Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86 results about "ProcessedProduct" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

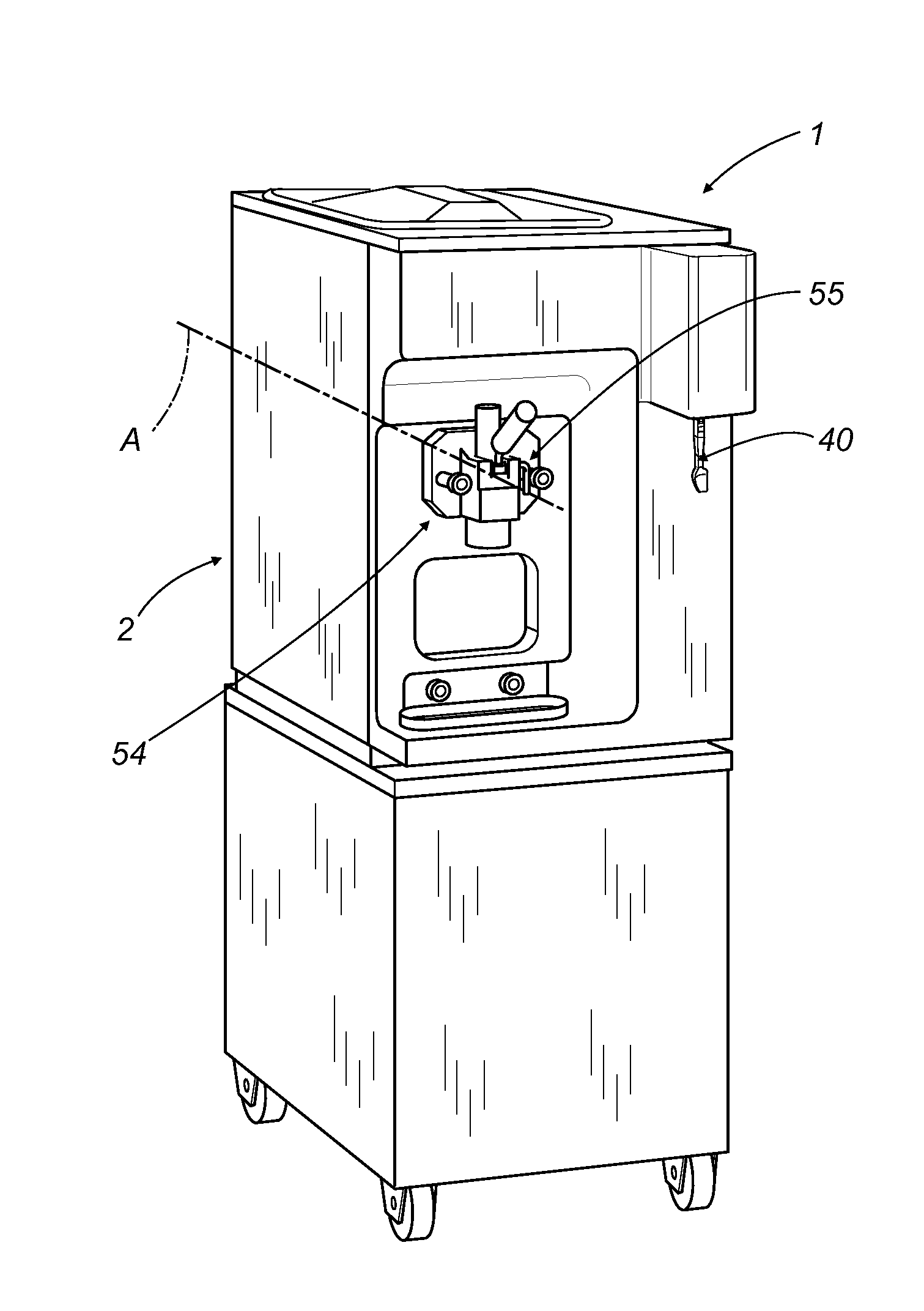

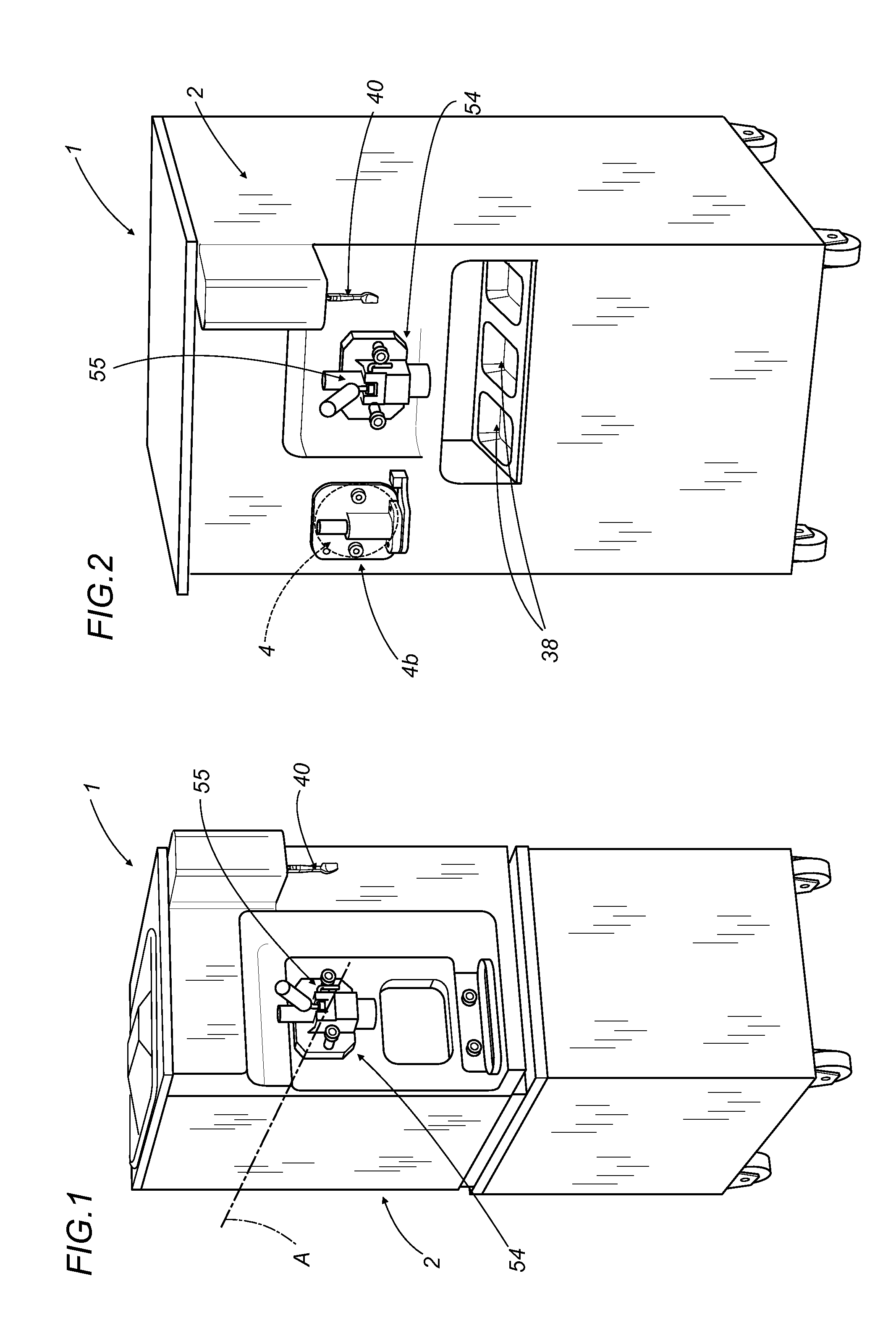

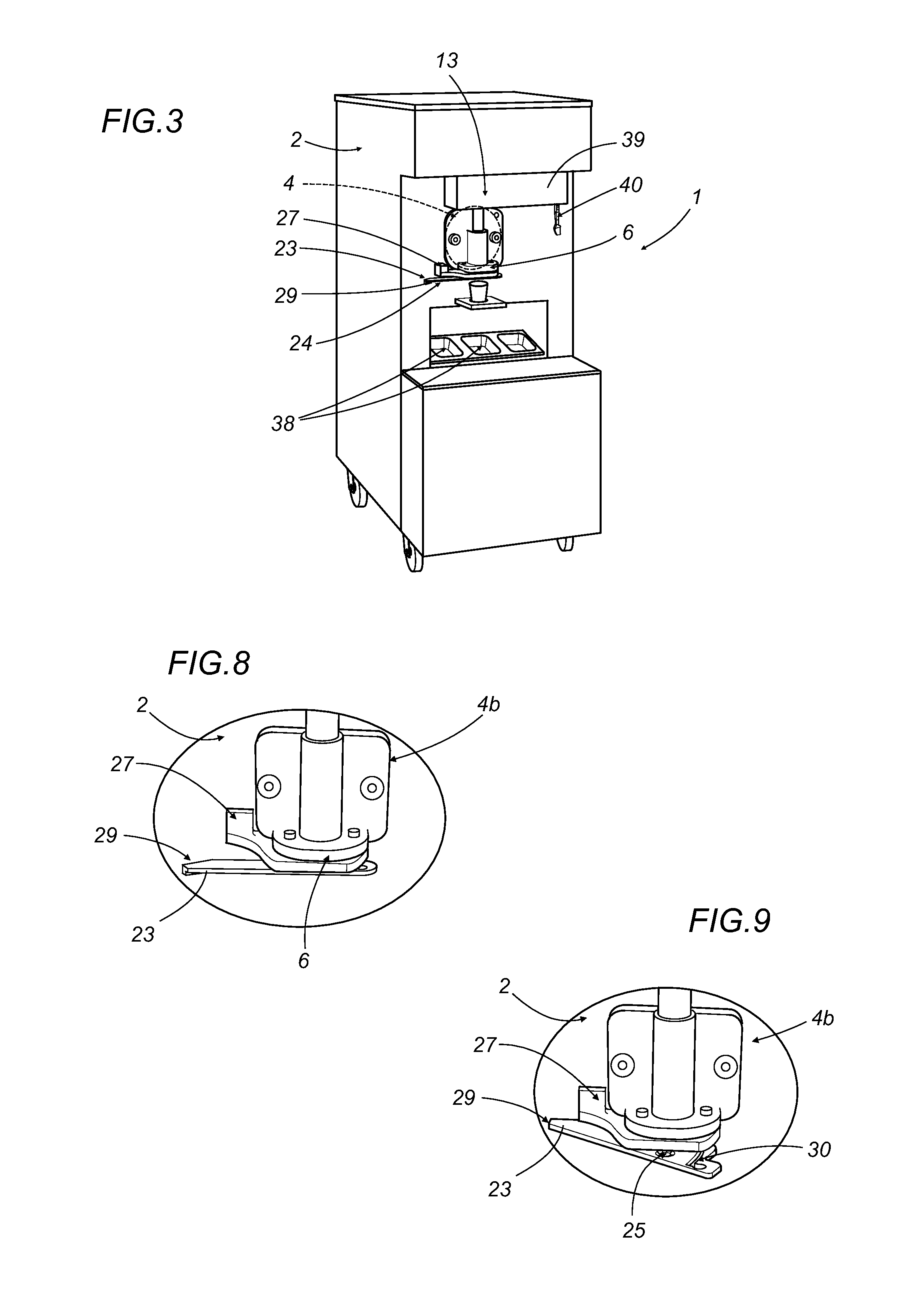

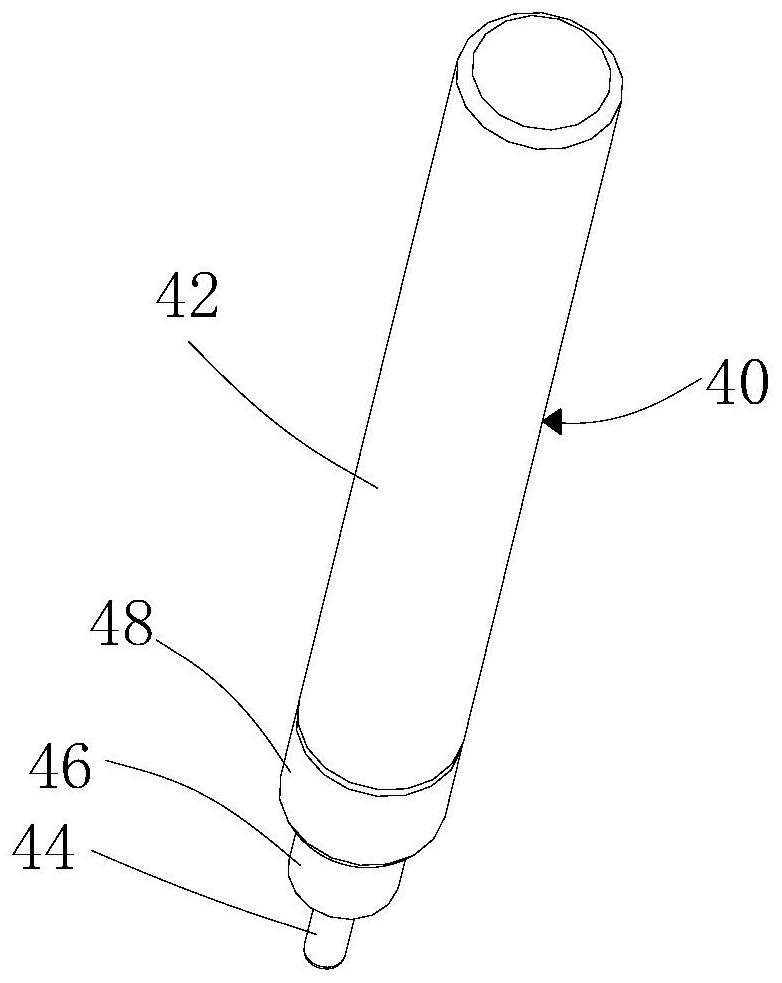

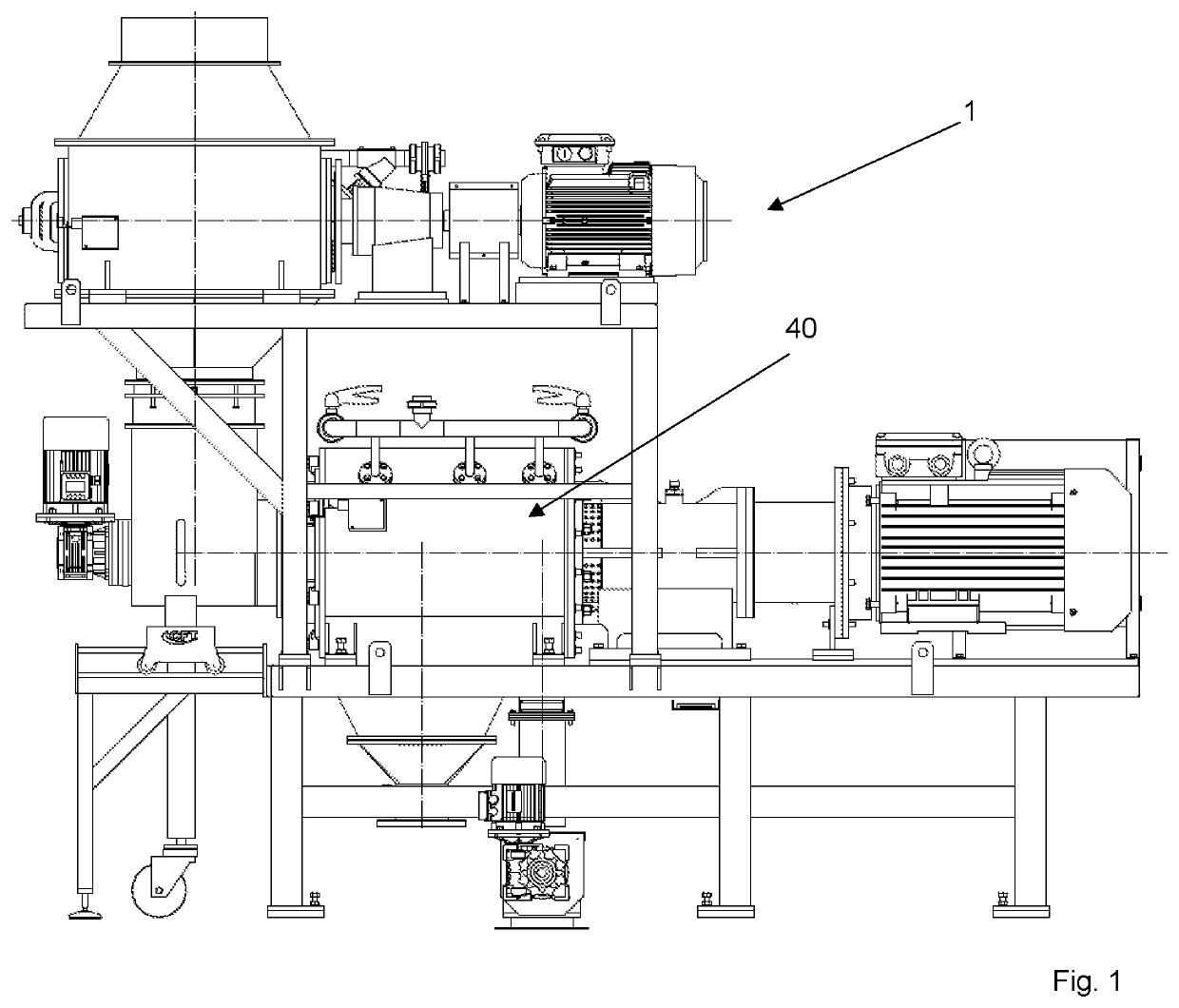

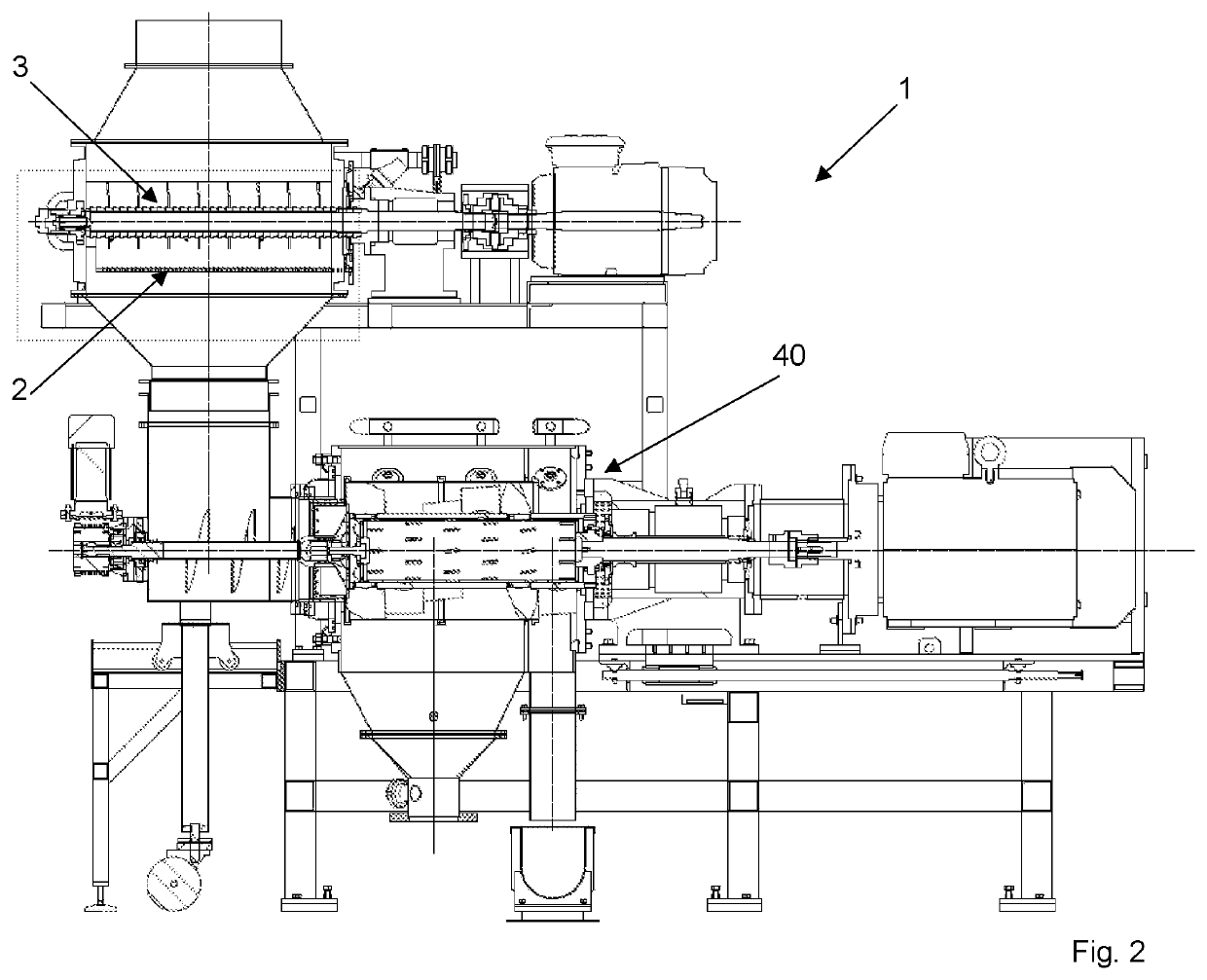

Machine for making and dispensing food products such as ice creams, ice cream shakes and the like

InactiveUS20100122539A1Domestic cooling apparatusLighting and heating apparatusIce CreamsProcess engineering

The invention relates to a machine (1) for making and dispensing food products such as ice creams, ice cream shakes and the like, in which a frame (2) supports and houses a tank (3) for containing a basic product to be processed and a processing circuit (5) for making products to be dispensed starting with the basic product; the processing circuit (5) comprises a processing chamber (37), fed by the tank (3), a stirrer (9), housed in the processing chamber (37), and a refrigerating unit for refrigerating the processing chamber (37); the machine (1) also comprises means (13) for dispensing doses of processed product, said means being connected to the processing chamber (37), and, supported by the frame (2) in a single integrated structure, a plurality of tanks (38) for containing additional condiments, in particular candied items, sweets, chocolates, hazelnuts, pistachios, and a mixer (39) equipped with a disposable spoon (40; 40′) for mixing the additional condiments with the product dispensed.

