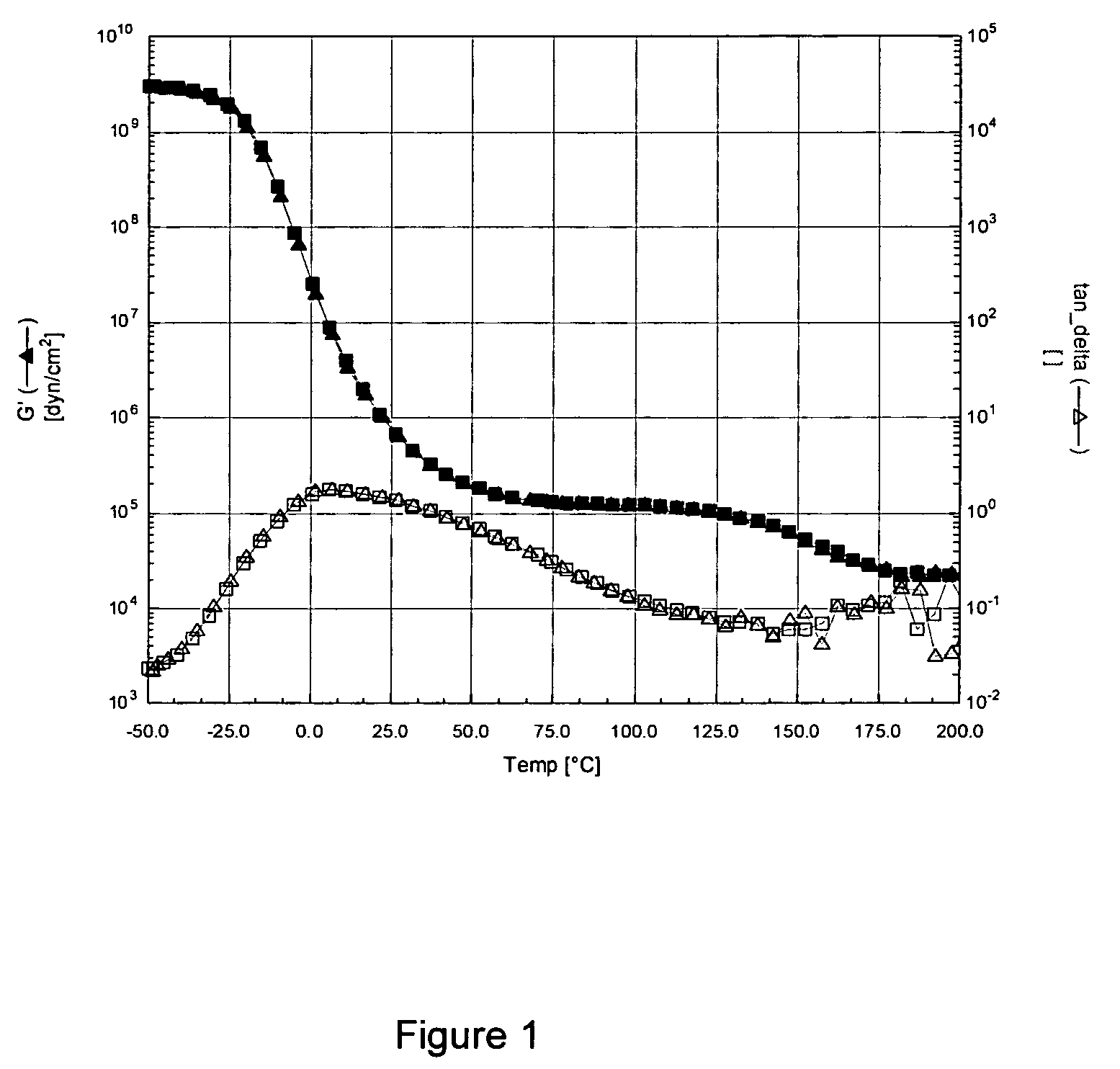

Low out-gassing room temperature curable rubbery polymer, preparation thereof and device comprising same

ActiveUS7723441B2Epoxidised polymerised polyene adhesivesConjugated diene hydrocarbon adhesivesRubber materialRoom temperature

Disclosed is polymer materials essentially free of silicone capable of room-temperature thermal cure and when cured having low modulus, low out-gassing rate. The material before cure typically comprises three components: (i) a cationically curable component comprising the backbone of a hydrocarbon-based rubber material essentially free of carbon-carbon double bonds and triple bonds; (ii) a hydroxyl-containing component having at least two hydroxyl groups per molecule; (iii) an initiator component having essentially no volatility at room temperature and also yield products after polymerization that have minimal or no volatility at room temperature; (iv) an optional viscosity adjustment component either homopolymerizable or capable of copolymerizing with the photo or electron beam curable material component of (i); and (v) an optional non-alkaline inert filler. Also disclosed are process for making such cured material and devices comprising such cured polymer materials.

Owner:CORNING INC

Adhesive for electronic component

InactiveUS7838577B2Good paintabilityHighly reliable electronic componentsNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsSolubilityPolymer science

Owner:SEKISUI CHEM CO LTD

Curable hot melt adhesive for casemaking

InactiveUS6858695B2Minimize warpageFast and efficientBookbinding casesSynthetic resin layered productsMoistureHot-melt adhesive

A curable casemaking adhesive, books and related articles bound thereby. In one embodiment, a UV curable hot melt adhesive is used to form the case, which is preferably also embossed. In another embodiment, a moisture curable hot melt adhesive is used to form the case, which is preferably also embossed.

