Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

177 results about "Head (vessel)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

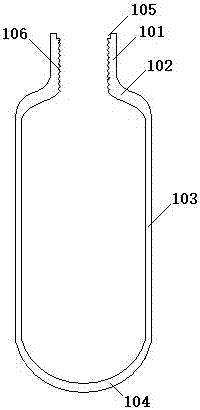

A head is one of the end caps on a cylindrically shaped pressure vessel.

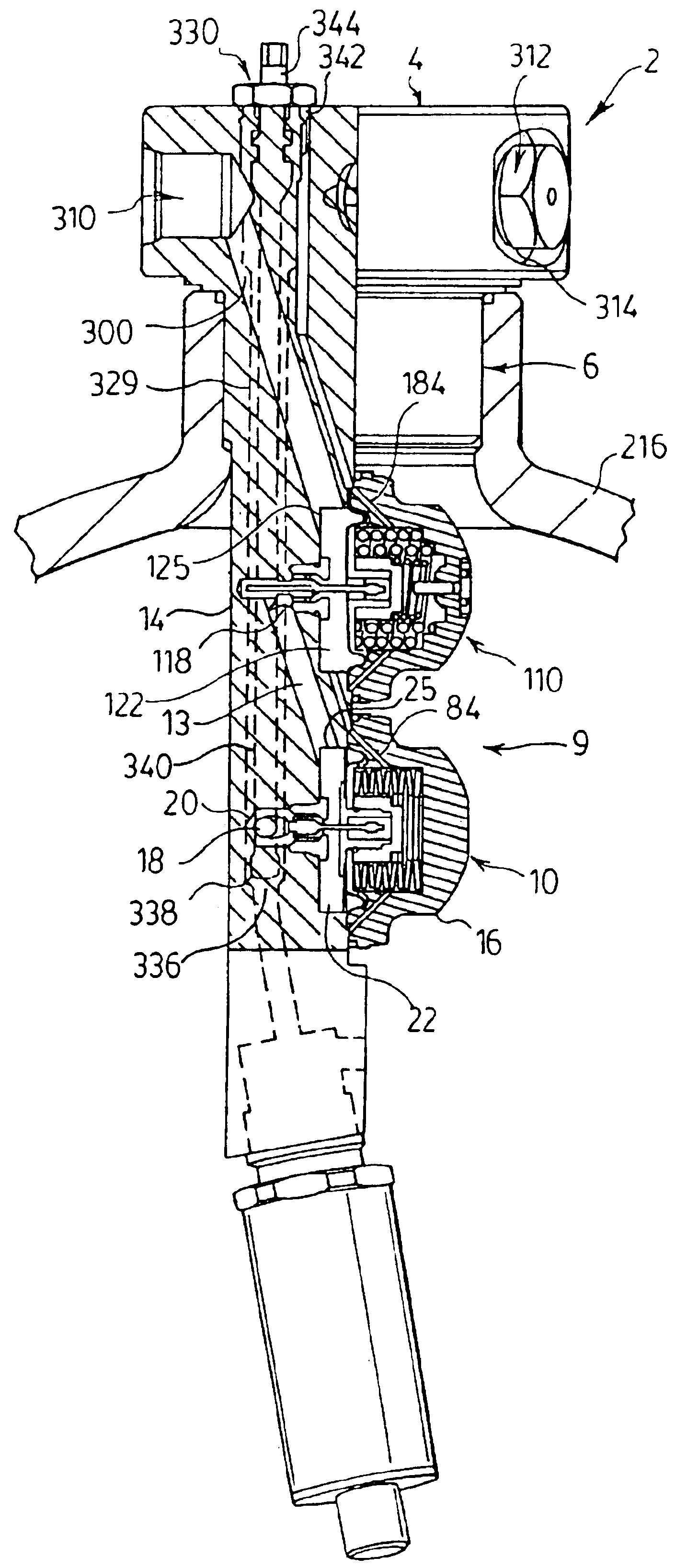

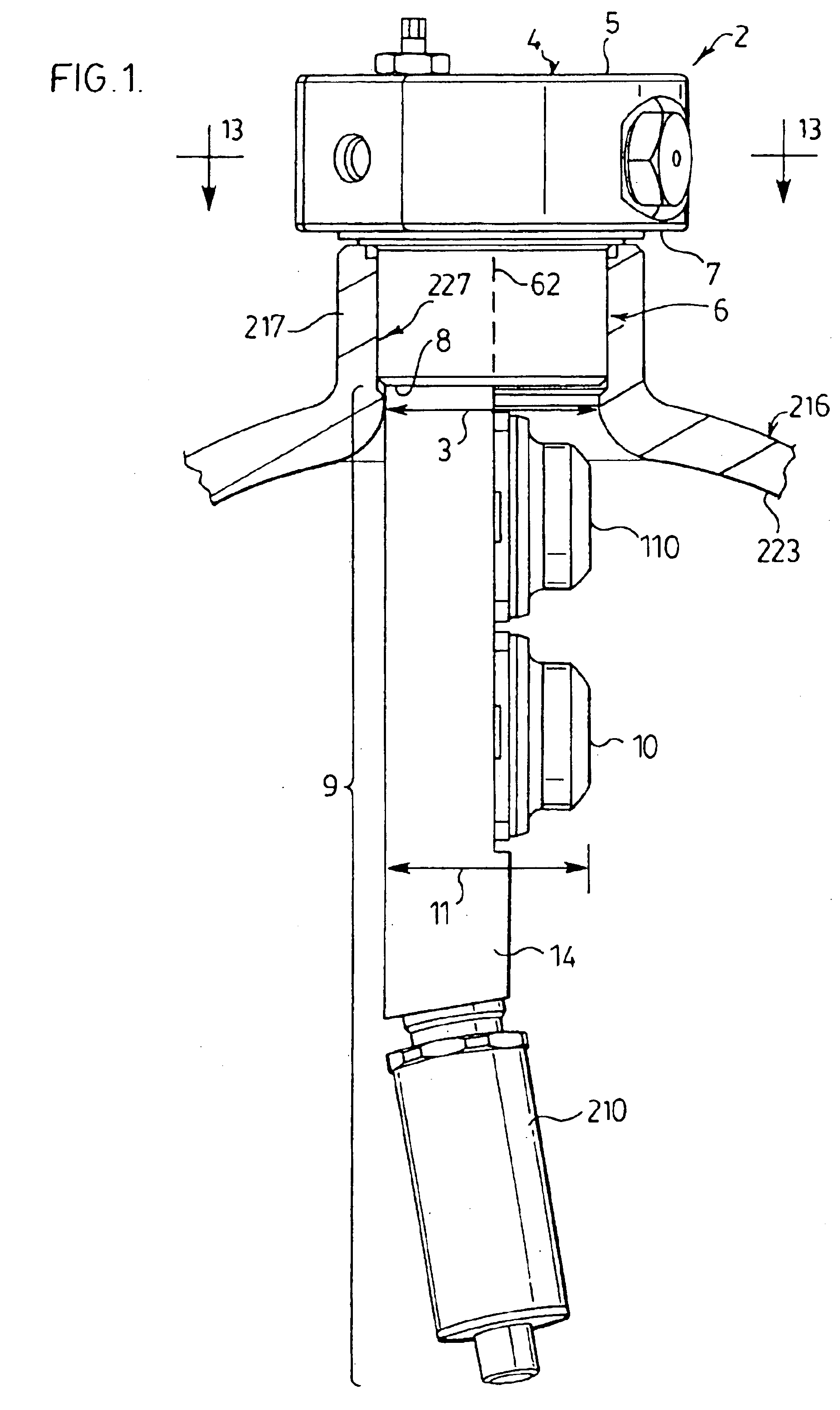

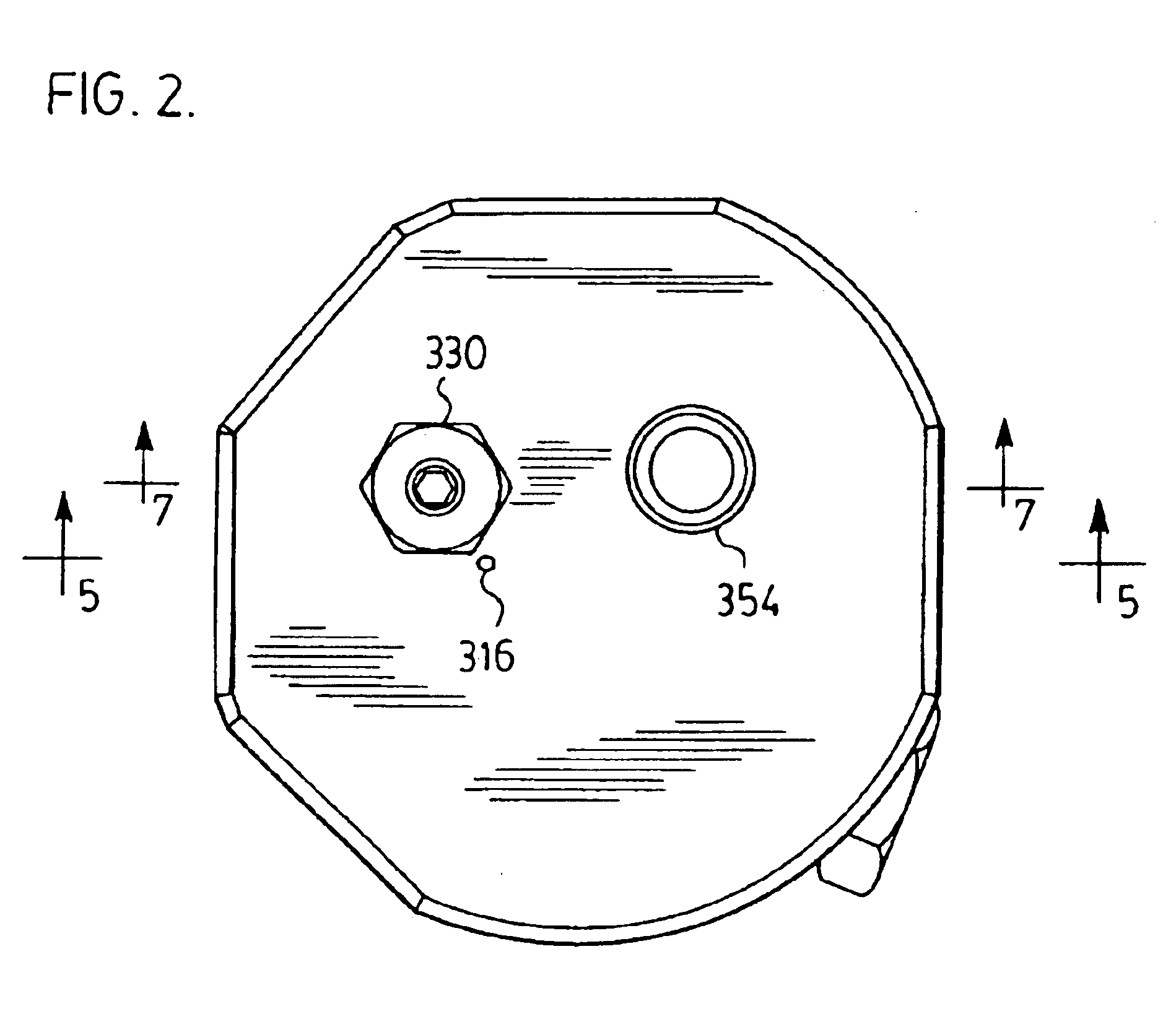

Gas flow regulation system

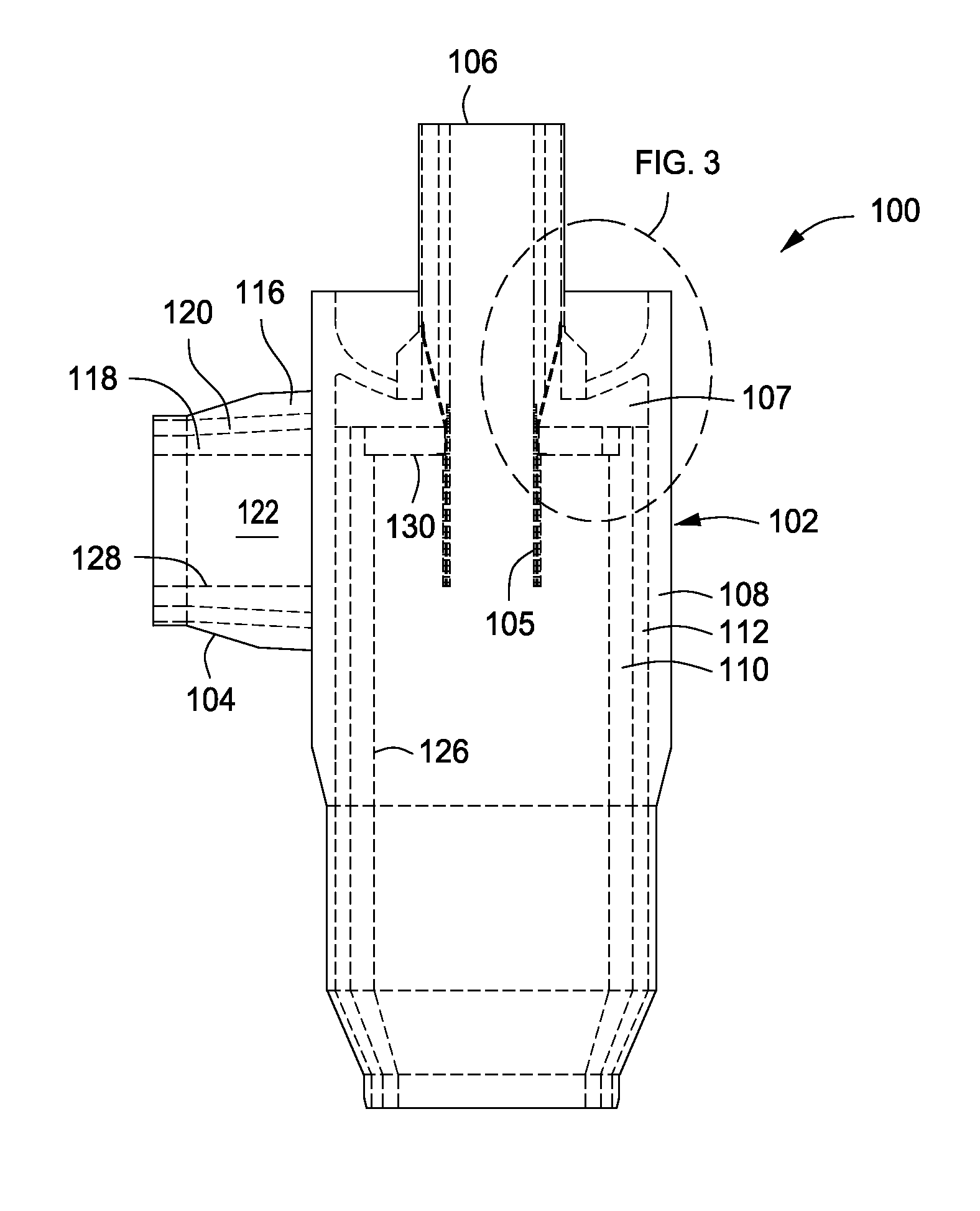

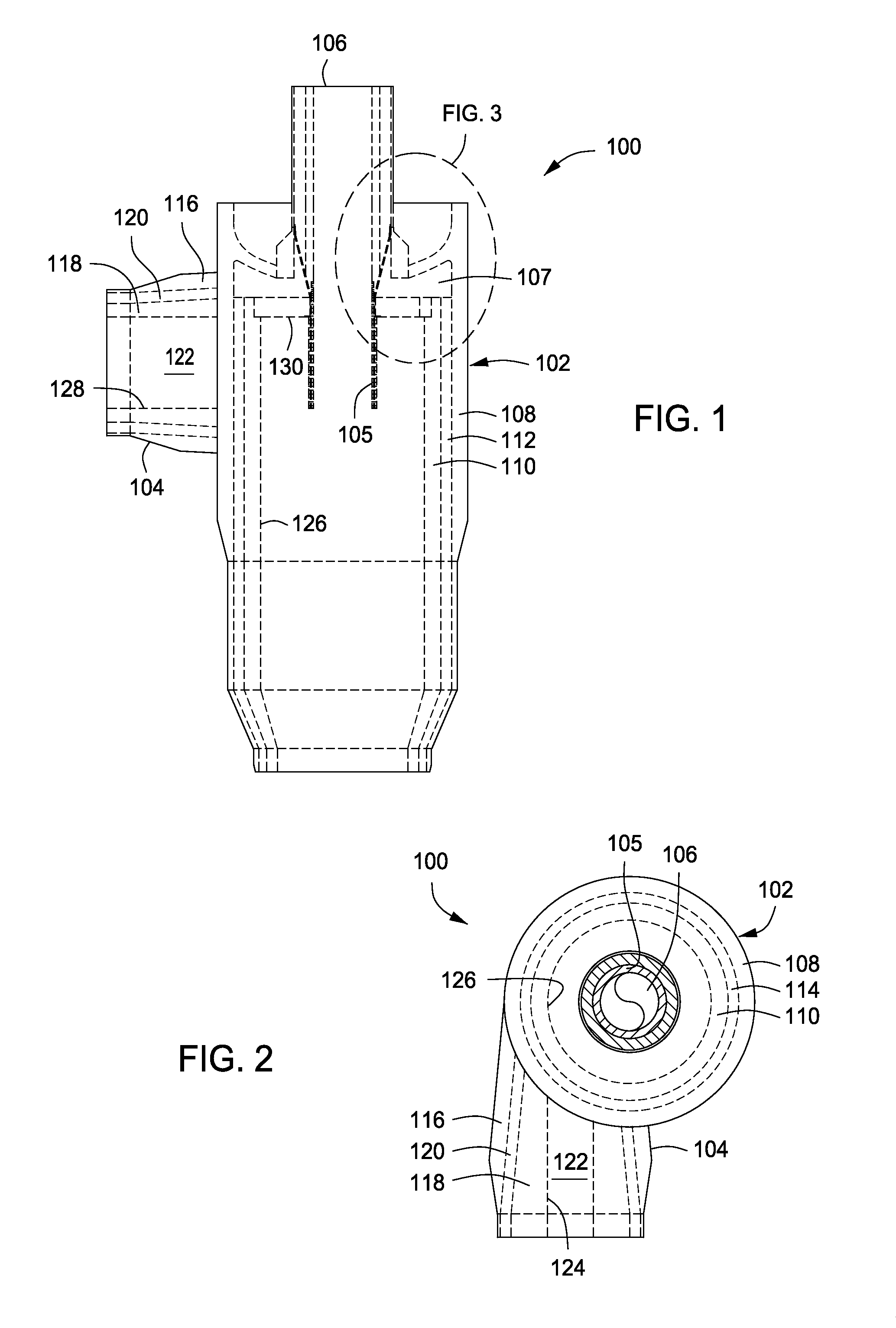

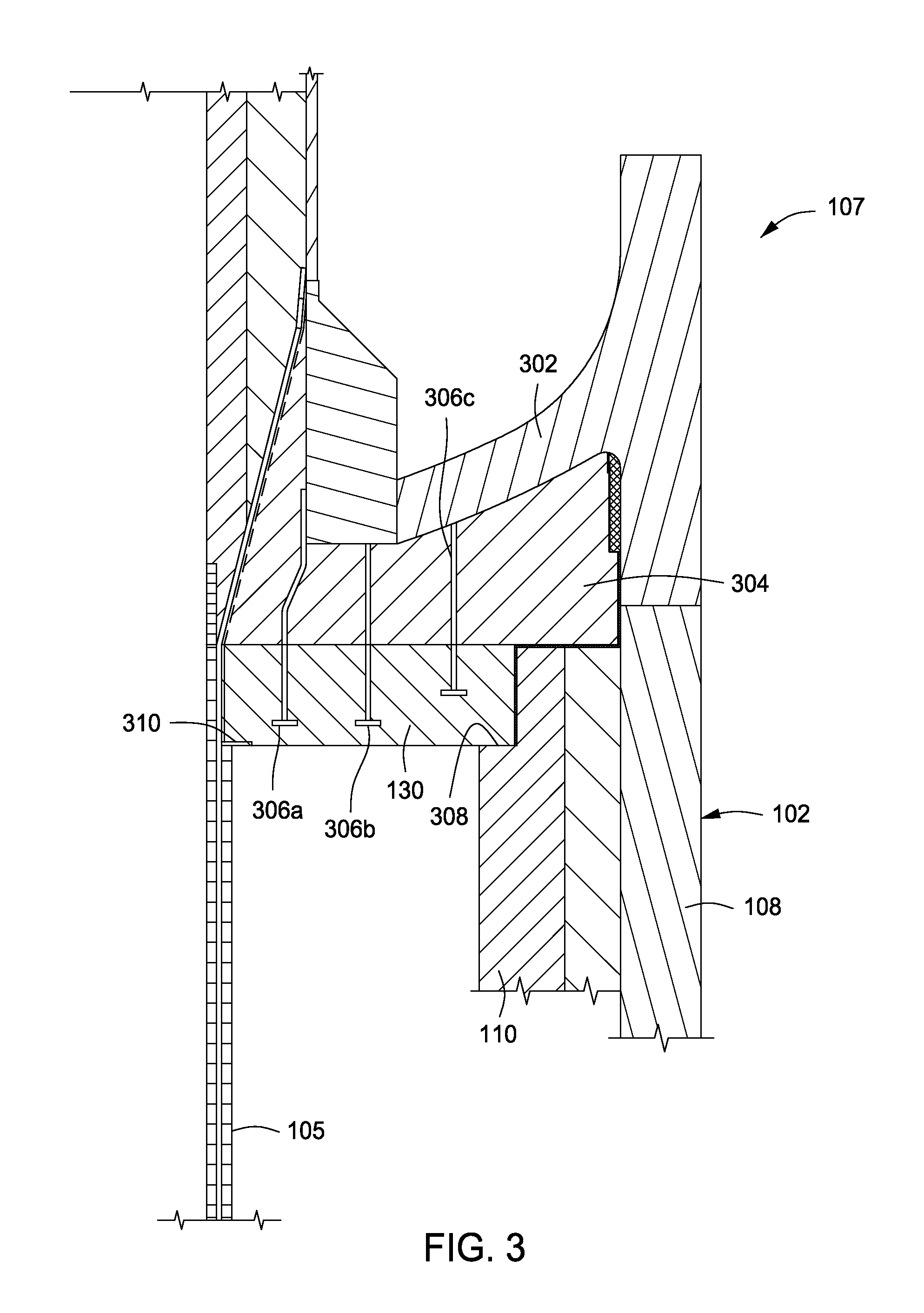

InactiveUS6901952B2Vessel mounting detailsOperating means/releasing devices for valvesInterior spaceMaximum diameter

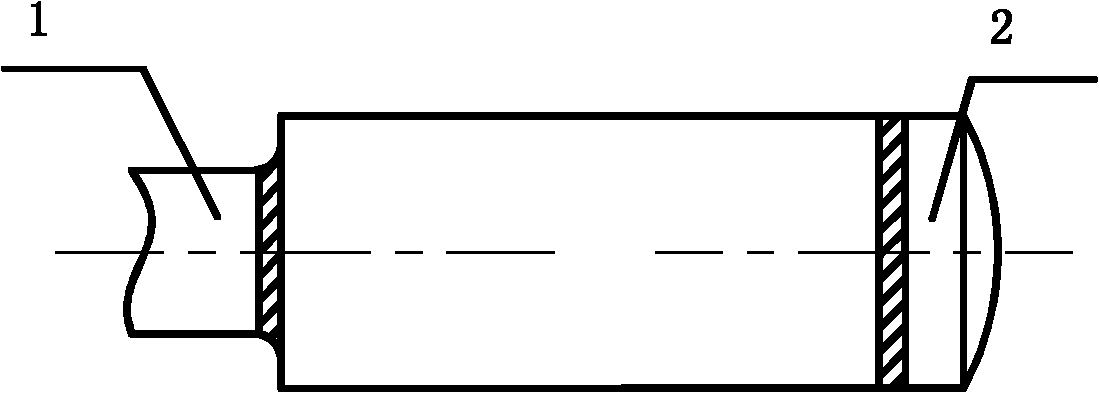

A gas flow regulation module for use in a pressure vessel including a wall with an opening having a minimum opening diameter. The wall defines an interior space in the pressure vessel. The module includes a head portion, a neck portion, and a body portion. The body portion has a maximum diameter which is less than the minimum opening diameter, so that the body portion fits through the opening for positioning in the interior space. The gas flow regulation module includes a manual shut-off valve for controlling the flow of fluid through the module.