Owner:ALI - CARPIGIANI GROUP

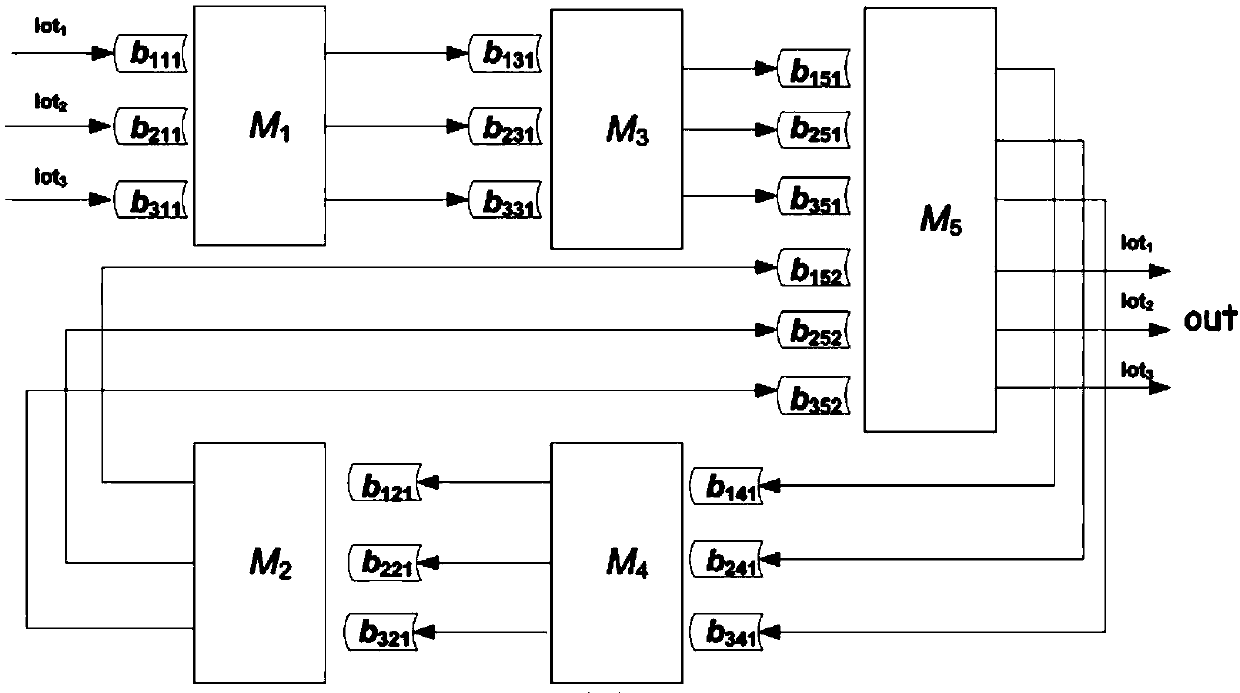

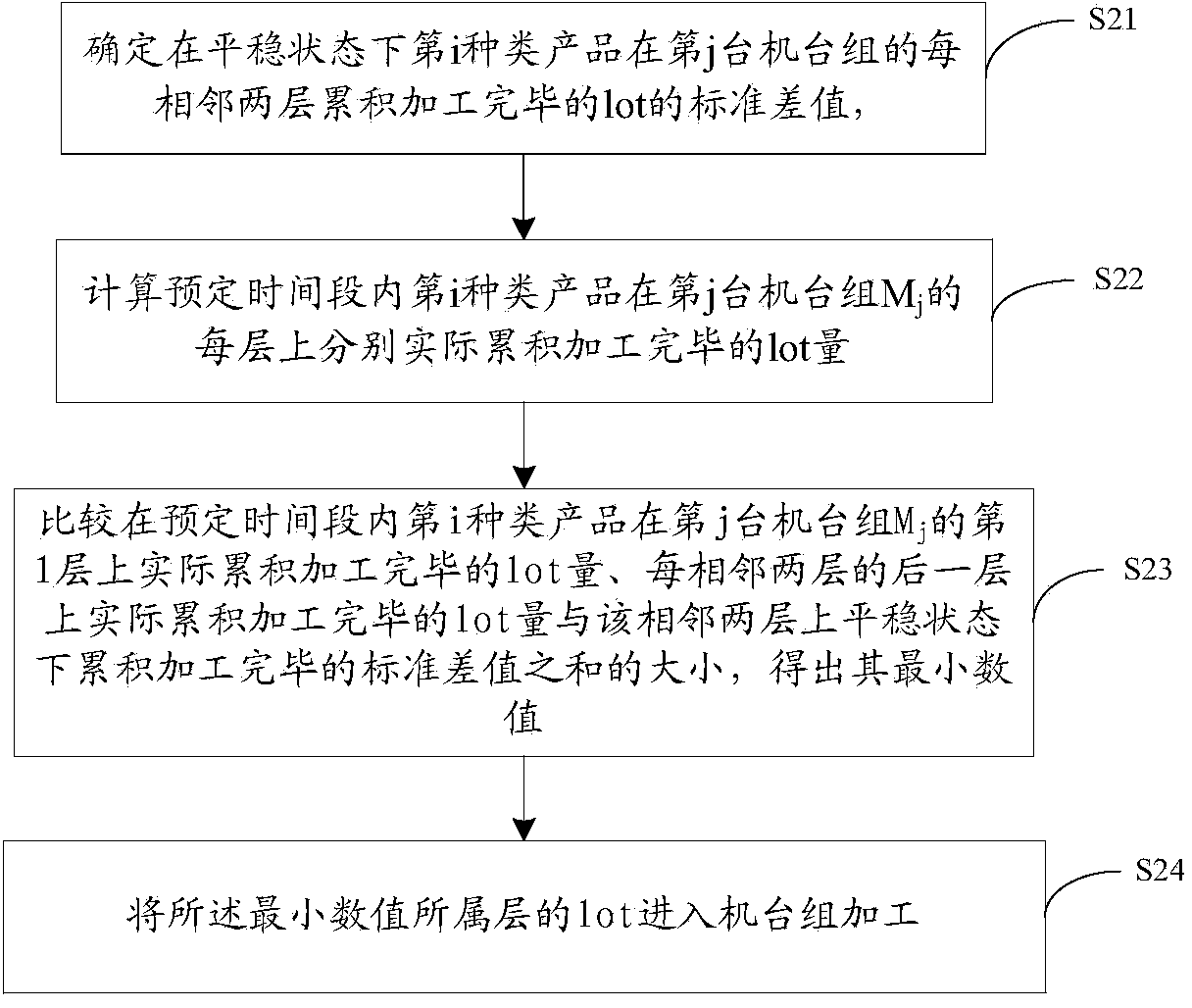

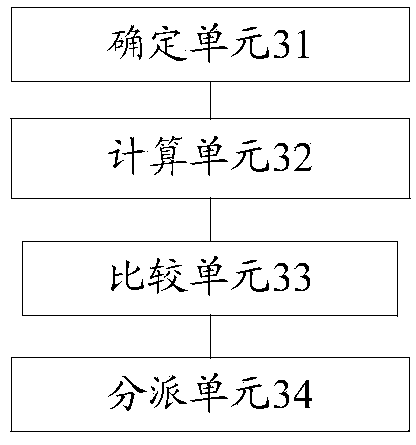

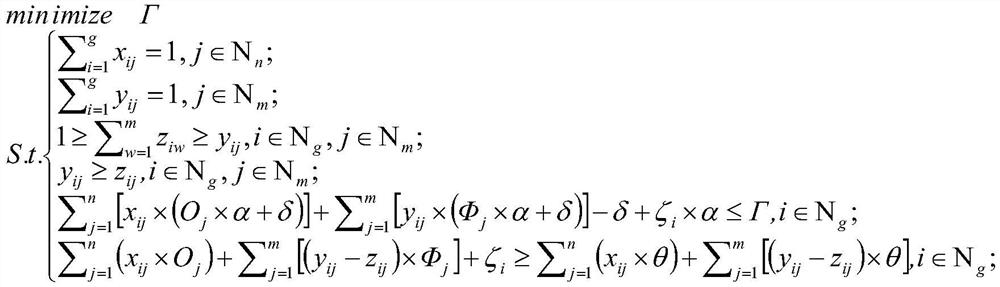

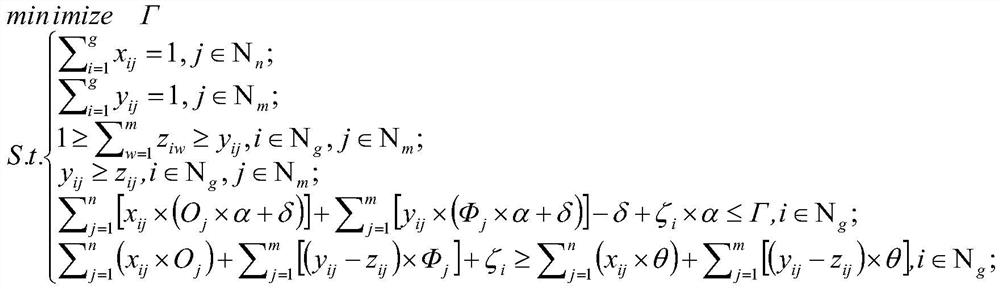

Methods and device for scheduling production of semiconductor products

InactiveCN103700022AShorten the average production cycleEasy to controlData processing applicationsManufacturing computing systemsWell controlSemiconductor

The invention provides a method and a device for scheduling production of semiconductor products, which are used for controlling the distribution of to-be-processed lots in the production process of semiconductor products, and also provides a method for scheduling the production of the semiconductor products, which is used for controlling the material feeding in the production process of the semiconductor products. The methods and the device for scheduling the production of the semiconductor products are based on the concept of processing the middle layer of each semiconductor, and the processed product leaves off a machine table unit after being processed on the machine table unit, namely that the processed product is released on the machine table unit. The methods and the device for scheduling the production of the semiconductor products have the advantages that through considering the influence on the distribution processing of the to-be-processed products by the releasing of the to-be-processed products on the machine table unit, the inventory of in-process products is well controlled, the average production cycle of the semiconductor products is shortened, and the inventory square of in-process products is reduced.

Owner:ZHEJIANG UNIV

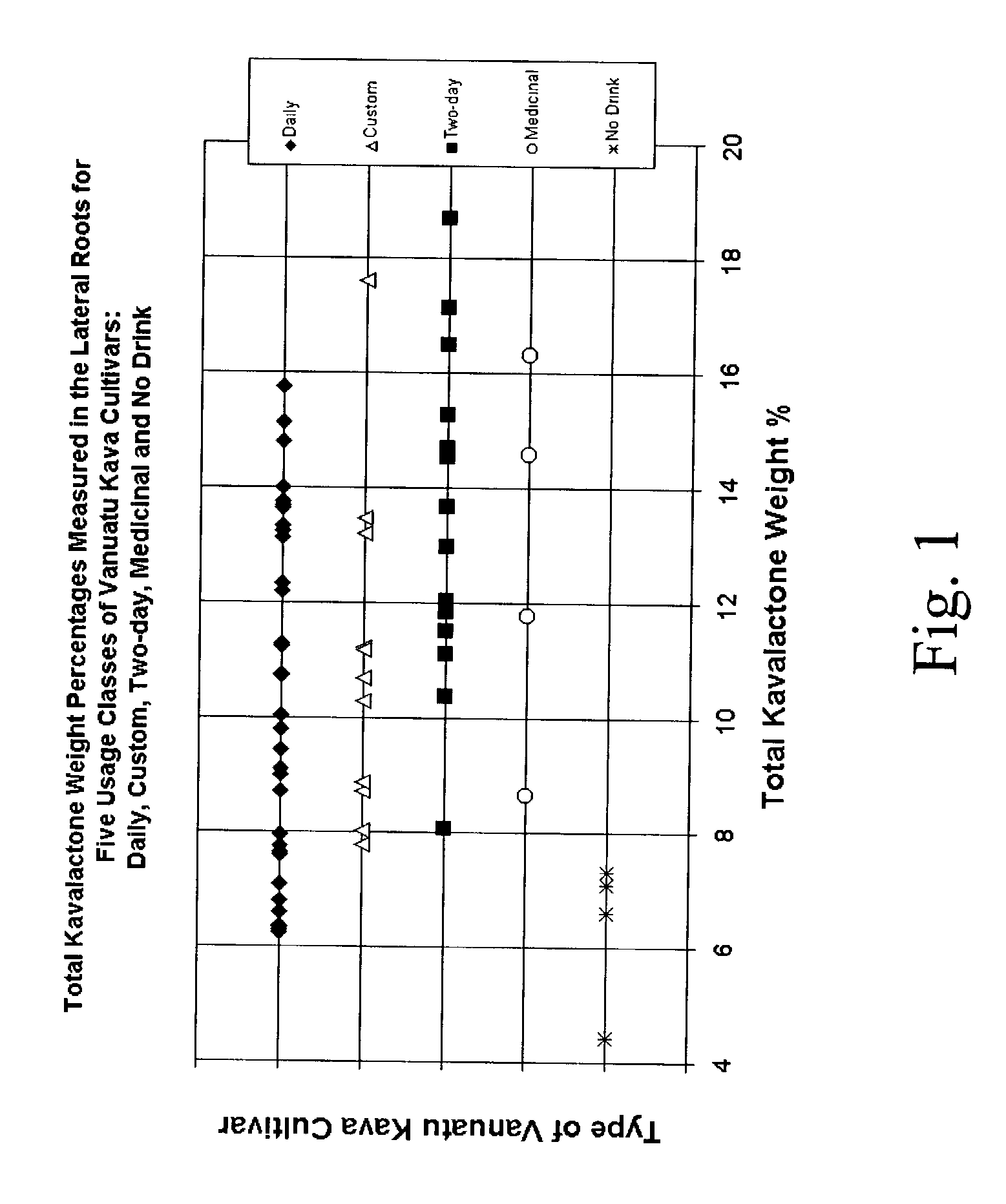

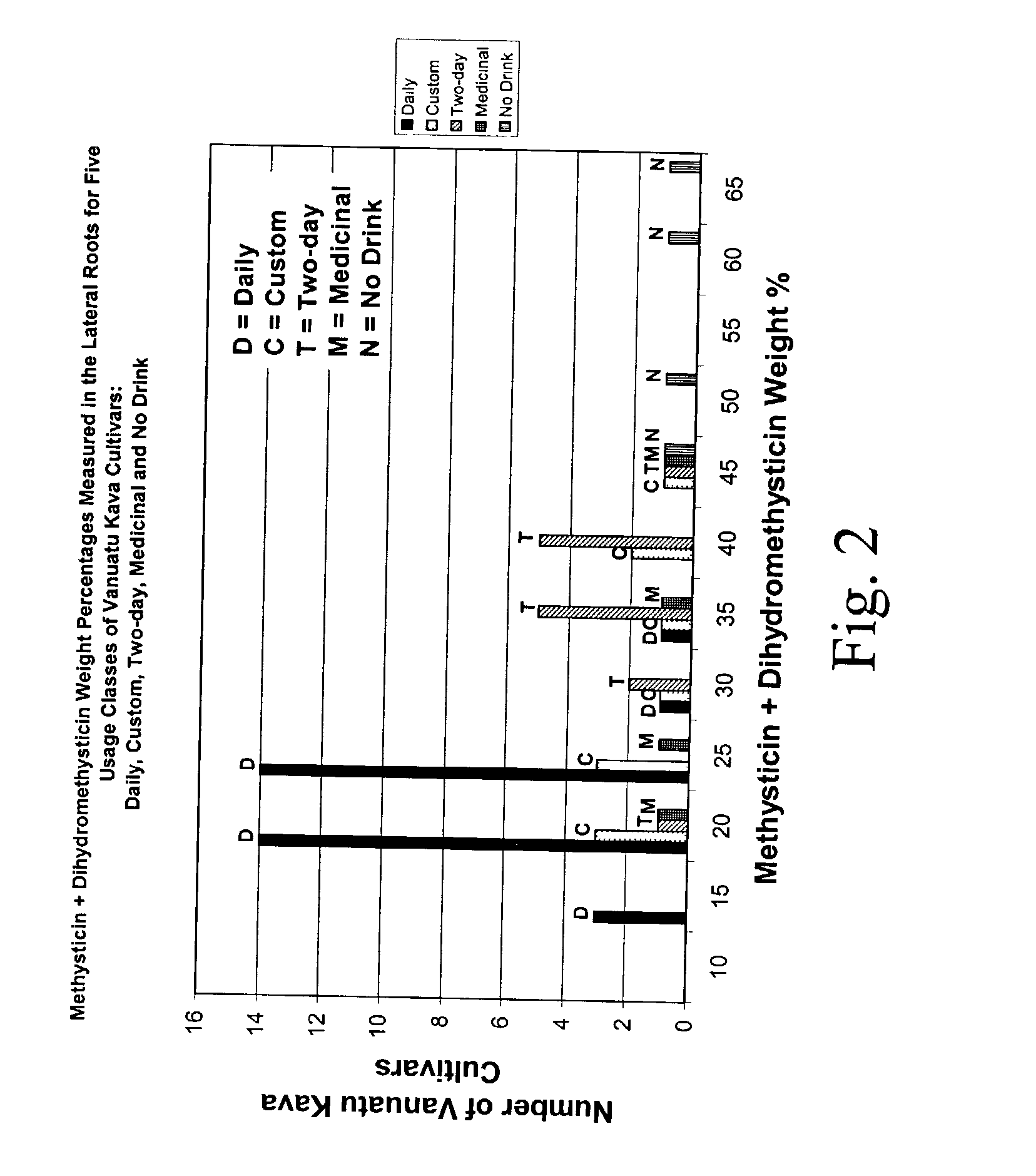

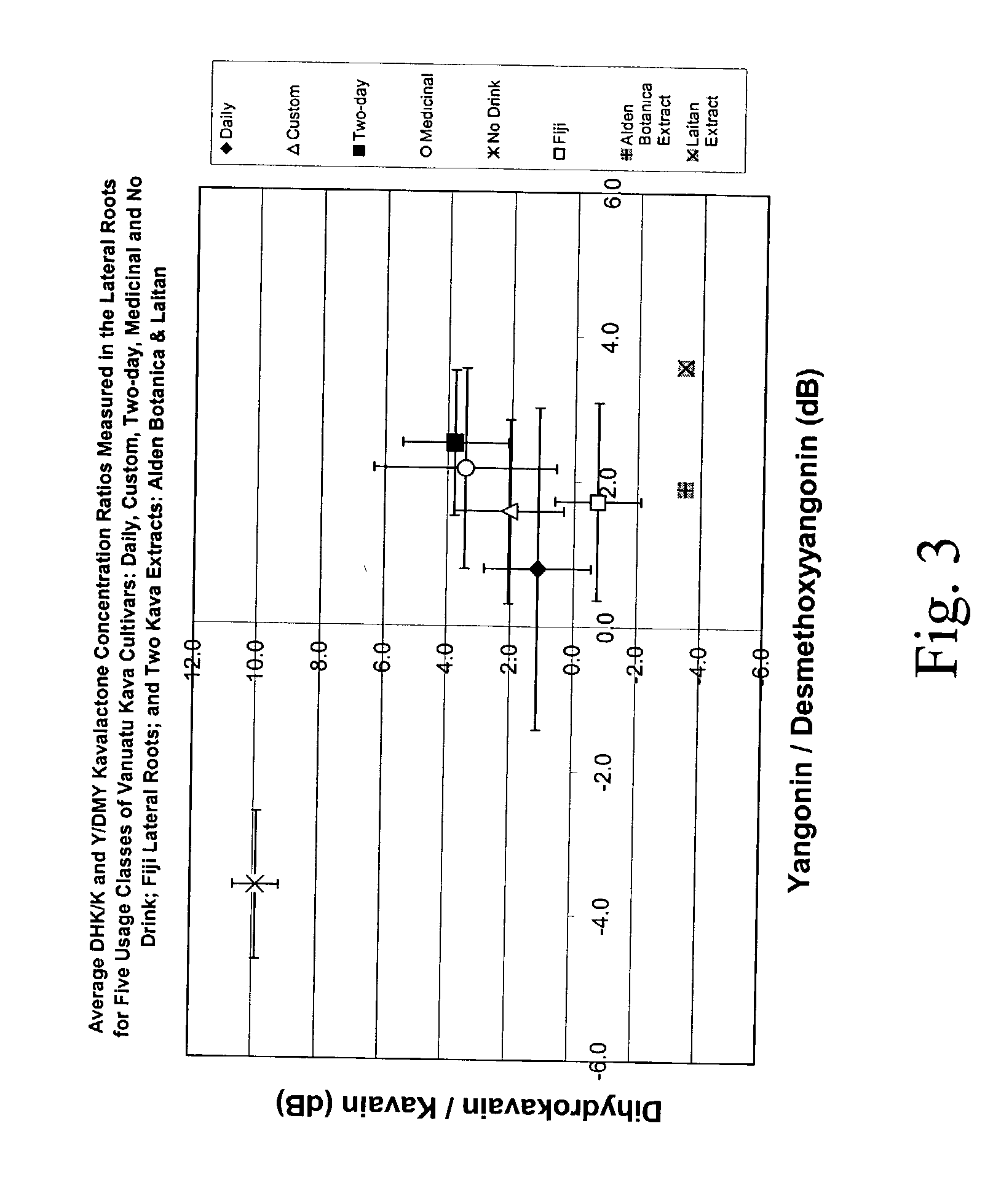

Method of producing a processed kava product having an altered kavalactone distribution and processed kava products produced using the same

InactiveUS20030099756A1Improve efficiencyReduce negative impactBiocideOrganic active ingredientsBiotechnologyTableting

A method of producing a processed kava product involves using an extraction solvent, such as liquid CO2, to preferentially extract different kavalactones from the source material at different rates. By controlling the extraction parameters and stopping the extraction before all of the kavalactones have been extracted or allowing the extracted kavalactones to be preferentially precipitated in one or more collection environments, a processed kava product can be produced that has a kavalactone distribution profile that can differ substantially from that of the source material. As a result, roots from a less desirable kava cultivar can be used to produce a processed kava product which has a kavalactone distribution profile that is similar to that of a highly desired cultivar. The kava paste can be further processed to produce a dry flowable powder suitable for use in, e.g., a tableting formula. A rapid dissolve tablet formulation for use in the delivery of kavalactones is also disclosed.

Owner:HERBALSCIENCE NUTRACEUTICALS INC

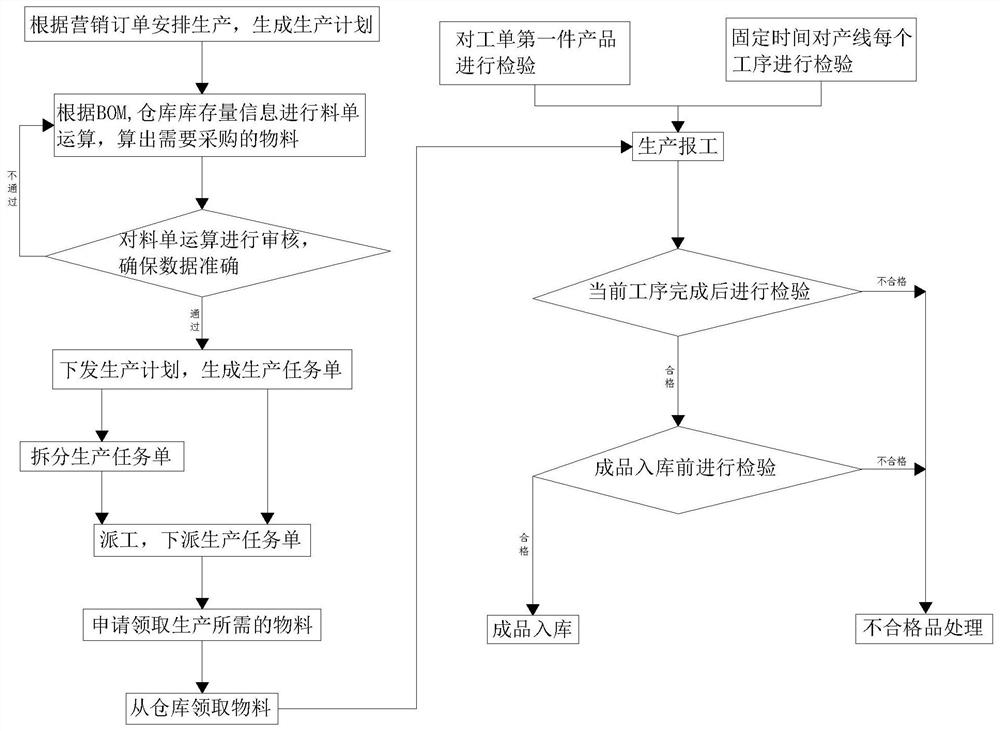

Discrete machining MES product production system

PendingCN111626611AAvoid errorsAvoid messy processingSustainable waste treatmentResourcesProcess engineeringProduct processing

The invention relates to the technical field of discrete machining MES product production, and discloses a discrete machining MES product production system. The discrete machining MES product production steps comprise the steps of: 1, enabling a manufacturer to arrange production according to a marketing order and generate a production plan; 2, carrying out material list operation on warehouse inventory information, and calculating materials needing to be purchased; 3, enabling the MES system to audit the bill operation to ensure the data accuracy; and 4, if the MES system in the step 3 does not pass the auditing, returning the material list to the step 2 for re-accounting. The production system effectively and orderly processes the processes from order starting to finished product warehousing and all the processes needing to be processed by product processing, is different from a traditional discrete machine processing product production process, improves the continuity between the product production processes, avoids disordered processing between the processes, and thus improves the high efficiency of product production.