Owner:HENKEL IP & HOLDING GMBH

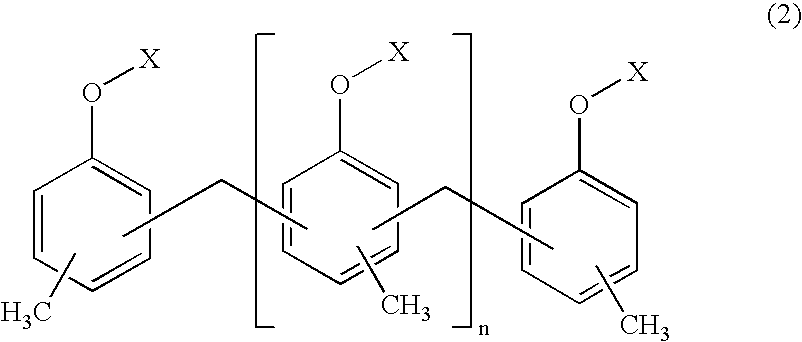

Resin composition for adhesive, adhesive containing same, adhesive sheet, and printed wiring board containing adhesive sheet as adhesive layer

ActiveCN102264855AImprove adhesionExcellent heat and humidity resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesAdhesiveSolvent

The present invention provides an adhesive which has a high degree of moist-heat resistance that enables the adhesive layer to withstand soldering with a lead-free solder under high-humidity conditions and which has excellent adhesiveness under high-temperature high-humidity conditions, while retaining adhesion to various plastic films, metals, and glass-epoxies. A B-stage adhesive sheet obtained from the adhesive is provided which has a satisfactory sheet life and can retain satisfactory adhesive properties even when used after having been transported under high-temperature high-humidity conditions. The resin composition for adhesives comprises a thermoplastic resin (A), an inorganic filler (B), a solvent (C), and an epoxy resin (D), wherein the thermoplastic resin (A) has an acid value and a number-average molecular weight which are in specific ranges, the epoxy resin (D) is an epoxy resin having a dicyclopentadiene skeleton, and a dispersion (a) having a specific makeup including the thermoplastic resin (A) and the inorganic filler (B) in a total amount of 25 parts by mass and in the same proportion as in the resin composition for adhesives has a thixotropic index (TI value) of 3-6 at 25 C.

Owner:TOYO TOYOBO CO LTD

High-reliability fast-curing filling glue

ActiveCN109401706AAchieve reworkabilityIncrease crosslink densityNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyPolymer science

The invention relates to filling glue and a preparation method thereof, in particular to high-reliability fast-curing filling glue. The high-reliability fast-curing filling glue is prepared from the following raw materials in percentage by weight: 10-50% of epoxy resin, 5-20% of an epoxy diluent, 5-15% of epoxy resin with capability of free radical reaction, 0-10% of an olefin monomer with capability of free radical reaction, 5-20% of a toughener, 0.5-3% of a coupling agent, 0.1-5% of a cationic initiator, 0.1-5% of a radical initiator, 0-5% of filler and 0-5% of pigment. The bottom filling glue provided by the invention can fast cure, has a high glass-transition temperature (Tg), a low expansion coefficient and good repair property, and can be mainly used for flip chip bottom filling to improve the connection reliability.

Owner:深圳广恒威科技有限公司

Adhesive composition, adhesive sheet, dicing die attach film and semiconductor device

InactiveCN101798490ASimple and adequate removalExcellent property stabilityLayered productsSemiconductor/solid-state device detailsEpoxyAcrylic resin

The invention provides an adhesive composition. The adhesive composition contains a component (A), a component (B) and a component (C), wherein the component (A) contains an epoxy group, a structural unit from acrylonitrile, and (methyl) acrylic resin with weight-average molecular weight of 50,000 to 1,500,000; the component (B) contains epoxy resin with a dicyclopentadiene skeleton structure; and the component (C) contains aromatic polyamide with a diphenyl sulfone skeleton structure. In addition, the invention also provides an adhesive sheet using the adhesive composition, a dicing die attach film using the adhesive composition and having excellent property stability and pickup stability, and a semiconductor device obtained by using the adhesive sheet or the dicing die attach film. The adhesive composition has excellent adhesive property, shows excellent embedded performance, and can provide a high-reliability semiconductor device when being used for manufacturing the semiconductor device.