Owner:WESTPORT POWER

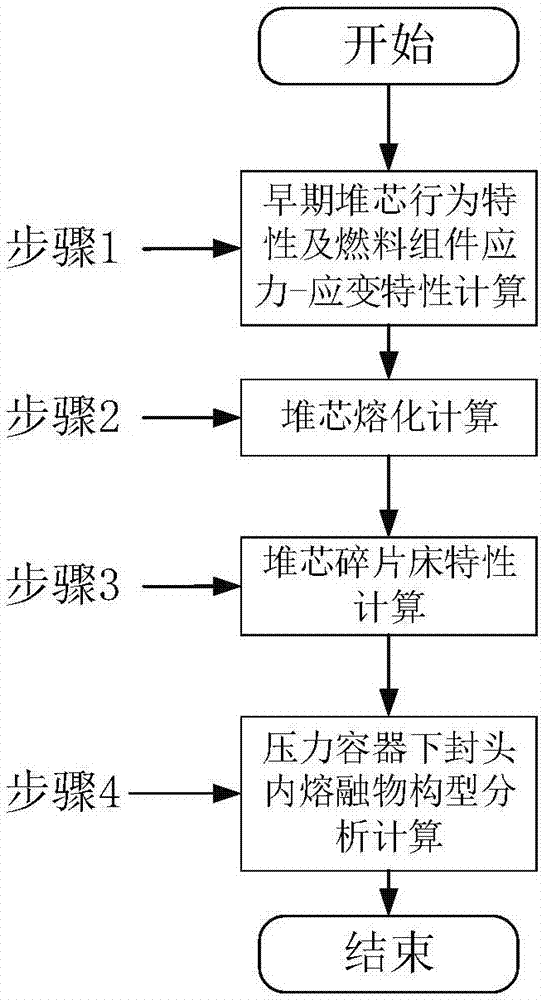

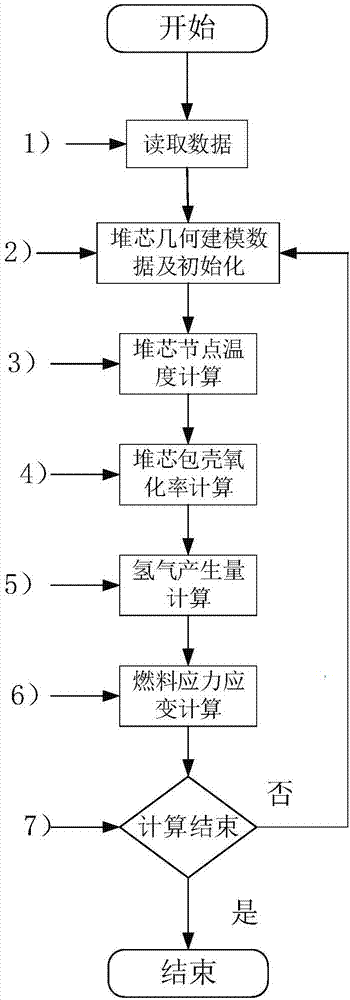

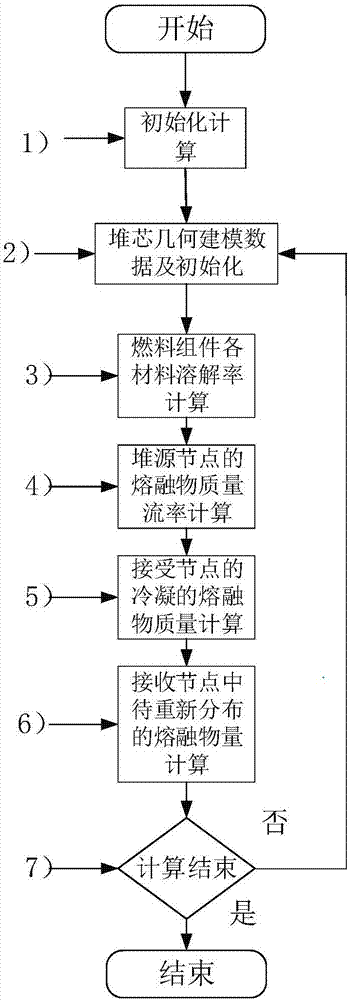

Method for analyzing severe accident of pressurized water reactor (PWR) nuclear power plant

ActiveCN107451398ASimple calculationSpecial data processing applicationsInformaticsRunge–Kutta methodPressurized water reactor

A method for analyzing a severe accident of a PWR nuclear power plant comprises: 1. calculating a behavioral characteristic of an early-stage core and a stress-strain characteristic of a fuel assembly of a severe accident; 2. calculating core melting; 3. calculating a core debris bed characteristic; and 4. analyzing and calculating a configuration of a melting matter in a head of a pressure vessel, wherein, a heat transfer between the melting matter and a surrounding material is calculated by a Runge-Kutta method at first, then steam flow that is released from the melting matter to the core during a cooling convection process is calculated, then mass and energy exchange between particles of the melting matter and a surrounding environment is calculated, and finally heat flow from a debris hard shell is calculated according to an inner temperature of the hard shell. Based on analysis of the mechanism and sequence of the severe accident of the large pressurized water reactor, management strategies and mitigation measures for severe accidents applicable to pressurized water reactors in our country are put forward, and technical support is offered for formulation of safety strategies of severe accidents of nuclear power plants in our country.

Owner:XI AN JIAOTONG UNIV

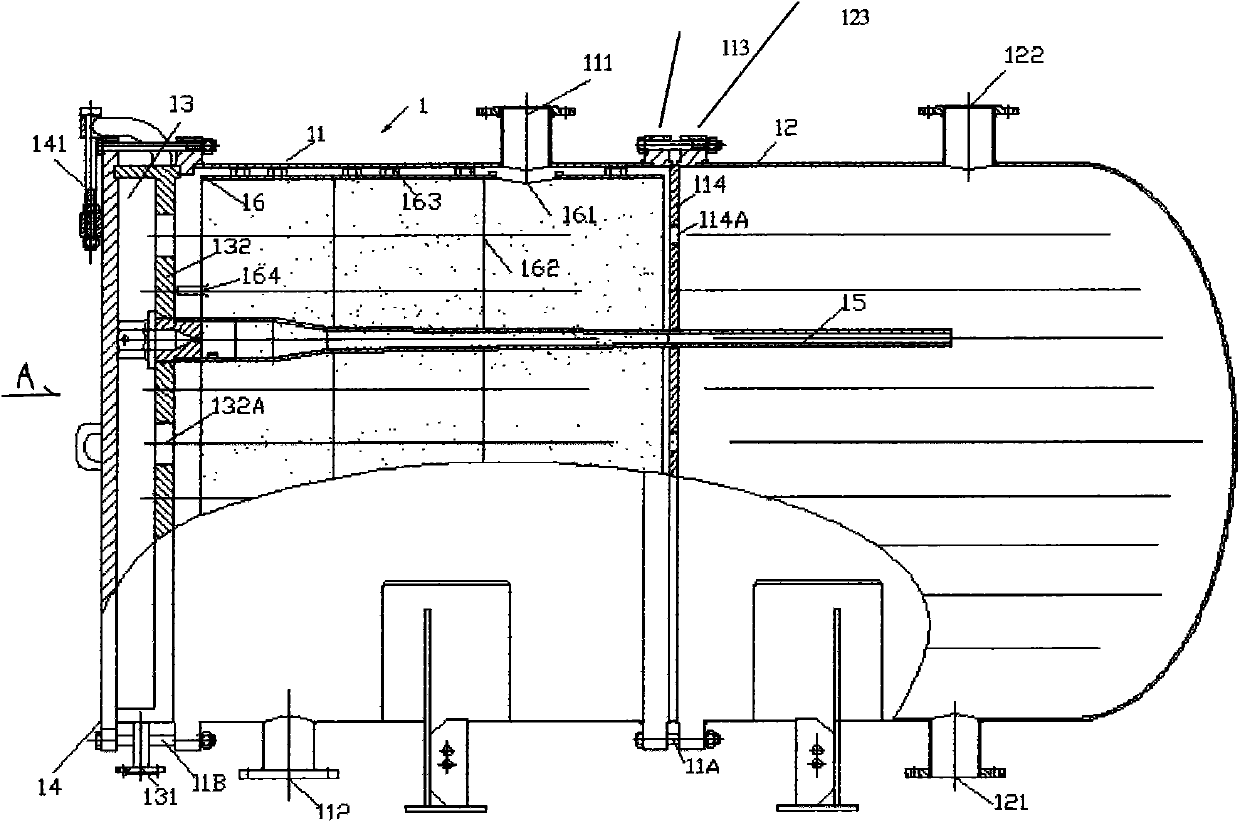

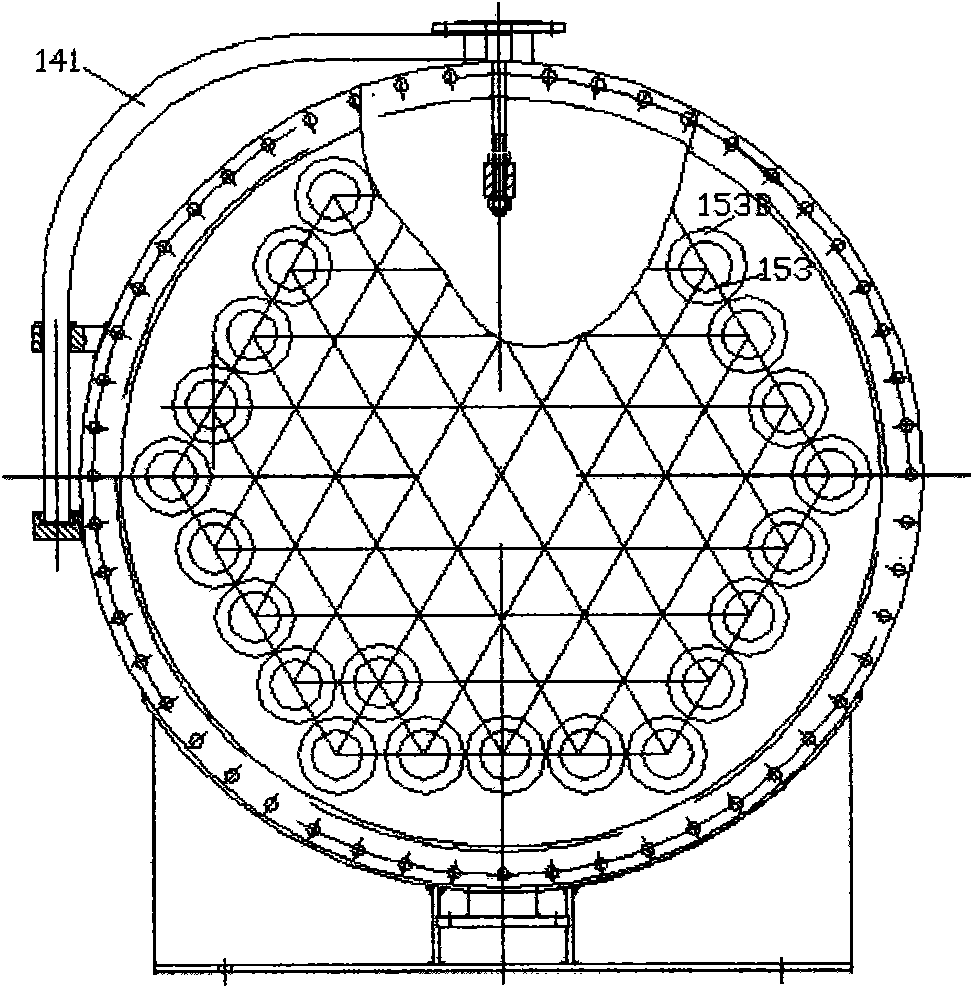

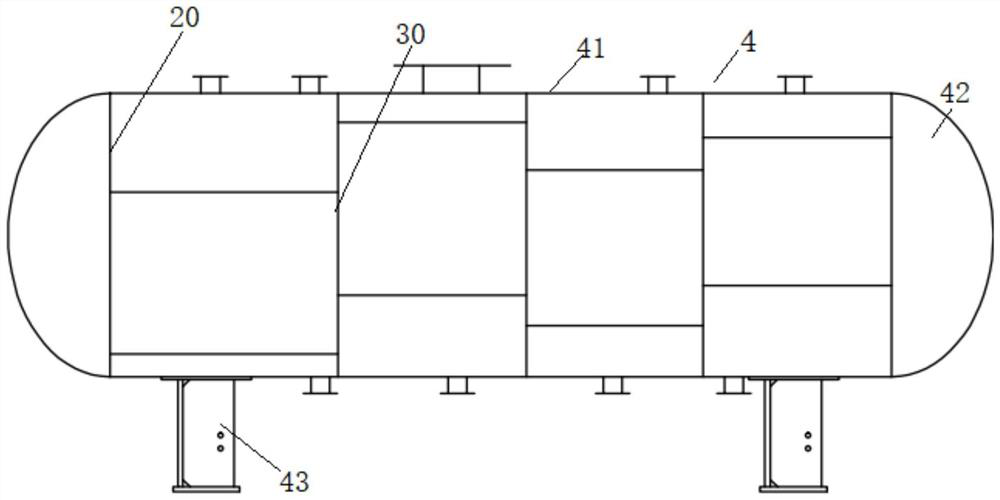

Equipment and method for treating oil extraction wastewater with integration of coalescence and hydrocyclone separation

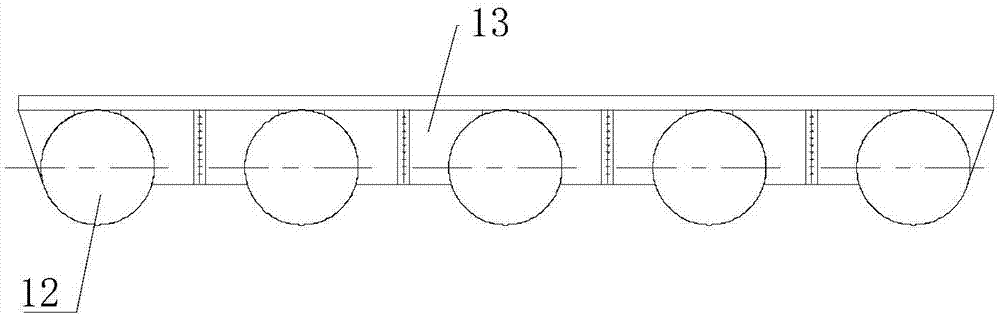

InactiveCN102020336AImprove separation efficiencyGreat operating flexibilityWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesWastewaterOil water

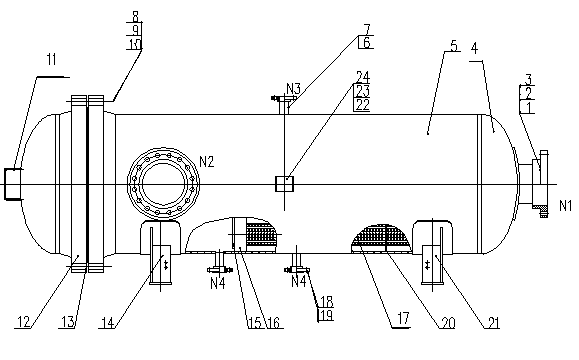

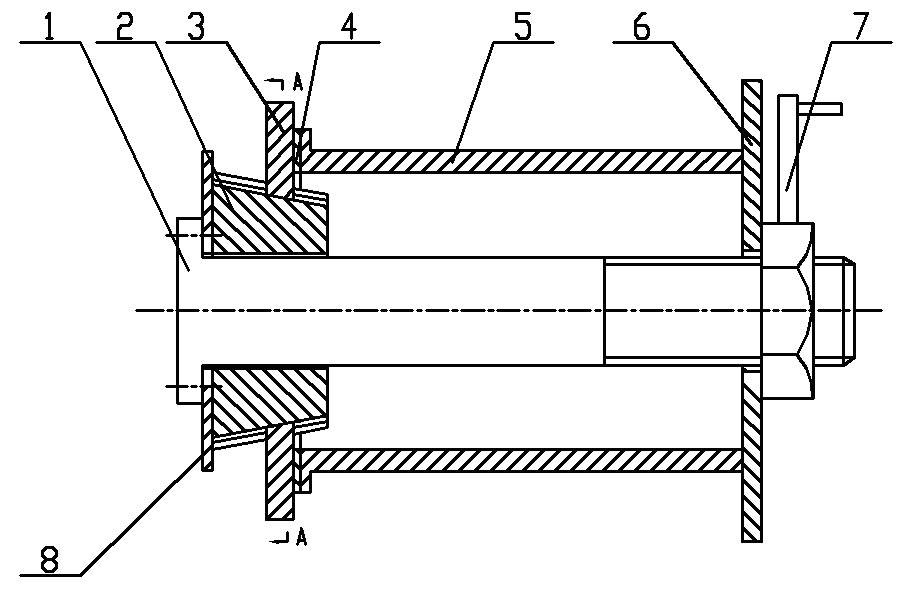

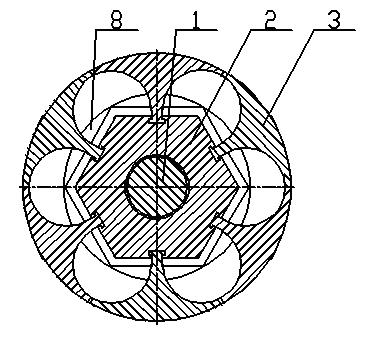

The invention relates to a piece of equipment and a method for treating oil extraction wastewater with integration of coalescence and hydrocyclone separation. The equipment mainly comprises an inlet chamber (11), an underflow chamber (12), an overflow chamber (13), and a flat seal head (14). In the inlet chamber (11) is arranged a coalescence cylinder (16) equipped with coalescence materials, and multiple assemblies of independent flow hydrocyclones (15) of each chamber are densely arranged in a hexagon manner and are transversely penetrated. The method in the invention includes the following steps: oil extraction wastewater pump is sent to an inlet of a pressure vessel, wastewater flows through the coalescence cylinder (16), small oil droplets in the dispersed phase aggregate, become larger and then enter the independent flow hydrocyclones (15) to form high-speed rotating vortex, heavy phase water is collected in the underflow chamber (12) and discharged from a water outlet (121), and light phase oil is forced to move to the axle center, flows to the top, is discharged from an overflow mouth (153D), is collected in the overflow chamber (13) and is finally discharged from an oil drain port (131). According to the method and the equipment in the invention, the size of oil droplets in the dispersed phase entering each independent flow hydrocyclone is large, so the oil-water separation efficiency is largely enhanced compared with conventional technologies and equipments. Both oil contents in the water outlet and water contents in the oil drain port are relatively low.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Production process of iron-removing filter

A production process of an iron-removing filter comprises the major machining tools and procedures of a sealing head, a barrel, a filtering element bushing, a flange C, a pore plate, a pipe flange, component assembly, product assembly and pressure test. A product produced with the process is suitable for matched equipment of a water treatment system. The product is simple in machining process, is low in cost, is the same as products of the same type in service life, but is one third lower than the price of the conventional product, and meets user demands. The product quality is consistent with the standards of GB150 Steel Pressure Vessel and Safety Monitoring Specification for Pressure Vessel, JB2932 Manufacturing Technical Conditions for Water Treatment Equipment and SDDZ037 Manufacturing Quality for Power Plant Water Treatment Equipment. The problems of long delivery period and high price for general production enterprises and users to bear due to the adoption of a composite plate as a major material in the conventional iron-removing filter are solved, and great contribution is made to the prevention of environmental pollution.

