Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60 results about "Wild silk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wild silks have been known and used in many countries from early times, although the scale of production is far smaller than that from cultivated silkworms.

Surgical seam of yamamai silk and preparation thereof

InactiveCN101244288AHigh strengthSmooth laneSuture equipmentsAnimal materialPancreatic juiceSurgical operation

The invention relates to wild silk surgical operation suture thread and the preparation method. The wild silk yarn surgical operation suture thread adopts wild silk woven or twisting thread as thread rod and the surface is covered by wild sericin. The preparation method comprises the following steps: (1) place and immerse the wild silk into the aqueous solution, which comprises 0.1-0.3wt% sodium salt, 0.1-0.2wt% surface-active agent and 0.01-0.03wt% penetrating agent for 15 to 20 minutes; (2) after fish out and dry the wild silk, use machine to weave and twist the wild silk into the thread rod with required specification; (3) apply the wild sericin on the thread rod; and (4) heat up the silk for forming and the heating temperature should be controlled between 80 to 100 degrees centigrade. The suture thread has the advantages of high strength, smooth thread, easy knotting, good absorbing performance, good pancreatic juice and bile tolerance, easy dialyneury and capability of promotion of nerve regeneration.

Owner:深圳前海南岭天蚕科技有限公司

Mixed silk quilt wadding and its producing method

InactiveCN1683624AAbsorb wellGood wet performanceNon-woven fabricsTextile shapingSurface layerEngineering

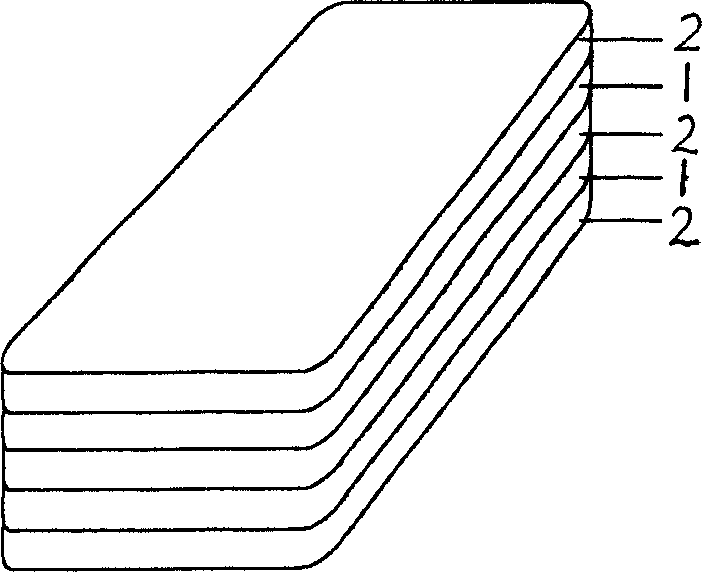

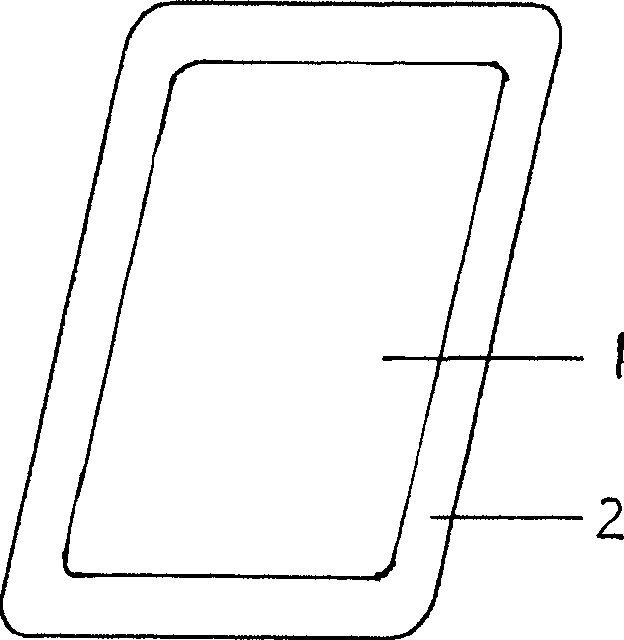

The present invention relates to a kind of mixed silk quilt wadding and its making process and solves the technological problem of making silk quilt wadding possess the advantages of both mulberry silk and oak silk and raising the integrity of two kinds of silk sheets. The mixed silk quilt wadding consists of is formed with several superposed silk sheets, has surface layers of mulberry silk and oak silk weight accounting for 10-90 %. The making process includes weighing material, stretching to form sheets, superposing and folding edge and twisting.

Owner:林德方

Method for manufacturing water washable wild tussah silk quilt

The invention relates to a production method of bedclothes, in particular to a method for manufacturing a water washable wild tussah silk quilt. The invention provides the method for manufacturing the water washable wild tussah silk quilt which has the advantages of low use cost, close-fitting use as well as comfortable and convenient use. The manufacturing method provided by the invention comprises the following steps of: (1) processing raw materials; (2) carrying out physical expansion; (3) adopting biological-chemical forming; (4) carding the neatened silk floss, lapping, assembling, quilting seam, checking and packing finished products.

Owner:杨永发

Ultraviolet-proof blended fabric and method for manufacturing same

The invention discloses an ultraviolet-proof blended fabric and a method for manufacturing the same. The ultraviolet-proof blended fabric comprises, by weight, 35-55 parts of dacron, 25-45 parts of polyester fibers, 12-25 parts of cotton fibers, 5-20 parts of spandex fibers, 2-15 parts of tea fibers, 2-15 parts of tussah silk fibers, 2-15 parts of cashmere fibers and 5-22 parts of sisal fibers. The method for manufacturing the ultraviolet-proof blended fabric includes manufacturing warps and wefts at first; weaving the warps and the wefts by the aid of weaving looms to obtain base cloth; processing the base cloth to ultimately acquire the ultraviolet-proof blended fabric.

Owner:JIANGSU XINCHEN CHEM FIBER

Cohensioned silk yarn and silk knit cloth

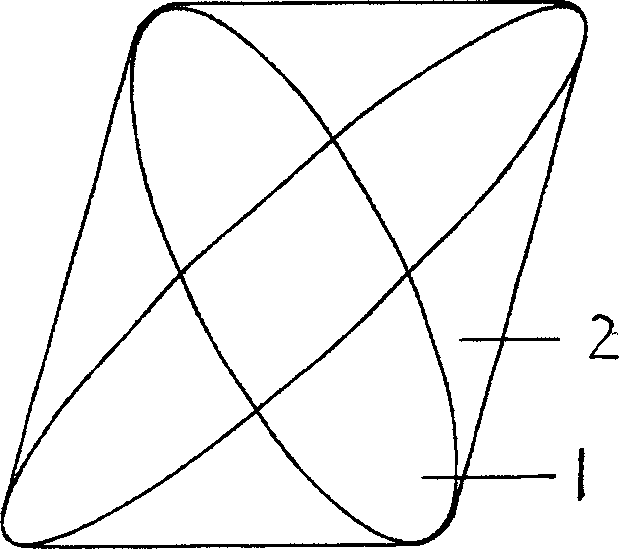

The present invention provides a yarn which is a covering yarn consisting of only silk and a yarn containing sericin. A cohesioned silk yarn is obtained by using raw silk, as a core yarn, with sericin in swollen state in reeling process at reel speed of 20 to 100 m / min, and by covering a raw silk in said reeling with a wild silk yarn, and by fusion-bonding a raw silk and a wild silk yarn by sericin. Said cohesioned silk yarn can be subjected to automatic knitting.

