Processing method of support product

A processing method and product technology, applied in the direction of metal processing equipment, metal processing machinery parts, supports, etc., can solve the problems of long processing time, low efficiency, high manufacturing cost, etc., and achieve the reduction of manufacturing cost, the improvement of processing accuracy, and the improvement of The effect on product quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

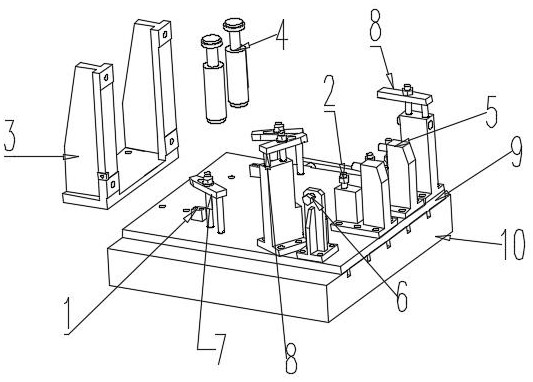

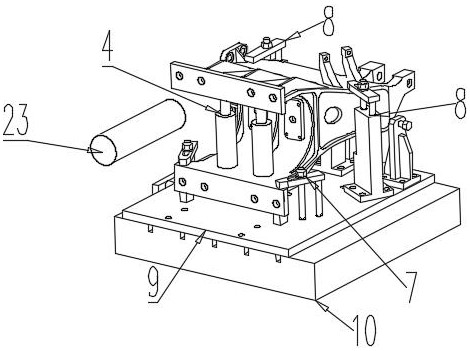

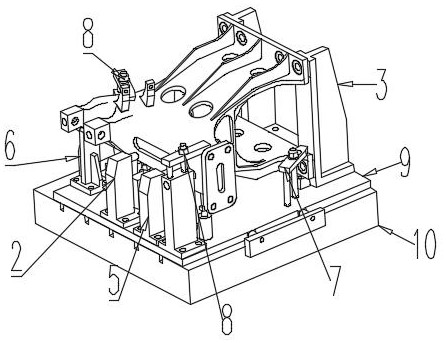

[0055] Embodiment: a kind of processing method of stent product, comprises the steps:

[0056] Step 1: Position the bracket on the equipment, place the bracket sideways, and then position and clamp it on the equipment. The side plane 16 on the lower part of the bracket is positioned on the two plane positioning blocks 1, and the side 13 on the upper part of the product is adjusted on the two planes. Positioning on the supporting part 2, by adjusting the two adjusting supporting parts 2, the installation plane of the lower part of the product is perpendicular to the equipment table 10 of the horizontal machining center; the upper surface 11 of the product is positioned on the two adjustable X-axis positioning parts 5; the upper part of the product The right side 12 is positioned on an adjustable Y-axis positioning member 6;

[0057] The second step: install the support, install two adjustable support rods 4 inside the bracket, because the rigidity of the bracket is very poor, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com