Owner:NAIR ENERGY EQUIP

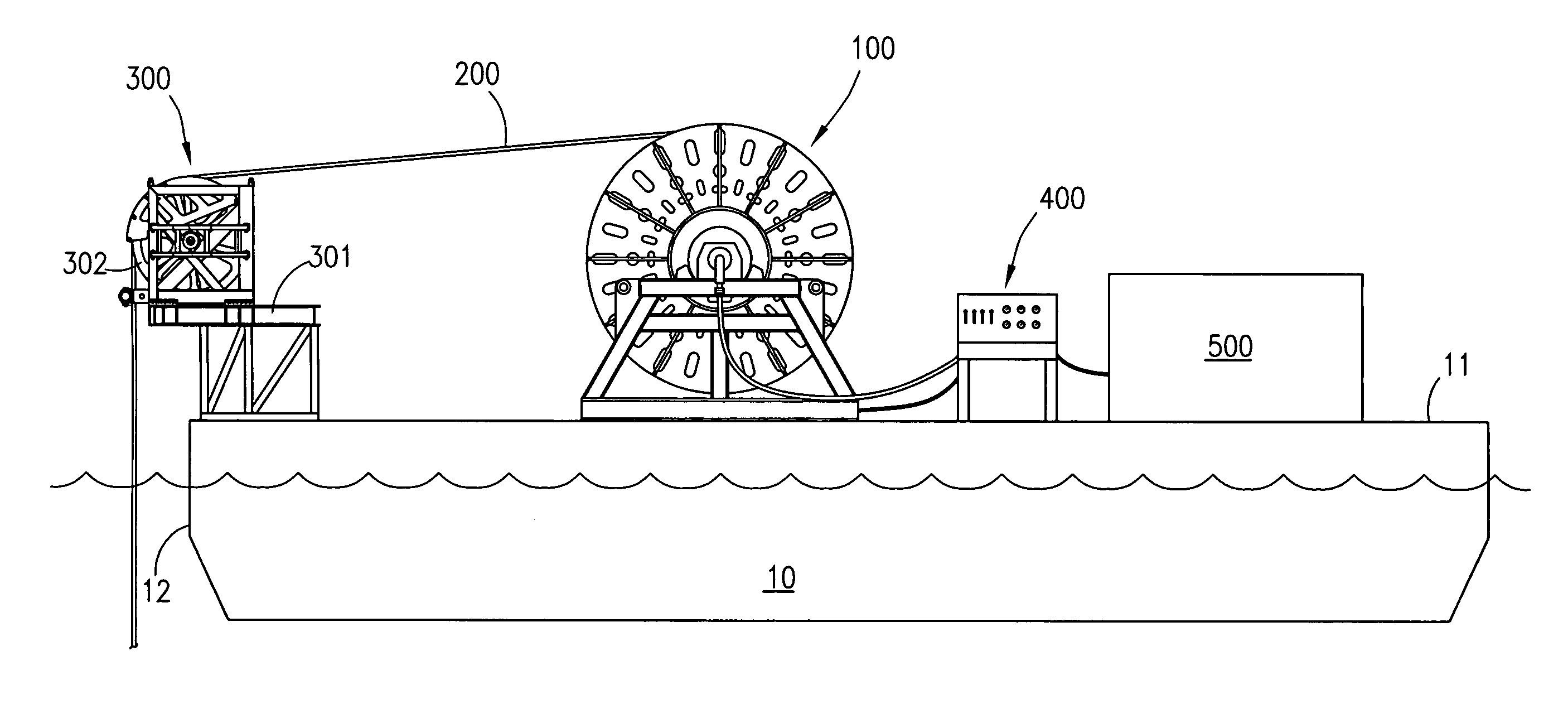

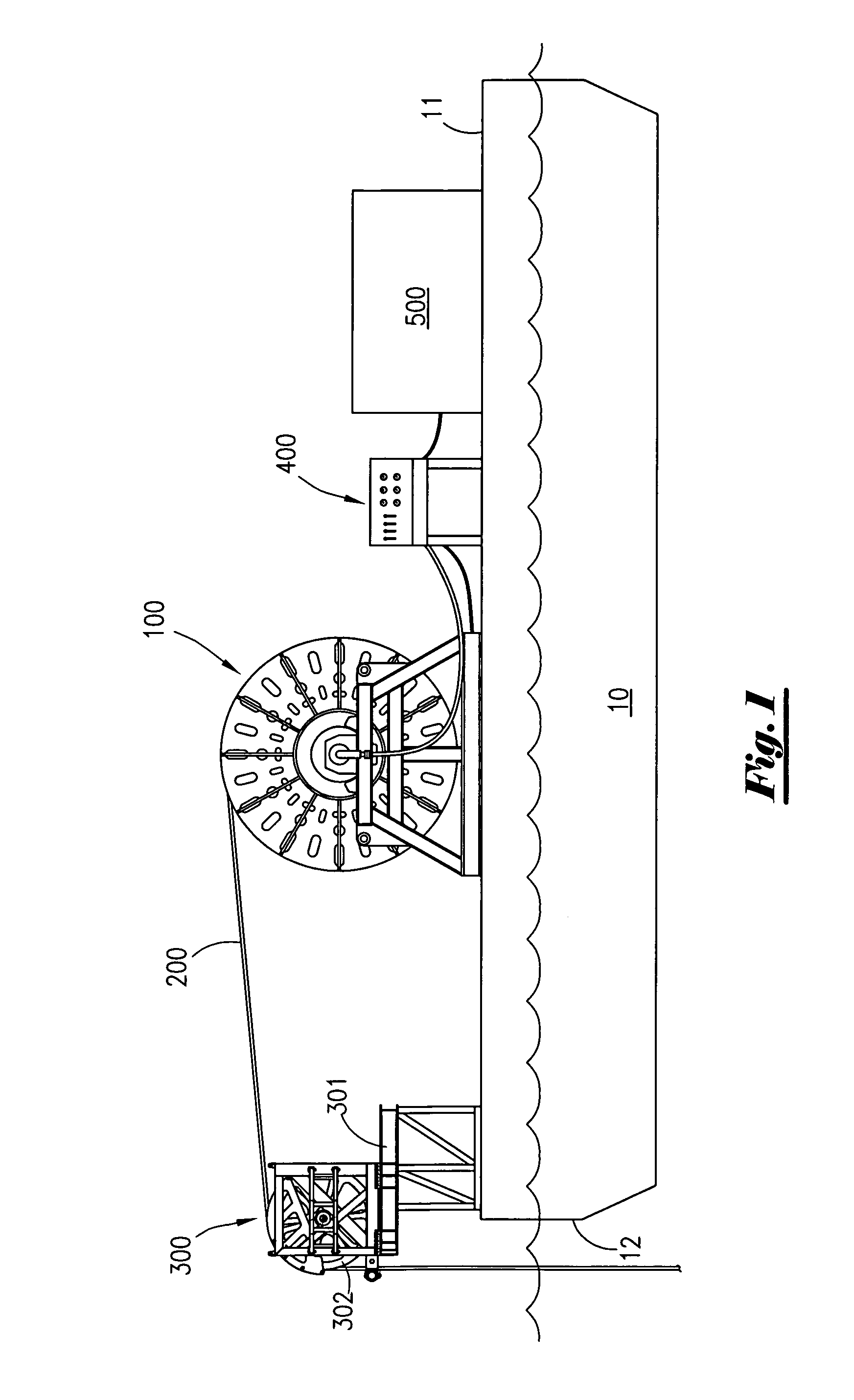

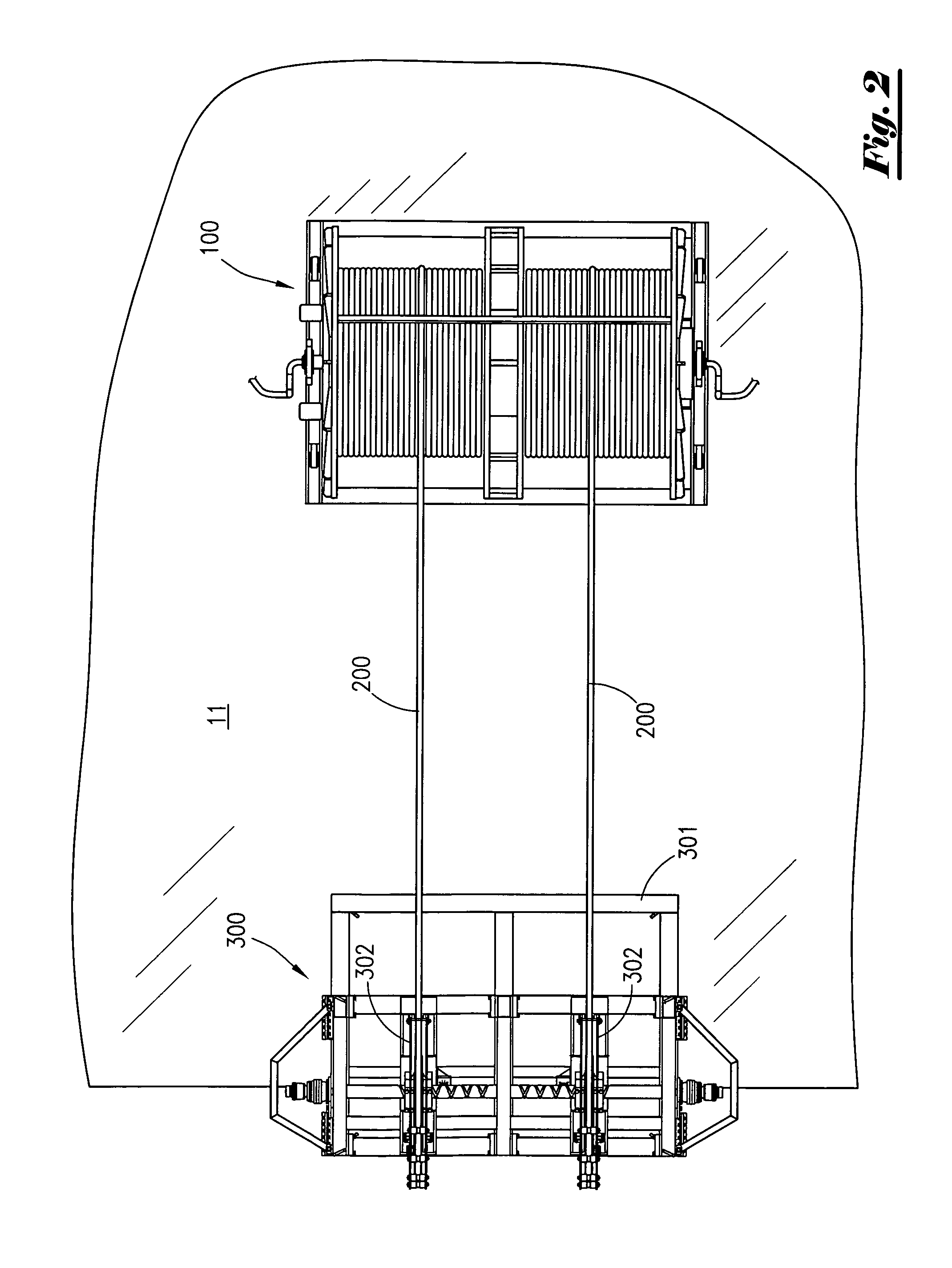

Method and apparatus for performing continuous tubing operations

InactiveUS8733433B2Sufficient pulling capacityGood flexibilityDrilling rodsFluid removalRemote controlEngineering

A spool for deploying and retrieving multiple separate strings of continuous tubing, such as over the side of or through the moon pool of a boat, rig or other vessel, without the need of an injector head. The spool has at least one rotating swivel to permit pumping of fluid(s) down, or back up, tubing strings while the spool is rotating or stationary. A level-wind assembly having at least one sheave directs the continuous tubing overboard, but also level-winds the tubing onto the spool in an orderly fashion through lateral movement of the sheave. The system is powered by a hydraulic power unit with a remote control console.

Owner:COLES ROBERT A

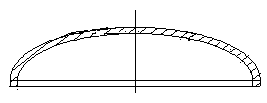

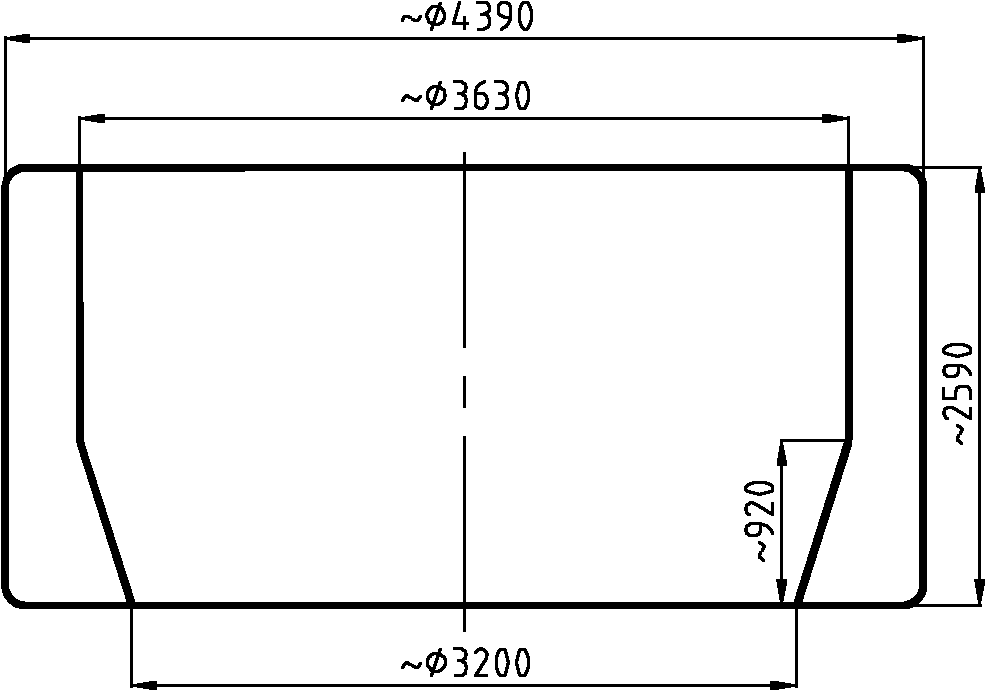

Forging method for pressure vessel bottom head transition section of second-generation nuclear power station and mould

InactiveCN102554088AReduce difficultyReduce the amount of cuttingForging/hammering/pressing machinesForgingNuclear power

The invention discloses a forging method for a pressure vessel bottom head transition section of a second-generation nuclear power station. The forging method is used for forging the pressure vessel bottom head transition section of the second-generation nuclear power station, the pressure vessel bottom head transition section comprises a straight section and a conical section, the inner diameter of the straight section is not less than 3000mm, the outer diameter of the straight section is not less than 4000mm, an inner hole of the conical section is provided with a bevel edge, the minimum inner diameter of the conical section is smaller than the inner diameter of the straight section, and the overall height of the conical section is not less than 2500mm. A megaton free forging press is used, and double-vacuum steel ingots are used as raw materials. The forging method includes the steps: firstly, primarily drawing; secondly, cogging; thirdly, upsetting, forging a central hole and pre-broaching; fourthly, secondarily drawing; fifthly, flattening a large end of a forging to form a conical hole of the forging; and sixthly, broaching. The forging manufactured by the forging method can meet the technical requirements of the pressure vessel bottom head transition section of the nuclear power station, and is compact, reasonable in metal flow line distribution and not easy to crack. The invention further discloses a special mould sleeve for the forging method.

Owner:SHANGHAI HEAVY MACHINERY PLANT

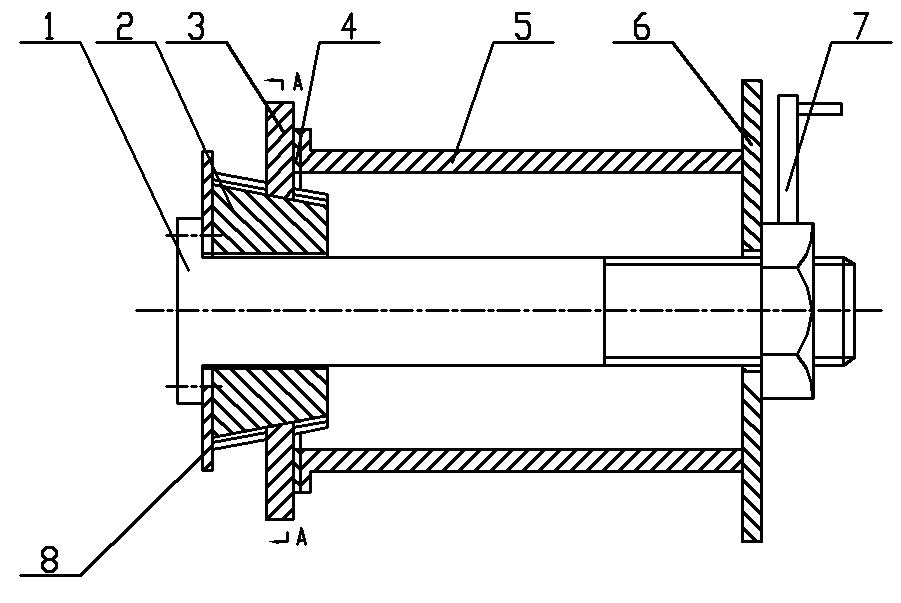

Expanding device of moving block

The invention discloses an expanding device of a moving block, comprising a pull rod, an expanding head, an expanding block, a guiding disc, a sleeve barrel, a positioning block, a locking handle and a stop disc, wherein the pull rod is arranged in the sleeve barrel; one end of the pull rod is extended out of the sleeve barrel and is sequentially sleeved with the circular stop disc, the pyramidal expanding head and the circular guiding disc which are respectively provided with a center hole; the other end of the pull rod, which is extended out of the sleeve barrel and is provided with screw threads, passes through a hole arranged on the positioning block and is connected with the locking handle by screw threads; the expanding head is fixedly connected with the pull rod; and a plurality of T-shaped grooves connected with the expanding block are arranged on the pyramidal surface of the expanding head by equal distance. The expanding device of the moving block has simple structure and low manufacturing cost, is convenient to assemble and disassemble and can effectively reduce or eliminate the welding deformation of a vessel or a steel tube.

Owner:JIANGSU UNIV OF SCI & TECH

Hydroelectric turbine system

The active water hydroelectric system uses a hydraulic ram pump to increase pressure to turbine blades using water from a low head water source, the system comprising a housing, drive pipe, delivery pipe, pressure vessel, turbine, waterwheel, and first and second generators. The drive pipe is fluidly coupled to the low head water source and pressure vessel. A primary flow moves across a turbine turning a first generator. Primary and secondary flows turn the waterwheel which turns the second generator. The passive hydroelectric system a floatation device such as a ship or barge. A vertical siphon pipe and vector siphon pipe comprise a siphon mechanism that delivers water to the hydraulic ram pump. A primary flow of water flows from the pump to a drive pipe to the turbine. Primary and secondary flows of water turn the waterwheel. Water exits through an exit pipe.