Owner:SHIN ETSU CHEM IND CO LTD

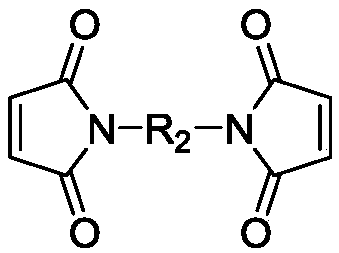

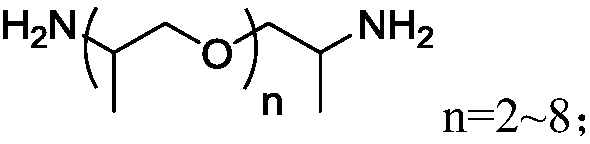

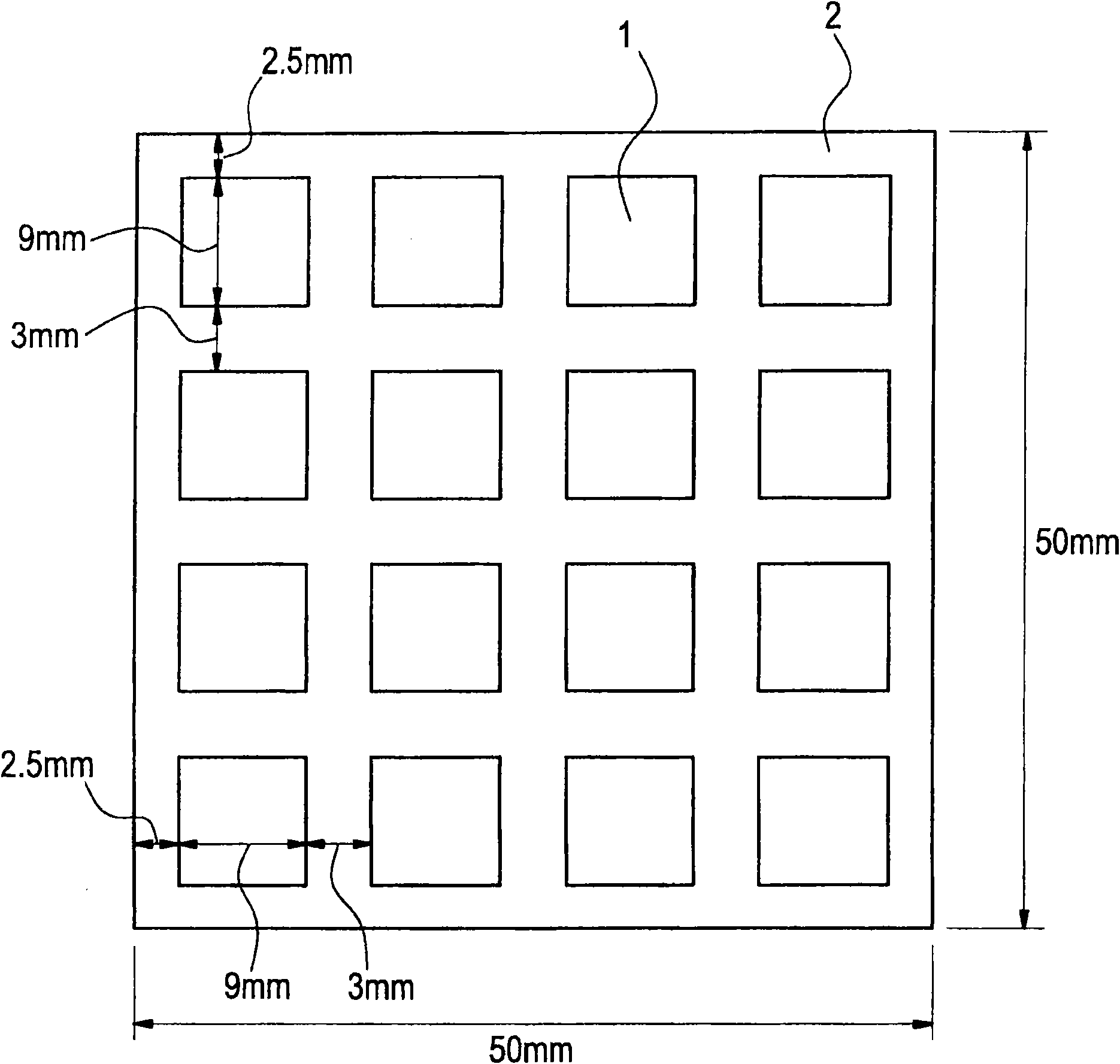

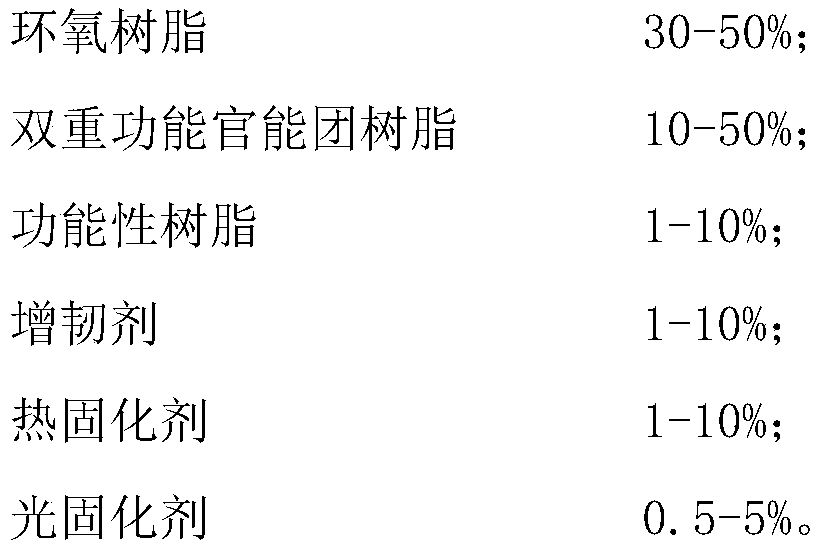

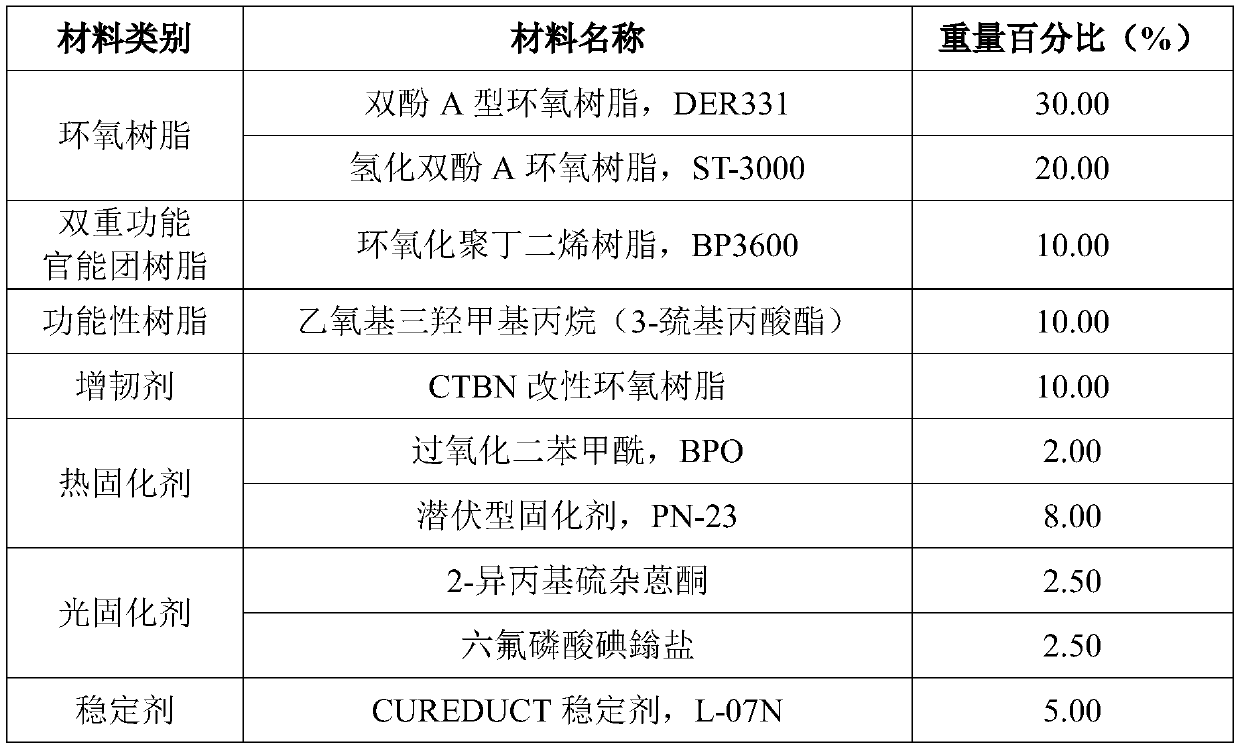

Adhesive for optical communication device

InactiveCN109705786AMeet the process requirementsMeet reliability requirementsNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyAdhesive

