Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57 results about "Polycrystalline silicon carbide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

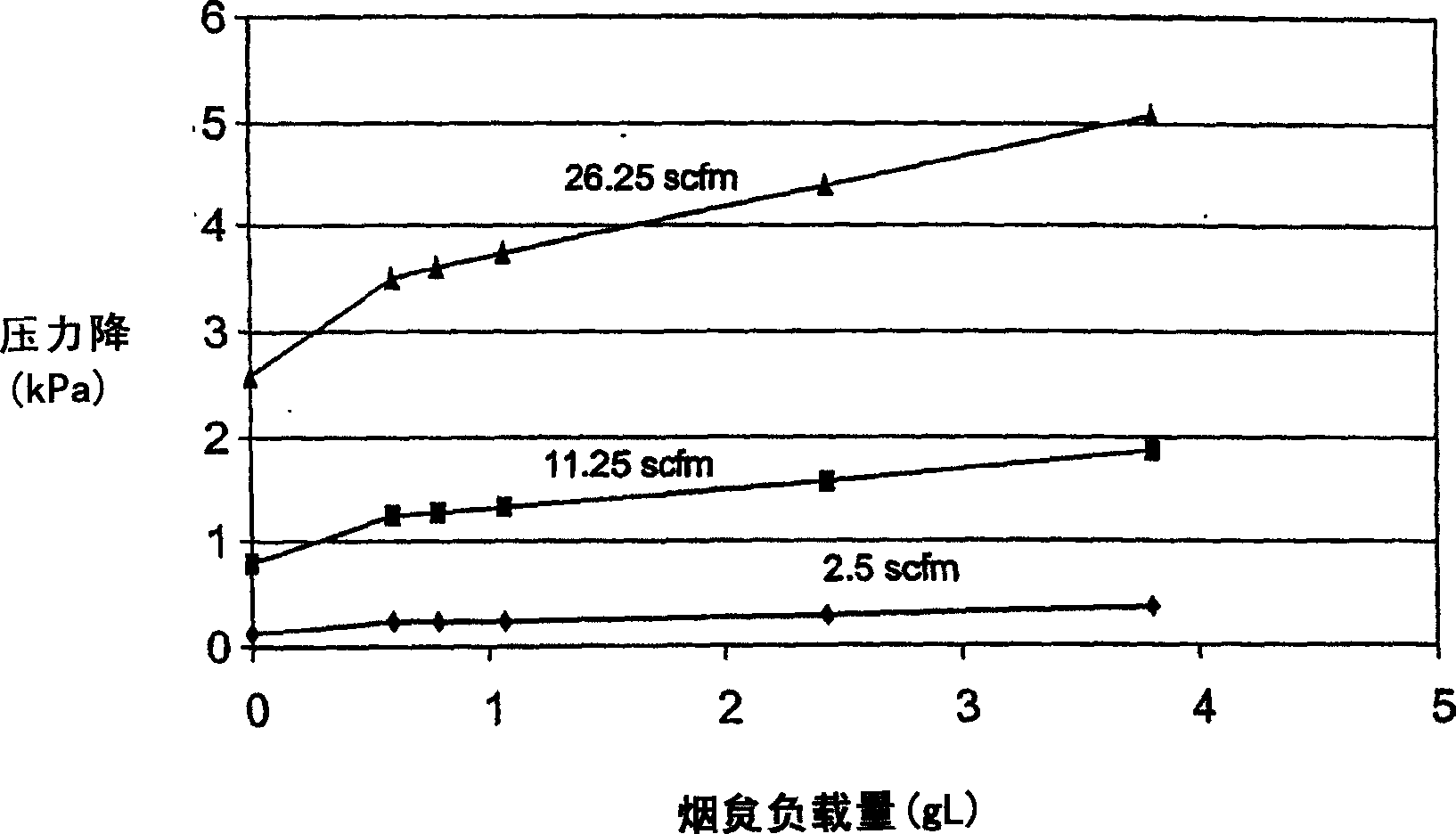

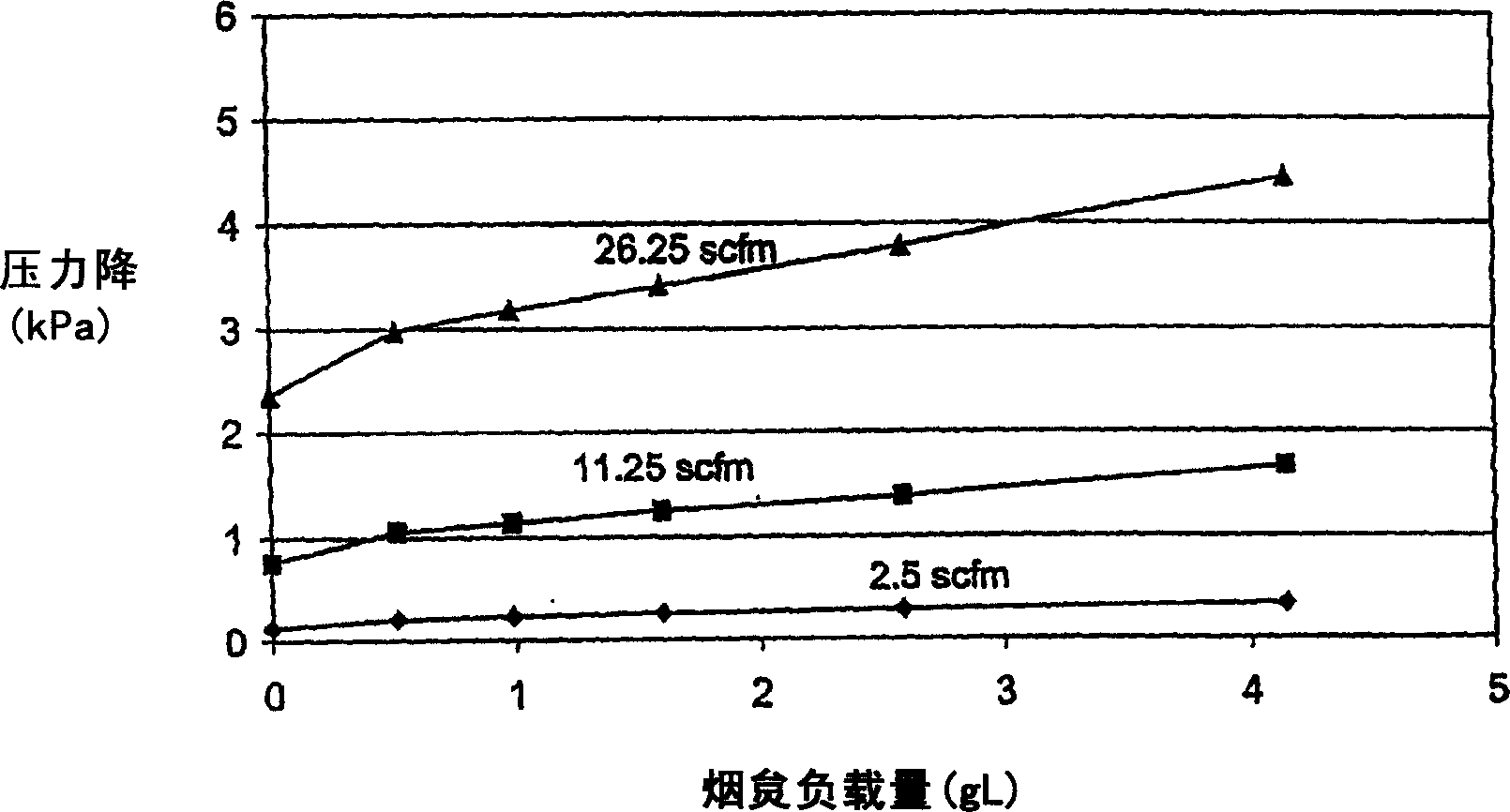

Composite cordierite filters

InactiveUS20030110744A1Improved thermalImprove mechanical propertiesCombination devicesAuxillary pretreatmentBoridePorosity

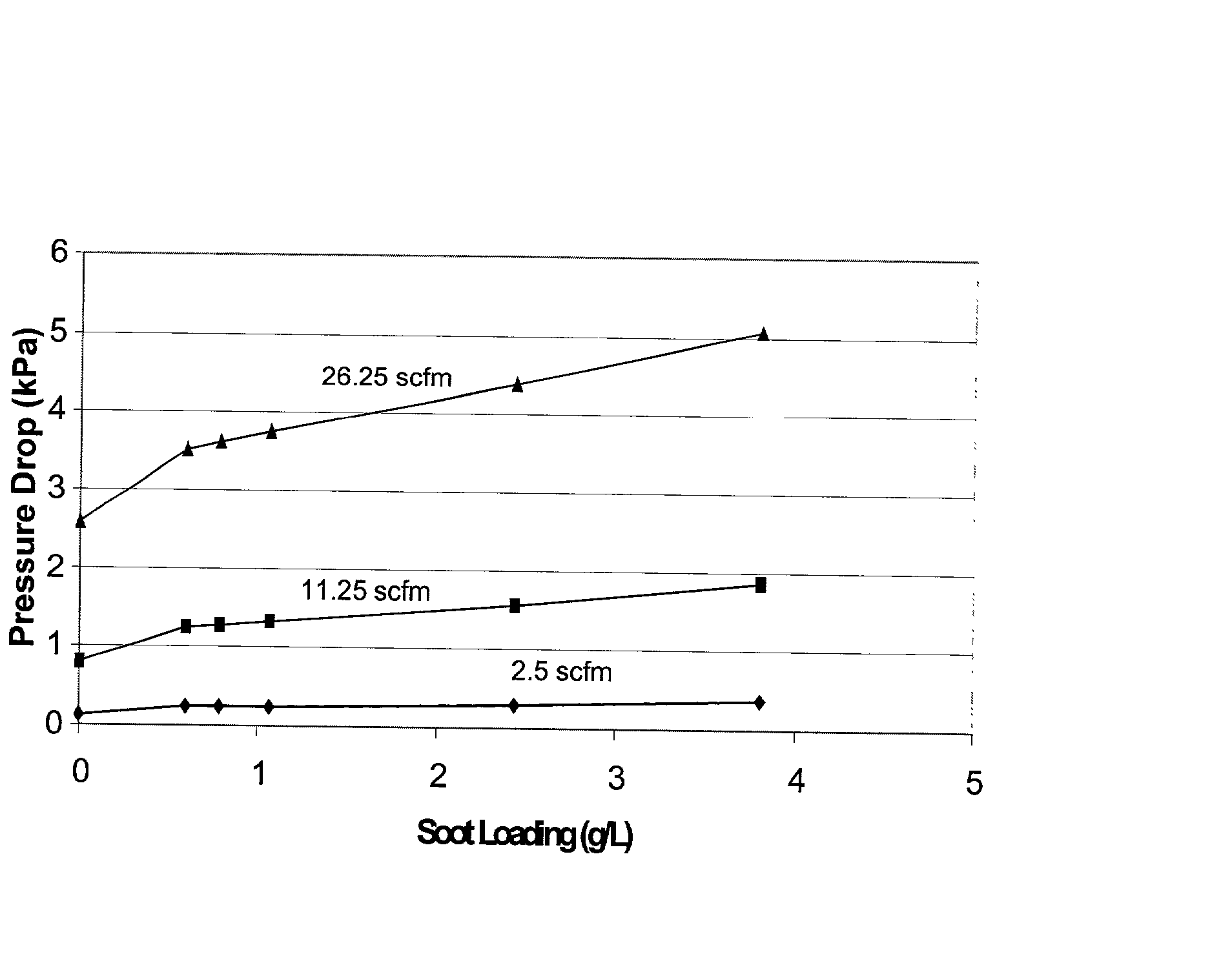

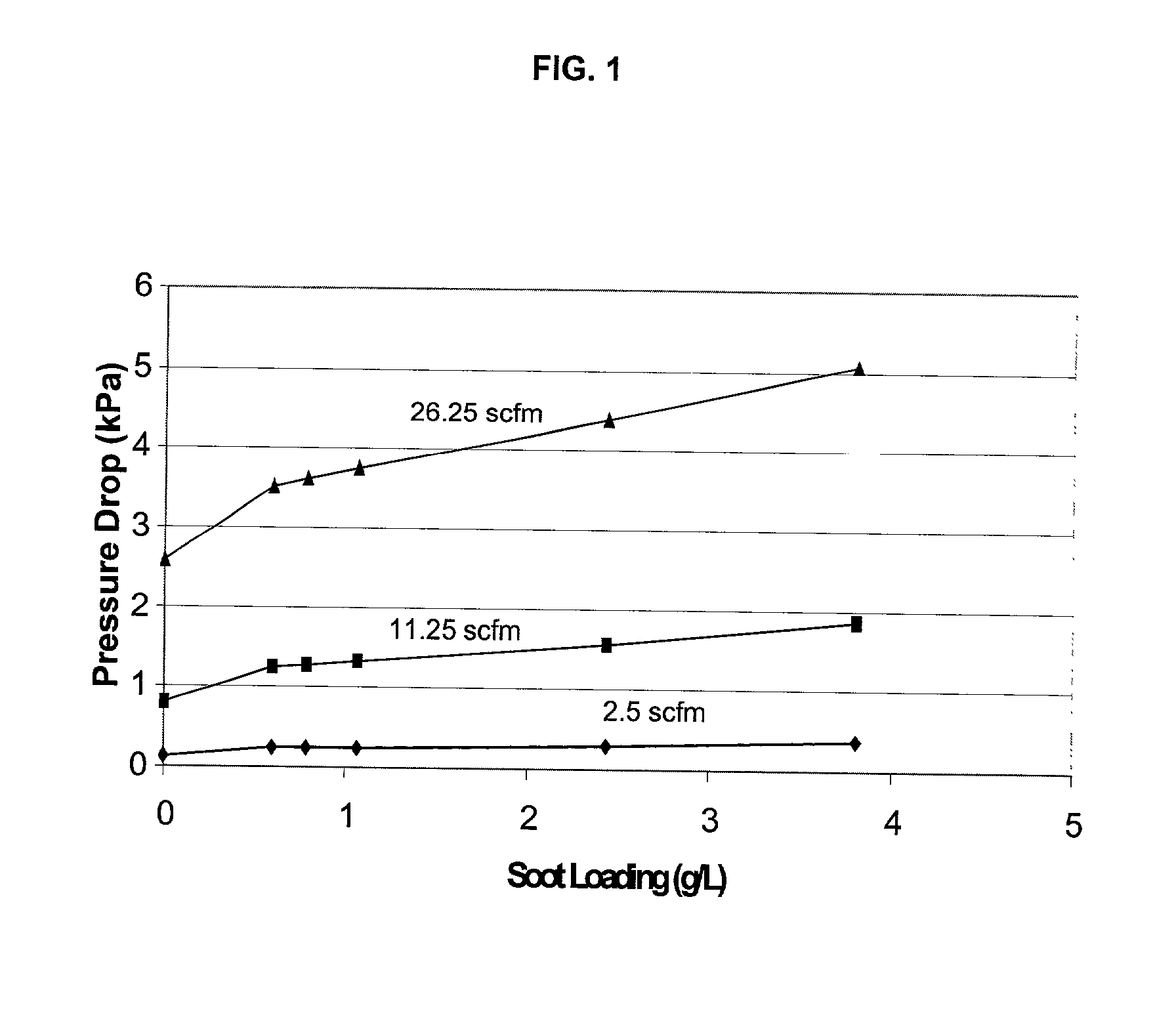

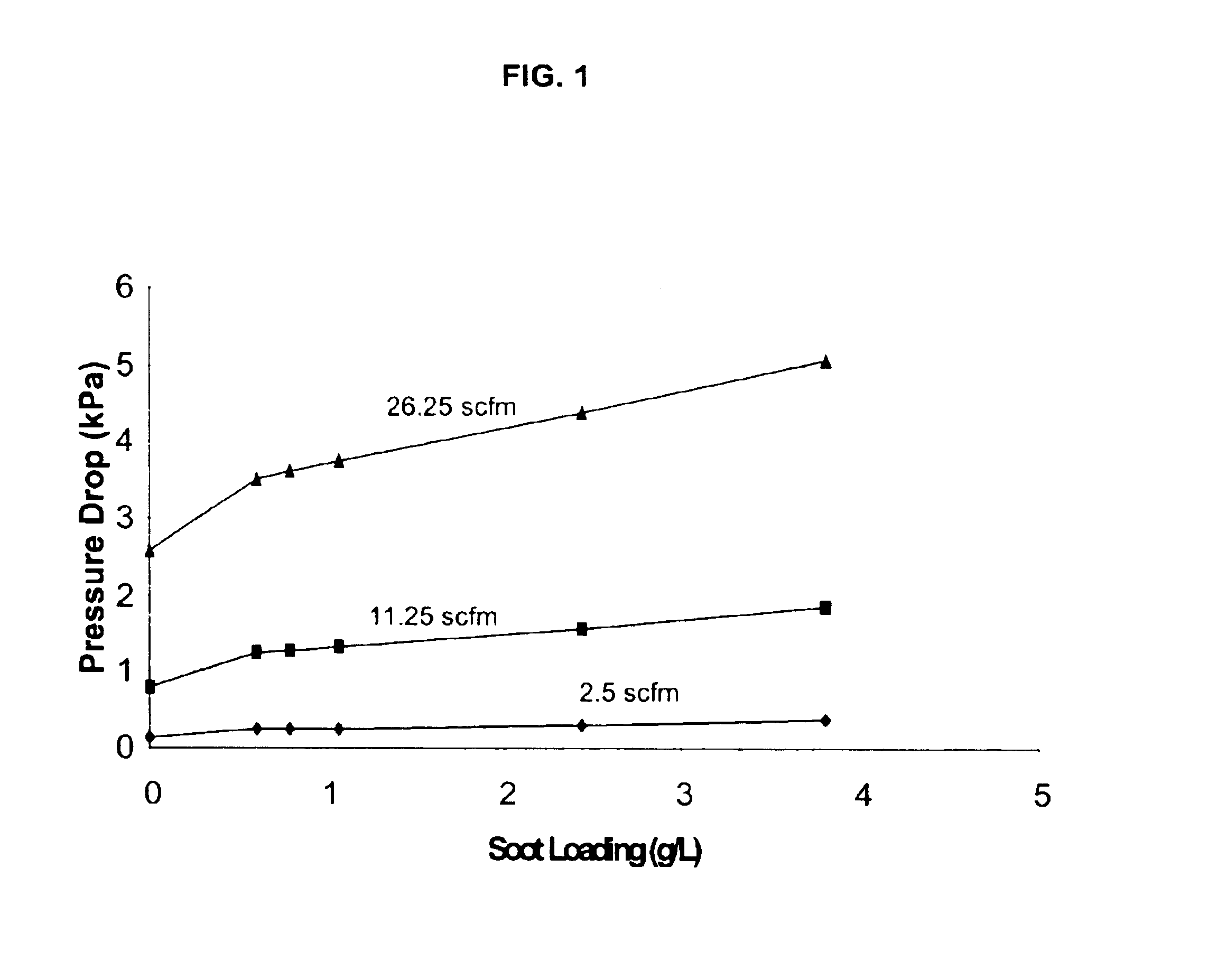

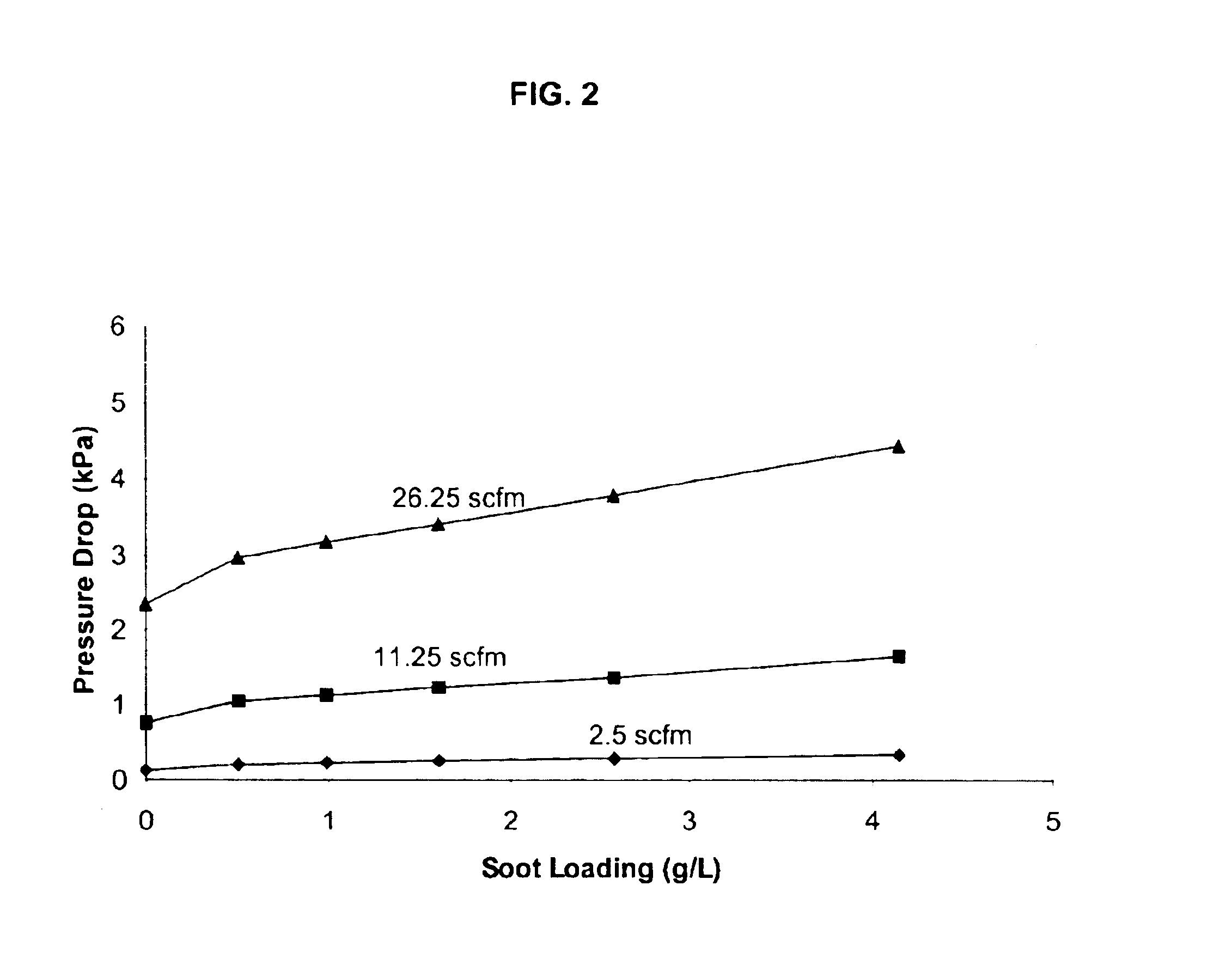

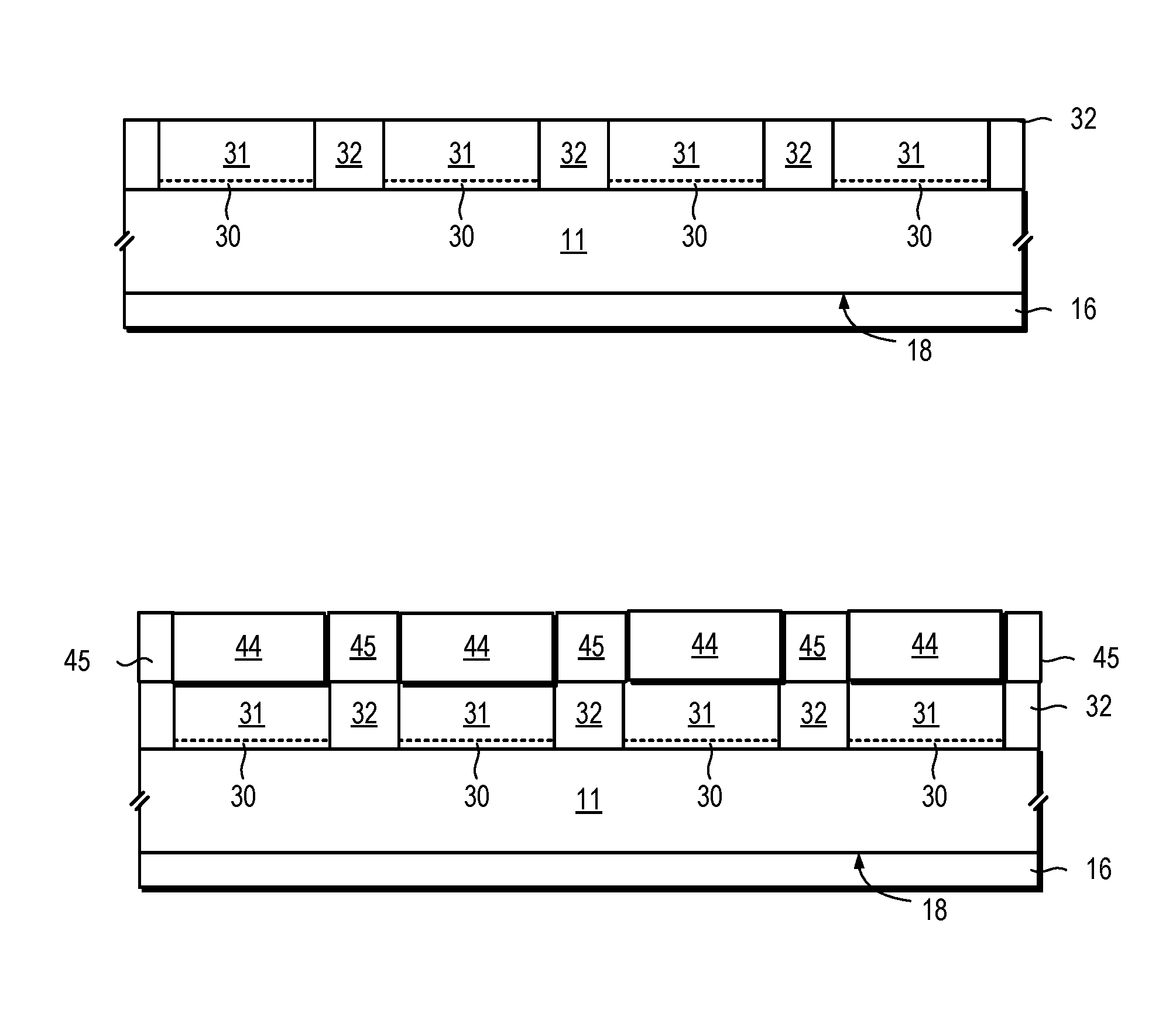

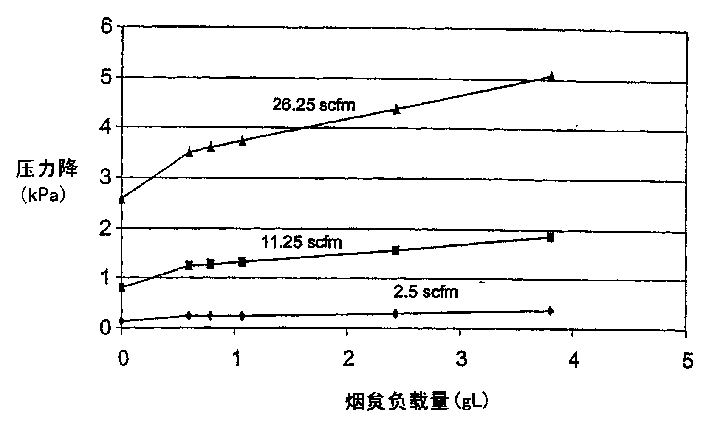

Composite cordierite honeycomb structures especially suitable for diesel exhaust filtration applications comprise a non-oxide polycrystalline phase constituting 10-70% by weight, with the remainder of the ceramic material constituting a cordierite phase, the non-oxide polycrystalline phase being selected from the group consisting of carbides, nitrides, and borides. Preferably the non-oxide phase is either polycrystalline silicon carbide or polycrystalline silicon nitride and has a particle aspect ratio of less than 3. Inventive ceramic bodies are porous with an open porosity of at least 30%, preferably between 40% and 60%, and a median pore size of at least 5 micrometers, more preferably greater than 8 micrometers and less than 12 micrometers.

