Digital intelligent workshop lightweight MES management system

A management system and a lightweight technology, applied in the field of MES workshop management, can solve the problems that the MES system cannot integrate the production line, the node plan and the operation plan of the production schedule, cannot be supervised in time, and the production efficiency of the digital workshop is low. Achieve the effect of ensuring product processing quality, facilitating later accountability, and realizing intelligent management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

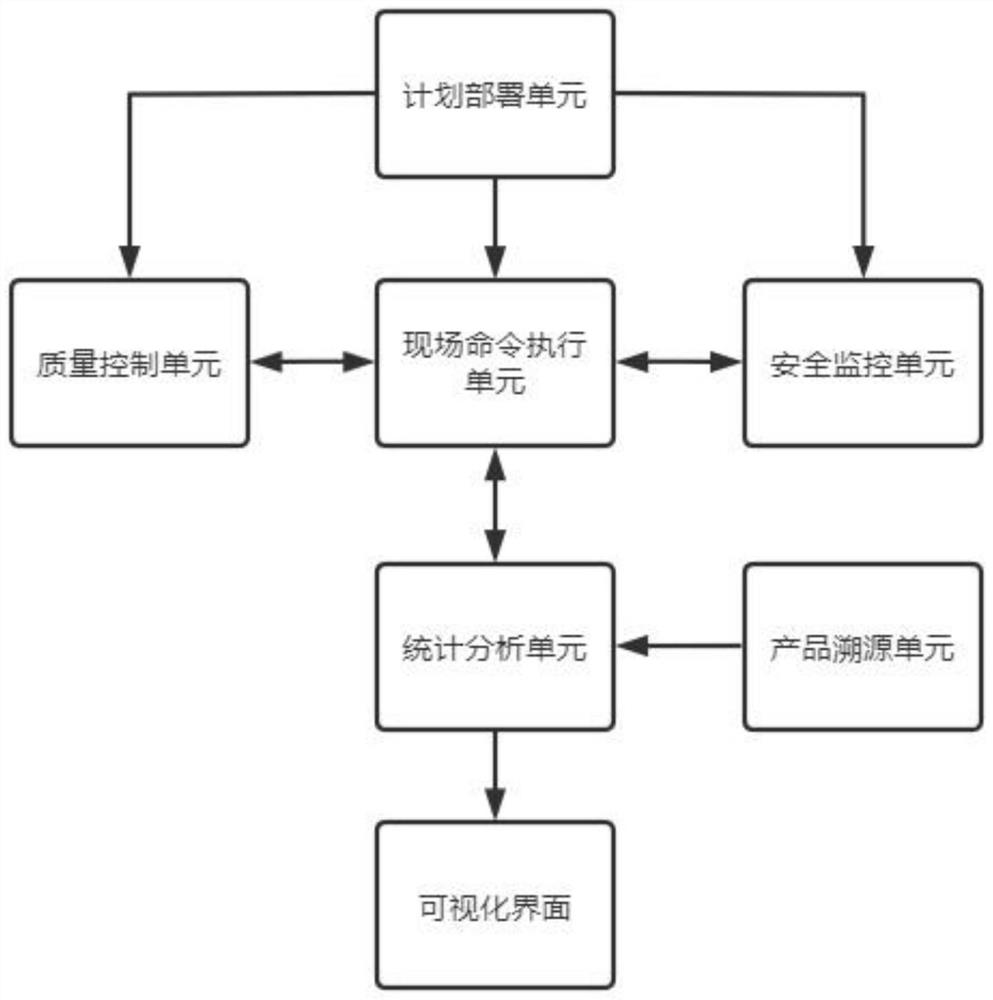

[0036] A lightweight MES management system for digital intelligent workshop, such as figure 1 As shown, it includes a plan deployment unit for setting specific production indicators according to production tasks, an on-site command execution unit for implementing order production, a quality control unit for controlling product quality, and a monitoring unit for product production workshops. A safety monitoring unit, a statistical analysis unit used to count order data information, a product traceability unit used to trace the detailed process before, during and after product processing, and a visual interface used to display data parameters of processed products; the planned deployment The unit is in communication connection with the on-site command execution unit, the quality control unit and the safety monitoring unit; the on-site command execution unit is in communication connection with the quality control unit, the safety monitoring unit and the statistical analysis unit; ...

Embodiment 2

[0059] A lightweight MES management system for digital intelligent workshop, such as figure 1 As shown, in order to further flexibly regulate production tasks; this embodiment makes the following improvements on the basis of Embodiment 1: the planned deployment unit also includes a preparatory remedy module for deploying products that are unqualified or equipment failures, etc. A release module for allocating task orders and production requirements in the production workshop; the release module is used to release task requirements to the product production workshop, such as production internal / external factors, task volume, completion cycle, etc.; through the preparatory remedial module, it is convenient to quickly do Provide alternatives to substandard products or malfunctioning equipment to reduce business losses.

[0060] When this embodiment is in use, the release module is used to release task requirements to the product production workshop, such as production internal / ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com