Owner:DAINIPPON SANSHIKAI +1

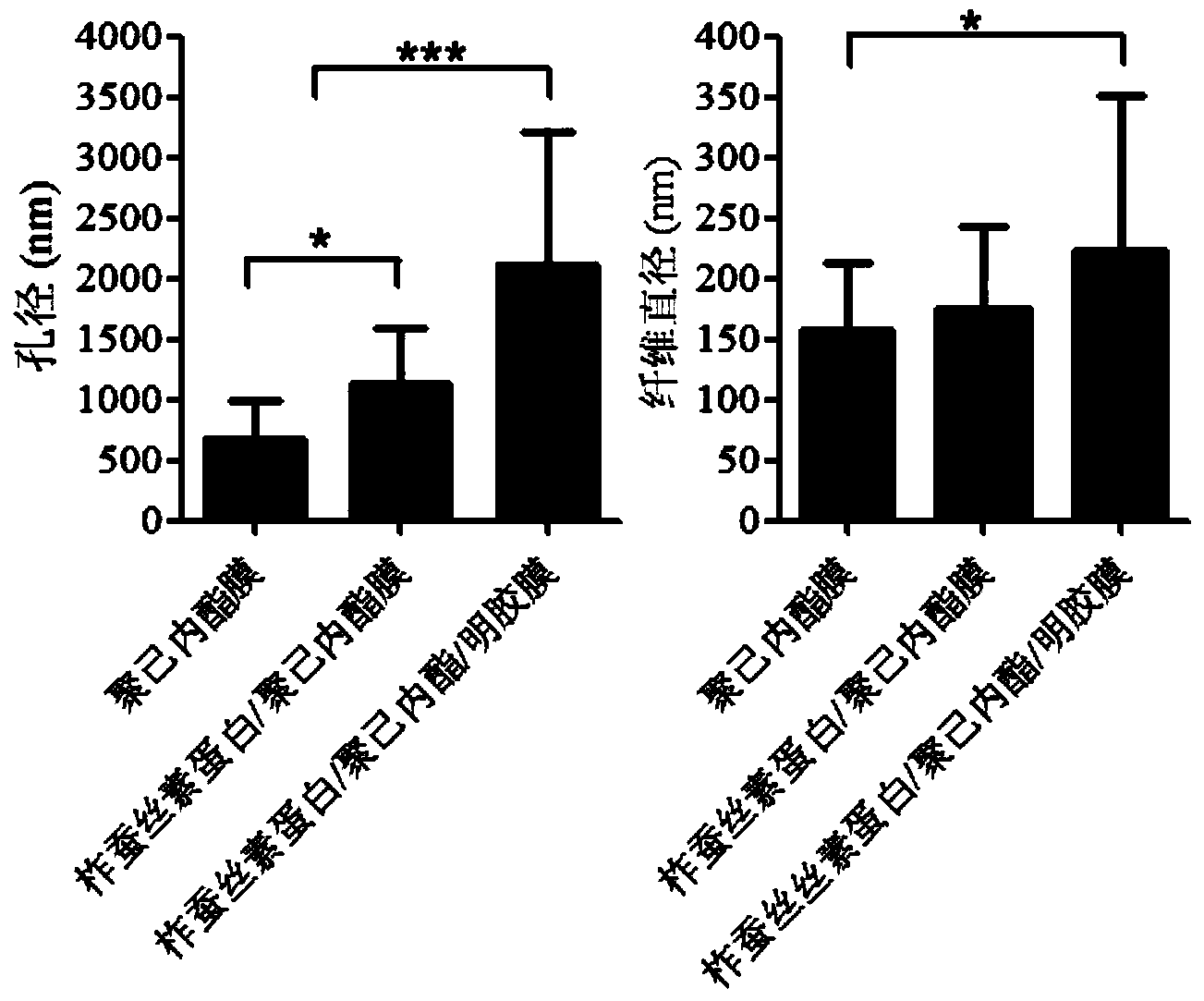

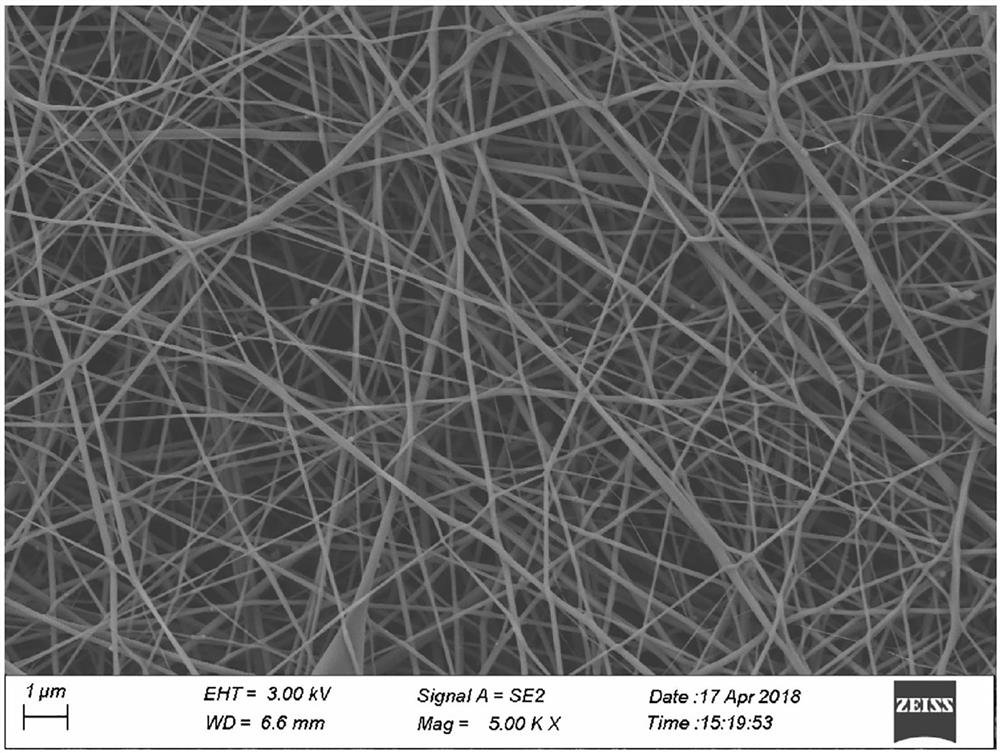

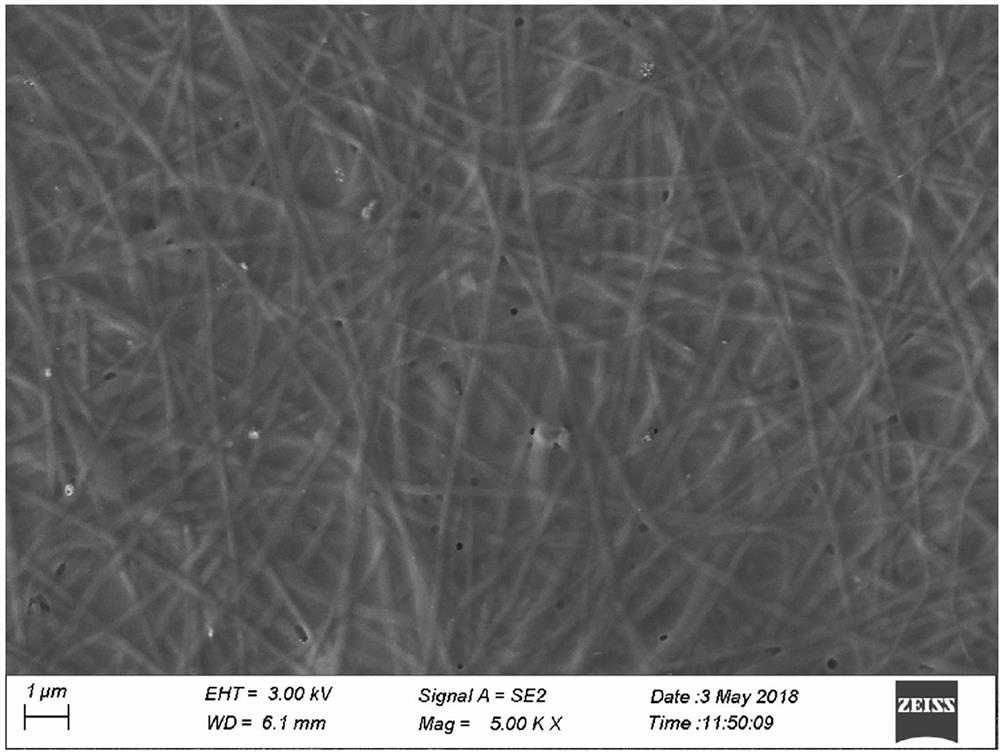

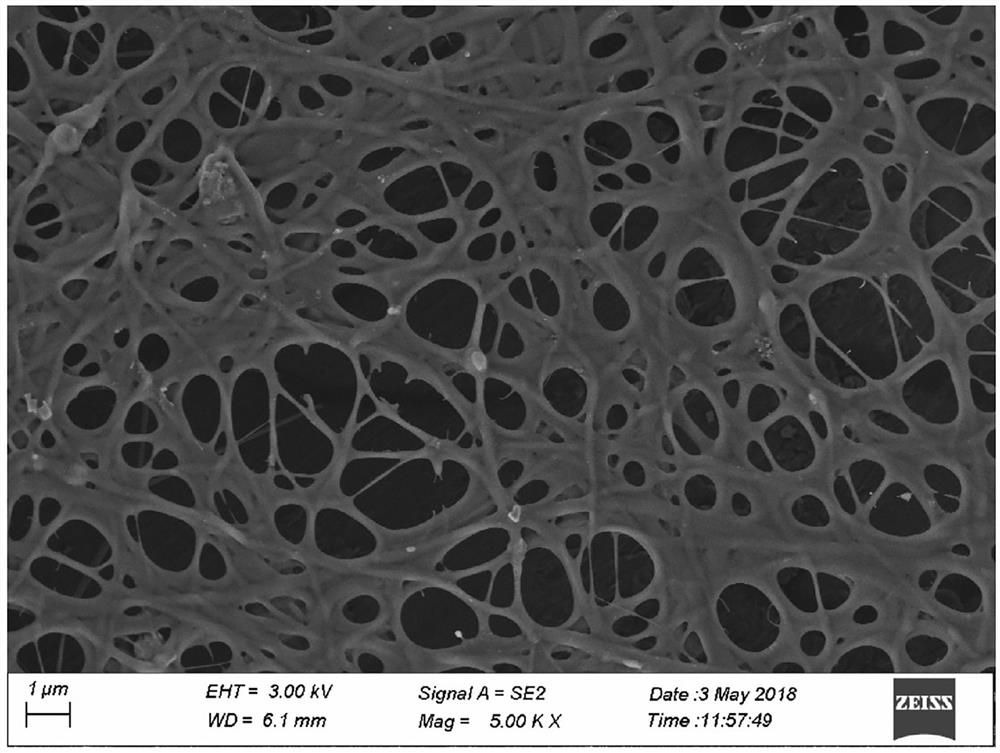

Electrostatic spinning production method for ultrathin porous composite-nanofiber bionic Bruch's film

The invention belongs to the field of biomedical engineering materials, and discloses a production method for an ultrathin porous composite-nanofiber bionic Bruch's film. The production method includes dissolving raw materials in organic solvent to obtain electrostatic spinning solvent, and performing electrostatic spinning on the electrostatic spinning solvent to obtain a composite-nanofiber film; obtaining the ultrathin porous composite-nanofiber bionic Bruch's film after drying of the composite-nanofiber film. The ultrathin porous composite-nanofiber bionic Bruch's film includes a polycaprolactone nanofiber bionic Bruch's film, a tussah silk fibroin / polycaprolactone composite-nanofiber bionic Bruch's film or a tussah silk fibroin / polycaprolactone / gelatin composite-nanofiber bionic Bruch's film. Products produced by the method can serve as carriers for retinal pigment epithelium transplantation.

Owner:WENZHOU MEDICAL UNIV +1

Tussah spun silk textile as well as manufacturing method and application thereof

InactiveCN104695199AImprove insulation effectReduce weightBleaching apparatusAnimal fibresFiberPolymer science

The invention discloses a tussah spun silk textile as well as a tussah spun silk treatment technological method and application thereof. The method is characterized by comprising the steps of selecting tussah shell, refining by bleaching, refining, carrying out softening treatment, printing and dyeing, wetting by an auxiliary agent and spinning to obtain the tussah spun silk textile, wherein the tussah spun silk textile can be a cotton blend, hemp, wool or chemical fiber tussah spun silk textile. The tussah spun silk textile or tussah spun silk blended product manufactured by the method can be used for making clothes or ornaments; the produced clothes or ornaments have the advantages of being good in thermal insulation property, soft, smooth, light in weight, strong in moisture absorption performance, odor-resistant and sweat-resistant, and avoiding hair shedding; furthermore, tussah silk is formed by natural animal protein fiber and contains multiple amino acids needed by the human body, thus being capable of effectively improving the cell viability when being contacted with the skin, preventing skin aging, resisting bacteria and preventing diseases; therefore, the tussah silk is an ideal and natural health care product; furthermore, the treatment method of the tussah silk has the advantages of being advanced in technology, simple in operation and low in cost.

Owner:HAIMEN RUNSHENG TEXTILE

Tussah silk fibroin hydrogel as well as preparation method and application thereof

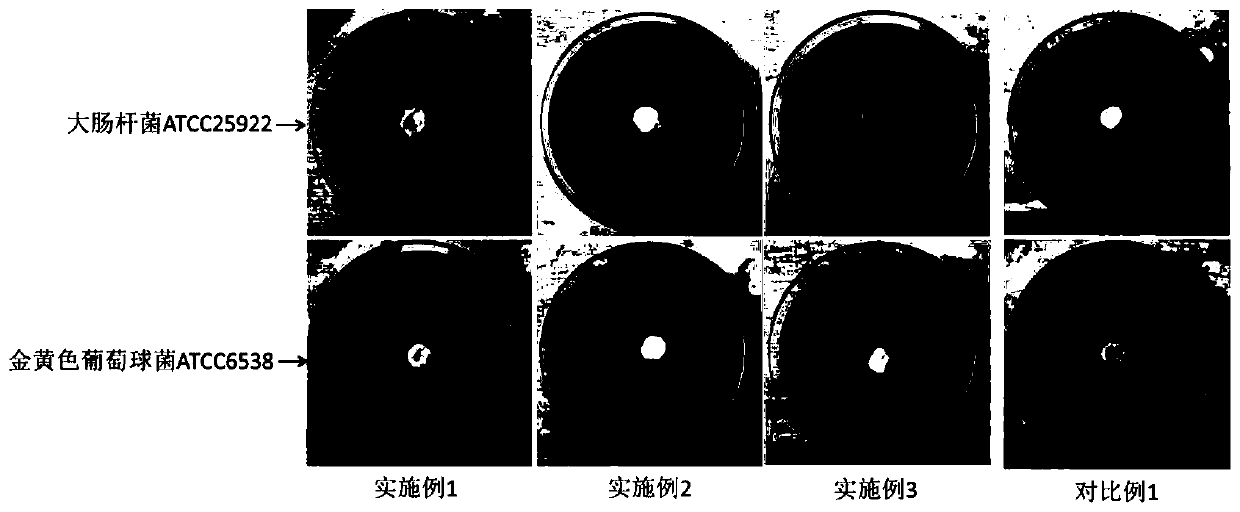

ActiveCN110627976AGood biocompatibilityStrong adhesionAntibacterial agentsAerosol deliveryCell adhesionFibroin

The invention relates to the technical field of biomedical materials, and in particular, relates to tussah silk fibroin hydrogel as well as a preparation method and an application thereof. The invention provides the preparation method of the tussah silk fibroin hydrogel, wherein the preparation method comprises the following steps: (1) mixing tussah silk fibroin with quaternary ammonium salt, andcarrying out ring-opening addition reaction to obtain quaternized tussah silk fibroin; and (2) mixing the quaternized tussah silk fibroin with N-isopropylacrylamide, and carrying out an in-situ polymerization reaction under the action of an initiator to obtain the tussah silk fibroin hydrogel. The tussah silk fibroin hydrogel prepared by the preparation method disclosed by the invention is good inbiocompatibility and strong in cell adhesion capability, can promote cell proliferation, and has good mechanical properties, temperature responsiveness and antibacterial property.

