Tussah silk fiber non-woven fabric and manufacturing method of tussah silk fiber non-woven fabric

A manufacturing method and non-woven technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of wiping equipment damage, hidden dangers of human skin damage, failure to propose solutions, etc., and achieve the effect of avoiding friction damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

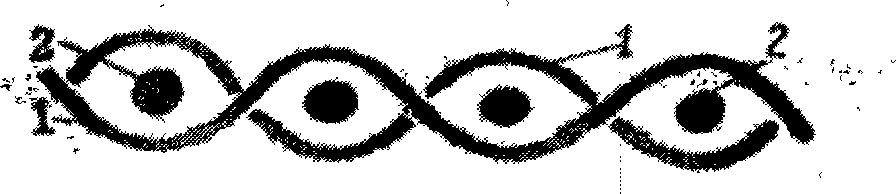

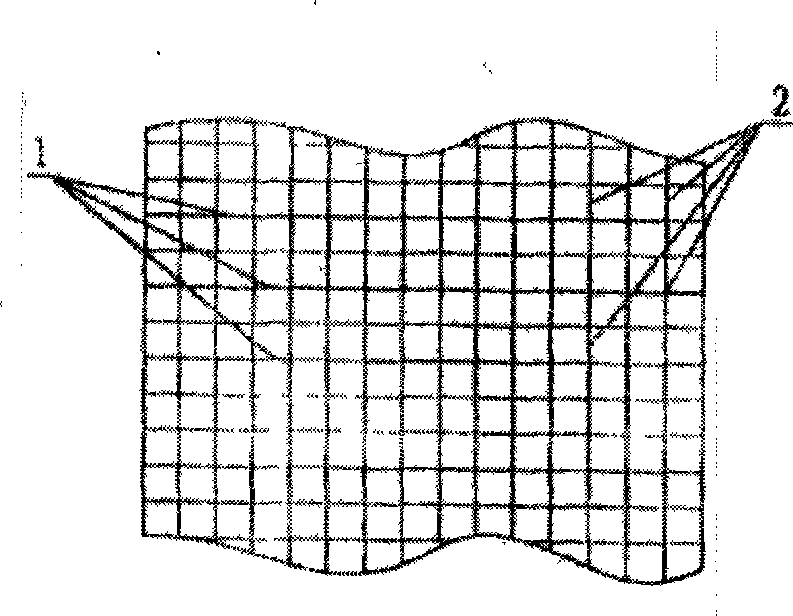

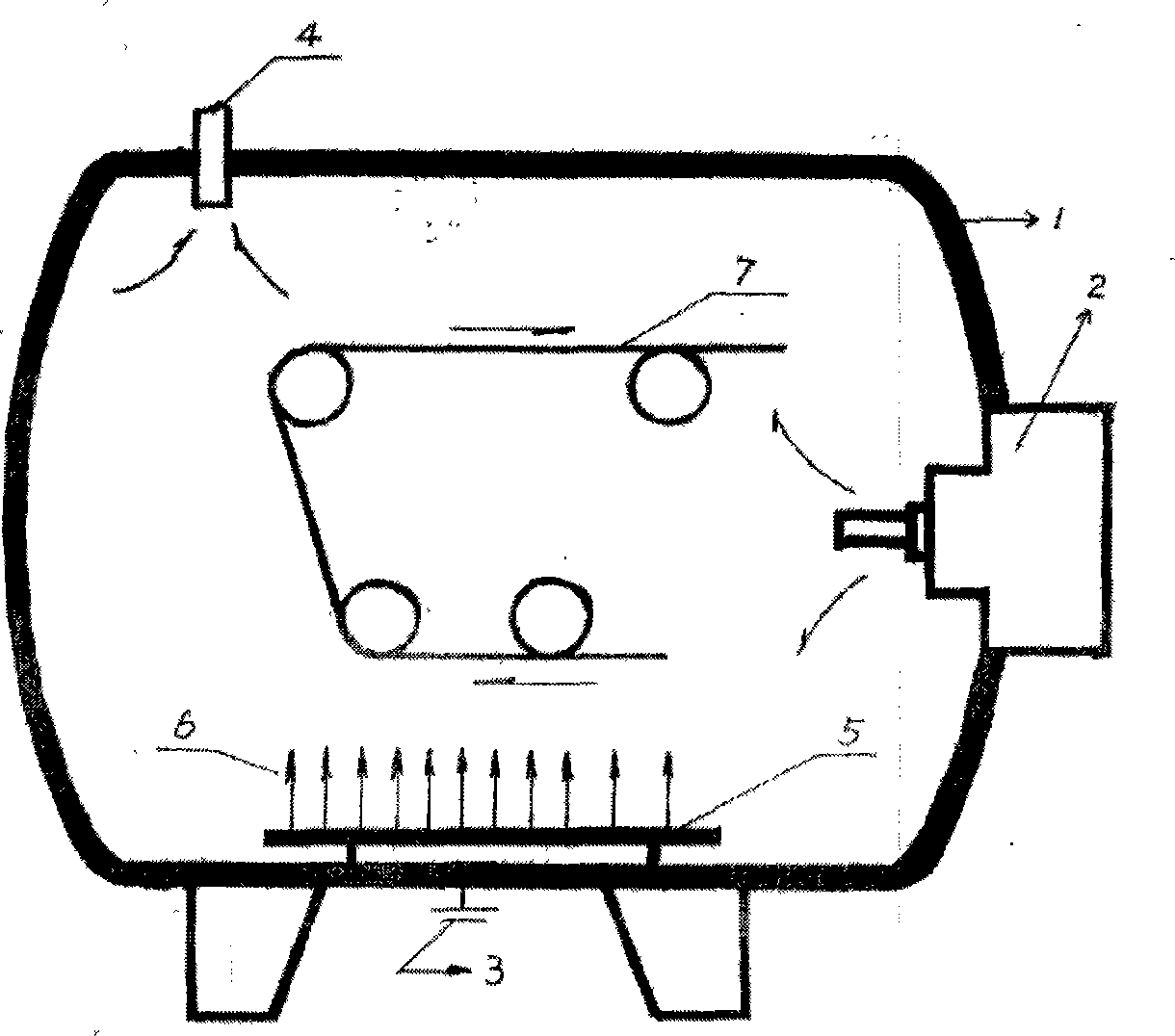

[0008] Embodiments of the invention are described in detail below, examples of which are shown in FIGS. 1 and 2 . The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

[0009] In the present invention, a kind of tussah silk fiber non-woven fabric and manufacture method thereof are provided, and its specific process steps are as follows:

[0010] (1) Select 100% tussah silk short fiber, the fiber length range is 30-40mm, the fineness range is 2.5-3.8tex, and it is reserved.

[0011] (2) Place the above-mentioned spare tussah silk short fibers in a cotton blender for cotton blending.

[0012] (3) After mixing the cotton, it enters the opener for opening treatment.

[0013] (4) Send the raw materials after opening treatment to the cotton blender for fine blending, in order to obtain finer raw materials.

[0014] (5) Then the finely mixed raw materials a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com