Hot-melt adhesive for preventing corrosion of repaired mouth of pipeline

A technology of hot melt adhesives and pipes, applied in the direction of adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc., can solve the problems of low peel strength at high temperature, interface damage, economic loss, etc., and achieve excellent bonding performance , high peeling strength and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: Weigh respectively epoxidized SBS resin 8kg, EVA (28 / 400) 2.4kg, SIS elastomer 1.6kg, terpene resin 4kg, talcum powder 1.6kg, other additives 0.4kg, in internal mixer Knead at 100°C for 20 minutes and discharge, add to a twin-screw extruder, control the temperature at 100-140°C, extrude and granulate, cool and dry to obtain a hot melt adhesive.

Embodiment 2

[0020] Embodiment 2: Weigh respectively epoxidized SBS resin 10kg, EVA (28 / 150) 2kg, butyl rubber 1.6kg, petroleum resin 3kg, calcium carbonate 1kg, other additives 0.4kg, in a banbury mixer at 100 ℃ Knead for 20 minutes and discharge, add to twin-screw extruder, control temperature at 100-140°C, extrude and pelletize, cool and dry to obtain hot melt adhesive.

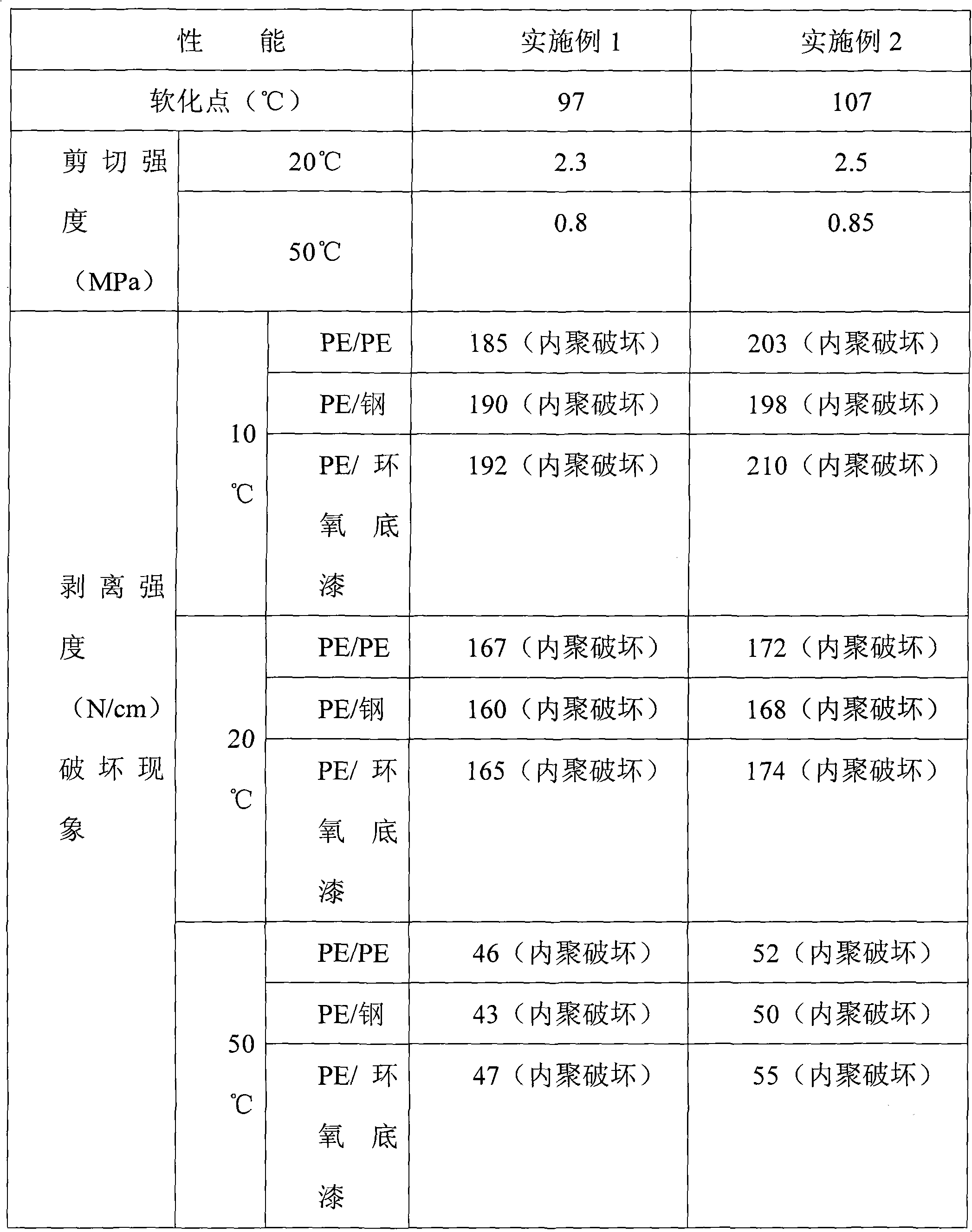

[0021] The pipeline anticorrosion sealing hot-melt adhesive test performance index prepared by the above-mentioned embodiment is as follows:

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com