Owner:EASTERN LIAONING UNIV

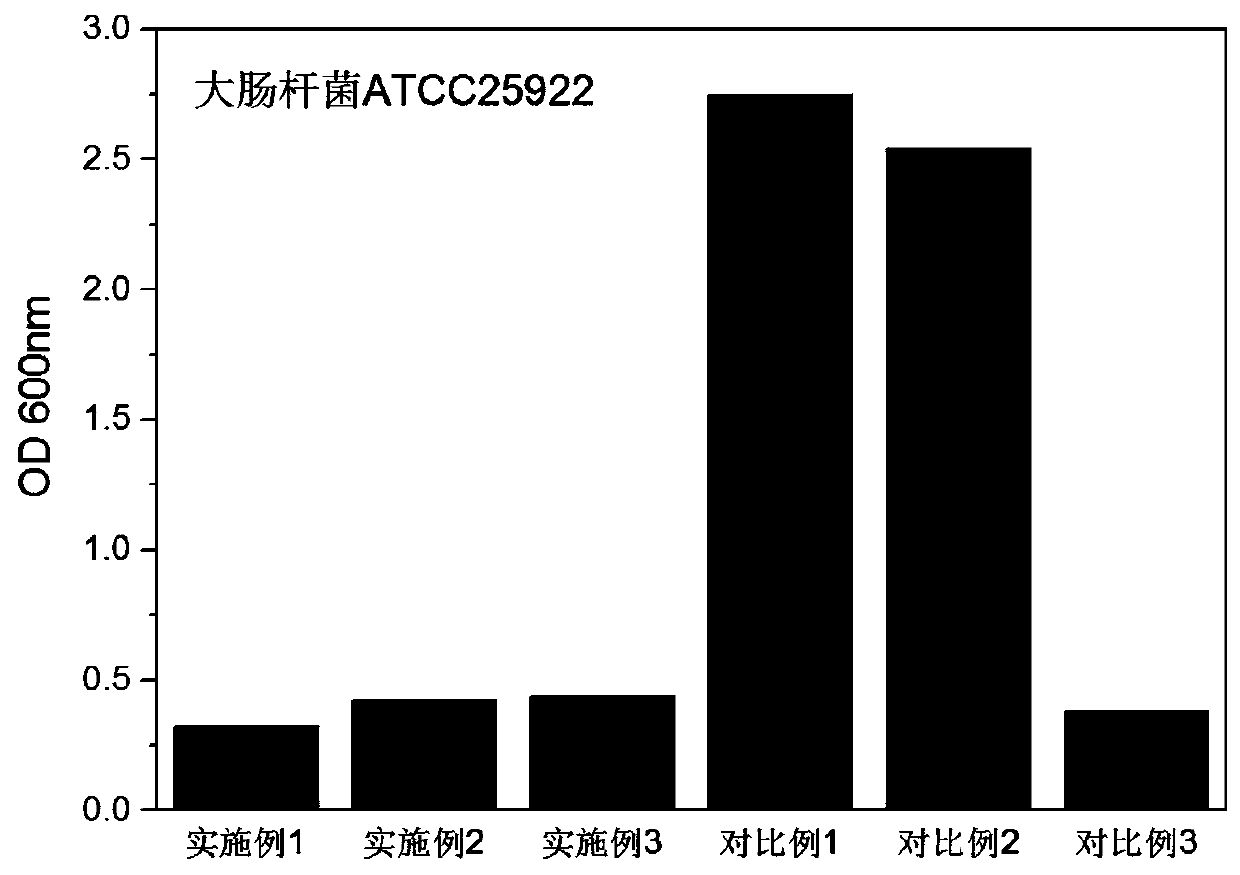

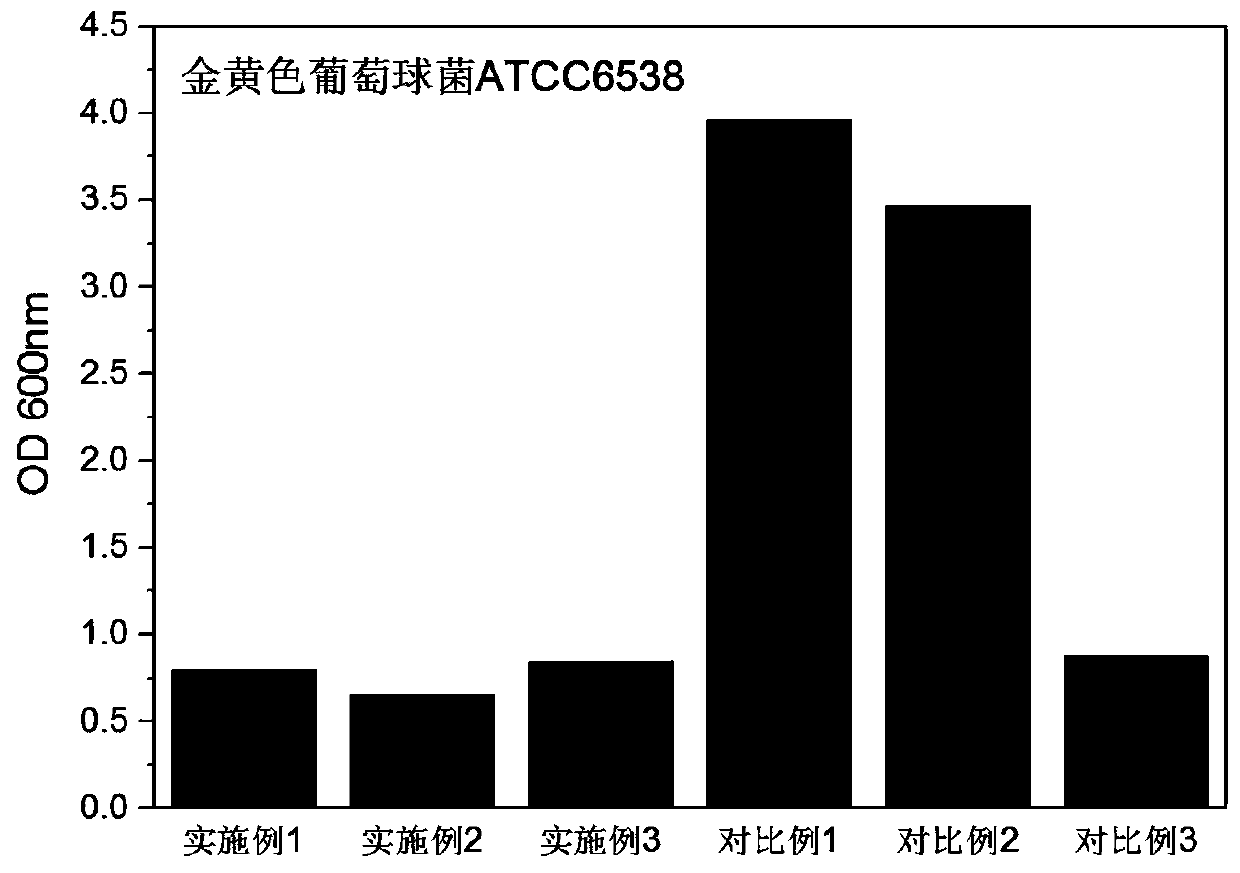

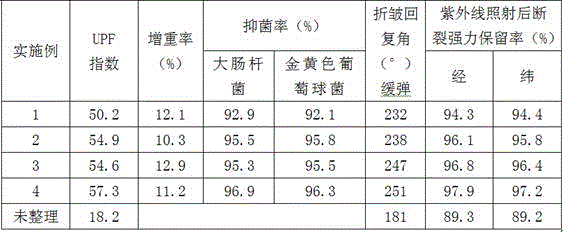

Tussah silk fabric functional finishing agent, finishing method and finished tussah silk fabric

ActiveCN104674544AEnhance absorption and finishing abilityLow mechanical strengthBiochemical fibre treatmentLiquid/gas/vapor removalPolymer scienceWild silk

The invention provides a novel tussah silk fabric functional finishing agent, a finishing method and a finished tussah silk fabric, wherein the functional components of the functional finishing agent are mainly originated from Chinese chestnut dull leaves which are rich in resource, easily available and low in cost. The tussah silk fabric functional finishing agent further comprises 1, 2-pentanediol and an acidic regulator. After the tussah silk fabric is finished by the functional finishing agent, the weight-gaining, the ultraviolet-resisting and wrinkle-resisting functions of the tussah silk fabric are fully enhanced at one time, and moreover, the fabric has an antibacterial function. The functional components are firm and durable to attach and the lowered range of the mechanical strength after ultraviolet irradiation is greatly reduced, so that the technical problem that the ultraviolet tendering of the tussah silk fabric is overcome. According to the technical scheme, the tussah silk fabric functional finishing agent has remarkable technical advantages of utilization of natural resources, simplification of process method, optimization of input cost and overall effect.

Owner:EASTERN LIAONING UNIV

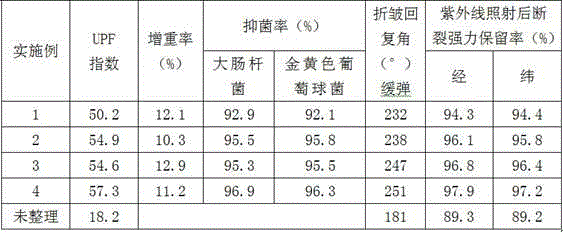

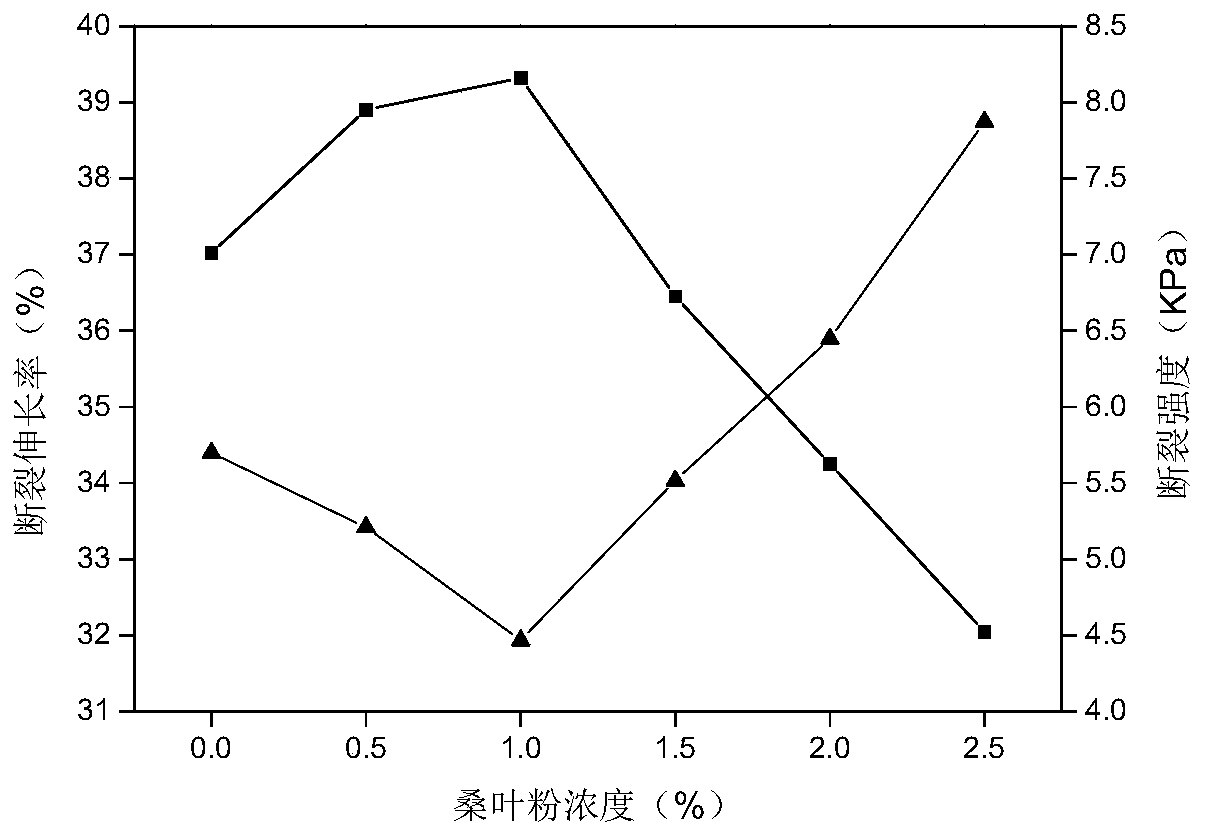

Mulberry leaf powder-mulberry silk sericin/tussah silk fibroin blending film and preparation method thereof