Owner:CORNING INC

Membrane pressure sensor containing silicon carbide and method of manufacture

InactiveUS20040079163A1Line/current collector detailsElectrical transducersPolycrystalline silicon carbideMembrane deformation

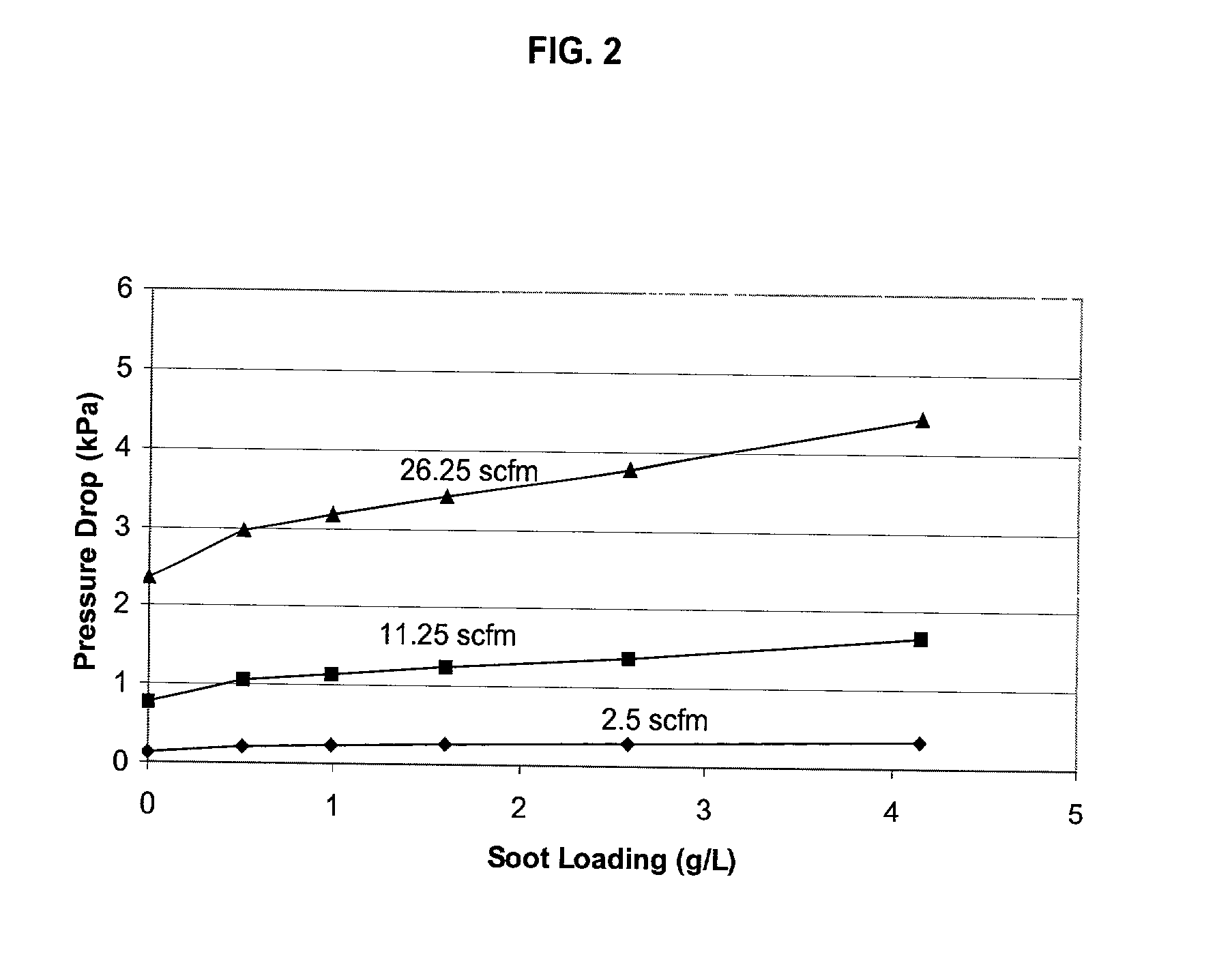

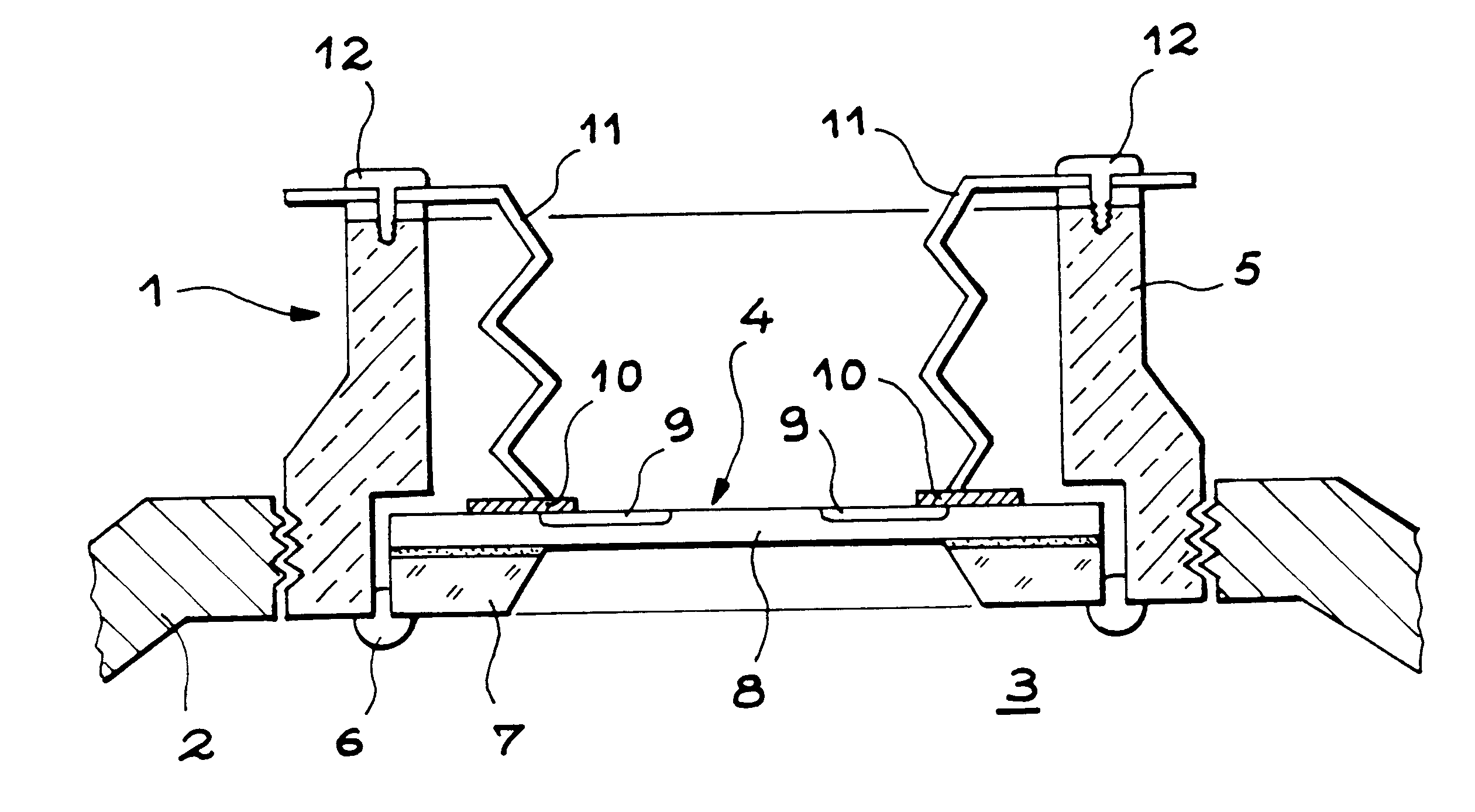

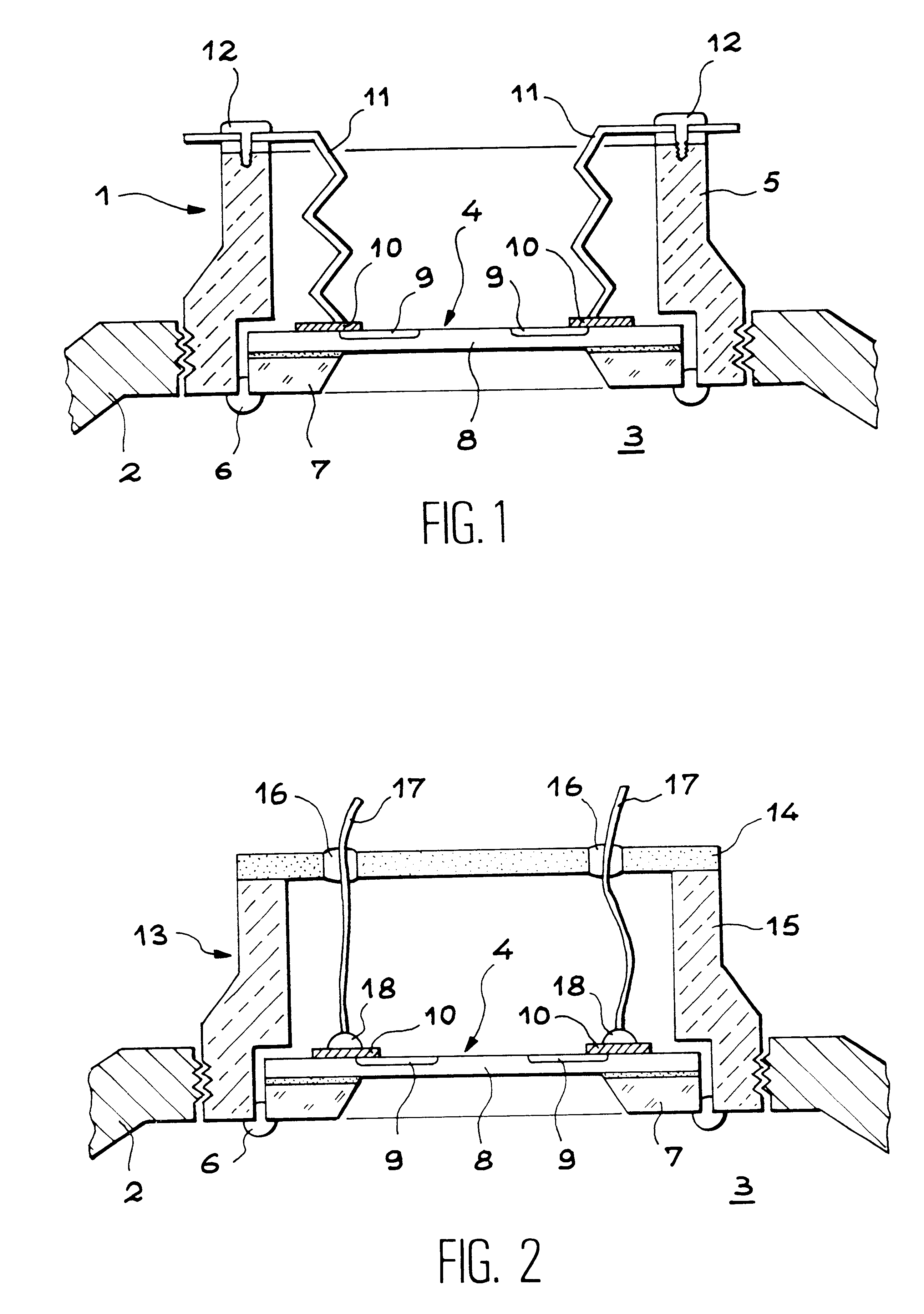

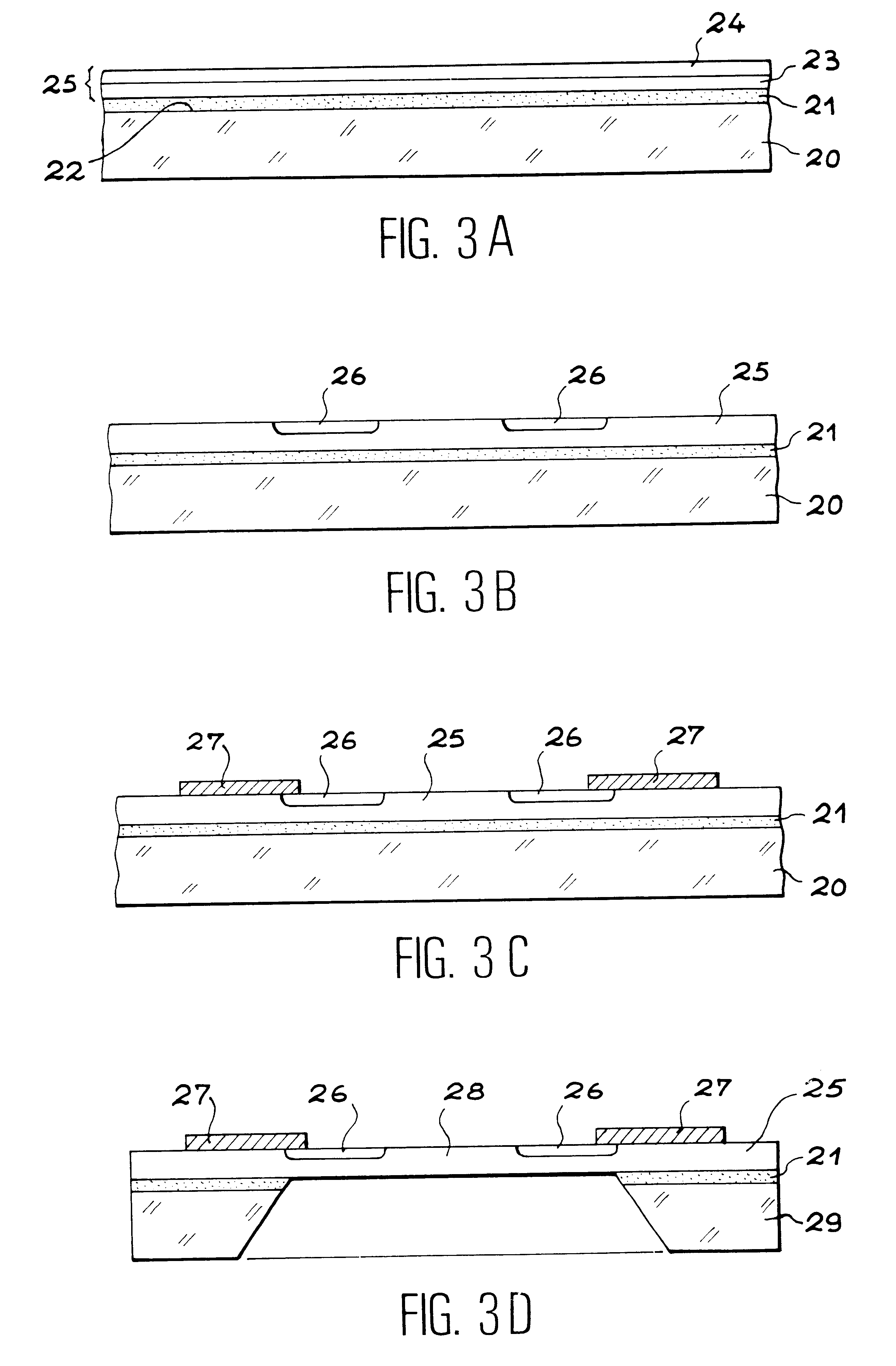

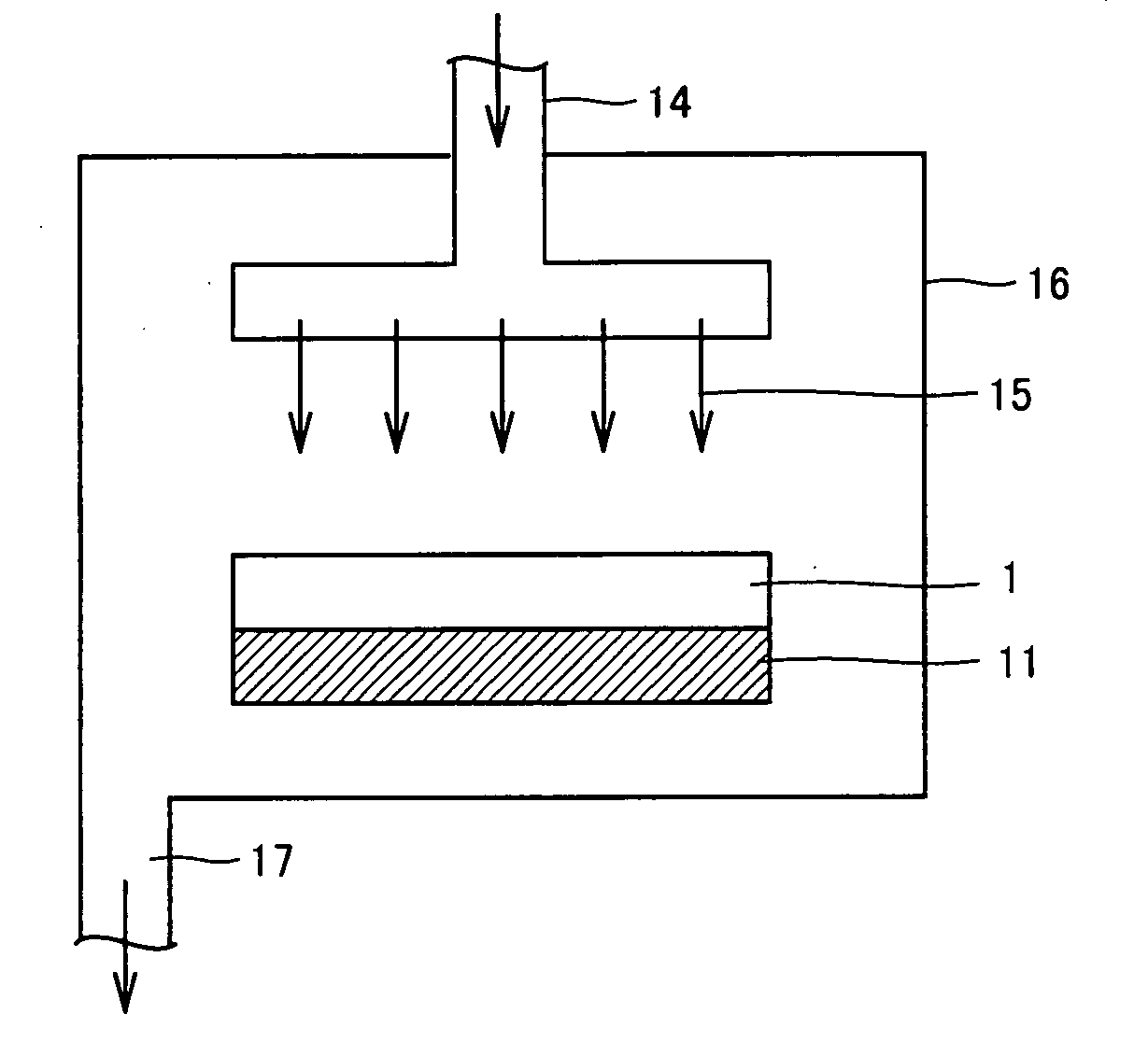

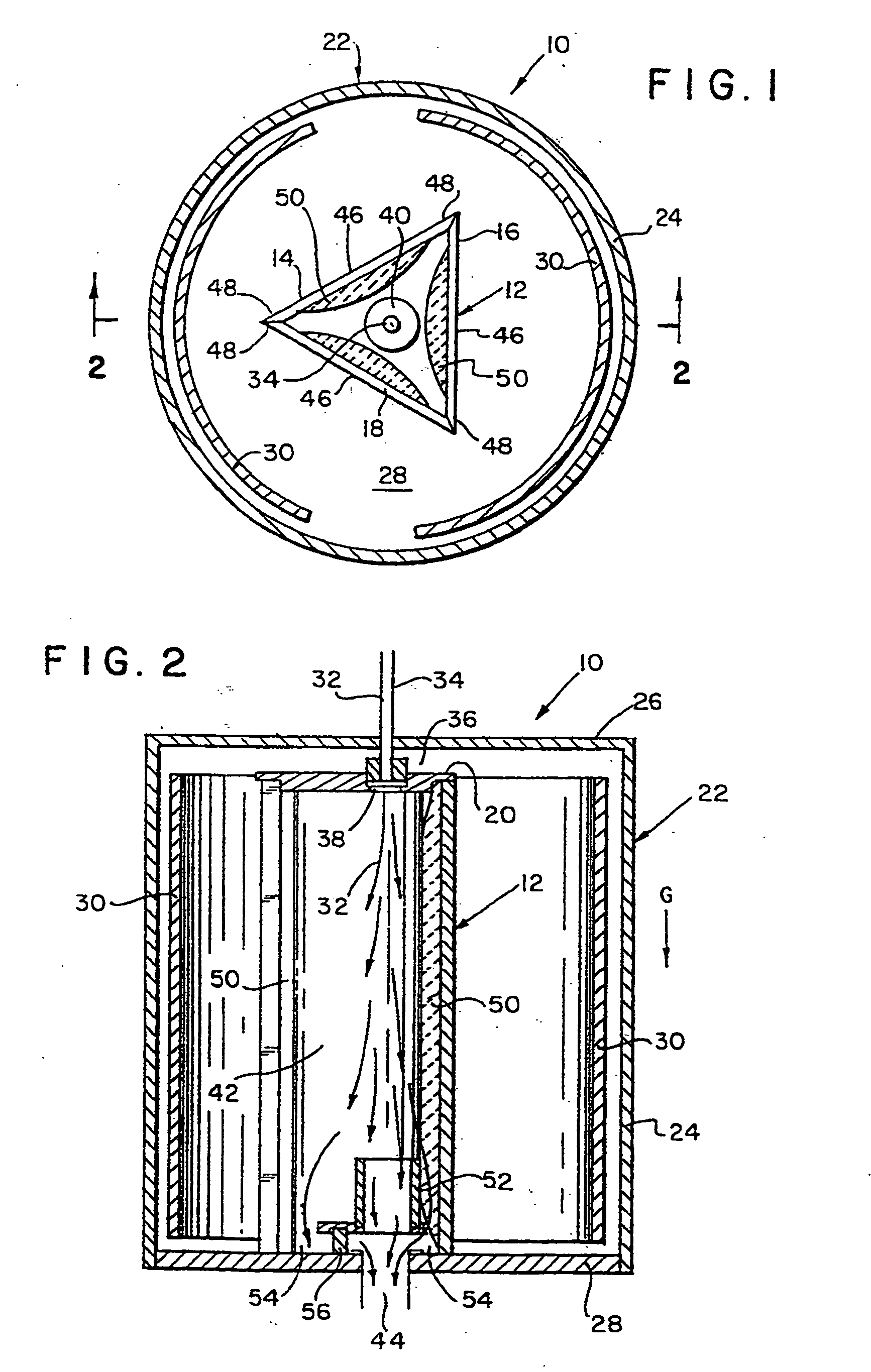

The invention concerns a pressure sensor (1), able to operate at high temperature and measure the pressure of a hostile medium, comprising: a sensing element (4) integrating a membrane (8) in monocrystalline silicon carbide, made by micro-machining a substrate in polycrystalline silicon carbide, a first surface of membrane (8) intended to contact said medium, a second surface of membrane (8) comprising membrane deformation detection means (9) connected to electric contacts (10) to connect electric connection means (11), the surfaces of sensing element (4) contacting said medium being chemically inert to this medium; a carrier (5) to support sensing element (4) so that said first surface of membrane (8) may be contacted with said medium and the second surface of membrane (8) may be shielded from said medium, carrier (5) being in polycrystalline silicon carbide; a seal strip (6), in material containing silicon carbide, brazed between carrier (5) and sensing element (4) to protect the second surface of membrane (8) from any contact with said medium.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Composite cordierite filters

InactiveUS6736875B2Improved thermal and mechanical propertyImprove thermal performanceCombination devicesAuxillary pretreatmentBoridePorosity

Composite cordierite honeycomb structures especially suitable for diesel exhaust filtration applications comprise a non-oxide polycrystalline phase constituting 10-70% by weight, with the remainder of the ceramic material constituting a cordierite phase, the non-oxide polycrystalline phase being selected from the group consisting of carbides, nitrides, and borides. Preferably the non-oxide phase is either polycrystalline silicon carbide or polycrystalline silicon nitride and has a particle aspect ratio of less than 3. Inventive ceramic bodies are porous with an open porosity of at least 30%, preferably between 40% and 60%, and a median pore size of at least 5 micrometers, more preferably greater than 8 micrometers and less than 12 micrometers.

Owner:CORNING INC

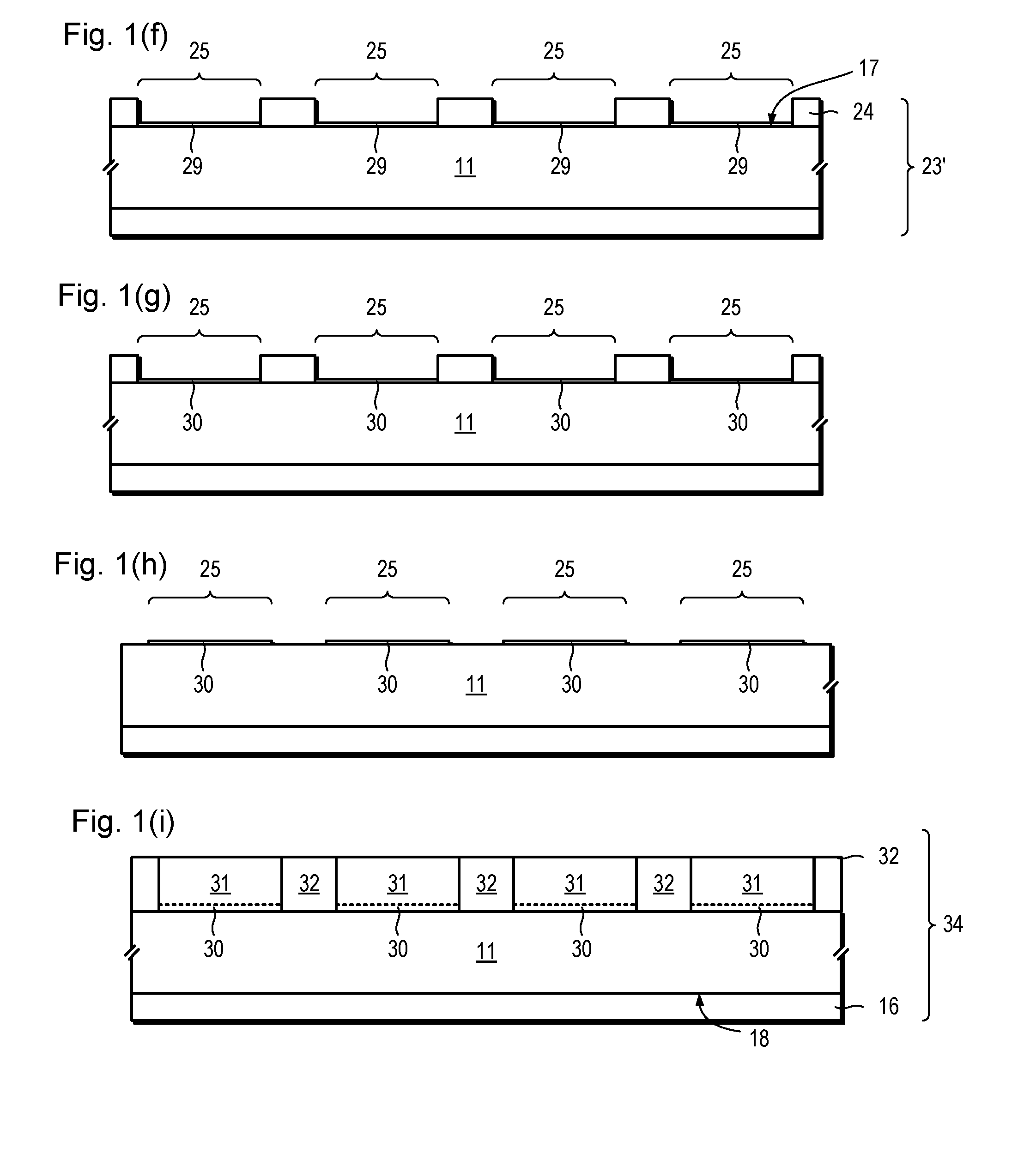

GALLIUM NITRIDE ON 3C-SiC COMPOSITE WAFER

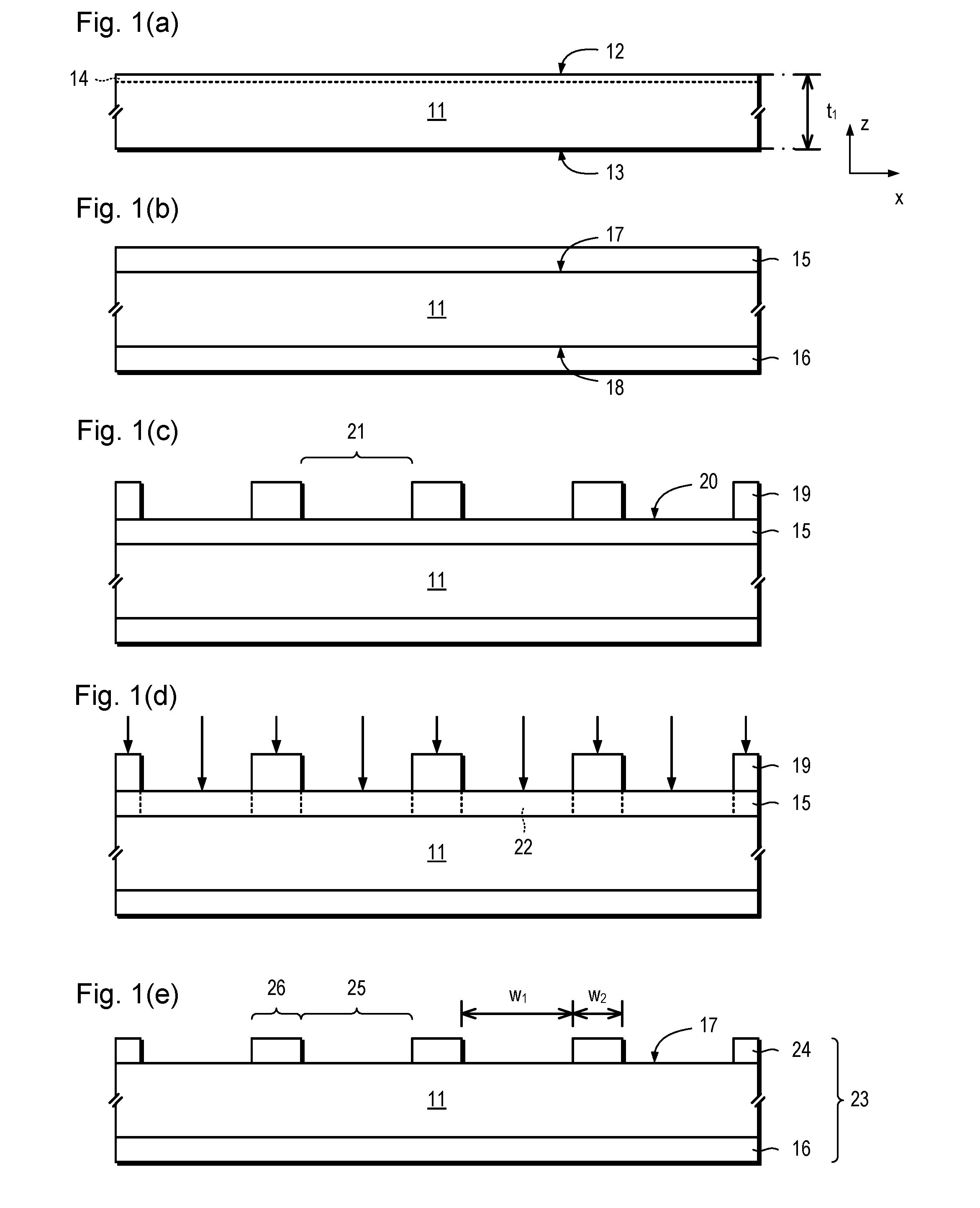

ActiveUS20160247967A1Reduce forceReduce stressSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureGallium nitride

We disclose a semiconductor structure comprising a monocrystalline silicon wafer; spaced apart monocrystalline silicon carbide layers disposed directly on the silicon wafer; amorphous and / or polycrystalline silicon carbide layers disposed directly on the silicon wafer between the monocrystalline silicon carbide layers; first gallium nitride layers disposed on the monocrystalline silicon carbide layers; and second gallium nitride layers disposed on the amorphous and / or polycrystalline silicon carbide layers.