The invention discloses an adhesive for an optical communication device. A formula for preparing the adhesive for the optical communication device comprises the following raw materials in percentagesby weight: 30-50% of epoxy resin, 10-50% of bifunctional resin, 1-10% of functional resin, 1-10% of a toughening agent, 1-10% of a thermal curing agent and 0.5-5% of a photo curing agent. According tothe adhesive for the optical communication device, the performance index of the adhesive meets the requirements on the process and reliability of an active or passive optical device, an existing method of improving reliability by using two adhesives (UV adhesive positioning and thermal curing adhesive) respectively can be replaced well, the adhesive has double curing functions of photo curing andheating curing, and the product has the characteristics of rapid UV positioning performance and high reliability of a heating curing adhesive.

Owner:上海熙邦新材料有限公司

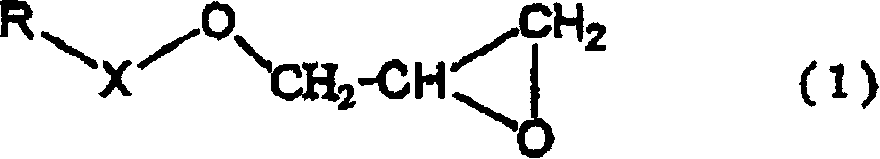

Adhesive resin composition and use thereof

InactiveCN1628163ASynthetic resin layered productsFilm/foil adhesives without carriersFoaming agentChemistry

The present invention provides: an adhesive resin composition containing the following components (A), (B) and (C), wherein, (A): an olefin resin containing an epoxy group, (B): a curing agent, (C): thermally decomposable foaming agent; an adhesive film formed by forming the adhesive resin composition into a film; an adhesive laminated film formed by laminating the adhesive film on a support substrate; A laminate formed by bonding an adherend to an adhesive layer obtained by heating the adhesive film; and a method of heating the laminate and peeling and recovering the adherend from the laminate .

Owner:SUMITOMO CHEM CO LTD

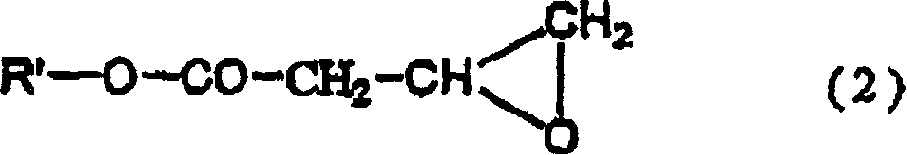

Radiation cross-linkable hot-melt contact adhesives

InactiveUS7682477B2Low viscosityFast cross-linkingLamination ancillary operationsSynthetic resin layered productsPolyolefinOligomer

The invention relates to a radiation crosslinkable hot melt pressure sensitive adhesive comprised of a radiation crosslinkable polymer as component (A) based on epoxidized polyolefins, wherein the epoxy groups are not consolidated in blocks; a tackifying resin possessing no epoxy groups as component (B); optionally a low molecular weight oligomer as component (C) that possesses reactive groups that can react with the epoxy groups of component (A); and an additive comprising a photo initiator as component (D).

Owner:HENKEL KGAA

Curable compositions

InactiveUS20130059945A1Slow curingEpoxidised polymerised polyene adhesivesEpoxy resin coatingsPolymer sciencePtru catalyst

A curable divinylarene dioxide resin composition having a stoichiometric excess of divinylarene dioxides cured with amines, anhydrides, or polyphenols. The curable divinylarene dioxide resin composition includes (a) a stoichiometric excess of at least one divinylarene dioxide, (b) a co-reactive curing agent, and a catalyst. A process for making the above curable divinylarene dioxide resin composition; and a cured divinylarene dioxide resin composition made therefrom are also disclosed. The curable divinylarene dioxide resin composition has a longer pot life prior to cure and produces a thermoset having a higher heat resistance after cure than analogous prior art compositions made using stoichiometric compositions. The curable compositions of the present invention are advantageously useful as thermoset materials, coatings, composites, and adhesives.

Owner:BLUE CUBE IP

Fluorine-containing anti-corrosion silicone adhesive and preparation method thereof

InactiveCN107142072AHigh bonding strengthCorrosion resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyHydrogen

The invention belongs to the technical field of high polymer materials and discloses a fluorine-containing anti-corrosion silicone adhesive and a preparation method thereof. The fluorine-containing anti-corrosion silicone adhesive comprises the following components in parts by weight: 30-50 parts of a fluorine-containing compound, 10-15 parts of an amine compound, 20-40 parts of an epoxy resin compound, 25-40 parts of hydrogen-containing phenyl silicone resin, 2-4 parts of a flexibilizer, 0.001-0.005 part of a catalyst and 1-2 parts of a curing agent. As the fluorine-containing compound is added and used in the fluorine-containing anti-corrosion silicone adhesive and can perform additive reaction with the epoxy resin compound, the silicone adhesive obtained after curing not only has high bonding strength of epoxy resin but also has corrosion resistance of the fluorine-containing compound, and therefore, has a wide application value.

Owner:FUDAN UNIV +1

Preparation process of adhesive suitable for adhesive coated copper foil

InactiveCN102732197AReduce manufacturing costSolve solubilityEpoxynovolac adhesivesEpoxidised polymerised polyene adhesivesSolventCopper foil

The invention relates to adhesive preparation processes, especially to a preparation process of an adhesive suitable for adhesive coated copper foil. The preparation process consists of: a. blending 30-70 parts of polybutadiene epoxy resin (by mass) with polybutadiene with 2-10 parts of an epoxy active diluent at a temperature of 30-70DEG C for 1-3h for compounding; b. blending the obtained compound with 5-20 parts of bisphenol A epoxy resin at a temperature of 30-70DEG C for 1-3h for compounding so as to obtain an epoxy dispersion liquid dispersible in methanol; and c. blending the epoxy dispersion liquid with 400-600 parts of phenolic resin and 500-700 parts of polyvinyl acetal resin at a temperature of 30-70DEG C for 5-12h for compounding, and carrying out dispersion with 1125-1750 parts of methanol as a solvent, thus obtaining the qualified copper foil adhesive. The process of the invention uses suitable epoxy resin and conducts compounding and modification on it so as to solve the problem of solubility in methanol, thus achieving the purpose of reducing the production cost of the copper foil adhesive.