Owner:江苏中智软创信息技术有限公司

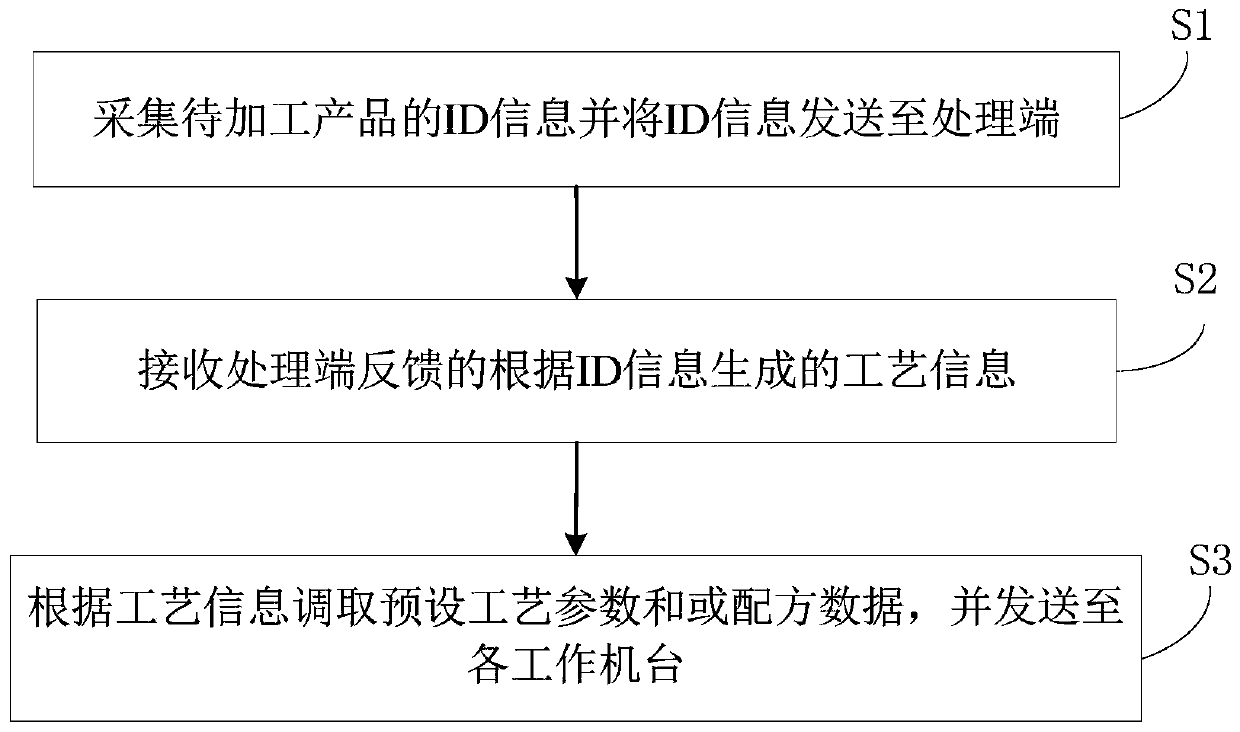

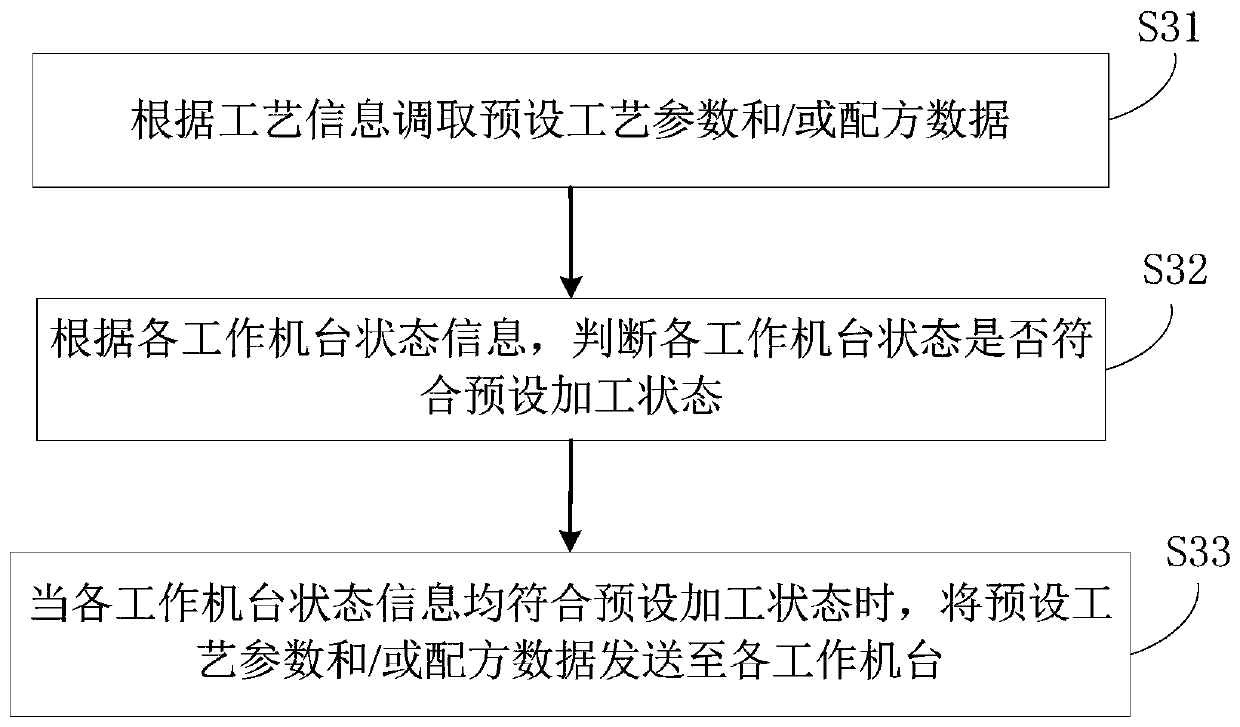

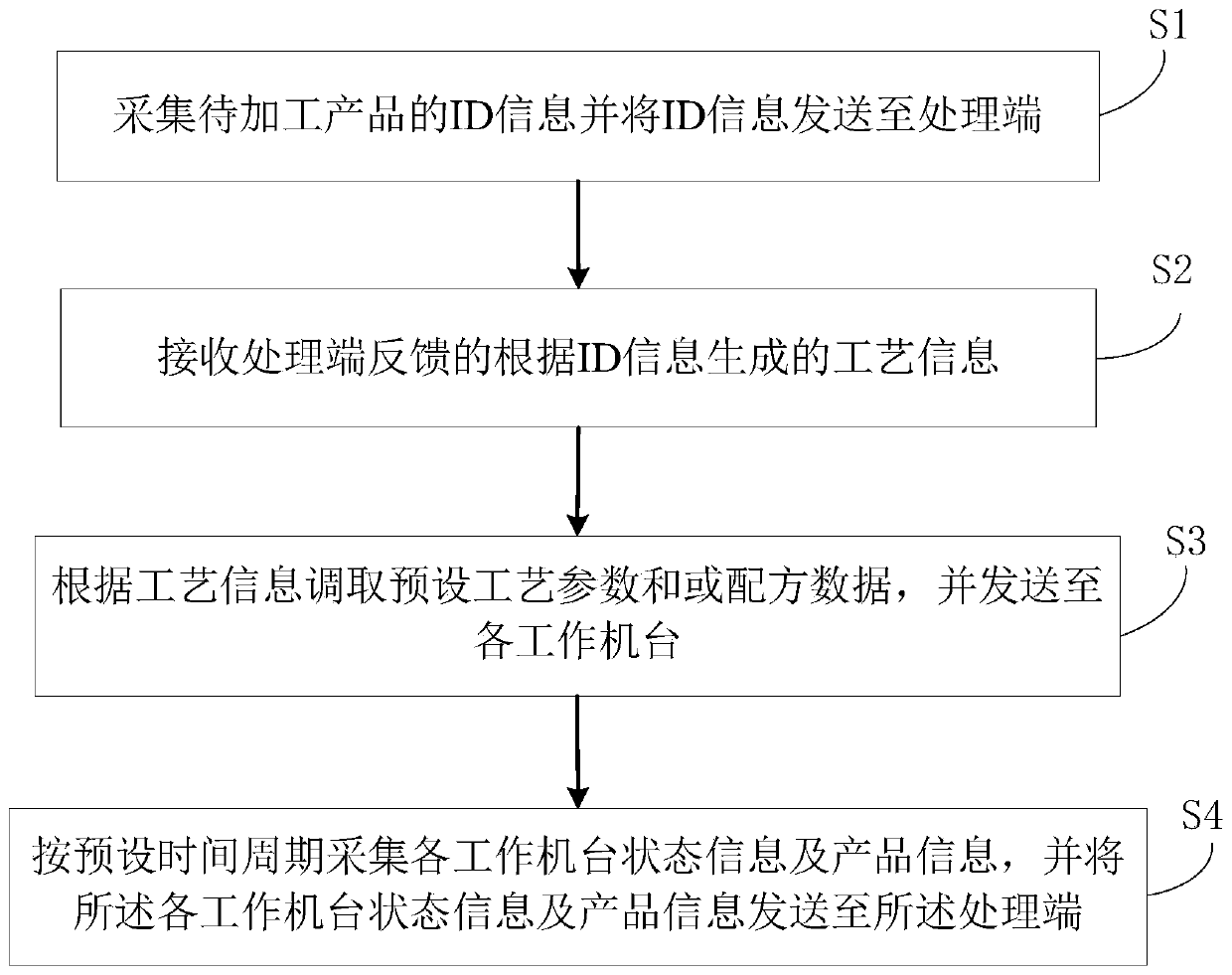

Automatic production line control method, device and system

PendingCN111308964AAvoid risk of leakageImprove confidentialityTotal factory controlProgramme total factory controlConfidentialityMachine

The invention discloses an automatic production line control method, device and system. The method comprises the steps: collecting the ID information of a to-be-processed product, and transmitting theID information to a processing end; process information generated according to the ID information and fed back by the processing end is received; calling preset process parameters and formula data according to the process information and sending the preset process parameters and the formula data to each working machine; the core technology of the production line process of the enterprise can be stored in the database of the main control system independently developed by the enterprise, the risk that the core technology is leaked due to the fact that core technology data is provided for MES suppliers in the prior art is avoided, and the confidentiality of the core technology of the enterprise is improved. When the MES system is abnormal, the MES system is started; the main control system temporarily stores the state information and the product information of each working machine, the main control system sends the state information and the product information of each working machine tothe MES system after the main control system returns to normal, the main control software is installed in the PC, and the storage space of the main control software is calculated by GB, so that the problem of insufficient storage space is solved.

Owner:DONGJUN NEW ENERGY CO LTD

Work order generation method, system and device based on discrete management, and storage medium

InactiveCN113807730ATimely changeImprove adaptabilityOffice automationResourcesProcess engineeringIndustrial engineering

The invention provides a work order generation method, system and device based on discrete management, and a storage medium, and the method comprises the steps: constructing a production technology architecture, determining the processing flow of a plurality of products in the production technology architecture, and obtaining a plurality of production technologies; obtaining a to-be-processed product, constructing a production plan architecture according to the to-be-processed product, determining a corresponding production process according to the production plan architecture, filling the production plan architecture with processing flow information in the production process, determining a product plan number, plan starting time and plan finishing time, and obtaining a production plan; and when it is detected that the current time reaches the plan starting time, generating a production work order according to the production plan, and sending the production work order to a corresponding worker. The production process and the production plan can be assembled and obtained, the production work order is generated according to the production process and the production plan, the production plan can be adaptively changed according to actual conditions, and adaptability and flexibility are improved.

Owner:重庆允成互联网科技有限公司

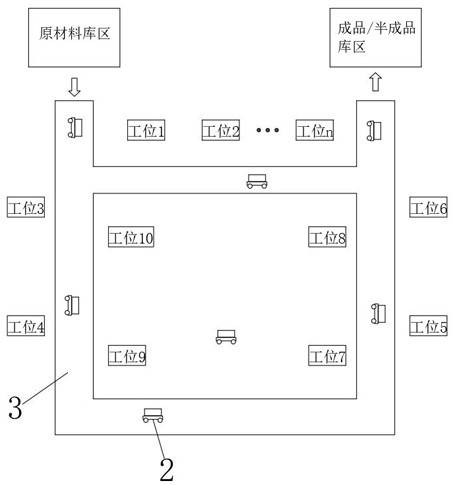

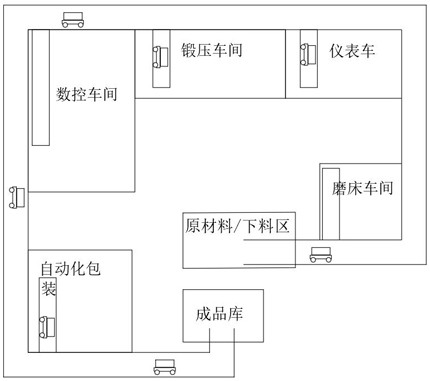

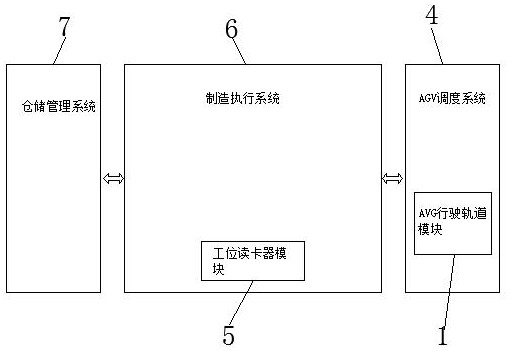

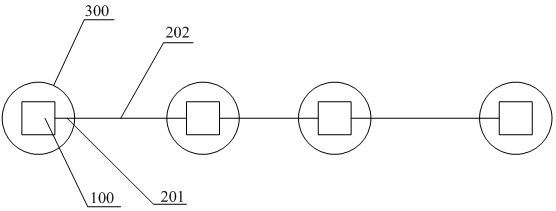

Low-cost track AGV flexible manufacturing system

ActiveCN113003127ASave production spaceImprove capital utilizationElectric/hybrid propulsionStorage devicesManufacture execution systemFlexible manufacturing system

The invention discloses a low-cost track AGV flexible manufacturing system. The low-cost track AGV flexible manufacturing system comprises an AGV driving track module, an AGV scheduling system, a station card reader module, a manufacturing execution system and a warehouse management system. The manufacturing execution system formulates a processing route according to information of a product to be processed and issues a work order to a production line; and the AGV scheduling system schedules the AGV to advance according to the processing route to complete each processing procedure, each procedure can make a material calling and feeding decision according to information on an all-in-one machine, and the material is sent to the warehouse management system after processing is completed. The system is low in cost, can reduce the stock waste, greatly reduces the production cost, and is suitable for small-batch and multi-product enterprises. A processing route is independently formulated according to product information, and mixed production of different products can be achieved.

Owner:宁波赛夫科技有限公司

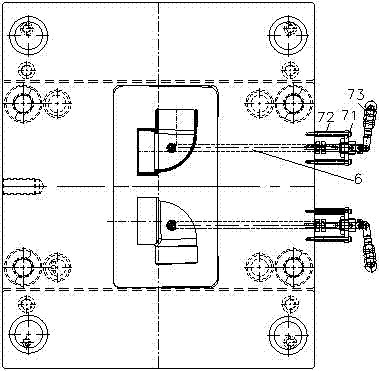

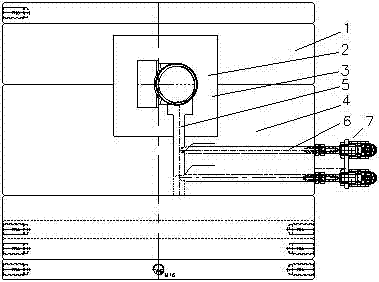

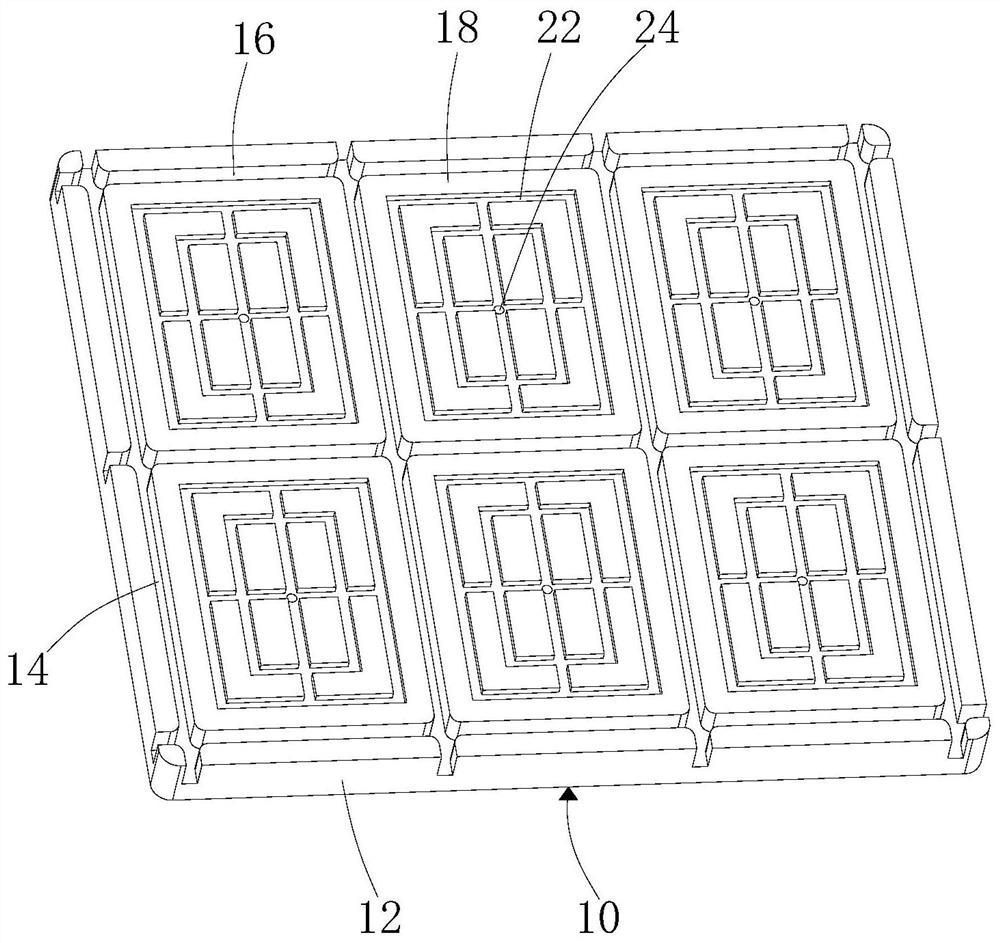

Automatic insert replacement structure

The invention discloses an automatic insert replacement structure which comprises a female template, a female die kernel, a male die kernel, a male template, an insert and an insert fixing structure, wherein the female die kernel is arranged under the female template; the male die kernel is arranged under the female die kernel; a cavity of a product to be processed is defined between the female die kernel and the male die kernel; the male template is arranged under the male die kernel; the insert passes through the male die kernel and the male template; the insert fixing structure comprises a fixed pin which passes through the male template; one end of the fixed pin is inserted into the insert, and the other end of the fixed pin is connected with an adjusting knob. The automatic insert replacement structure has the characteristics of being convenient to install and simple in processing, enabling the insert to be replaced at any time, being time-saving and labor-saving and small in needed space, and reducing waste.

Owner:KUNSHAN SHUNKANGDA IND PROD DESIGN

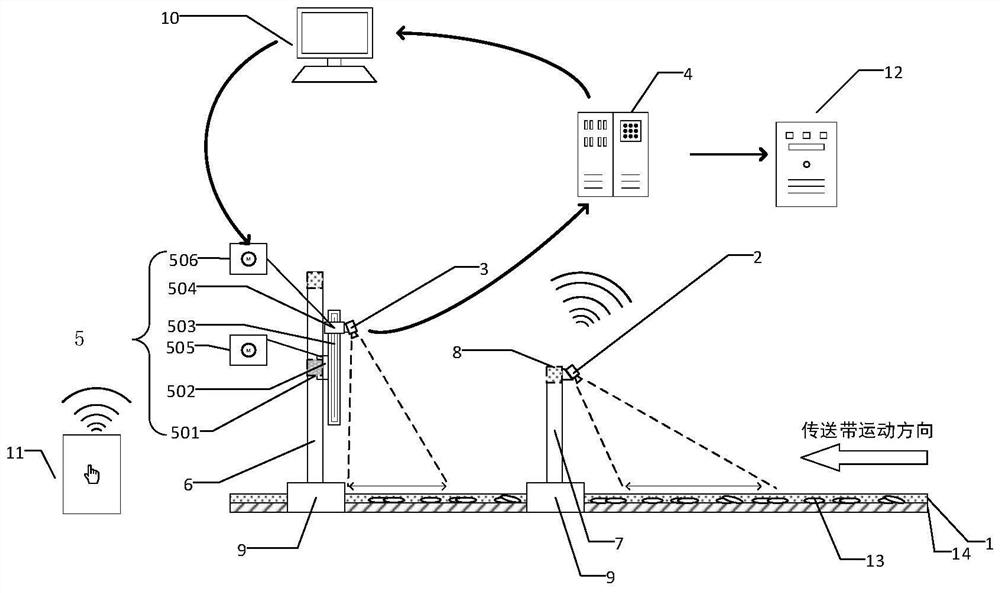

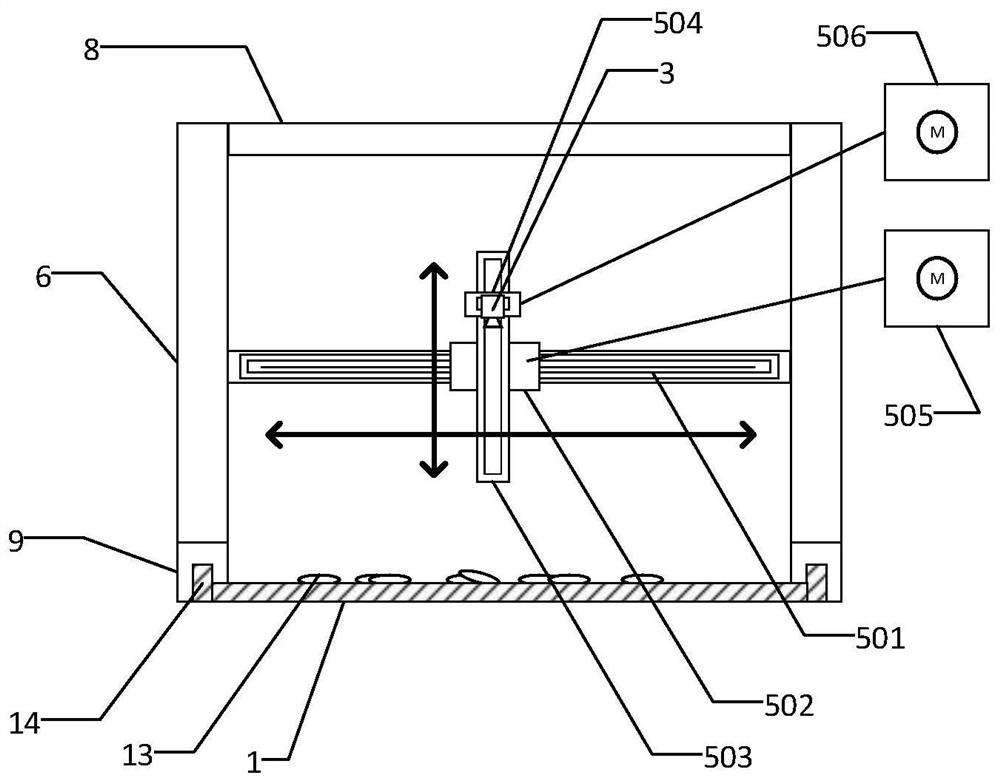

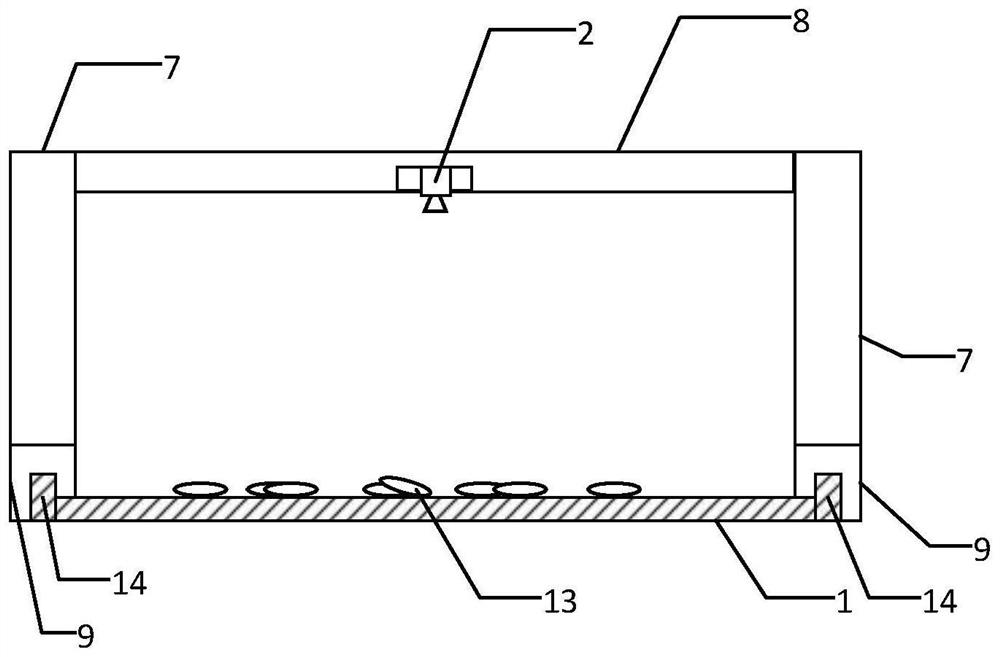

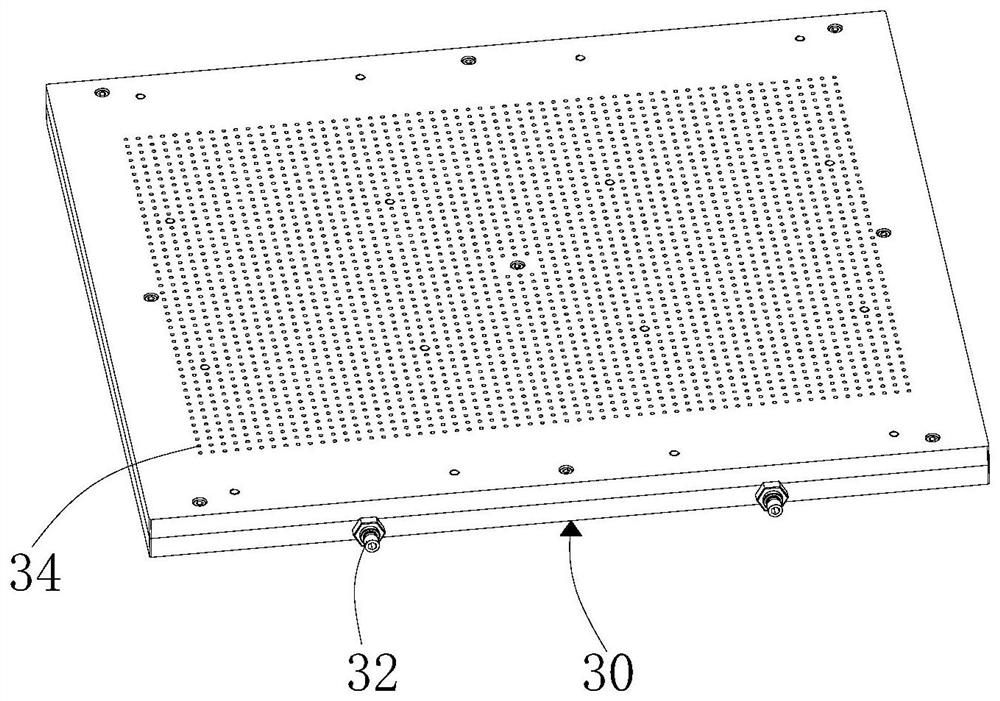

Processed product image acquisition device

InactiveCN112468719AImprove clarityQuality improvementTelevision system detailsImage analysisComputer graphics (images)Engineering

The invention provides a processed product image acquisition device. The processed product image acquisition device comprises a conveyor belt, a first camera, a second camera, an operation server andan adjusting device, wherein the second camera is used for collecting an image of a processed product on the conveying belt and sending the image collected by the second camera to the operation server; the shooting position of the first camera is located in front of the shooting position of the second camera in the moving direction of the conveying belt. The operation server is used for acquiringthe area of the processed product in the image, calculating the position of the area of the processed product in the image and sending the position to the adjusting device; wherein the area of the processed product is an area containing all processed products in the image; and the adjusting device is used for adjusting the position of the first camera according to the position, so that the areas of the processed product in the image of the processed product acquired by the first camera after position adjustment are uniformly distributed. According to the invention, a clearer image of a processed product is acquired, and the quality of the processed product image is improved.

