Copying machining fixture

A profiling processing and fixture technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of shaft scrapping, shaft deformation, difficult positioning, etc., and achieve the effect of improving quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

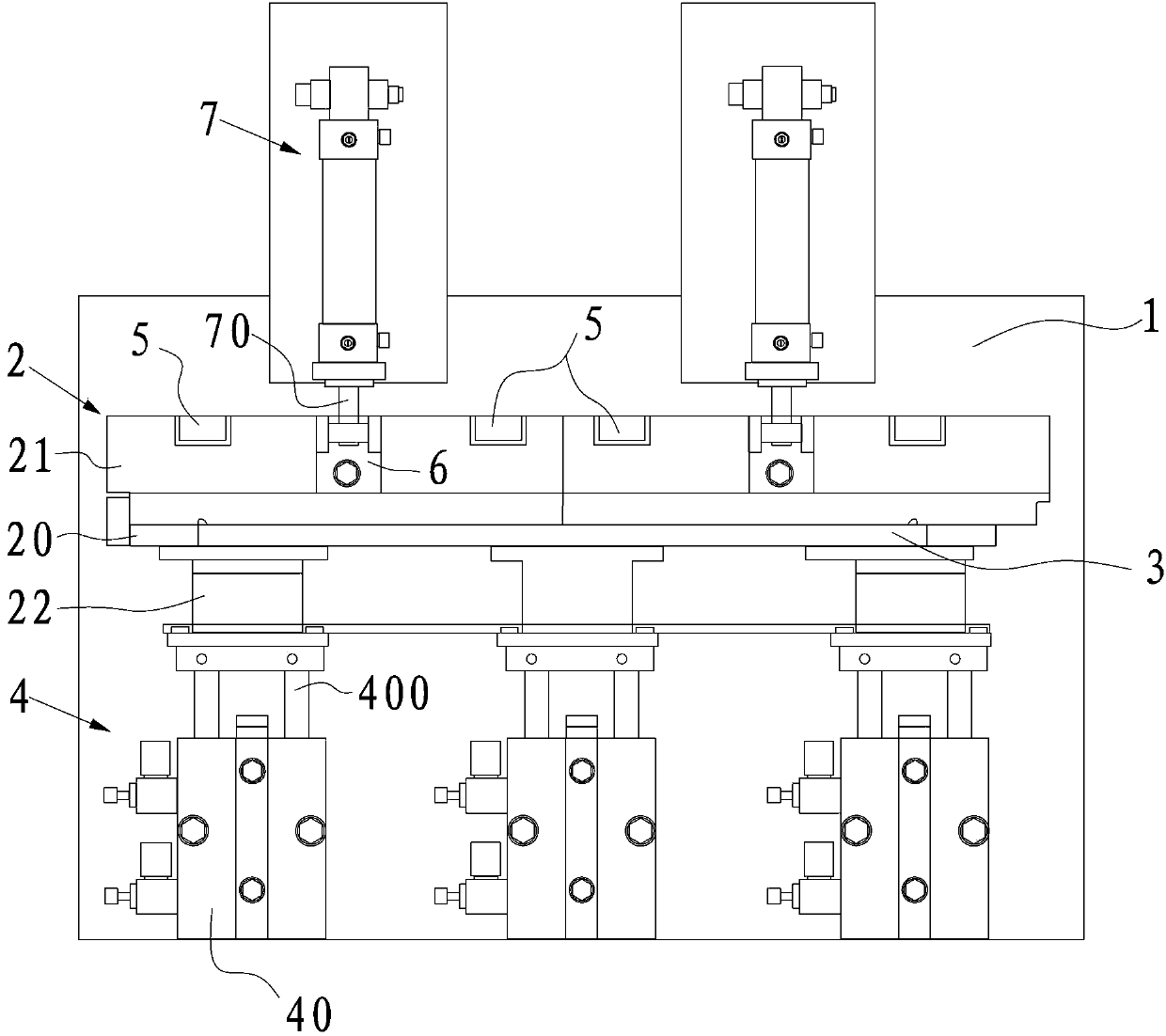

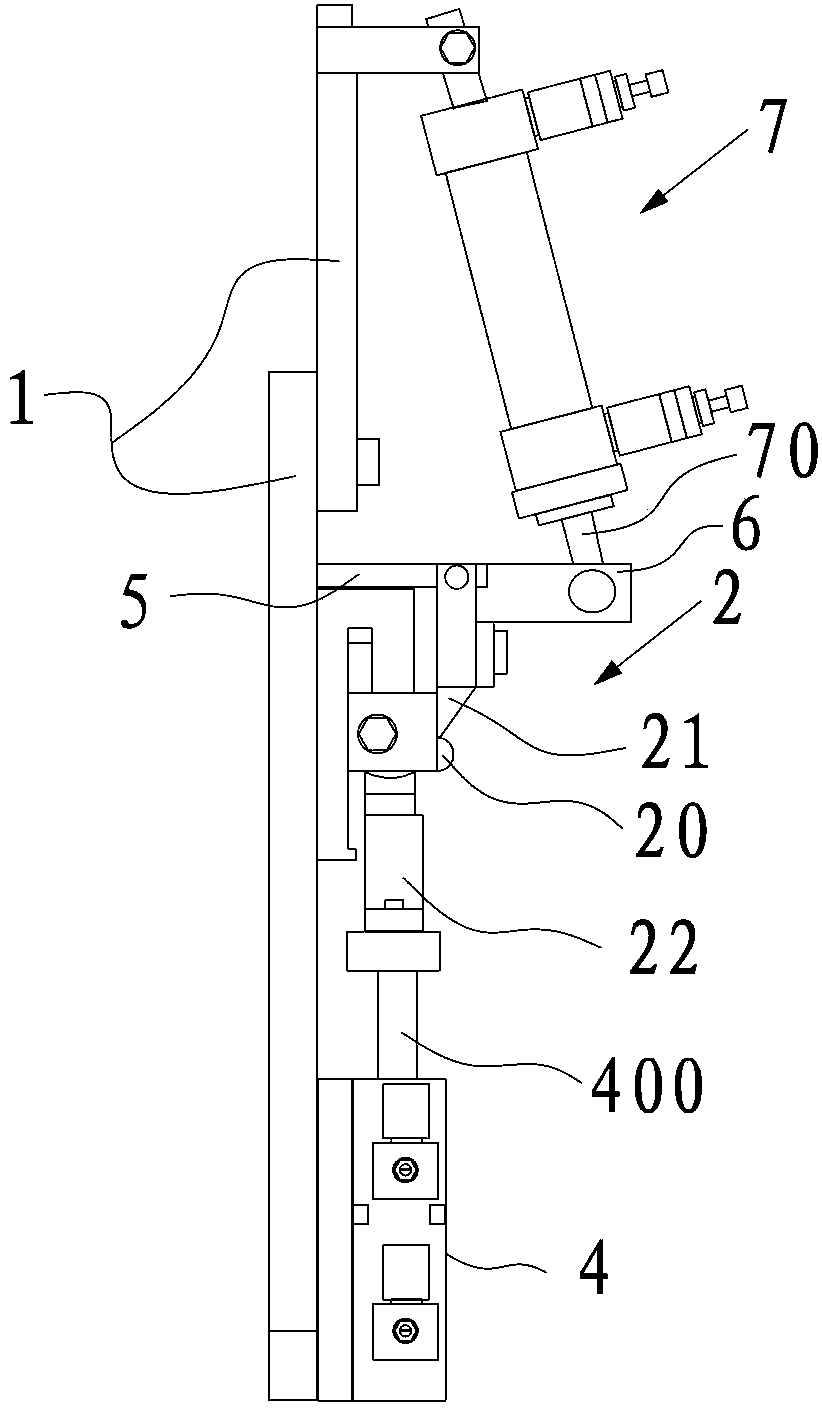

[0019] Such as figure 1 and figure 2 As shown, the profiling fixture provided in this embodiment is specifically used to fix the computer shaft, and its structure includes a base 1 and a positioning module 2 arranged on the base 1. The positioning module 2 has a shaft capable of placing the shaft. The type groove 3 extends along the length direction of the base 1 .

[0020] The above-mentioned positioning module 2 includes a first module 20 fixed on the base 1, and a second module 21 and a third module 22 whose splicing parts form the groove 3, wherein the first module 20 extends along the length direction of the groove 3 and its shape It is the same as the inner hole of the rotating shaft, and the rotating shaft can be inserted on the outer surface of the first module 20, the second module 21 is fixed on the base 1 and can touch the side of the rotating shaft, and the third module 22 can be along the width of the base 1 Move towards the second module 21 to adjust the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com