Owner:佛冈建滔实业有限公司

Flexible microelectronics adhesive

InactiveUS20080063873A1High bulk thermal conductivityModulus improvementSynthetic resin layered productsSolid-state devicesElastomerAdhesive

A curable thermal interface material is provided comprising a functionalized elastomer and a filler. Preferred materials comprise an epoxidized polybutadiene cured with an iodonium catalyst and a filler comprising silver and / or aluminum oxide.

Owner:LORD CORP

Low out-gassing room temperature curabble rubbery polymer, preparation thereof and device comprising same

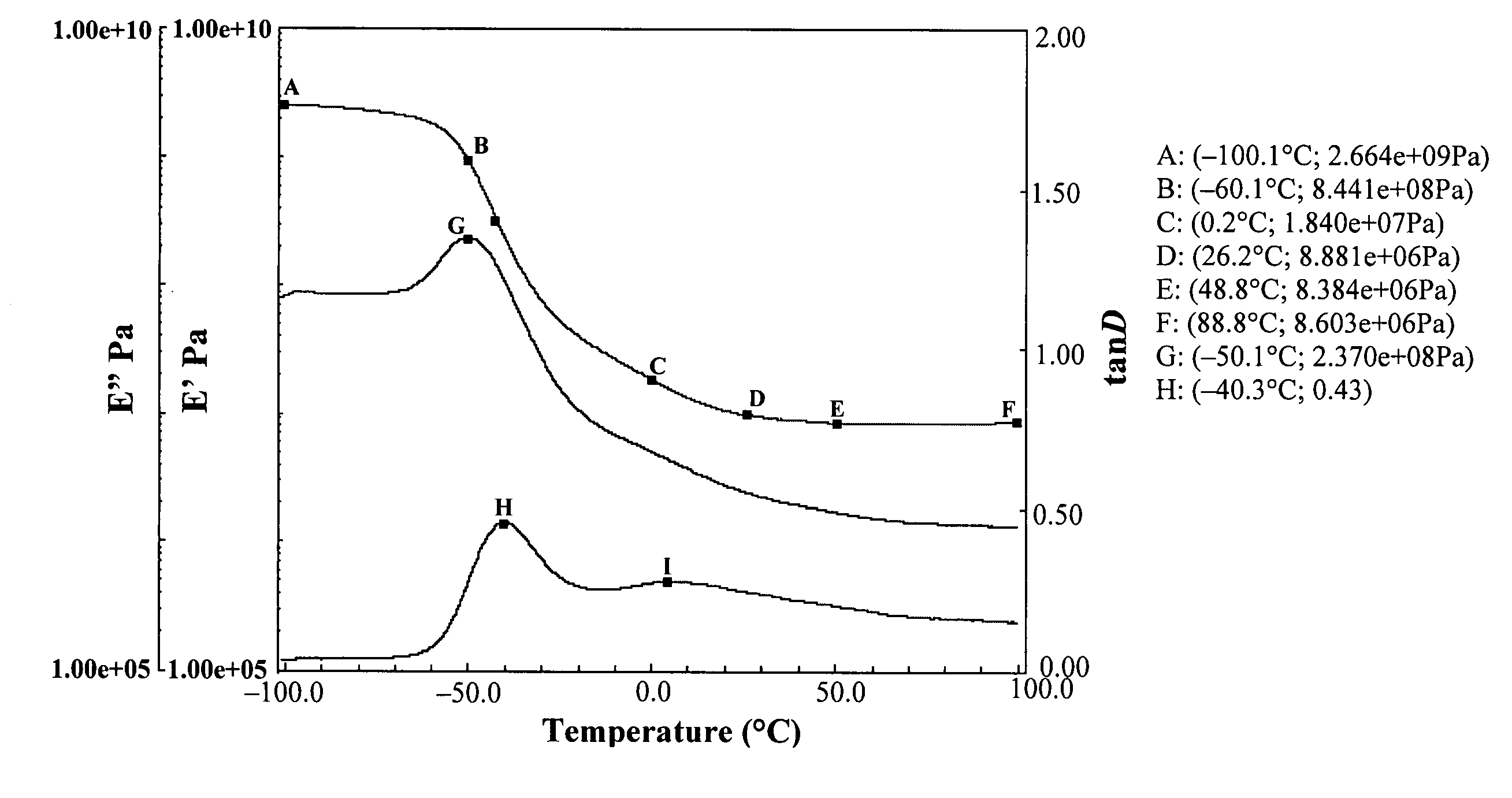

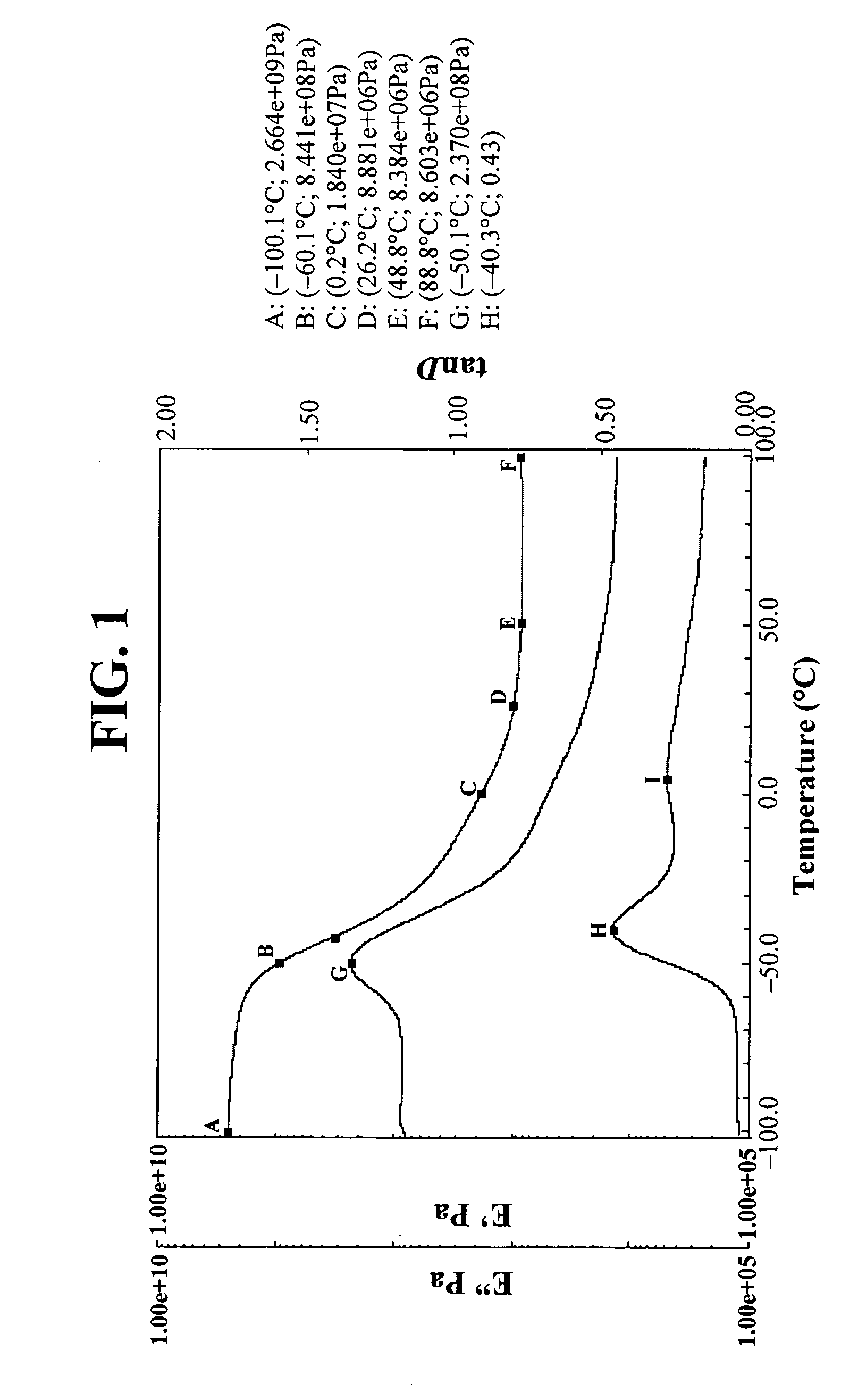

ActiveUS20070155850A1Reduce outgassingEasy to useEpoxidised polymerised polyene adhesivesConjugated diene hydrocarbon adhesivesRubber materialPolymer science

Disclosed is polymer materials essentially free of silicone capable of room-temperature thermal cure and when cured having low modulus, low out-gassing rate. The material before cure typically comprises three components: (i) a cationically curable component comprising the backbone of a hydrocarbon-based rubber material essentially free of carbon-carbon double bonds and triple bonds; (ii) a hydroxyl-containing component having at least two hydroxyl groups per molecule; (iii) an initiator component having essentially no volatility at room temperature and also yield products after polymerization that have minimal or no volatility at room temperature; (iv) an optional viscosity adjustment component either homopolymerizable or capable of copolymerizing with the photo or electron beam curable material component of (i); and (v) an optional non-alkaline inert filler. Also disclosed are process for making such cured material and devices comprising such cured polymer materials.