Owner:NAVARRO RICHARD M

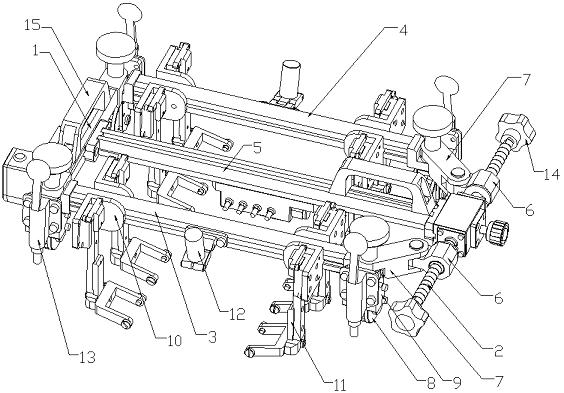

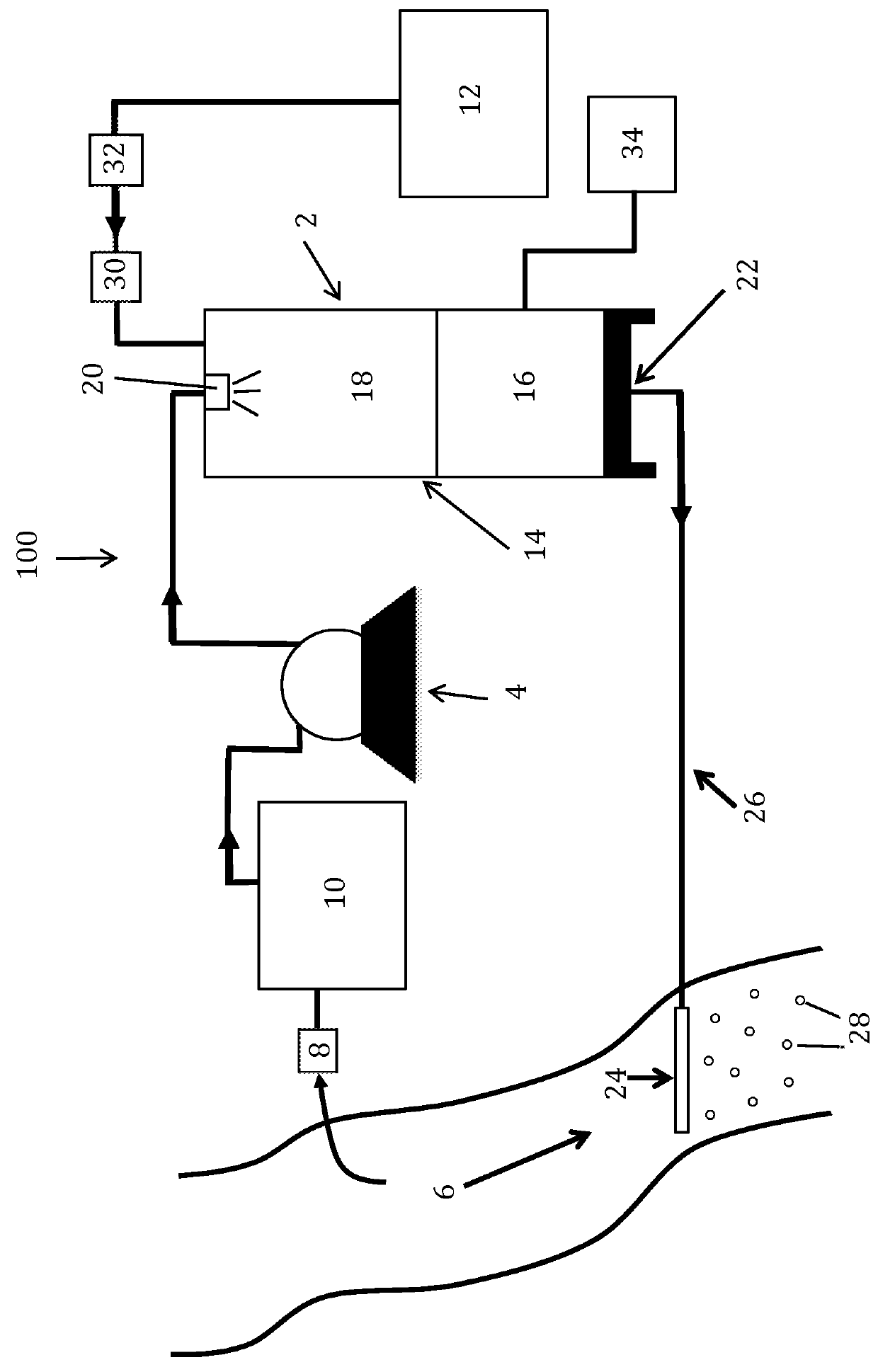

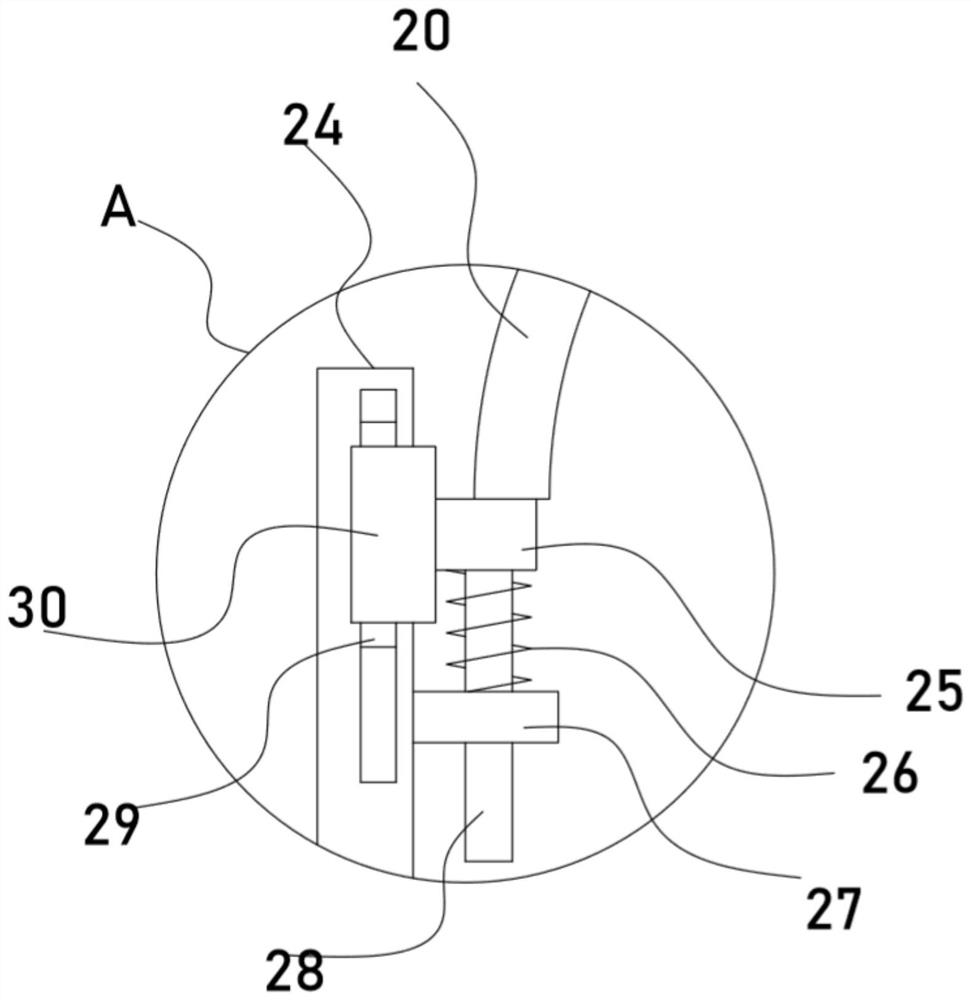

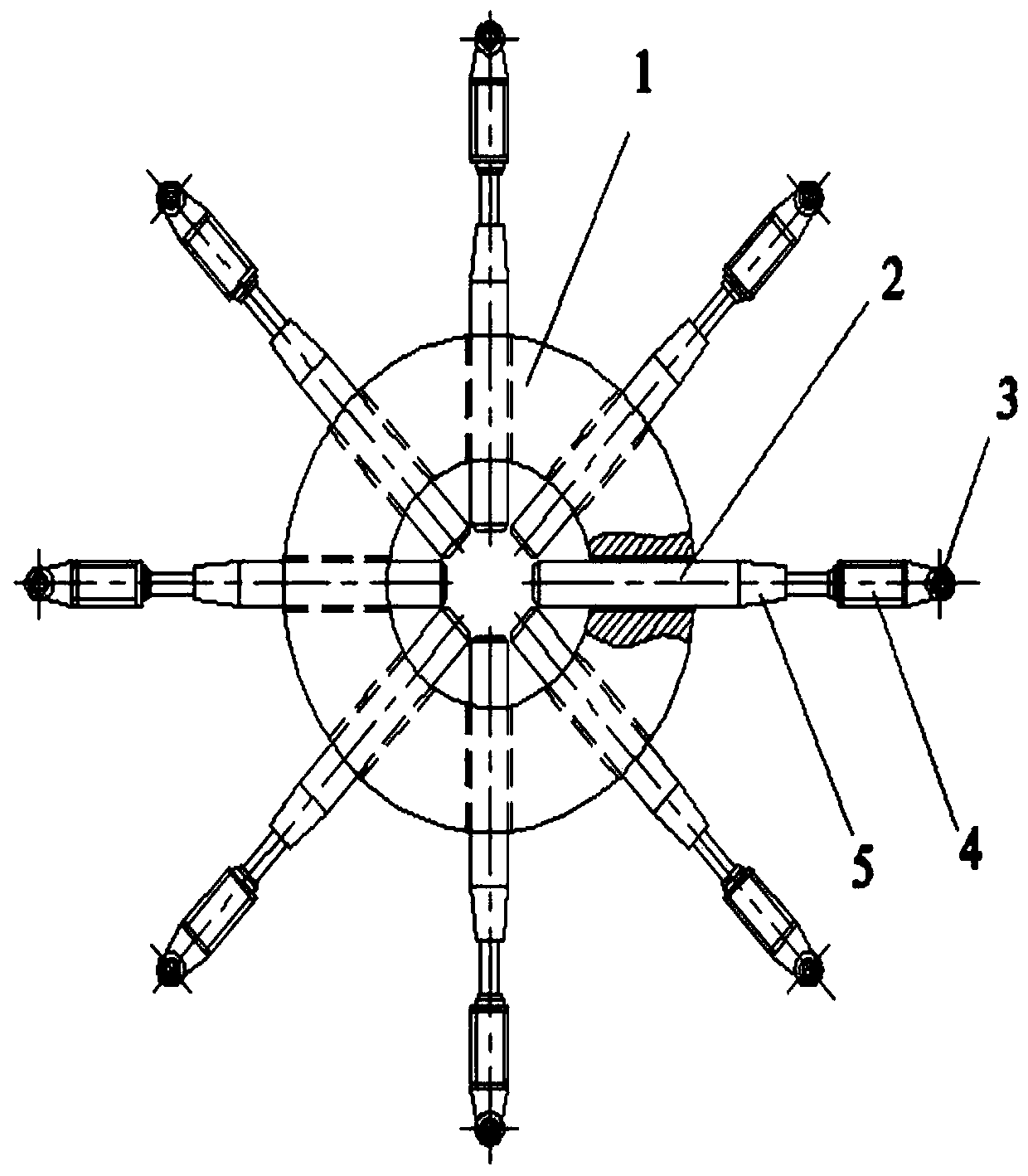

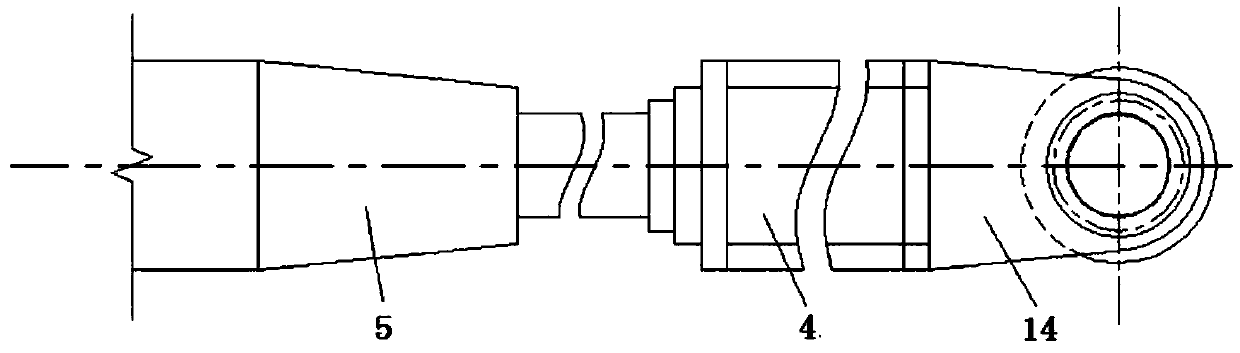

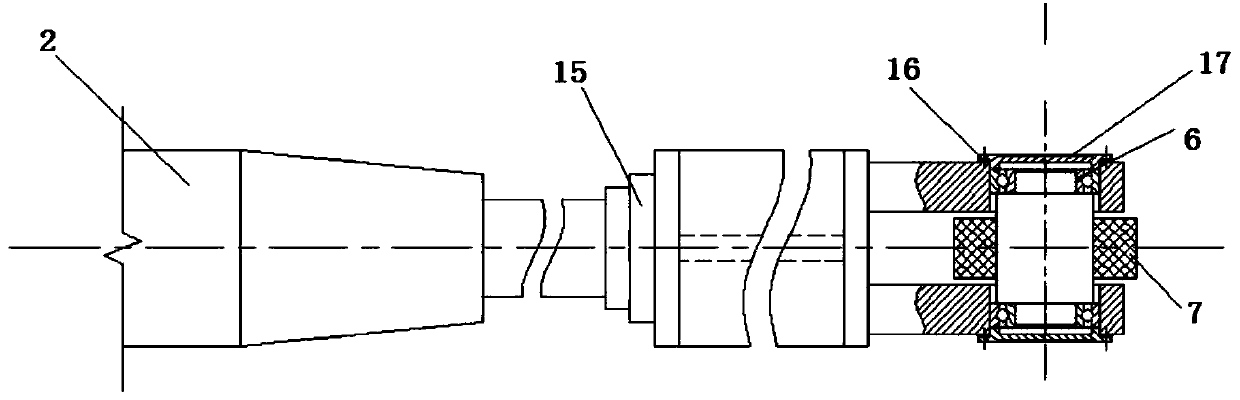

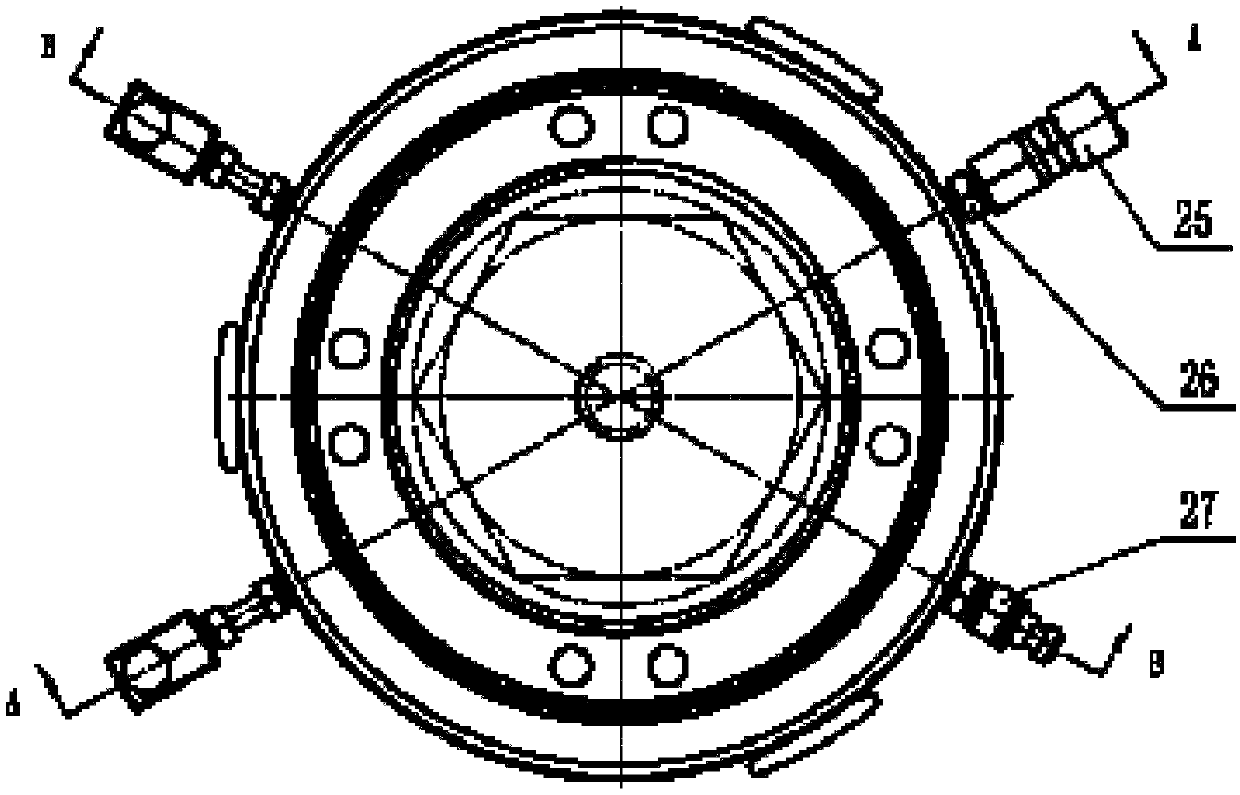

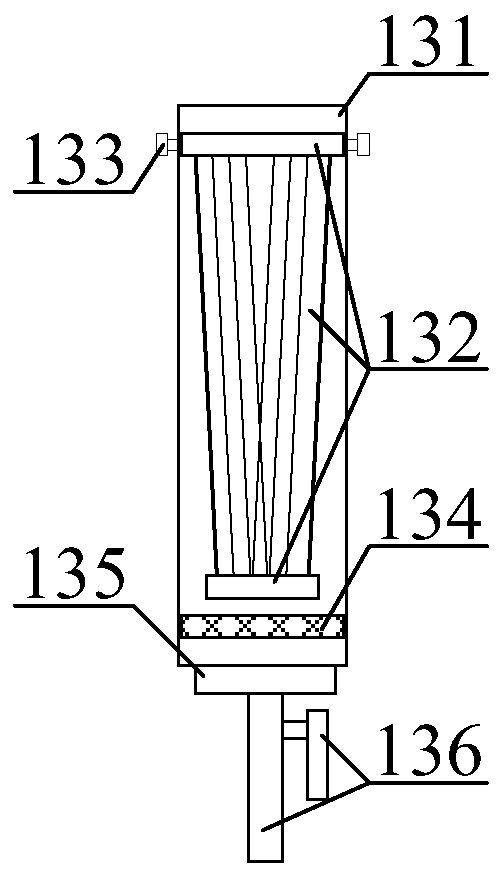

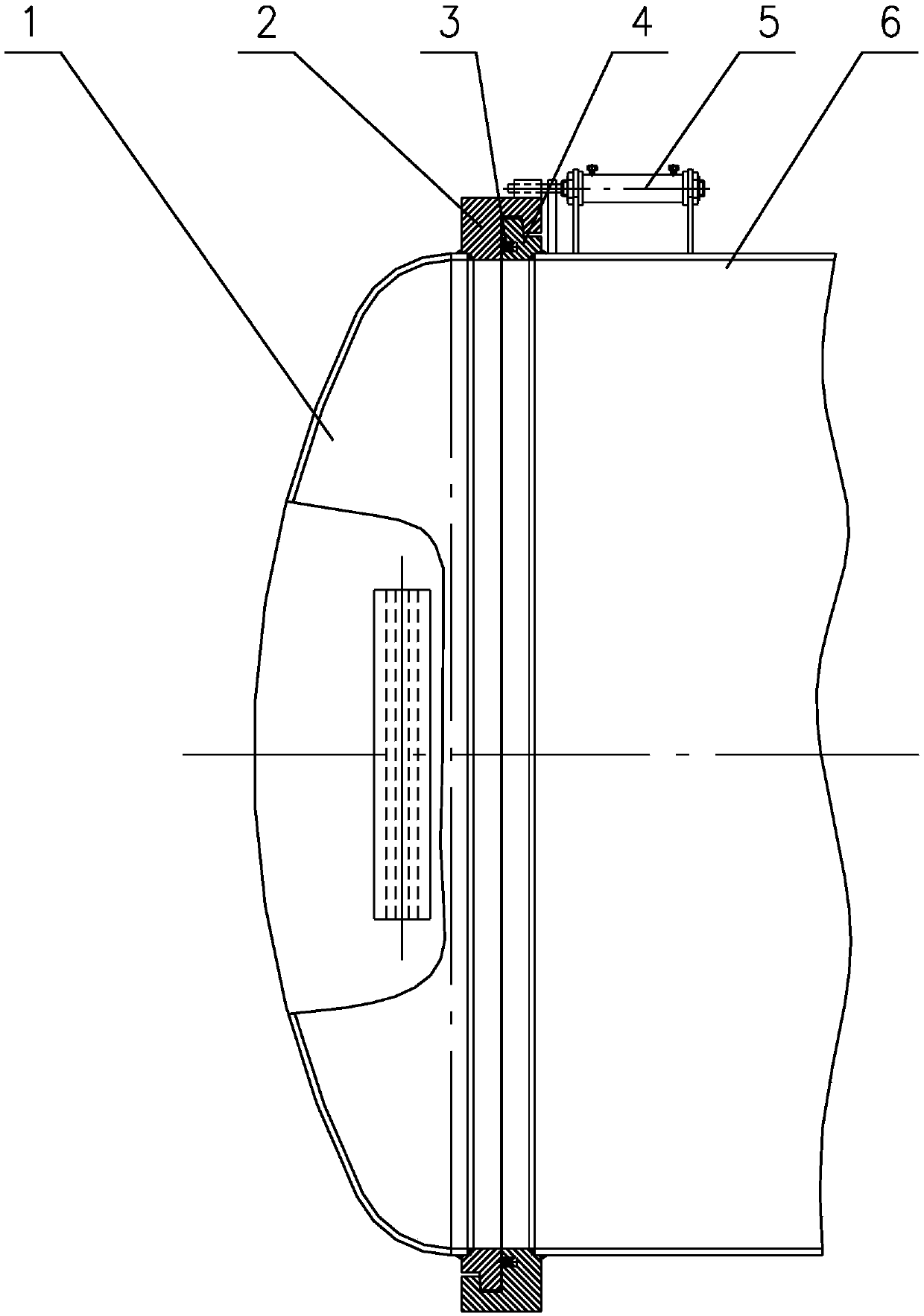

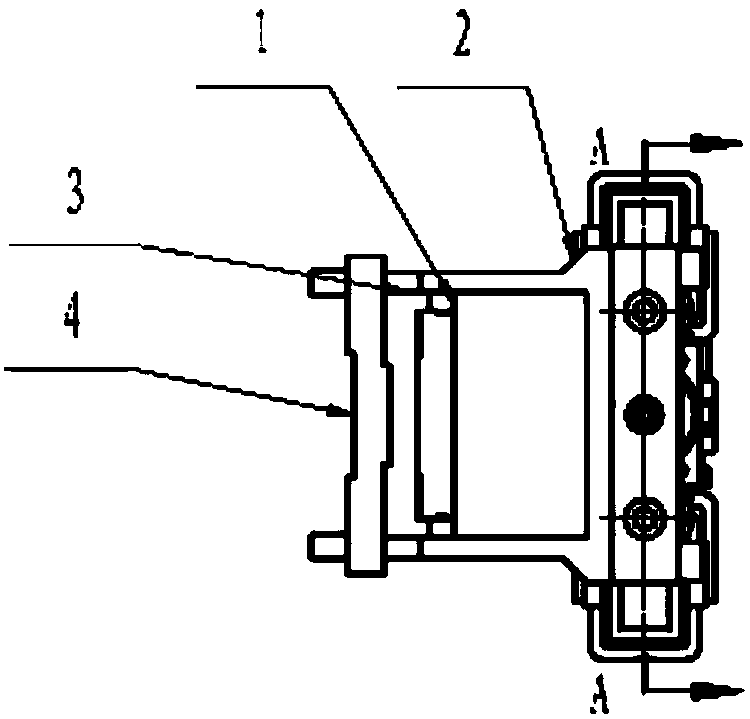

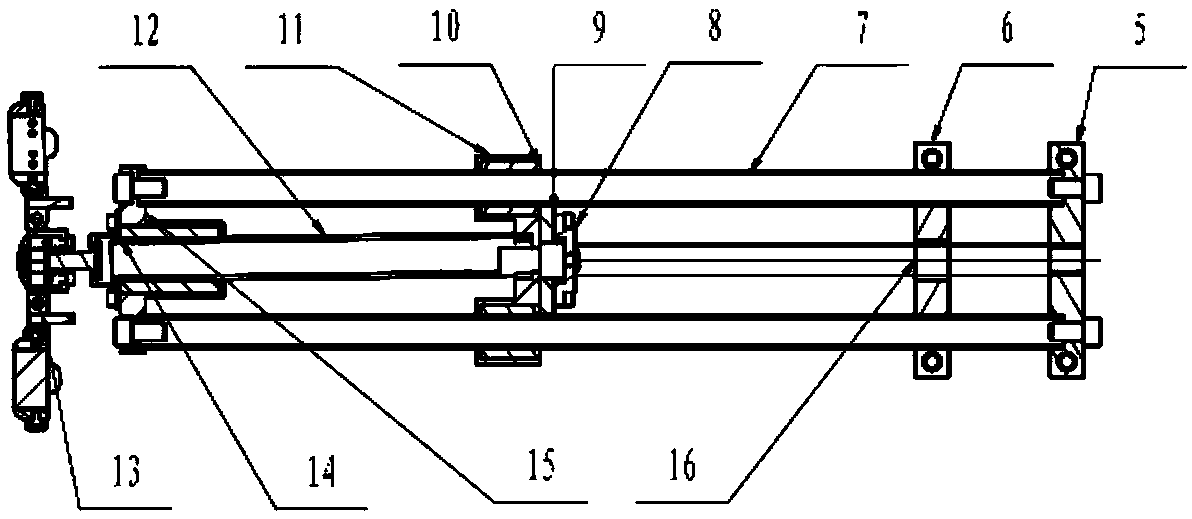

Combined TOFD and phased array imaging scanner for weld of seal head for pressure vessel

ActiveCN102495137APrecise positioningAvoid wear and tearMaterial analysis using sonic/ultrasonic/infrasonic wavesScannerEngineering

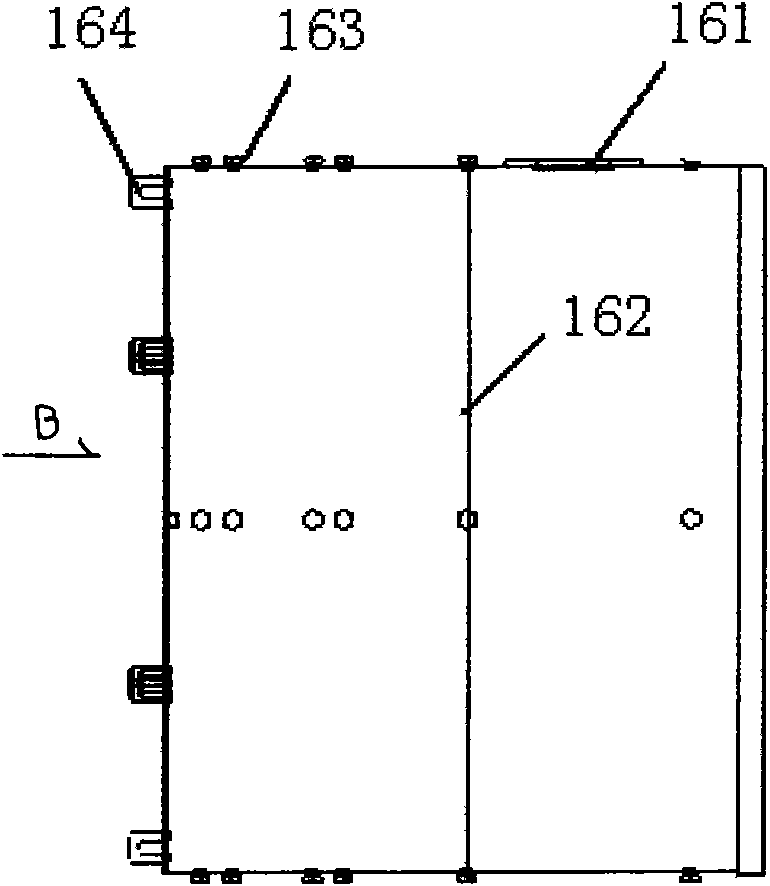

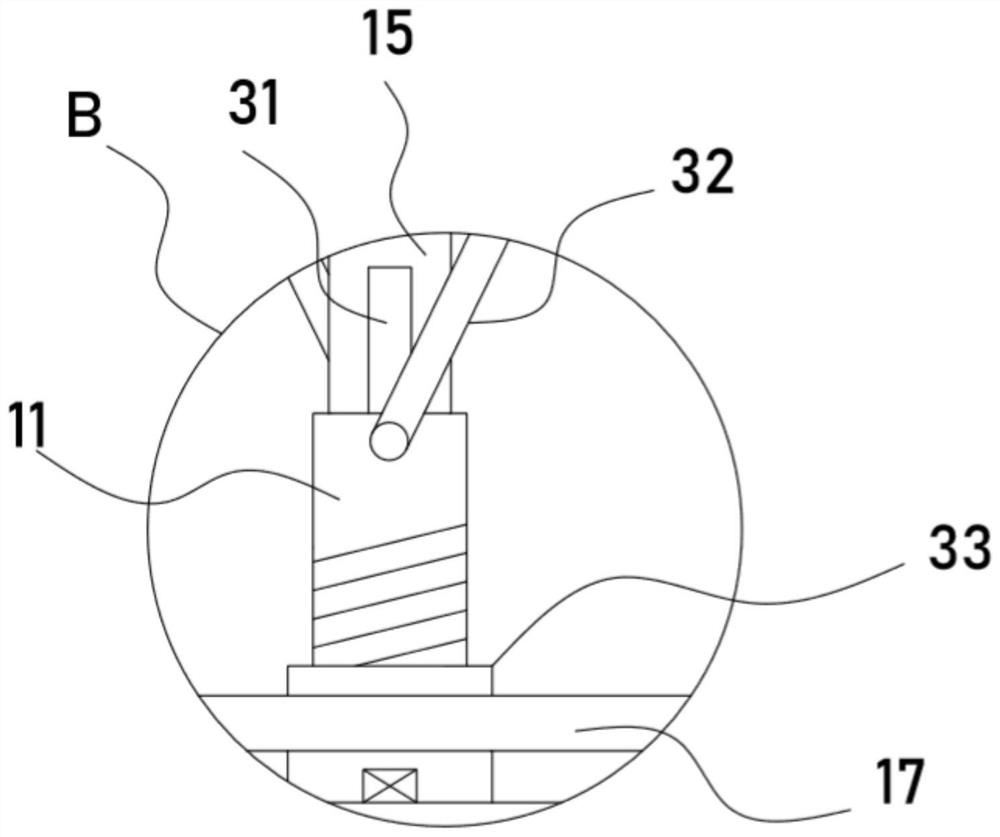

The invention relates to a combined TOFD and phased array imaging scanner for a weld of a seal head for a pressure vessel. The scanner comprises a main support composed of a front beam, a back beam, a left beam, a right beam and a middle beam; the front ends of the left beam and the right beam are respectively hinged with two ends of the front beam, the front part of the middle beam is in fixed connection with the middle part of the