Owner:CHINA AGRI UNIV

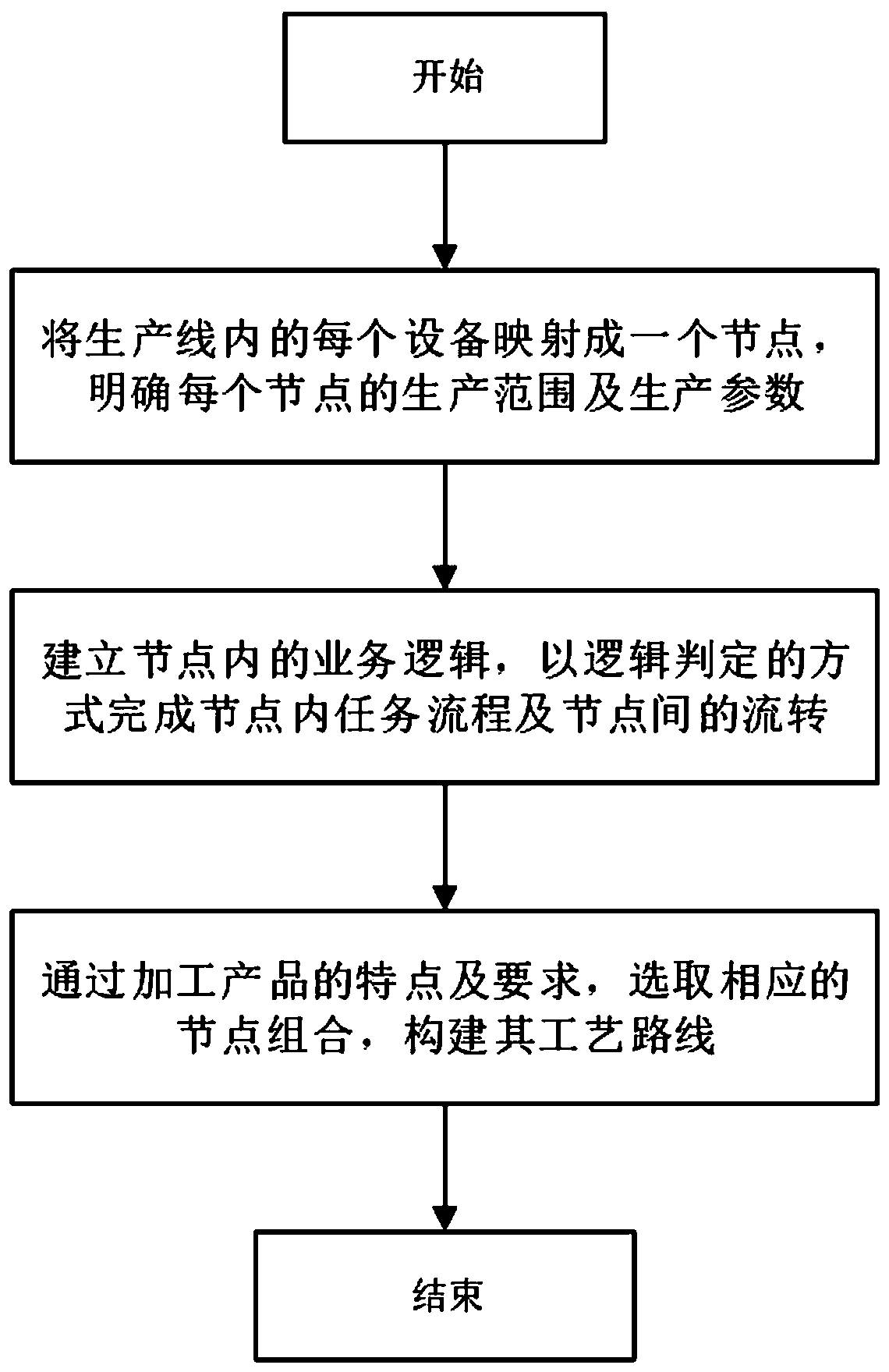

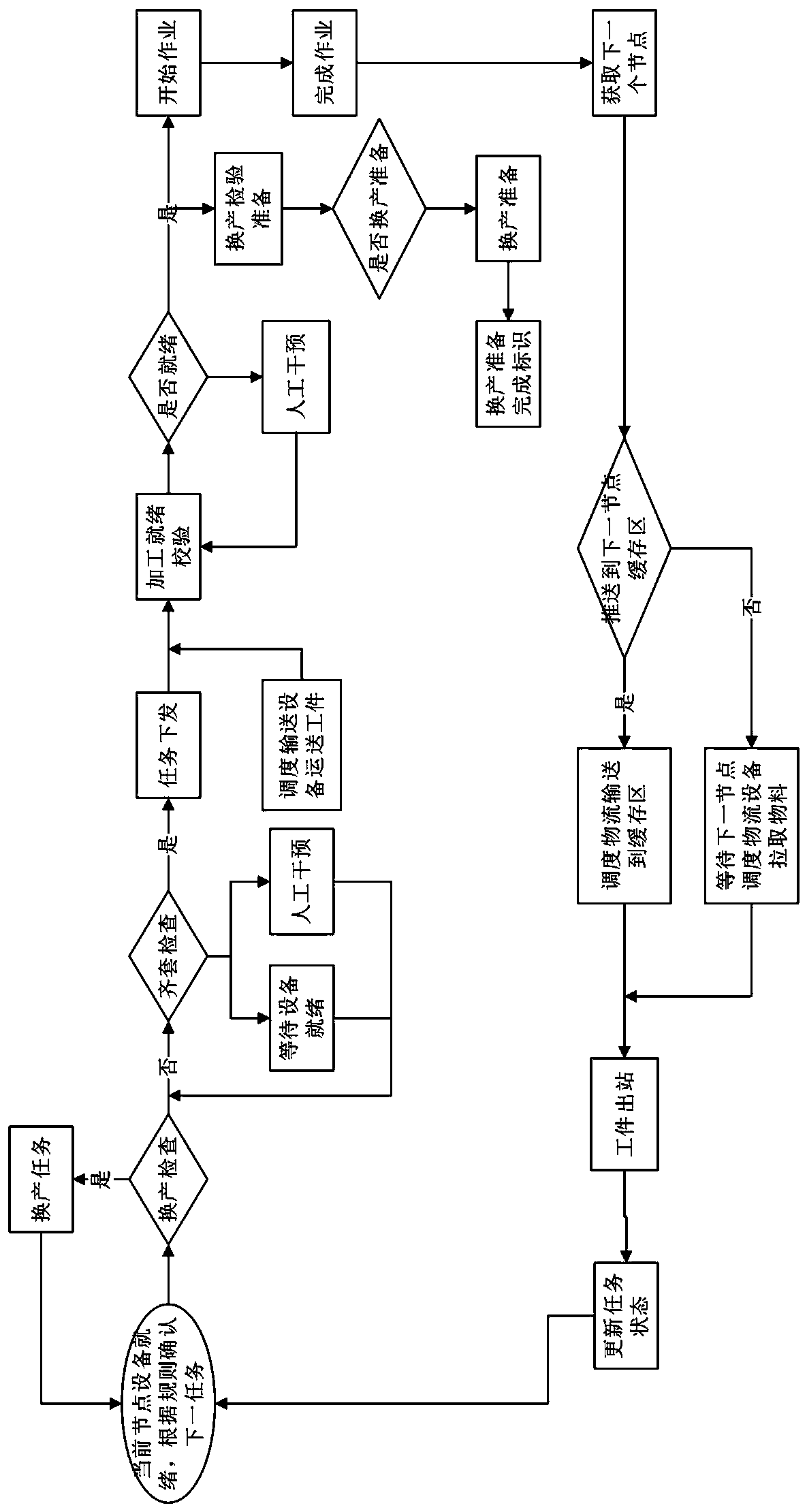

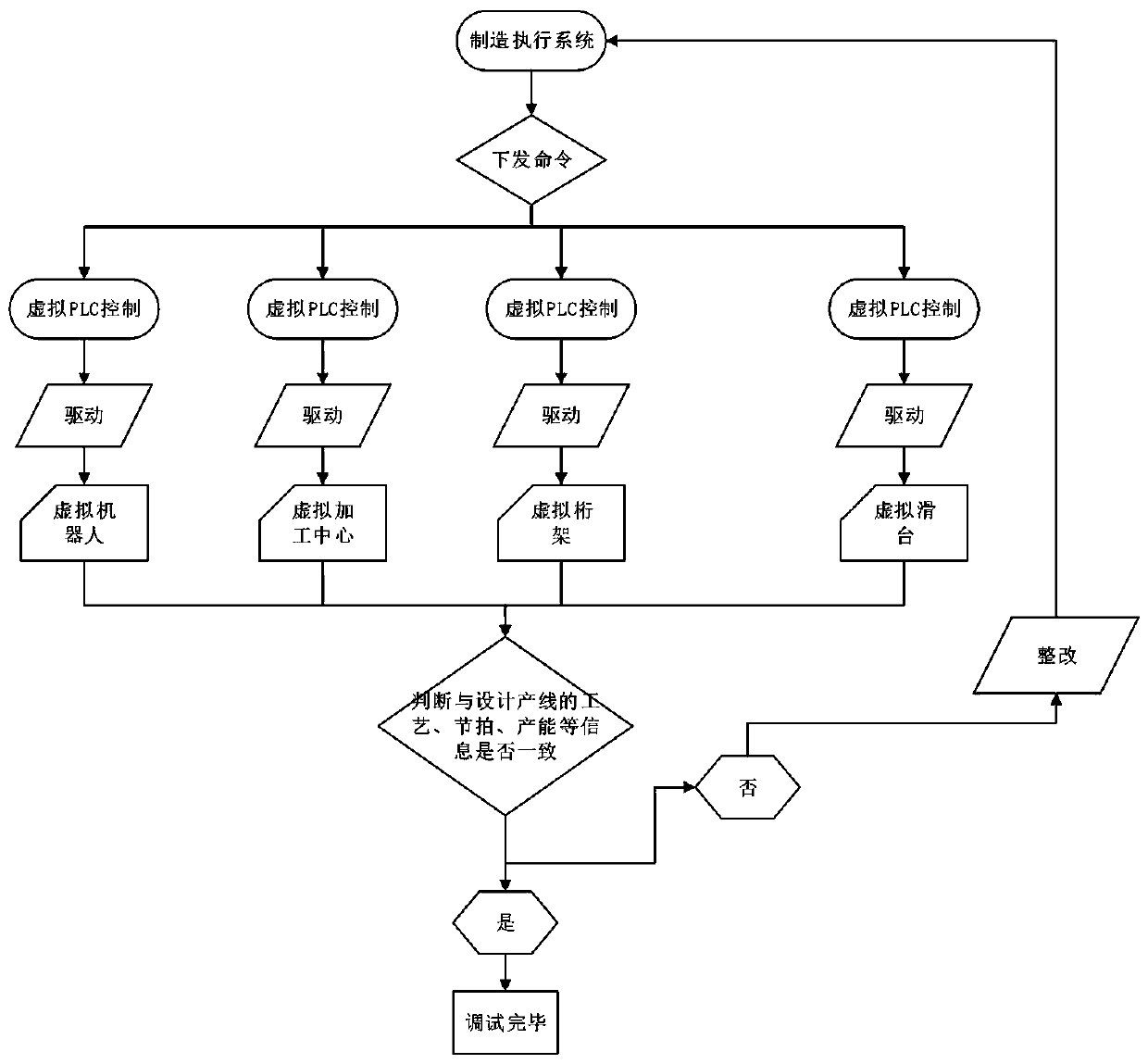

Process route modeling method and system for manufacturing execution system

ActiveCN111538307AFlexible controlFlexible Task SchedulingTotal factory controlProgramme total factory controlManufacturing execution systemManufacturing line

The invention provides a process route modeling method and system for a manufacturing execution system. The method comprises the steps of enabling each piece of equipment in a production line to be mapped into a node, determining the production range and production parameters of each node, and guaranteeing that the equipment is used in a specific parameter range; establishing service logic in thenodes, and completing task flows in the nodes and circulation among the nodes in a logic judgment mode; according to the characteristics and requirements of processed products, selecting correspondingnode combinations , and constructing a process route. According to the method for flexibly constructing the process route, the nodes serve as the minimum units in the process route, circulation between the nodes is completed in a judgment mode, the problem that the process route of a traditional manufacturing execution system is solidified, and the circulation efficiency is low is solved, and themanufacturing execution system can flexibly manage, control and schedule tasks on the production line.

Owner:SHANGHAI SMARTSTATE TECH CO LTD

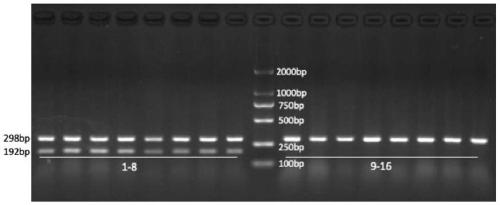

Primer pair, reagent kit and method for distinguishing brachymystax lenok from Hucho taimen

ActiveCN110042168ATroubleshoot problems with logo errors, etc.Meet the needs of rapid identificationMicrobiological testing/measurementAgainst vector-borne diseasesHucho taimenMicrobiology

The invention discloses a primer pair, reagent kit and method for distinguishing brachymystax lenok from Hucho taimen. The primer pair comprises a primer pair 1 and a primer pair 2, wherein the primerpair 1 comprises an upstream primer ITS-F and a downstream primer ITS-R, and the primer pair 2 comprises an upstream primer mtDNA-F and a downstream primer mtDNA-R; the sequence of the ITS-F is shownas SEQID NO.1, the sequence of the ITS-R is shown as SEQID NO.2, the sequence of the mtDNA-F is shown as SEQID NO.3, and the sequence of the mtDNA-R is shown as SEQID NO.4. A new method for distinguishing brachymystax lenok from Hucho taimen based on a molecular biology technique principle is adopted for the first time at home and abroad, 1 pair of specific primers is designed by using ITS genesand mitochondrial genome of the brachymystax lenok and the Hucho taimen, and a new method for identifying the brachymystax lenok and the Hucho taimen can be realized by a PCR reaction. The primer pair, the reagent kit and the method can be used for distinguishing the brachymystax lenok from the Hucho taimen complete individual and processed products thereof, and have the characteristics of being accurate, quick, objective, fair, economical and practical.

Owner:HEILONGJIANG RIVER FISHERY RES INST CHINESE ACADEMY OF FISHERIES SCI

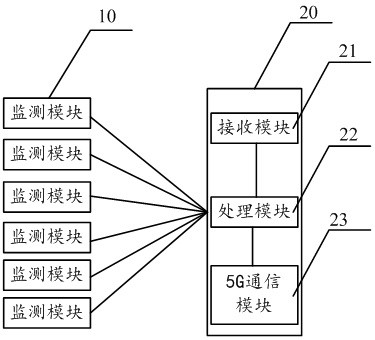

Smart factory system with 5G communication management

ActiveCN114493553AShorten or extend timeReduce waiting timeOffice automationTransmission rate adaptationCommunications managementSmart factory

The invention relates to a smart factory system with 5G communication management, the system comprises a plurality of monitoring modules and generates monitoring data, a plurality of processing devices form a processing factory, and the flow of processed products among different processes is realized; the receiving module is used for receiving monitoring data, the processing module is used for processing the monitoring data and obtaining a processing result, and the 5G communication module is used for sending a message instruction to processing equipment according to the processing result; the processing module is used for adjusting the structure of the message instruction according to the processing result and the return time of the test message in the message instruction. By adjusting the transmission rate, the time for the processed product to arrive at the next processing device can be shortened or prolonged, so that the time for completing extraction of the instruction code in the instruction information received by the next processing device is matched, the next processing device can be operated immediately when the processed product arrives at the next processing device, and the processing efficiency of the next processing device is improved. The waiting time for processing products is reduced, and the processing efficiency of the smart factory is improved.

Owner:SHENZHEN GESHEM TECH CO LTD

Semiconductor packaging line bonding equipment organization method based on processing task capability matching

ActiveCN103632220ARealize dynamic matchingEasy to controlResourcesManufacturing computing systemsProduct typeDevice type

The invention relates to a semiconductor packaging line bonding equipment organization method based on processing task capability matching, which belongs to the technical field of semiconductor production processes. The semiconductor packaging line bonding equipment organization method is characterized in that the semiconductor packaging line bonding equipment organization method includes the following steps: bonding process equipment is abstracted into a multi-row and multi-column equipment point array; the equipment organization relations between the points in the rows and the columns are represented by '0' and '1'; an organization relation matrix and an equipment organization matrix are established; organization relations are corrected, and incomplete relation information is supplemented; equipment organization closed position relation constraint check and equipment type and processed product type matching constraint check are carried out; according to the capacities provided by equipment organizations and the capacity required by a processing task, an equipment organization is matched with the processing task; according to a matching result of the processing task and the equipment organization, punishment and a function are established, and the matching result is quantified. The semiconductor packaging line bonding equipment organization method can correspondingly organize bonding equipment according to the capacities required by processing tasks, thus meeting the requirement for the dynamic matching relation between production operations and equipment resources.