Owner:CORNING INC

Pressure sensitive adhesive tapes from cationic cure adhesives

Pressure sensitive adhesive tapes produced by a process where cationic cure is conducted against a paper film substrate and an optional second film substrate, both having low moisture content. The low moisture content is maintained during cationic cure by putting the pressure sensitive adhesive tapes in an environment where moisture ingress is prevented. The maintenance of low moisture during cure provides enhanced SAFT values.

Owner:HENKEL KGAA

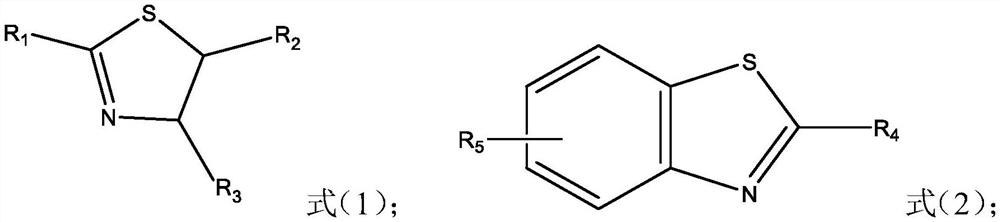

Epoxy resin composition as well as preparation method and application thereof

PendingCN114456755AGood adhesionLiquidityNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsEpoxyPolymer science

The invention relates to the field of semiconductor packaging, and discloses an epoxy resin composition and a preparation method and application thereof, the epoxy resin composition comprises epoxy resin, phenolic resin, a curing accelerator, a filler, a release agent, a coupling agent and an adhesion accelerator; wherein the adhesion promoter comprises a first adhesion promoter and an optional second adhesion promoter; the first adhesion promoter is selected from at least one of a thiazole compound, a thiadiazole compound and a pyrazole compound. According to the epoxy resin composition, groups such as amino groups, sulfydryl groups and the like in molecules of the adhesion promoter and hydroxyl groups on metal form hydrogen-bond interaction or N and S atom lone electron pairs and metal atom empty orbits form covalent bonds, so that adhesion between a system and a nickel-plated copper framework is enhanced; meanwhile, the epoxy resin composition has necessary flowability, formability and flame retardance.

