Method for rapidly and efficiently preparing native tussah silk fibroin protein powder

A technology of tussah silk and plain powder, applied in the field of natural polymers, can solve the problems of unfriendly environment, destroying the natural structure of silk, and cumbersome preparation methods, and achieve the effects of structural integrity preservation, wide application prospects, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In the present embodiment, a method for preparing native tussah silk fibroin powder rapidly and efficiently comprises the following steps in turn:

[0038] (1) Put the cleaned tussah cocoon shells into 0.75% sodium carbonate solution and boil for 0.5 h, repeat this step once, remove the sericin, wash them, place them in an oven at 50° C. and dry them for later use.

[0039] (2) Take 1.0 g of tussah silk fiber degummed in step (1) and put it into a crushing tank, and put 1 stainless steel rotating bead into it, and close the lid tightly. Immerse the crushing tank with the sample in liquid nitrogen for 2 minutes to pre-cool, take it out and quickly fix it on the stainless steel adapter of the crushing instrument. The frequency is set to 30 Hz, and the time is set to 30 s to prepare tussah silk fibroin powder.

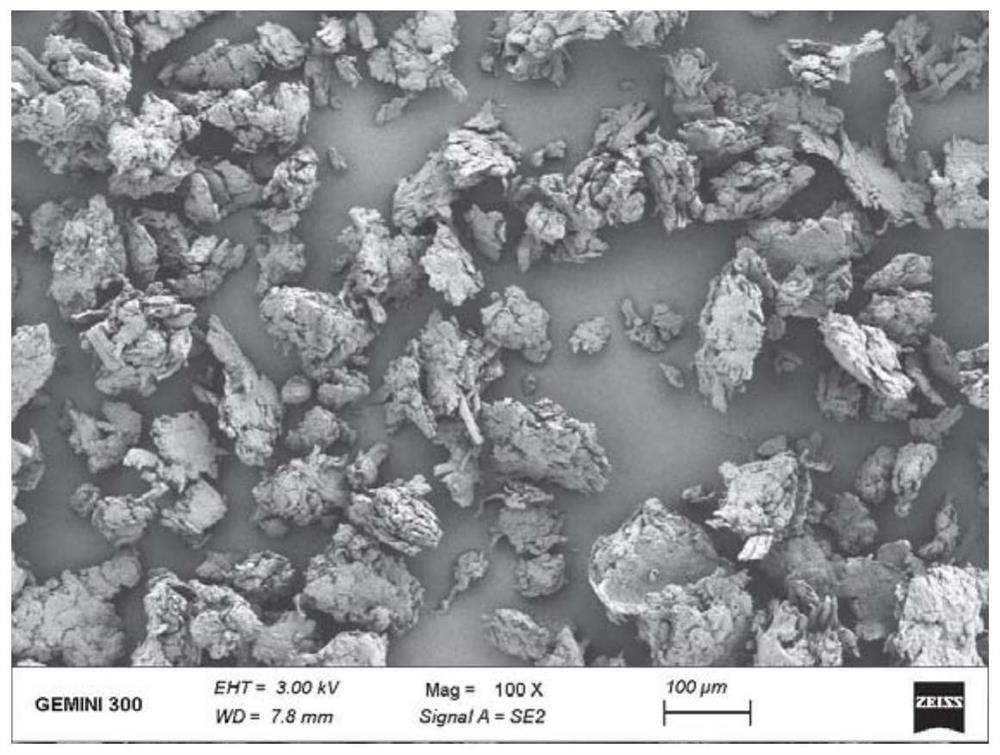

[0040](3) move the tussah silk powder obtained in step (2) into a 100-mesh standard sieve, and after sieving and separating, the tussah silk powder with a particl...

Embodiment 2

[0042] (1) Put the cleaned tussah cocoon shells into 0.75% sodium carbonate solution and boil for 0.5 h, repeat this step once, remove the sericin, wash them, place them in an oven at 50° C. and dry them for later use.