Owner:ANVIL SEMICON

Preparation method for flexible polycrystalline silicon carbide micro-nanofiber mat

InactiveCN103320966AImprove flexibilityImprove high temperature resistanceHeating/cooling textile fabricsNon-woven fabricsElectrospinningNanofiber

The invention provides a preparation method for a flexible polycrystalline silicon carbide micro-nanofiber mat, and relates to silicon carbide fiber mats. The flexible polycrystalline silicon carbide micro-nanofiber mat is good in flexibility, and has chalking resistance at the temperature higher than 160 DEG C, the fiber diameter is 1.5micrometer around, strength is larger than modulus, cutting and processing are facilitated, the preparation method is controllable, art is simple, and the flexible polycrystalline silicon carbide micro-nanofiber mat is adaptable to continuous and large-scale preparation. The method includes 1, dissolving polycarbosilane containing heterogeneous elements in pre-prepared spinning solvent, and obtaining precursor spinning solution; 2, performing electrostatic spinning of the precursor spinning solution prepared in the step 1 through an electrostatic spinning machine, and obtaining a precursor fiber mat; 3, drying the precursor fiber mat obtained in the step 2, then performing oxidation crosslinking immediately; after heat insulating, pyrolyzing and calcining in an inert atmosphere, and obtaining the flexible polycrystalline silicon carbide micro-nanofiber mat.

Owner:XIAMEN UNIV

Membrane pressure sensor comprising silicon carbide and method for making same

InactiveUS6688181B1Fluid pressure measurement using elastically-deformable gaugesPressure difference measurement between multiple valvesPolycrystalline silicon carbideMembrane deformation

The invention concerns a pressure sensor (1), able to operate at high temperature and measure the pressure of a hostile medium, comprising:a sensing element (4) integrating a membrane (8) in monocrystalline silicon carbide, made by micro-machining a substrate in polycrystalline silicon carbide, a first surface of membrane (8) intended to contact said medium, a second surface of membrane (8) comprising membrane deformation detection means (9) connected to electric contacts (10) to connect electric connection means (11), the surfaces of sensing element (4) contacting said medium being chemically inert to this medium;a carrier (5) to support sensing element (4) so that said first surface of membrane (8) may be contacted with said medium and the second surface of membrane (8) may be shielded from said medium, carrier (5) being in polycrystalline silicon carbide;a seal strip (6), in material containing silicon carbide, brazed between carrier (5) and sensing element (4) to protect the second surface of membrane (8) from any contact with said medium.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

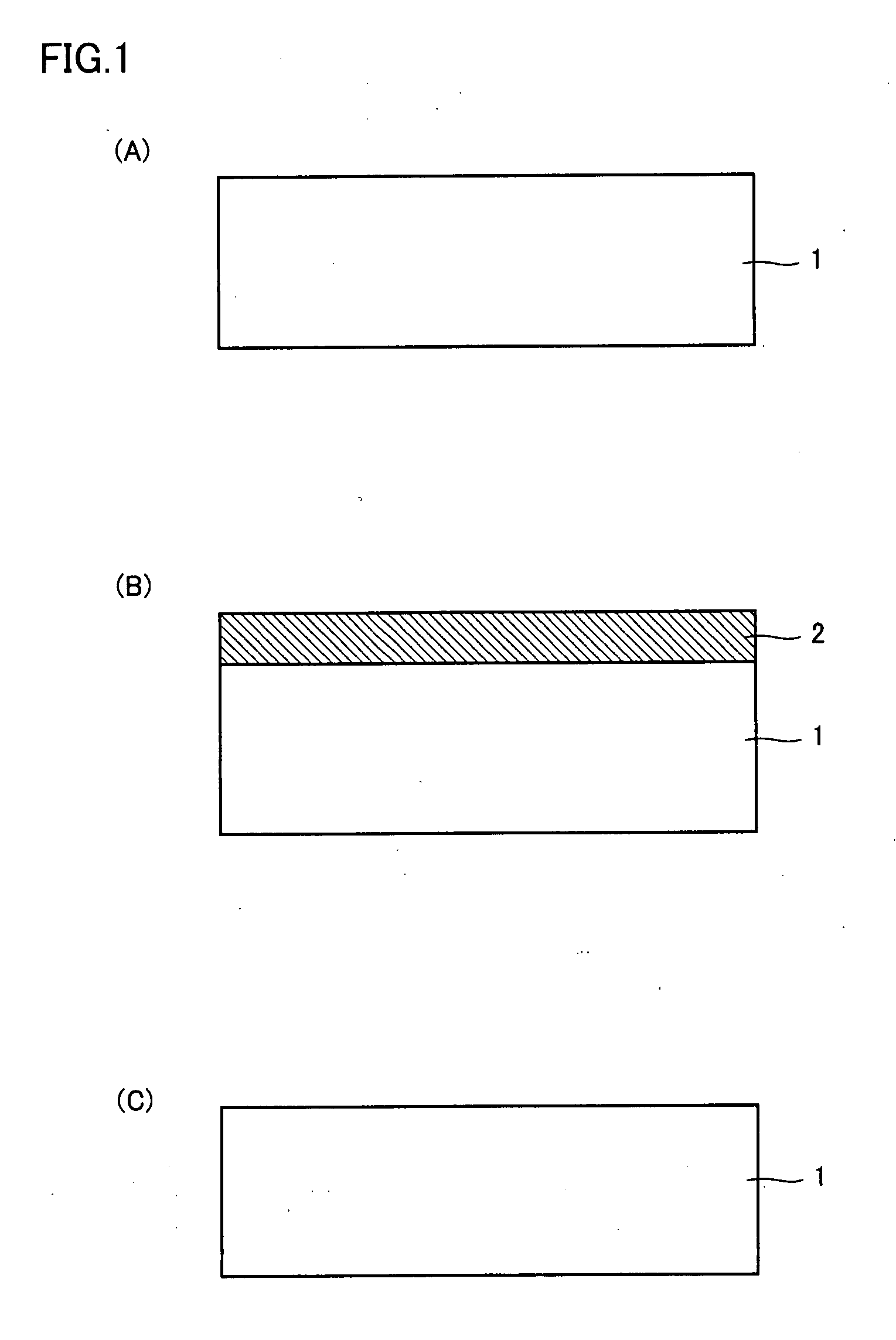

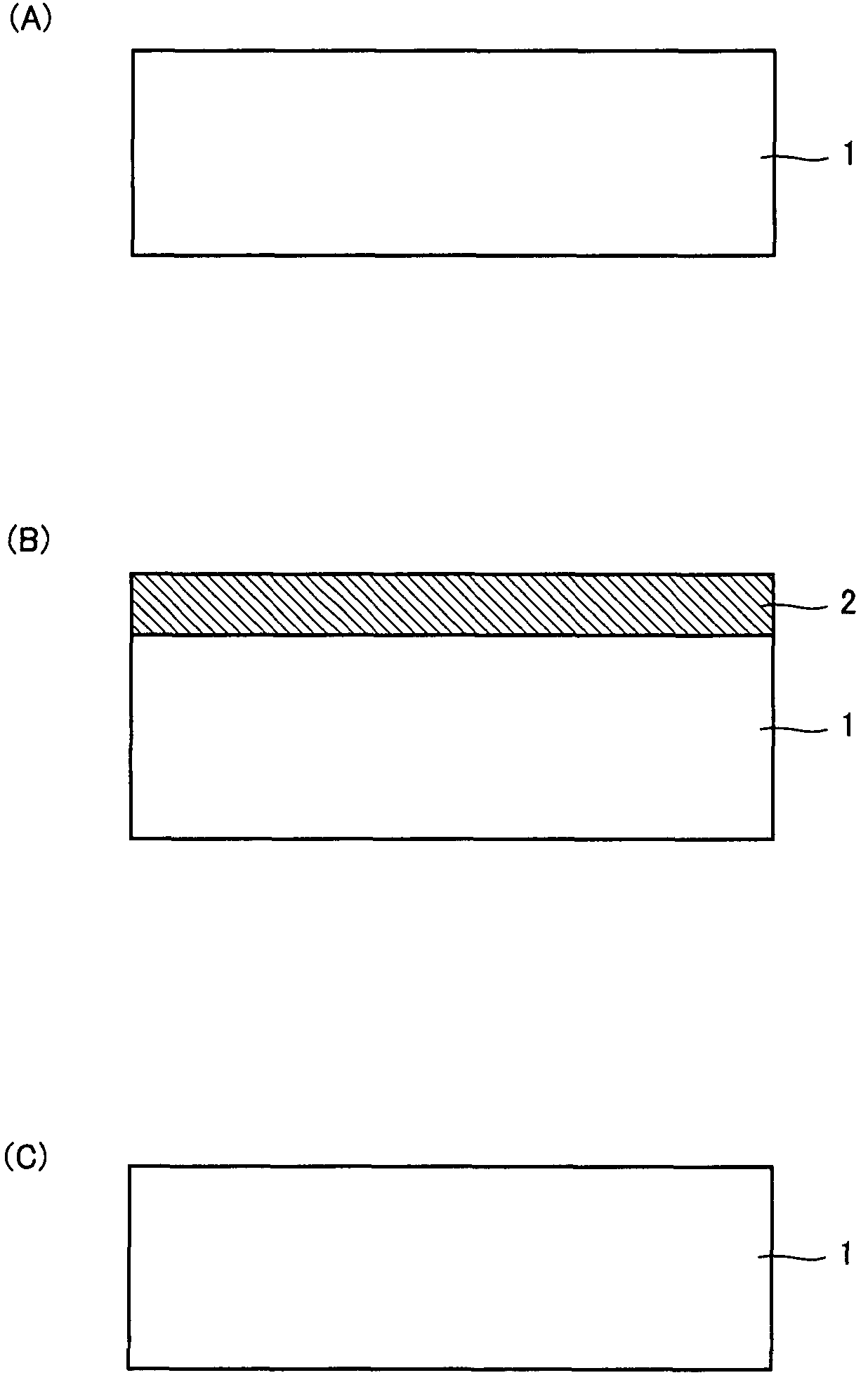

Surface Reconstruction Method for Silicon Carbide Substrate

A surface reconstruction method for a silicon carbide substrate (1) includes a silicon film forming step of forming a silicon film (2) on a surface of the silicon carbide substrate (1) and a heat treatment step of heat-treating the silicon carbide substrate (1) and the silicon film (2) without providing a polycrystalline silicon carbide substrate on a surface of the silicon film (2). Here, after the heat treatment step, a silicon film removal step of removing the silicon film (2) may be included. Further, a silicon oxide film forming step of oxidizing the silicon film (2) after the heat treatment step to generate a silicon oxide film, and a silicon oxide film removal step of removing the silicon oxide film may-be included.

