Machine and method for processing a continuous semi-processed product

A technology for semi-finished products and equipment, which is applied in the manufacture of inductors/transformers/magnets, electric components, coils, etc., and can solve problems such as processing productivity limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

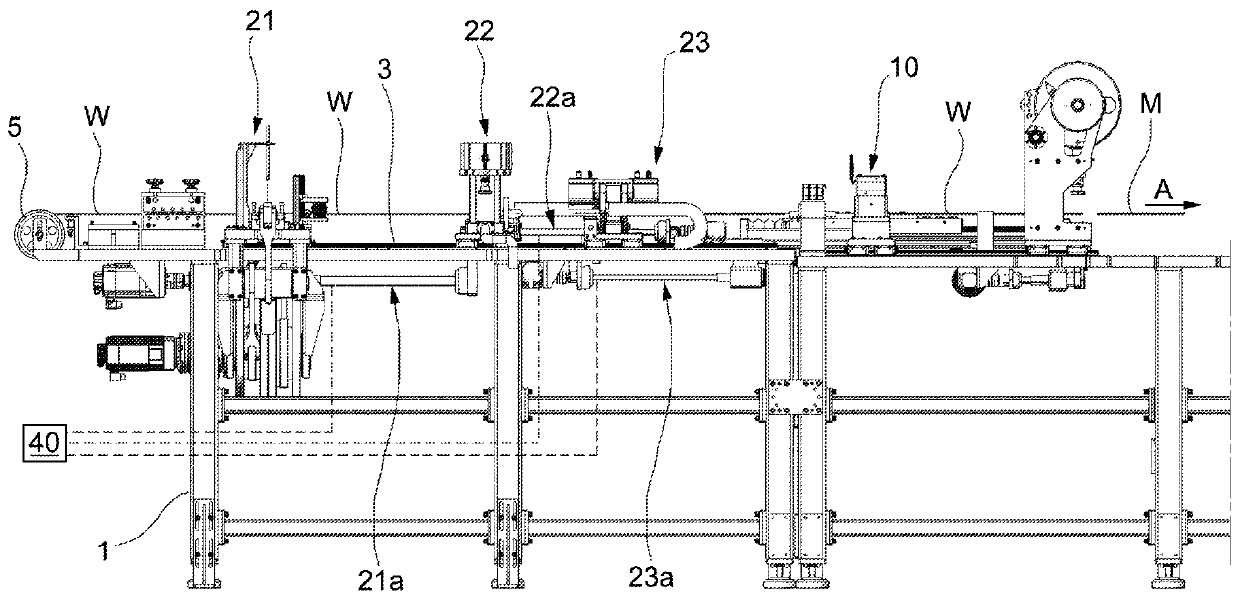

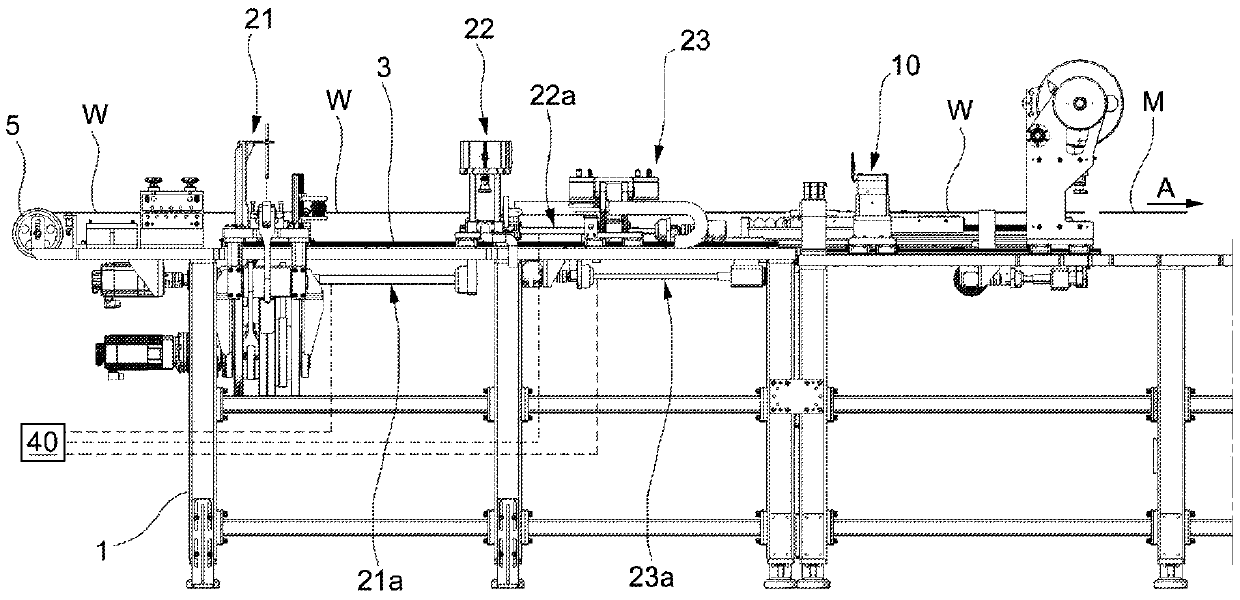

[0035] figure 1 Shown is a plant for processing continuous semi-finished products, in particular continuous conductive rods or wires coated with a sleeve of insulating material.

[0036] The plant comprises a support frame 1 on top of which comprises a processing path 3 along which a continuous semi-finished product W is moved forward according to the feed direction indicated by the arrow A. In the example shown, the continuous semi-finished product W is unwound from the winding reel 5 .

[0037] The shown plant also comprises a feed unit or station 10 arranged to move the semi-finished product W forward along the feed direction A according to feed steps which can be varied, as will be explained later. The feed unit 10 may comprise, for example, drive rollers which engage the outer surface of the semi-finished product and which movement causes the semi-finished product W to move forward. According to other embodiments suitable for other types of semi-finished products, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com