ActiveCN110841103AImprove mechanical propertiesGood antibacterial effectCosmetic preparationsToilet preparationsPolymer scienceSILK SERICIN

The invention belongs to the technical field of biological materials, and discloses a mulberry leaf powder-mulberry silk sericin / tussah silk fibroin blending film (MLP-MSS / TSF-BF), a preparation method thereof and an application of the blending film. The preparation method of the blending film includes the steps: firstly, preparing mulberry silk sericin solution and tussah silk fibroin solution and uniformly mixing the mulberry silk sericin solution and the tussah silk fibroin solution; secondly, adding gelatin solution and polyethylene glycol 200 solution; finally, adding mulberry leaf powderto obtain mulberry leaf powder-mulberry silk sericin / tussah silk fibroin mixed liquid and drying the mixed solution to obtain the mulberry leaf powder-mulberry silk sericin / tussah silk fibroin blending film. The prepared blending film has excellent tensile properties and antibacterial activity and has an important application potential in the field of medical treatment and cosmetics.

Owner:SOUTH CHINA AGRI UNIV +2

Tussah silk yarn and spinning process thereof

The invention provides tussah silk blended yarn. The tussah silk blended yarn comprises, by weight, 20% to 30% of mulberry silk, 20% to 30% of modal long fibers and 40% to 50% of tussah silk. The invention further provides a spinning process of the tussah silk blended yarn. The spinning process comprises the steps of blow carding, drawing, roving, spinning and spooling. A compact siro spinning mode is adopted, the advantages of siro spinning and compact spinning are combined in compact siro spinning, the evenness CV value and nub and snick indexes are very good, the single thread strength is high, the structure is compact, wear resistance is good, less hair is generated, the amount of harmful hair of 3 mm or above is extremely small, the yarn is smooth and clean, and the fabric quality ishigh. The yarn made through the process can be used for making common underwear, bath towels and other comfortable, soft and high-moisture absorption textile raw materials next to the skin.

Owner:上海纺织(集团)大丰纺织有限公司

Cohensioned silk yarn and silk knit cloth

InactiveUS20060162313A1Good skin feelSuperior in heat retaining propertySilk reelingYarnSilk clothWild silk

Owner:SHIMIZU SHIGETO +1

Tussah silk fiber non-woven fabric and manufacturing method of tussah silk fiber non-woven fabric

The invention provides tussah silk fiber non-woven fabric and a manufacturing method of the tussah silk fiber non-woven fabric. The tussah silk fiber non-woven fabric is characterized by being made of tussah silk short fibers with the non-woven needling technology.

Owner:EASTERN LIAONING UNIV

Method for making tussah silk summer sleeping mat and tussah silk summer sleeping mat

The invention discloses a method for making a tussah silk summer sleeping mat and the tussah silk summer sleeping mat. The tussah silk summer sleeping mat is woven from warp double weave or weft double weave. Original weave or changing weave or combined weave is adopted as surface weave of a textile to increase the design and color varieties of the summer sleeping mat. Original weave or simple changing weave is selected as back weave. The whole surface of the summer sleeping mat is made of tussah silk, the tussah silk is in contact with skin, people can feel soft, cool and comfortable, the skin is helped to improve metabolism of the surface panniculus adiposus, and skin aging can be delayed. The whole back face of the summer sleeping mat is made of pure cotton yarn or polyester cotton yarn, is not prone to slide when in contact with a Simmons mattress, and is good in fitness. The tussah silk does not need to be dyed, the surface of the summer sleeping mat shows the natural ginger of the tussah silk, and the pure cotton yarn or the polyester cotton yarn does not need to be dyed either, so that production procedures are reduced, and environment friendliness is promoted. The tussah silk summer sleeping mat is fine and smooth in surface, good in moisture absorption, light, thin, not prone to wrinkle and capable of being washed through a machine easily.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Tussah silk fibroin composite nanofiber for wound repair

ActiveCN114540977AEnhance antibacterial and anti-inflammatoryIncrease liquid absorptionPharmaceutical delivery mechanismConjugated cellulose/protein artificial filamentsFiberPolymer science

The invention discloses a tussah silk fibroin composite nanofiber for wound repair. The composite nanofiber is prepared from tussah silk fibroin, carboxymethyl chitosan, gelatin and an antibacterial agent according to a proper ratio through an electrostatic spinning technology under a certain spinning condition. Meanwhile, ethanol is also added into the tussah silk fibroin solution, so that the tussah silk fibroin in the composite nanofiber membrane is ensured to form a beta-folded structure from an angelica-free curled structure; the problems that in the prior art, a nanofiber membrane formed by spinning is immersed in an ethanol solution, so that the nanofiber membrane is adhered, and nanofibers are dissolved in ethanol are solved, meanwhile, the mechanical strength of the nanofibers is improved, and the application range of the nanofiber membrane is widened; the obtained nanofiber has a good application prospect in the aspect of wound repair.

Owner:HENAN INST OF ENG

Mint fiber and tussah silk blended yarn and spinning technology thereof

The invention discloses a mint fiber and tussah silk blended yarn and a spinning technology thereof. The mint fiber and tussah silk blended yarn comprises a blended yarn body which is prepared by spinning mint fibers and tussah silks, wherein the weight percentage of the mint fibers is 70%, and the weight percentage of the tussah silks is 30%. The invention relates to the technical field of spinning. According to the mint fiber and tussah silk blended yarn and the spinning technology thereof, through a dyeing process, dyeing after uniform mixing, a carding process, a drawing process, a rovingprocess and a spooling process, 70% of the mint fibers and 30% of the tussah silks are blended, and the blended yarn has the characteristics of the mint fibers and the tussah silks, has unique jewelrygloss and is natural, sumptuous, cool and comfortable. The smell of the blended yarn has the advantage of repelling mosquitoes, the blended yarn can be used for a high-end fabric, and wide application and popularization are facilitated.

Owner:张家港市华益纺织有限公司

Silk scarf fabric based on superfine mulberry silk fiber/tussah silk fiber

ActiveCN109505048BImprove cohesionReduce wire breakageScarvesDry-cleaning apparatus for textilesPolyesterPolymer science

The invention discloses a real silk scarf fabric based on superfine mulberry silk fiber / tussah silk fiber. A sizing solution composed of dodecylazacyclohept-2-ketone, nanoparticles, binder SD28, curcumin and water is subjected to sizing treatment and then dried to obtain sizing superfine mulberry silk; the sizing superfine mulberry silk After winding, doubling and twisting, warp mulberry silk fiber and weft mulberry silk fiber are prepared, and degummed warp mulberry silk fiber and degummed weft mulberry silk fiber are obtained by refining; then the degummed warp mulberry silk fiber, degummed weft silk fiber The silk scarf fabric based on superfine mulberry silk fiber / tussah silk fiber is prepared by mixed weaving of mulberry silk fiber and degummed warp tussah silk fiber. The invention has the advantages of not easy to break during weaving, good cloth surface elasticity and good warmth retention.