Owner:SUMITOMO ELECTRIC IND LTD

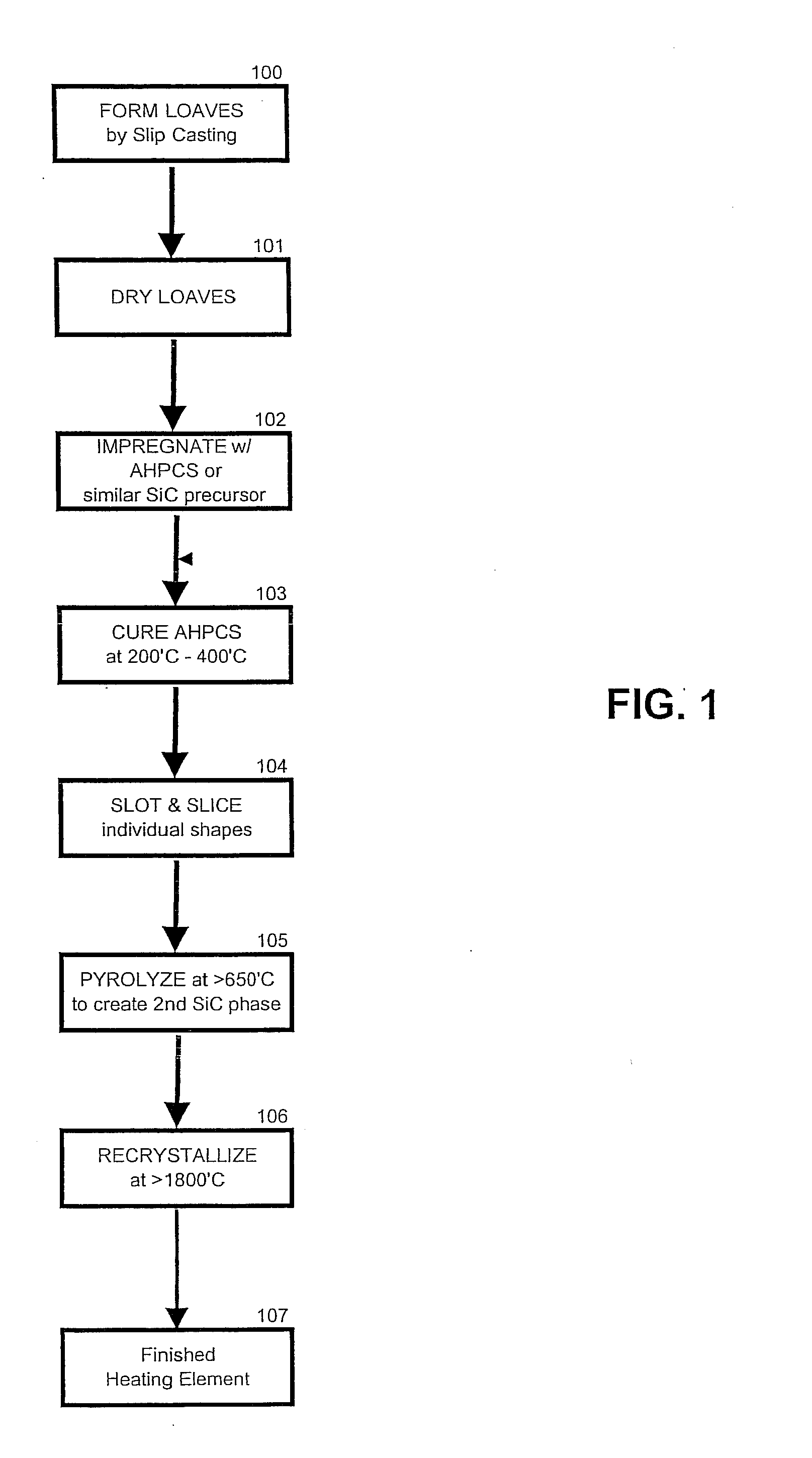

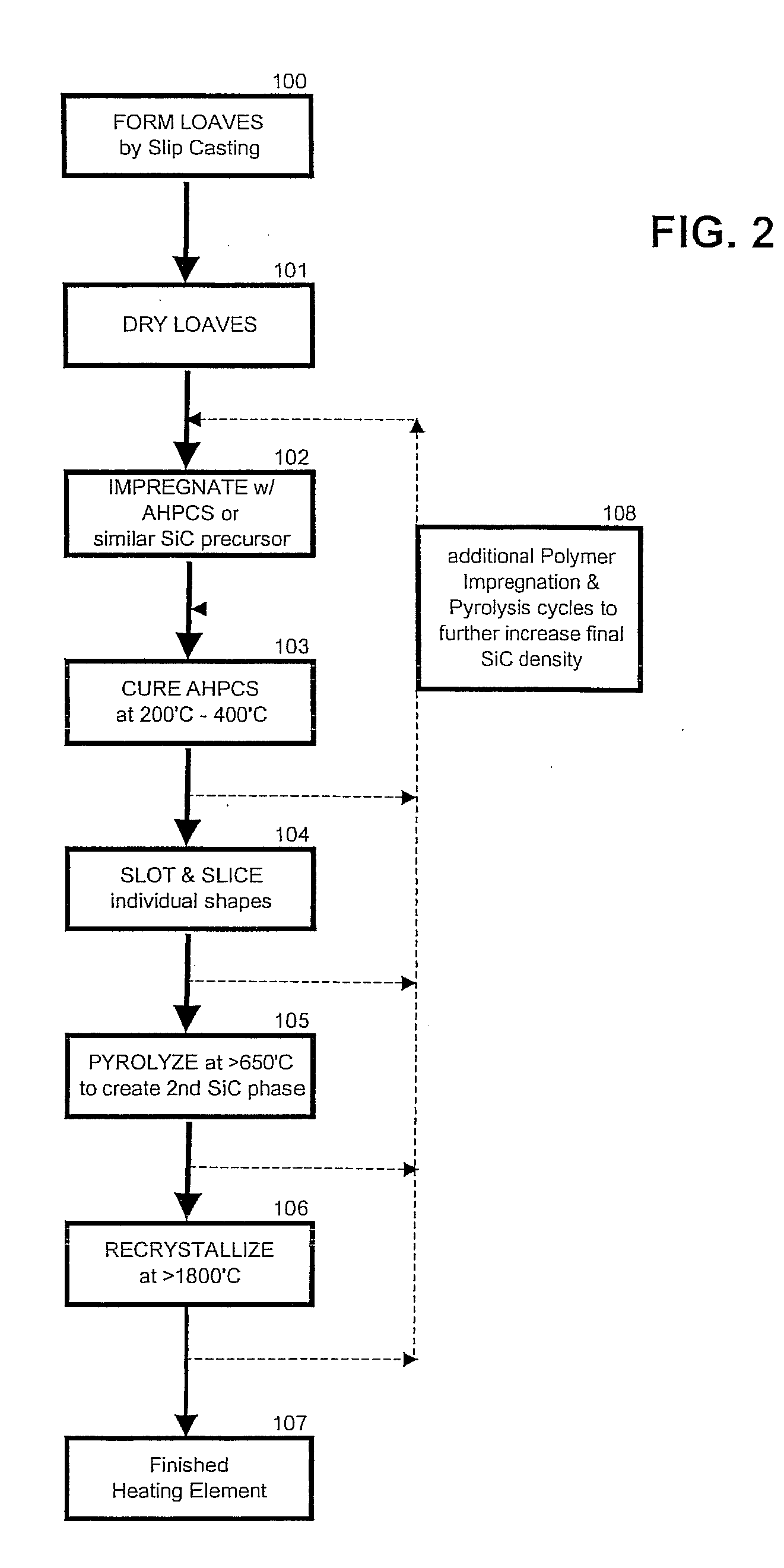

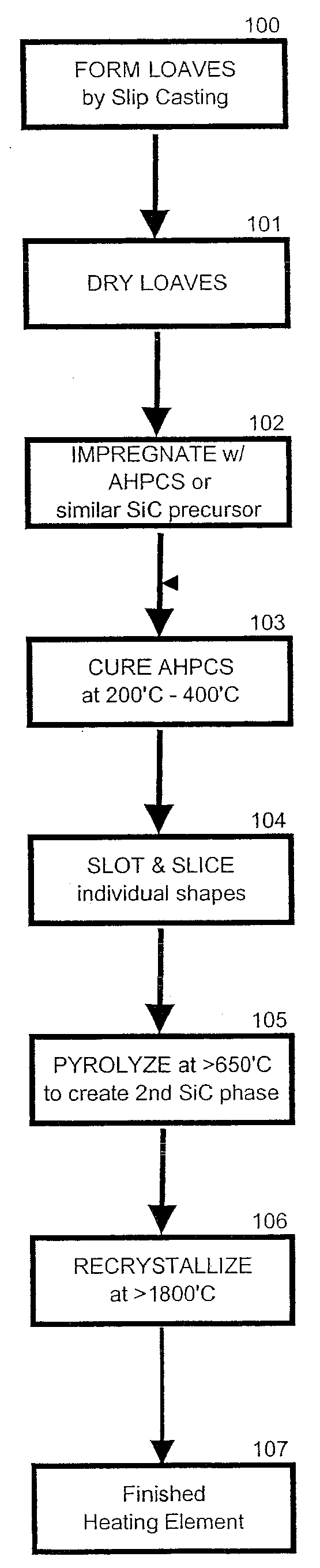

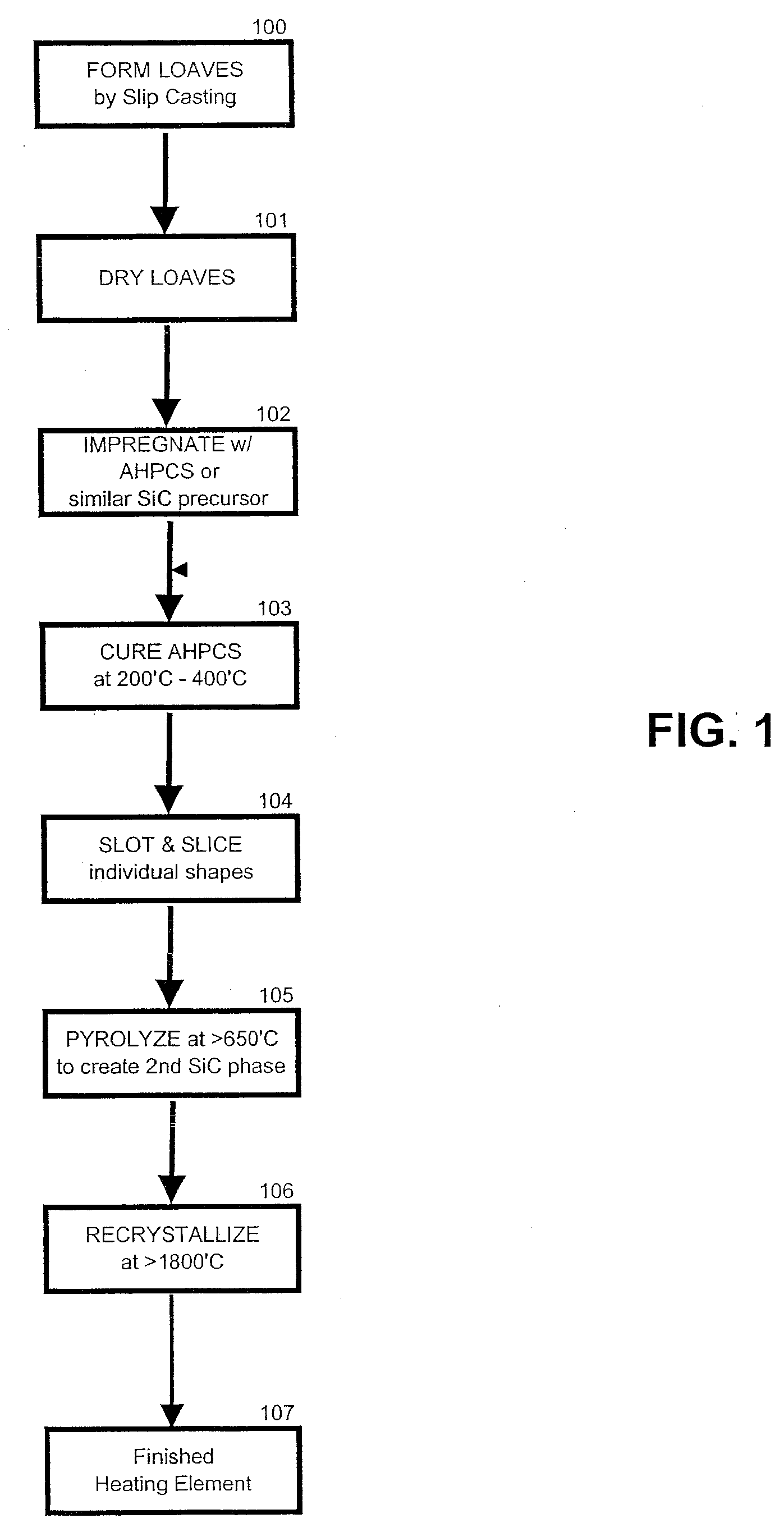

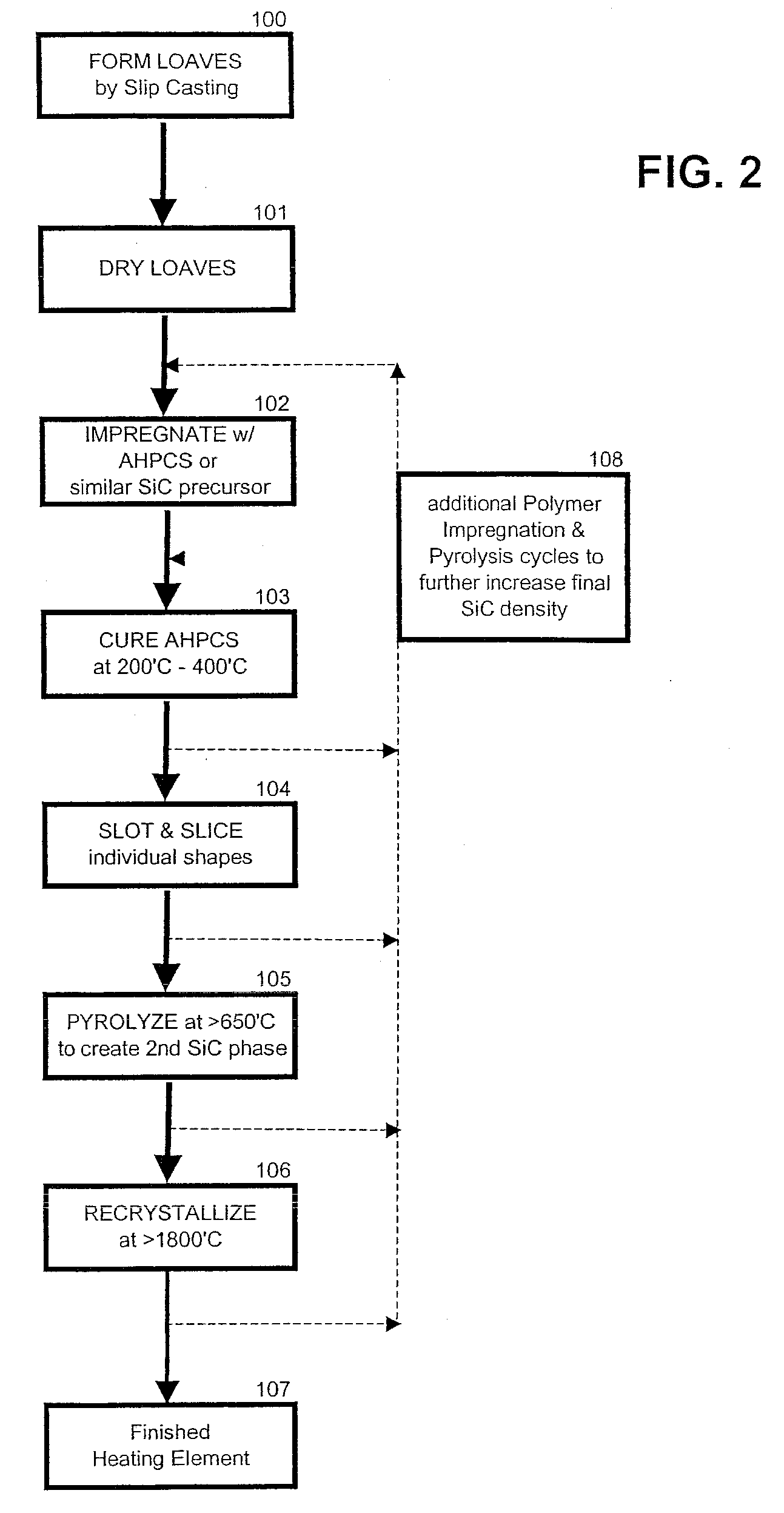

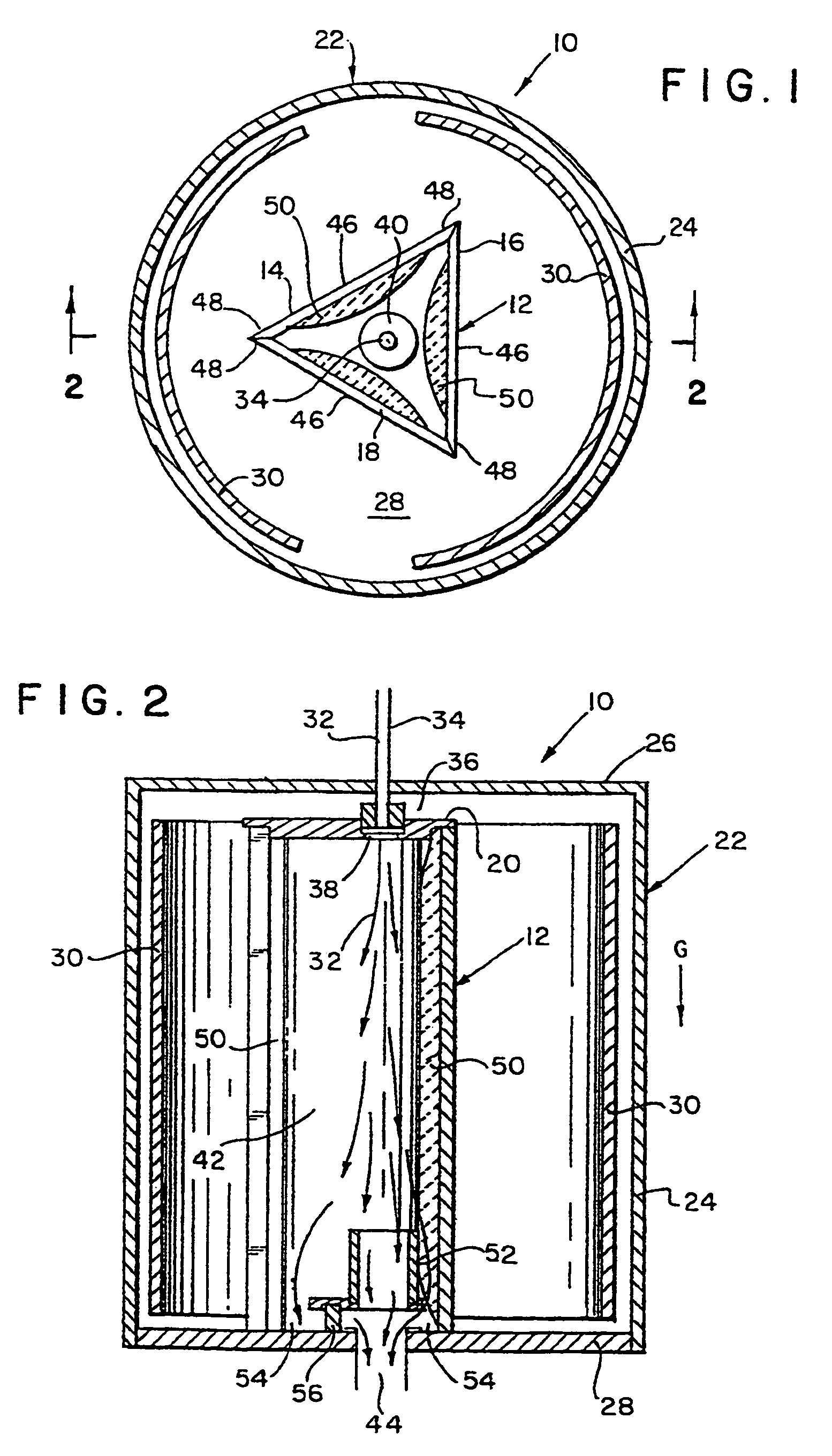

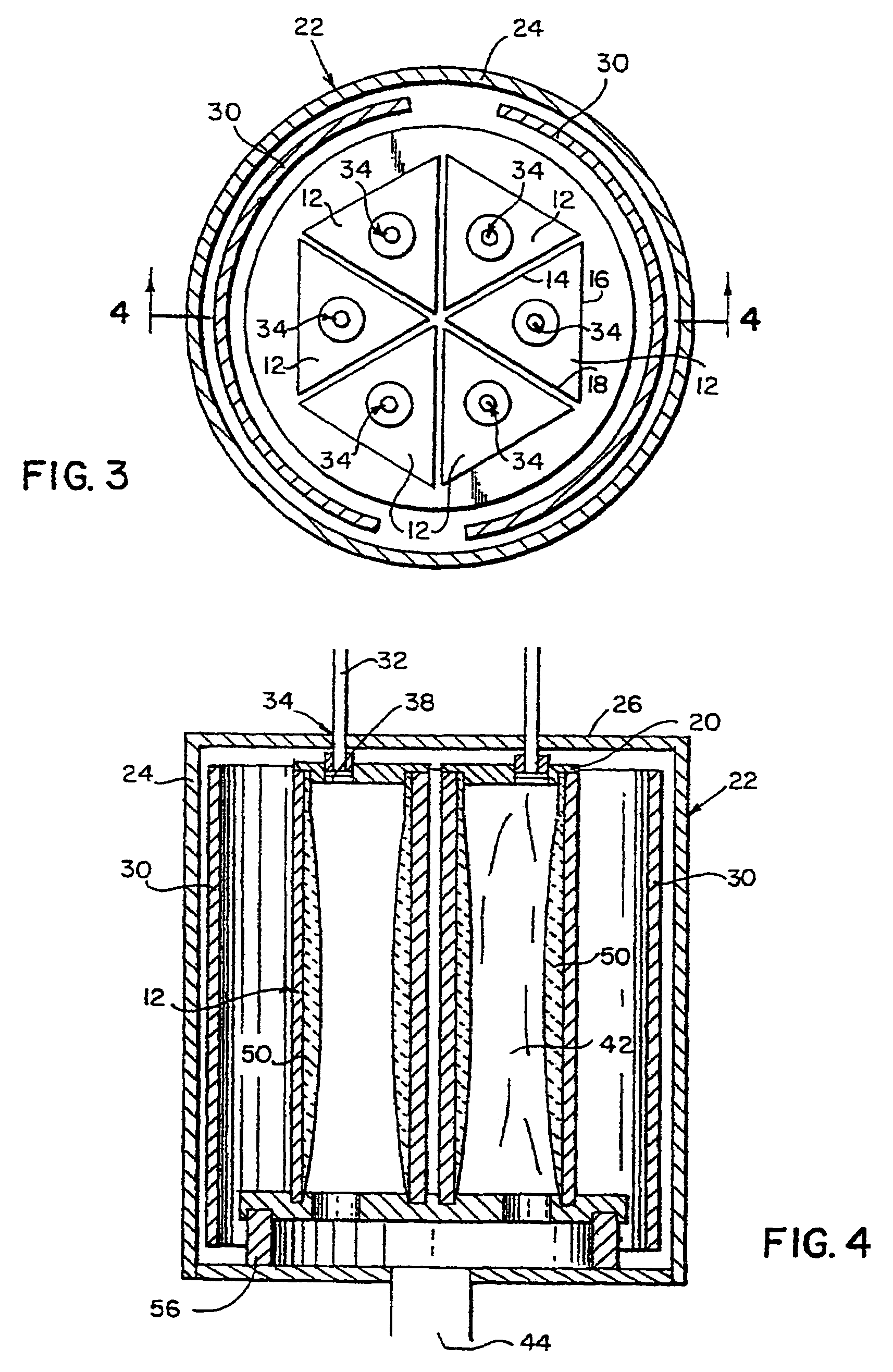

Polycrystalline sic electrical devices and methods for fabricating the same

ActiveUS20110148011A1Control DimensionsQuality improvementCeramic shaping apparatusCombustion ignition/checkingPorosityMetallurgy

The present invention relates to a novel electrical devices fabricated from polycrystalline silicon carbide (SiC) and methods for forming the same. The present invention provides a method for fabricating polycrystalline silicon carbide (SiC) products infiltrated with SiC-containing preceramic precursor resins to substantially mask the deleterious effects of trace contaminants, typically nitrogen and aluminum, while reducing operative porosity and enhancing manufacturing ease.

Owner:SURFACEIGNITER

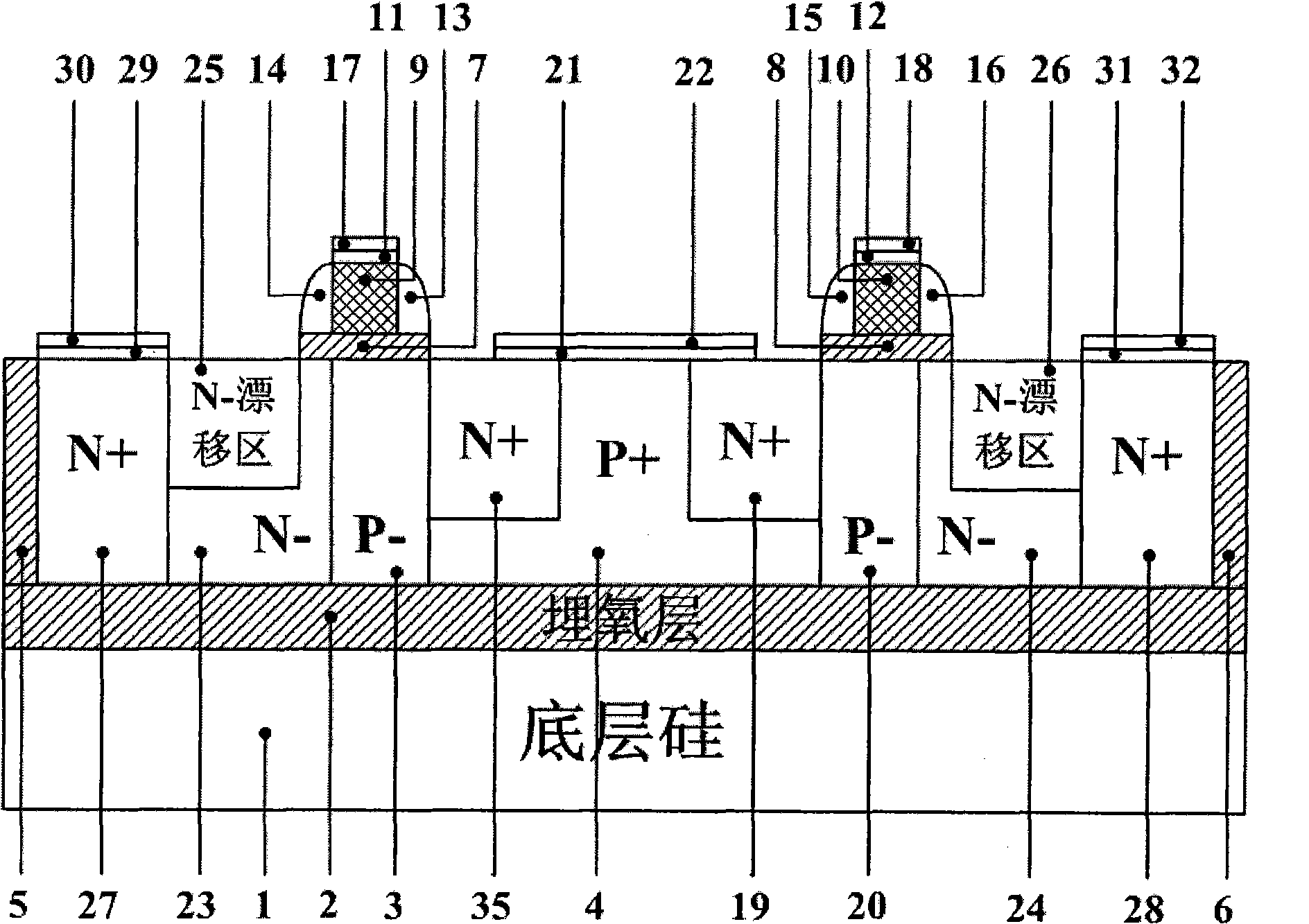

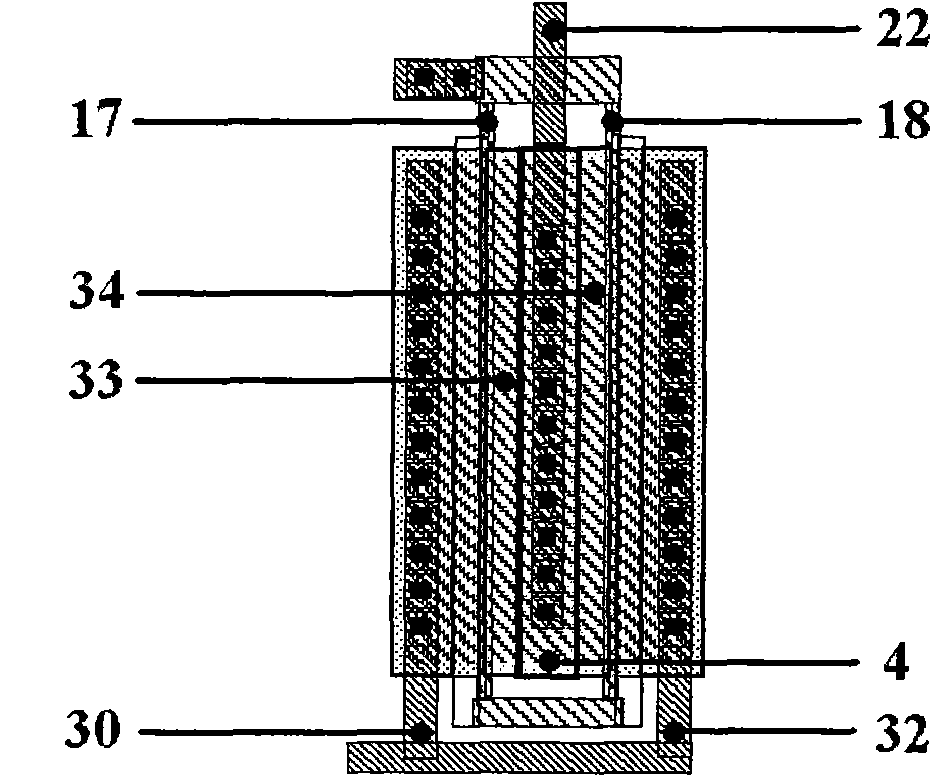

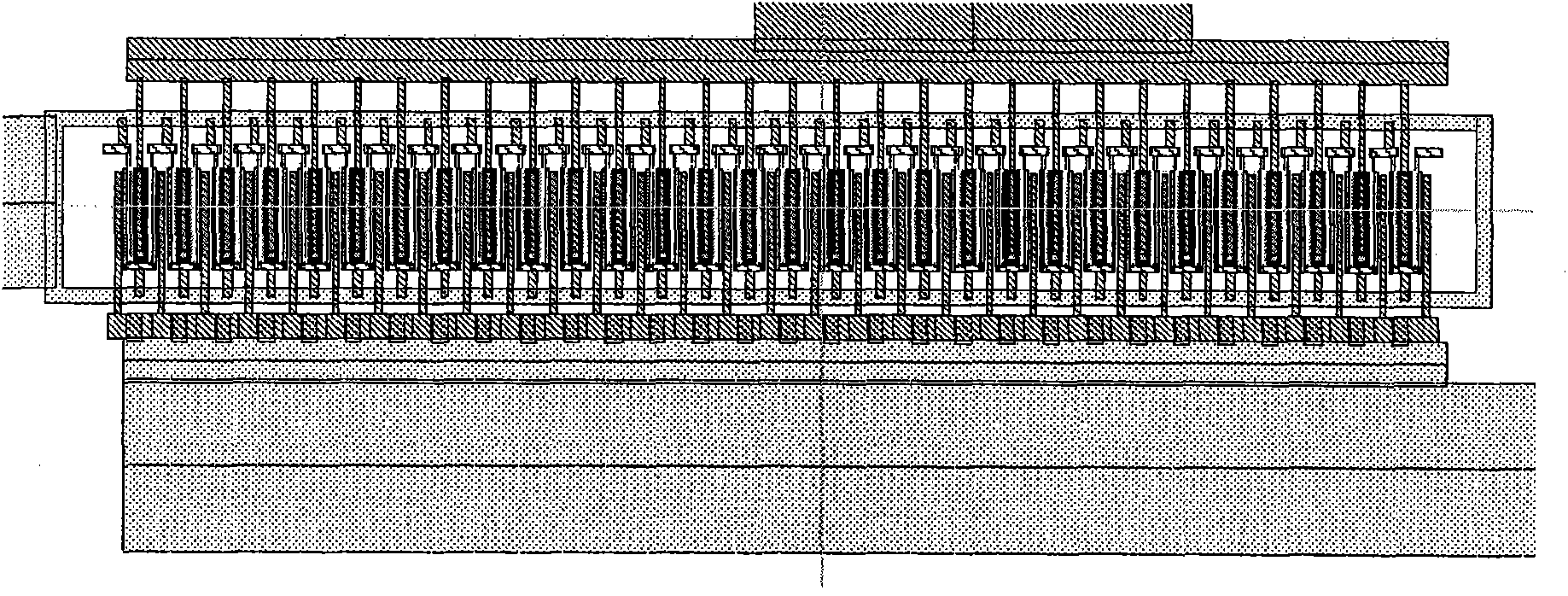

Radio frequency laterally diffused metal oxide semiconductor (LDMOS) device based on silicon on insulator (SOI) and method for injecting device

ActiveCN102054845AIncrease working frequencyImprove breakdown voltageSemiconductor/solid-state device detailsSolid-state devicesRadio frequencyPolycrystalline silicon carbide

The invention discloses a radio frequency silicon on insulator(SOI) laterally diffused metal oxide semiconductor (LDMOS) device provided with a low potential barrier body lead-out, which comprises a bottom layer silicon, a concealed oxide layer, a top layer silicon, a P-region, a N-region, a gate oxide layer, a polysilicon gate layer, a gate polycrystalline silicon carbide layer, a gate electrode, a side wall, a N-drift region, a drain region, a drain region silicate layer, a leakage electrode, a source region, a low potential barrier body lead-out region, a body region, a source region silicide layer, and a source electrode. In the invention, the radio frequency LDMOS device is manufactured on an SOI substrate, and a low potential barrier body lead-out is in a short circuit with the source region is formed by utilizing a heavily doped region homotypic with the P- region; the source / body, leakage / body as well as a gate is interconnected with each electrode by utilizing a silicide; a plurality of grate bars are in interdigital type parallel connection so as to enlarge the driving power of the device; and the invention provides a method for rectifying, back gate injection, N-region injection as well as N-drift region injection compatible with a complementary metal-oxide-semiconductor (CMOS) technology, as well as a N-drift region silicide conceal method compatible with the CMOS technology.

Owner:BEIJING ZHONGKE XINWEITE SCI & TECH DEV

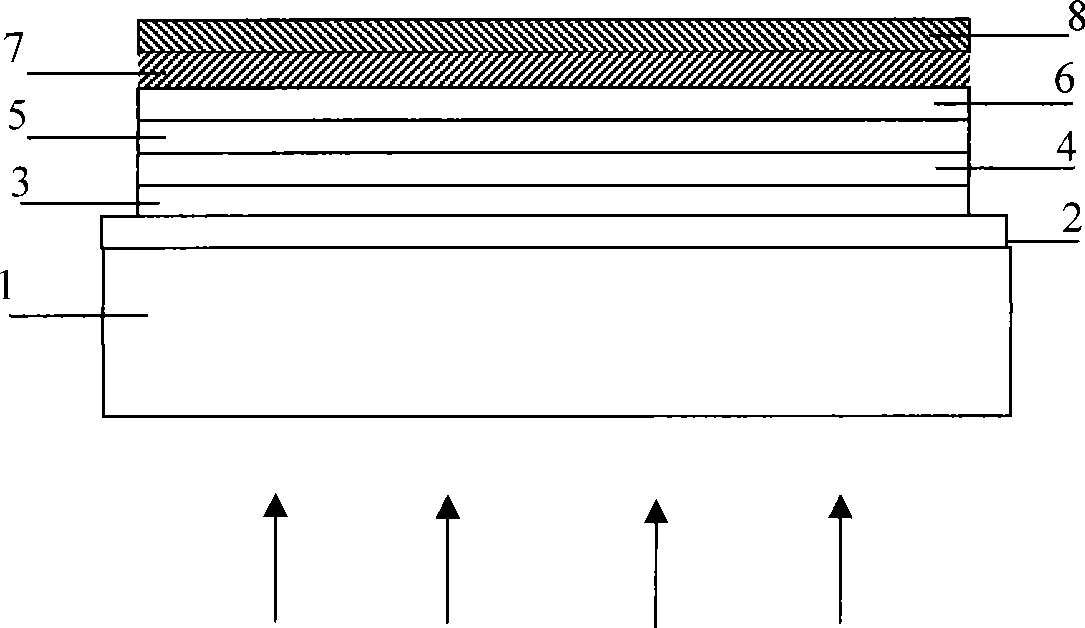

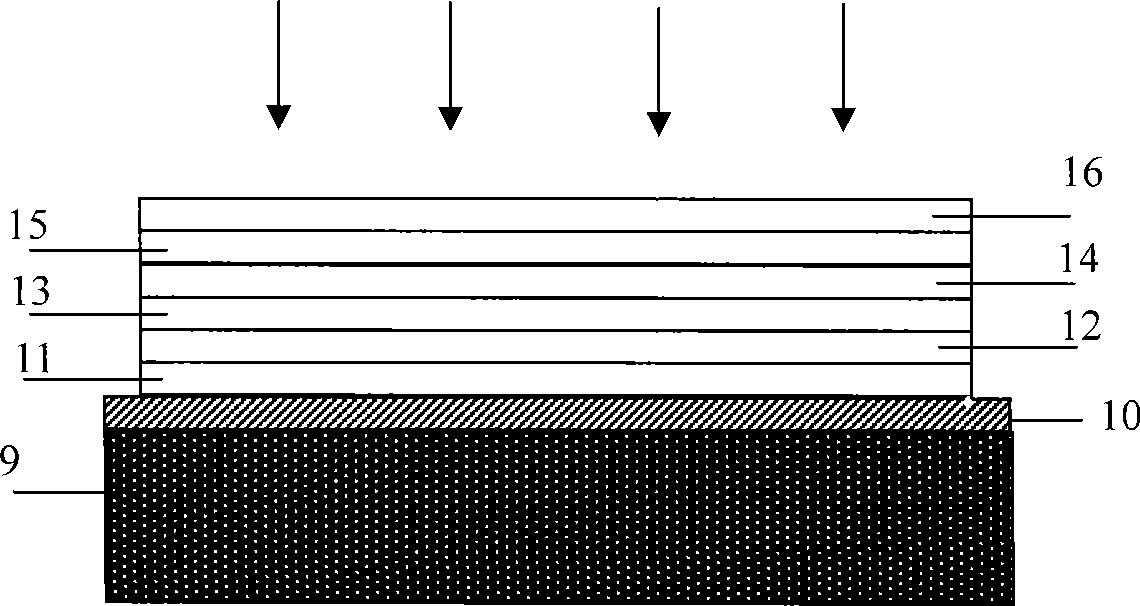

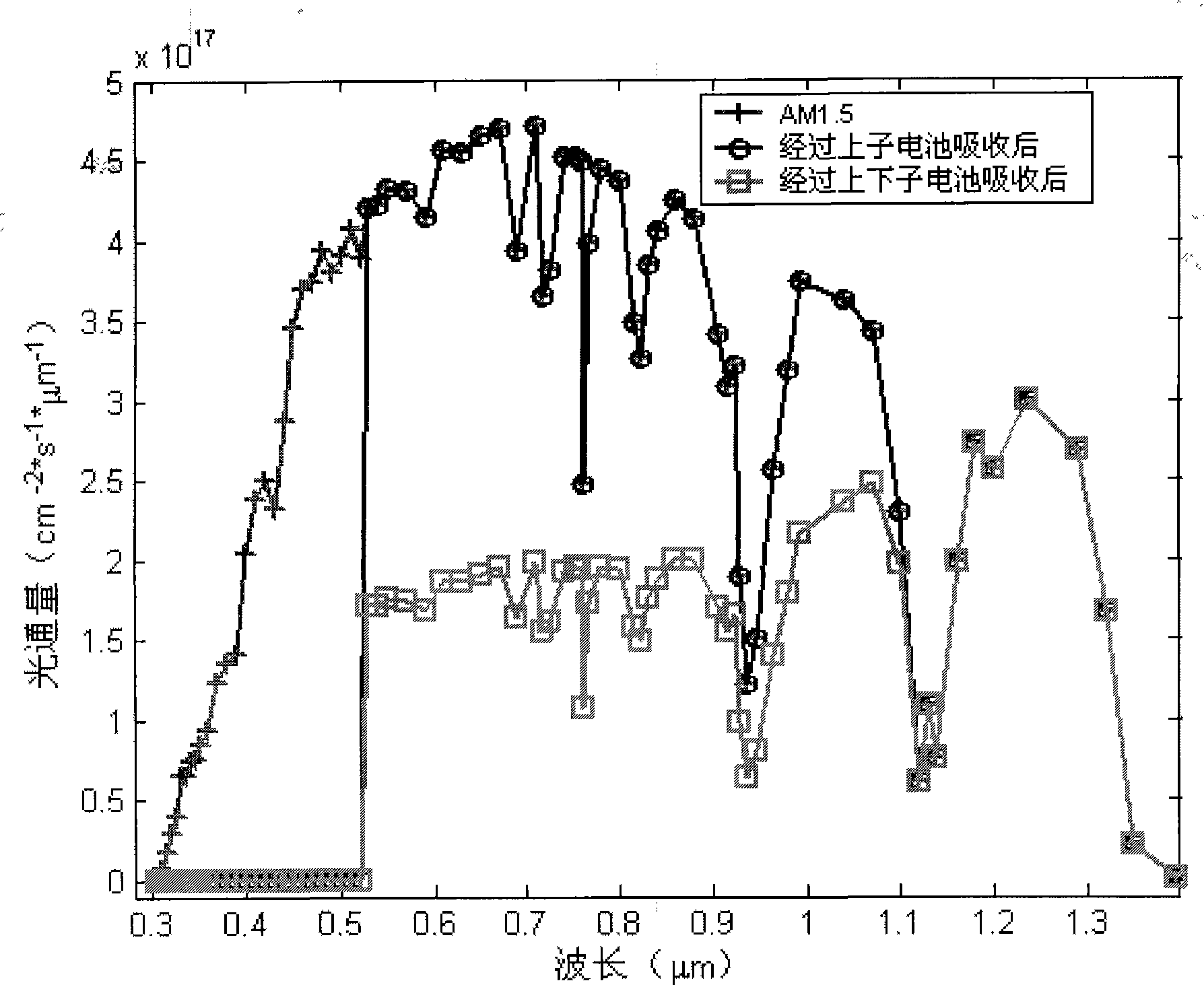

Polycrystalline-silicon carbide lamination thin-film solar cell

InactiveCN101393942ASave materialSimple structurePhotovoltaic energy generationSemiconductor devicesSource materialGas phase

The invention discloses a polycrystalline silicon and silicon carbide stacked film solar cell, and belongs to the technical field of solar cells. The solar cell is characterized in that a glass substrate or a stainless steel substrate is taken as a substrate for the solar cell; and the solar cell comprises a transparent conductive oxide layer, the deposition of which is triggered by the magnetron sputtering, and two stack-connected film sub-solar cells prepared by using the hot filament chemical vapor deposition method on the substrate, wherein, one sub-cell is composed of a p-type silicon carbide layer / n-type silicon carbide layer, and the other sub-cell is composed of a p-type polycrystalline silicon layer / n-type polycrystalline silicon layer. The invention is characterized in that the two silicon-based materials of different band gap widths are in stack-connection with each other, so that the availability of solar spectrum and the photoelectric conversion efficiency are improved. With the inexpensive substrate and a low cost film growing source material, the invention reduces the cost of the solar cell, and gains a consequent competitive edge against a crystalline silicon solar cell.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Composite cordierite filters

InactiveCN1602222ALower peak temperatureImprove thermal conductivityDispersed particle filtrationExhaust apparatusBorideCarbide silicon

Composite cordierite honeycomb structures especially suitable for diesel exhaust filtration applications comprise a non-oxide polycrystalline phase constituting 10-70% by weight, with the remainder of the ceramic material constituting a cordierite phase, the non-oxide polycrystalline phase being selected from the group consisting of carbides, nitrides, and borides. Preferably the non-oxide phase is either polycrystalline silicon carbide or polycrystalline silicon nitride and has a particle aspect ratio of less than 3. Inventive ceramic bodies are porous with an open porosity of at least 30%, preferably between 40% and 60%, and a median pore size of at least 5 micrometers, more preferably greater than 8 micrometers and less than 12 micrometers.

