Electrostatic spinning production method for ultrathin porous composite-nanofiber bionic Bruch's film

A composite nanofiber, electrospinning technology, applied in the field of biomedical engineering materials, to achieve the effect of promoting cell adhesion, increasing biocompatibility, and increasing cell adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

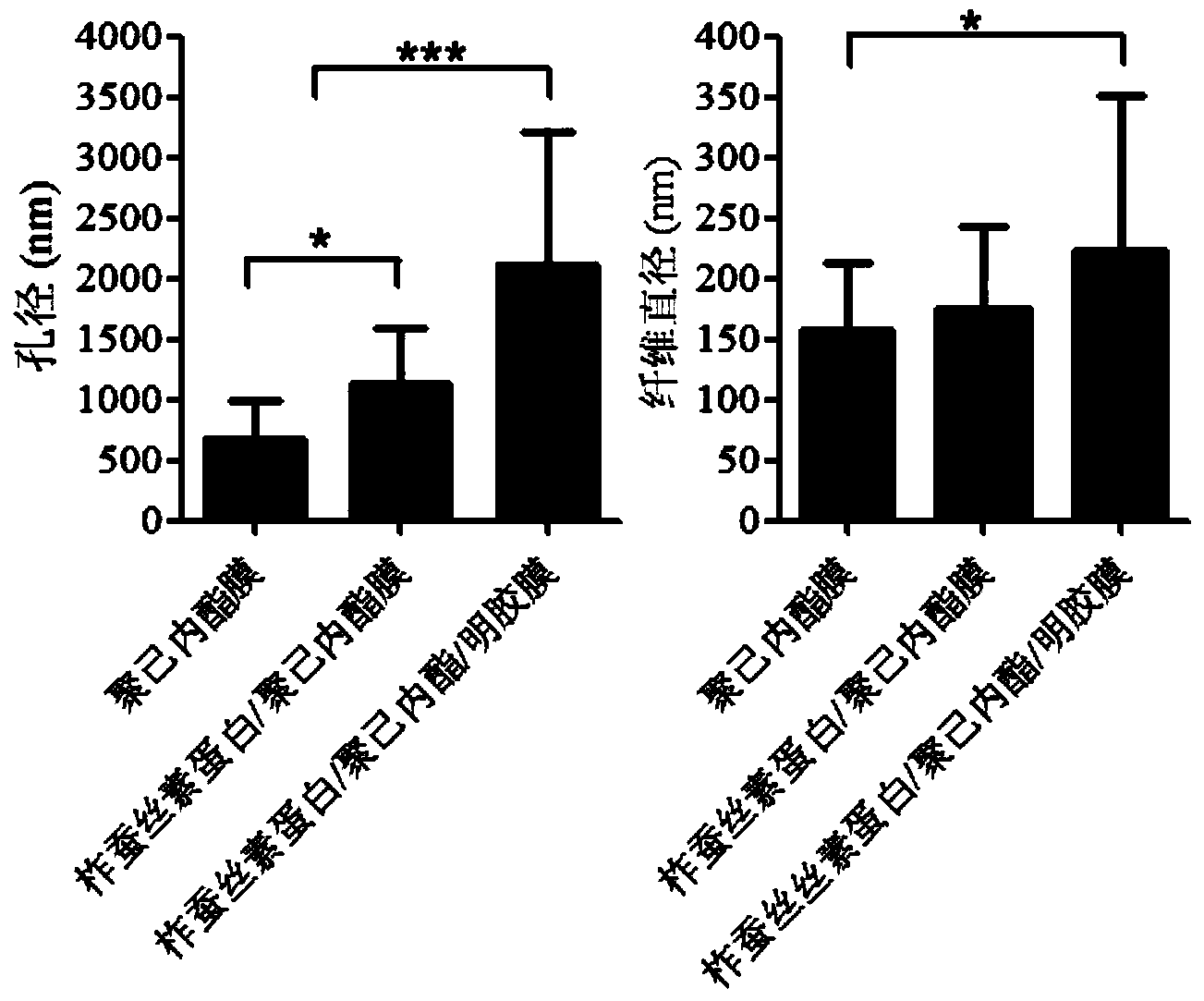

[0037] Embodiment 1 ultrathin porous polycaprolactone nanofiber biomimetic Bruch's film

[0038] The preparation method comprises the following steps:

[0039] 1. Preparation of electrospinning solution: Weigh 2.5 g of polycaprolactone, add 10 mL of 98% formic acid solution to a 50 mL Erlenmeyer flask, and stir overnight at room temperature to obtain an electrospinning solution;

[0040] 2. Electrospinning process: put the electrospinning solution into the syringe, and the syringe is equipped with a blunt needle with a diameter of 0.6mm. Electrospinning is performed under the conditions of voltage 12-20kv, collection distance 10-20cm, and extrusion speed 1-5mL / h. ;The preferred voltage is 18kv, the collection distance is 15cm, and the extrusion speed is 2mL / h;

[0041] 3. Post-processing: After the electrospinning is completed, place the electrospun membrane in a fume hood for 1-4 hours until the residual organic solvent is completely volatilized;

[0042] 4. Obtain ultra-th...

Embodiment 2

[0043] Example 2 Preparation of ultra-thin porous tussah silk fibroin / polycaprolactone composite nanofiber biomimetic Bruch's membrane

[0044] The preparation method comprises the following steps:

[0045] 1. Preparation of electrospinning solution: Weigh 0.125g of tussah silk fibroin protein and 2.125g of polycaprolactone into a 50mL conical flask, add 10mL of 98% formic acid solution, and magnetically stir overnight at room temperature to obtain an electrospinning solution;

[0046] 2. Electrospinning process: put the electrospinning solution into the syringe, and the syringe is equipped with a blunt needle with a diameter of 0.6mm. Electrospinning is performed under the conditions of voltage 12-20kv, collection distance 10-20cm, and extrusion speed 1-5mL / h. ;The preferred voltage is 18kv, the collection distance is 15cm, and the extrusion speed is 2mL / h;

[0047] 3. Post-processing: After the electrospinning is completed, place the electrospun membrane in a fume hood for ...

Embodiment 3

[0049] Example 3 Preparation of Ultrathin Porous Tussah Silk Fibroin / Polycaprolactone / Gelatin Composite Nanofiber Biomimetic Bruch's Membrane

[0050] The preparation method comprises the following steps:

[0051] 1. Preparation of electrospinning solution: Weigh 0.125g of tussah silk fibroin protein, 2.125g of polycaprolactone, and 0.25g of gelatin in a 50mL conical flask, add 10mL of 98% formic acid solution, and stir overnight at room temperature with magnetic force to obtain electrospinning silk solution;

[0052] 2. Electrospinning process: put the electrospinning solution into the syringe, and the syringe is equipped with a blunt needle with a diameter of 0.6mm. Electrospinning is performed under the conditions of voltage 12-20kv, collection distance 10-20cm, and extrusion speed 1-5mL / h. ;The preferred voltage is 18kv, the collection distance is 15cm, and the extrusion speed is 2mL / h;

[0053] 3. Post-processing: After the electrospinning is completed, place the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com