Owner:SHANGHAI WOO BRAND MANAGEMENT CO LTD

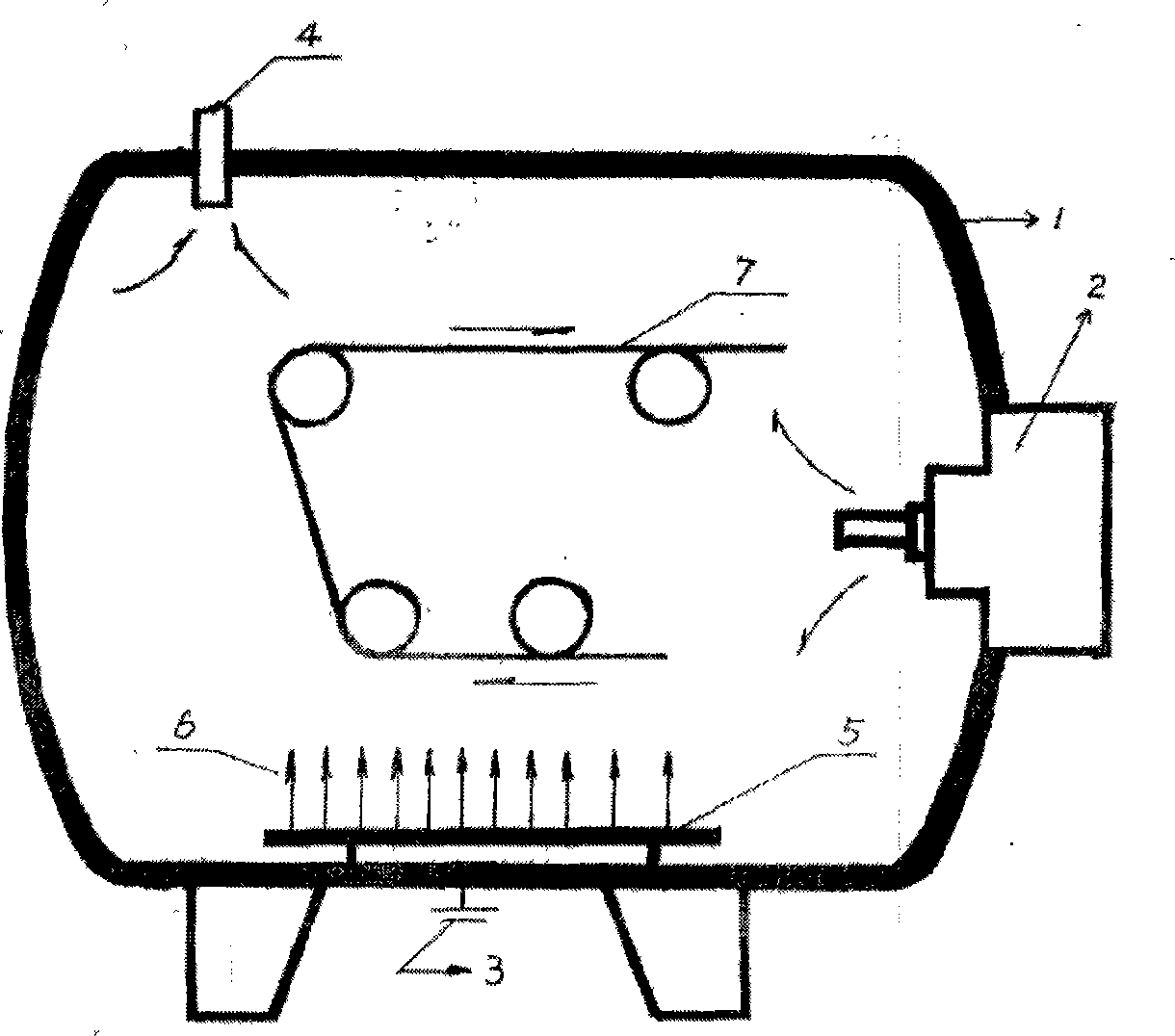

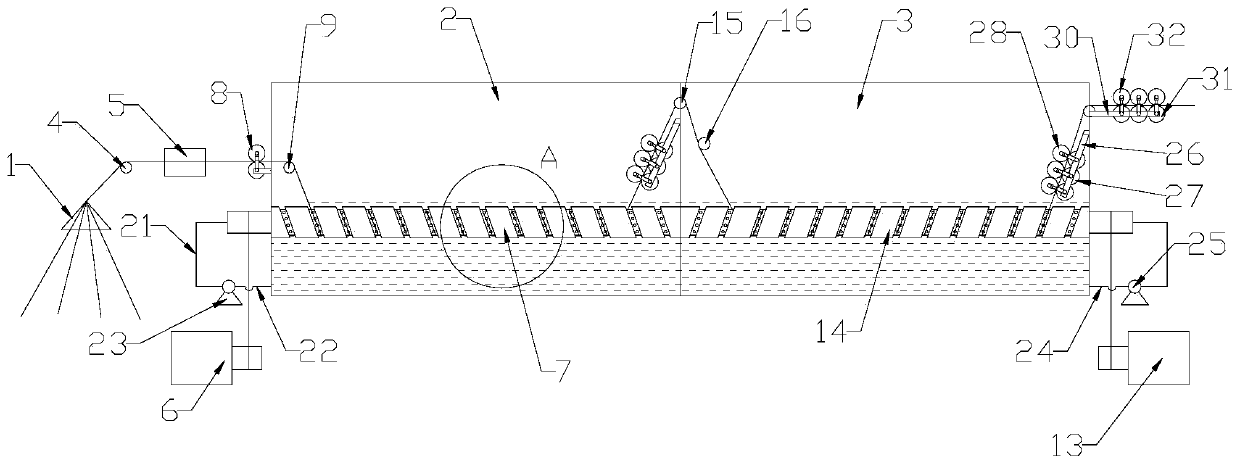

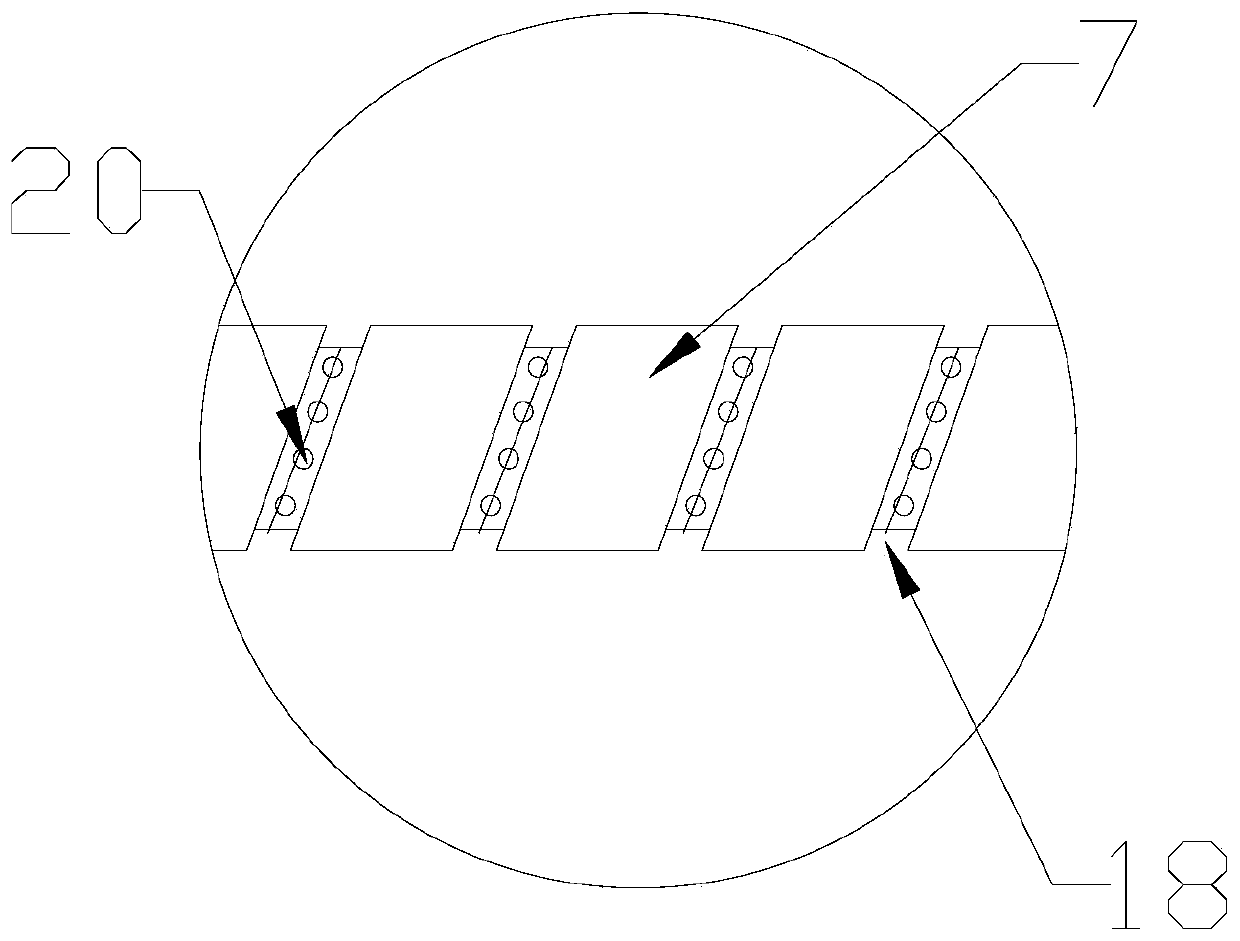

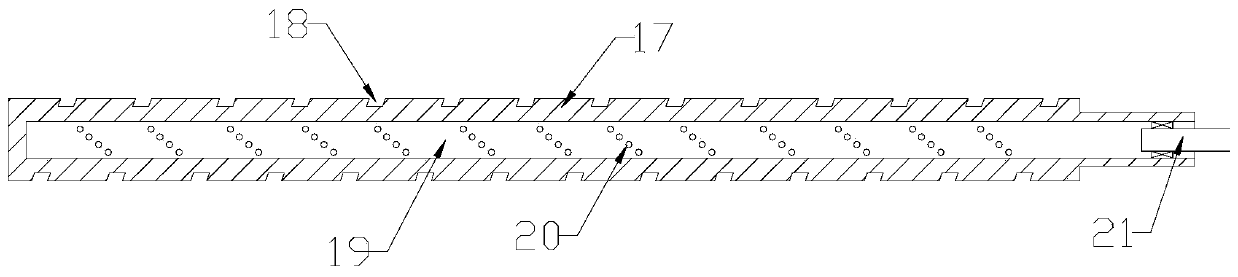

Tussah silk adhesion preventive carding device and carding method

PendingCN110747516ASimplify processing stepsSoak quickly and evenlyFilament handlingLiquid/gas/vapor removal by squeezing rollersWild silkElectric machinery

The invention provides a tussah silk adhesion preventive carding device and carding method; the carding device comprises a filament collector, a soaking tank and a cleaning tank;a first direction-adjusting wheel and a drying device are arranged between the filament collector and the soaking tank; a soaking shaft driven by a first motor is horizontally arranged in the soaking tank; a silk feeding positioning mechanism is arranged above one end, close to the drying device, of the soaking shaft; a first dewatering mechanism which is inclined upwards is arranged above the other end of the soakingshaft; a cleaning shaft driven by a second motor is horizontally arranged in the soaking tank; a silk feeding adjustment is arranged above one end, close to the soaking tank, of the cleaning shaft; asecond dewatering mechanism which is inclined upwards is arranged above the other end of the cleaning shaft; and one side, far away from the silk feeding adjustment, of the second dewatering mechanismis provided with a compaction silk-finishing mechanism. According to the invention, reeling, soaking and cleaning are integrated, so that the processing steps of silk are simplified, and rapid uniform soaking and cleaning of the silk are achieved.

Owner:HENAN MINXING COCOON SILK

Brewing process and preparation method of health-preserving silkworm moth wine

The invention discloses a brewing process and preparation method of health-preserving silkworm moth wine. The health-preserving silkworm moth wine comprises the following materials: male original silkworm moth, selenium-enriched mushrooms, non-woven fabric, a tank and sorghum liquor. A production process method comprises the following steps: step 1, selecting materials: selecting fresh and live male original silkworm moth of wild tussah, wild honey, the 100% pure natural wild tussah silk spunlace non-woven fabric, the wine brewing tank and the pure sorghum liquor by a user; and step 2, performing preparation: wrapping the wild tussah fresh and live male original silkworm moths with the 100% pure natural wild tussah silk spunlace non-woven fabric. The raw materials of the silkworm moth wine are improved and selected from the fresh male original silkworm moth of wild tussah, the selenium-enriched mushrooms, the 100% pure natural wild tussah silk spunlace non-woven fabric, the wine brewing tank and the pure sorghum liquor, so that the raw materials have excellent qualifications, the taste improvement of the finished silkworm moth wine is promoted, the silkworm moth wine is better in taste, and the silkworm moth wine has a good market prospect. The achieved health preserving effect of the health-preserving silkworm moth wine is more obvious than that of similar products.

Owner:辽宁中天蚕业科技有限公司

Resorbable implantable devices

InactiveCN101208113AHigh strengthImprove toughnessSuture equipmentsProsthesisProsthesisBiomedical engineering

A resorbable implantable device, such as a suture or prosthesis, comprising one or more silk elements made at least partially (poly)alanine Wild silk proteins of a saturnid moth or analogues thereof.