Owner:CORNING INC

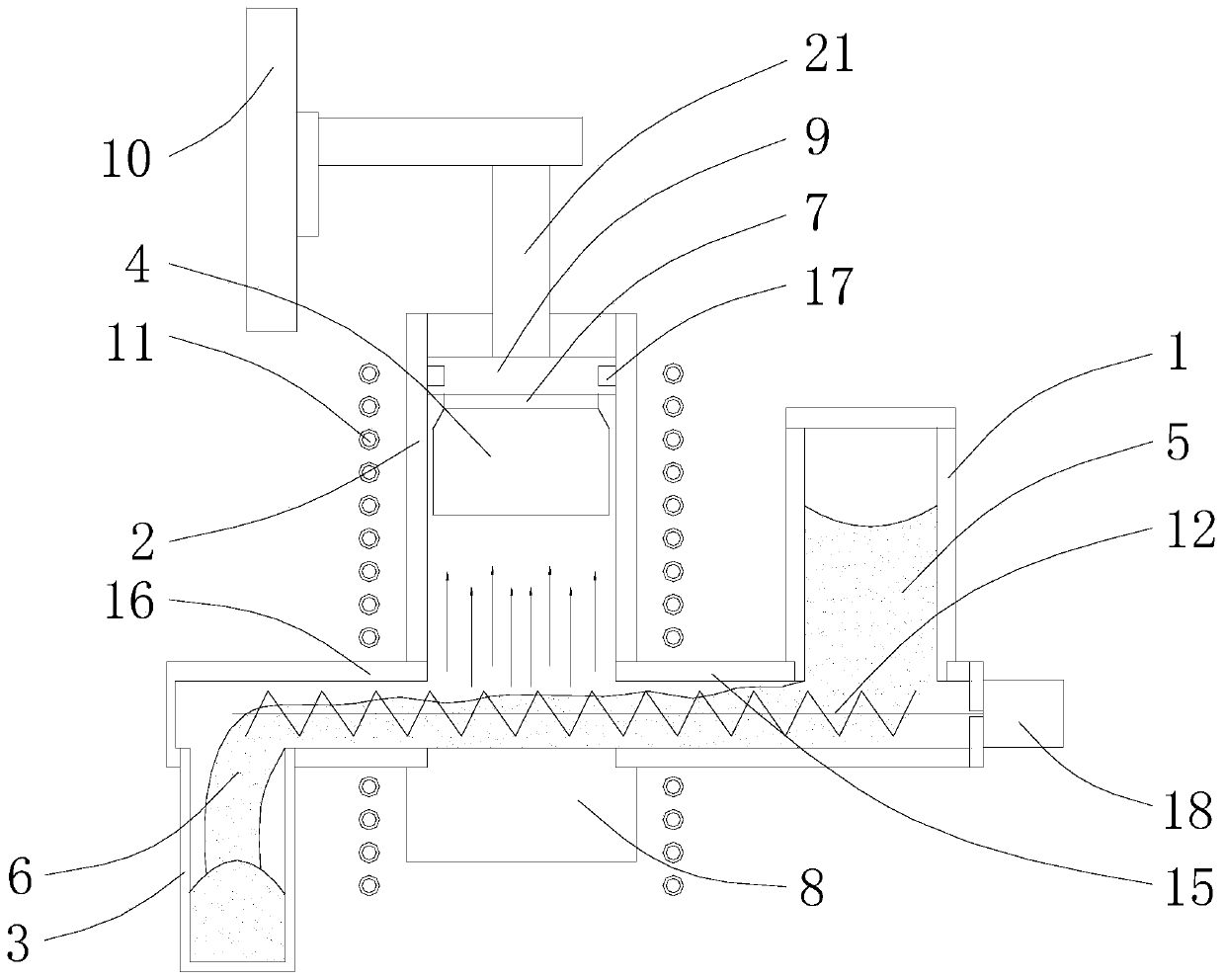

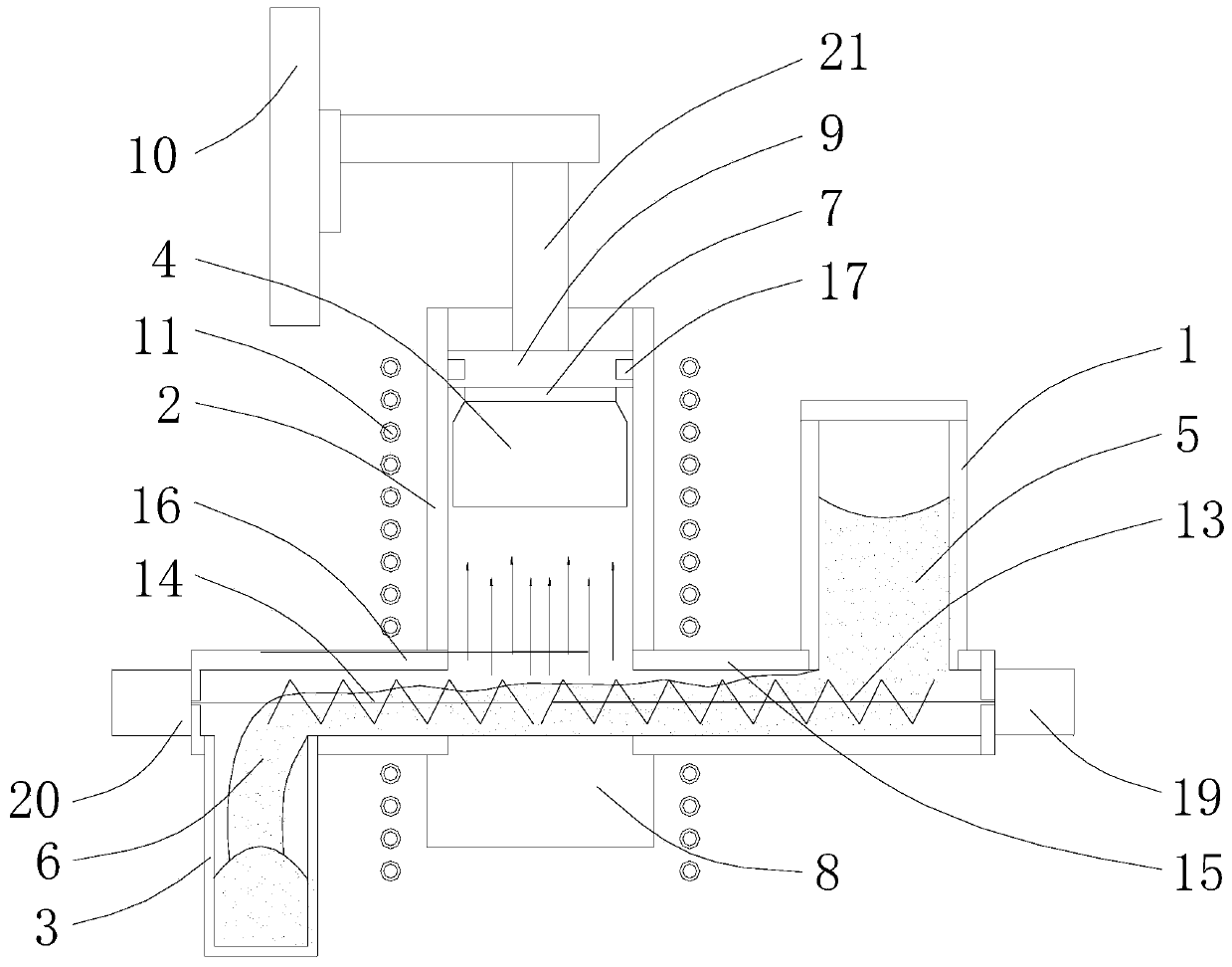

Silicon carbide single crystal continuous growth device and growth method thereof

ActiveCN110408998AContinuous Growth GuaranteeDoes not affect growing conditionsPolycrystalline material growthFrom condensed vaporsCrucibleLarge size

The invention discloses a silicon carbide single crystal continuous growth device, the silicon carbide single crystal continuous growth device comprises a raw material bin, a growth bin and a recoverybin which are communicated in sequence, and a feeding mechanism for feeding silicon carbide polycrystalline raw materials in the raw material bin into the growth bin, the feeding mechanism is also used for feeding residues in the growth bin into the recovery bin, and the feeding mechanism sequentially passes through the raw material bin, the growth bin and the recovery bin along the feeding direction; the growth bin comprises a crucible body, a liftable crucible cover which sleeves or penetrates the upper part of the crucible body and is used for installing seed crystals on the lower surfaceof the crucible body, a driving mechanism for driving the crucible cover to lift, and a heating mechanism for heating the crucible body; and the crucible cover is positioned above the feeding mechanism. According to the silicon carbide single crystal continuous growth device, the polycrystalline silicon carbide raw materials in the crucible body can be continuously supplemented to ensure continuous growth of silicon carbide single crystals so as to obtain large-size silicon carbide single crystals; meanwhile, the transportation of the silicon carbide polycrystalline raw materials and the growth conditions of the silicon carbide single crystals are not affected.

Owner:江苏星特亮科技有限公司

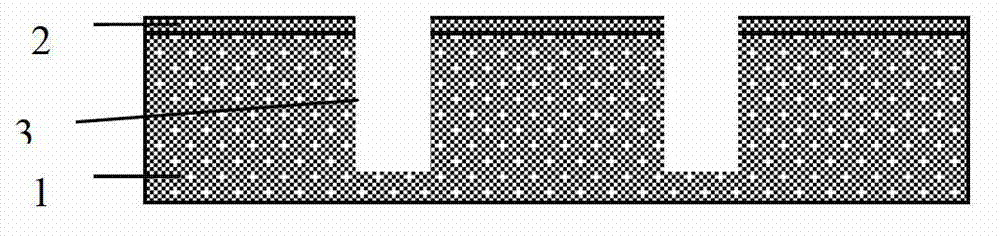

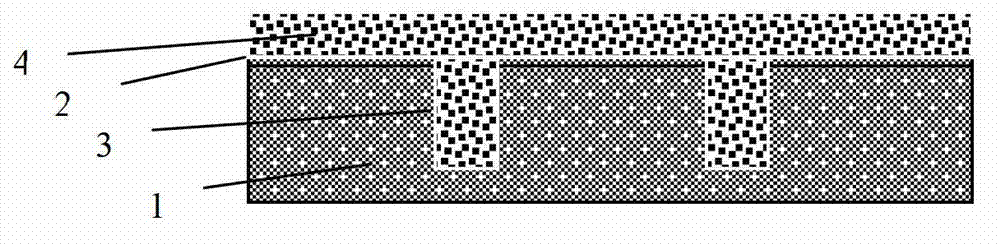

Formation method of groove-shaped semiconductor structure

InactiveCN103035488AReduce stressReduce defect densitySemiconductor/solid-state device manufacturingSemiconductor structureAmorphous silicon

The invention discloses a formation method of a groove-shaped semiconductor structure. Due to the fact that polycrystalline silicon or amorphous silicon is mixed with carbide (C) to fill a groove, or polycrystalline silicon carbide (Si C) or amorphous Si C replaces the polycrystalline silicon or the amorphous silicon to fill the groove, stress of a component is capable of being reduced, and thereby defects inside silicon caused by the stress of the polycrystalline silicon or the amorphous silicon are prevented, and therefore the trench gate semiconductor structure with low stress and defect concentration or a groove access with low resistance is obtained.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

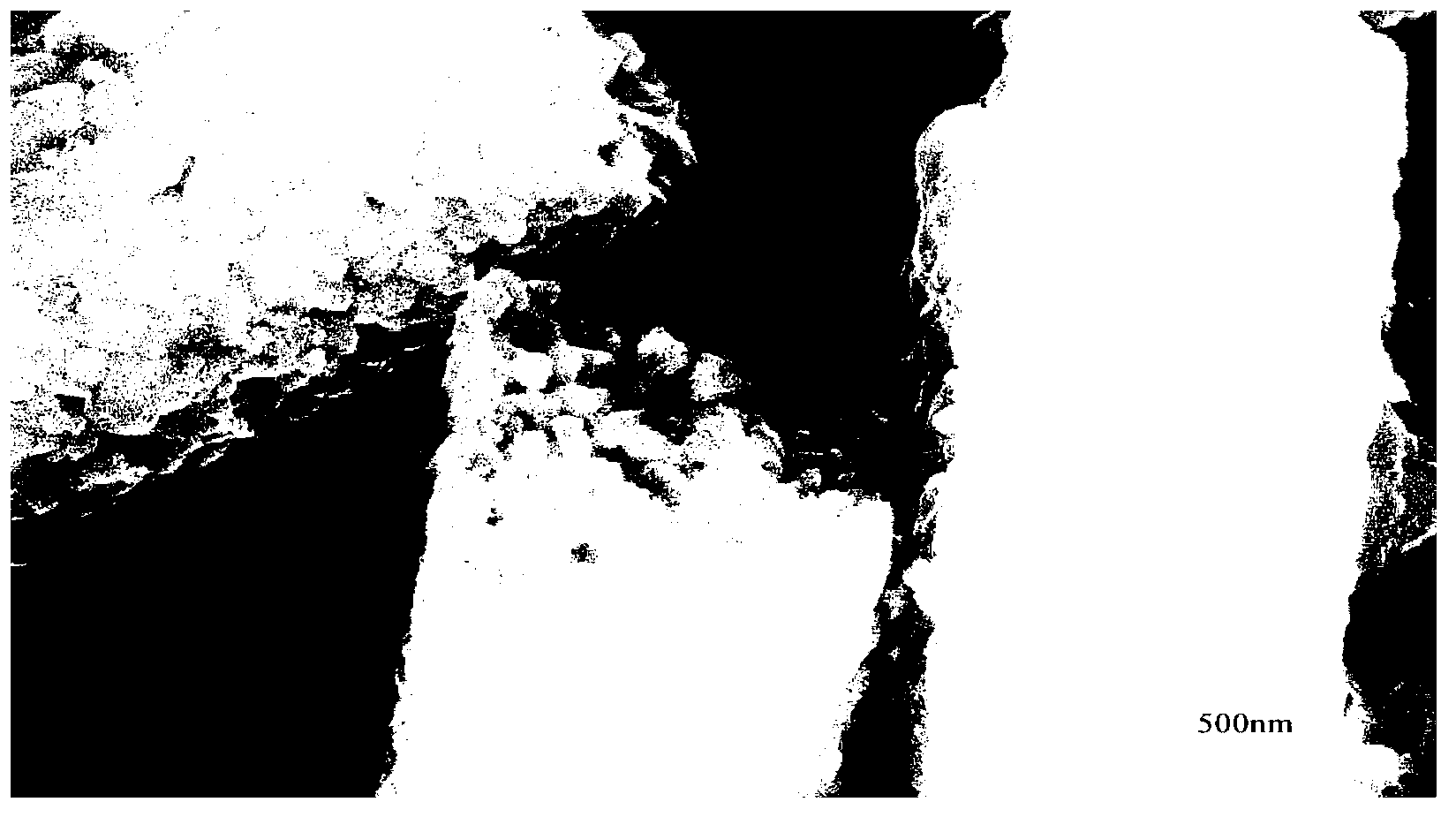

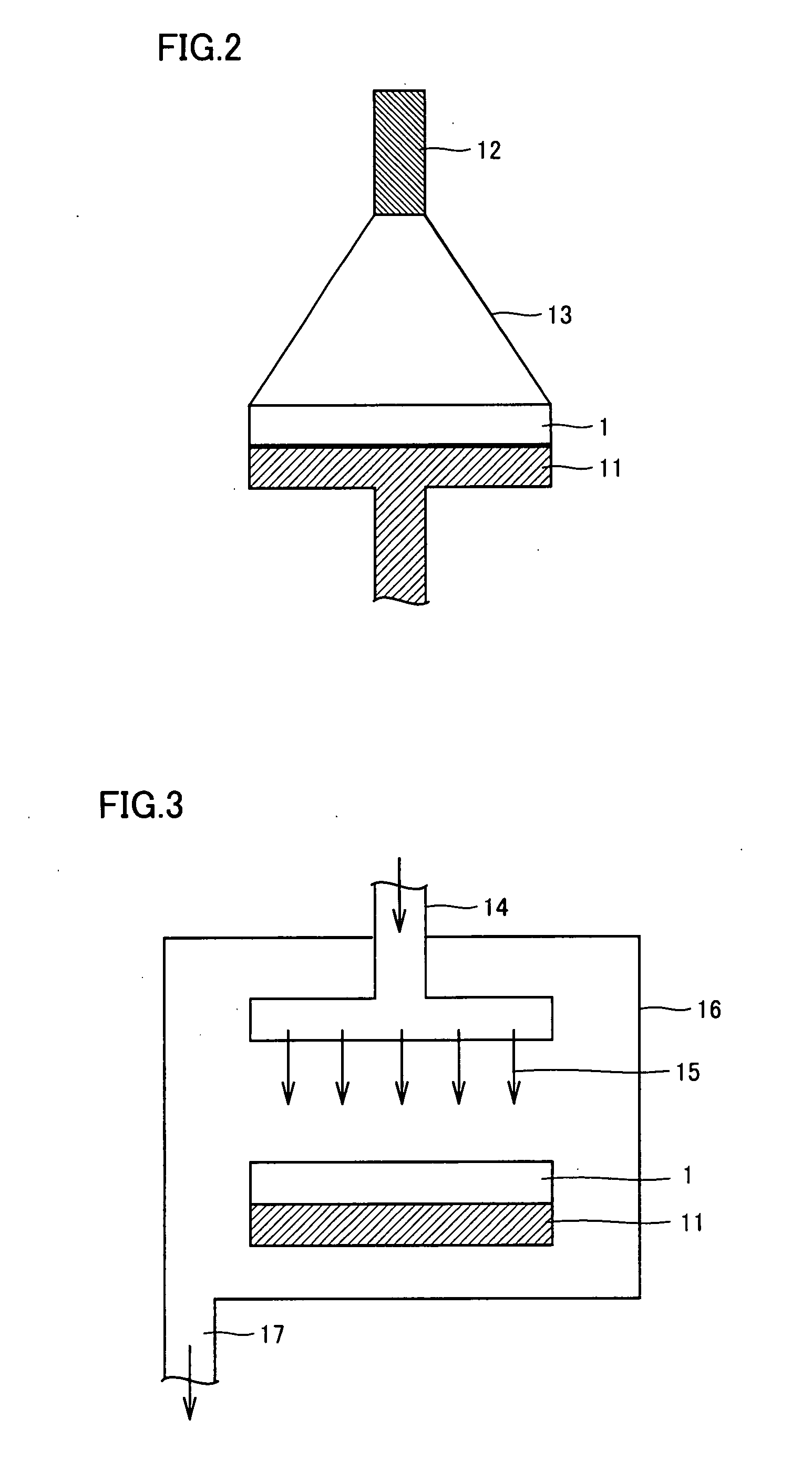

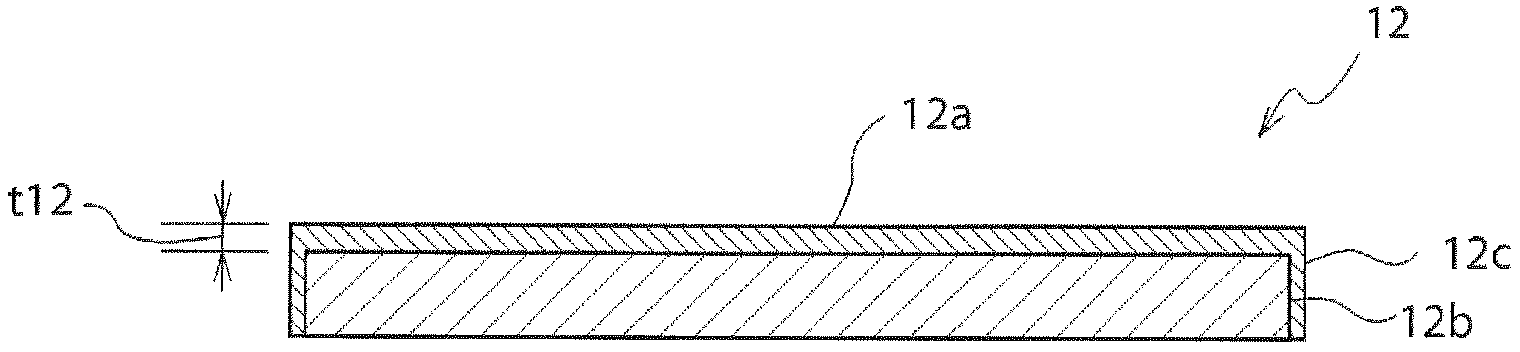

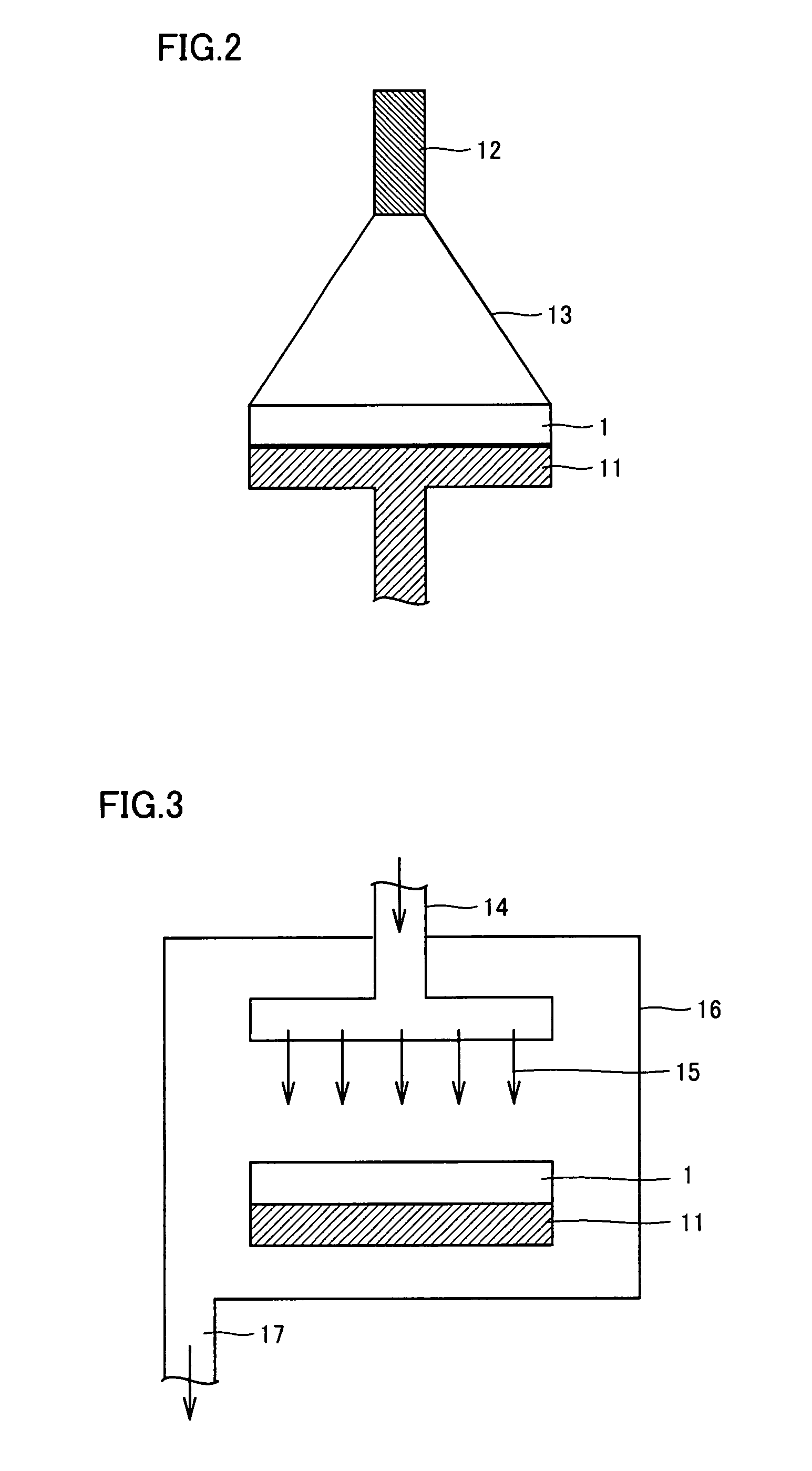

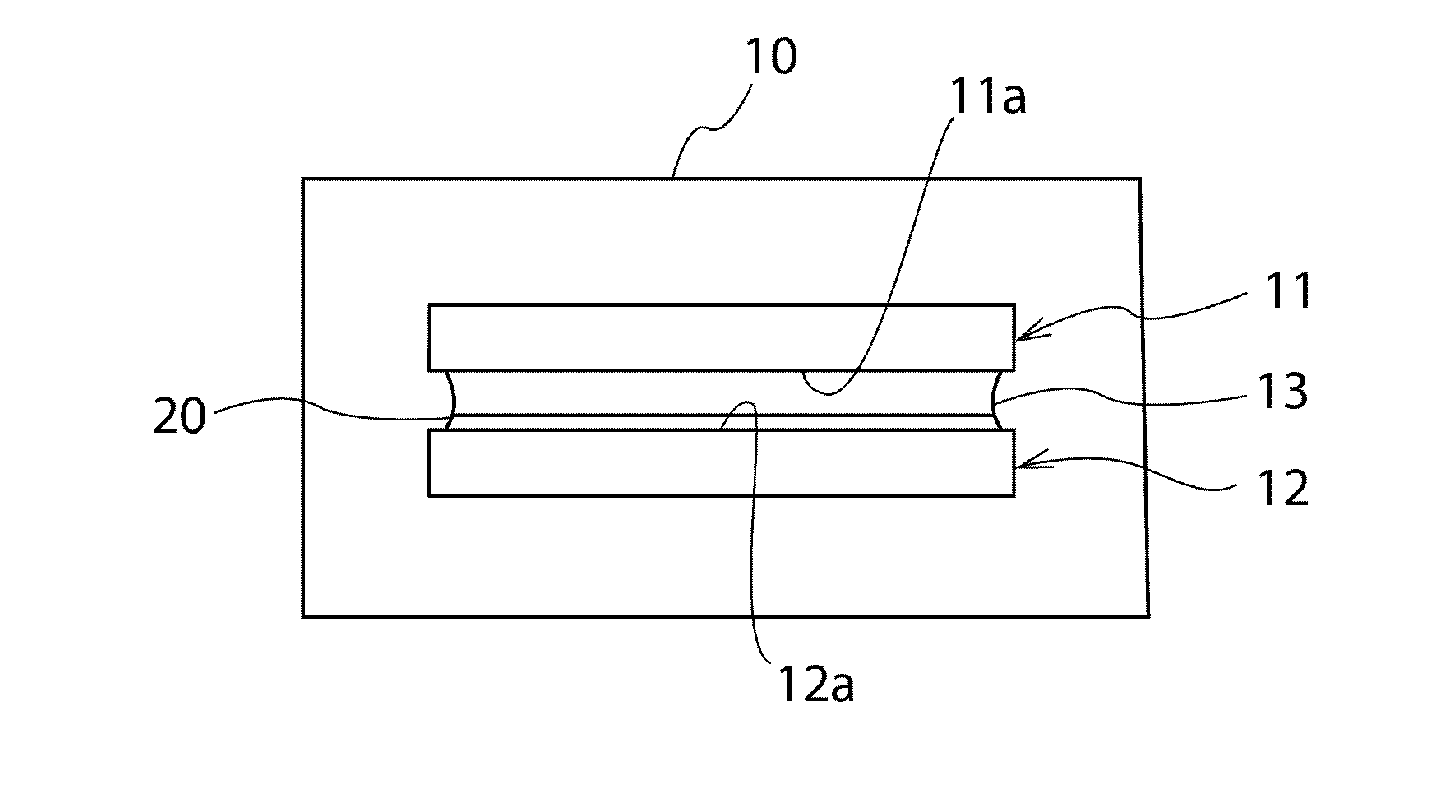

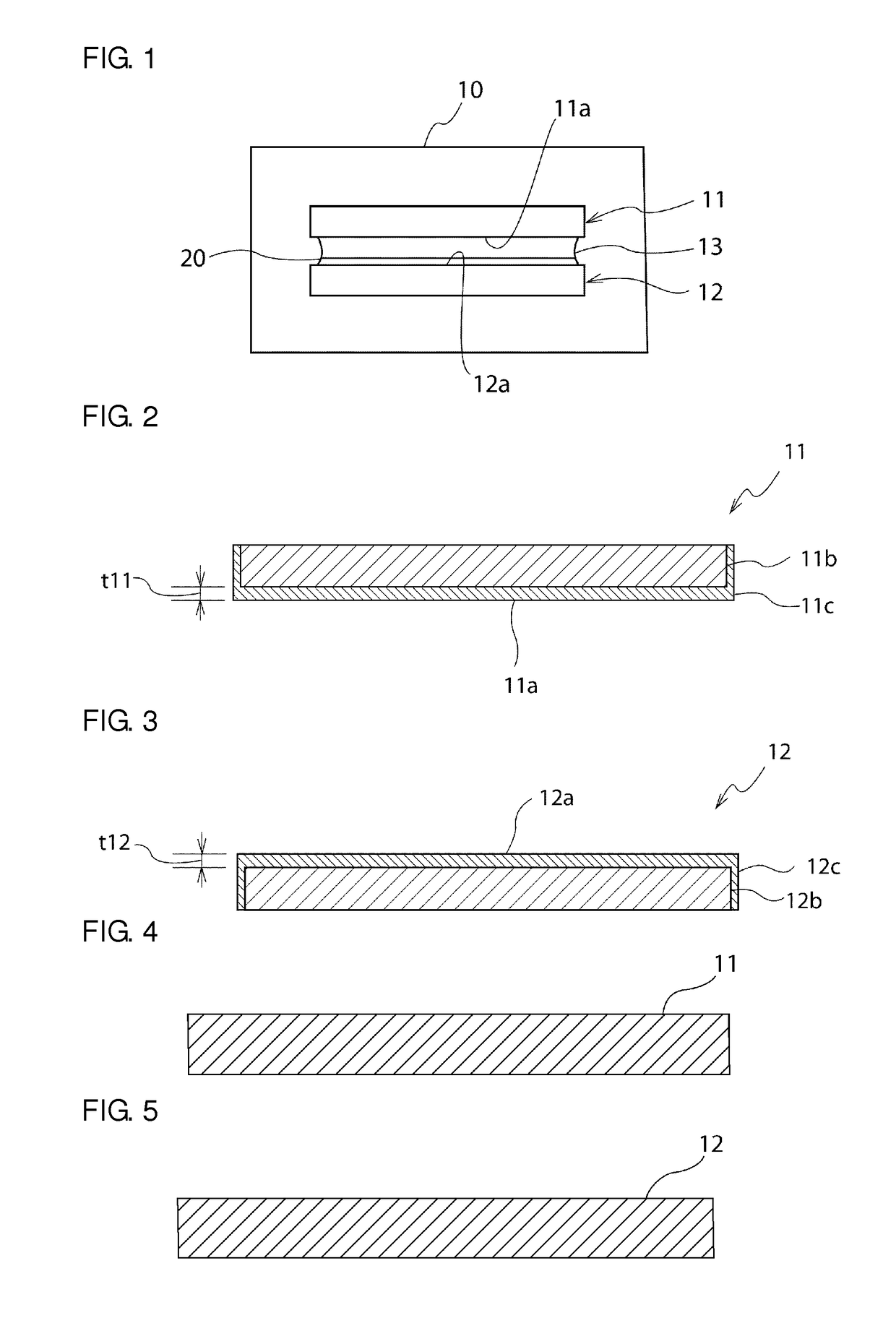

Seed material for liquid phase epitaxial growth of monocrystalline silicon carbide, and method for liquid phase epitaxial growth of monocrystalline silicon carbide

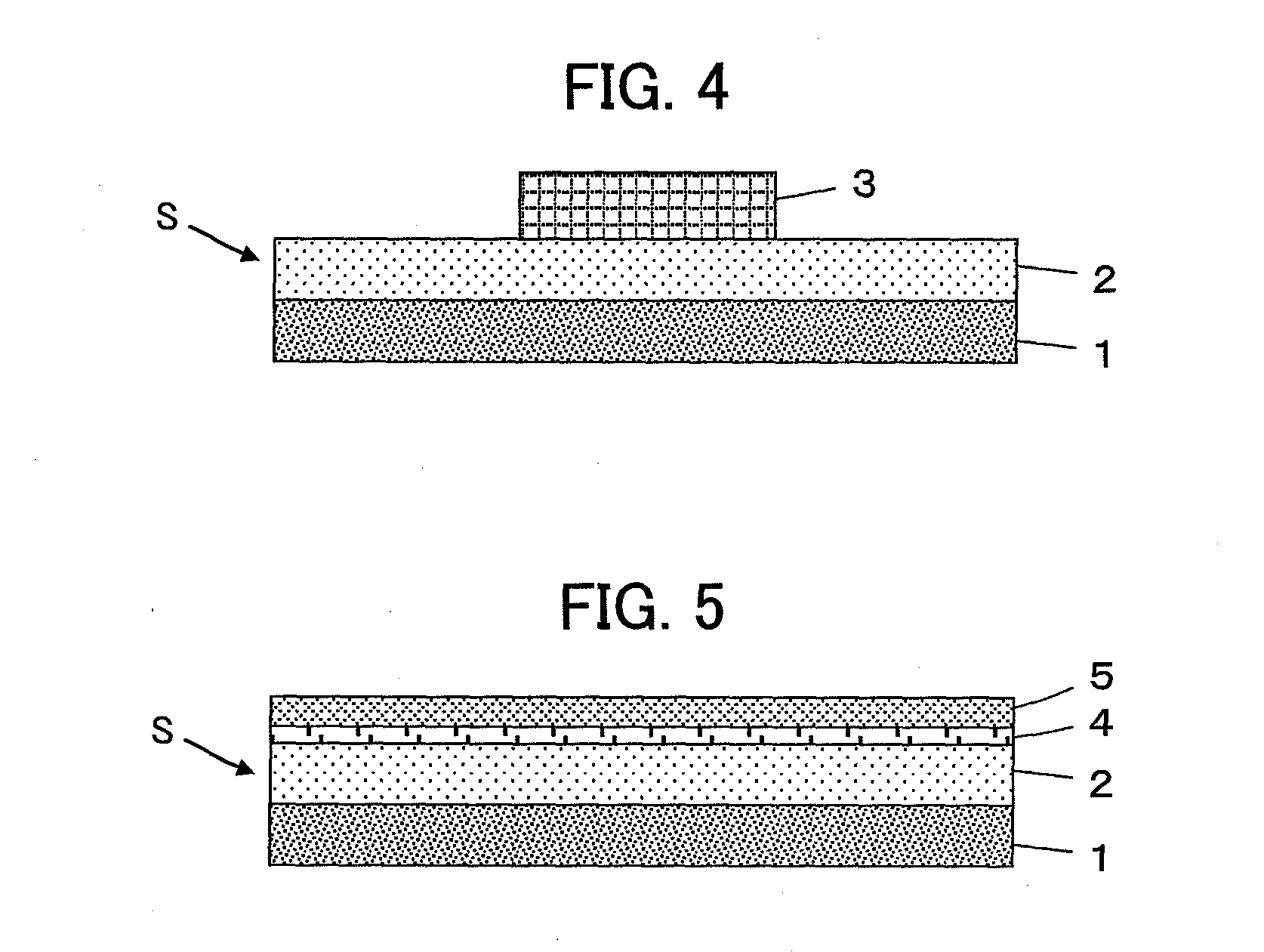

InactiveCN103270201APolycrystalline material growthLiquid-phase epitaxial-layer growthSurface layerCubic crystal system

Provided is an inexpensive seed material for liquid phase epitaxial growth of a silicon carbide. A seed material (12) for liquid phase epitaxial growth of a monocrystalline silicon carbide has a surface layer containing a polycrystalline silicon carbide having a crystal polymorph of a cubic crystal system. When said surface layer is subjected to X-ray diffraction, a primary diffraction peak corresponding to a (111) crystal surface is observed and other primary diffraction peaks having a diffraction strength equal to or greater than 10% of the diffraction strength of the primary diffraction peak corresponding to the (111) crystal surface are not observed as the diffraction peaks corresponding to the polycrystalline silicon carbide having a crystal polymorph of a cubic crystal system.

