Process route modeling method and system for manufacturing execution system

A technology of manufacturing execution system and process route, which is applied in the field of vehicles, can solve problems such as low circulation efficiency and process route solidification, and achieve the effect of simple and complete process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

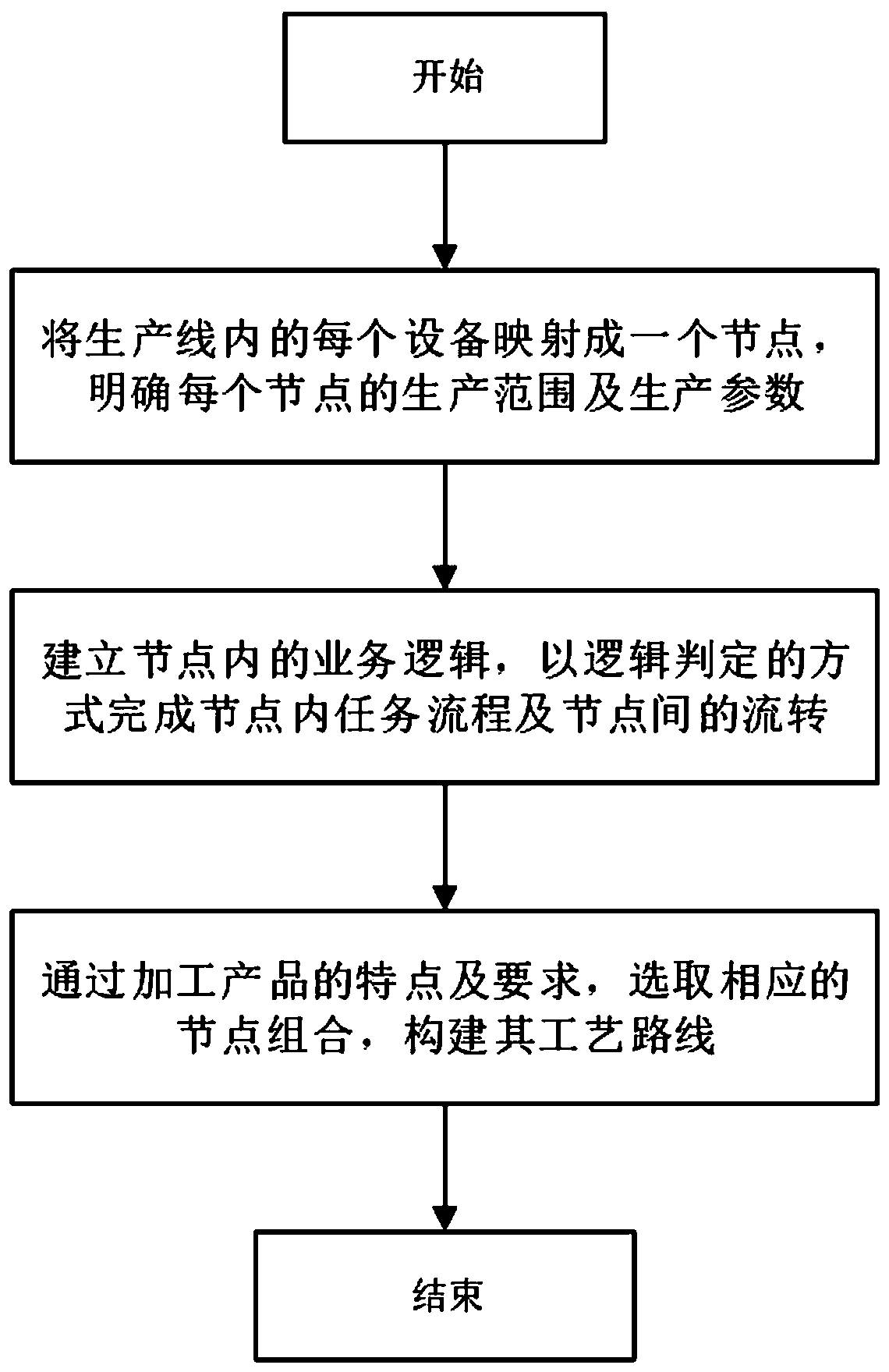

Method used

Image

Examples

Embodiment 2

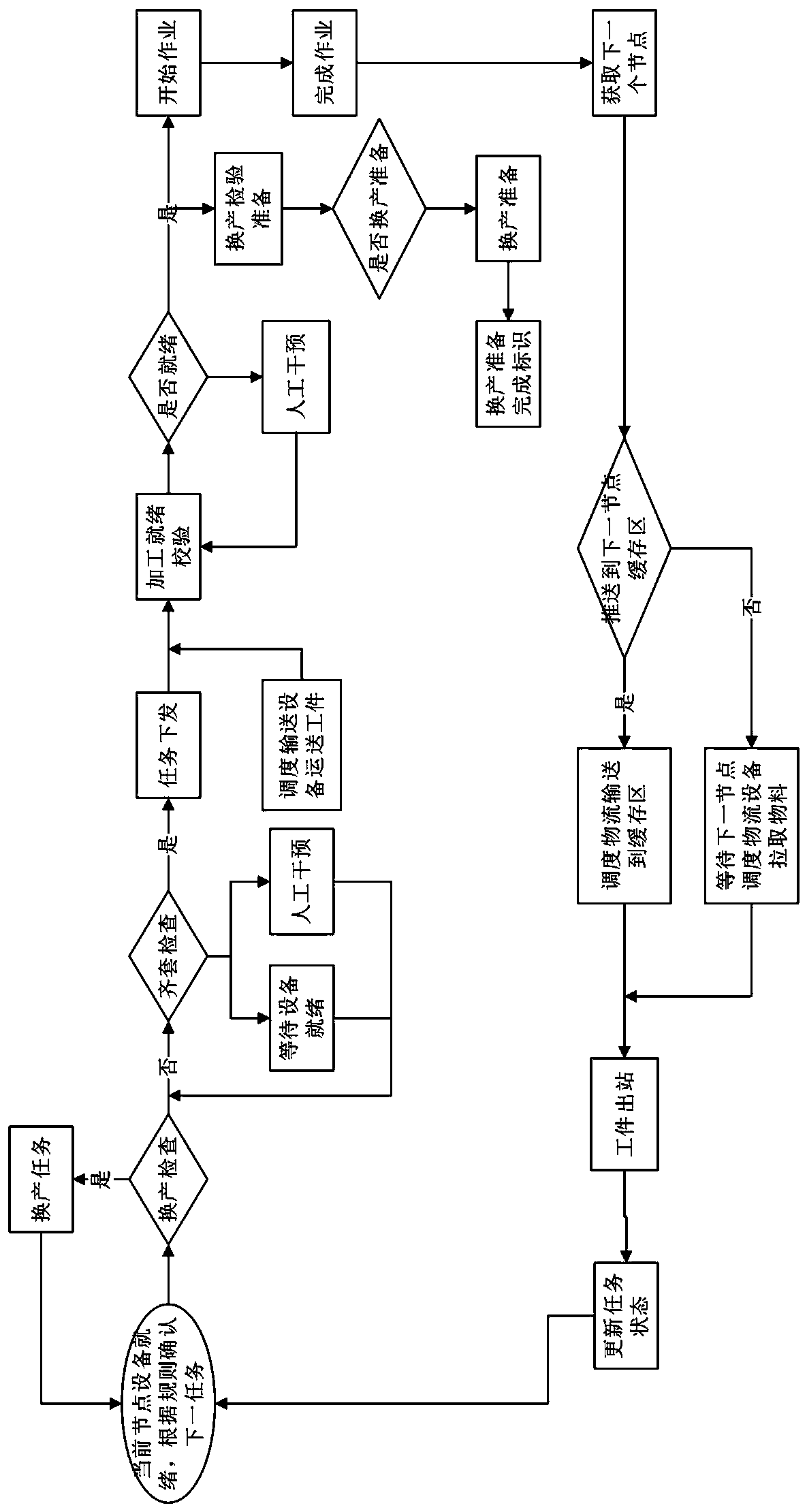

[0157] Embodiment 2 is a modification of embodiment 1

[0158] For the production queue of the manufacturing execution system of the flexible replacement production line, the production sequence is constructed in the form of dynamic reconstruction to improve production efficiency. like Figure 5 as shown,

[0159] Further, the basic approach is that there are several production sequences in the control system of the entire production line, and there are different parts A, B, etc. in these production sequences.

[0160] Furthermore, when A is processed and then B is processed, we need to change the production process formula slightly. If it is artificially replaced, it may not be possible for the heavy fixtures to be humanly accessible. We need AGV to carry the fixtures and other preparations for production change.

[0161] Furthermore, if you just wait for the processing of product A to be completed, and then issue a production replacement preparation command in the manageme...