Owner:江苏中科科化新材料股份有限公司

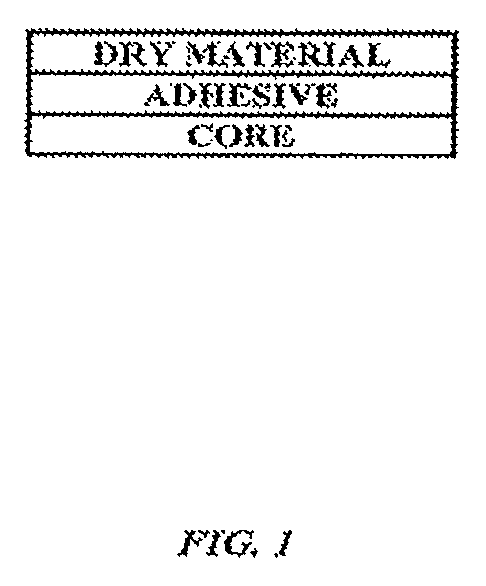

Adhesive sheet and bonding method using the same

ActiveUS9512335B2Improve adhesion strengthAdhesive processesLamination ancillary operationsEpoxyAcrylic resin

There is provided an adhesive sheet that has initial adhesiveness, can realize bonding between metals, between a metal and an organic material, and between organic materials, and can retain an excellent adhesion strength without undergoing a temperature change. The adhesive sheet comprises a first release paper, an adhesive layer, and a second release paper stacked in that order, the adhesive layer containing an adhesive, the adhesive containing at least an acrylic resin, an epoxy resin, and a curing agent, the content of the epoxy resin being 175 to 300 parts by weight per 100 parts by weight of the acrylic resin.

Owner:DAI NIPPON PRINTING CO LTD

One component epoxy structural adhesive composition prepared from renewable resources

Owner:PPG IND OHIO INC

Process for making pressure sensitive adhesive tapes from cationic cure adhesives

A process for the preparation of pressure sensitive adhesive tapes where cationic cure is conducted against liners and substrates with low moisture content and in an environment where moisture ingress during cure is prevented.

Owner:HENKEL KGAA

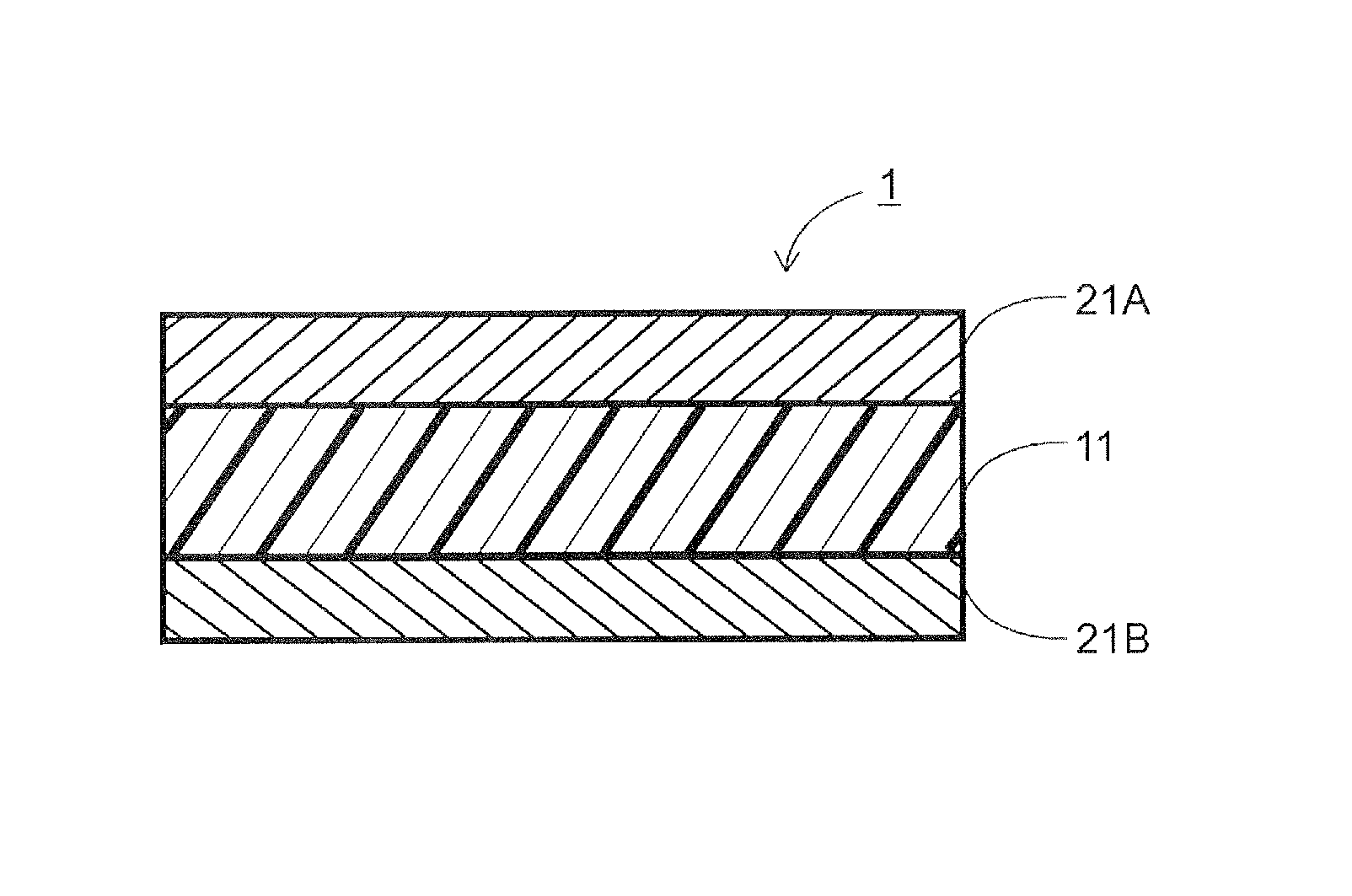

Underfill material and process for producing semiconductor device using same

ActiveCN105518842AGood Solder BondabilityWide mounting edgeNon-macromolecular adhesive additivesFilm/foil adhesivesPower semiconductor deviceAcrylic resin

Provided are: an underfill material which enables a wide mounting margin; and a process for producing a semiconductor device using the same. This underfill material (20) comprises an epoxy resin, an acid anhydride, an acrylic resin and an organic peroxide, and exhibits a lowest-melt-viscosity reaching temperature of 100 to 150 DEG C and a lowest melt viscosity of 100 to 5000Pa s as determined under temperature rise conditions of 5 to 50 DEG C / min. Since the lowest-melt-viscosity reaching temperature of the underfill material varies only slightly as measured under various temperature rise conditions, the underfill material can ensure void-less mounting and good solder jointing even when the temperature profile in thermocompression bonding is not strictly controlled, thus enabling a wide mounting margin.

