Methods and device for scheduling production of semiconductor products

A technology of production scheduling and scheduling methods, which is applied in the direction of instruments, manufacturing computing systems, data processing applications, etc., and can solve problems such as the impact of release strategies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

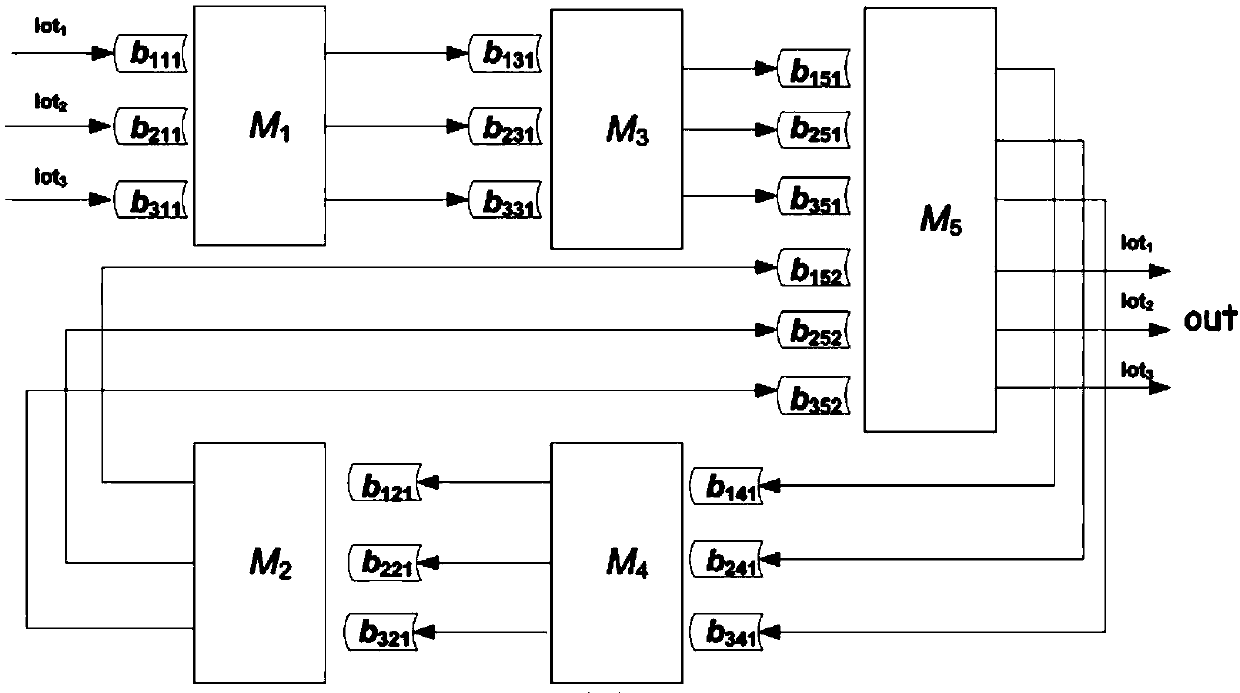

[0079] In order to clearly understand the semiconductor product production scheduling method of the embodiment of the present invention, figure 1 shows a simplified semiconductor production wafer layered flow model, in this layered flow model, there are five machine groups M 1 , M 2 , M 3 , M 4 and M 5 , process 3 different types of product lot 1 、lot 2 、lot 3 . The production process for each product is:

[0080] In->M 1 -> M 3 -> M 5 -> M 4 -> M 2 -> M 5 ->out.

[0081] It can be seen from the production process that each product has to pass through the machine group M 5 Twice, that is, for machine group M 5 Each product has two layers.

[0082] In the production process of semiconductor products, when the production line is in a steady state, for a certain layer of a certain machine group, for example, for the k-th layer of the j-th machine group, the product lot of the i-th product type i Within the predetermined time interval [t, t+Δt], the number of lot...