front beam, the back beam comprises a double-end screw which has symmetrical left and right sides, screw threads at a left part and a right part of the screw havedifferent spiral directions, the middle part of the screw is connected with the rear part of the middle beam, the screw threads at the left part and the right part of the screw are respectively spirally connected with a left nut and a right nut, the left and right nuts are connected with the rear ends of the left and right beams, and four corners of the main support are respectively provided witha magnetic wheel mechanism. The scanner provided in the invention is applicable to detection of circumferential welds of heads with different sizes for containers, enables a probe to always carry outdetection along a circular weld, ensures detection precision and supports weld detection of a plurality of workpieces like pipelines, butt flat plates, etc.

Owner:北京欧宁航宇检测技术有限公司

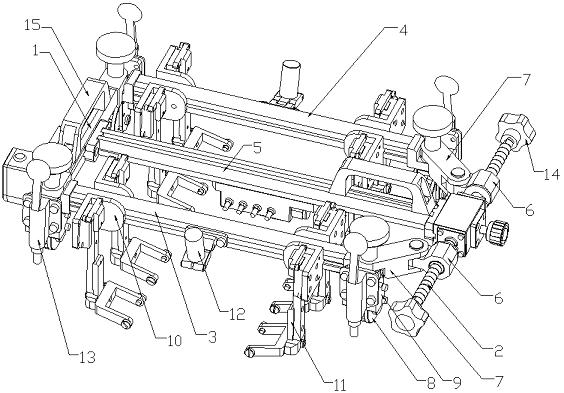

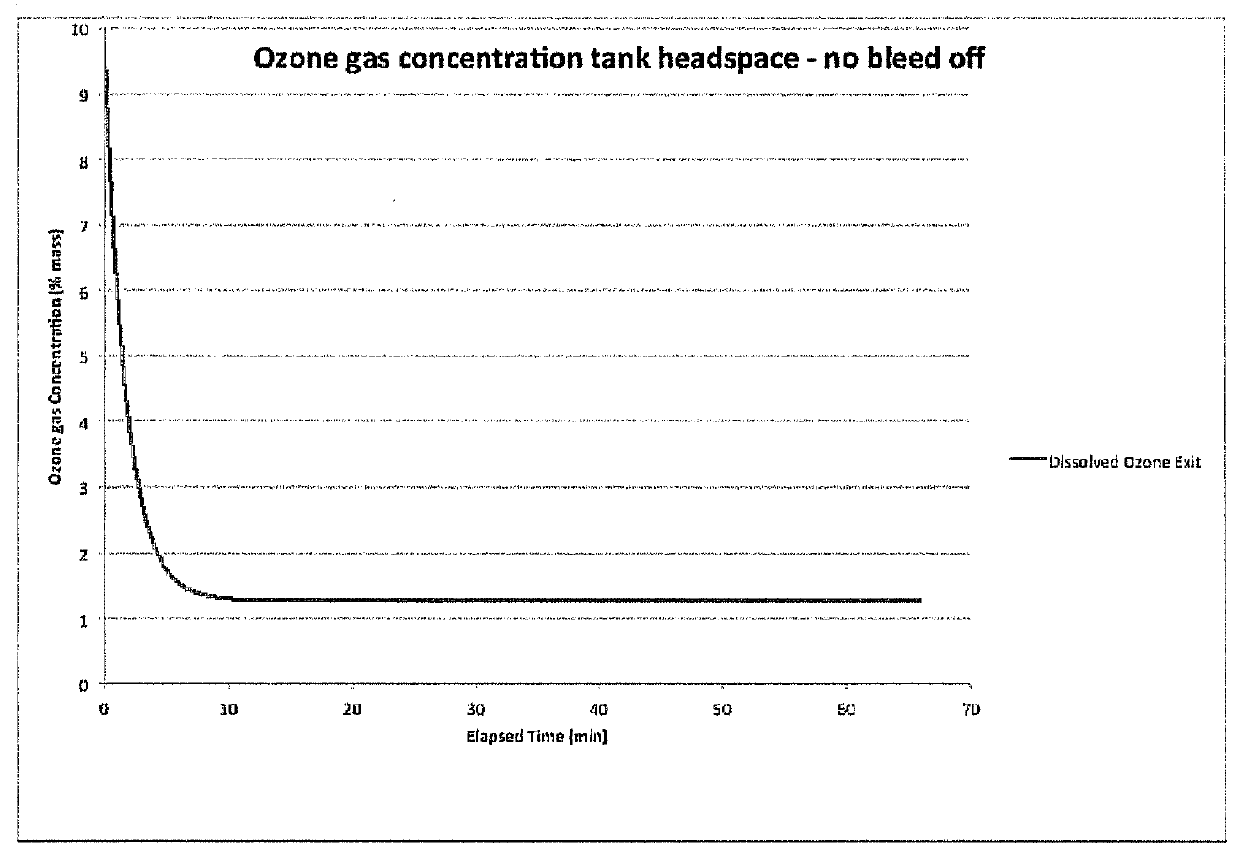

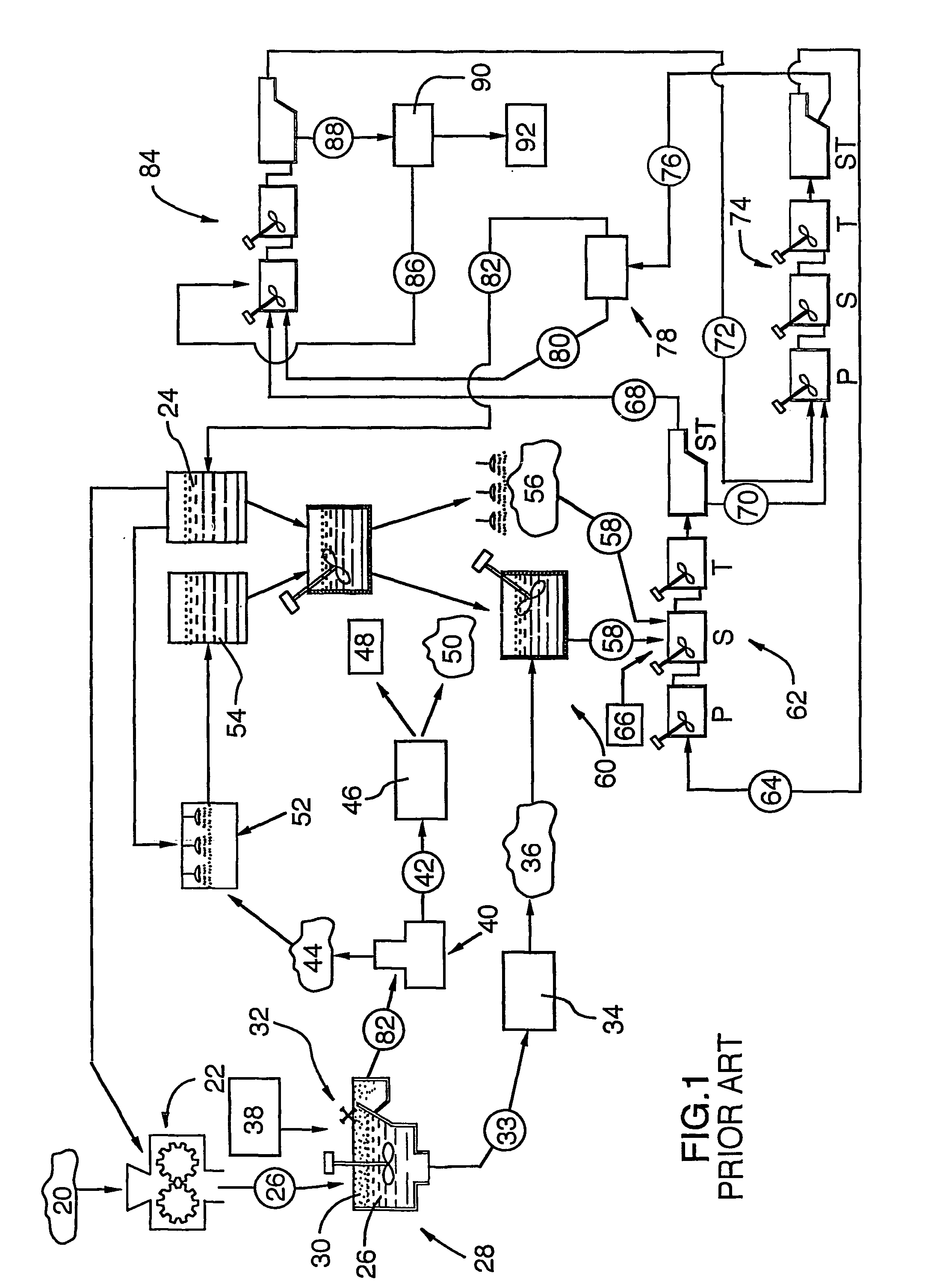

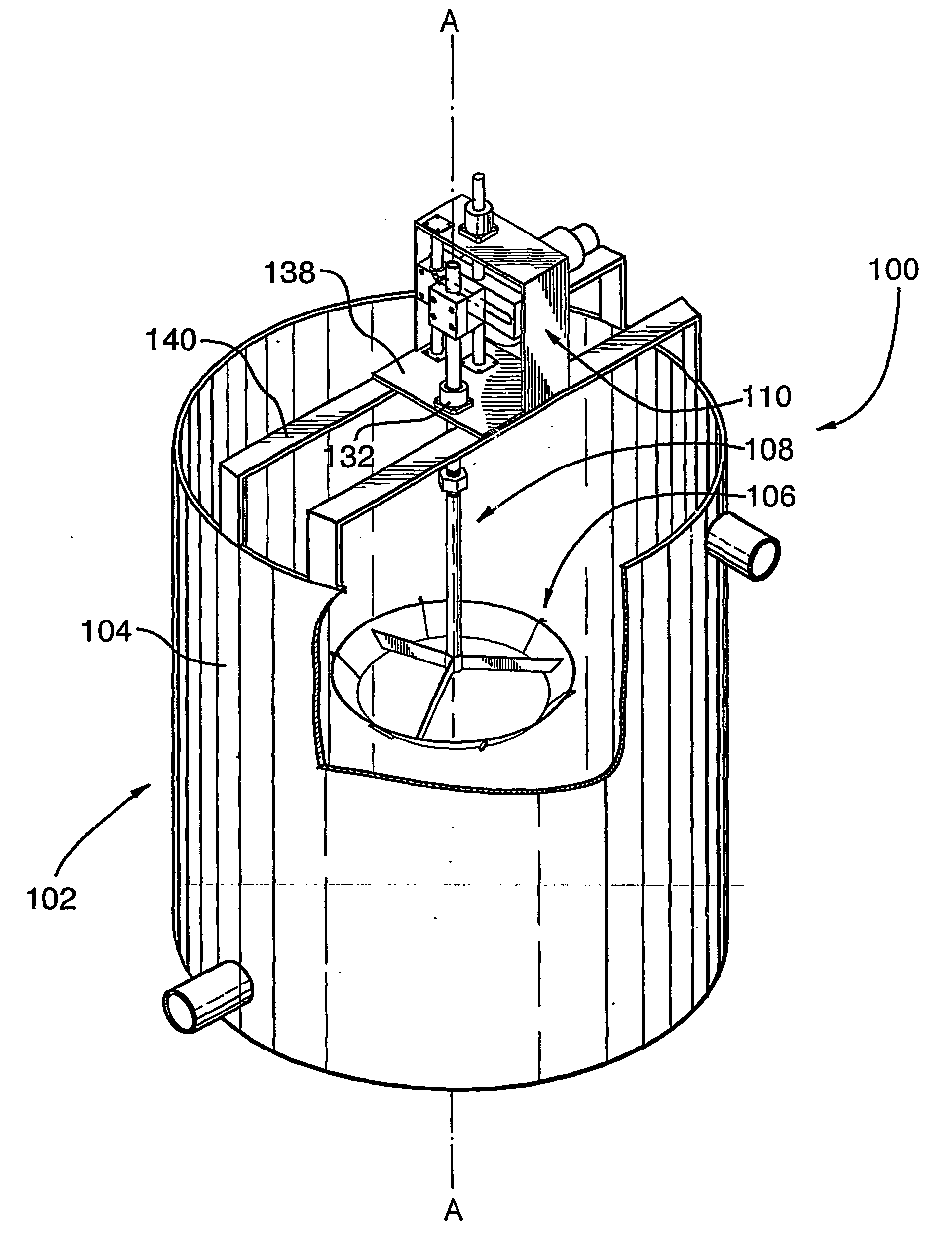

Systems and methods for maximizing dissolved gas concentration of a single species of gas from a mixture of multiple gases