[0043] (2) Get 0.2 g of tussah silk fiber degummed in step (1) and put it into a crushing tank, and put 1 stainless steel rotating bead into it, and close the lid tightly.

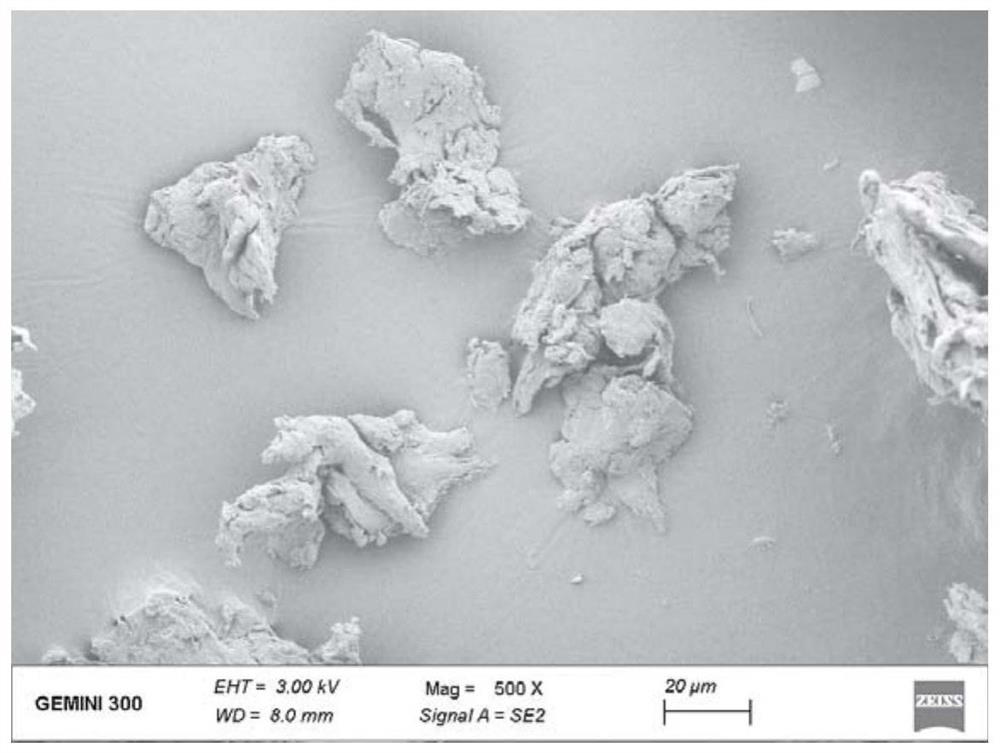

[0044] Immerse the crushing tank with the sample in liquid nitrogen for 10 minutes to pre-cool, take it out and quickly fix it on the stainless steel adapter of the crushing instrument. The frequency is set to 60Hz, and the time is set to 60s to prepare tussah silk powder (such as image 3 shown).

[0045] (3) The tussah silk fibroin powder obtained in the step (2) is transferred into a 100-mesh standard sieve, and after sieving and separation, the tussah silk fibroin powder with a particle size of 20-50 microns can be prepared.

[0046] (4) Take the tussah silk fibroin powder in step (3...

Embodiment 3

[0050] (1) Weigh 0.5 g of shredded tussah silkworm cocoon shells and put them into a crushing tank, put stainless steel rotating beads into them, and close the lid tightly.

[0051] (2) Immerse the crushing jar with the sample in step (1) in a -80°C refrigerator for 30 minutes, and quickly fix it on the stainless steel adapter of the crushing instrument after taking it out. The frequency is set to 60 Hz, and the time is set to 60 s to prepare tussah cocoon powder.

[0052] (3) Move the tussah powder obtained in step (2) into a 100-mesh standard sieve, and then sieve and separate to prepare tussah cocoon powder with a particle size of about 20-100 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com