Owner:TOYO TANSO KK

Polycrystalline Sic Electrical Devices and Methods for Fabricating the Same

InactiveUS20080265471A1Control DimensionsQuality improvementCeramic shaping apparatusCombustion ignition/checkingPorosityMetallurgy

The present invention relates to a to novel electrical devices fabricated from polycrystalline silicon carbide (SiC) and methods for forming the same. The present invention provides a method for fabricating polycrystalline silicon carbide (SiC) products infiltrated with SiC-containing preceramic precursor resins to substantially mask the deleterious effects of trace contaminants, typically nitrogen and aluminum, while reducing operative porosity and enhancing manufacturing ease.

Owner:COLOPY CURTIS M

Chemical vapor deposition method and device for preparing polycrystalline silicon carbide

PendingCN110644048AHigh purityNo crackPolycrystalline material growthChemical vapor deposition coatingCarbide siliconMeth-

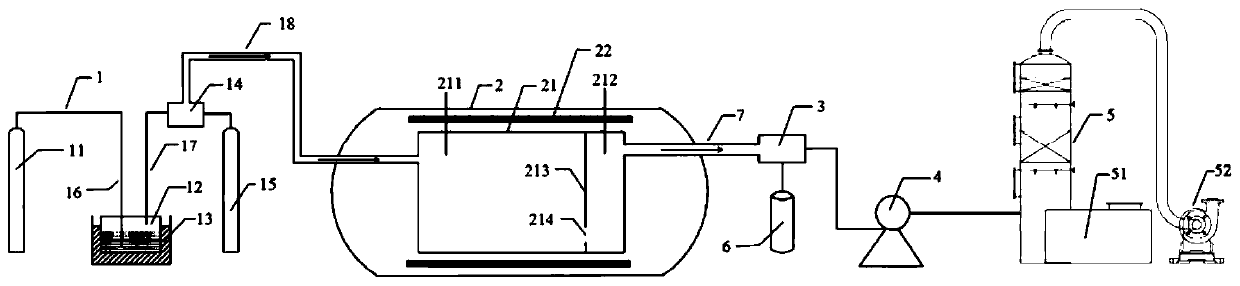

The invention provides a chemical vapor deposition method and device for preparing polycrystalline silicon carbide, and belongs to the technical field of chemical vapor deposition. The method comprises the steps: raising the temperature of a chemical vapor deposition chamber to 400-500 DEG C within 2-4 h, and carrying out heat preservation for 4-6 h; raising the temperature to 1100-1500 DEG C within 4-10 h, and carrying out heat preservation for 1-2 h; then carrying out chemical vapor deposition, cooling to 700-800 DEG C within 30-55 h, and carrying out heat preservation for 4-6 h, and coolingto room temperature within 40-60 h, so as to ensure that the obtained silicon carbide product is complete, free of cracking, higher in purity, flatter and smoother in surface and smaller in particlesize. The deposition chamber is divided into the chemical vapor deposition chamber and a dust collection chamber by a partition plate with holes; a gas inlet of the chemical vapor deposition chamber and a gas outlet of the dust collection chamber are positioned above the holes, so airflow flows in the chamber in a Z-shaped mode, the walking path and the retention time of the airflow in the chambers are prolonged, the decomposition degree of methyl trichlorosilane is increased, the yield is increased, meanwhile, methyl trichlorosilane entering a rear-end gas outlet pipeline is reduced, pipelineblockage is avoided, and production is guaranteed to be smoothly carried out.

Owner:安徽中飞科技有限公司

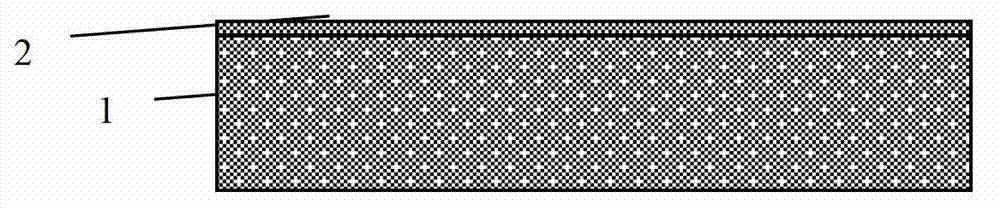

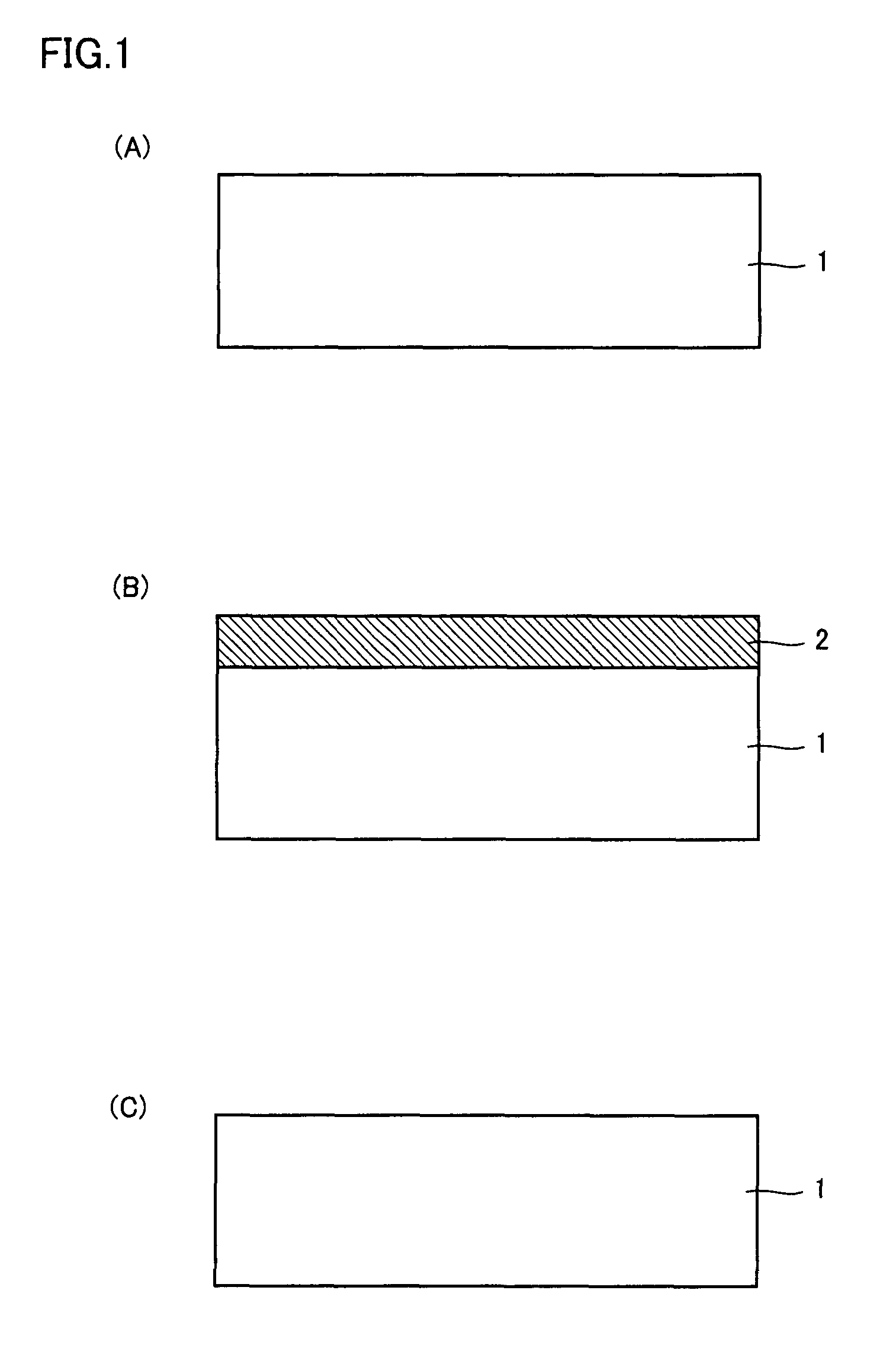

Silicon carbide substrate production method and silicon carbide substrate

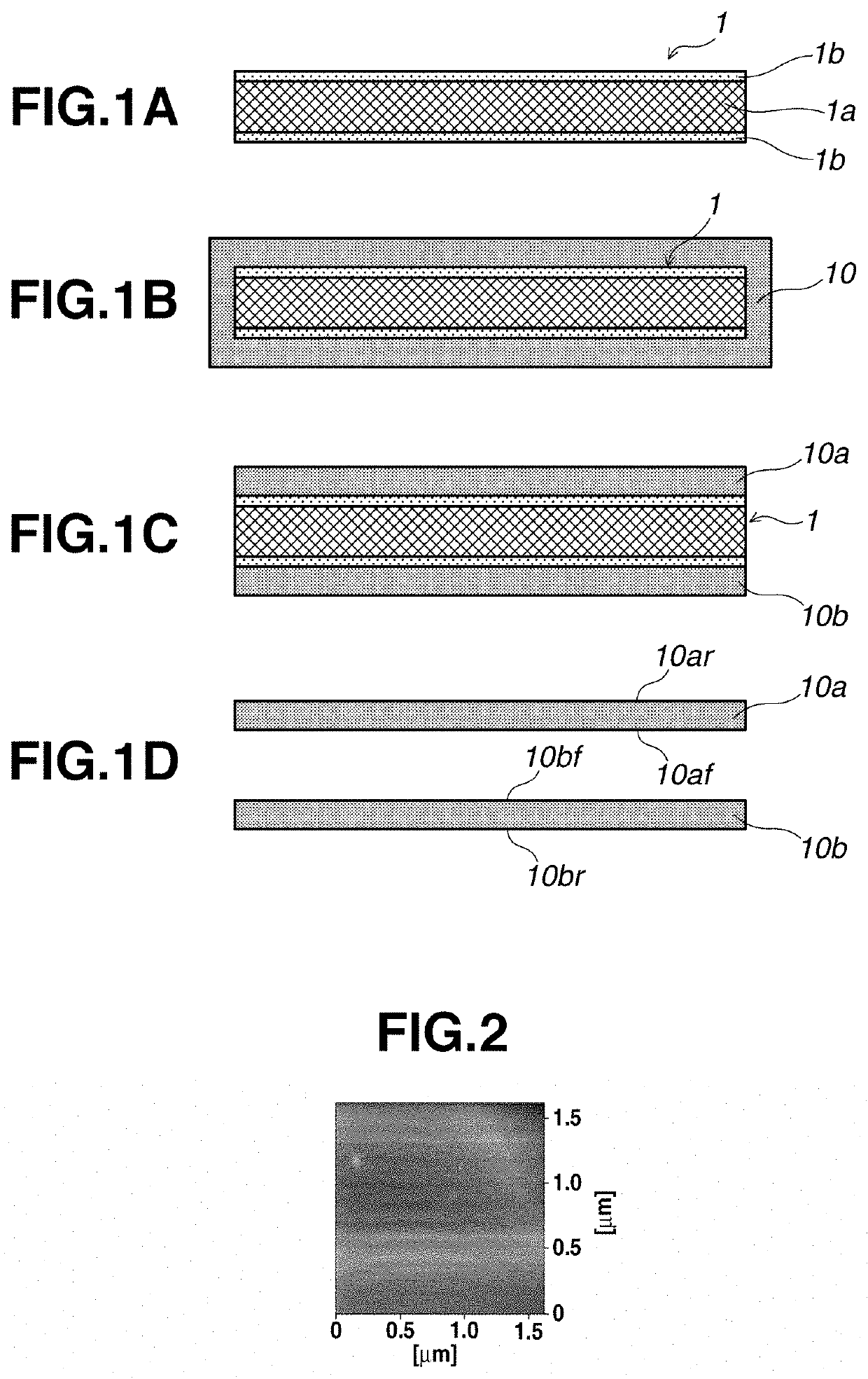

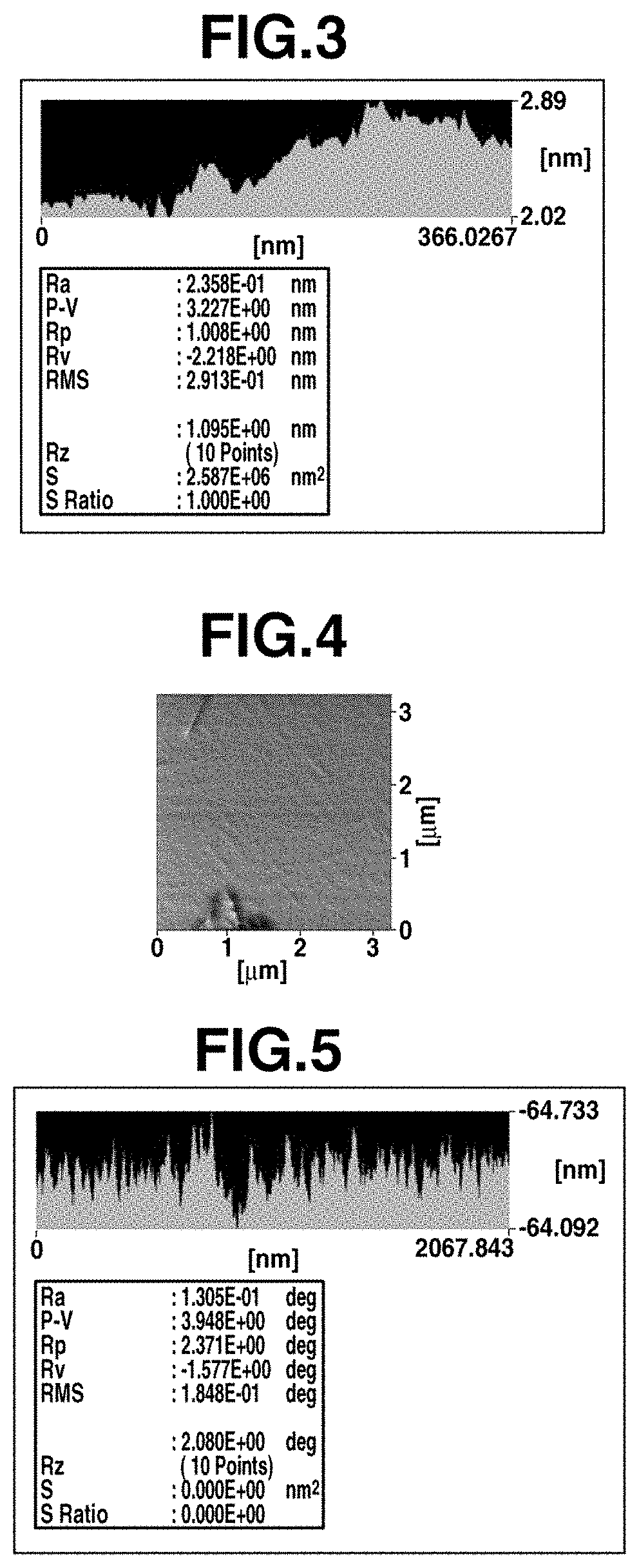

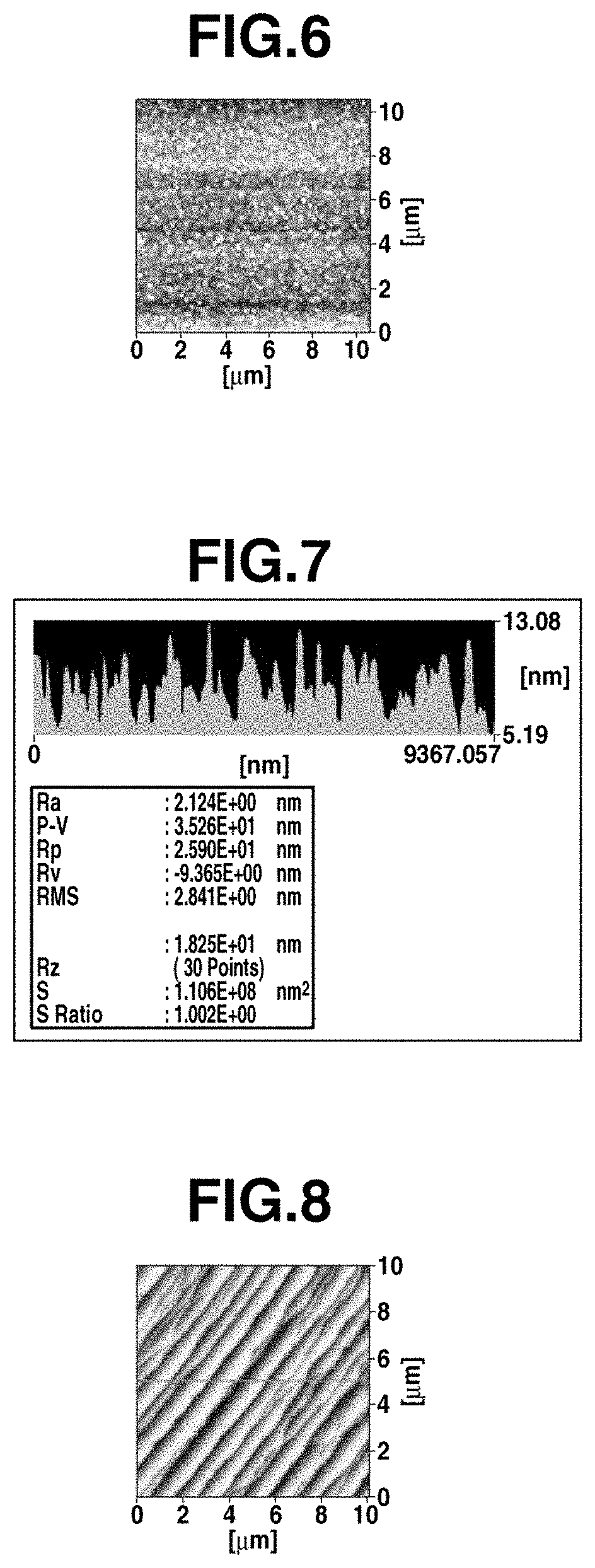

A silicon carbide substrate production method includes: the step of providing covering layers 1b, 1b, each containing silicon oxide, silicon nitride, silicon carbonitride, or silicide, respectively on both surfaces of a base material substrate 1a carbon, silicon or silicon carbide, and turning the surface of each of the covering layers 1b, 1b into a smooth surface to prepare a support substrate 1; a step of forming a polycrystalline silicon carbide film 10 on both surfaces of the support substrate 1 by a gas phase growth method or a liquid phase growth method; and a step of separating the polycrystalline silicon carbide films from the support substrate while preserving, on the surface thereof, the smoothness of the covering layer surfaces 1b, 1b by chemically removing at least the covering layers 1b, 1b, from the support substrate 1. The silicon carbide substrate has a smooth surface and reduced internal stress.

Owner:SHIN ETSU CHEM IND CO LTD +1

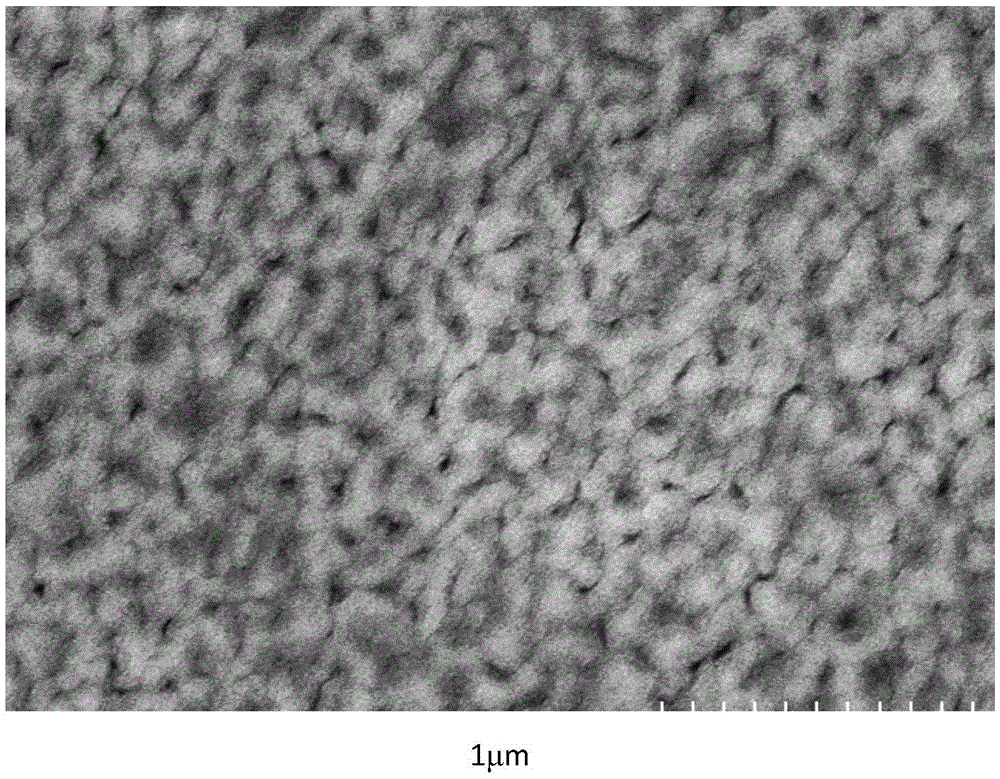

Growing method for polycrystalline silicon carbide thin film

InactiveCN105543795AIncrease deposition rateImprove compactnessVacuum evaporation coatingSputtering coatingSputteringPhotovoltaic industry

The invention provides a growing method for a polycrystalline silicon carbide thin film, and relates to silicon carbide thin films. According to the growing method for the polycrystalline silicon carbide thin film, impurities and defects inside the silicon carbide thin film can be effectively reduced and overcome, the thin film rupture phenomenon caused by large tensile stress in the thin film is avoided, and the quality of the silicon carbide thin film is significantly improved. The growing method for the polycrystalline silicon carbide thin film comprises the steps that 1, a cleaned substrate is fed into a magnetron sputtering apparatus to be sputtered; 2, after sputtering is completed, cooling is conducted, so that an amorphous silicon carbide thin film sample is formed; and 3, after annealing is conducted, the polycrystalline silicon carbide thin film is obtained. A polycrystalline silicon carbide thin film sample is prepared on the aluminum-doped zinc oxide substrate through the magnetron sputtering apparatus. The silicon carbide thin film of uniform dimensions is obtained by controlling growth parameters. The preparation process is simple, the technology is stable, the repeatability is good and toxic or hazardous gases do not need to be used; in addition, the prepared polycrystalline silicon carbide thin film is high in deposition rate and good in compactness. The growing method for the polycrystalline silicon carbide thin film can be applied to the microelectronic industry and the photovoltaic industry and has the advantages of being low in cost, easy to produce in a large scale, free of pollution and the like.