Owner:SHENYANG JIANZHU UNIVERSITY

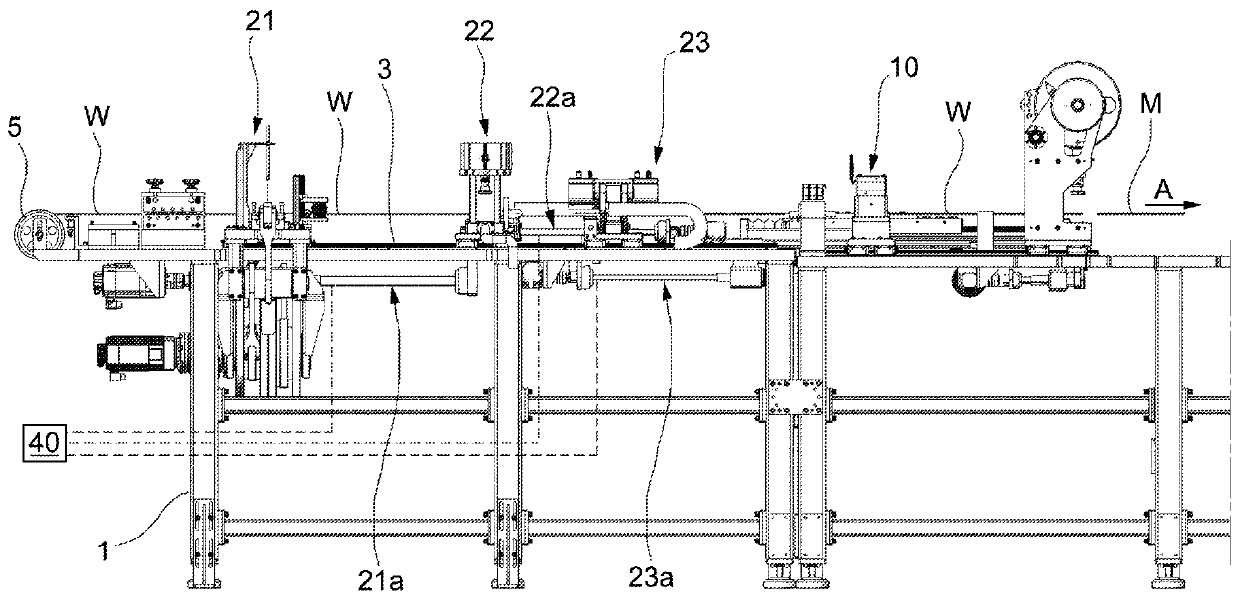

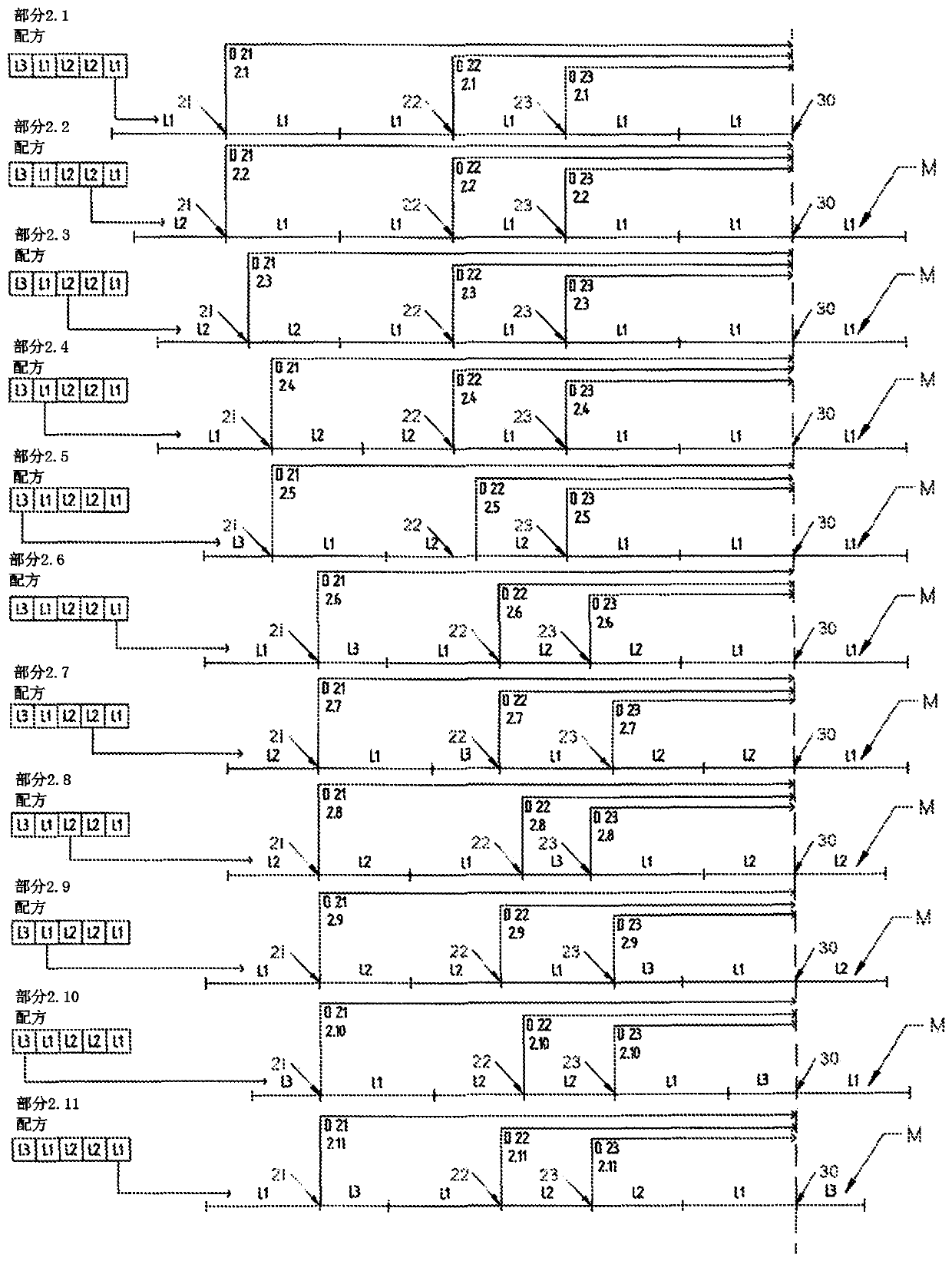

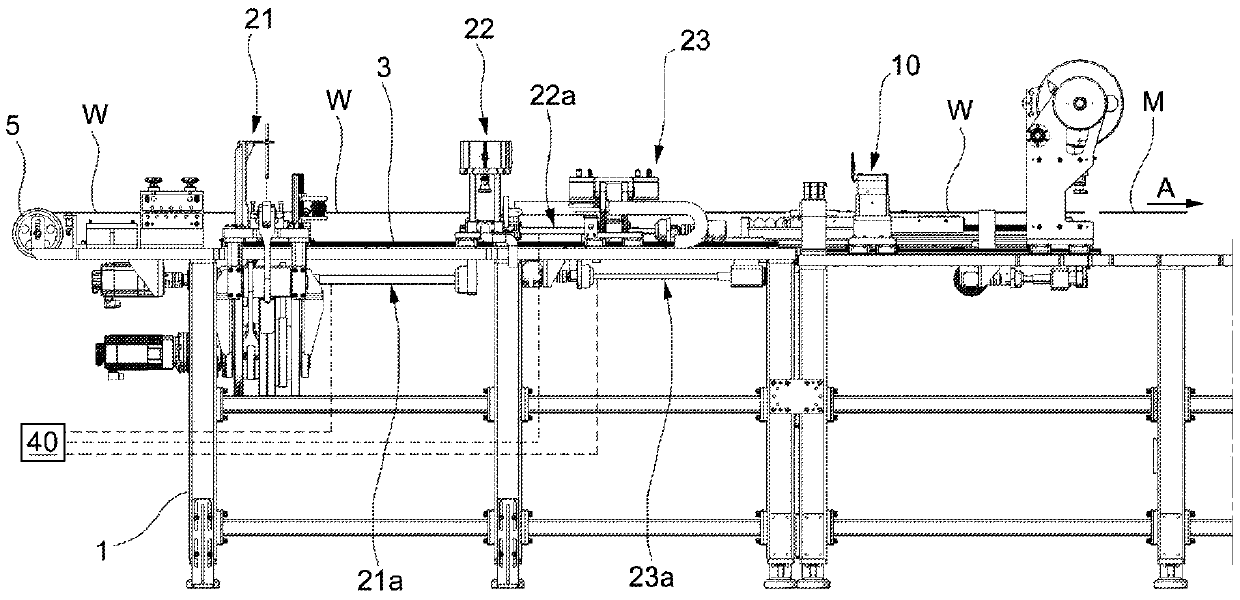

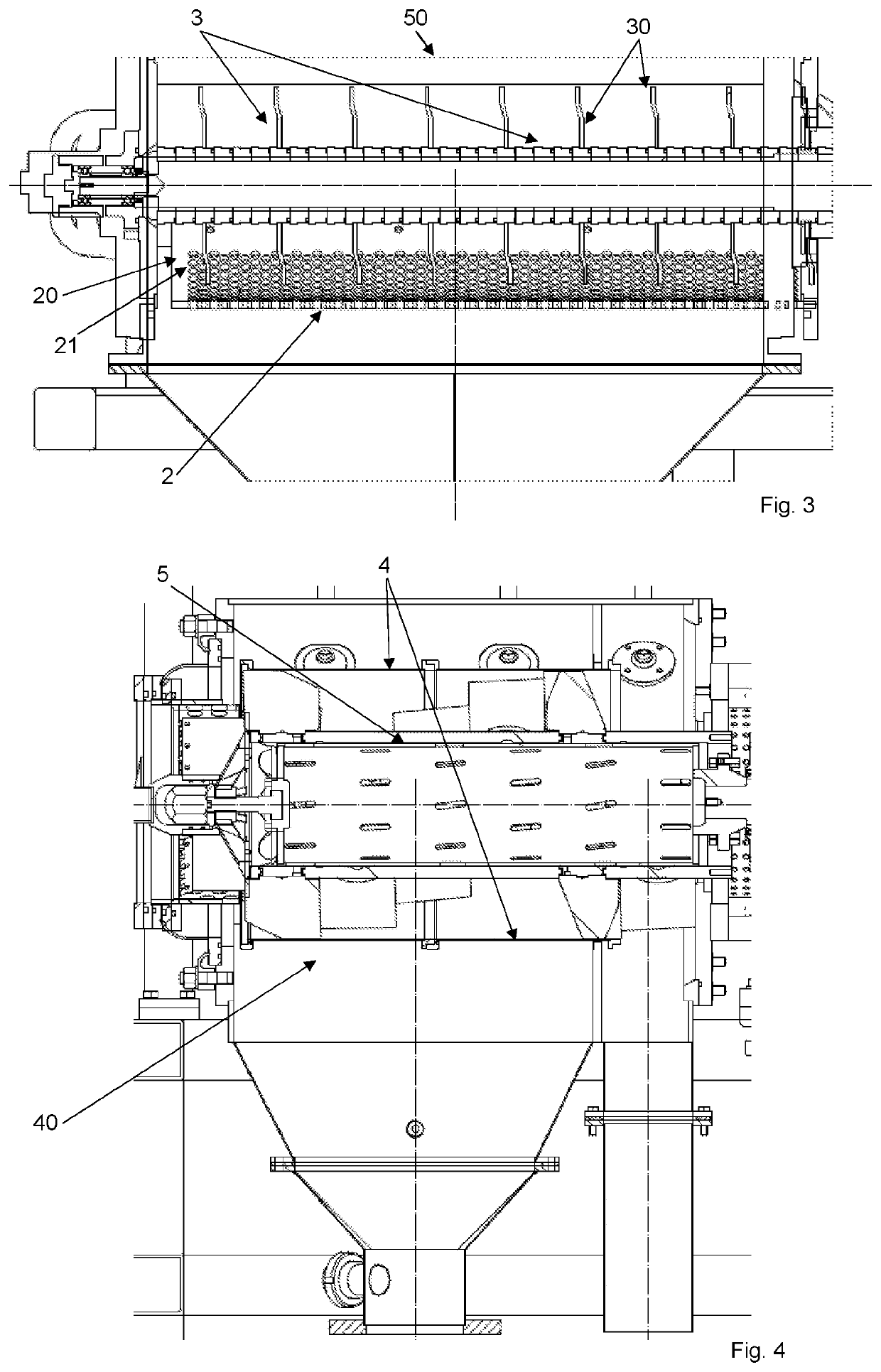

Machine and method for processing a continuous semi-processed product

ActiveCN111183572AManufacturing dynamo-electric machinesCoils manufactureControl systemProcess engineering

A machine for processing a continuous semi-processed product (W), comprising a feeding unit (10), a processing unit (21, 22, 23), and a terminal cutting unit (30) past which processed segments (M) ofthe semi-processed product (W) are producible, which width (LI, L2, L3) is correlated to the feed step. The feeding unit (10) is automatically adjustable in the feed step. The machine further comprises actuators (21a, 22a, 23a) configured to adjust the position of the processing unit along the feed direction (A) of the semi-processed product (W), and a control system (40) configured to read inputinstructions relating to a series of consecutive segments to be produced, determine the required position of the processing unit (21, 22, 23) as a function of the input instructions, and determine therequired feed step as a function of the input instructions.

Owner:TECNOMATIC

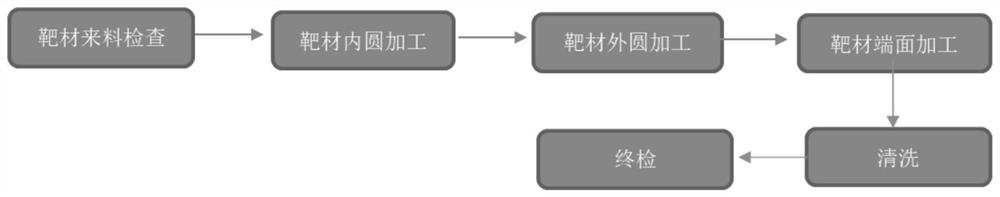

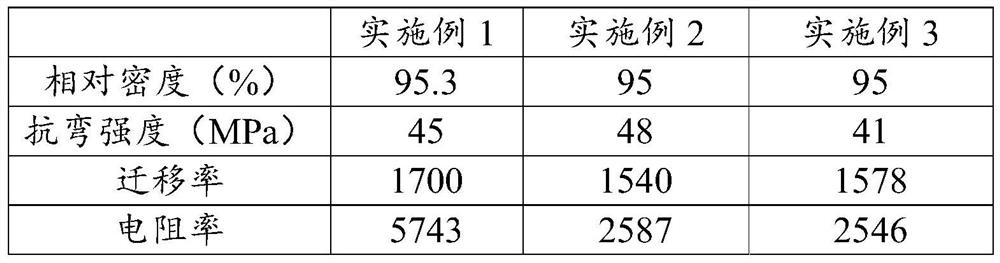

Processing method of cadmium oxide target material

PendingCN113857953AEasy to processAvoid surface crackingRevolution surface grinding machinesPlane surface grinding machinesMetallurgySurface roughness

The invention discloses a processing method of a cadmium oxide target material, and belongs to the field of target material processing. According to the processing method of the cadmium oxide target material, through the reasonable processing steps and sequence, the number of grinding wheels suitable for the target material is selected and reasonable processing parameters are set, so that the quality of a processed product is effectively improved, the surface roughness of the target material is regulated and controlled to meet the application requirements, and the outer circle of the target material meets the requirement of a sputtering face. Meanwhile, the surface of the outer circle can meet the qualified binding rate requirement of the welding flux and the back plate. By using the coolant, the processing effect of the target material can be improved, the problem of surface cracks of the target material due to local overheating in the course of processing is avoided, meanwhile, the heat consumption wear of a processing appliance can be reduced, the replacement frequency of the appliance is further reduced, and the processing efficiency of the target material is improved.

Owner:XIANDAO THIN FILM MATERIALS GUANGDONG CO LTD

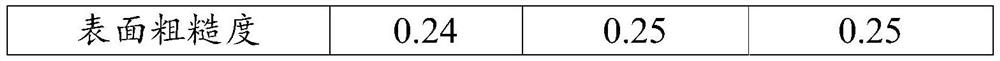

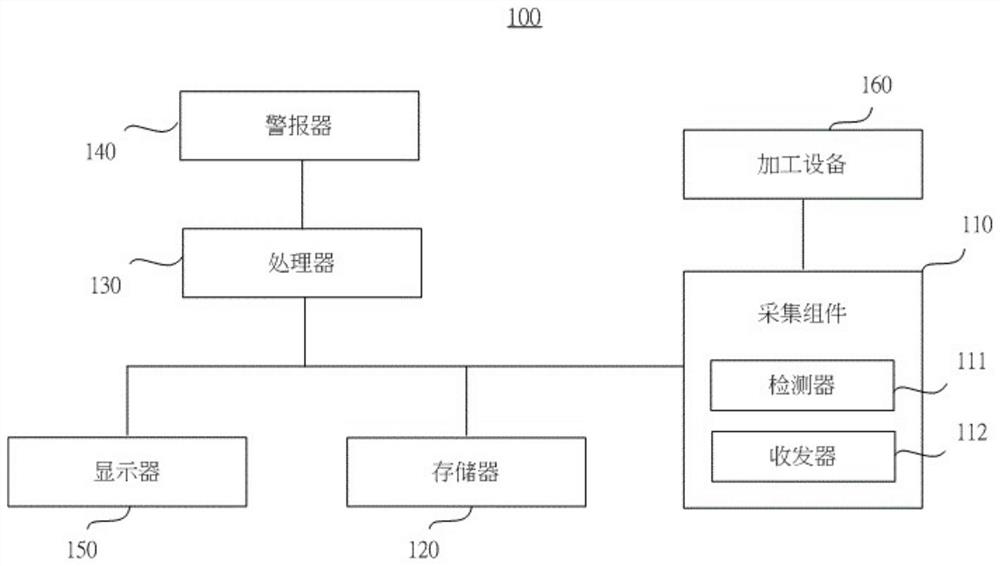

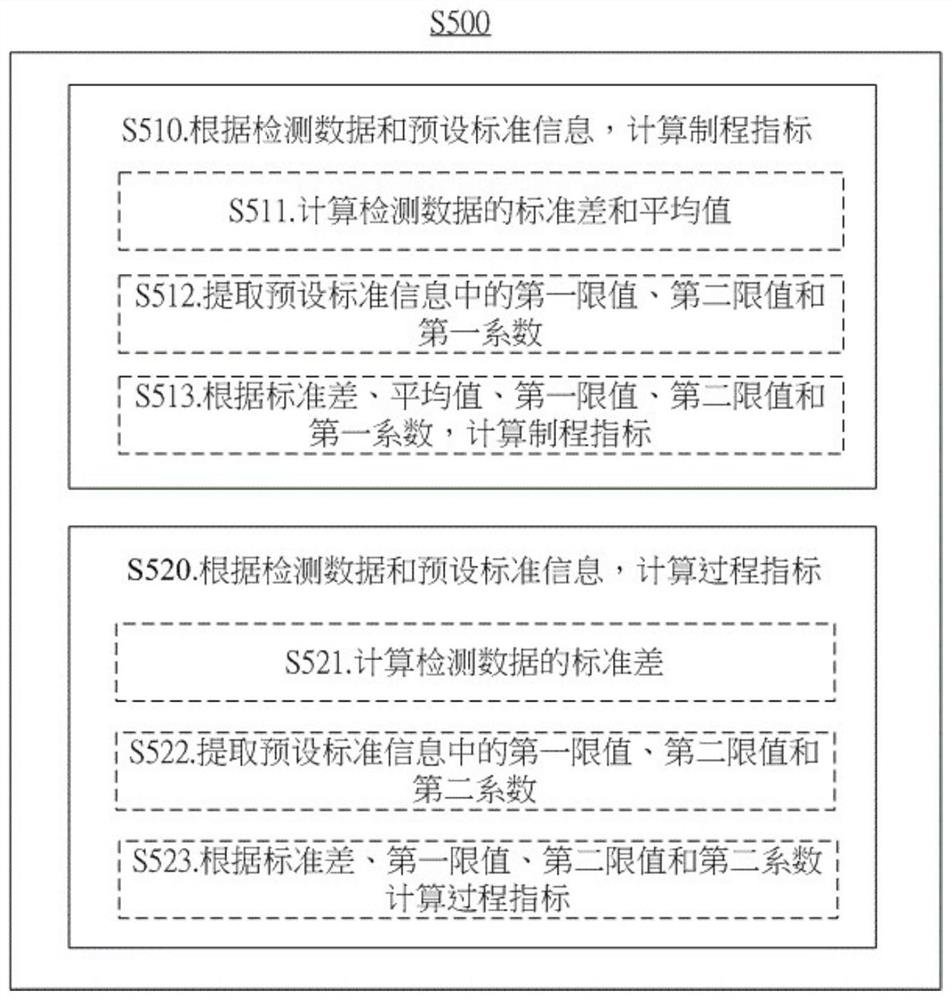

Data processing system and method of processing equipment

PendingCN112749885AResourcesManufacturing computing systemsData processing systemProcess engineering

The invention provides a data processing system and method for processing equipment, and the data processing system comprises: a memory which is used for storing preset standard information of a product processed by the processing equipment; a processor which is coupled with the memory and is used for acquiring detection data of the product, calculating a process index according to the detection data and the preset standard information, and calculating first production condition information of the processing equipment according to the process index and the preset standard information. According to the data processing system, the invention also provides a data processing method, and through the data processing system and the data processing method, the production quality, the operation method, the quality fluctuation and other production and processing capability conditions of the processing equipment can be reflected in time so as to guide the regulation and the improvement of the processing equipment, thereby improving the production efficiency and the product quality.

Owner:ZHENGZHOU FULIAN INTELLIGENT WORKSHOP CO LTD

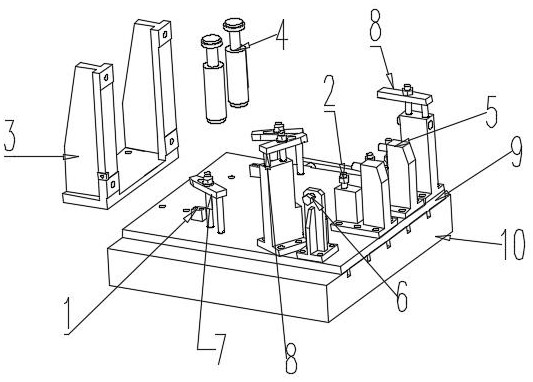

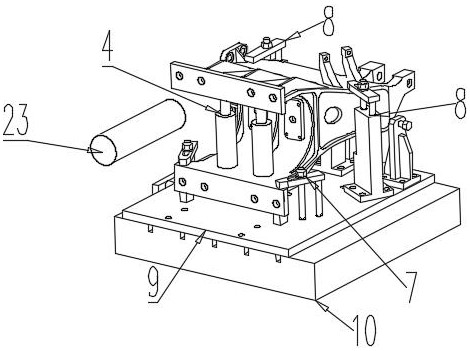

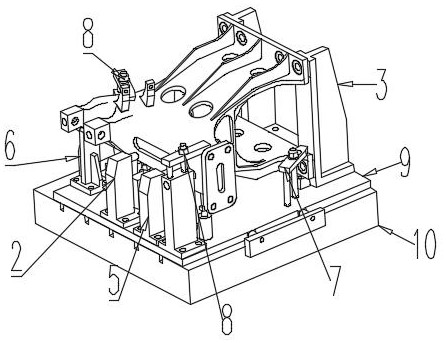

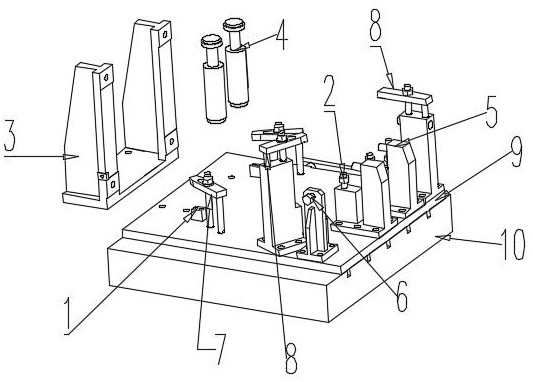

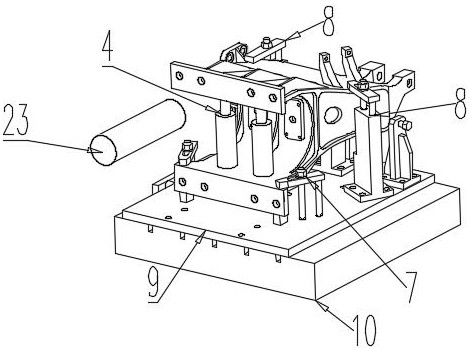

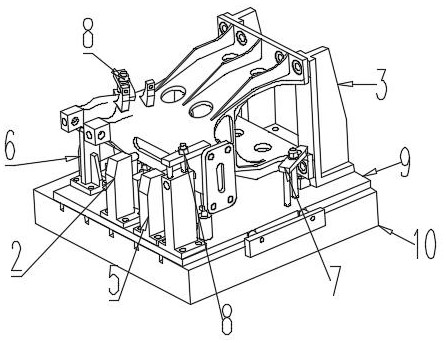

Processing method of support product

ActiveCN112496686AChange the processing methodReduce manufacturing costPrecision positioning equipmentOther manufacturing equipments/toolsProcess engineeringMachining process

The invention relates to the technical field of support processing, and particularly relates to a processing method of a support product. The processing method comprises the following steps that 1, asupport is positioned on equipment; 2, a supporting piece is installed; 3, the support is pressed; 4, a lower installation face and a lower installation hole of the support are processed; 5, the supporting piece is disassembled, and a side face supporting frame is installed; 6, the internal plane of the product is processed; 7, a first side installation face and holes in the surface of the first side installation face are processed; 8, surface holes of a second side installation face of the product are processed; 9, the second side installation face of the product is processed; 10, a third side installation face of the product and holes in the surface of the third side installation face are processed; and 11, a workpiece is disassembled. According to the processing technology and processing equipment of the support product, one operator can position and clamp one set of equipment and one set of equipment at a time, all processing contents of the product are completed, the manufacturingcost of the product is greatly reduced, and the processing precision of the product is improved.

Owner:CRRC QISHUYAN CO LTD

Foldable glass cutting and CNC finish machining one-time forming process

PendingCN113696066AReduce usageReduce riskGrinding carriagesGrinding drivesManufactured materialGrinding wheel

The invention discloses a foldable glass cutting and CNC finish machining one-time forming process, which comprises the following steps that S2, mounting a positioning jig; S4, mounting a special grinding wheel; S6, mounting foldable glass raw materials; S8, cutting the foldable glass raw materials into a plurality of blanks; S10, performing pre-finish machining on each blank; and S12, performing finish machining on each pre-finish machining product. Cutting, pre-finish machining and finish machining of foldable glass can be achieved on one CNC machine table, so that the needed foldable glass finished product is obtained, the risk caused by defective products is reduced, the production efficiency is improved, and the cost is reduced.

