Assembling method of heat exchanger

An assembly method and heat exchanger technology, applied in assembly machines, metal processing, metal processing equipment, etc., can solve problems such as low efficiency, increasing the workload and labor intensity of technicians, affecting equipment utilization rate and OEE indicators, etc. To achieve the effect of rapid adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

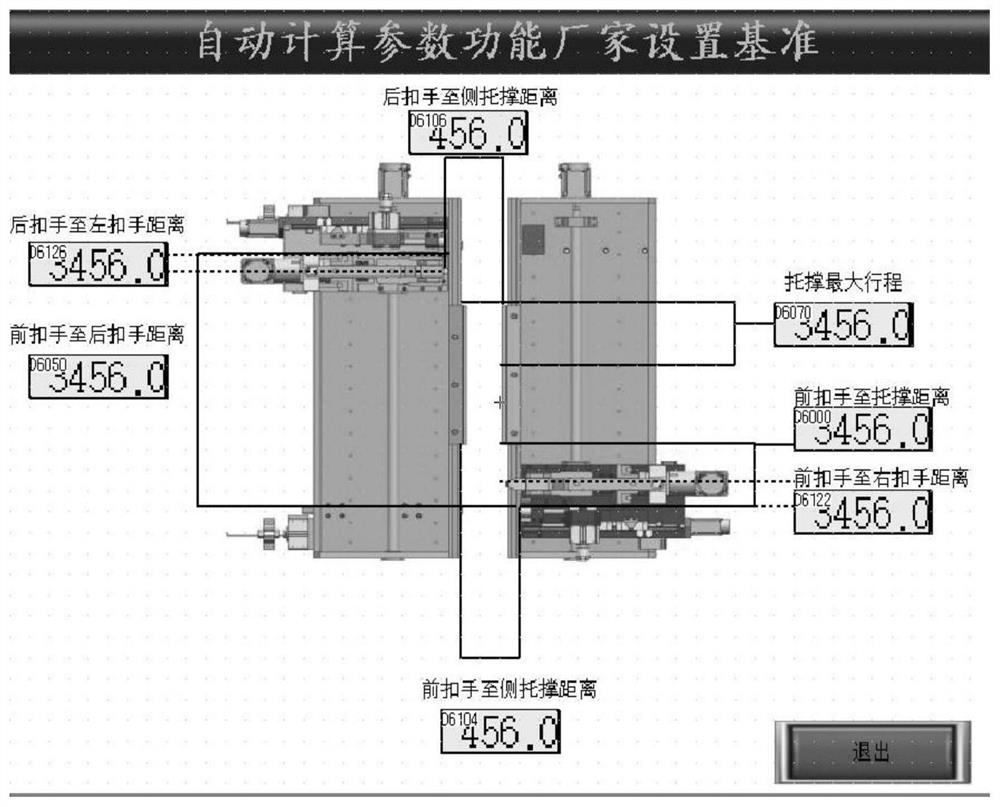

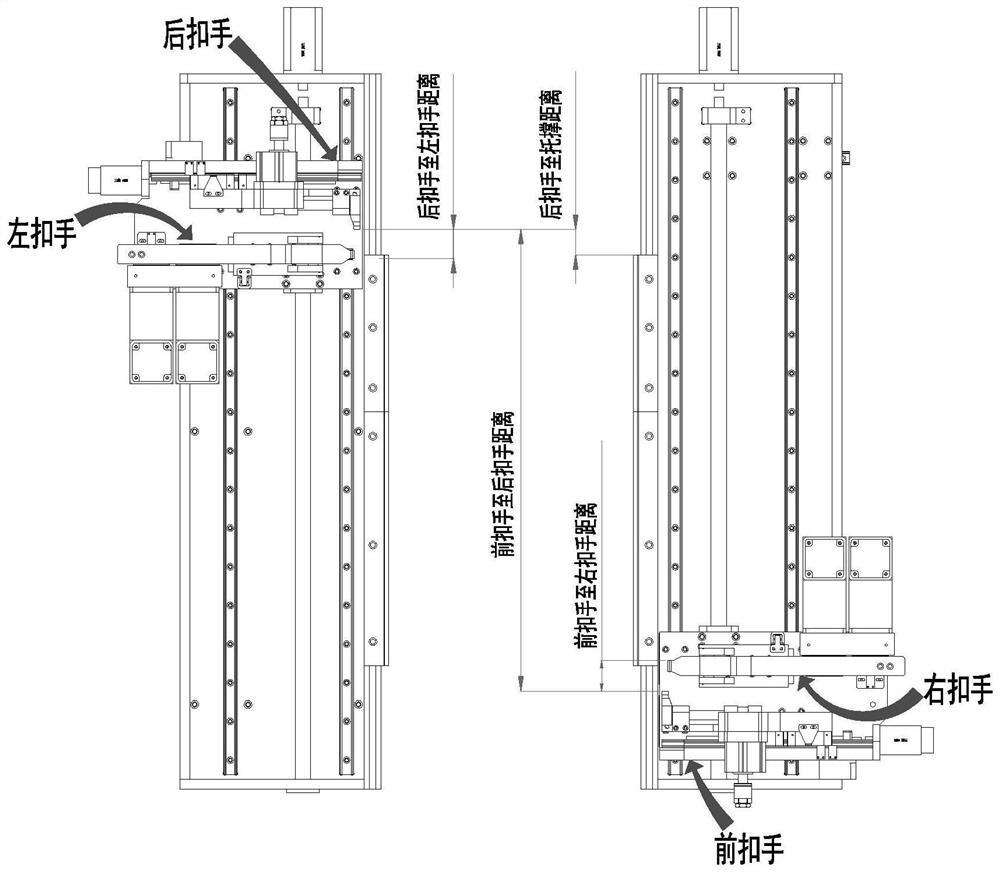

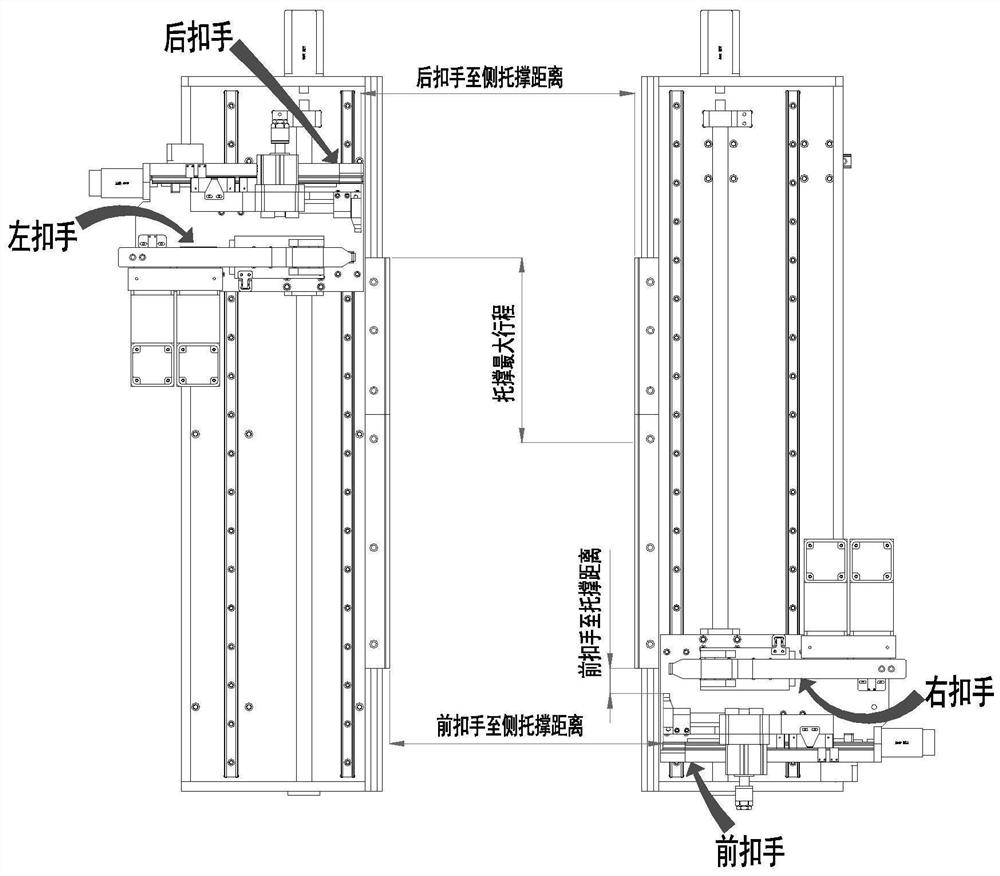

[0048] The present invention discloses an assembly method of a heat exchanger, in order to understand, first, a brief description of the correlation between the equipment and the product, the device can be referenced Figure 1 - Figure 3 Products Figure 4 . In this application, Figure 1-4 The view is the same, that is, the front button is pressed by the right left to complete the front teeth (ie, the teeth of the front side of the front side), and the rear button is subjected to the back to the right to complete the post-teeth (ie the back side of the short side). Rebudes; the left buckle manually completes the press of the left tooth (ie, the left side of the teeth), and the right buckle is sequentially completed by the right tooth (ie the right side of the teeth). .

[0049] Please refer to Figure 5 As shown, the present invention is mainly including the steps of:

[0050] S1, based on device parameters and product characteristics establish models;

[0051] S11, for the front buc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com