Owner:XIAMEN UNIV

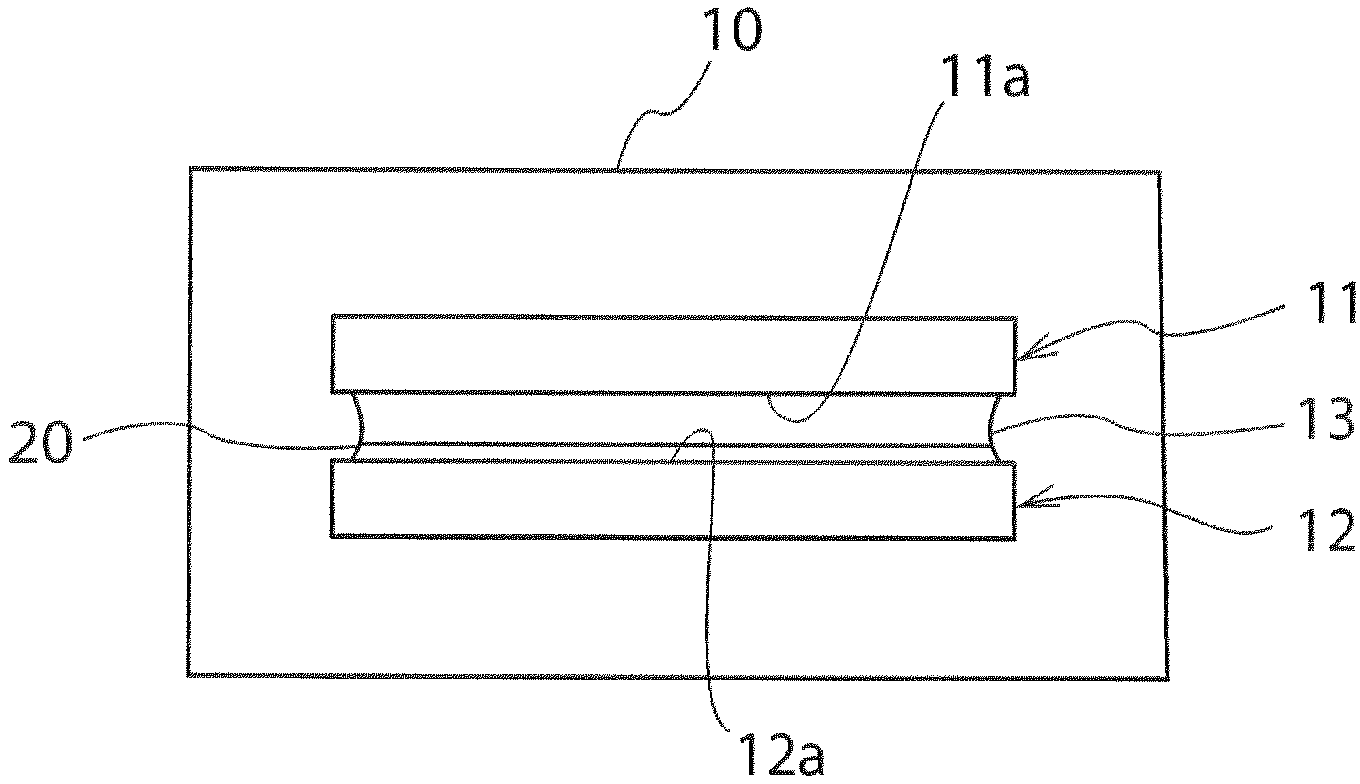

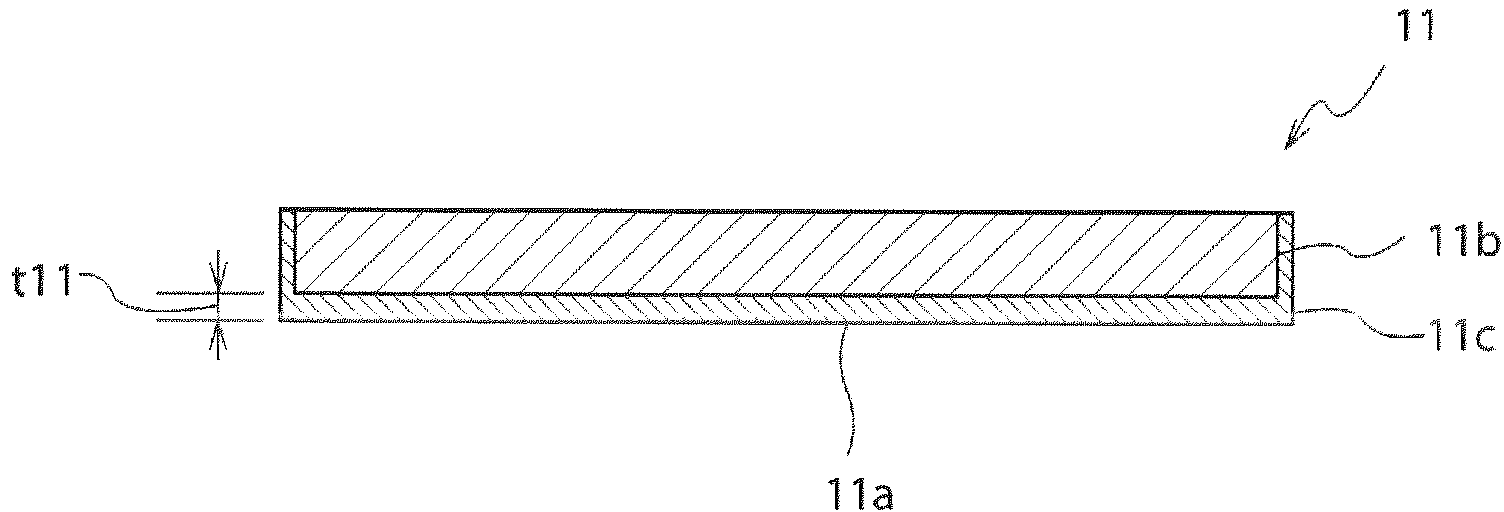

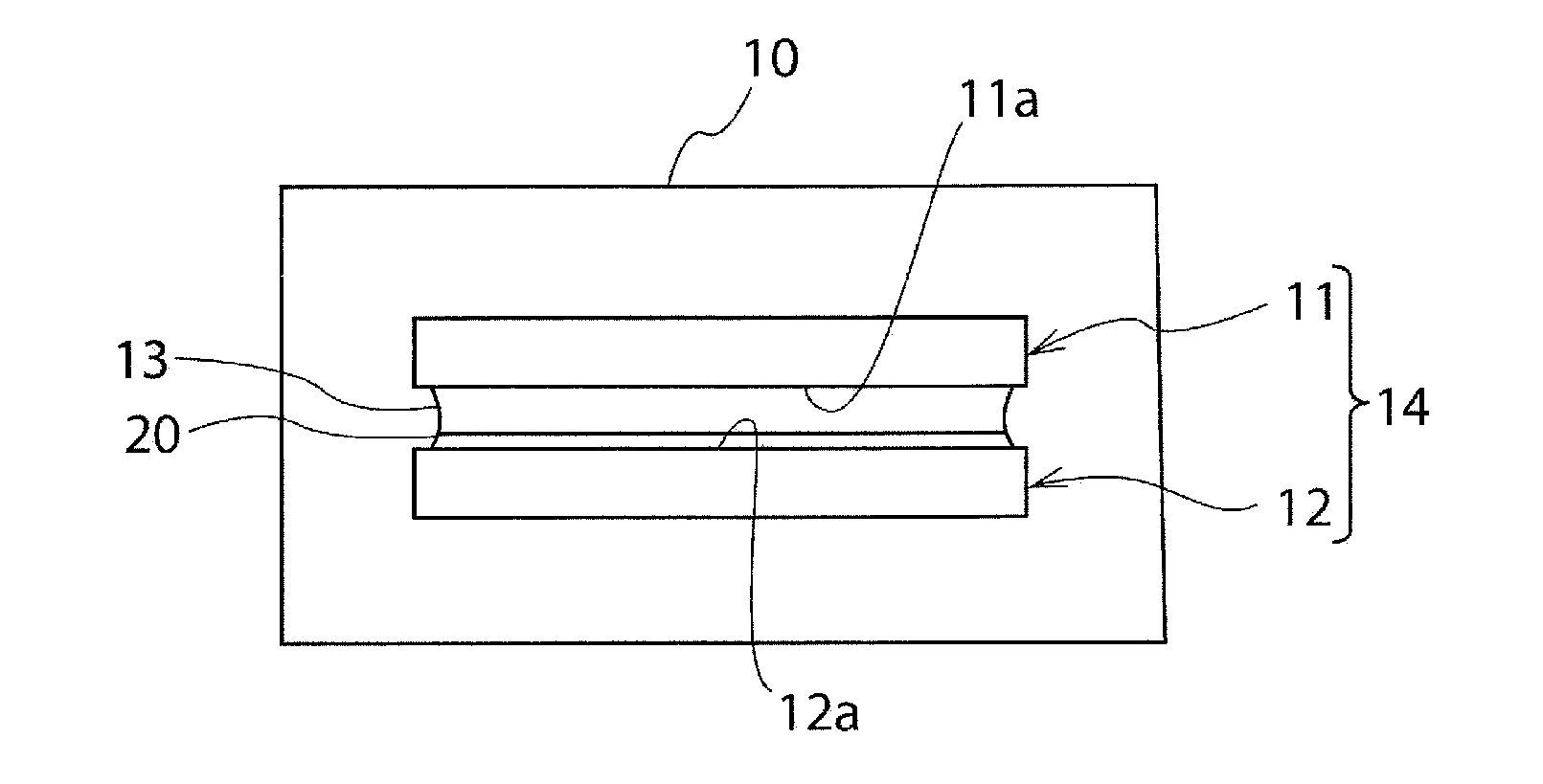

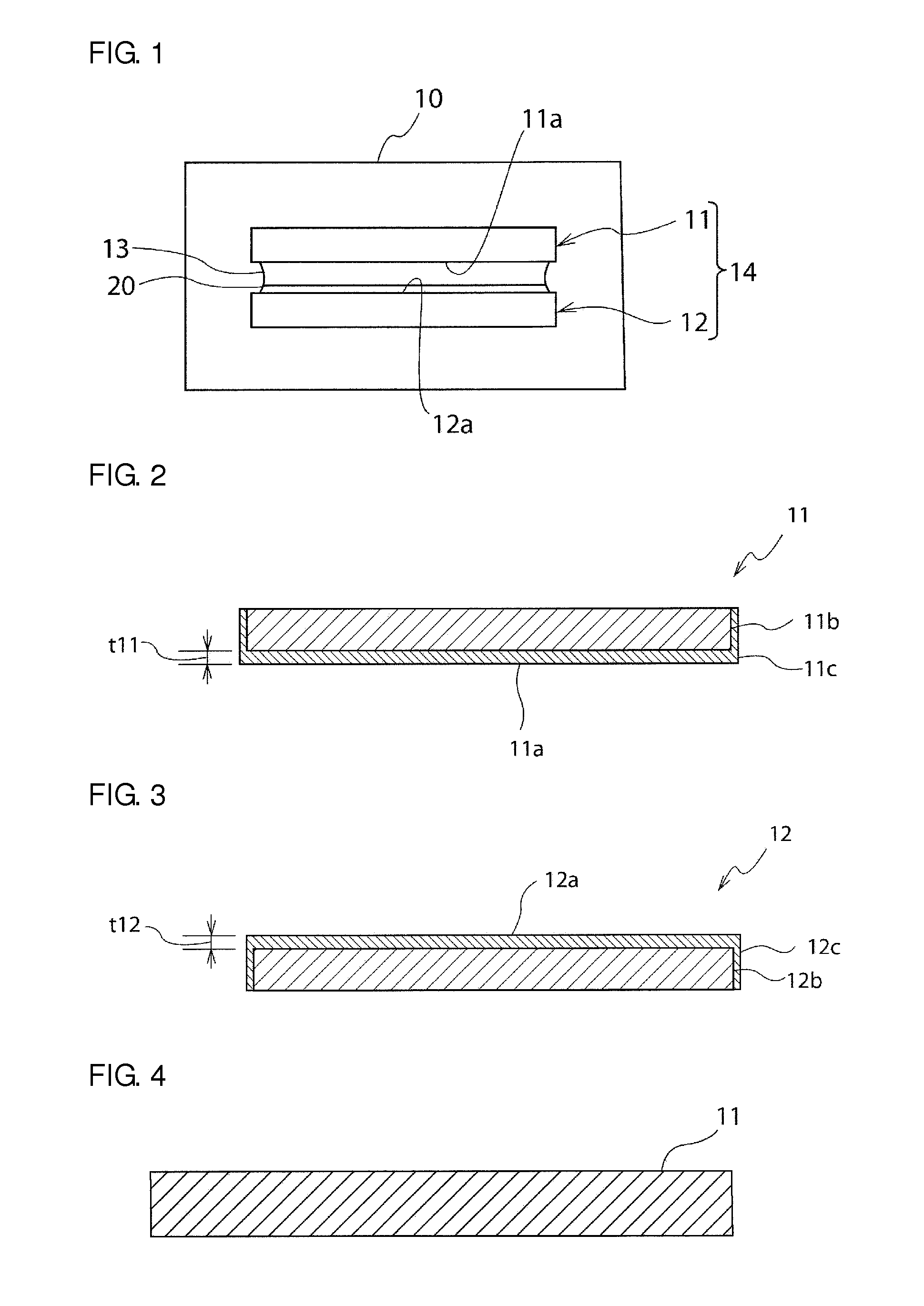

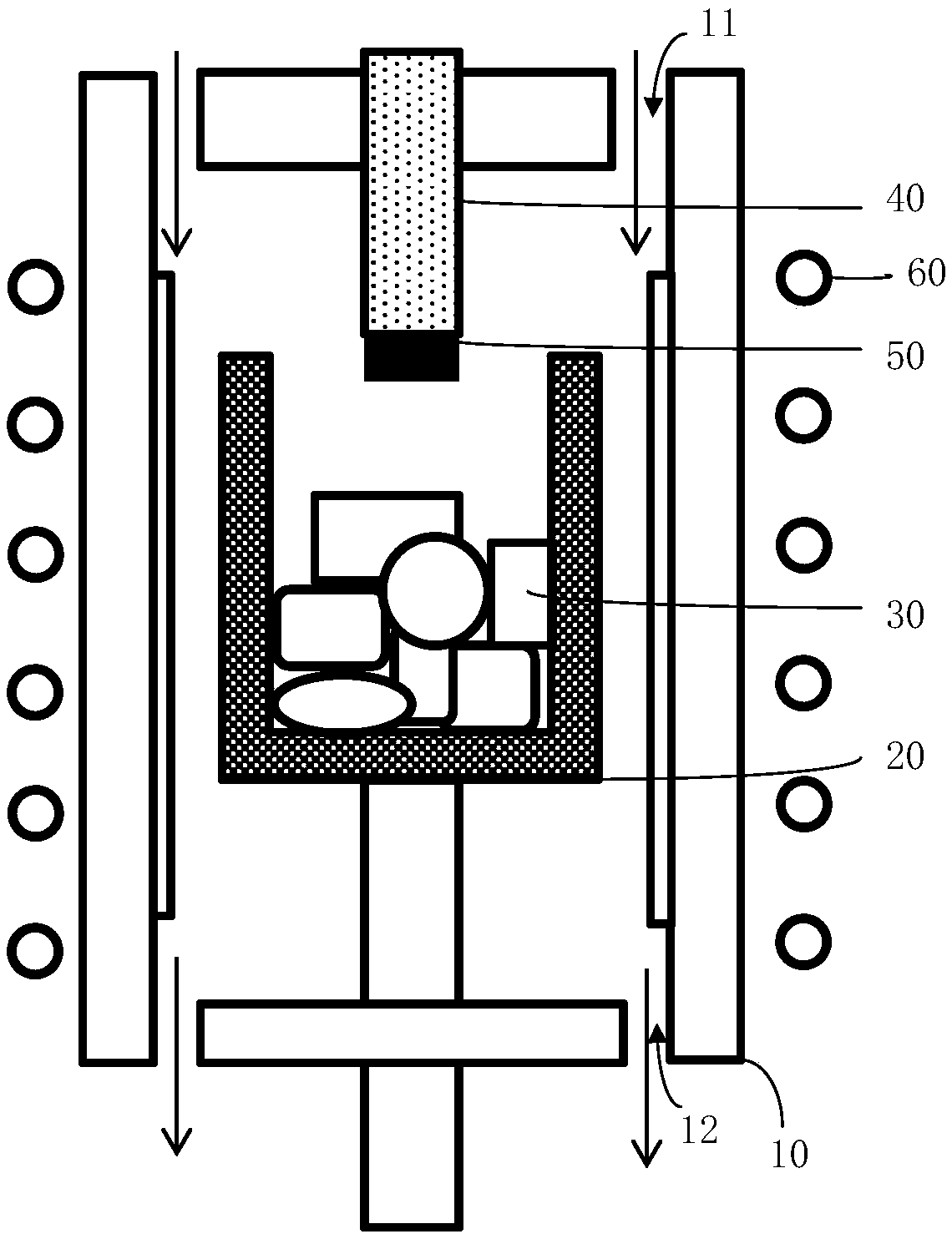

Unit for liquid phase epitaxial growth of monocrystalline silicon carbide, and method for liquid phase epitaxial growth of monocrystalline silicon carbide

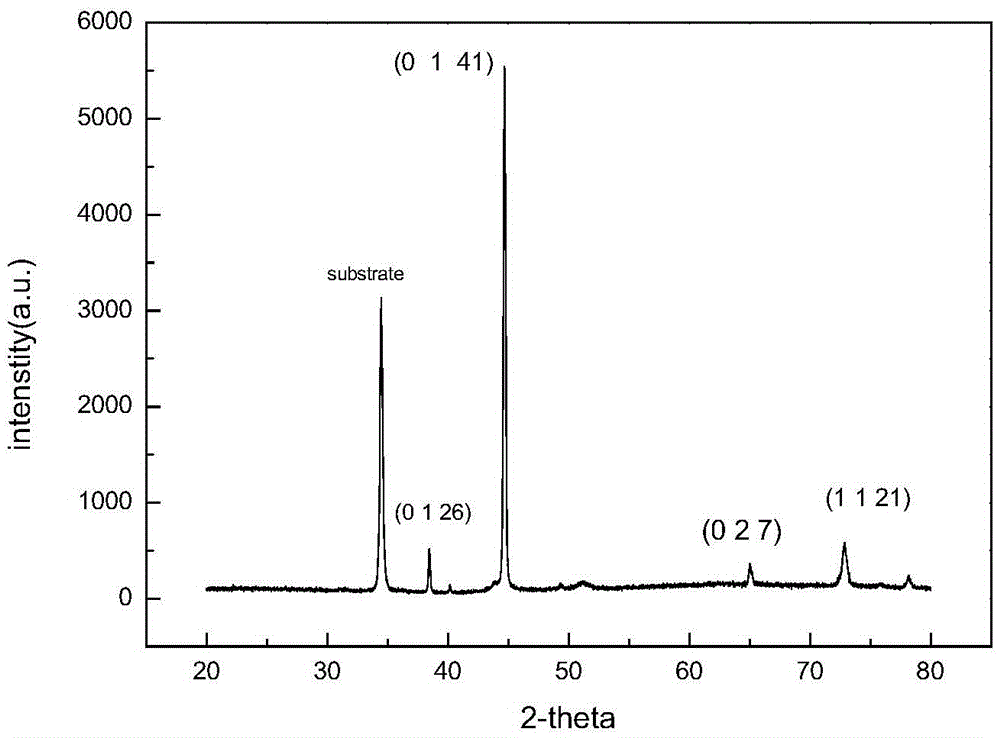

ActiveUS20130285060A1Low costEasy to producePolycrystalline material growthLiquid-phase epitaxial-layer growthSurface layerX-ray

The cost of liquid phase epitaxial growth of a monocrystalline silicon carbide is reduced. A feed material 11 is such that when a surface layer thereof containing a polycrystalline silicon carbide with a 3C crystal polymorph is subjected to X-ray diffraction, a diffraction peak corresponding to a (111) crystal plane and a diffraction peak other than the diffraction peak corresponding to the (111) crystal plane are observed as diffraction peaks corresponding to the polycrystalline silicon carbide with a 3C crystal polymorph. A seed material 12 is such that when a surface layer thereof containing a polycrystalline silicon carbide with a 3C crystal polymorph is subjected to X-ray diffraction, a first-order diffraction peak corresponding to a (111) crystal plane is observed as a diffraction peak corresponding to the polycrystalline silicon carbide with a 3C crystal polymorph but no other first-order diffraction peak having a diffraction intensity of 10% or more of the diffraction intensity of the first-order diffraction peak corresponding to the (111) crystal plane is observed.

Owner:TOYO TANSO KK

Superfine fiber suede leather generating negative oxygen ion and preparation method thereof

InactiveCN108894003AIncrease contact areaImprove air qualityTextiles and paperFiberPhysical chemistry

Disclosed are a superfine fiber suede leather generating negative oxygen ion and a preparation method thereof. The superfine fiber suede leather generating negative oxygen ion comprises superfine fiber as a skeleton, polyurethane as an infilling, and a polycrystalline silicon carbide which is distributed in the polyurethane. In the natural environment, a negative oxygen ion concentration of 2000-20000 per cubic centimeter is generated around the leather, and the leather is prepared by dispersing the polycrystalline silicon carbide material into an impregnated polyurethane slurry, followed by impregnation, solidification, decrement and subsequent processing. The superfine fiber suede leather prepared by the technology can generate and release negative oxygen ions in the air and change the concentration of the negative oxygen ions around the leather, thereby improving the air quality in a certain range, and can be used in clothes, shoes, caps, bags and suitcases, sofas, cars, boats, aircraft cushions, interior decorations and the like, and is particularly suitable for relatively closed occasions.

Owner:SICHUAN UNIV

Silicon carbide substrate, semiconductor device, and soi wafer

ActiveUS20130112997A1Less high-frequency lossGood heat dissipationPolycrystalline material growthSemiconductor/solid-state device detailsPolycrystalline silicon carbideSemiconductor

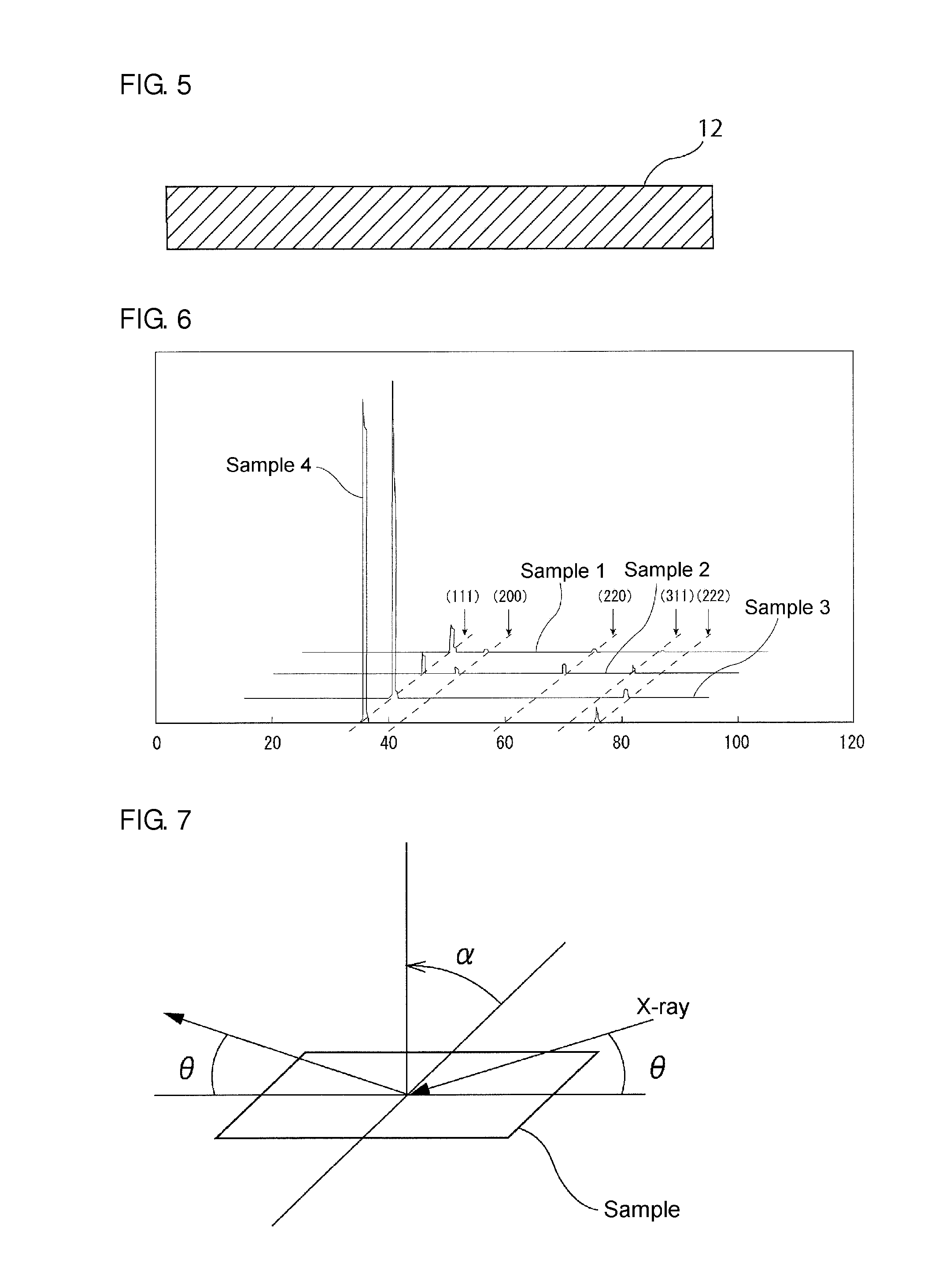

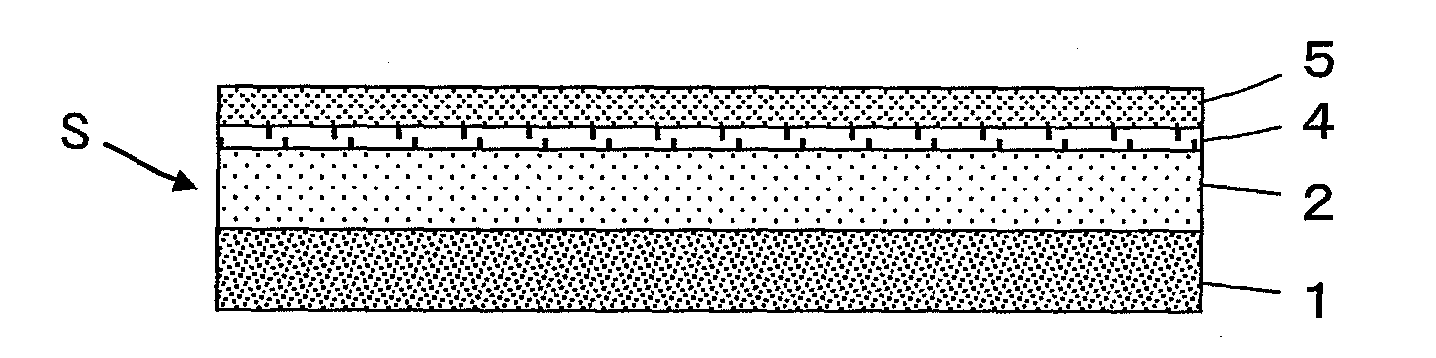

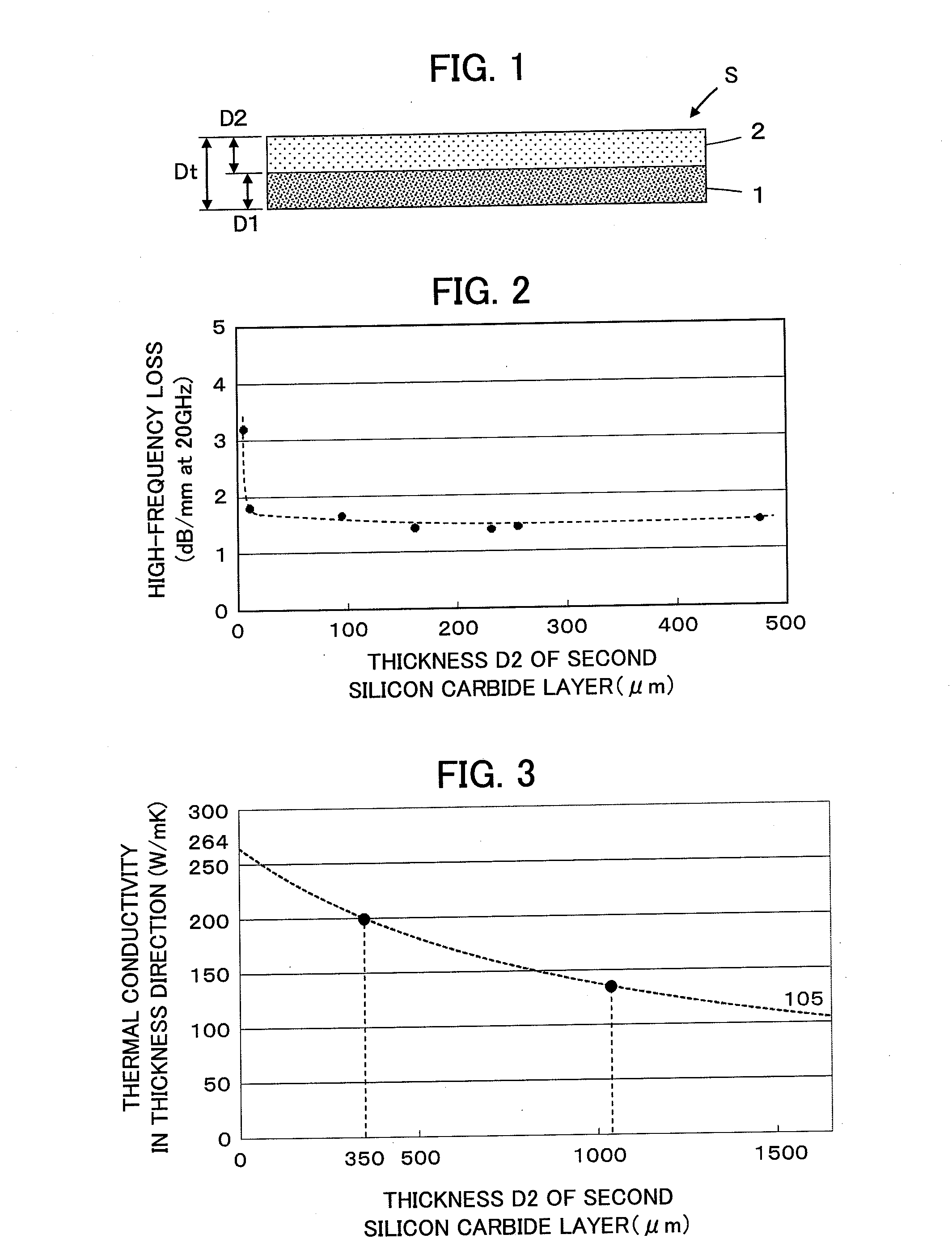

Disclosed is a silicon carbide substrate which has less high frequency loss and excellent heat dissipating characteristics. The silicon carbide substrate (S) is provided with a first silicon carbide layer (1), which is composed of a polycrystalline silicon carbide, and a second silicon carbide layer (2), which is composed of polycrystalline silicon carbide formed on the surface of the first silicon carbide layer. The second silicon carbide layer (2) has a high-frequency loss smaller than that of the first silicon carbide layer (1), the first silicon carbide layer (1) has a thermal conductivity higher than that of the second silicon carbide layer (2), and on the surface side of the second silicon carbide layer (2), the high-frequency loss at a frequency of 20 GHz is 2 dB / mm or less, and the thermal conductivity is 200 W / mK or more.