Owner:深圳市信濠光电科技股份有限公司

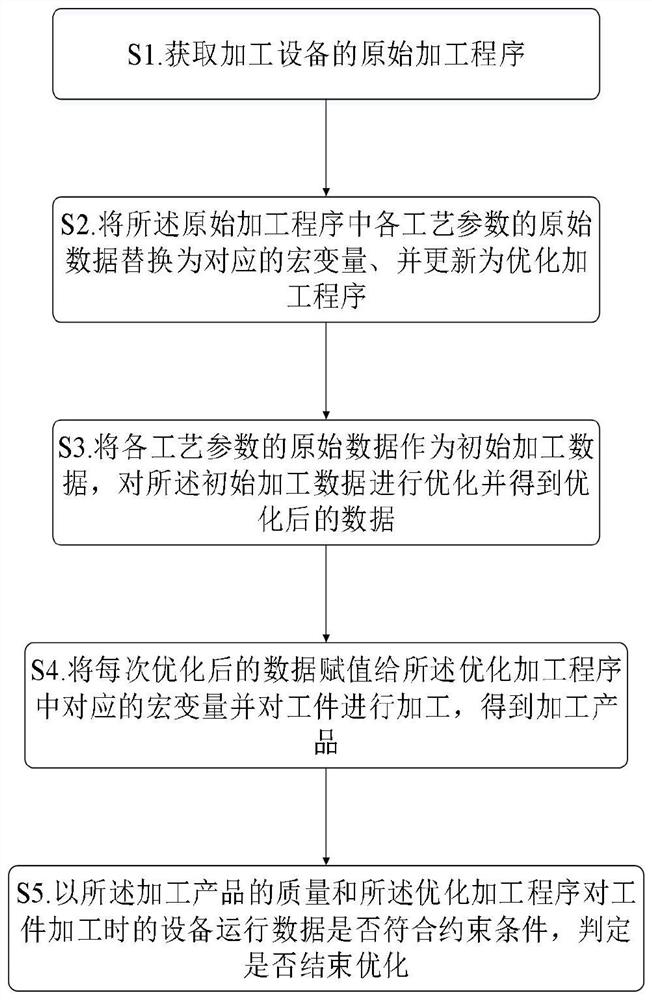

Cutting process parameter optimization method and system, computer equipment and storage medium

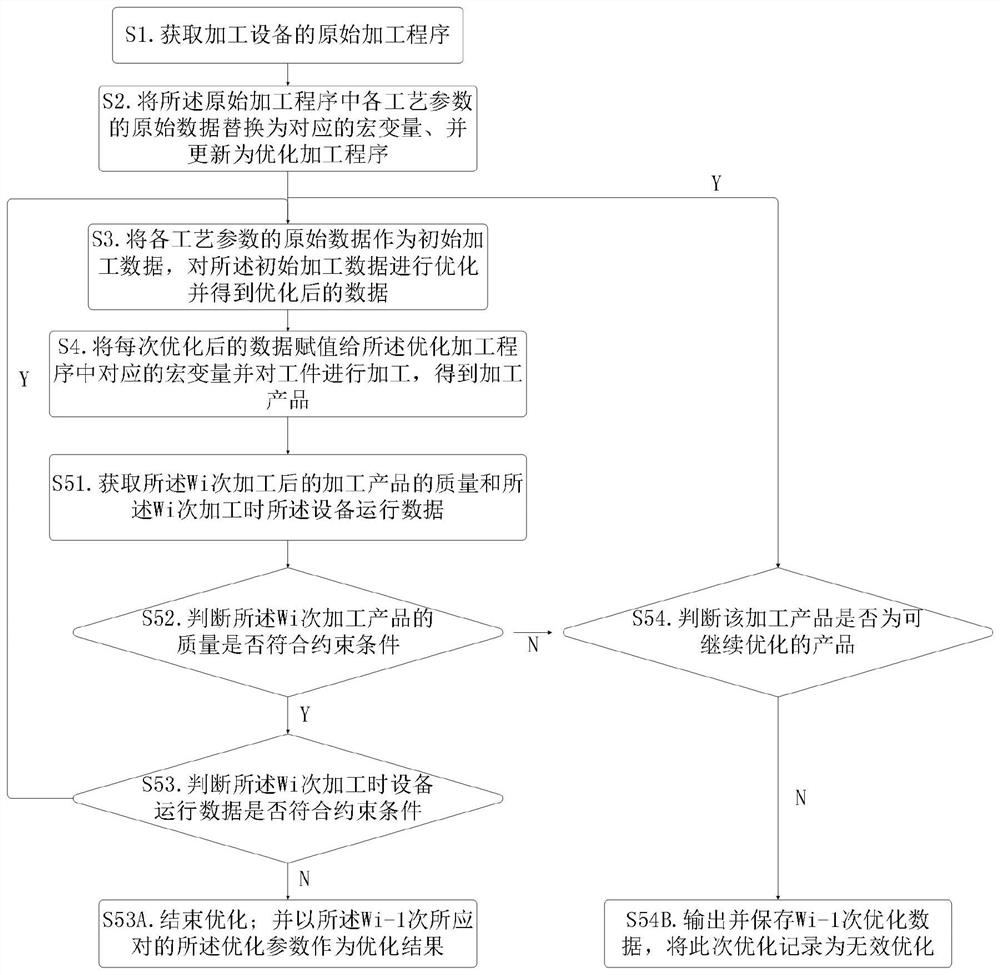

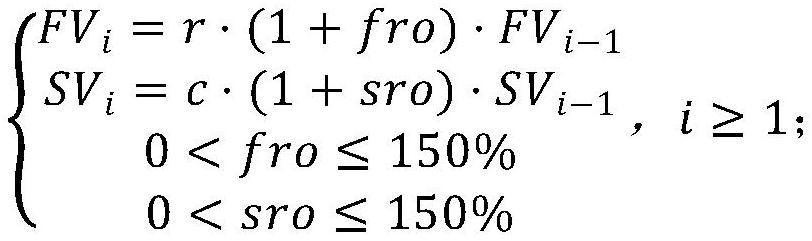

PendingCN114859823AGood adaptation and optimizationSolution to short lifeProgramme controlComputer controlOriginal dataProcess engineering

The invention provides a cutting process parameter optimization method and system, computer equipment and a storage medium. The cutting process parameter optimization method comprises the following steps that an original machining program of machining equipment is obtained; replacing the original data of each process parameter in the original processing program with the corresponding macro-variable, and updating the original processing program into an optimized processing program; taking the original data of each process parameter as initial processing data, and optimizing the initial processing data to obtain optimized data; assigning the data after each optimization to a corresponding macro variable in the optimization processing program, and processing the workpiece to obtain a processed product; whether optimization is finished or not is judged according to the quality of the machined product and whether equipment operation data meets constraint conditions or not when the workpiece is machined through the optimized machining program.

Owner:江苏西格数据科技有限公司

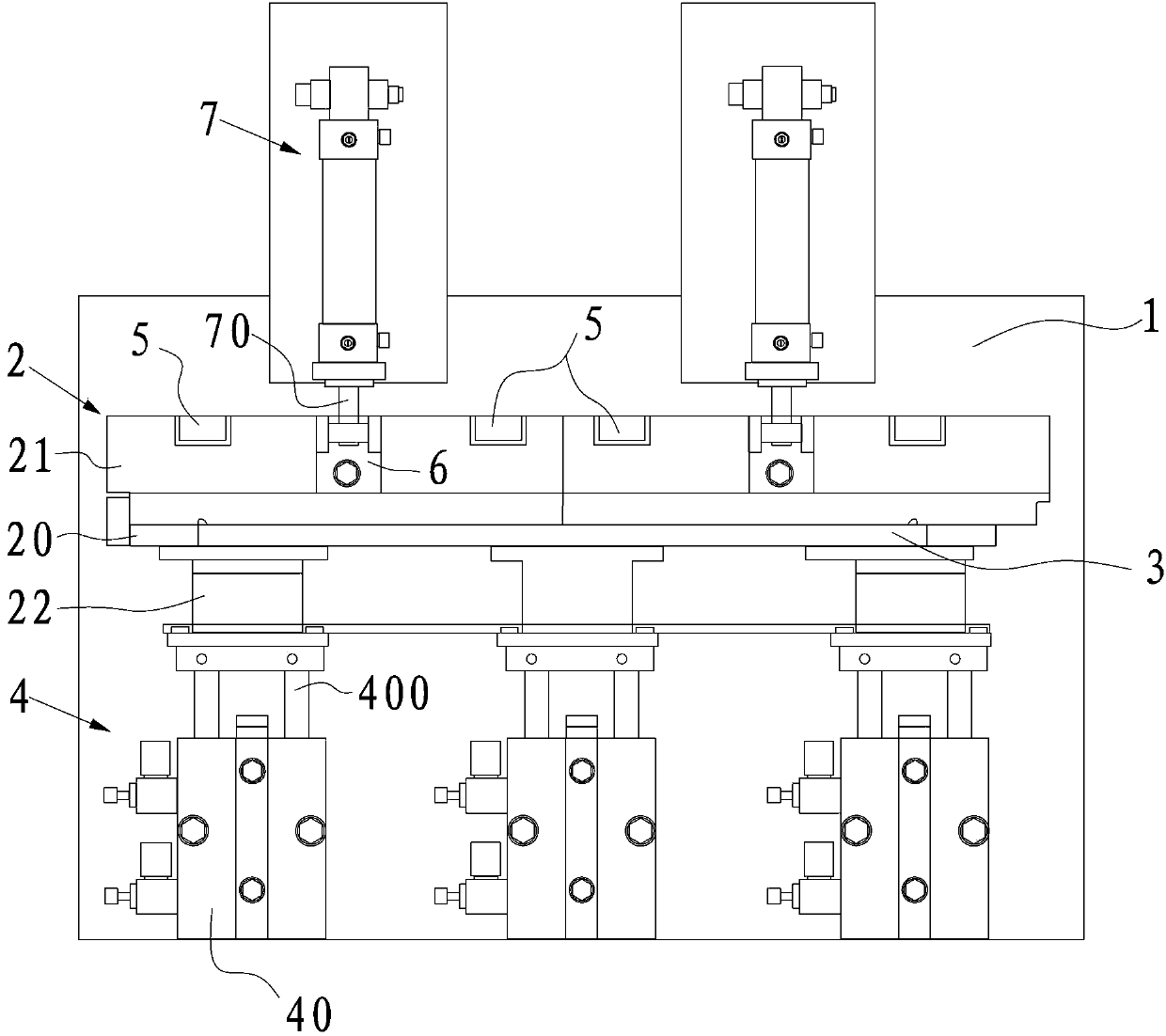

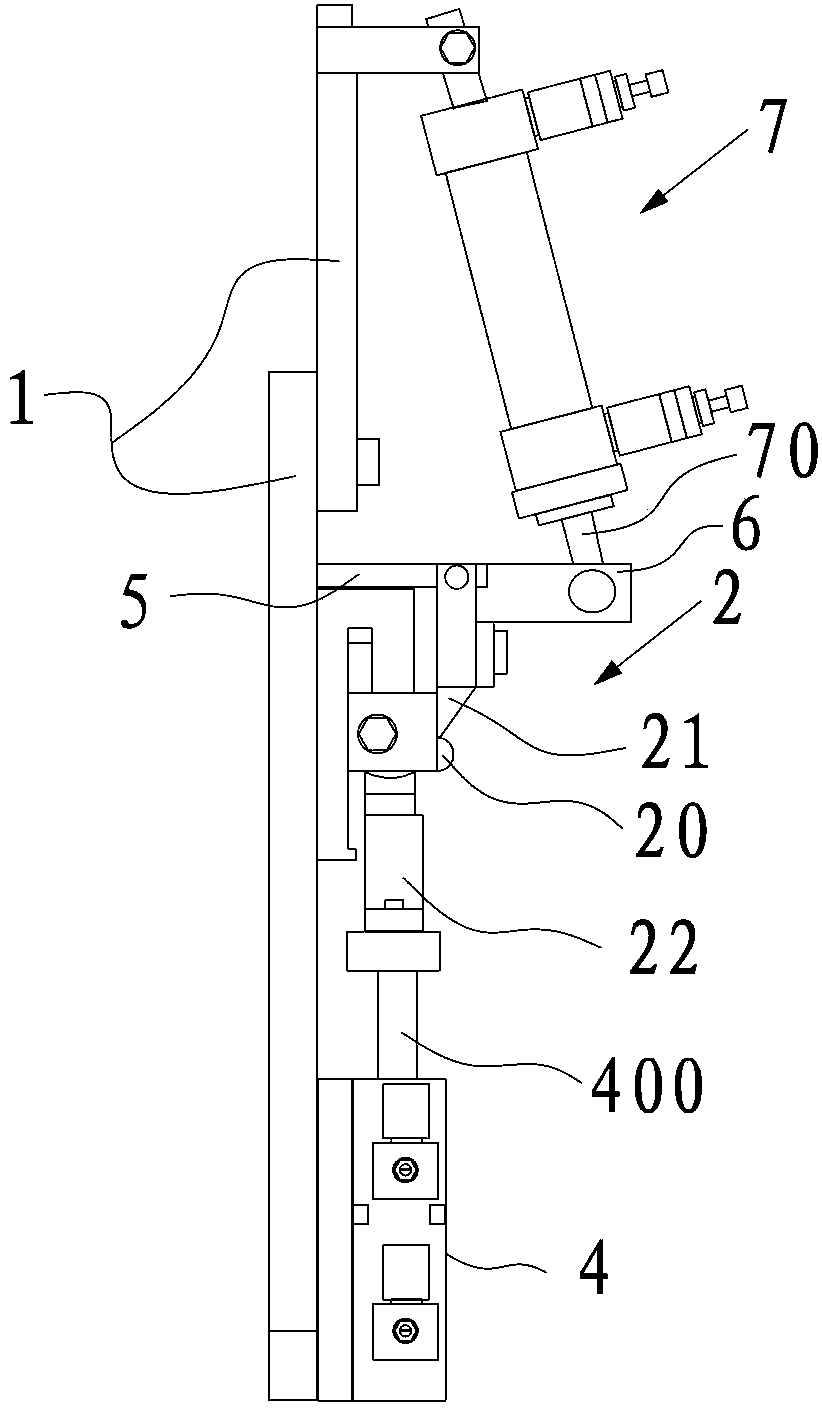

Copying machining fixture

ActiveCN103386623AAchieve fixationFixed and accuratePositioning apparatusMetal-working holdersMechanical engineeringProcessedProduct

The invention relates to a copying machining fixture, which comprises a base and a positioning module, wherein the positioning module is arranged on the base and is provided with a groove which is used for containing a to-be-processed product, the groove extends in the length direction of the base, the positioning module comprises a first module, a second module and a third module, the first module is fixedly arranged on the base, the splicing parts of the second module and the third module forms the groove, the first module extends in the length direction of the groove, the shape of the first module is the same as the shape of an inner hole of the to-be-processed product, the to-be-processed product is inserted into the outer surface of the first module, the second module is fixedly arranged on the base and is abutted against the side surface of the to-be-processed product, and the third module can move in the width direction of the base to the second module so as to adjust the width of the groove. The to-be-processed product is inserted into the first module, the second module is abutted against one side of the to-be-processed product, and meanwhile, the width of the groove is reduced by adjusting the third module, so the to-be-processed product is fixed, the to-be-processed area of the to-be-processed product is accurately positioned, and the quality and the efficiency of the product are improved.

Owner:太仓伟利达铭板科技有限公司

Preparation method of natto pure powder tablet without any auxiliary material

InactiveCN104522640AProtects Bioactive IngredientsReduce natto ammonia odorFood ingredient functionsFood preparationAdditive ingredientFreeze-drying

The invention relates to a preparation method of a natto pure powder tablet without any auxiliary material and belongs to the field of medicines and health products. The preparation method specifically comprises the following steps: mashing natto and immersing the natto into water with the volume being 10-20 times as much as that of the natto; decompressing and distilling at a low temperature ranging from 30 DEG C to 40 DEG C until the water is completely evaporated; taking out the natto, and carrying out low-temperature vacuum drying or freezing drying on the natto until the moisture content is 5%-11%; and crushing and sieving to obtain refined natto powder. The refined natto powder has small ammonia odor and few grease components; and active components including nattokinase and the like are not lost, so that the refined natto powder is a natto deep processing product which is good for health. The refined natto powder has good mobility and compressibility and is very suitable for being pressed into tablets, and the 100% pure natto powder tablets can be prepared. The prepared natto pure powder tablets have a pure mouth feel and are very suitable for consumers liking eating pure natto with original flavor.

Owner:SHENYANG PHARMA UNIVERSITY

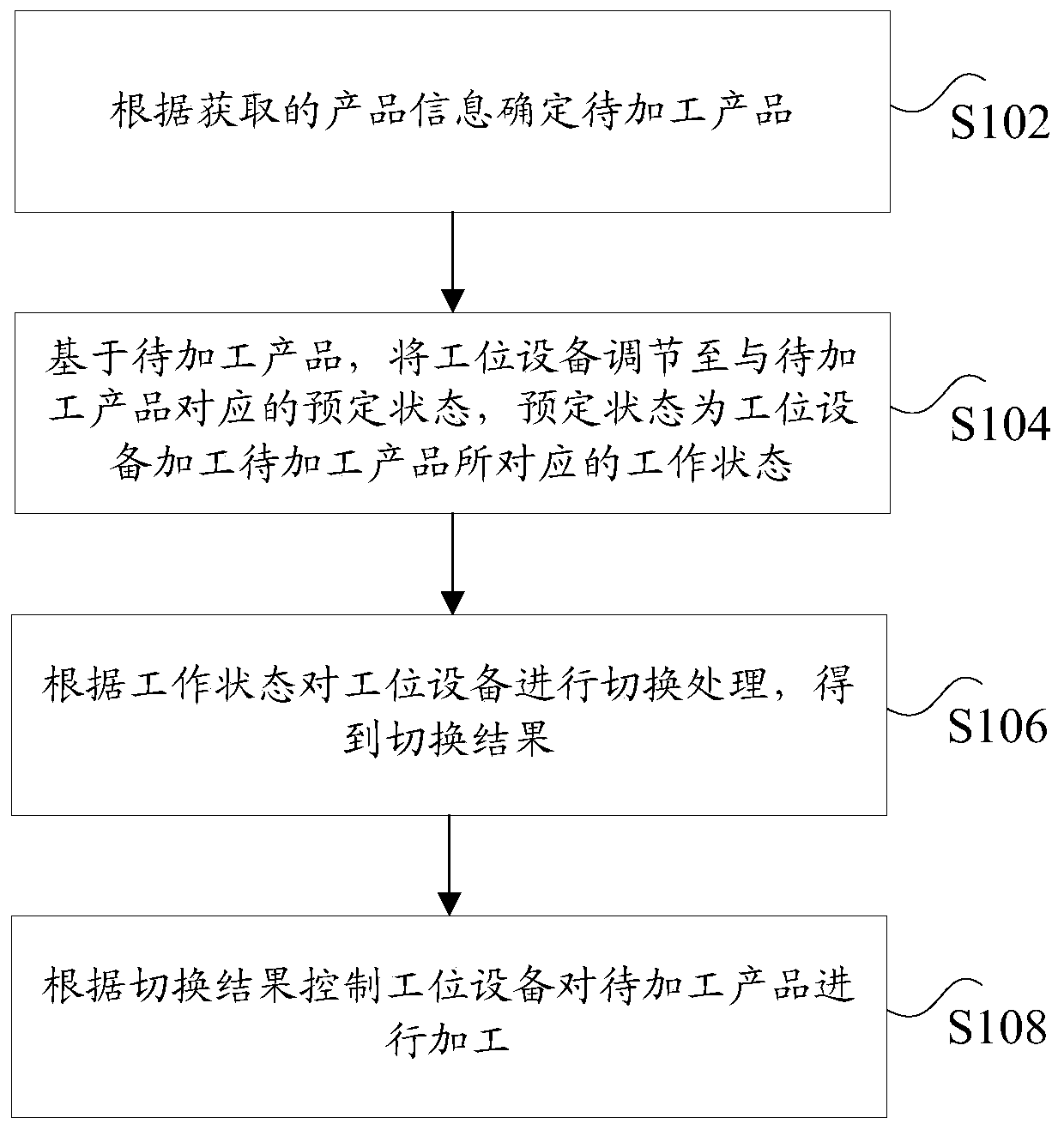

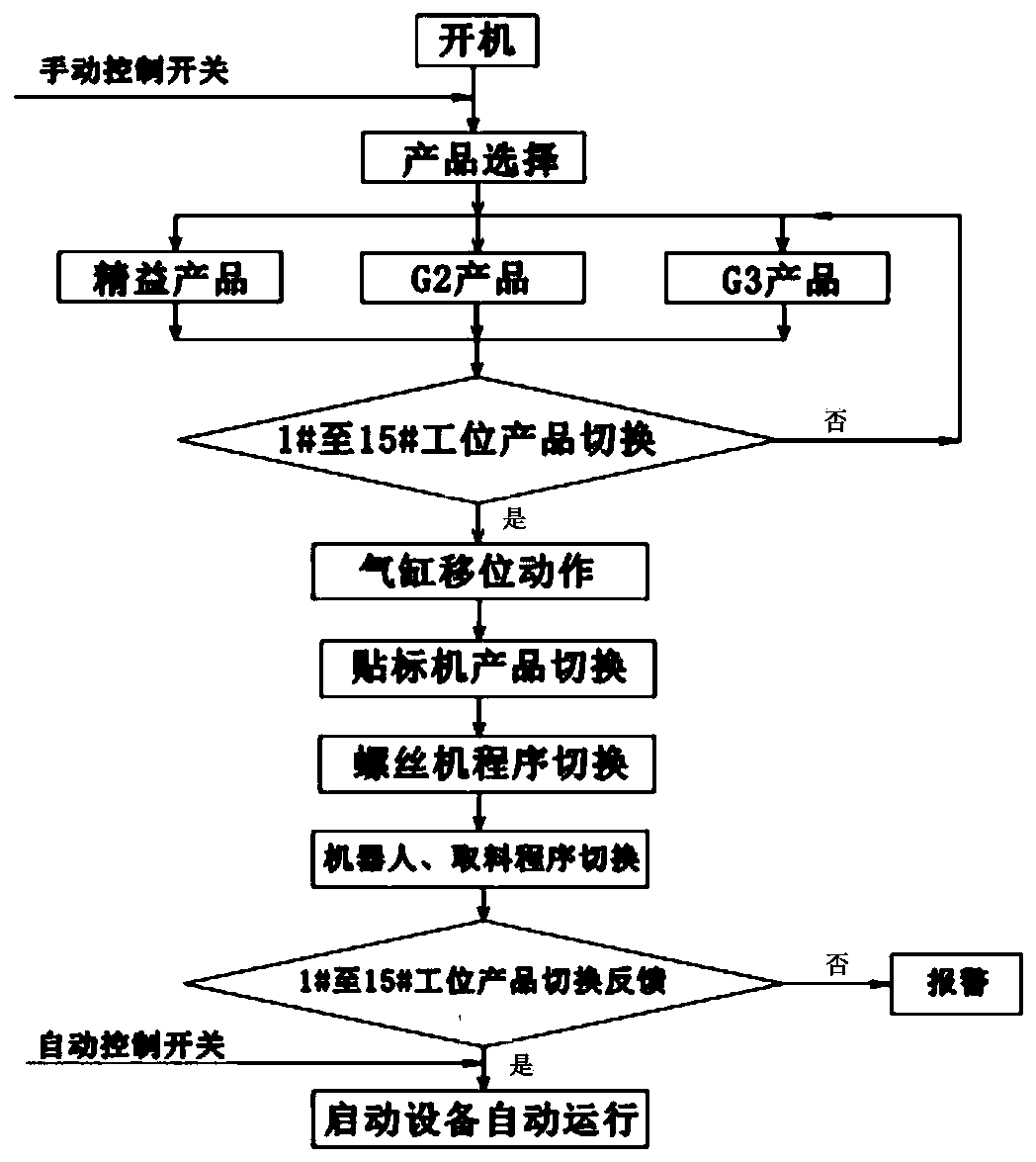

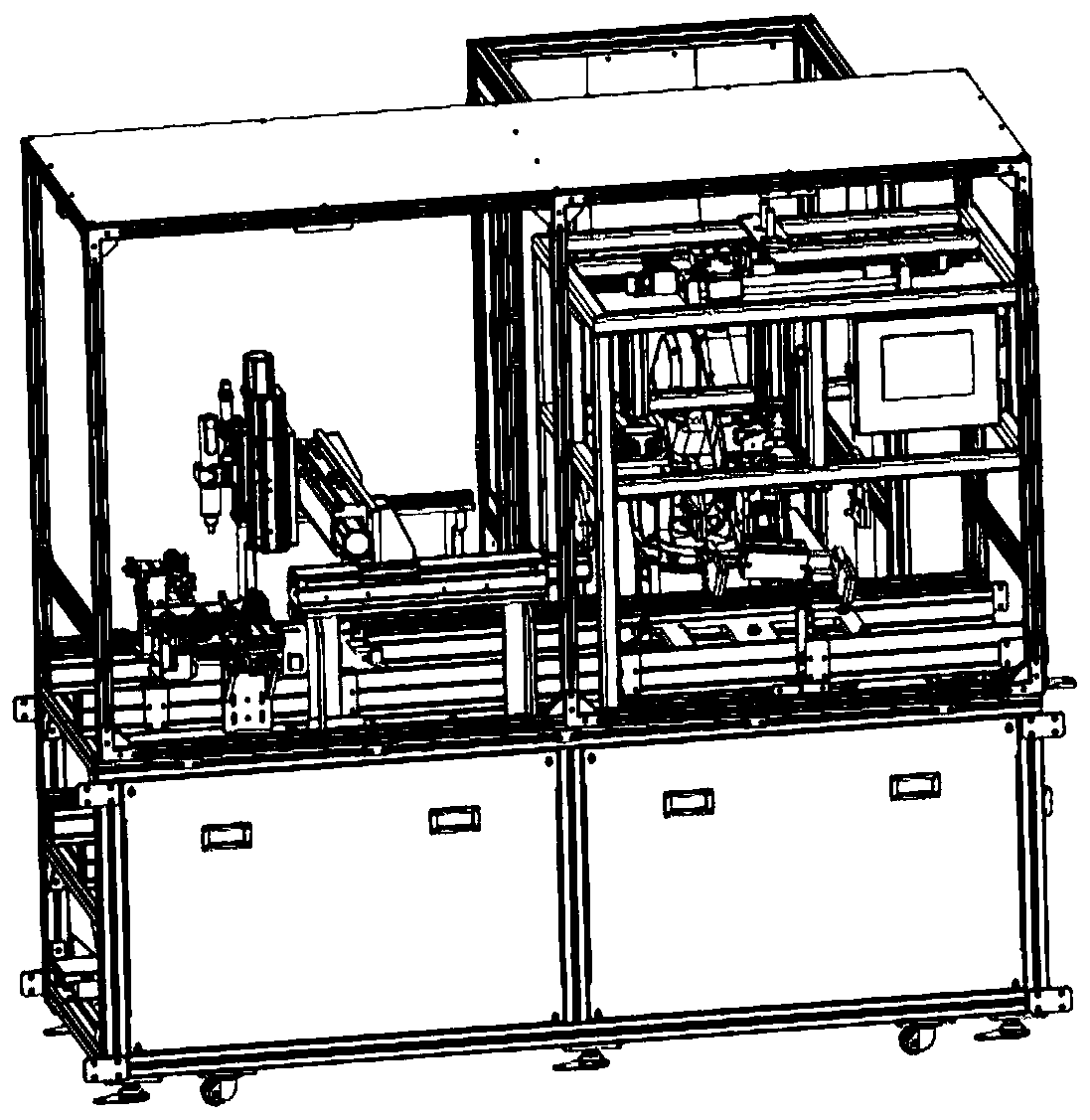

Control method and device for product processing, storage medium and processor

InactiveCN110837249AIncrease productivityImprove product reliabilityTotal factory controlProgramme total factory controlProcess engineeringDependability