Owner:DEXERIALS CORP

Semiconductor device manufacturing method and underfill film

ActiveUS10280347B2Reduce impactImprove adhesionSemiconductor/solid-state device detailsSolid-state devicesAcrylic resinSemiconductor chip

A method for manufacturing a semiconductor device and an underfill film which can achieve voidless mounting and excellent solder bonding properties even in the case of collectively bonding a plurality of semiconductor chips are provided. The method includes a mounting step of mounting a plurality of semiconductor chips having a solder-tipped electrode onto an electronic component having a counter electrode opposing the solder-tipped electrode via an underfill film; and a compression bonding step of collectively bonding the plurality of semiconductor chips to the electronic component via the underfill film. The underfill film contains an epoxy resin, an acid anhydride, an acrylic resin, and an organic peroxide and has a minimum melt viscosity of 1,000 to 2,000 Pa*s and a melt viscosity gradient of 900 to 3,100 Pa*s / ° C. from a temperature 10° C. higher than a minimum melt viscosity attainment temperature to a temperature 10° C. higher than the temperature.

Owner:DEXERIALS CORP

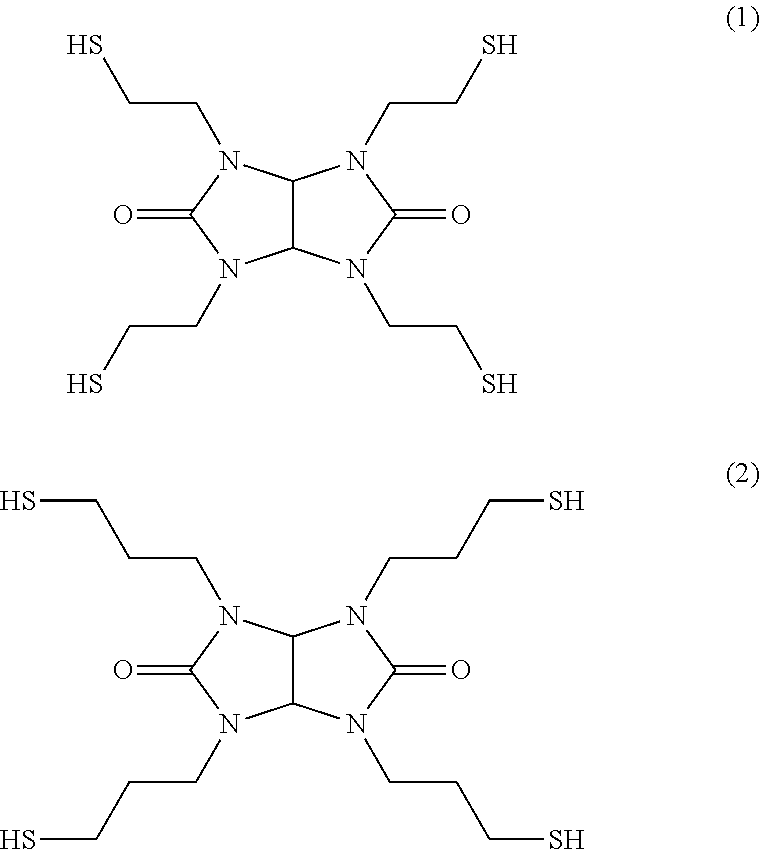

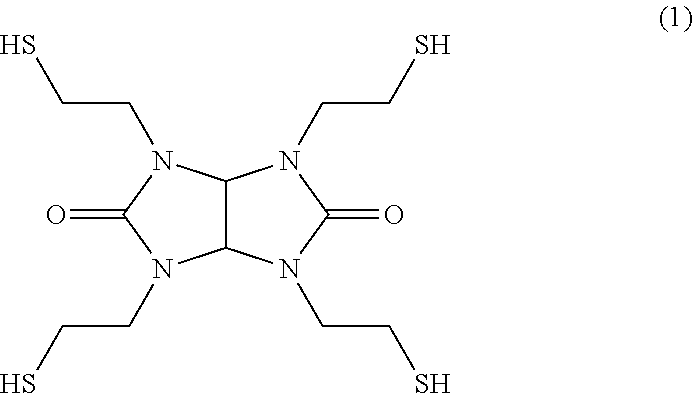

Resin composition, adhesive agent, and sealing agent

ActiveUS20180044478A1Reduced adhesion strengthLong application periodNon-macromolecular adhesive additivesOther chemical processesAcrylic resinNitrogenous heterocyclic compound

There is provided a photocurable and thermosetting resin composition which suppresses decrease of adhesive strength in a moisture resistance test of the cured resin composition, and has a sufficiently long pot life. The resin composition includes (A) an acrylic resin, (B) a multifunctional nitrogen-containing heterocyclic compound represented by a specific chemical formula, (C) a latent curing agent, (D) a radical polymerization inhibitor, and (E) an anionic polymerization retarder. The resin composition preferably further includes (F) a compound having a glycidyl group, other than the acrylic resin.

Owner:NAMICS CORPORATION

Curable resin composition

InactiveUS7632895B2High elongationIncrease elasticityPhotomechanical apparatusEpoxidised polymerised polyene adhesivesPolymer scienceAdhesive

Owner:KURARAY CO LTD

Adhesive composition, adhesion method using the same, laminate and tire

InactiveUS20140048194A1Improve adhesionImproved air retentionWithout separate inflatable insertsSynthetic resin layered productsPolymer scienceNatural rubber

The present invention provides an adhesive composition that may improve both adhesiveness to a film layer and adhesiveness to a rubber layer, and an adhesion method using the same, as well as a laminate and a tire. The adhesive composition according to the present invention includes a rubber component, at least 80 mass % of which rubber component is an epoxidized natural rubber.

Owner:BRIDGESTONE CORP

Vacuum infusion adhesive and methods related thereto

ActiveUS9624411B2Avoid creatingIncreased shear strengthAdhesive processesSynthetic resin layered productsInfusion techniqueSolvent

An epoxy adhesive that is adapted to enable spray delivery and seamless polymerization during epoxy resin vacuum infusion techniques is disclosed. The epoxy adhesive can include one or more epoxy resins and one or more solvents that are used to dissolve the one or more epoxy resins. An adduct, a tackifier, and fumed silica can also be added to the adhesive.

Owner:WESTECH AEROSOL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com