Owner:SUTUROX

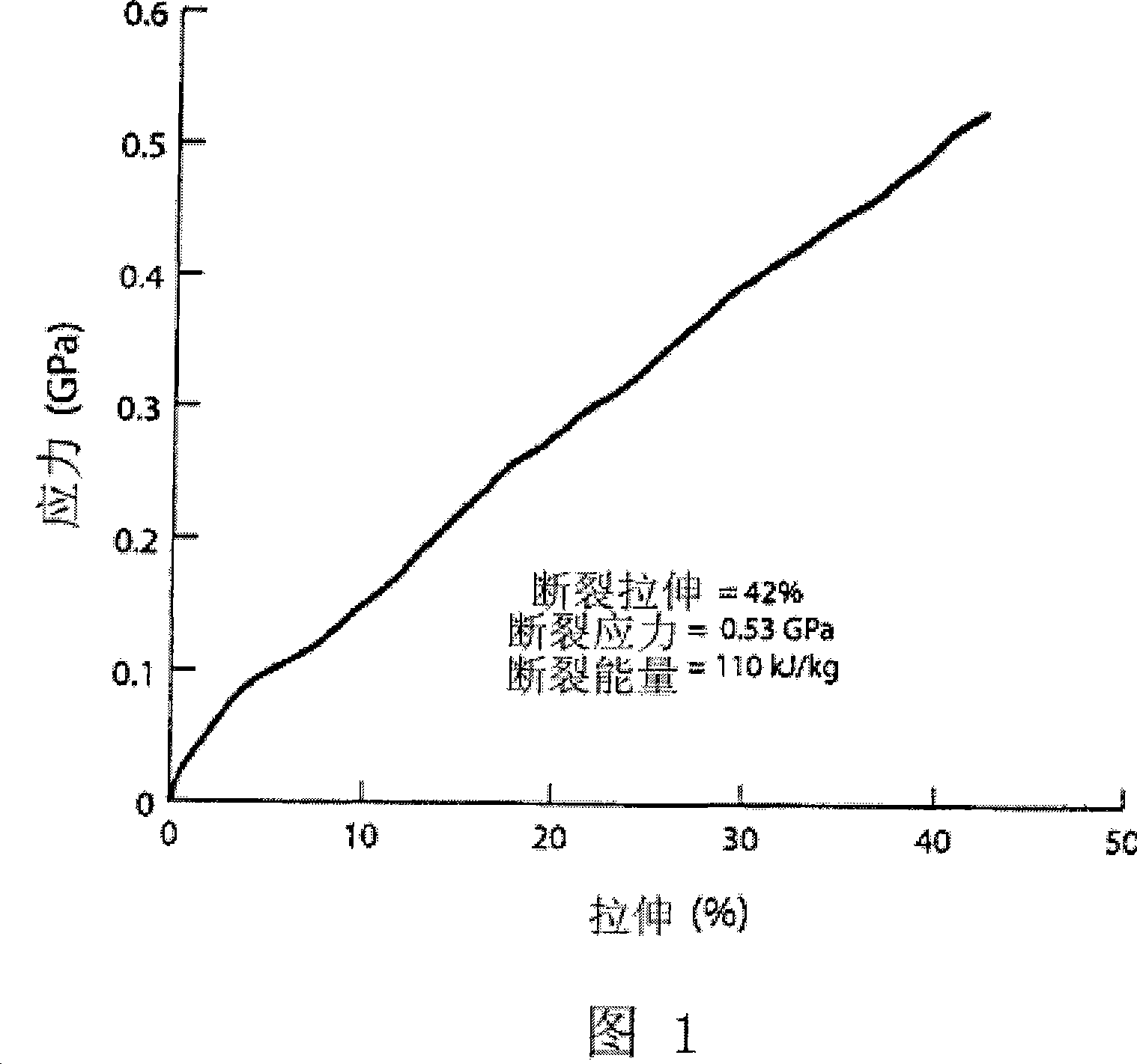

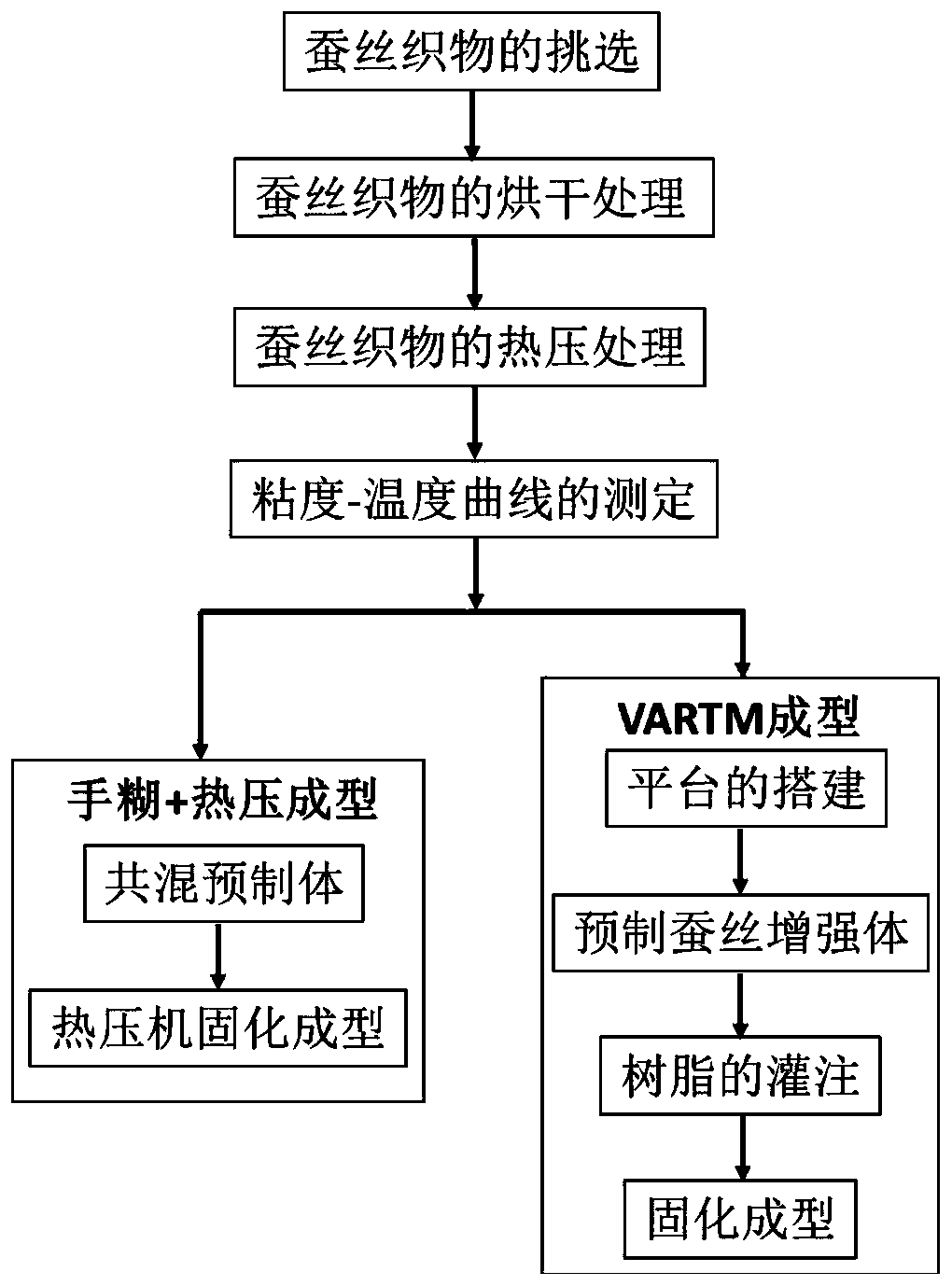

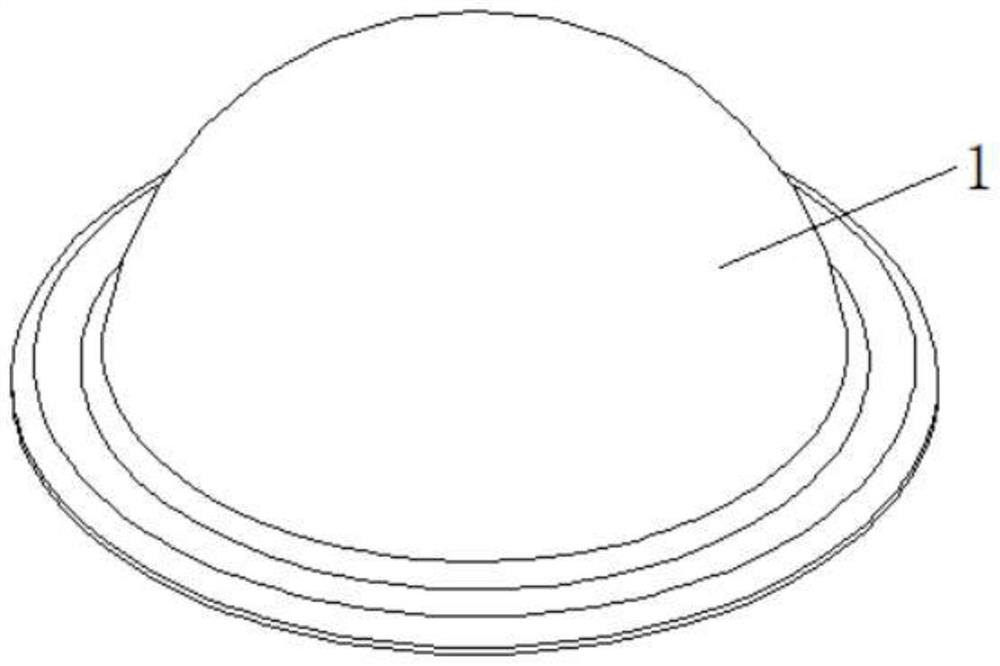

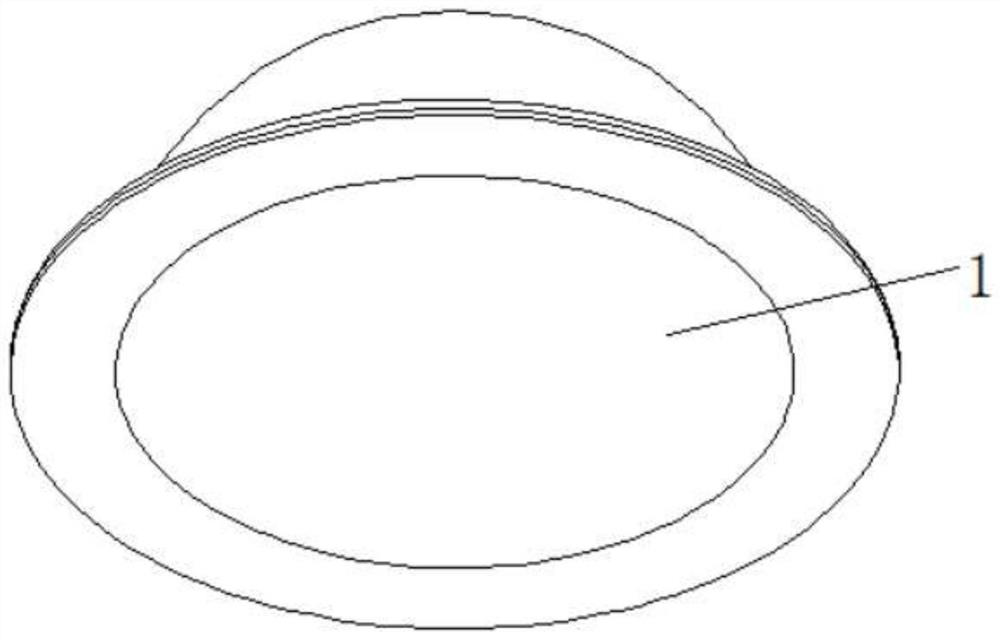

Preparation method of natural mulberry silkworm/tussah silk fabric reinforced epoxy resin composite material

The invention provides a preparation method of a natural mulberry silkworm / tussah silk fabric reinforced epoxy resin composite material. The preparation method comprises the following steps: selectingand pretreating mulberry silkworm / tussah silk fabric; and preparing the natural mulberry silkworm / tussah silk fabric reinforced epoxy resin composite material by a hand lay-up and hot press molding process and a vacuum resin transfer molding (VARTM) process. The raw material silk fiber adopted by the invention comes from natural sources, is biodegradable and has environmental friendliness; the silk fabric is easy to obtain and mature in textile process; the prepared natural mulberry silkworm / tussah silk fabric reinforced epoxy resin composite material is a low-carbon and environment-friendlygreen engineering material. According to the invention, different forming processes can be adopted, the preparation method is simple, a final composite material finished product has higher tensile strength, bending strength and toughness, and the natural mulberry silkworm / tussah silk fabric reinforced epoxy resin composite material shows excellent energy absorption capacity under the condition ofhigh-speed impact load.