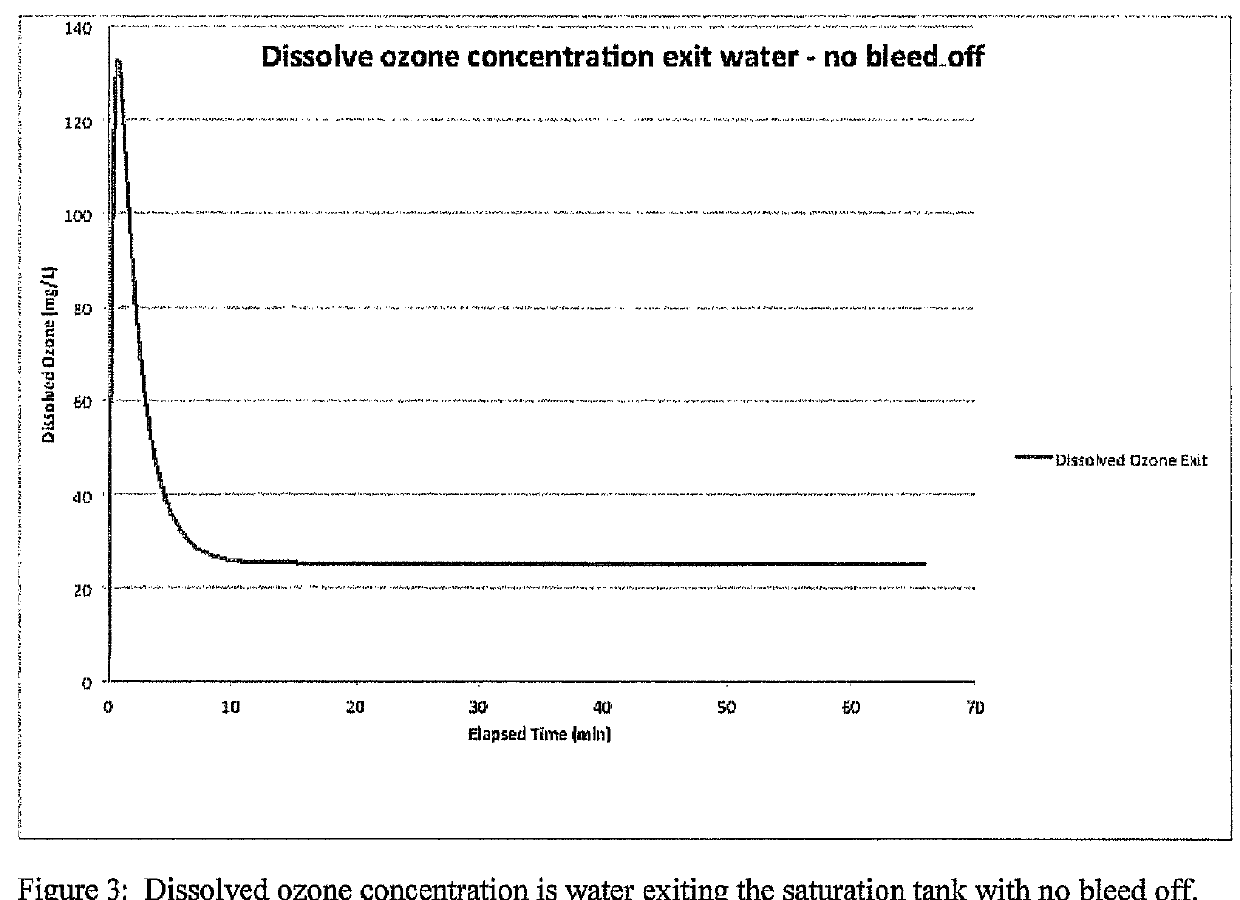

ActiveUS9248415B2Improve economyWater treatment parameter controlFlow mixersProduct gasEnvironmental engineering

An apparatus and method for maximizing the dissolved concentration of ozone in a liquid. The apparatus includes a dissolution tank having a pressure vessel configured to contain a treated fluid and at least one gas in a head space above the treated fluid, an inlet configured to permit passage of an untreated fluid into the head space, and an outlet configured to permit passage of the treated fluid out of the vessel; a gas supply system configured to transport the at least one gas to the head space; a fluid supply system configured to provide the untreated fluid to the tank; a bleed-off system for removing gas from the head space so as to maximize the dissolved concentration of the ozone gas in the liquid; and a discharge device configured to pass the treated fluid from the tank into the target liquid.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS +1

