Automatic production line control method, device and system

A technology of automatic production line and control method, applied in the direction of general control system, control/regulation system, program control, etc., can solve the hidden dangers of production line process leakage, achieve the effect of solving insufficient storage space and improving confidentiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

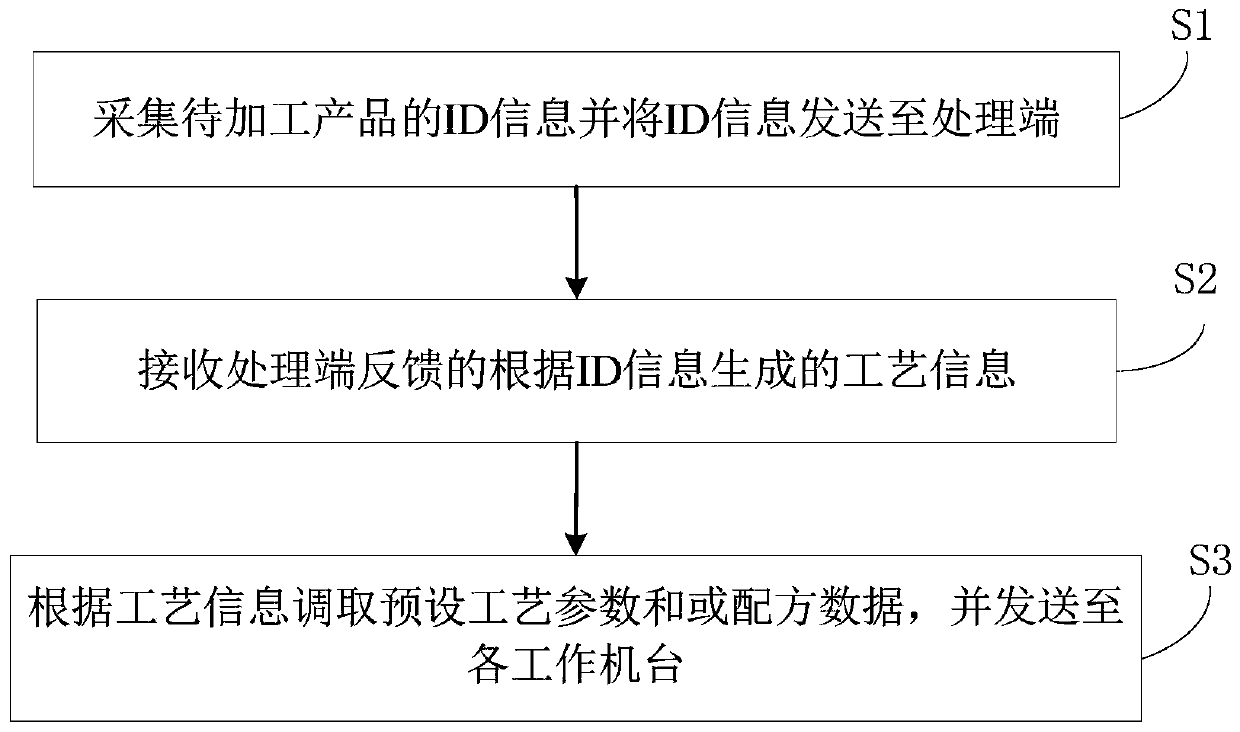

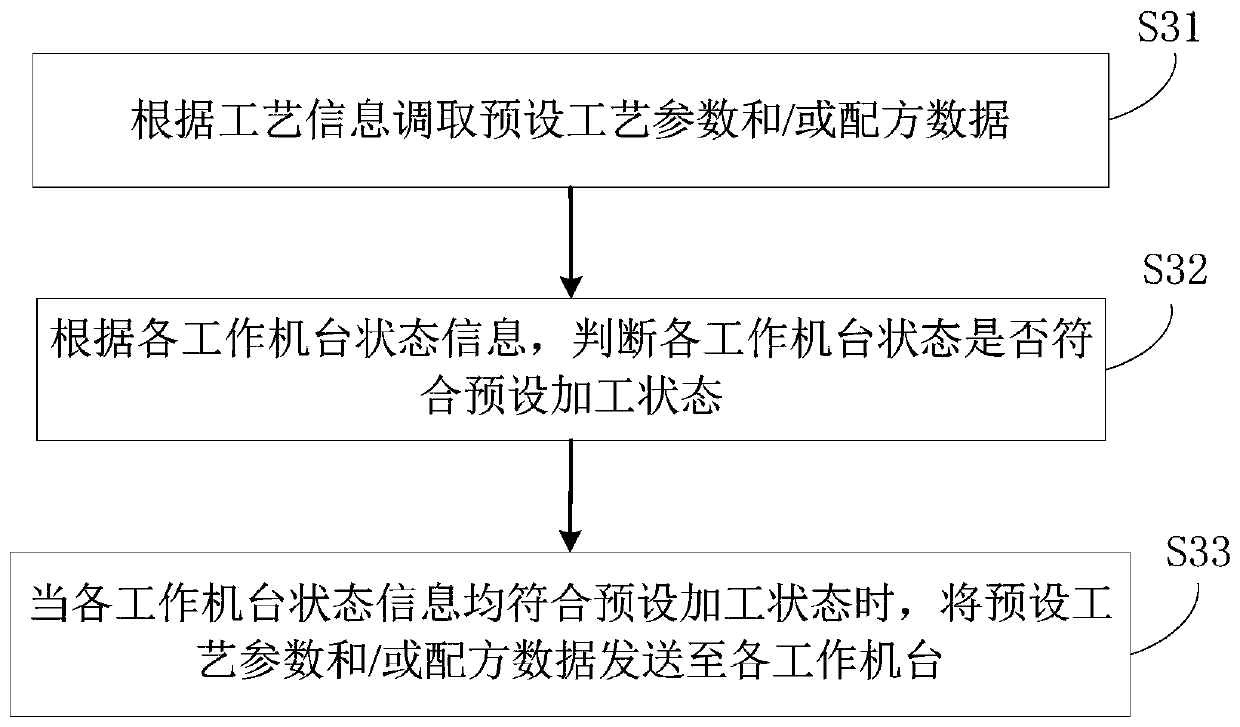

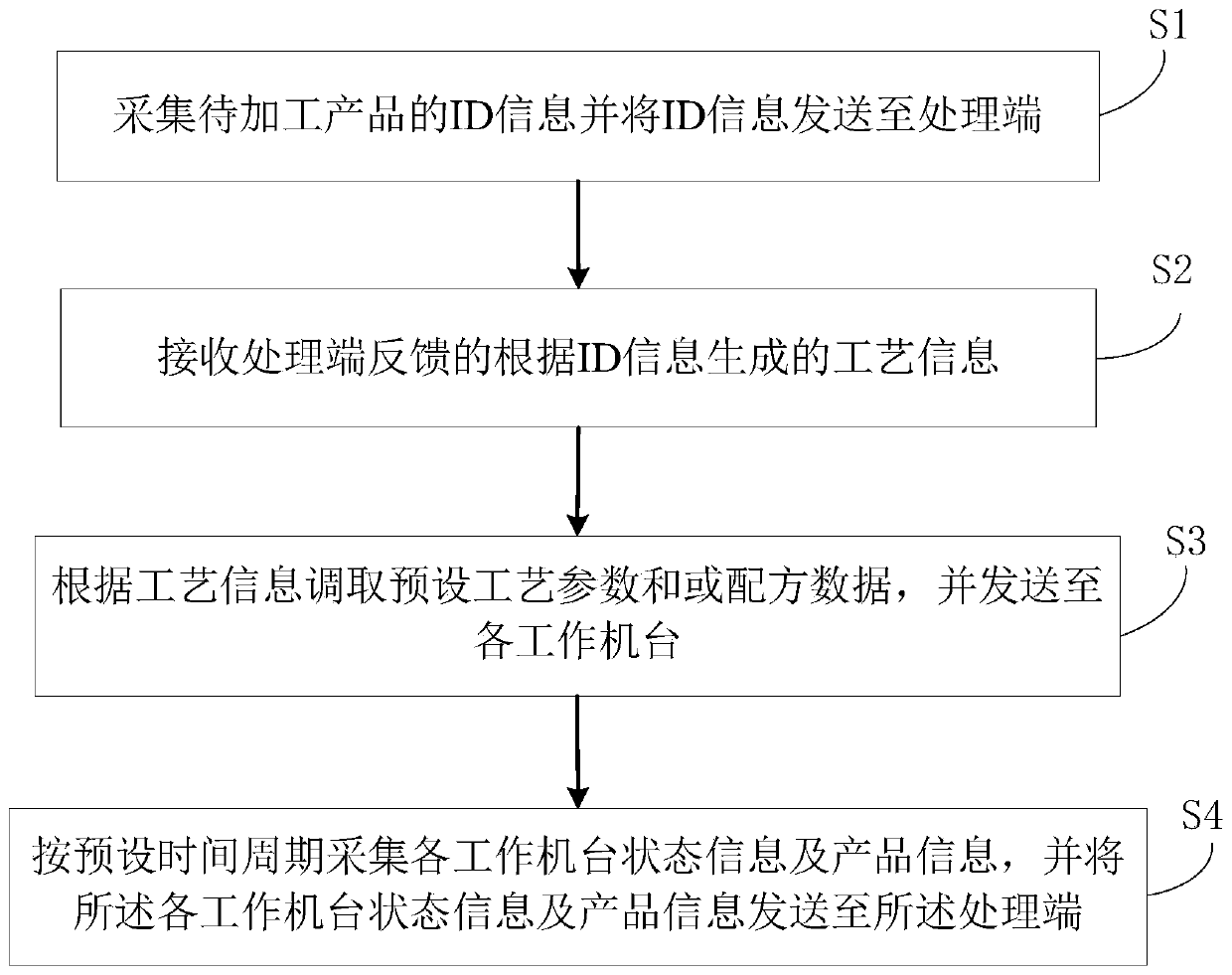

[0036] Embodiments of the present invention provide a method for controlling an automated production line. In practical applications, the method can be executed by the main control system loaded on the PC through the main control software developed by C# or VC, such as figure 1 As shown, the automatic production line control method includes the following steps:

[0037] Step S1: Collect the ID information of the product to be processed and send the ID information to the processing end.