Owner:FERROTEC MATERIAL TECH CORP

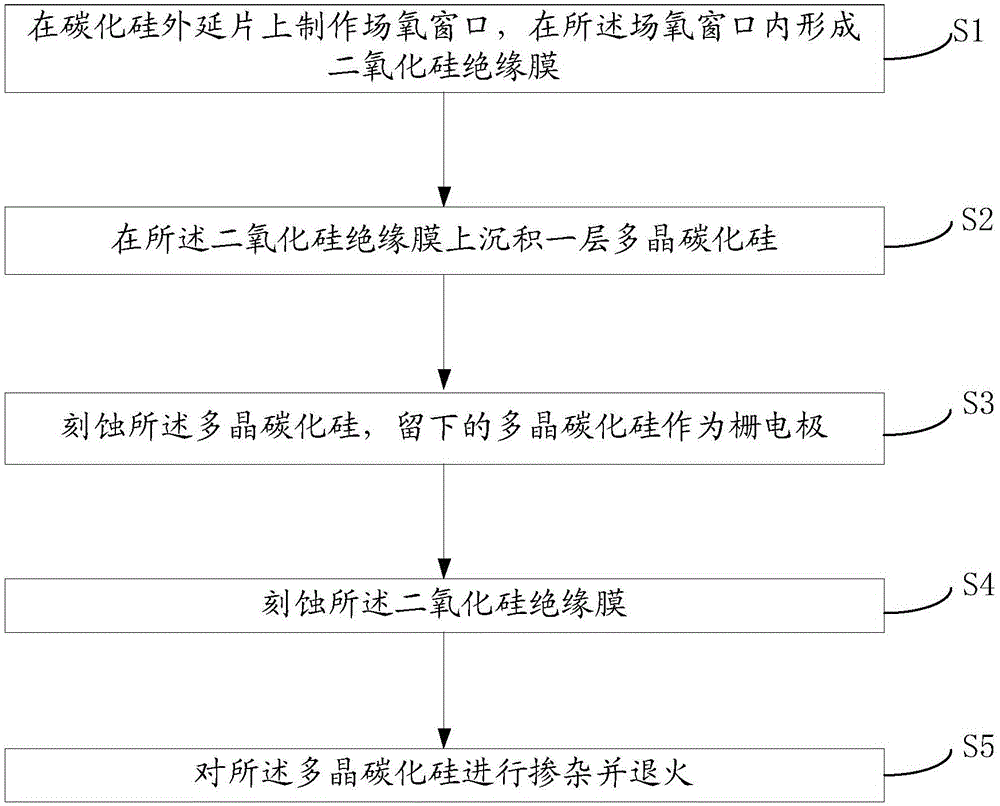

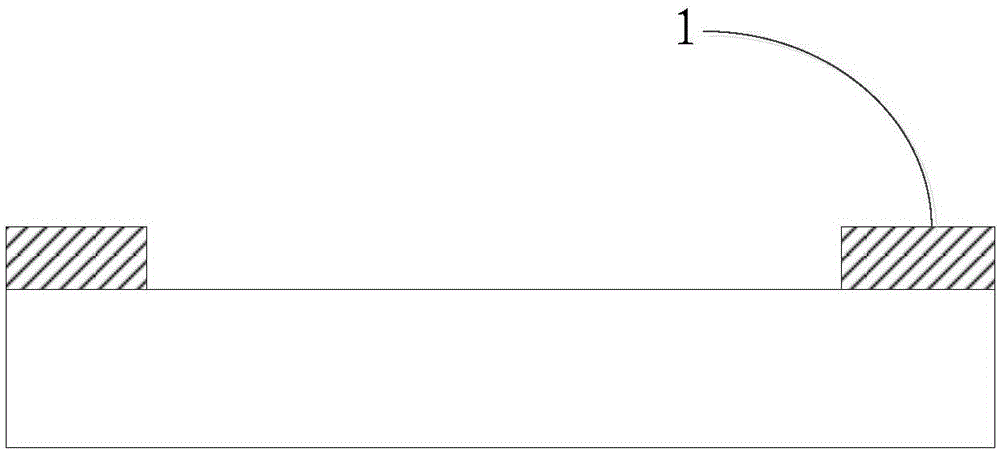

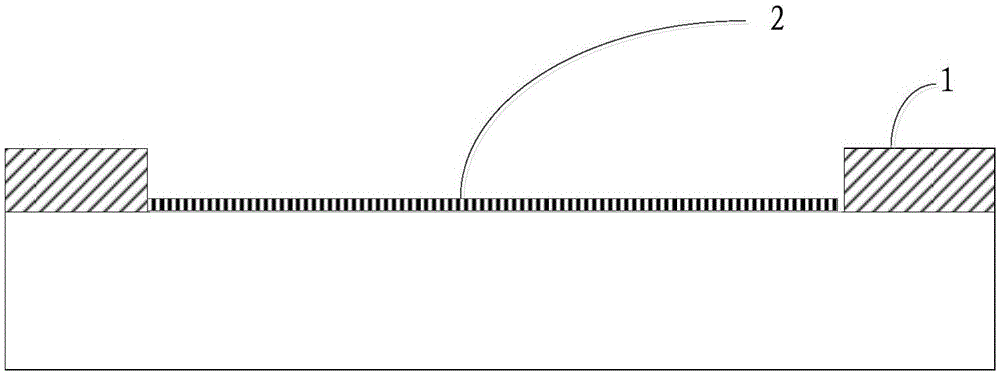

Method for manufacturing silicon carbide MOSFET

InactiveCN105070662AEasy to adjustReduce latencySemiconductor/solid-state device manufacturingSemiconductor devicesMOSFETPolycrystalline silicon carbide

The present invention discloses a method for manufacturing a silicon carbide MOSFET. The method comprises the steps of making a field oxide window on a silicon carbide epitaxial piece and forming a silicon dioxide insulating film in the field oxide window, depositing a layer of polycrystalline silicon carbide on the silicon dioxide insulating film, etching the polycrystalline silicon carbide and taking the remaining polycrystalline silicon carbide as a gate electrode, etching the silicon dioxide insulating film, and doping the polycrystalline silicon carbide and carrying out annealing. Due to the above methods, the deposed polycrystalline silicon carbide is used to make the gate electrode of the silicon carbide MOSFET, thus the adjustment ability of device threshold voltage can be improved, and the gate signal delay time can be reduced.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

Surface reconstruction method for silicon carbide substrate

A surface reconstruction method for a silicon carbide substrate includes a silicon film forming step of forming a silicon film on a surface of the silicon carbide substrate and a heat treatment step of heat-treating the silicon carbide substrate and the silicon film without providing a polycrystalline silicon carbide substrate on a surface of the silicon film. Here, after the heat treatment step, a silicon film removal step of removing the silicon film may be included. Further, a silicon oxide film forming step of oxidizing the silicon film after the heat treatment step to generate a silicon oxide film, and a silicon oxide film removal step of removing the silicon oxide film may be included.

Owner:SUMITOMO ELECTRIC IND LTD

Silicon carbide with high thermal conductivity

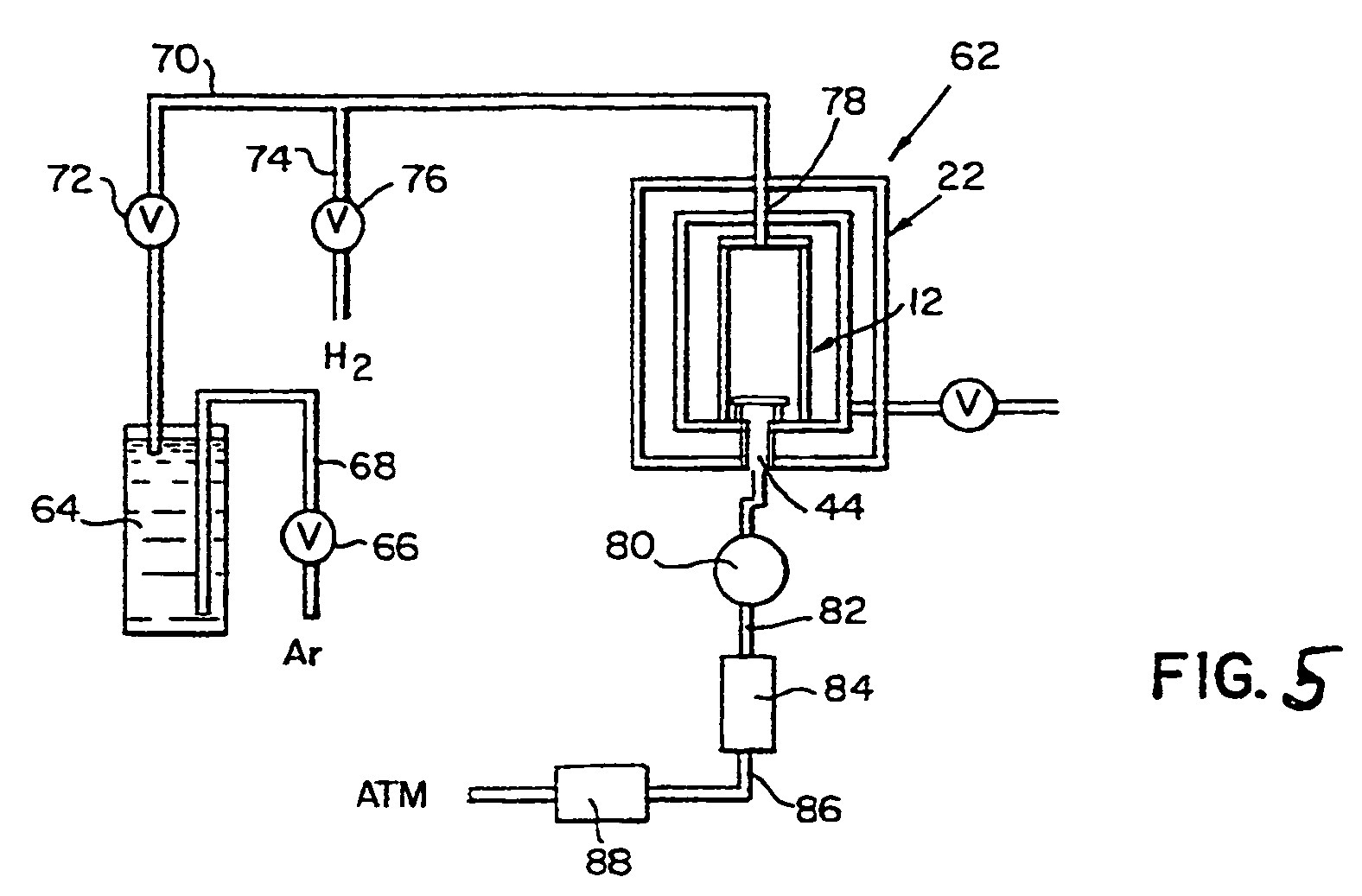

InactiveUS7438884B2Reduced stacking faultsImprove thermal conductivityPolycrystalline material growthFrom chemically reactive gasesThermoelectric coolingHydrogen

A chemical vapor deposited, β phase polycrystalline silicon carbide having a high thermal conductivity and reduced stacking faults. The silicon carbide is synthesized under specific conditions using hydrogen gas and methyltrichlorosilane gas as reactants. The thermal conductivity of the silicon carbide is sufficiently high such that it can be employed as parts of apparatus and components of electrical devices where a high heat load is generated. Such components may include active thermoelectric coolers, heat sinks and fans.

Owner:TOKAI CARBON CO LTD

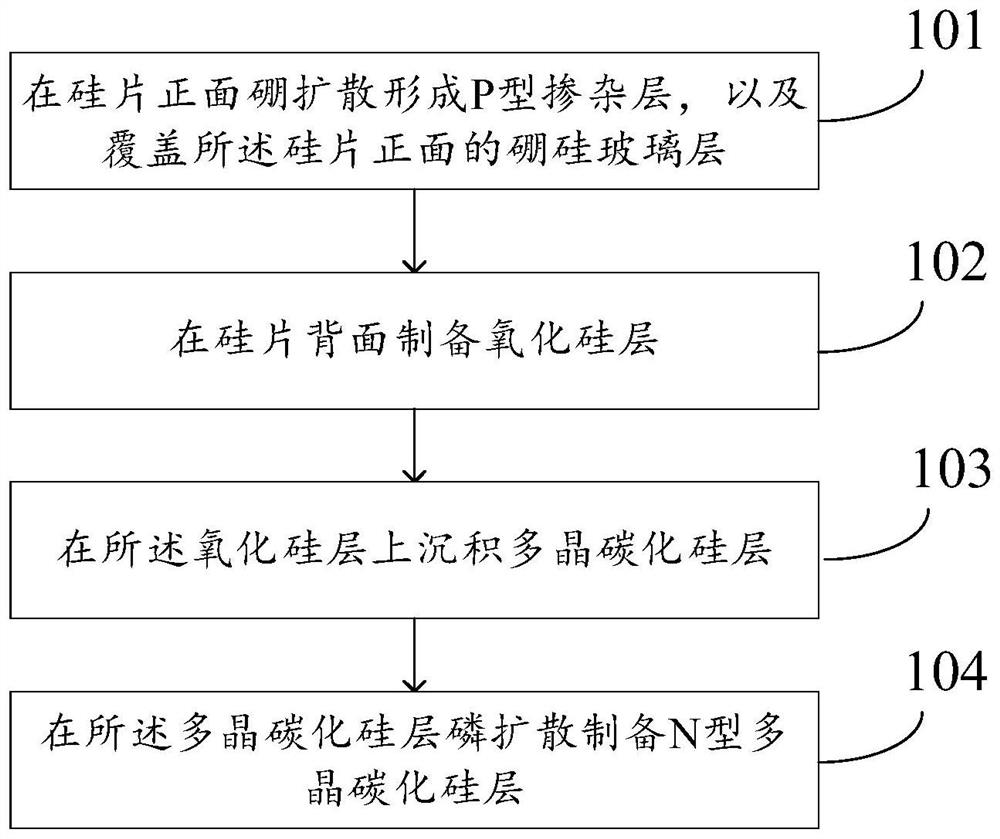

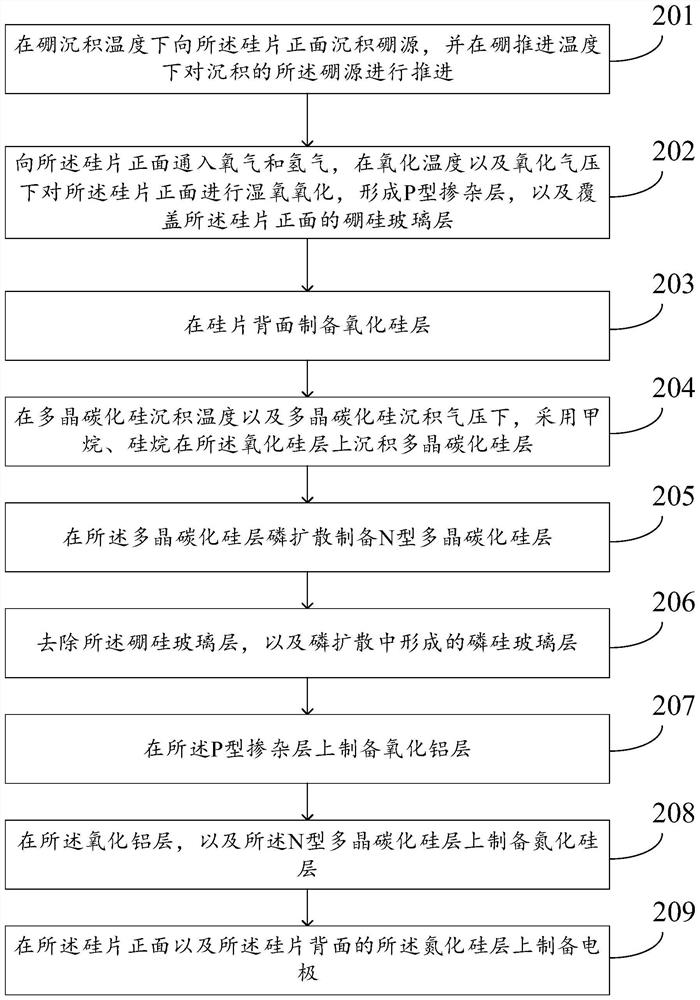

Preparation method of passivated contact cell and passivated contact cell

PendingCN114420786AAvoid destructionControllable depositionFinal product manufactureSemiconductor devicesCarbide siliconPolycrystalline silicon carbide

The invention provides a preparation method of a passivation contact cell and the passivation contact cell, and relates to the technical field of solar photovoltaics. Wherein in the process of preparing the passivation contact cell, boron diffusion is performed on the front surface of a silicon wafer to form a P-type doped layer, and a borosilicate glass layer covering the front surface of the silicon wafer is formed, so that an effective mask protection effect can be achieved in the subsequent process, and the front surface structure is prevented from being damaged; the polycrystalline silicon carbide layer is adopted on the back face of the silicon wafer to achieve the field passivation effect, loss of light parasitic absorption is avoided, phosphorus diffusion preparation is carried out after deposition of the N-type polycrystalline silicon carbide layer, deposition of the polycrystalline silicon carbide layer is more controllable, it can be guaranteed that the film layer is uniform and not prone to falling off or blistering, high-temperature crystallization is not needed after diffusion, and the process efficiency and the passivation effect are guaranteed.

Owner:LONGI SOLAR TECH (XIAN) CO LTD

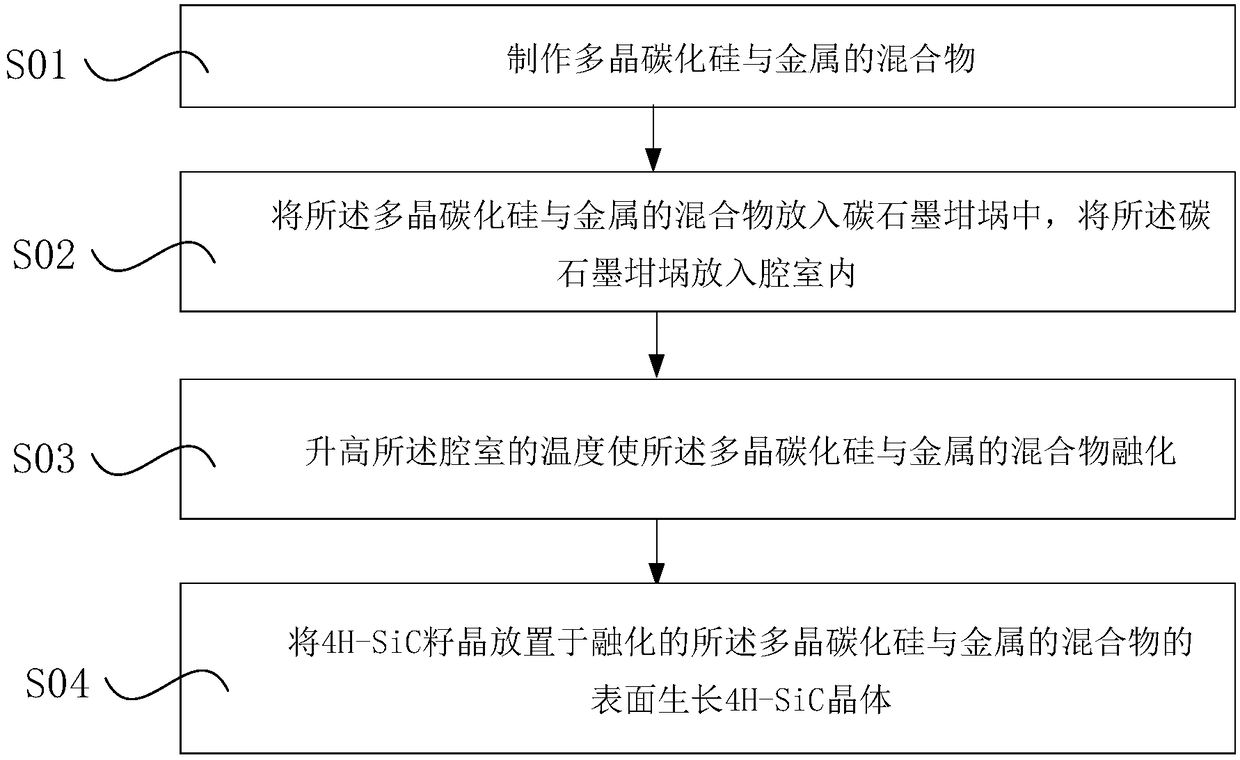

4H-SiC crystal growing method

InactiveCN108166058AQuality improvementGuaranteed contentPolycrystalline material growthFrom melt solutionsPolycrystalline silicon carbideMetal

The invention provides a 4H-SiC crystal growing method, comprising the following steps: preparing a mixture of polycrystalline silicon carbide and metal; allowing 4H-SiC crystals to grow with the mixture of polycrystalline silicon carbide and metal as a raw material; and heating the mixture of polycrystalline silicon carbide and metal until the mixture is molten. The method can realize uniform mixing of silicon and carbon, guarantee the content of silicon in formed 4H-SiC crystals and improve the quality of the 4H-SiC crystals.

Owner:ZING SEMICON CORP

Seed material for liquid phase epitaxial growth of monocrystalline silicon carbide, and method for liquid phase epitaxial growth of monocrystalline silicon

InactiveUS20130263774A1Polycrystalline material growthLiquid-phase epitaxial-layer growthSurface layerPolycrystalline silicon carbide

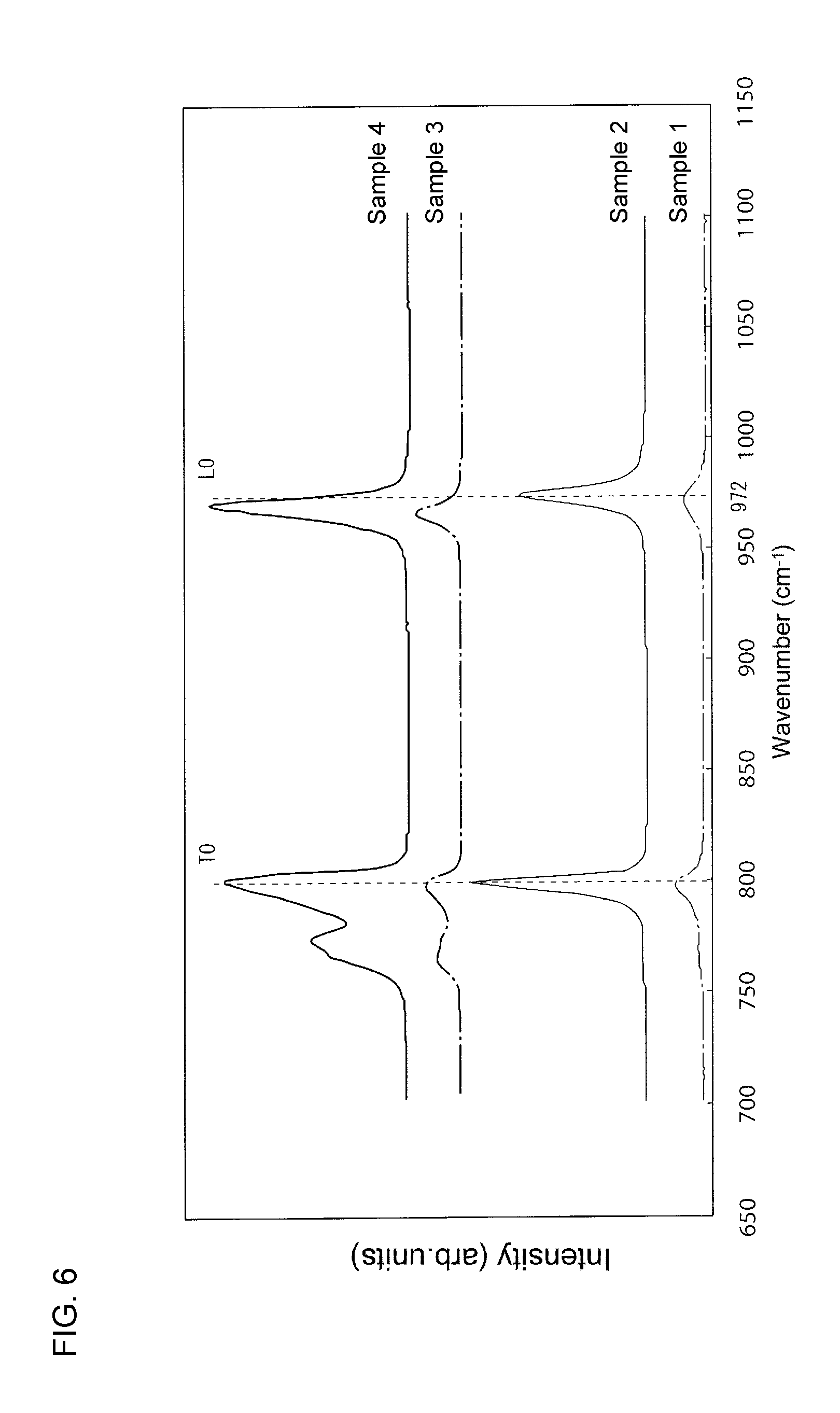

Provided is an inexpensive seed material for liquid phase epitaxial growth of silicon carbide. A seed material 12 for liquid phase epitaxial growth of a monocrystalline silicon carbide includes a surface layer containing a polycrystalline silicon carbide with a 3C crystal polymorph. Upon Raman spectroscopic analysis of the surface layer with an excitation wavelength of 532 nm, a peak other than a TO peak and an LO peak is observed as a peak derived from the polycrystalline silicon carbide with a 3C crystal polymorph.

Owner:TOYO TANSO KK

Silicon carbide with high thermal conductivity

InactiveUS20050000412A1Improve thermal conductivityIncrease heat loadPolycrystalline material growthFrom chemically reactive gasesThermoelectric coolingHydrogen

A chemical vapor deposited, β phase polycrystalline silicon carbide having a high thermal conductivity and reduced stacking faults. The silicon carbide is synthesized under specific conditions using hydrogen gas and methyltrichlorosilane gas as reactants. The thermal conductivity of the silicon carbide is sufficiently high such that it can be employed as parts of apparatus and components of electrical devices where a high heat load is generated. Such components may include active thermoelectric coolers, heat sinks and fans.

Owner:TOKAI CARBON CO LTD

Terminal structure of power semiconductor device and power semiconductor device

ActiveCN102208436AReduce holdupImprove breakdown voltageSemiconductor devicesPower semiconductor deviceDielectric

The invention provides a terminal structure of a power semiconductor device and a power semiconductor device. The terminal structure of the power semiconductor device comprises a channel ring in the main body semiconductor area of the power semiconductor device, wherein the material of the channel ring is intrinsic polycrystalline material whose relative dielectric constant is a value from 1 to 15, and the intrinsic polycrystalline material is intrinsic polycrystalline silicon carbide. In the invention, the intrinsic polycrystalline silicon carbide with relative dielectric constant within15 is used in the channel ring in the terminal structure of the power semiconductor device. Thus electric field line which goes through the channel ring area is nearly level. There is no extreme point in the area. The carrier hold-up is substantially reduced. Thereby breakdown voltage is raised.

Owner:BYD SEMICON CO LTD

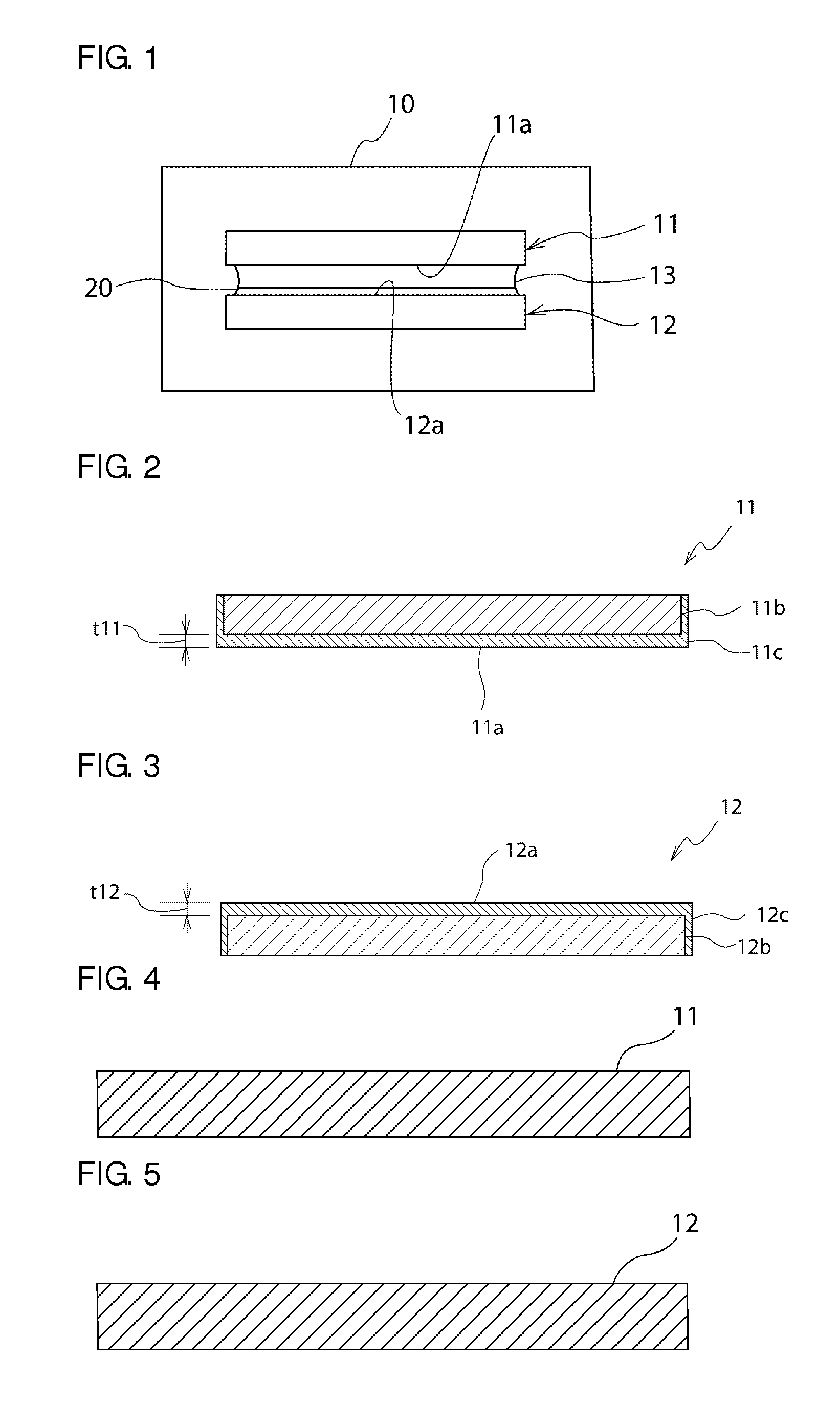

Method for epitaxial growth of monocrystalline silicon carbide using a feed material including a surface layer containing a polycrystalline silicon carbide with a 3C crystal polymorph

InactiveUS9725822B2Increase rate increasePolycrystalline material growthLiquid-phase epitaxial-layer growthSurface layerX-ray

Provided is a feed material for epitaxial growth of a monocrystalline silicon carbide capable of increasing the rate of epitaxial growth of silicon carbide. A feed material 11 for epitaxial growth of a monocrystalline silicon carbide includes a surface layer containing a polycrystalline silicon carbide with a 3C crystal polymorph. Upon X-ray diffraction of the surface layer, a diffraction peak corresponding to a (111) crystal plane and a diffraction peak other than the diffraction peak corresponding to the (111) crystal plane are observed as diffraction peaks corresponding to the polycrystalline silicon carbide with a 3C crystal polymorph.

Owner:TOYO TANSO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com