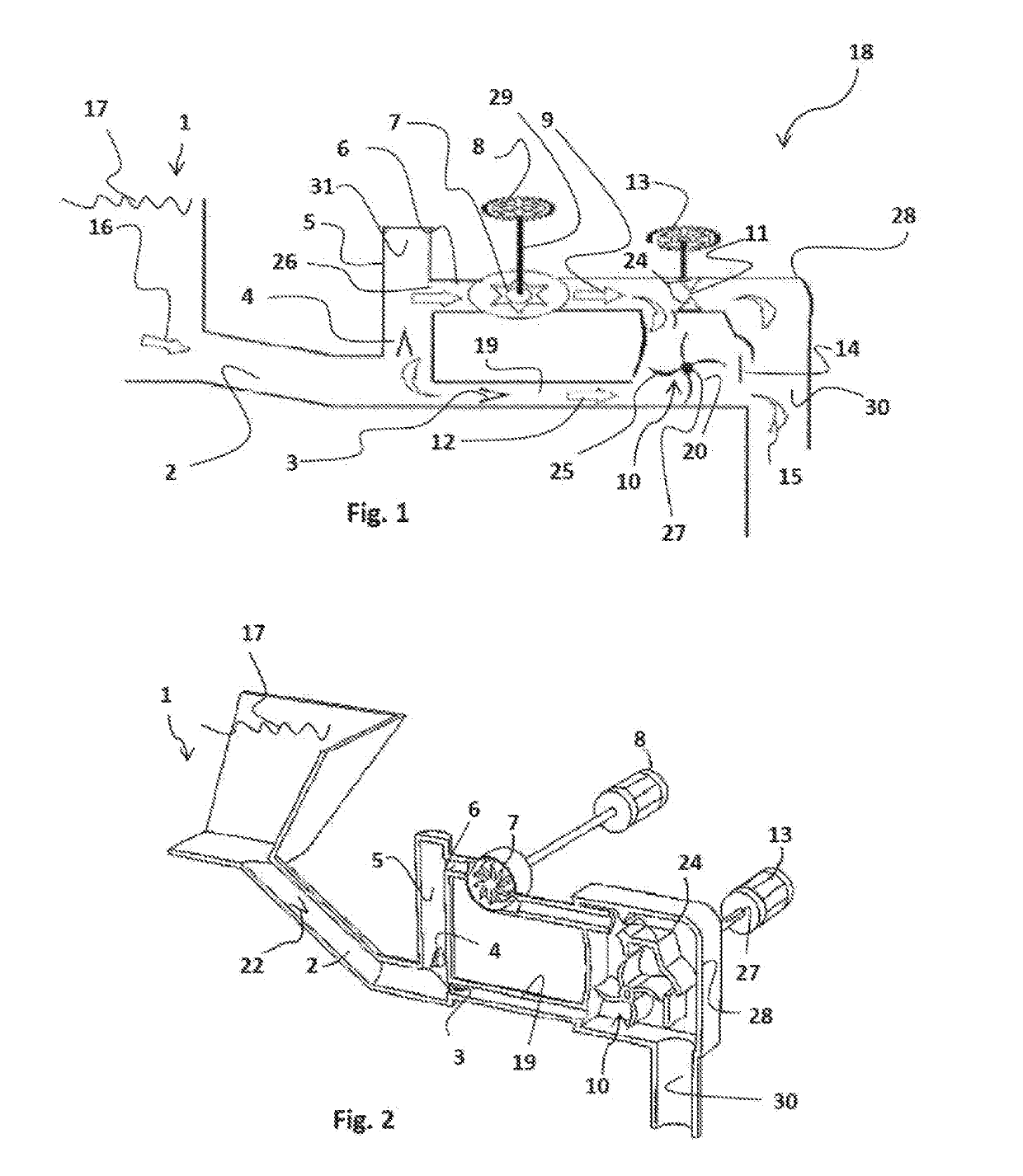

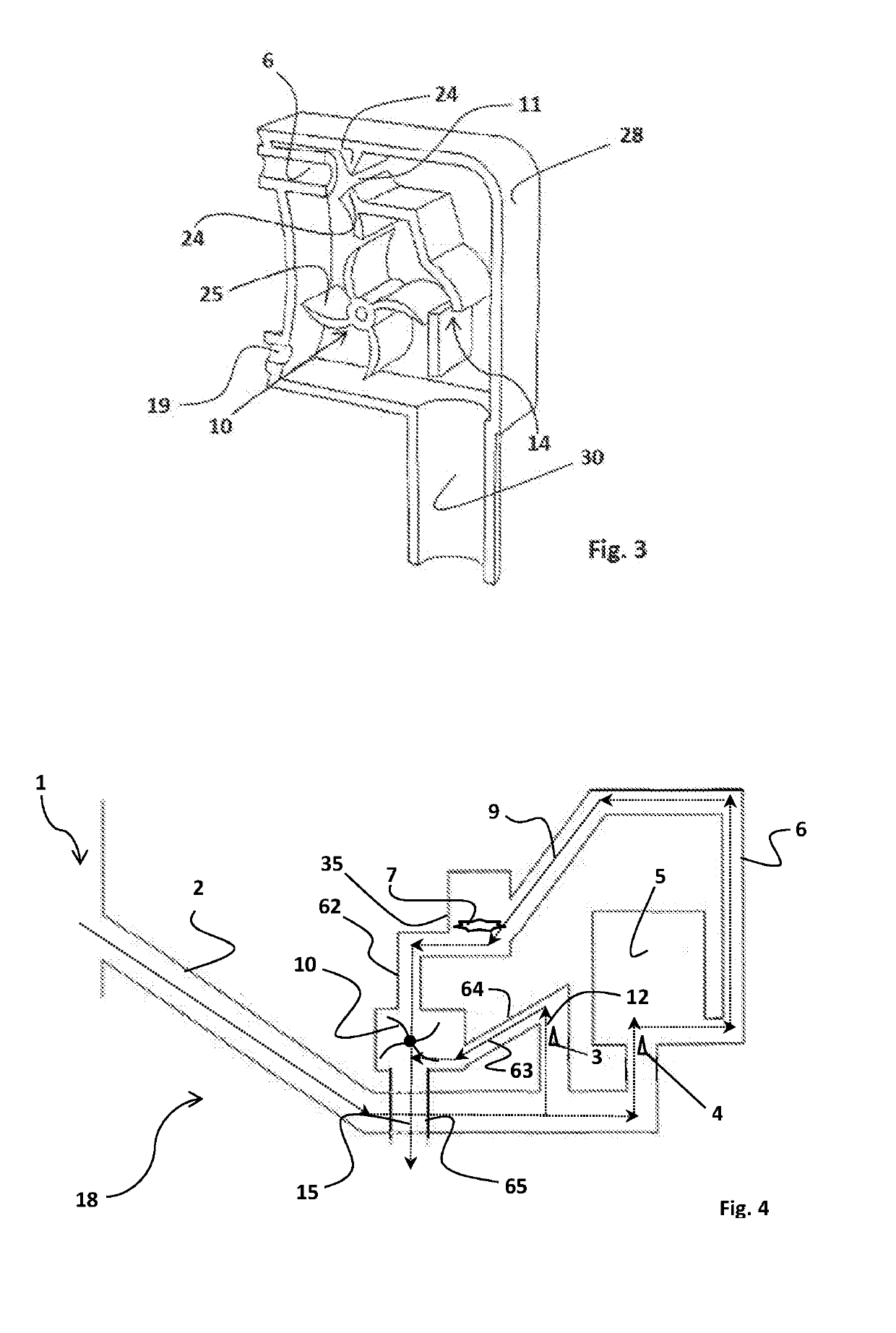

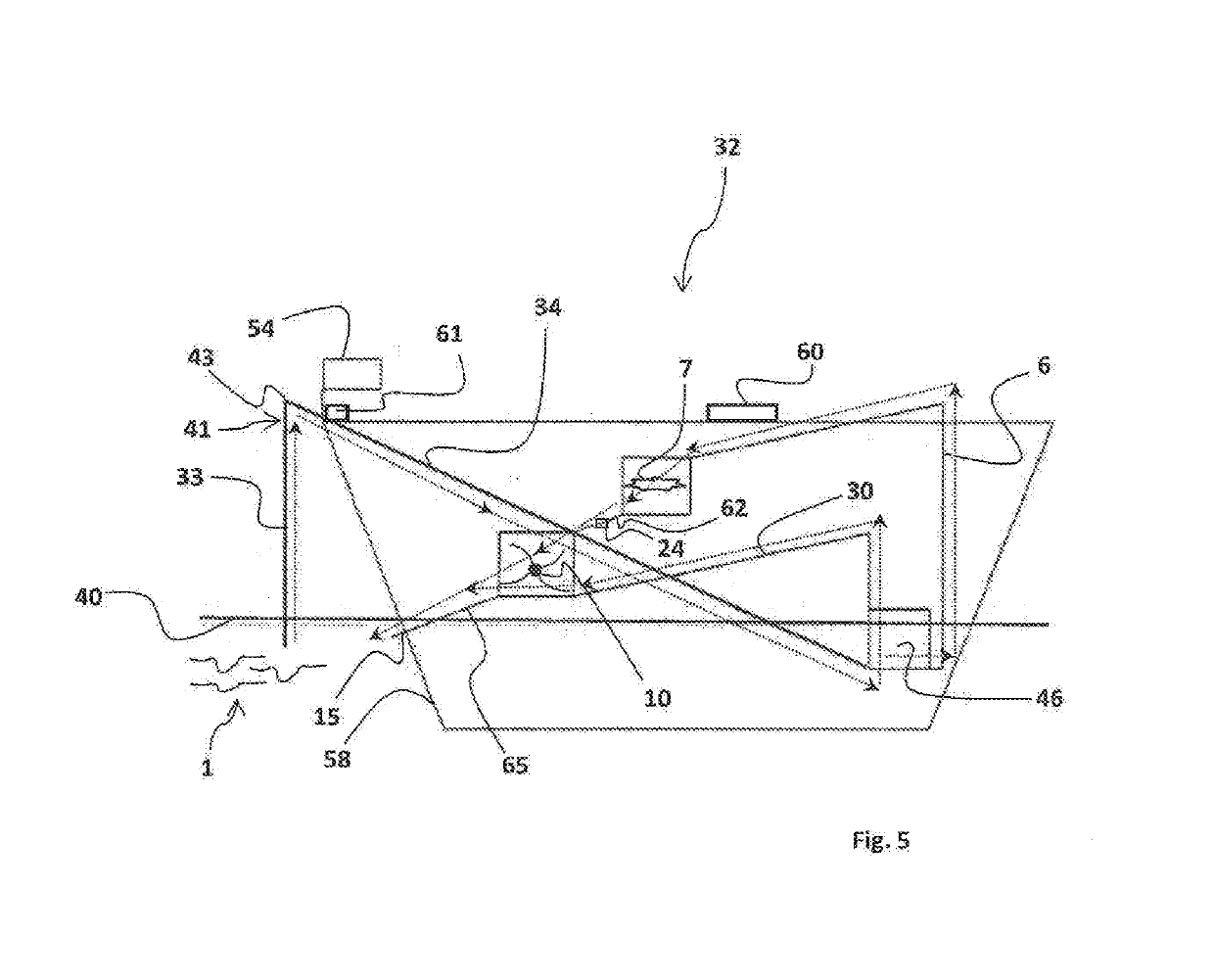

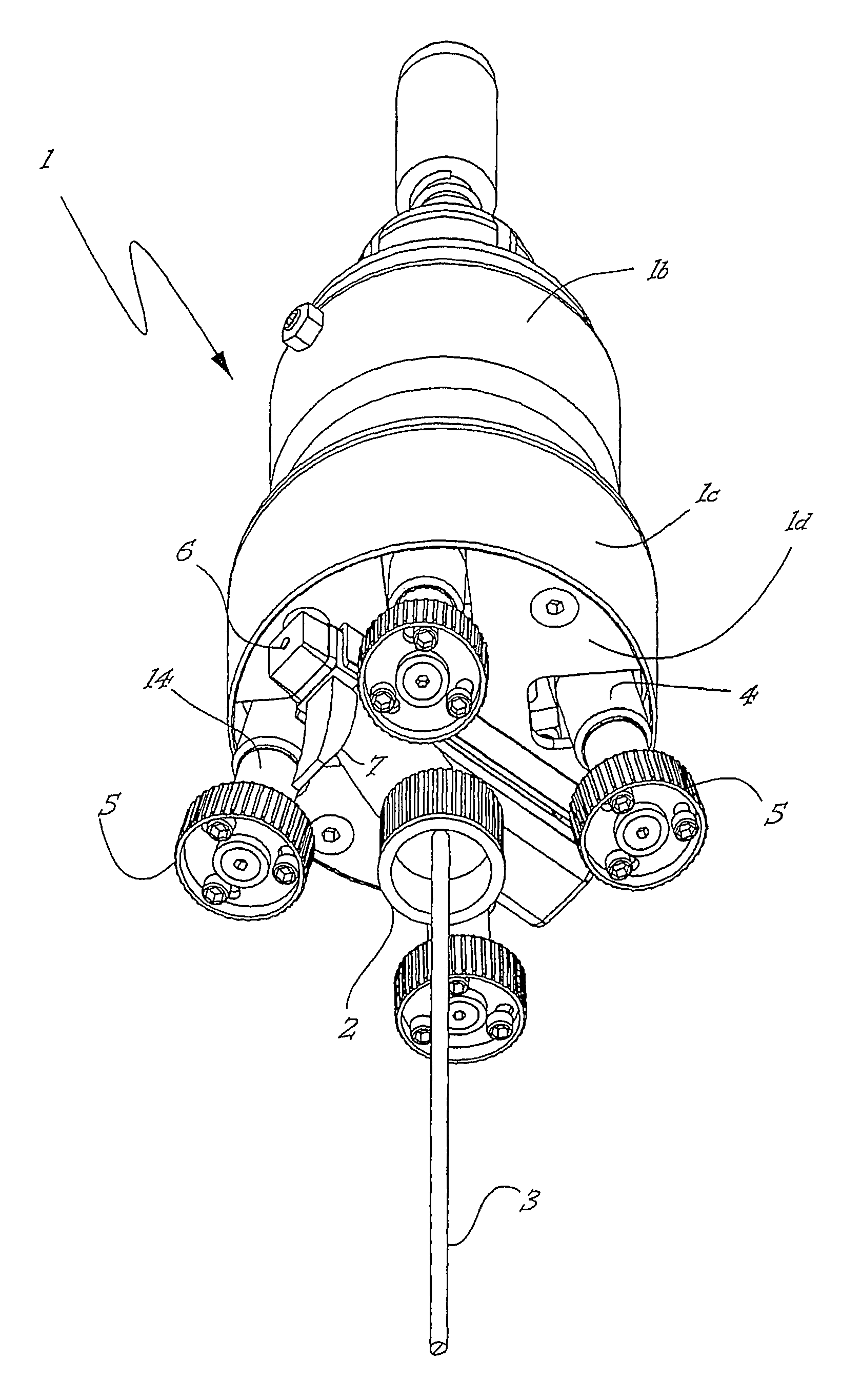

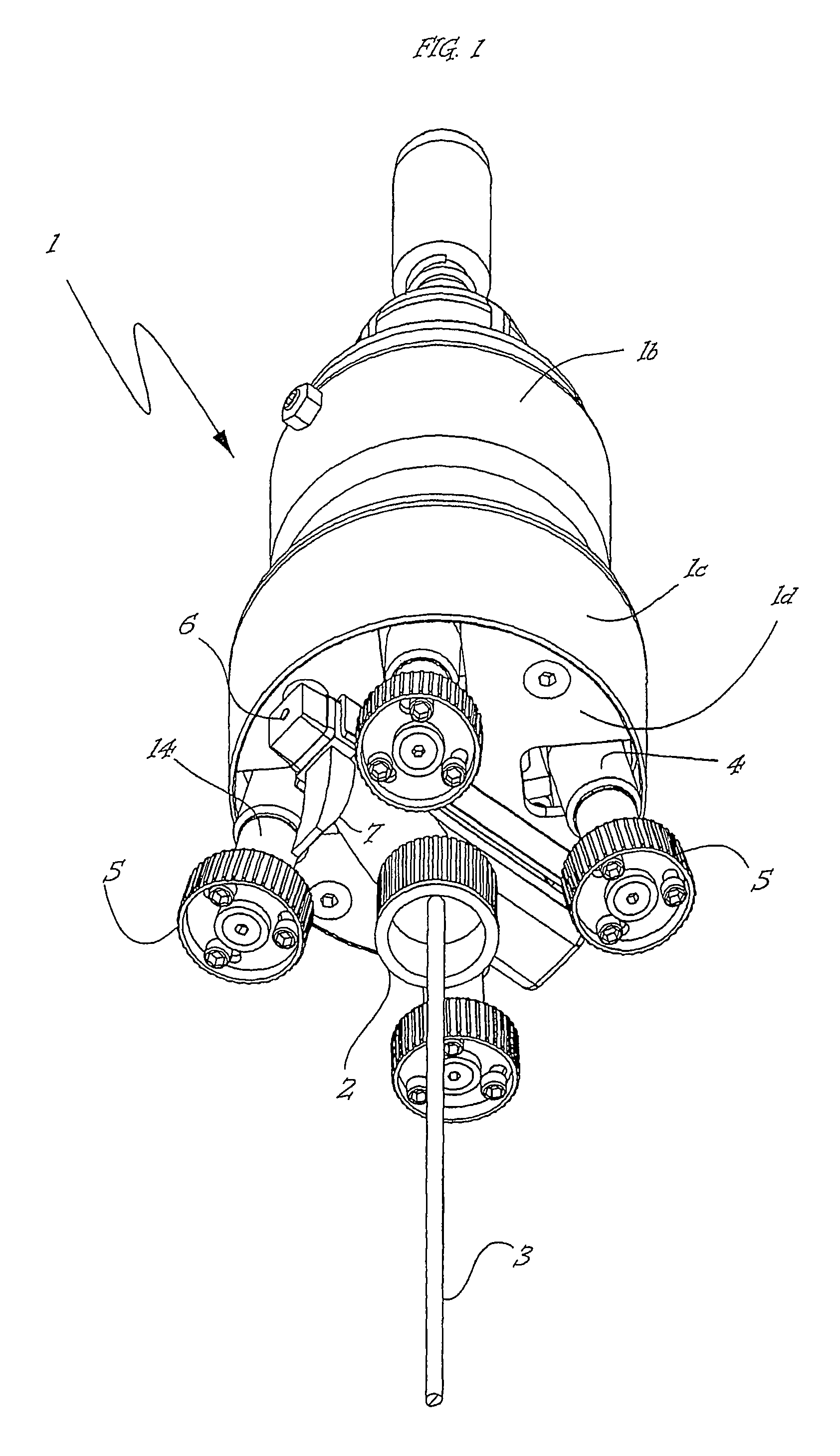

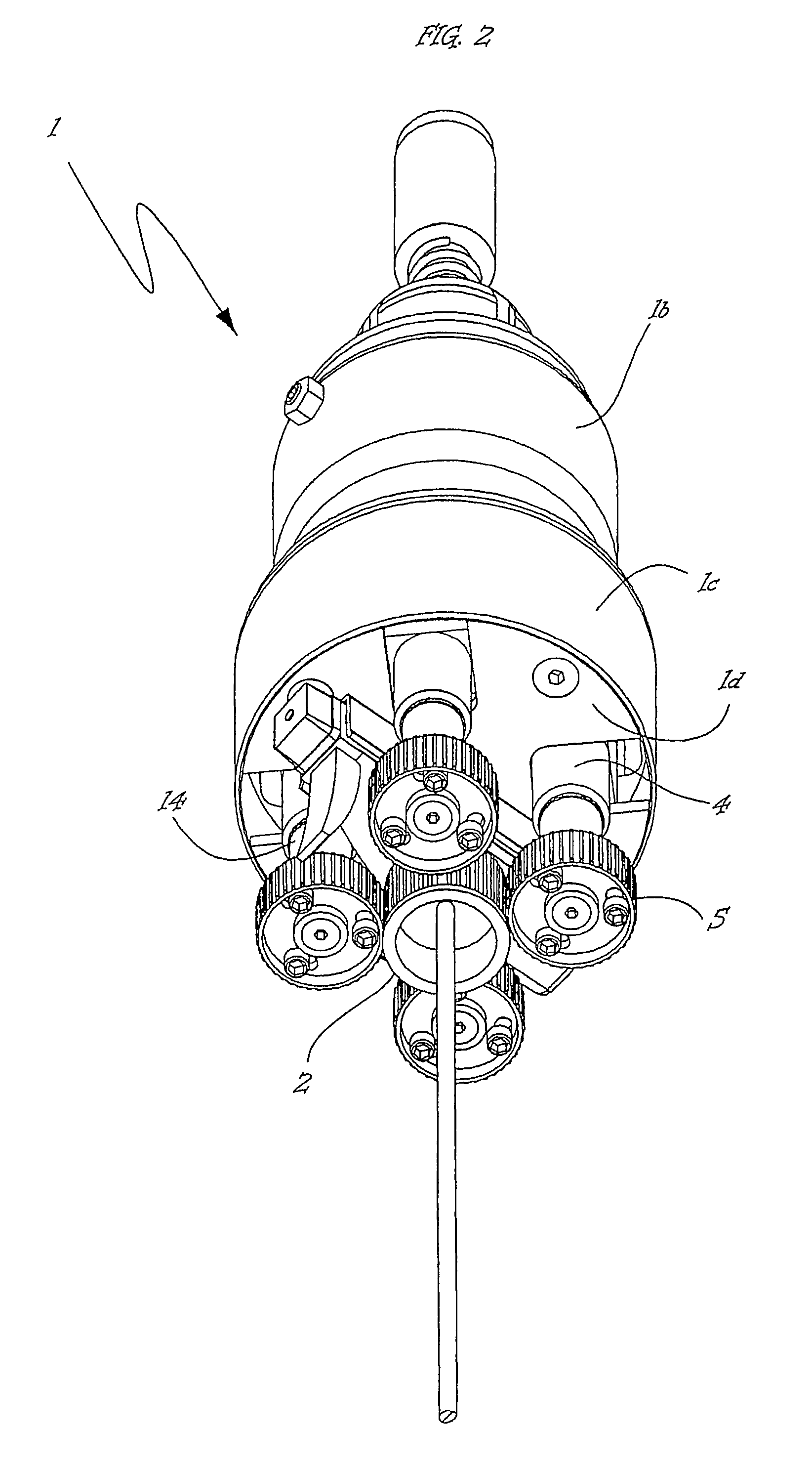

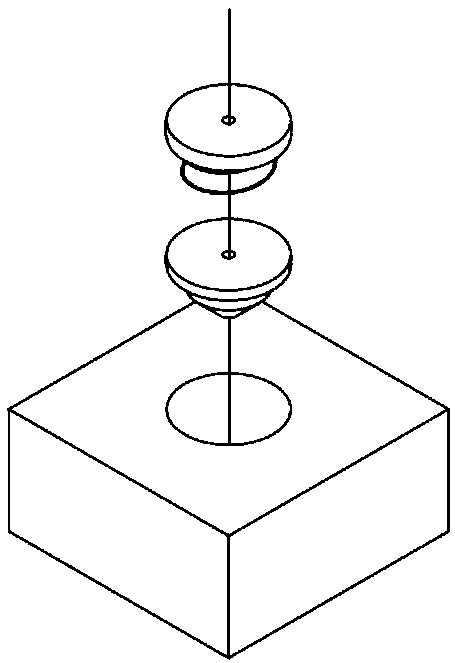

Screwing head for screwing the ring nut of a small trigger-type pump on a vessel

InactiveUS7866237B2Optimum ratio of operatingSuitable operating angleClosing machinesCapsRotational axisEngineering

The invention deals with the field of screwing heads for small trigger-type pumps or triggers and namely for applying, on vessels, triggers equipped with a threaded securing ring nut (2). This screwing head (1) is rotated around a vertical axis through a permanent magnet-type clutch and comprises four rollers (5) which tighten the toothed ring nut (2) when screwing it; said rollers (5) are supported by vertical arms (4) whose axes are arranged at 90° one from the other on a circumference with its center on the rotation axis of the screwing head. The vertical arms (4) and the four rollers (5) are simultaneously carried along a radial direction towards said ring nut through an oscillating movement.

Owner:REJVES

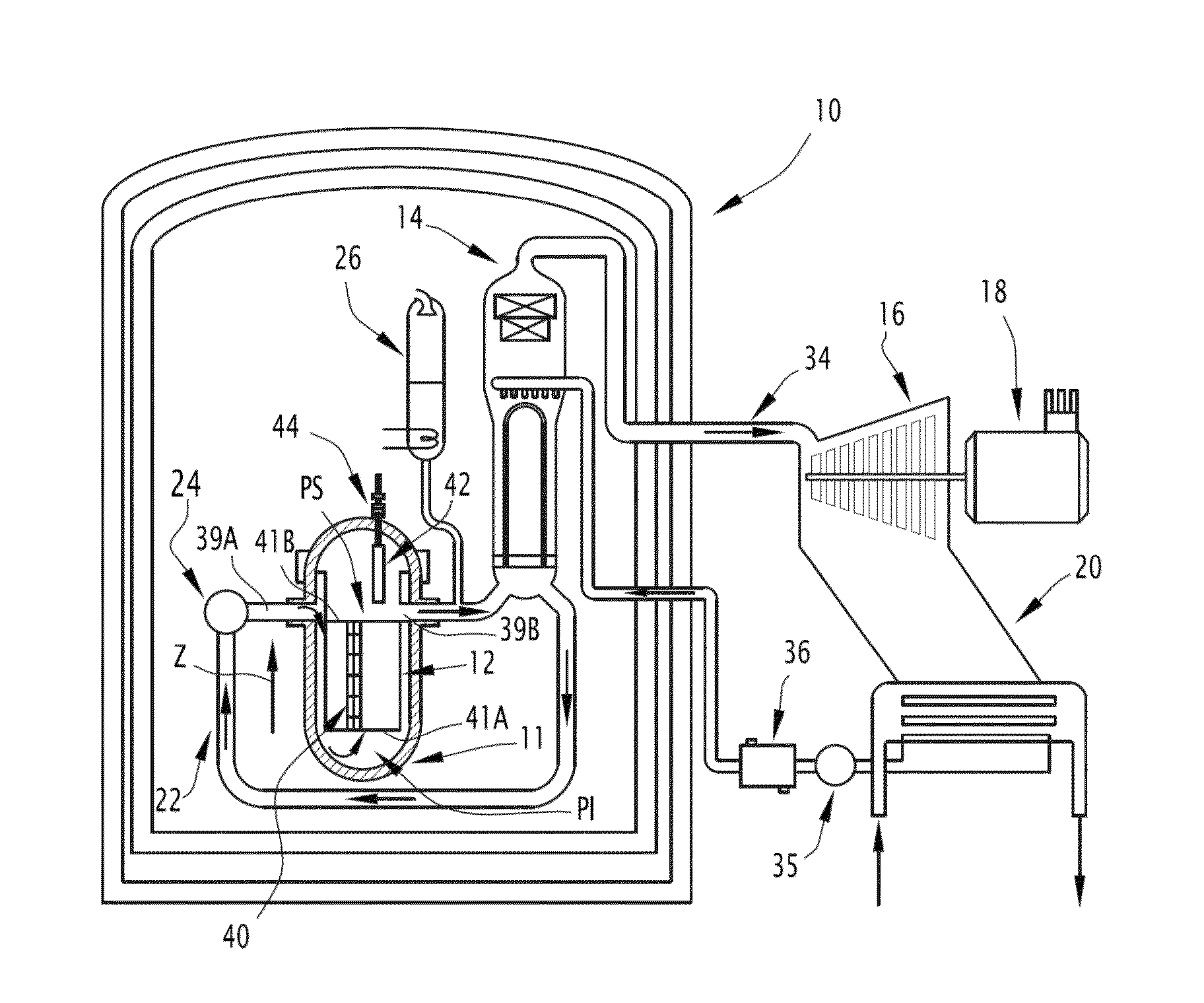

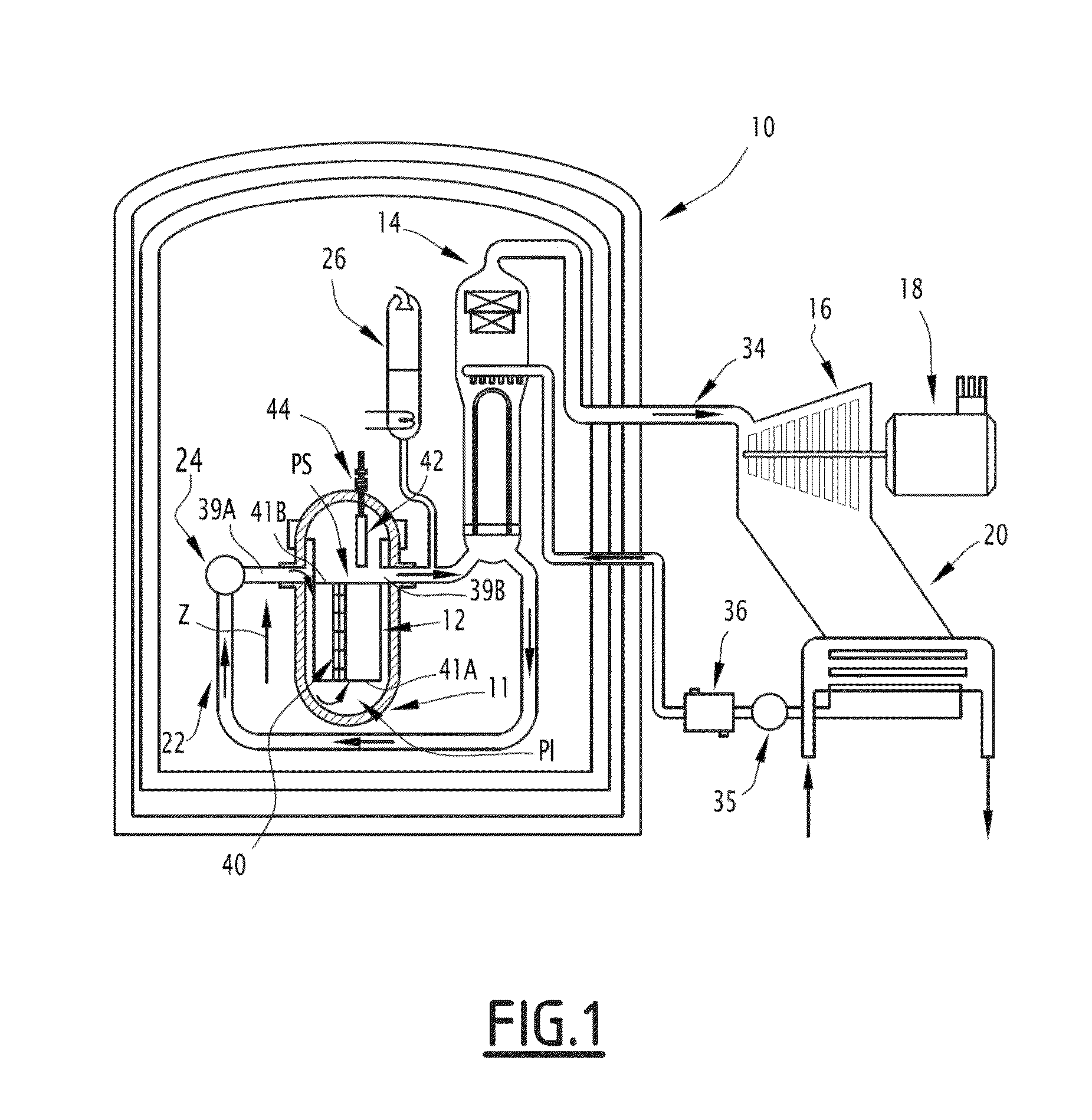

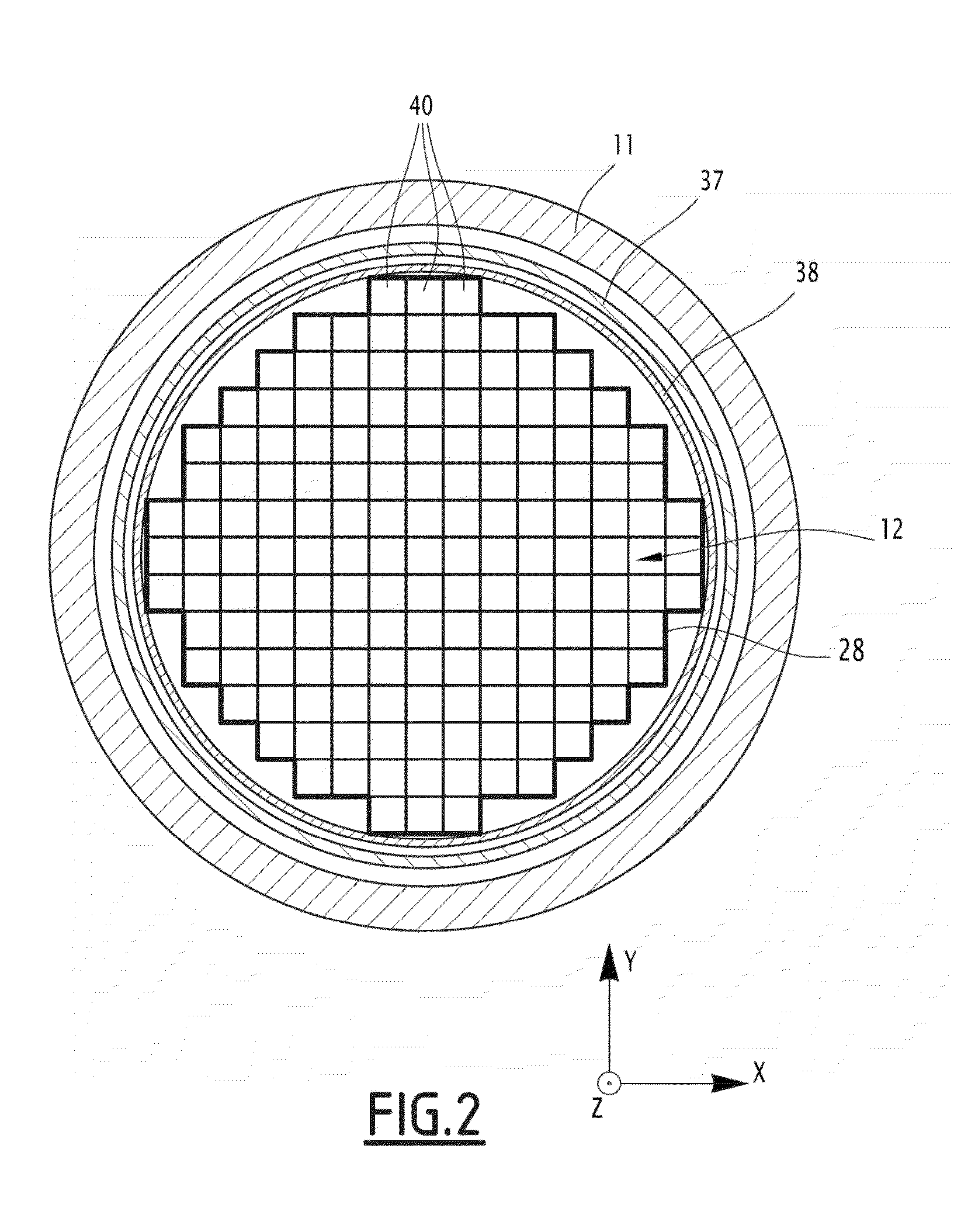

Methods for simulating the flow of a fluid in a vessel of a nuclear reactor and for calculating the mechanical deformation of assemblies of a nuclear reactor core, and associated computer program products

ActiveUS20160042823A1Improve computation mechanical deformationNot requiring excessive computing powerNuclear energy generationComputation using non-denominational number representationNuclear reactor coreNuclear reactor

A method for simulating the flow of a fluid in a vessel of a nuclear reactor is provided. The nuclear reactor includes the vessel and a core inside the vessel, the core including nuclear fuel assemblies, each one extending in an axial direction, including nuclear fuel rods and a grid for maintaining the rods, and being spaced apart from another by a clearance between the grids in a transverse direction.This method for simulating a fluid flow in the vessel of a nuclear reactor includes determining of head loss coefficients in the core, and computing the fluid pressure and speed component(s) in the core using the equation: ∇P=−K×V where P is the component of the fluid pressure, K is a matrix including the determined head loss coefficients, and V is a vector including the fluid speed component(s).A transverse head loss coefficient in the assemblies is determined from a transverse Reynolds number, and an axial head loss coefficient in the clearance is from the dimension of the clearance in the transverse direction.

Owner:AREVA NP SAS

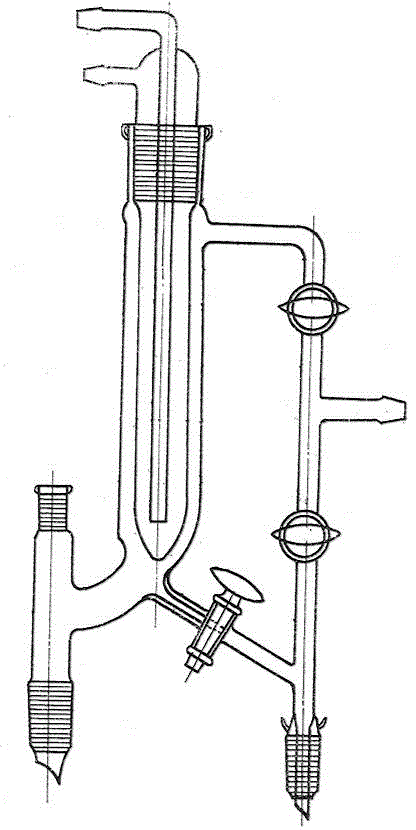

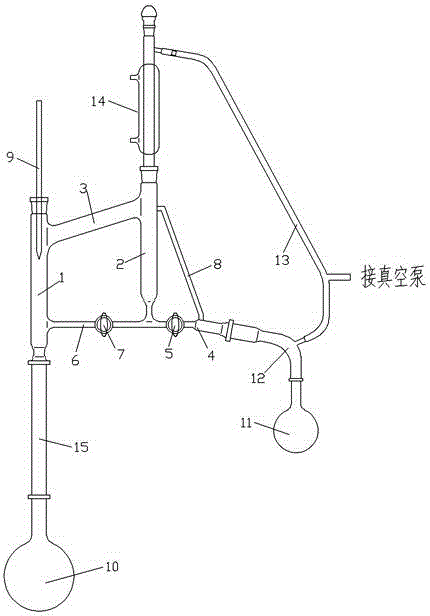

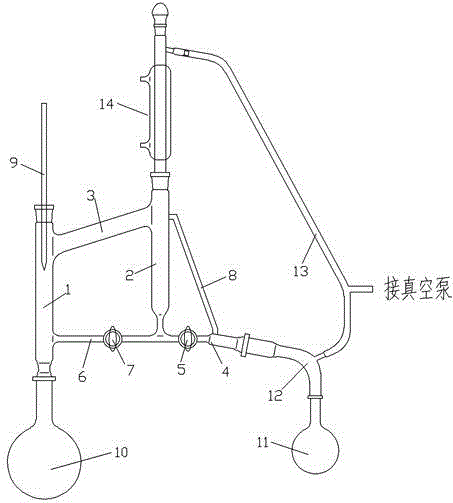

Reduced-pressure distillation device

The invention discloses a reduced-pressure distillation device with the advantages of simple structure, economy and convenience. The reduced-pressure distillation device comprises a distillation head; the distillation head comprises a steam pipe, a water distribution pipe and a connecting pipe, wherein the steam pipe is provided with an upper port and a lower port; the water distribution pipe is provided with an upper port; the lower end of the water distribution pipe is communicated with a branch pipe with a control valve I for the outflow of liquid in the water distribution pipe; the outer end of the branch pipe is provided with an outer port; the connecting pipe is used for communicating the upper end of the steam pipe and the upper end of the water distribution pipe; a backflow pipe with a control valve II communicated with the lower end of the water distribution pipe and the steam pipe is arranged below the connecting pipe; a thermometer is inserted at the upper port of the steam pipe; the lower port of the steam pipe is directly communicated with a distillation vessel or is communicated with the distillation vessel through a rectifying column; the upper port of the water distribution pipe is connected with a condenser; the outer port of the branch pipe is connected with a receiving vessel through a vacuum receiving head; both the upper end of the condenser and the vacuum receiving head are connected with an air suction pipe; and the air suction pipe is connected with a vacuum pump.