[0038]In the embodiment of the present invention, the ID of the workpiece to be processed is obtained by the working machine, and sent to the main control system, and the main control system sends the ID of the collected workpiece to the processing end. The processing end is, for example, an MES system, etc., but not in This is the limit.

[0039] Step S2: Receive the process information generated according to the ID information fed back by the processing end.

[0040] In the embodiment of t...

Embodiment 2

[0055] An embodiment of the present invention provides a method for controlling an automated production line. In practical applications, the method can be executed by an MES system, such as Figure 4 As shown, the automatic production line control method includes:

[0056] Step S11: receiving the ID information of the product to be processed.

[0057] Step S12: Retrieve the preset work order information according to the ID information of the product to be processed, obtain the process information and send it.

[0058] Specifically, match the product information to be processed with the preset work order information; when the product information to be processed is successfully matched with the preset work order information, obtain the process information corresponding to the product to be processed, and The above process information is sent.

[0059] In the embodiment of the present invention, the MES system receives the ID information of the product to be processed, such as ...

Embodiment 3

[0065] An embodiment of the present invention provides an automatic production line control device, such as Figure 6 shown, including:

[0066] The information collection module 1 of the product to be processed is used to collect the ID information of the product to be processed and send the ID information to the processing end. This module executes the method described in step S1 in Embodiment 1, which will not be repeated here.

[0067] The process information receiving module 2 is configured to receive the process information generated according to the ID information fed back by the processing terminal. This module executes the method described in step S2 in Embodiment 1, which will not be repeated here.

[0068] The preset process data acquisition module 3 is used to retrieve preset process parameters and formula data according to the process information, and send them to each working machine. This module executes the method described in step S4 in Embodiment 1, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com