Owner:BEIHANG UNIV

Tussah carbon fiber composite helmet based on multi-element coupling bionics and preparation method

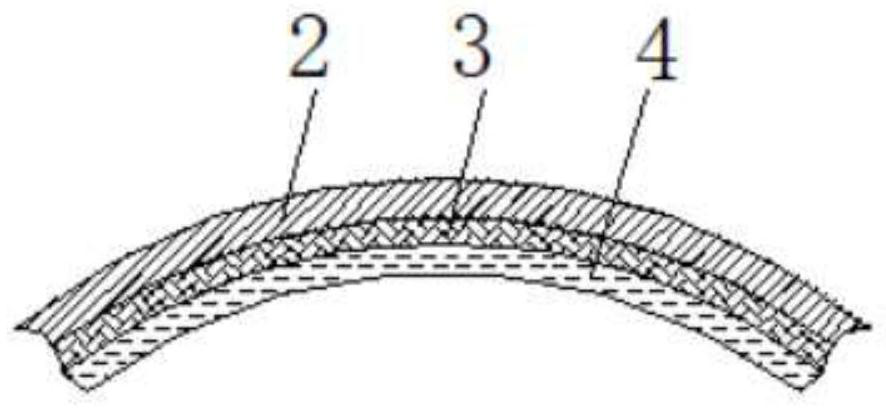

PendingCN114683578AReduce damage areaEnsure safetyDomestic articlesHelmetsWild silkFibrous composites

The invention discloses a tussah silk carbon fiber composite helmet based on multi-element coupling bionics and a preparation method, the tussah silk carbon fiber composite helmet comprises a helmet shell and multi-element bionic elements, the helmet shell comprises a reinforcing layer, the inner wall of the reinforcing layer is bonded with a tussah silk carbon fiber hybrid composite layer, and the tussah silk carbon fiber hybrid composite layer is bonded with the reinforcing layer. A buffer layer is adhered to the inner wall of the tussah silk carbon fiber hybrid composite material layer, and finally the helmet shell which is wrapped by the reinforcing layer, the hybrid composite material layer and the buffer layer layer by layer is prepared. The multi-element bionic elements comprise an exponential stiffness gradient structure, a cross-scale multi-stage wave interface form, a controllable pore content, size and space distribution structure and a soft and hard collaborative bionic structure. The problems that after an existing helmet is subjected to external acting force, the helmet is prone to being sunken, the helmet is damaged when the external acting force is serious, impact force cannot be effectively absorbed, safety of the head of a user cannot be guaranteed, and certain potential safety hazards exist are solved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A modified tussah silk fibroin 3D printing scaffold and its preparation method

ActiveCN110859994BImprove mechanical propertiesImprove the modulus of compressionAdditive manufacturing apparatusPharmaceutical delivery mechanism3d printPolymer science

The invention relates to a modified tussah silk fibroin 3D printing support and a preparation method thereof. Core part printing ink prepared by using chemically modified tussah silk fibroin nano microfibers and shell part printing ink prepared by using a chemically modified tussah silk fibroin nano microfiber / gelatin composite system are used for carrying out 3D printing to prepare a modified tussah silk fibroin 3D printing support. The compression modulus of the modified tussah silk fibroin 3D printing support is 100 to 600 MPa after soaking in genipin with the mass concentration of 0.1 to 5wt% and subjection to a cross-linking reaction for 24 h; and after culture for 10 days, the survival rate and the proliferation rate of induced pluripotent stem cells are high. The finally prepared modified tussah silk fibroin 3D printing support comprises printing lines with core-shell structures. According to the invention, the preparation method is relatively simple; and the prepared 3D printing support has excellent mechanical properties, excellent biocompatibility and good tissue repair capability.

Owner:DONGHUA UNIV

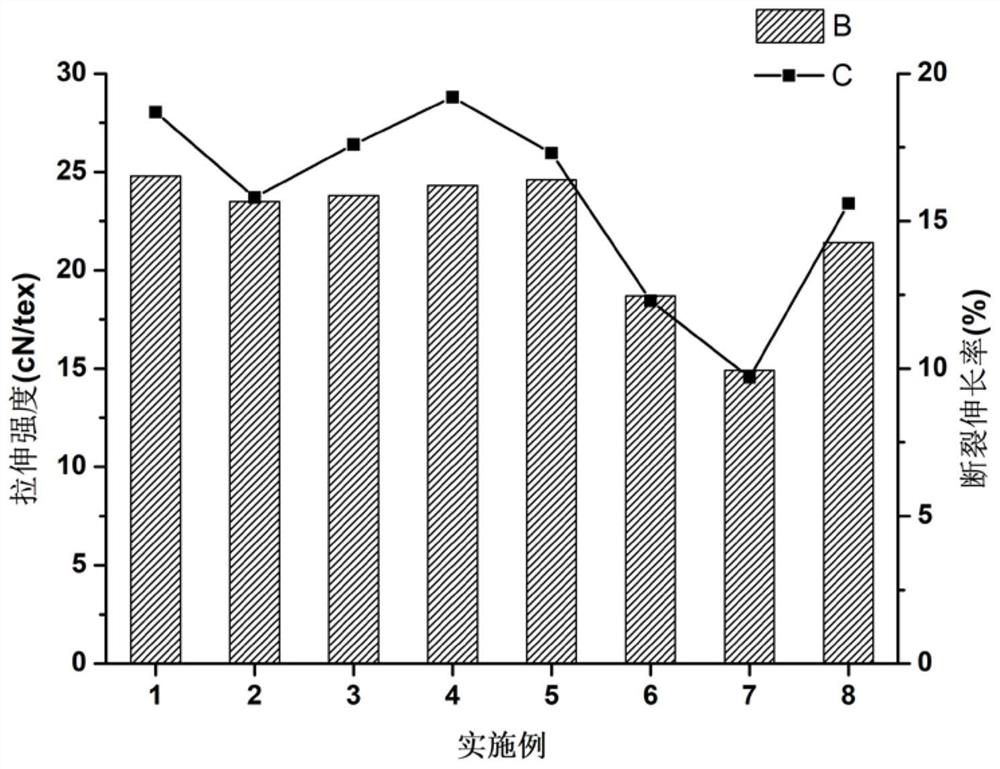

A kind of wild tussah silk brushed yarn and preparation method thereof

ActiveCN112981647BImprove antistatic performanceImprove stabilityYarnAnimal fibresYarnPolymer science

The invention discloses an antistatic agent used for preparing wild tussah silk woolen yarn, and the antistatic performance of the brushed yarn prepared from wild tussah silk through antistatic treatment is greatly improved; the invention also discloses a wild tussah silk yarn Wool yarn and preparation method thereof, wherein nylon filament is used as core solid yarn, tussah silk / basolan wool blended roving is used as decorative yarn to obtain brushed yarn, which can give full play to the characteristics of raw materials, and the brushed yarn is soft to the touch, smooth and glutinous and has body bones , The hair feels elegant, the stiffness is good, the tensile performance is high, the anti-wrinkle performance and the anti-static performance are excellent, the dust is difficult to adhere, and the maintenance is convenient.

Owner:康宝莱(宁波)织造有限公司

Silk flocking material and preparation method and application thereof

ActiveCN111118917BFlame retardantAntibacterialLiquid surface applicatorsCoatingsFiberPolymer science

Owner:SUZHOU UNIV

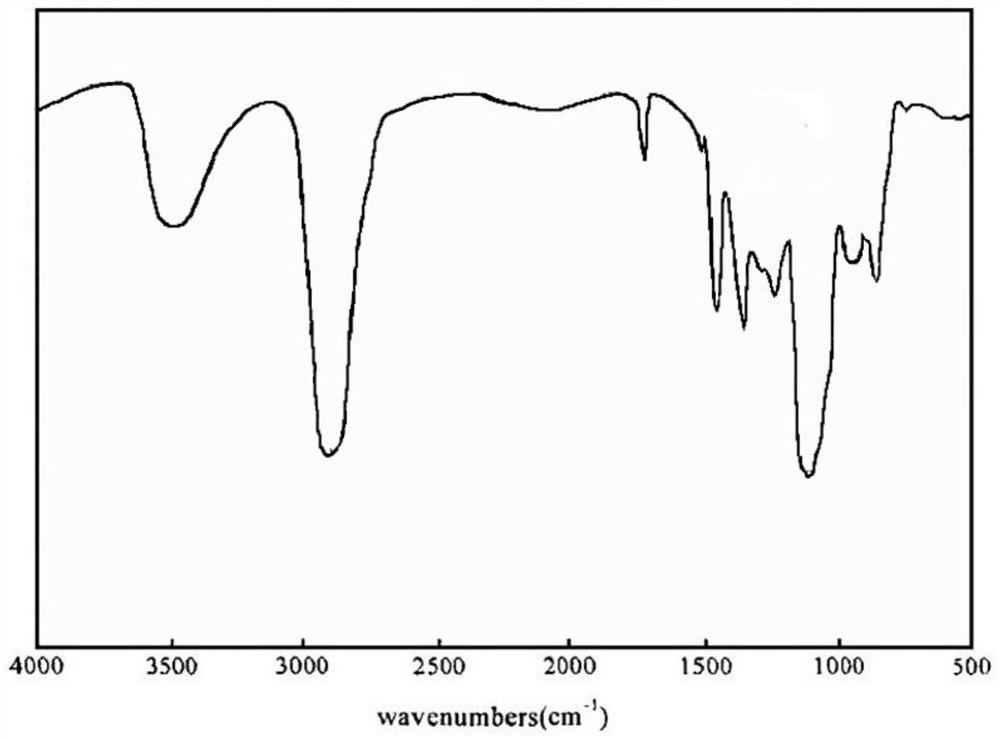

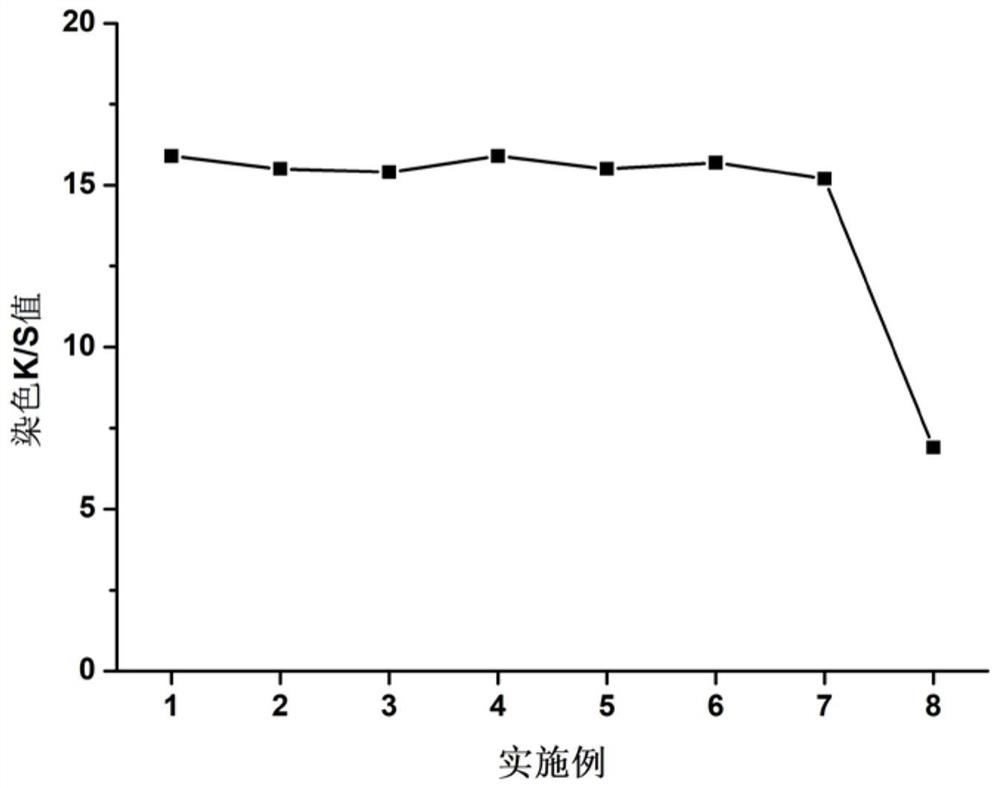

Tussah silk fabric functional finishing agent, finishing method and tussah silk fabric obtained by finishing

ActiveCN104674544BLow mechanical strengthLess reduction in mechanical strengthBiochemical fibre treatmentLiquid/gas/vapor removalPolymer scienceWild silk

The application of the present invention provides a novel functional finishing agent for tussah silk fabrics, a finishing method and the finished tussah silk fabrics. Leaves also contain 1,2-pentanediol and acid regulators. After tussah silk fabrics are finished with functional finishing agents, the tussah silk fabrics can be comprehensively improved in terms of weight gain, anti-ultraviolet rays, and anti-wrinkle functions. It has antibacterial function, and the functional components are firmly and persistently attached, and the decrease in mechanical strength is greatly reduced after ultraviolet radiation, which overcomes the technical problem of tussah silk fabric's ultraviolet brittleness. The technical scheme has outstanding technical advantages in terms of utilization of natural resources, simplification of process methods, optimization of input costs and finishing effect.