The invention discloses a control method and device for product processing, a storage medium and a processor. The method comprises the following steps of determining a to-be-processed product according to acquired product information; adjusting station equipment to a predetermined state corresponding to the to-be-processed product based on the to-be-processed product, wherein the predetermined state is a working state for processing the to-be-processed product by the station equipment; performing switching processing on the station equipment according to the working state to obtain a switchingresult; and controlling the station equipment to process the to-be-processed product according to the switching result. The technical problems of large intensity, low efficiency and bad reliability due to a fact that the station equipment is manually debugged in the related technology are solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

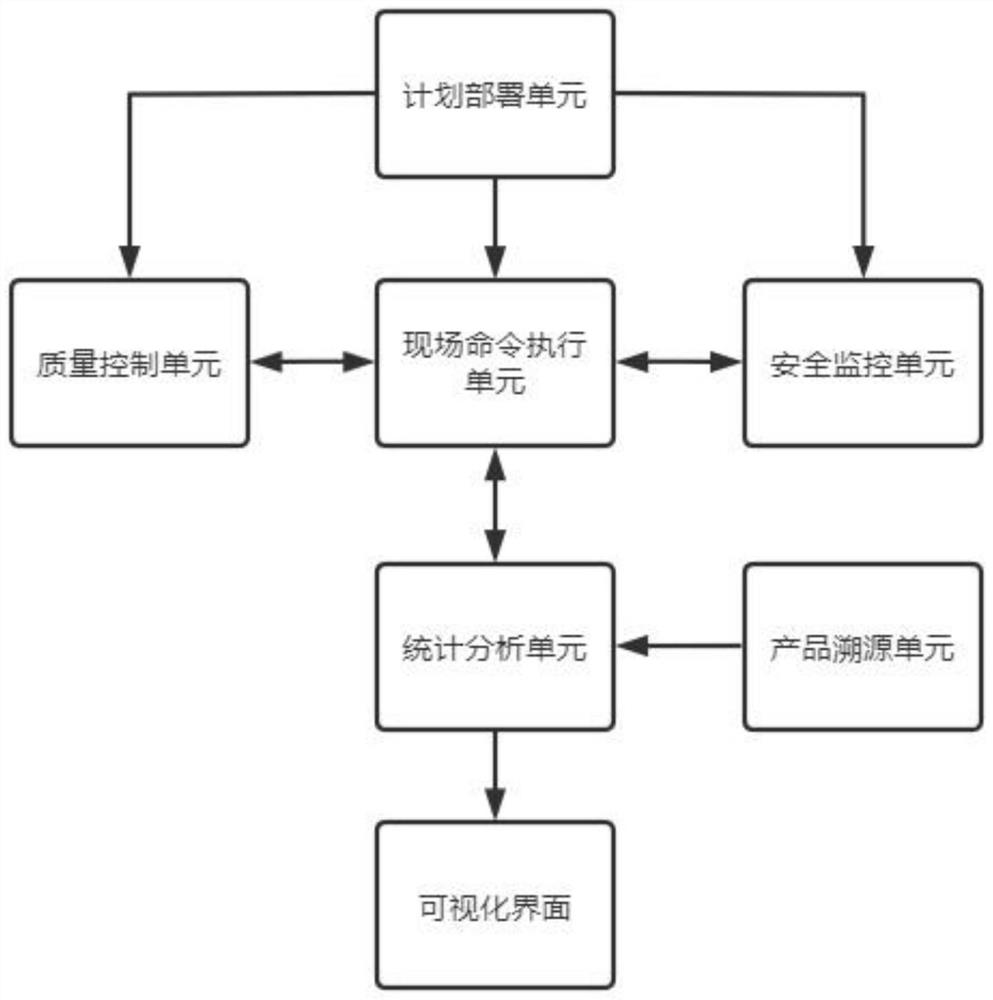

Digital intelligent workshop lightweight MES management system

PendingCN114742347AEfficient integrationAchieve integrationResourcesLogisticsInformatizationStatistical analysis

The invention discloses a digital intelligent workshop lightweight MES management system, and relates to the technical field of MES workshop management. The problem of low production efficiency is solved. The system specifically comprises a plan deployment unit used for setting specific production indexes according to production tasks, a field command execution unit used for implementing order production, a quality control unit used for controlling product quality, a safety monitoring unit used for monitoring a product production workshop, and a statistical analysis unit used for counting order data information. The product tracing unit is used for tracing detailed processes before, during and after product processing; and the visual interface is used for displaying data parameters of processed products. According to the invention, scattered production data information is effectively integrated, combination of product digitization and process standardization is realized, unnecessary time waste is avoided, intelligent management of workshop orders and integration of production and supply business process informatization can be realized, production efficiency is improved, and later responsibility investigation is facilitated.

Owner:宁夏巨能机器人股份有限公司

Numerically-controlled machine tool with automatic feeding and discharging functions and using method of numerically-controlled machine tool

PendingCN114147600AReduce scratchesImprove reliabilityGrinding carriagesGrinding drivesNumerical controlElectric machinery

The invention discloses a numerical control machine tool with an automatic feeding and discharging function and a using method thereof, and relates to the technical field of numerical control machine tools. Comprising a storage assembly used for storing to-be-processed glass and processed glass, the storage assembly comprises a material frame and a material frame arranged in the material frame, the rotary feeding and discharging assembly is used for taking the glass out of the storage assembly and putting the glass in the storage assembly, and the rotary feeding and discharging assembly comprises a rotary motor. By arranging the storage assembly, the double-manipulator Y-axis assembly, the double-manipulator Z-axis assembly and the X / Y / Z-axis set on the machine tool, four pieces of glass can be machined, loaded and unloaded at the same time, each grinding head can independently move up and down, the reliability is good, the long-term use stability is good, the expansibility is high, and the machine tool can be suitable for single-axis or double-axis or multi-axis grinding. Product feeding and discharging and automatic machining of a three-axis machine tool and a four-axis machine tool are achieved, a frame inserting mode is adopted for product feeding and discharging, scratches in the glass taking and placing process are reduced, the next procedure of products can be better connected, the production rate is improved, and manpower is saved.

Owner:深圳市中科智联数控设备有限公司

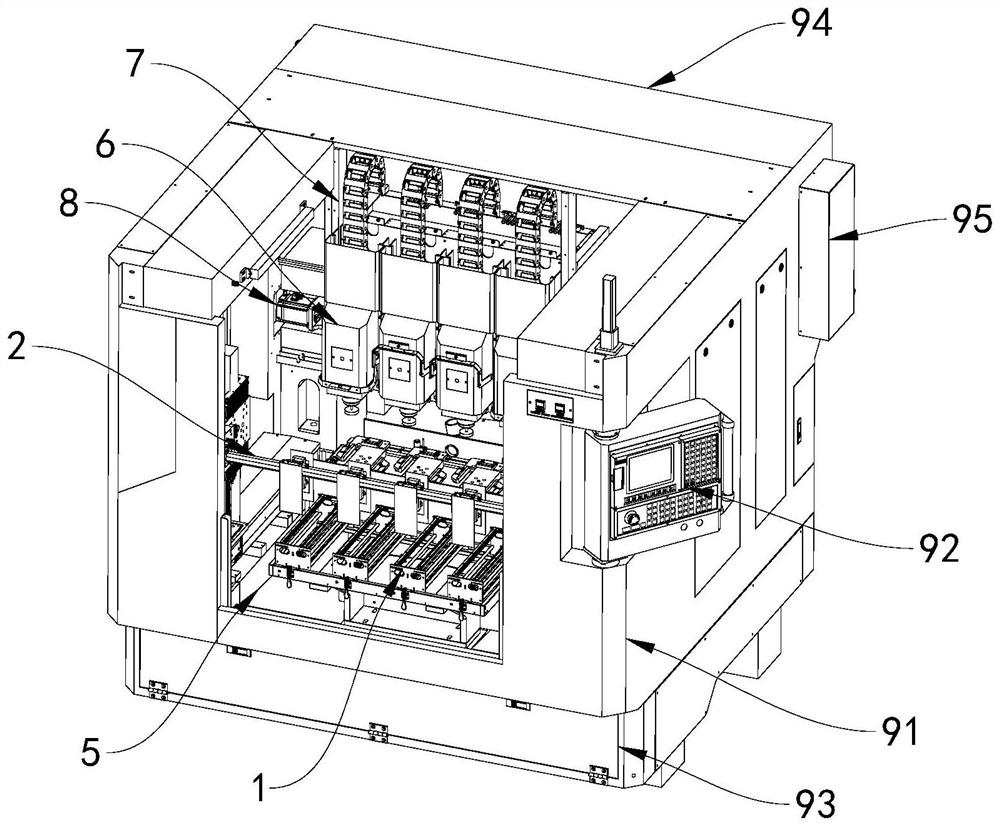

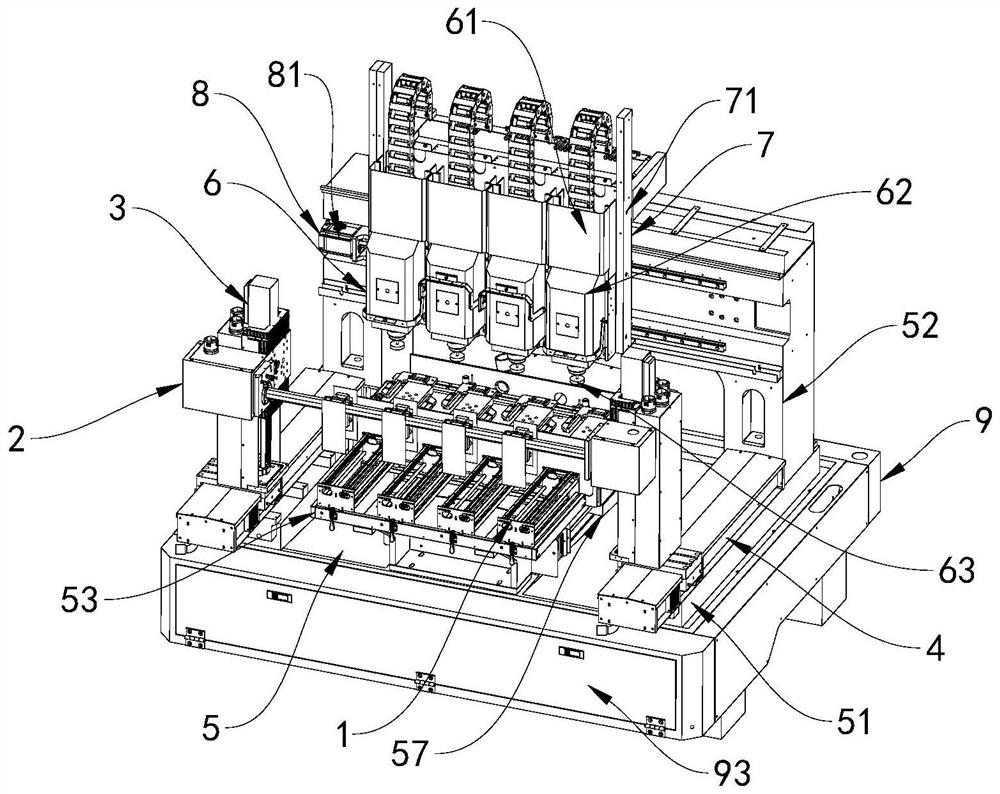

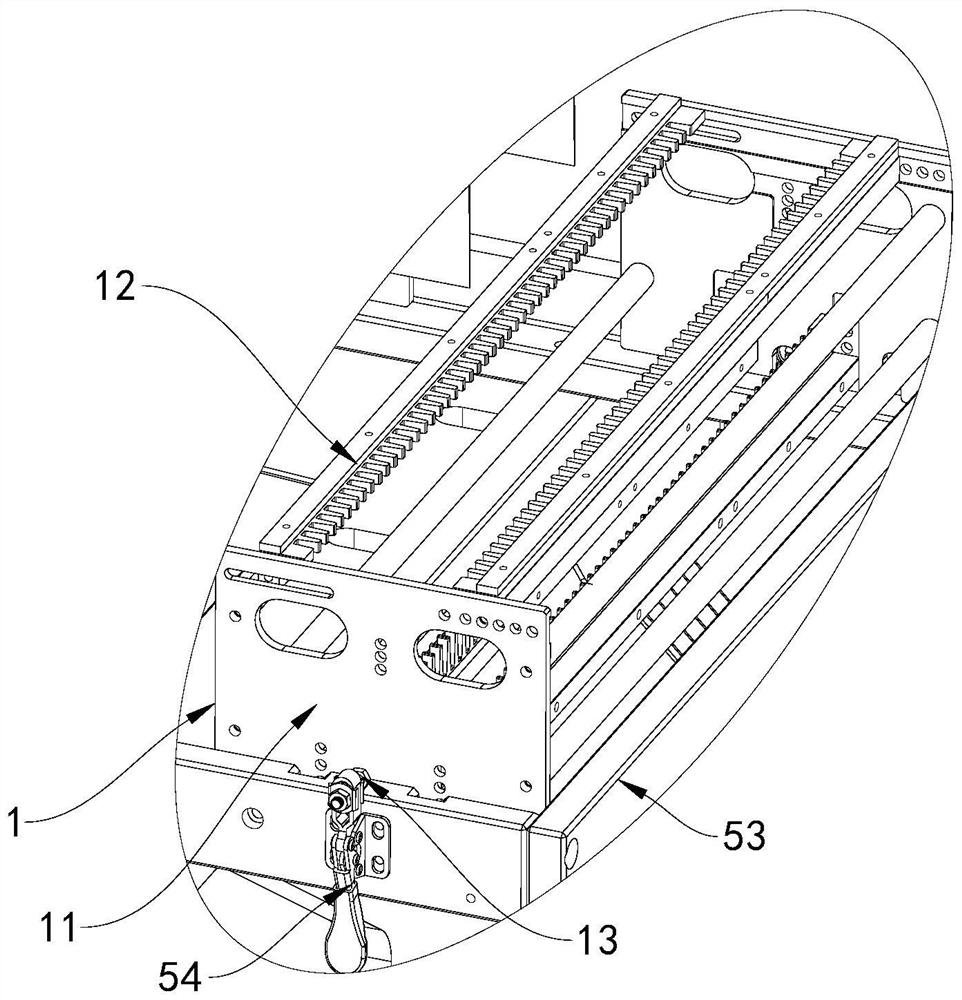

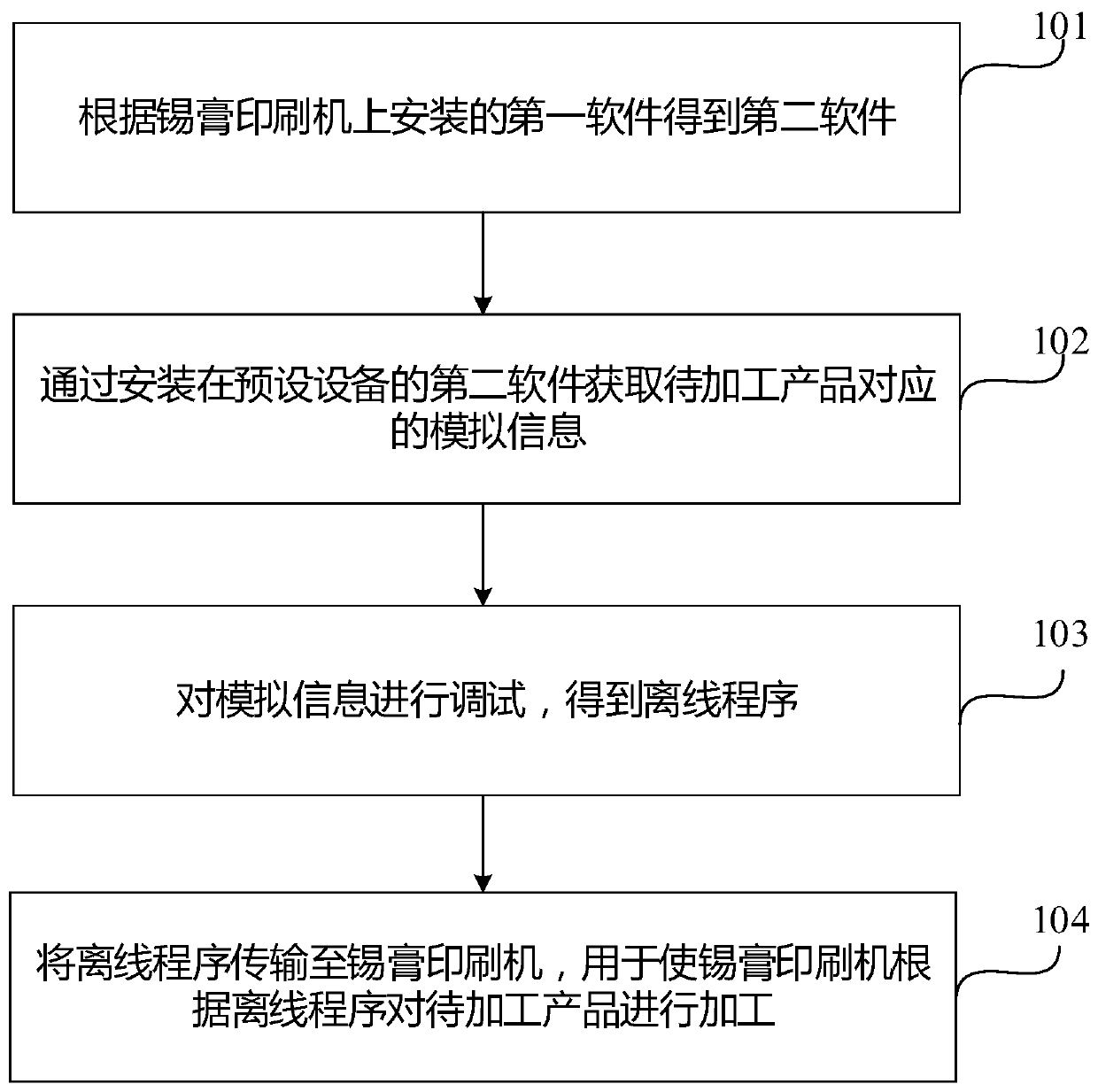

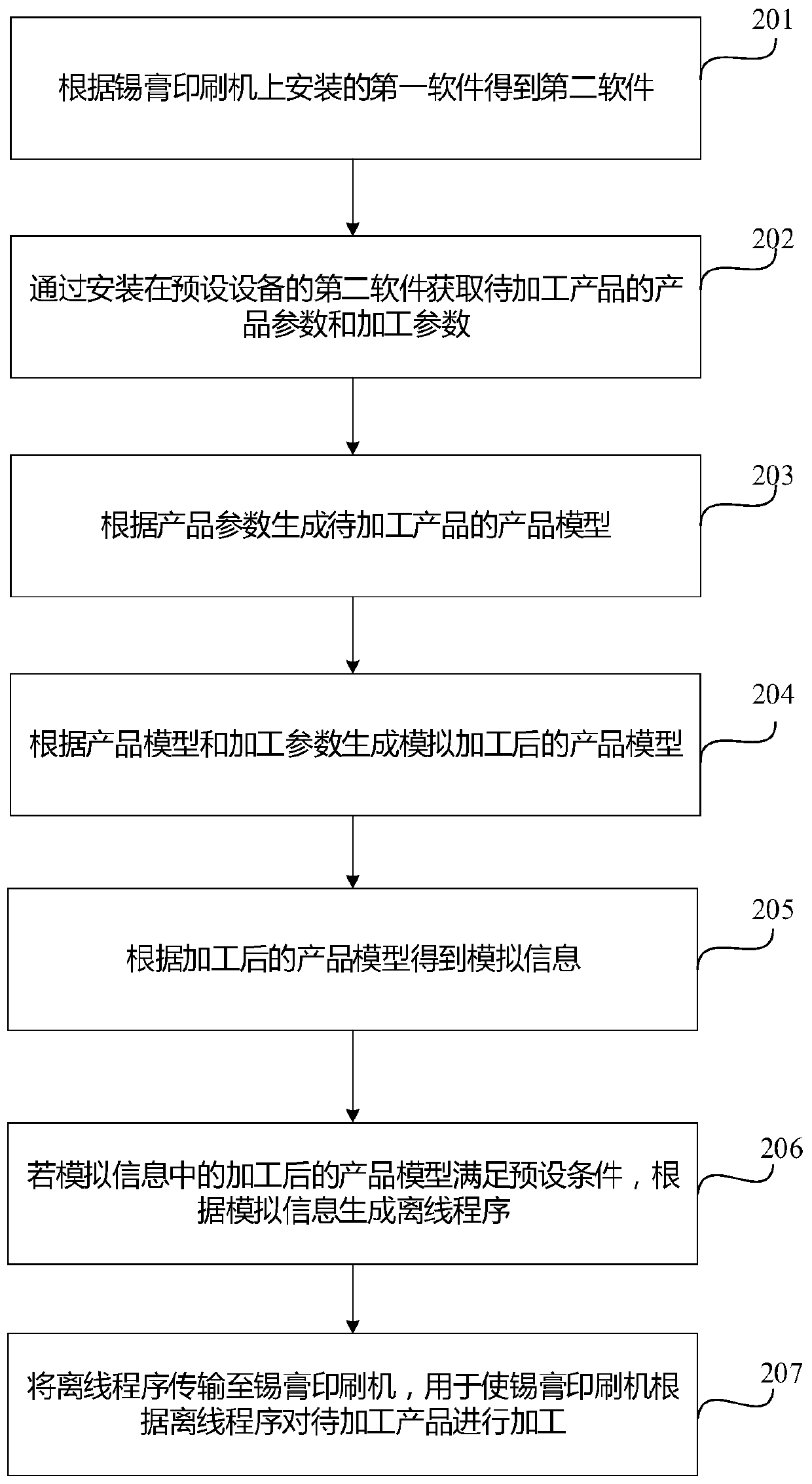

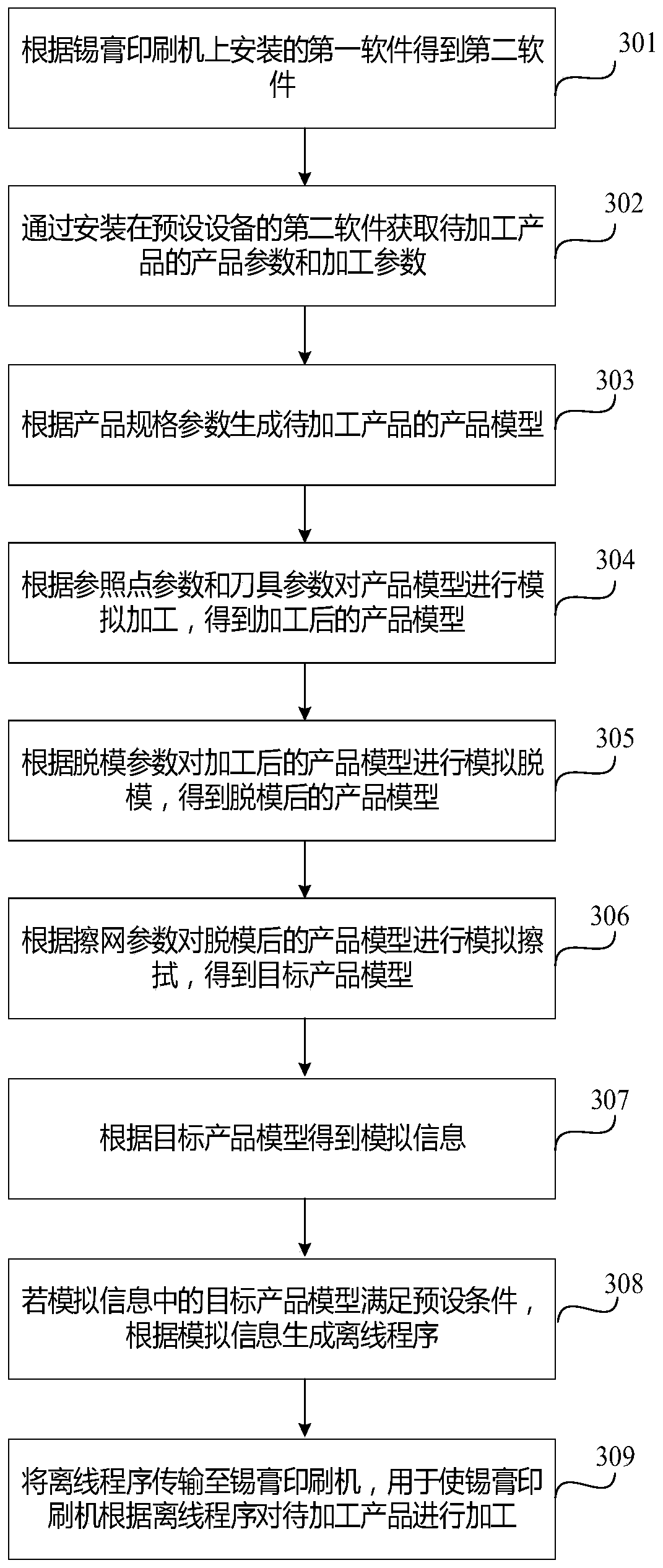

Program offline production method and device, storage medium and electronic equipment

ActiveCN111427591AIncrease productivityTotal factory controlSoftware deploymentProcess engineeringPrinting press

The embodiment of the invention provides a program offline manufacturing method and device, a storage medium and electronic equipment, the program offline manufacturing method is applied to a solder paste printing machine, and the program offline manufacturing method comprises the steps of obtaining second software according to first software installed on the solder paste printing machine; obtaining simulation information corresponding to the to-be-processed product through the second software installed in preset equipment; debugging the simulation information to obtain an offline program; transmitting the offline program to the solder paste printing machine, wherein the offline program is used for enabling the solder paste printer to process the to-be-processed product according to the offline program and generating an offline target program capable of being used for processing on external equipment; in the production application of the solder paste printing machine, if different products need to be processed, line stop waiting is not needed to carry out line changing debugging on the solder paste printing machine, and the production efficiency of the solder paste printing machineis improved.

