Processing method of cadmium oxide target material

A processing method and cadmium oxide technology, which are applied in metal processing equipment, manufacturing tools, machine tools suitable for grinding workpiece planes, etc., can solve the problems of inability to effectively control the surface roughness of the target material, low processing efficiency, and surface chipping. , to achieve the effect of improving processing effect, improving quality and reducing heat consumption and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

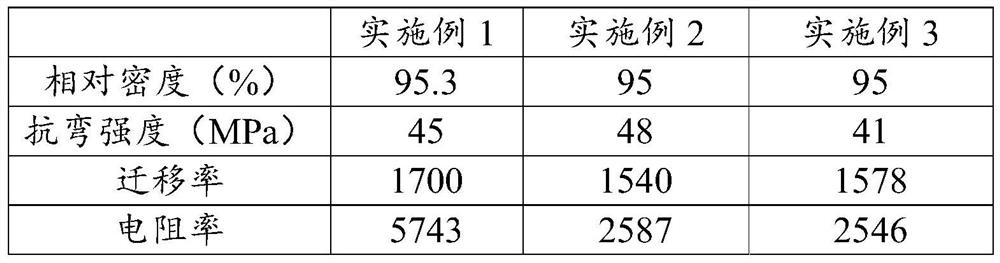

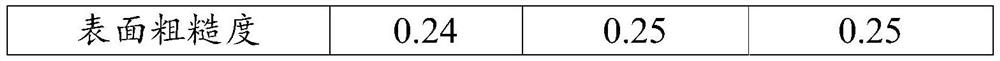

Embodiment 1

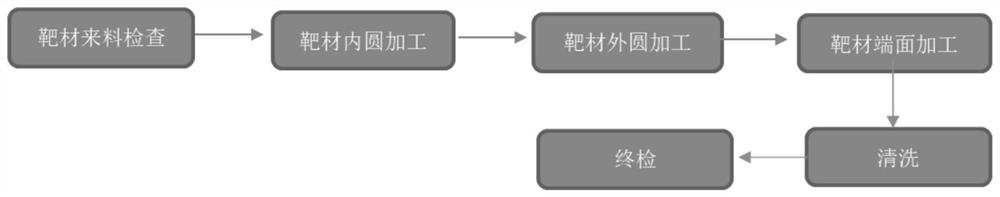

[0025] An embodiment of the processing method of the cadmium oxide target in the present invention, the process is as follows figure 1 shown, including the following steps:

[0026] (1) Check the size, density and surface integrity of the cadmium oxide rotating target to avoid abnormal raw materials, and start the processing equipment at the same time;

[0027] (2) Processing of the inner circle of the target: Place the cadmium oxide target on the chuck of the grinder, adjust the air pressure of the pneumatic chuck to 0.3MPa to clamp the target, align it with the position of the tool feed, and perform the inner circle position of the target in turn. Rough machining and finishing treatment; the rough machining process adopts a resin diamond grinding wheel with a grinding wheel mesh number of 60 meshes, and the finishing treatment adopts a grinding wheel mesh number of 250 mesh resin diamond grinding wheels to carry out;

[0028] The rotational speed of the resin diamond grindi...

Embodiment 2

[0038] An embodiment of the processing method of the cadmium oxide target in the present invention comprises the following steps:

[0039] (1) Check the size, density and surface integrity of the cadmium oxide rotating target to avoid abnormal raw materials, and start the processing equipment at the same time;

[0040] (2) Processing of the inner circle of the target: Place the cadmium oxide target on the chuck of the grinder, adjust the air pressure of the pneumatic chuck to 0.3MPa to clamp the target, align it with the position of the tool feed, and perform the inner circle position of the target in turn. Rough machining and finishing treatment; the rough machining process adopts a resin diamond grinding wheel with a grinding wheel mesh number of 60 meshes, and the finishing treatment adopts a grinding wheel mesh number of 250 mesh resin diamond grinding wheels to carry out;

[0041] The rotational speed of the resin diamond grinding wheel during the rough processing is set ...

Embodiment 3

[0051] An embodiment of the processing method of the cadmium oxide target in the present invention comprises the following steps:

[0052] (1) Check the size, density and surface integrity of the cadmium oxide rotating target to avoid abnormal raw materials, and start the processing equipment at the same time;

[0053] (2) Processing of the inner circle of the target: Place the cadmium oxide target on the chuck of the grinder, adjust the air pressure of the pneumatic chuck to 0.3MPa to clamp the target, align it with the position of the tool feed, and perform the inner circle position of the target in turn. Rough machining and finishing treatment; the rough machining process adopts a resin diamond grinding wheel with a grinding wheel mesh number of 60 meshes, and the finishing treatment adopts a grinding wheel mesh number of 250 mesh resin diamond grinding wheels to carry out;

[0054] The rotational speed of the resin diamond grinding wheel during the rough processing is set ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com