Owner:EASTERN LIAONING UNIV

Expanded silk quilt based on mulberry silk and preparation method thereof

ActiveCN109730497BGood bulkImprove insulation effectPhysical treatmentBlanketCellulosePolymer science

The invention discloses an expanded silk wadding quilt based on mulberry silk and a preparation method of the expanded silk wadding quilt. The preparation method comprises the following steps: addinga mixed solution of turmeric extract, acetic acid and carboxymethylcellulose into a degummed silk fiber solution, performing ultrasonic treatment, adding polyurea-formaldehyde and selenocysteine hydrochloride, and performing ultrasonic treatment; preparing perforated silk into silk floss pieces, and impregnating in an aqueous solution of amino polyethylene glycol so as to obtain treated silk flosspieces; putting the treated silk floss pieces into a rotatable closed container filled with a rupture disk, and expanding to obtain expanded wet silk floss pieces; dehydrating the expanded wet silk floss pieces, manually garneting, and drying to obtain expanded silkworm dried silk floss pieces; and combining and sewing the expanded silkworm dried silk floss pieces and treated tussah silk floss pieces, thereby obtaining the expanded silk wadding quilt. The porous expanded silk floss pieces with excellent service performance are successfully prepared, and the expanded silk wadding quilt has excellent antibacterial property and also has positive practical significance.

Owner:NANTONG LOVER APPL +1

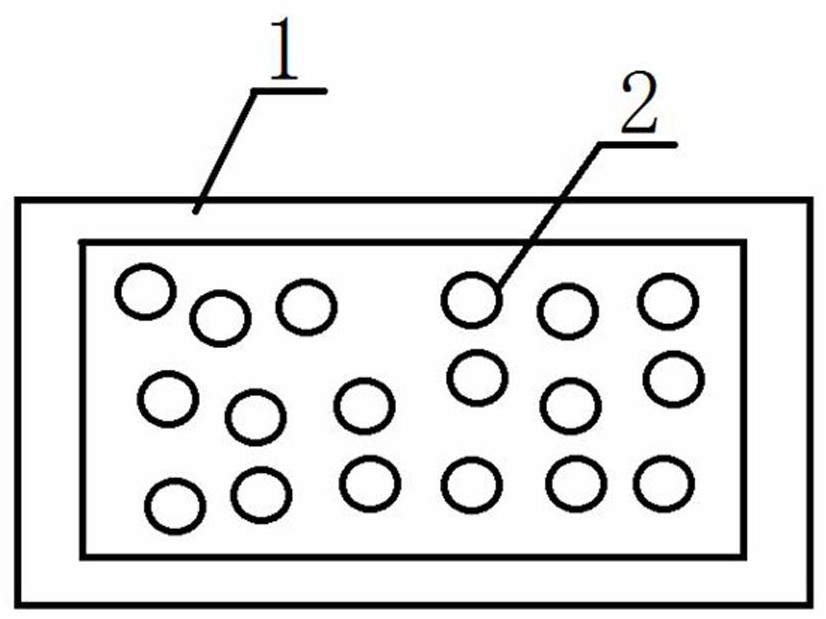

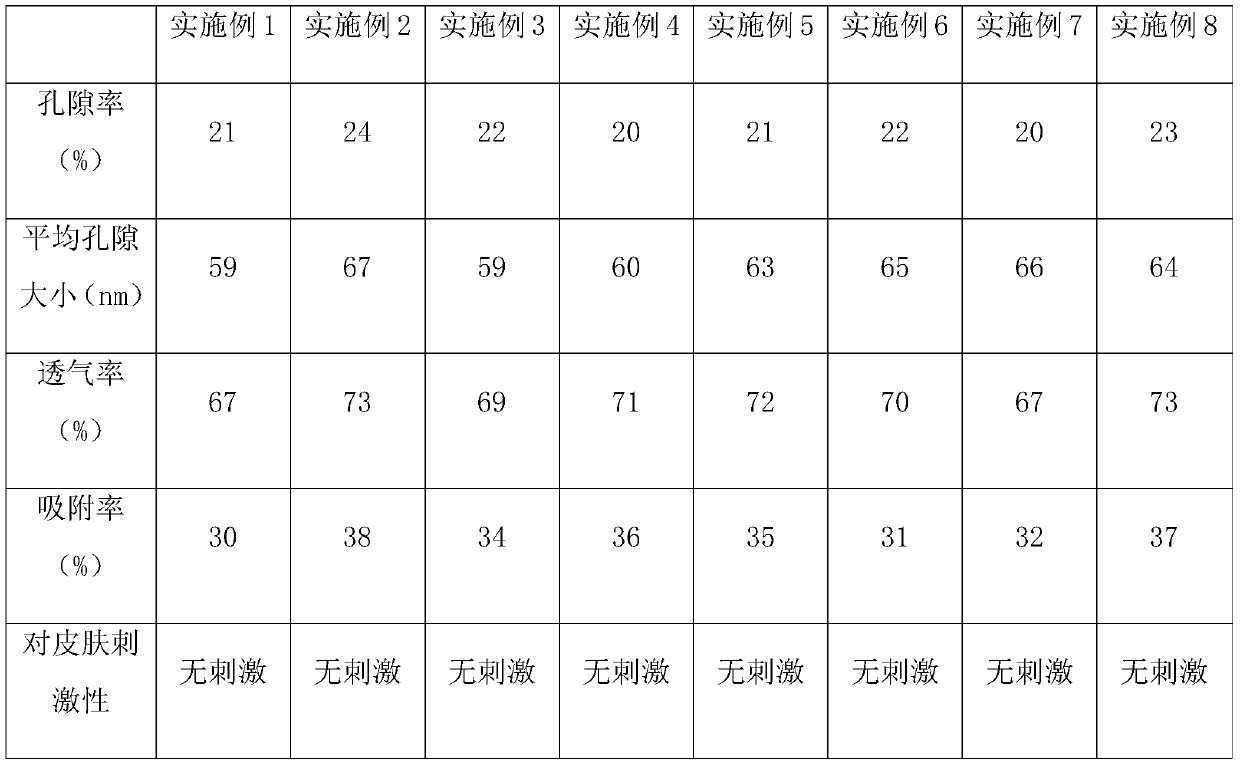

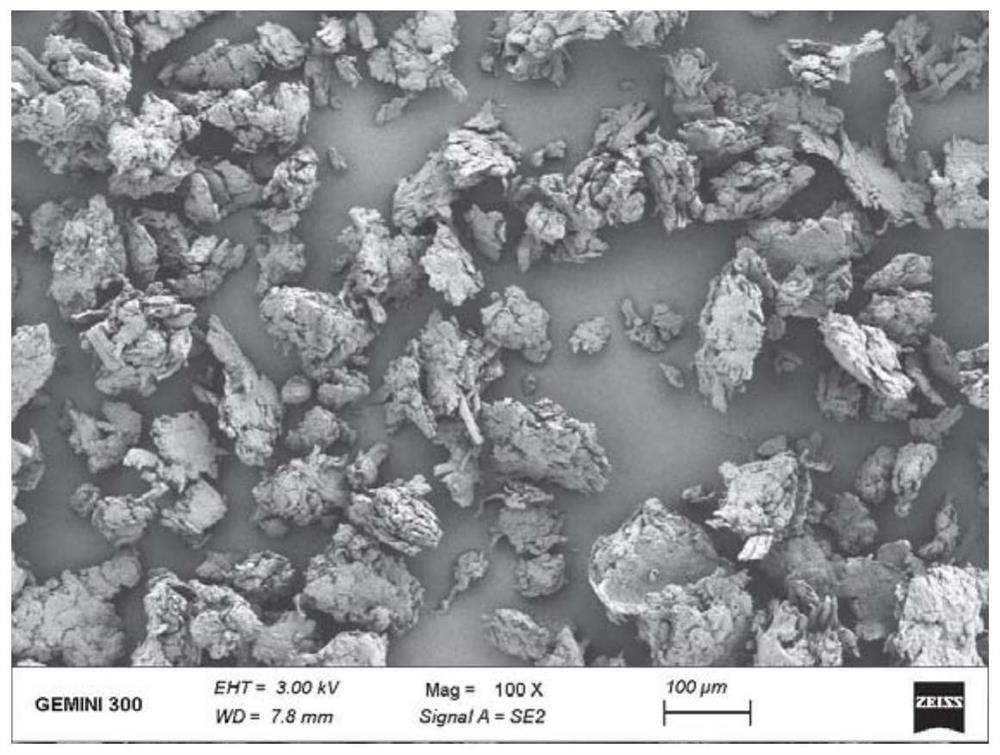

A kind of tussah silk fibroin protein microsphere containing three-dimensional hole structure and preparation method thereof

InactiveCN106637969BHigh porosityLoose structureFibre treatmentMicroballoon preparationProtein solutionPolymer science

The invention provides a tussah fibroin protein microsphere including a three-dimensional porous structure and a production method thereof. The method comprises the steps of using tussah silk as raw material, degumming the tussah silk, placing degummed tussah silk into solvent to dissolve completely, dialyzing, separating, adding enzyme solution for enzymolysis, heating, and concentrating to obtain tussah fibroin protein solution; adding a foaming agent and a cross-linking agent into the tussah fibroin protein solution, standing, stirring and centrifugally separating to form tussah fibroin protein particles; and adding the tussah fibroin protein particles into sodium chloride solution, heating, stirring, centrifugally separating sediments, washing with ethyl alcohol, taking the washed sediments out, drying and placing into a low temperature environment to cool and dry, thus acquiring the tussah fibroin protein microspheres with three-dimensional porous structures. The production method provided by the invention is simple, and the produced silk fibers are good in porosity and have the properties of being skin-friendly, air and vapor permeable and adsorptive.

Owner:上海寓尚电子商务有限公司

Method for rapidly and efficiently preparing native tussah silk fibroin protein powder

PendingCN113666995ANo side effectsPromotes early adhesionPeptide preparation methodsAnimals/human peptidesFiberPolymer science

The invention discloses a method for rapidly and efficiently preparing native tussah silk fibroin powder. The method comprises the steps of boiling cleaned tussah cocoon shells in a sodium carbonate solution, repeatedly conducting boiling, removing sericin, and conducting cleaning and drying; and loading the dried tussah silk fibroin fibers into a crushing tank, putting rotating beads into the crushing tank, conducting tight covering with a cover, then immersing the crushing tank into liquid nitrogen or a refrigerator or dry ice for freezing, fixing the fully frozen crushing tank to a stainless steel adapter, starting a freezing crusher for crushing, and conducting screening to prepare the tussah silk fibroin powder with the particle size being micron. The method provided by the invention has the characteristics of rapidness, high efficiency, no pollution and the like, can retain the biological function of the tussah silk fibroin and the natural conformation structure of the nanoscale, overcomes many problems brought by the existing method for processing the tussah silk fibroin powder, and is wide in application.

Owner:ZHEJIANG UNIV

Method for preparing wholetussah silk powder from silk fibers with preserved sericin and fibroin

PendingCN112391056APreservation of biological valueSimple production processAnimal fibresOXALIC ACID DIHYDRATESILK SERICIN

The invention discloses a method for preparing wholetussah silk powder from silk fibers with preserved sericin and fibroin. The method comprises the following steps: putting the silk fibers with preserved sericin and fibroin into a degradation solution for degradation at 80-90 DEG C for 5-12 hours at a constant temperature, and conducting homogenizing with an ultrahigh-pressure homogenizer to obtain the whole tussah silk powder, wherein the degradation solution is composed of oxalic acid, ammonium chloride and ethylenediamine tetraacetic acid, the mass concentration of oxalic acid in the degradation solution is 2%-4%, the mass concentration of ammonium chloride in the degradation solution is 0.2%-0.8%, and the mass concentration of ethylenediamine tetraacetic acid in the degradation solution is 0.01%-0.5%. According to the method, the sericin and the fibroin can be completely utilized to prepare the whole tussah silk powder, so the biological value of tussah silk is kept; and the method is simple in production process, high in preparation rate, friendly to environment and suitable for standardized production.

Owner:辽宁新宜环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com