Adhesive for optical communication device

A binder and optical communication technology, applied in the direction of adhesives, adhesive types, polymer adhesive additives, etc., can solve the problems of high labor costs, low displacement, low production efficiency, etc., to reduce labor costs, shorten Process flow, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

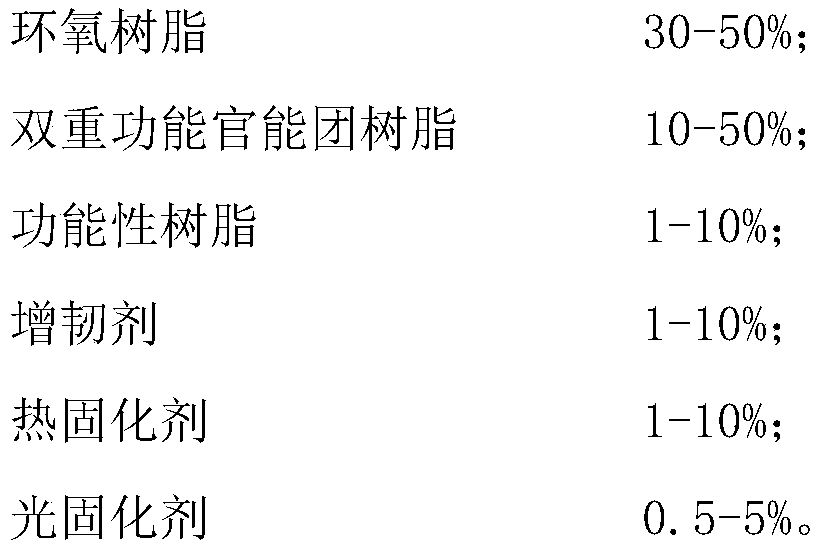

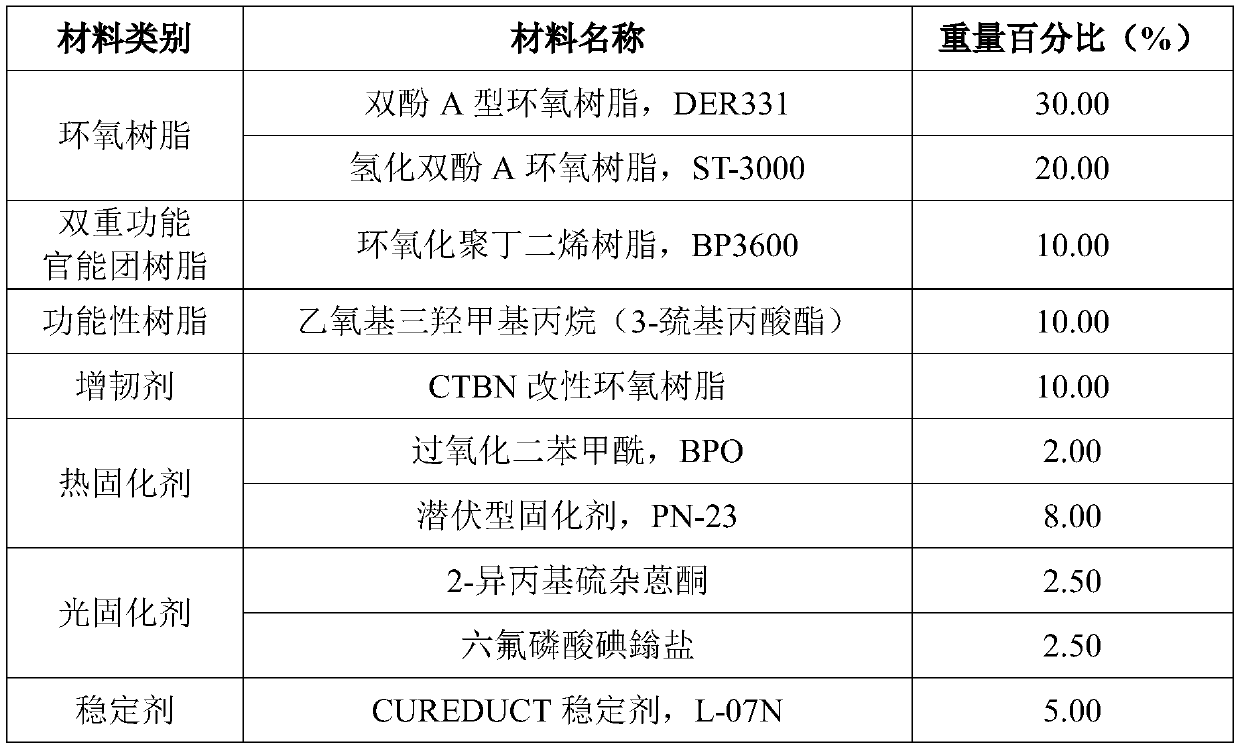

[0026] Embodiment 1~5, the preparation of adhesive for optical communication device

[0027] According to the formulations listed in Tables 1 to 5, the adhesive for optical communication devices was prepared through the following steps:

[0028] 1) Add epoxy resin, dual-functional functional group resin, and functional resin into the double-planetary vacuum mixer with stepless speed regulation, control the temperature of the material in the mixer within the range of 60-80°C, and start the mixing mixer at a speed of 100 ~300 rpm, start the high-speed disperser at the same time, the speed is 1500-2000 rpm, keep stirring for 60-90 minutes, so that the functional resin, epoxy resin and dual-functional resin can be fully contacted and fused and mixed evenly;

[0029] 2) After the temperature of the mixed resin is lowered to 20-25°C, add transparent filler and mix evenly, take it out and further disperse it through a non-metallic roller three-roll mill, and control the fineness to l...

Embodiment 6

[0044] Embodiment 6, adhesive bond strength test

[0045] Get the adhesive for optical communication devices obtained in Examples 1 to 5, and carry out a bond strength test on BOSA (Bi-Directional Optical Sub-Assembly, light emitting and receiving components), and simultaneously use ordinary secondary dispensing (UV glue+thermal Cured glue) as a control, the specific test results are shown in Table 6.

[0046] Table 6. Performance test results

[0047]

[0048] It can be seen from the results of the bonding strength test in Table 6 that the bonding strength of the adhesives obtained in Examples 1 to 5 in the bonding of the optical fiber communication device BOSA is greater than 1.0 kg after UV curing. After 10 minutes of thermal curing, the pulling force is greater than 15 kg, which meets the process and reliability requirements of active or passive optical devices, and can well replace the existing two kinds of adhesives (UV glue positioning + thermal curing) glue) to im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com