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

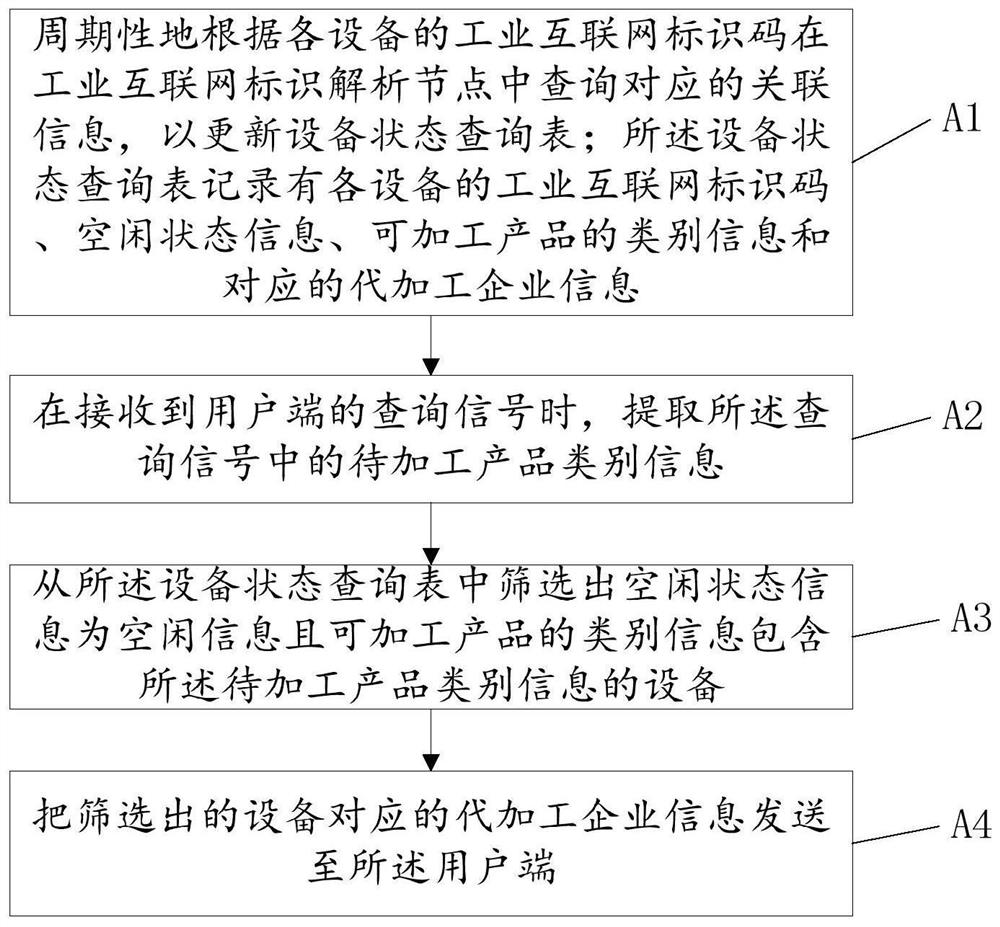

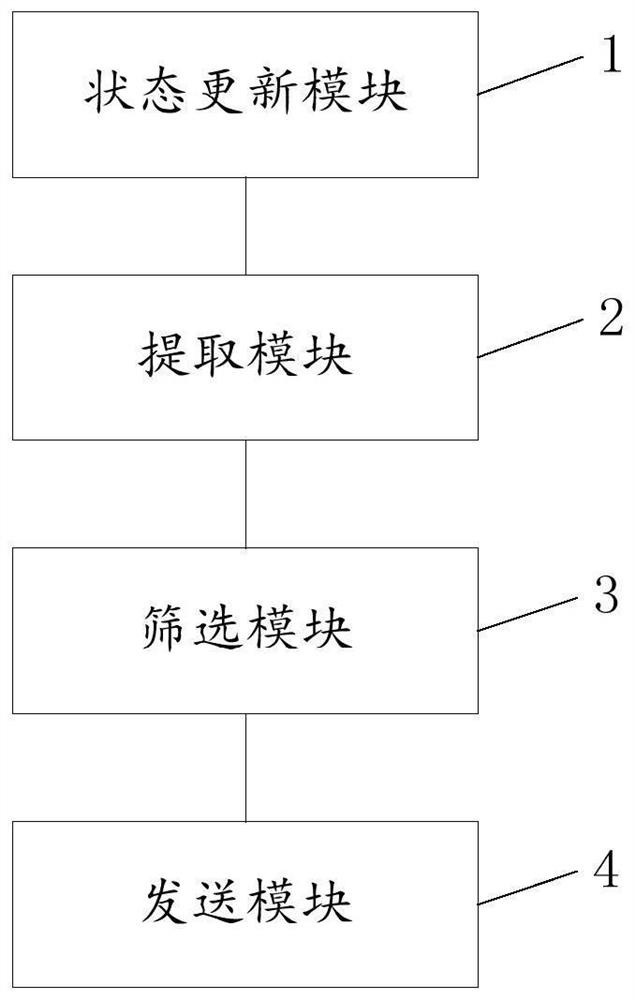

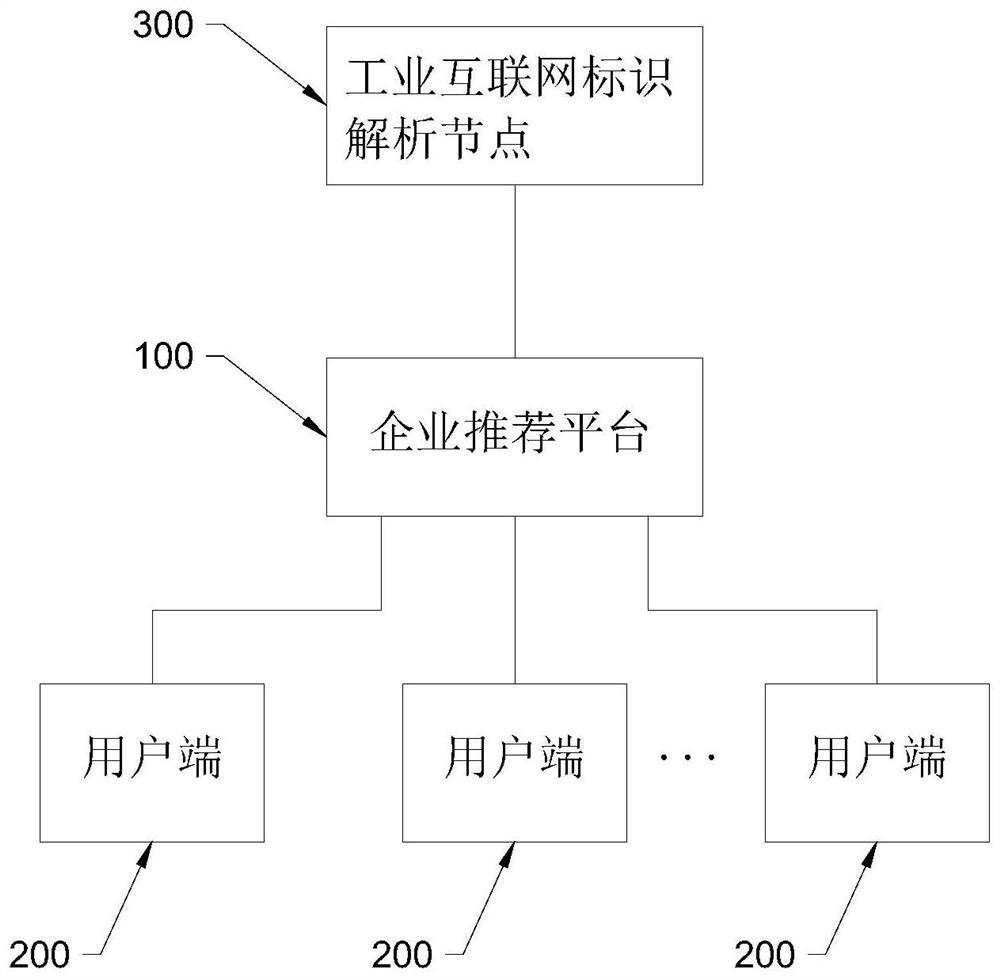

Enterprise recommendation method, device and system based on industrial internet identifier

PendingCN113779404AEasy to findDigital data information retrievalData processing applicationsBusiness enterpriseThe Internet

The invention relates to the technical field of data management, and particularly provides an enterprise recommendation method, device and system based on an industrial internet identifier, which comprises the following steps: periodically querying corresponding associated information in an industrial internet identifier analysis node according to an industrial internet identifier code of each device so as to update a device state query table; when a query signal of a user side is received, extracting category information of a to-be-processed product in the query signal; screening out equipment of which the idle state information is idle information and the category information of processable products contains the category information of the to-be-processed products from an equipment state query table; sending to-be-processed enterprise information corresponding to the screened equipment to the user side. Therefore, the processing enterprise with the corresponding production capacity and idle production equipment can be recommended to the user according to the production demand of the user, so that the user can find the proper processing enterprise more conveniently.

Owner:广东省智能家电研究院

A kind of processing method of bracket product

ActiveCN112496686BChange the processing methodReduce manufacturing costPrecision positioning equipmentOther manufacturing equipments/toolsSurface mountingMachining process

The present invention relates to the technical field of bracket processing, especially a processing method for bracket products, comprising the following steps: the first step: positioning the bracket on the equipment; the second step: installing the support; the third step: pressing the bracket; the fourth Step 1: Processing the lower mounting surface of the bracket and the mounting holes of the lower part; Step 5: Remove the support and install the side support frame; Step 6: Process the internal plane of the product; Step 7: Process the side mounting surface of the product and the holes on the surface; Step 8: Process the surface hole of the second mounting surface of the product; Step 9: Process the second mounting surface of the product; Step 10: Process the mounting surface 3 of the product and the holes on the surface; Step 11: Disassemble the workpiece. The processing technology and processing equipment of this bracket product realizes one set of equipment for one operator and one set of equipment for one positioning and clamping, and then completes all the processing content of the product, which greatly reduces the manufacturing cost of the product and improves the product quality. Precision.

Owner:CRRC QISHUYAN CO LTD

Assembling method of heat exchanger

ActiveCN113458778AEasy to adjustAssembly machinesMetal working apparatusAcquisition apparatusProcess engineering

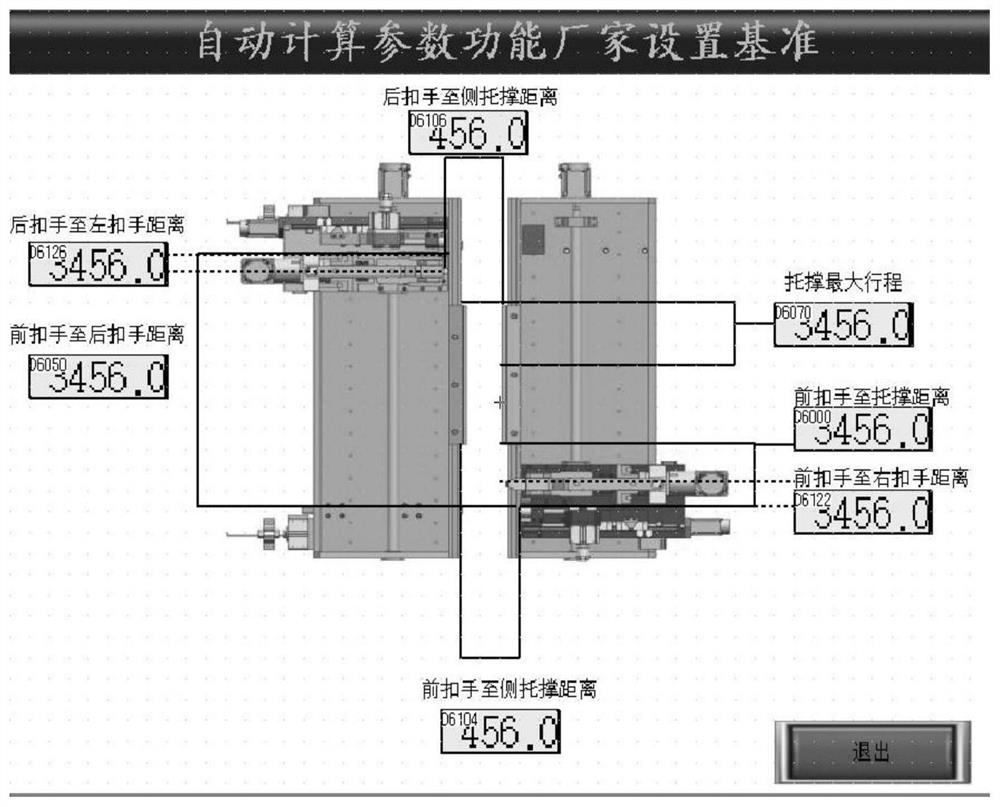

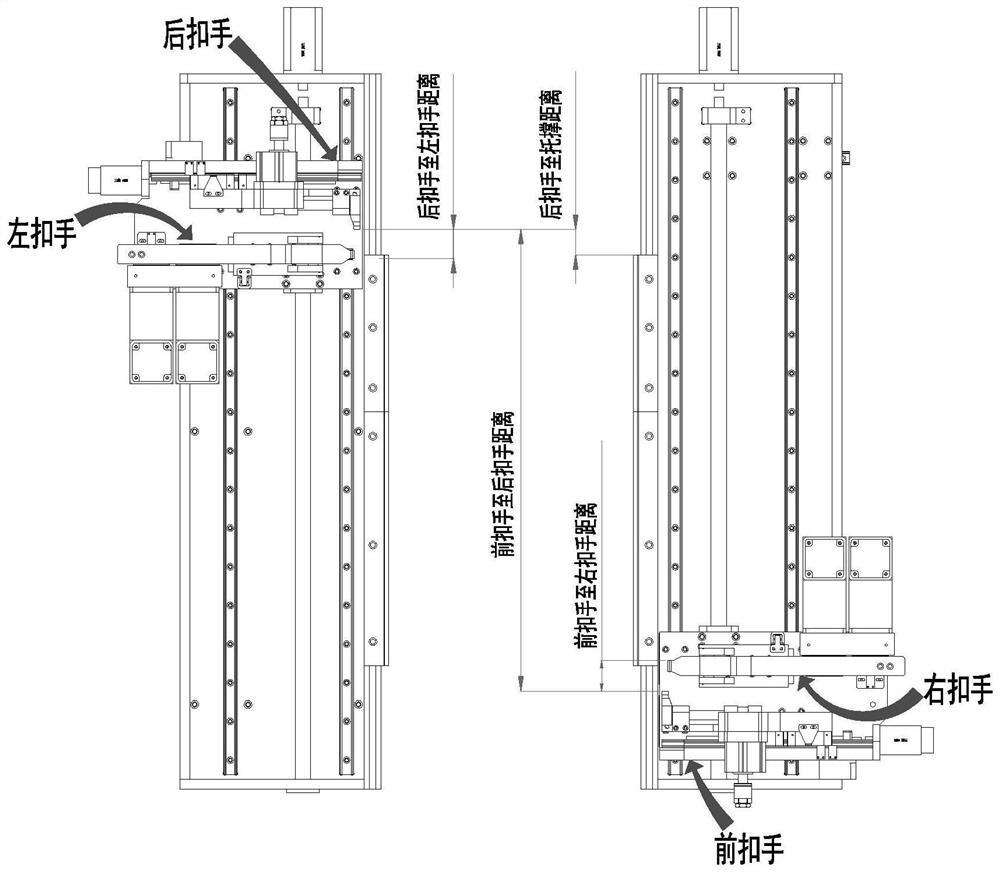

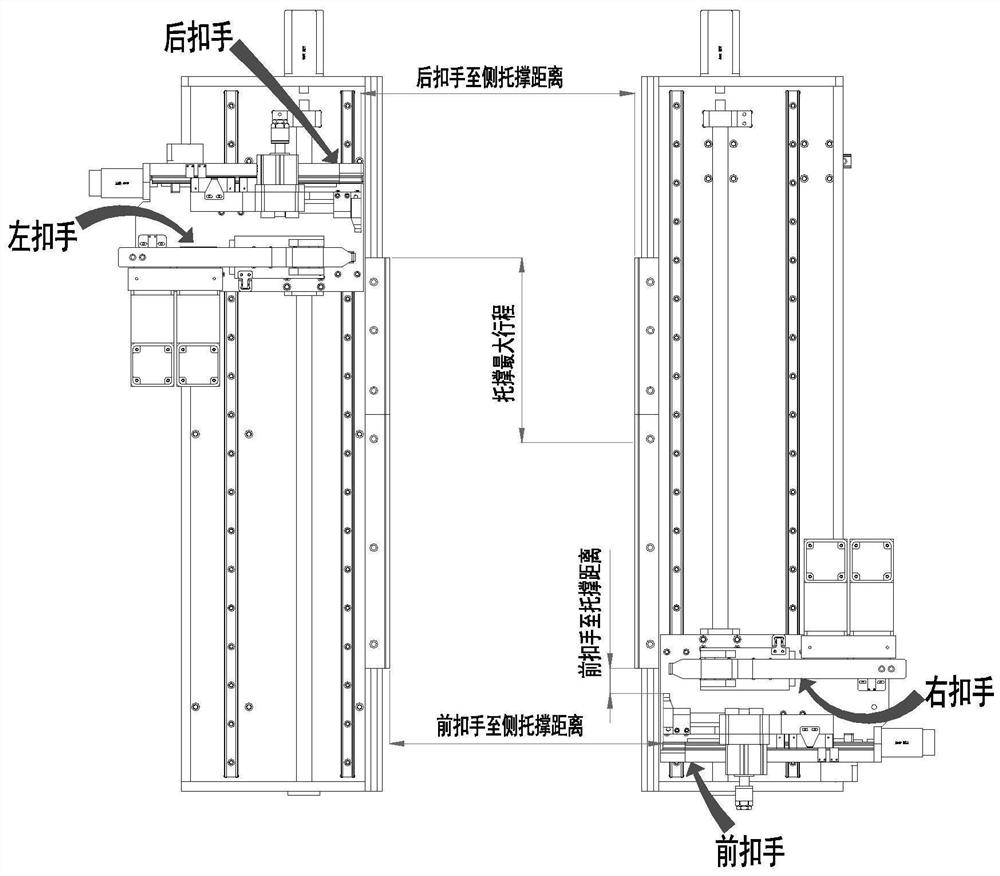

The invention discloses an assembling method of a heat exchanger. The assembling method comprises the steps that S1, a model is established based on equipment parameters and product characteristics; S11, zero correction is carried out on a front buckle, a rear buckle, a left buckle and a right buckle; S12, buckle parameters, support parameters and associated parameters of the buckles and a support are collected; S13, a matching model is established based on the relevance between the product characteristics and the parameters collected in S12; S2, parameters of a to-be-machined product are input; S3, the model is called to be matched with the to-be-machined product, and equipment operation parameters are generated; and S4, product clamping, tool setting and production are completed. According to the assembling method of the heat exchanger, the equipment parameters are collected, the relevance between the equipment parameters (the buckles and the support) and the product parameters is explored, the universality model is established, then the equipment operation parameters can be quickly generated according to the input parameters of the to-be-machined product, then an operator perfects the machining process program of the product by referring to the operation program, and repeated adjustment records do not need to be carried out, so that rapid machine adjustment is realized.

Owner:福建省鑫锐机械设备有限公司

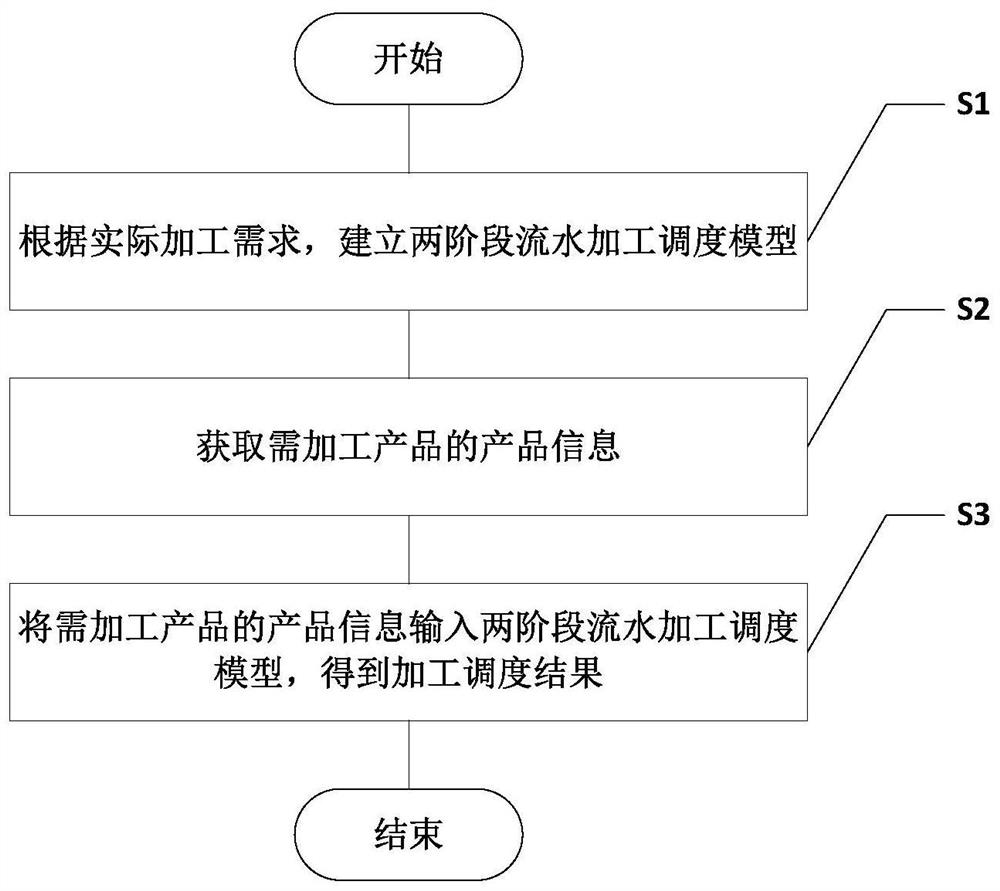

A Two-Stage Flow Processing Scheduling Method

ActiveCN112101820BOptimal Scheduling SchemeUninterrupted productionForecastingResourcesProcess engineeringWater processing

Owner:埃克斯工业有限公司

Method and apparatus for processing stone fruit

PendingUS20210244065A1Overcomes drawbackProduct quality can be optimisedJuice extractionFruit stoningHuskMechanical engineering

A method for processing fruit (10) that has a central stone (11) and flesh (12) surrounding the stone, said method comprising the steps of:—positioning the fruit (10) inside a casing (2) in which a rotating element (3) rotates, said casing (2) comprising at least one outlet hole (21);—removing from the stone (11) at least a part of the flesh (12) attached to the stone (11); The step of removing from the stone (11) at least a part of the flesh (12) attached to the stone (11) comprises the step of pushing the fruit (10) by centrifugal force against the casing (2) and bringing said rotating element (3) into contact with the flesh (12) until the stone (11) manages to pass through said at least one outlet hole (21). The method further comprises the steps of:—obtaining a semi-processed product downstream of the casing (2) formed by the stone (11) and the flesh (12) that was separated from the stone (11);—making said semi-processed product pass through a sieve (4) that retains the stone (11) allowing the passage of the flesh (12).

Owner:CFT SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com