Embodiment 2

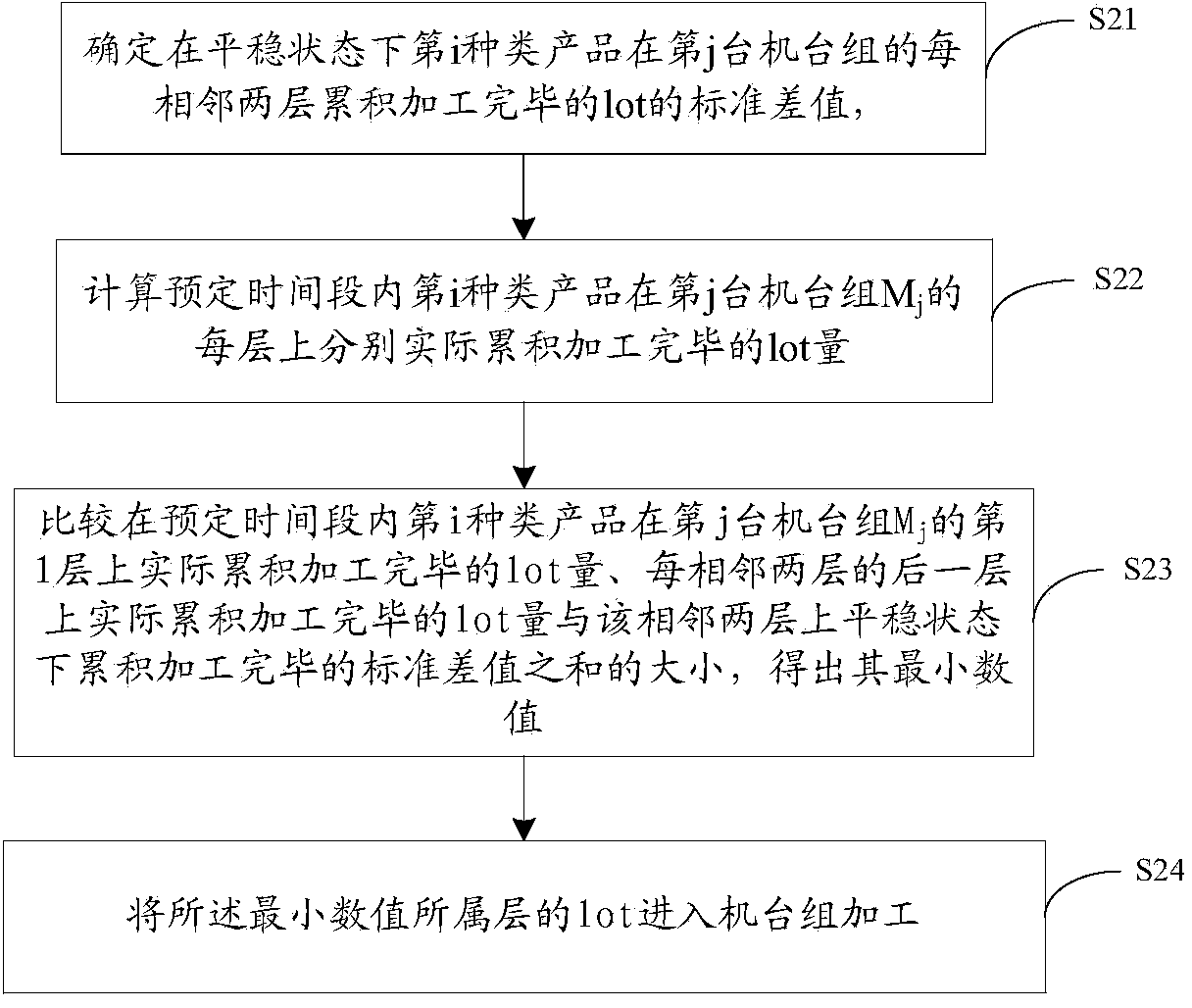

[0138] combine Figure 4 The semiconductor product production scheduling method according to Embodiment 2 of the present invention will be described in detail.

[0139] The semiconductor production scheduling method includes the following steps:

[0140] S41, obtain the current load I of the current lot quantity on the production line to the production line curr :

[0141] First of all, it needs to be explained that the load is the sum of the processing time on all machine groups from the current lot on the production line to the bottleneck machine group for the first time. Therefore, the current lot quantity on the production line is related to the current load I of the production line curr has the same dimension as time. The bottleneck machine group is a preset machine group. On a production line, multiple bottleneck machine groups can be set up. The machines in the bottleneck machine group are defined as those machines whose actual processing capacity is less than the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com