Embodiment 3

[0167] Embodiment 3 is a variation of embodiment 1

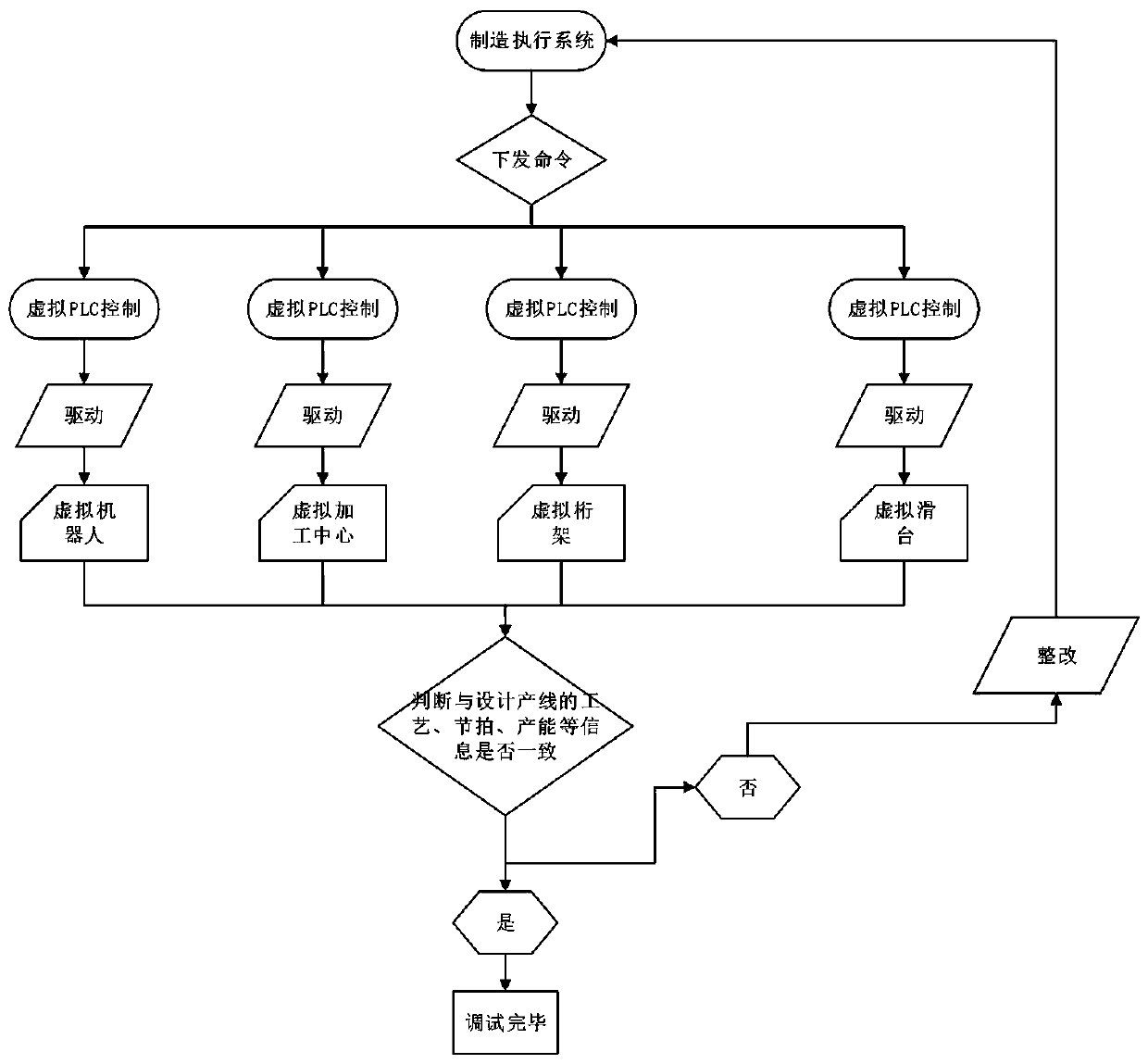

[0168] Embodiment 3 discloses a virtual commissioning method integrated with manufacturing execution system and production line, see image 3 As shown, the method includes:

[0169] Step N01: Judging whether the control result of the virtual PLC program is the same as that of the real PLC program, see Figure 4 shown;

[0170] Step N02: Use the written virtual PLC program to control the operation of the virtual production line. If the production capacity, tempo and process information of the virtual production line are the same as those of the designed production line, it means that the control results of the virtual PLC program and the real PLC program are the same ;

[0171] Step N03: If the production capacity, tempo and process information of the virtual production line under the control of the manufacturing execution system are different from the designed production line, then gradually modify the virtual PLC program...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com