Owner:UNIV OF JINAN

Gas expansion device and machining method and application of neckings of expansion pipe

The invention discloses a gas expansion device and a necking processing method and application of an expansion tube. The expansion device includes an expansion tube and an inflatable ignition head. The method is to fix the expansion tube through the clamp first, then rotate the expansion tube and heat the end of the expansion tube through the clamp, heat the end of the expansion tube until it is close to or reach plastic deformation, and after the front part of the shrinking mold touches the end of the expansion tube, The end of the expansion pipe moves from the front to the rear of the shrinking die, and the shrinking die extrudes and thickens the end of the expansion pipe, and the end of the shrinking end is thickened axially outward, and then the end of the expansion pipe is processed with a through-hole knife. Through-hole fixed aperture. The expansion tube is made into a pressure vessel by shrinking. The utility model has the advantages of simple structure, easy processing of structural components, low manufacturing cost, no flying head, no air leakage, safe transportation, no hidden danger of squib, and large expansion force.

Owner:郭远军

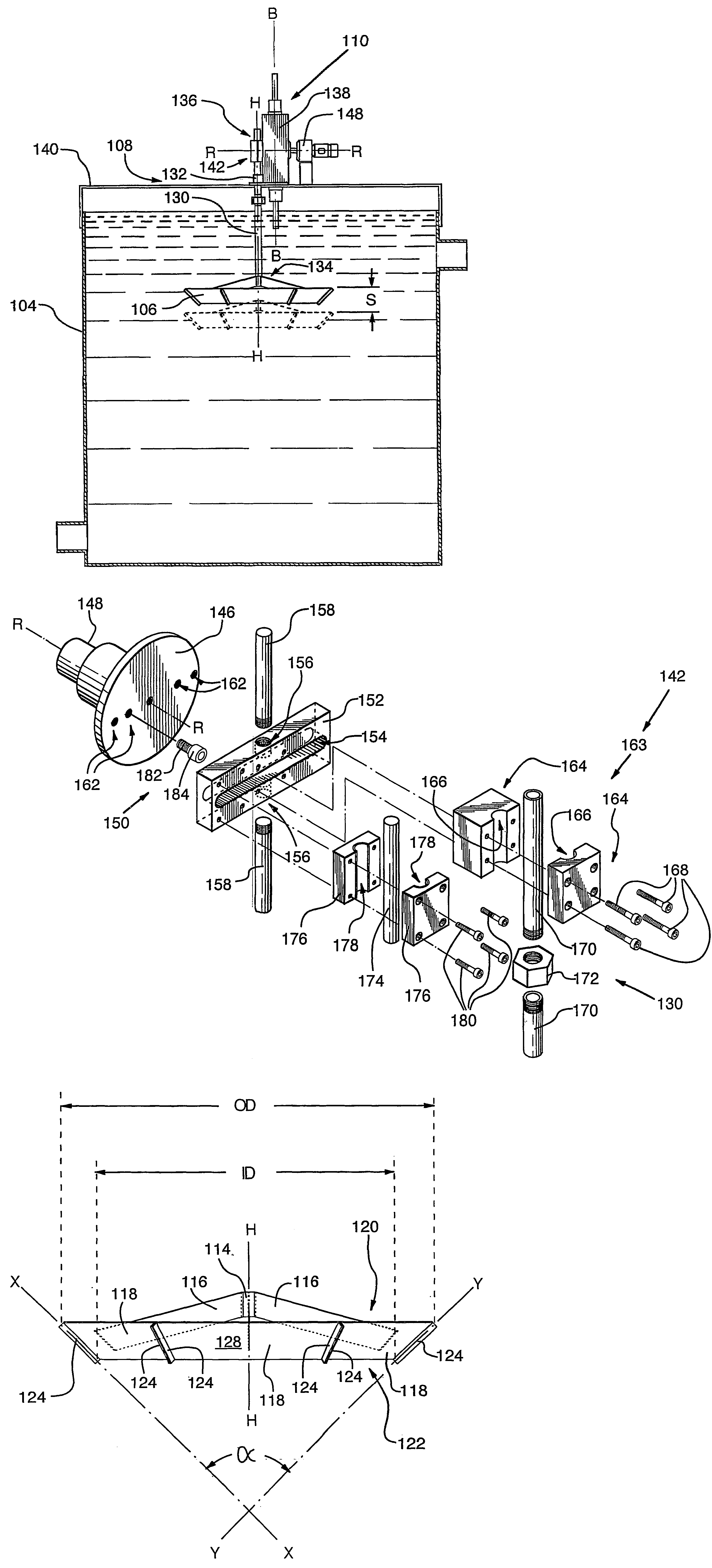

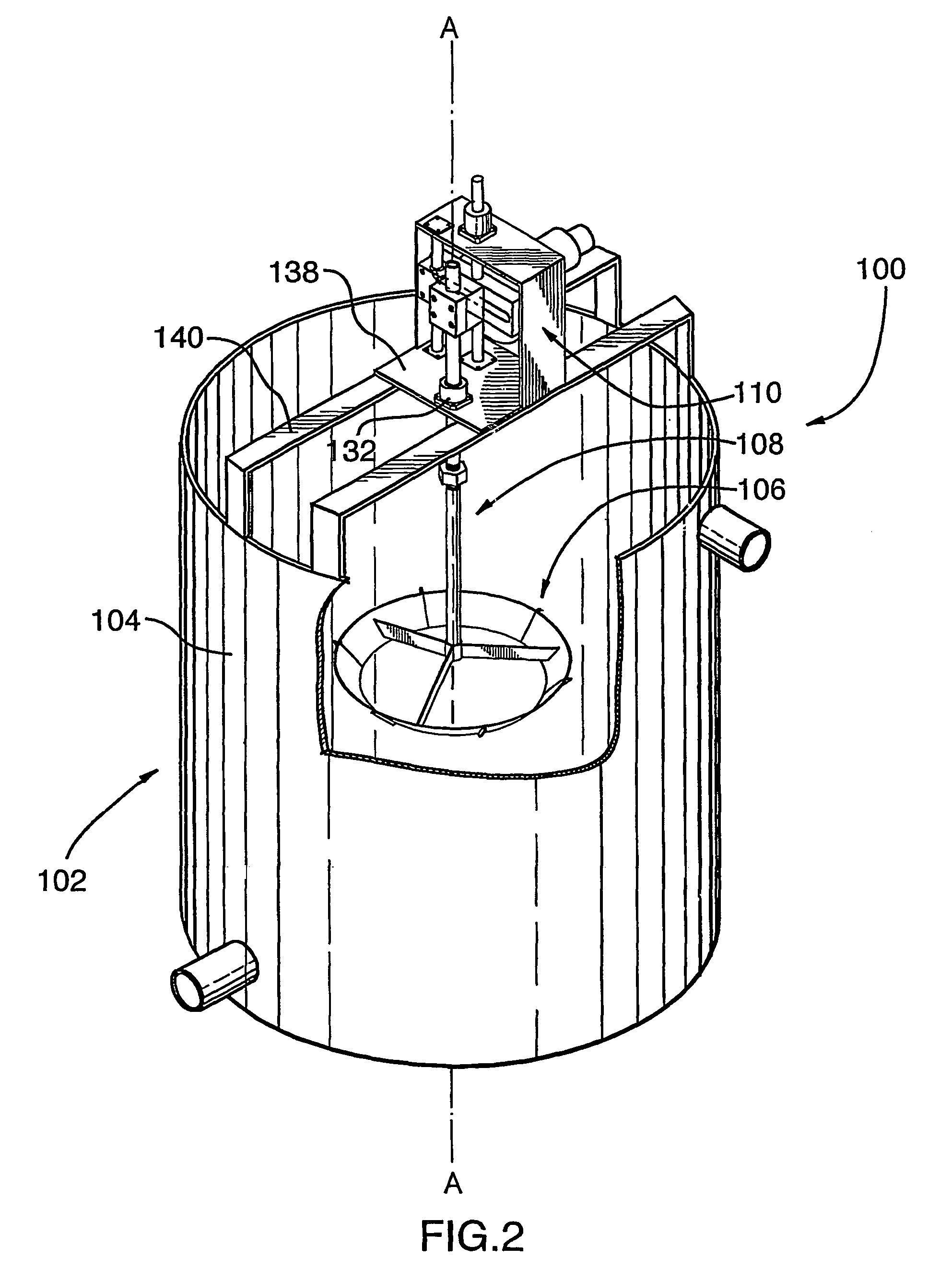

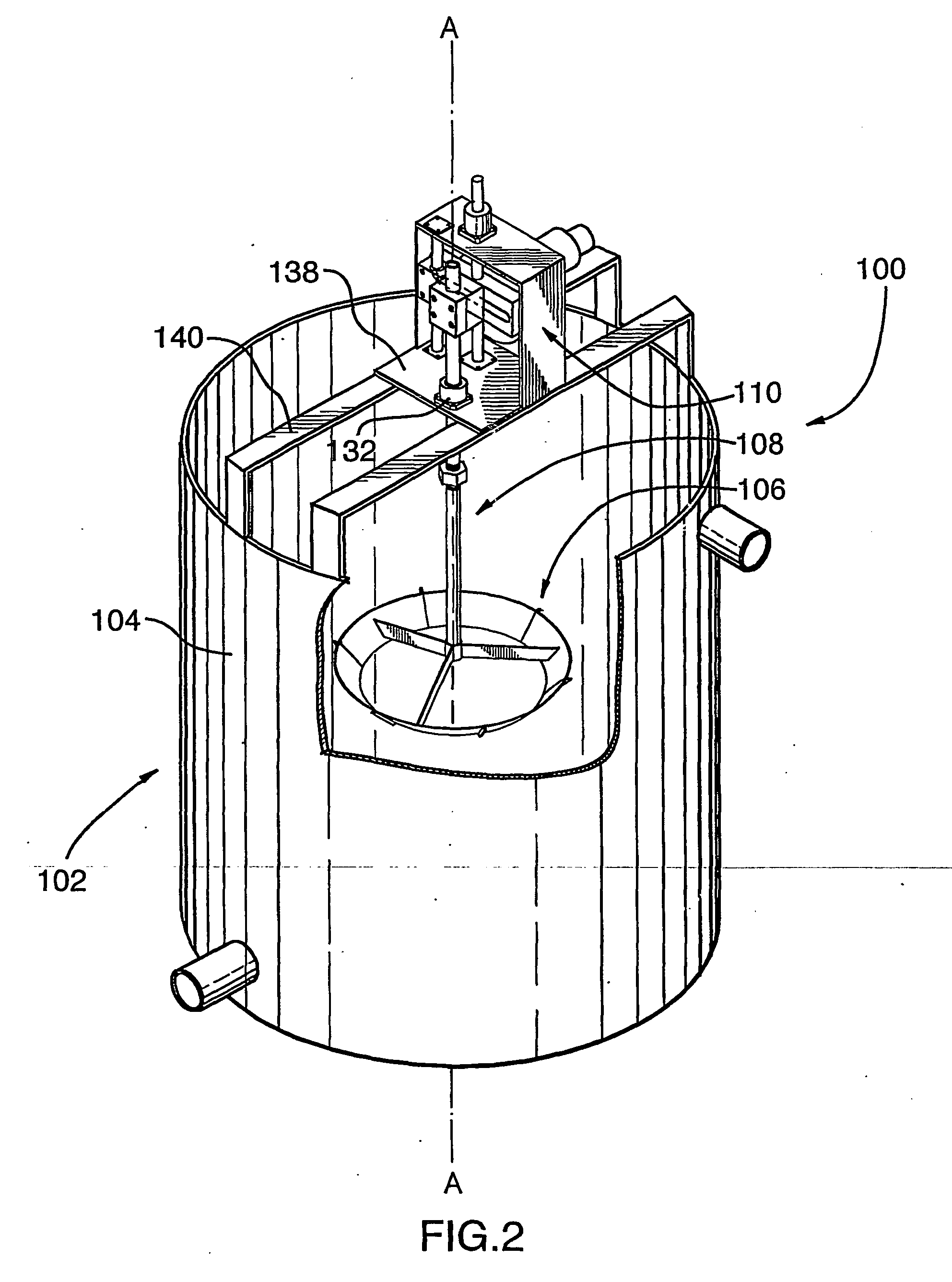

Fluid mixing apparatus

InactiveUS7278781B2Shaking/oscillating/vibrating mixersTransportation and packagingMechanical engineeringScotch yoke

Owner:ENERSAVE FLUID MIXERS

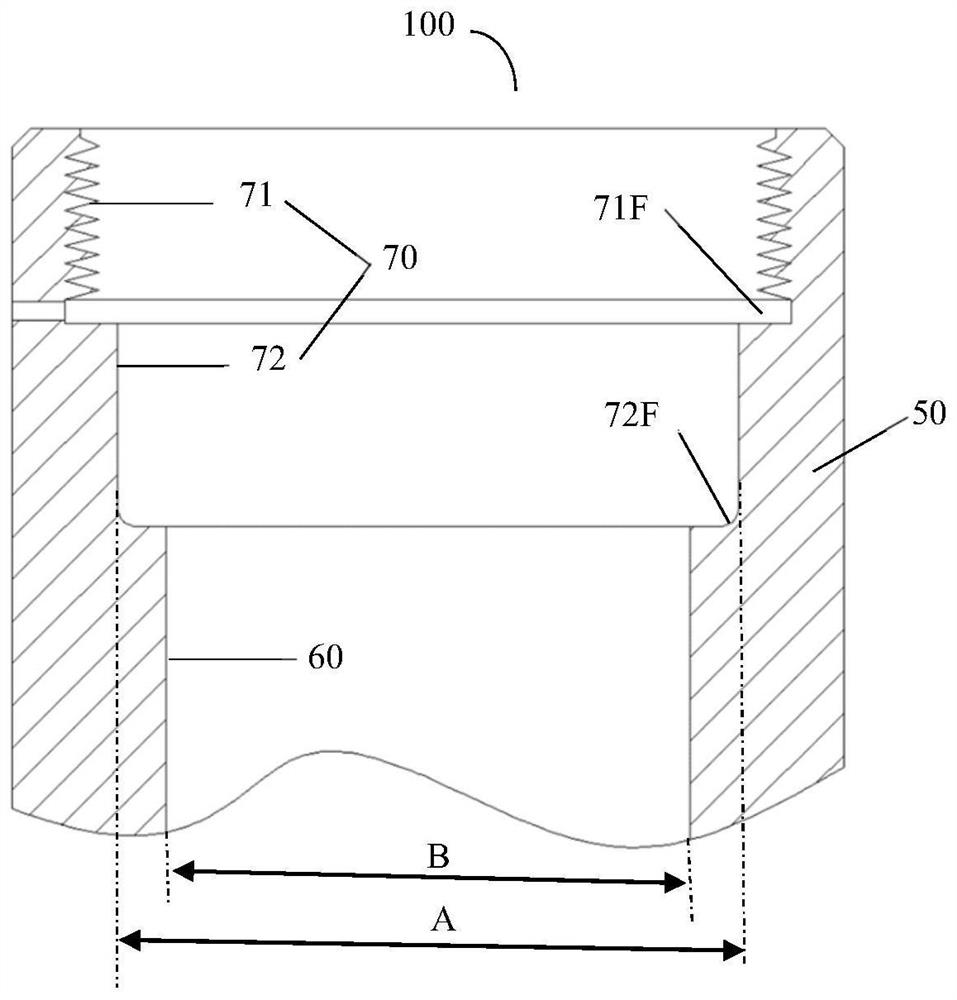

System for reducing head space in a pressure cyclone

A pressure cyclone is disclosed having a concave top head, wherein the concave top head has a substantially flat roof disposed in the interior of the cyclone vessel. An inlet is tangentially-coupled to the vessel and has an inlet nozzle disposed therein and configured to smoothly transition into the cyclone vessel to create a vortex that separates solid particulates from an incoming particulate-fluid suspension. In particular, the one surface of the inlet nozzle is tangent to the inner surface of cyclone vessel and another surface of the inlet nozzle is parallel and continuous with the substantially flat roof. An inlet casing is disposed around a length of the inlet nozzle and configured to transition from a circular casing to an elliptical casing along the length of the inlet nozzle, and couple to the vessel with the elliptical casing.

Owner:KELLOGG BROWN & ROOT LLC

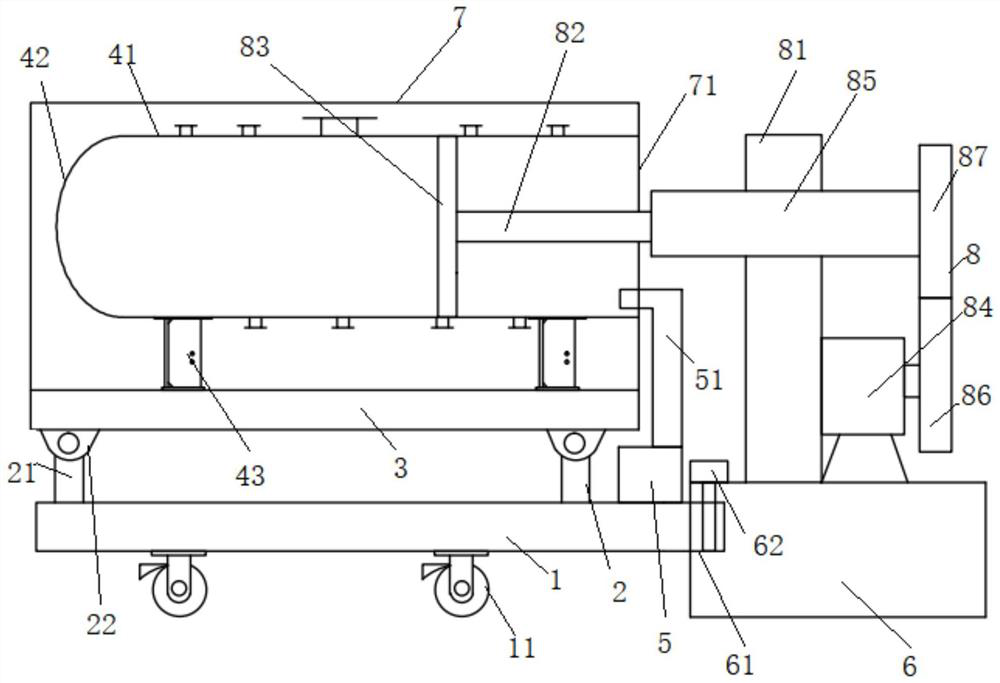

Device for polishing welding seam inside pressure vessel

InactiveCN112917299AEasy to install and disassembleEasy to follow upEdge grinding machinesGrinding carriagesPolishingStructural engineering

The invention provides a device for polishing a welding seam inside a pressure vessel. The device comprises a moving base; a first angle adjusting device, wherein the first angle adjusting device is arranged at the upper end of the moving base; a mounting base, wherein the mounting base is arranged at the working end of the upper end of the first angle adjusting device, the to-be-polished pressure vessel is mounted at the upper end of the mounting base, and a dust suction device is further connected to the mounting base or the moving base. a fixed base, wherein the fixed base is located on one side of the moving base, and the moving base is provided with a limiting block used for being inserted into a limiting groove in the fixed base and locked through a locking piece; a sealing cover, wherein the sealing cover is detachably connected to the upper end of the mounting base, a first opening is formed in the side, close to a sealing head, of the sealing cover, a sealing door capable of being opened or closed is connected to the first opening, and a dust suction pipe of the dust suction device is connected to the sealing cover; and a polishing device, wherein the polishing device is installed at the upper end of the fixed base, and the polishing end of the polishing device extends into the pressure vessel to be polished from the first opening. By arranging the automatic polishing device, automatic polishing is achieved, workers are prevented from entering the vessel for polishing, and the device is safe, environmentally friendly and high in polishing efficiency.

Owner:湛立宁

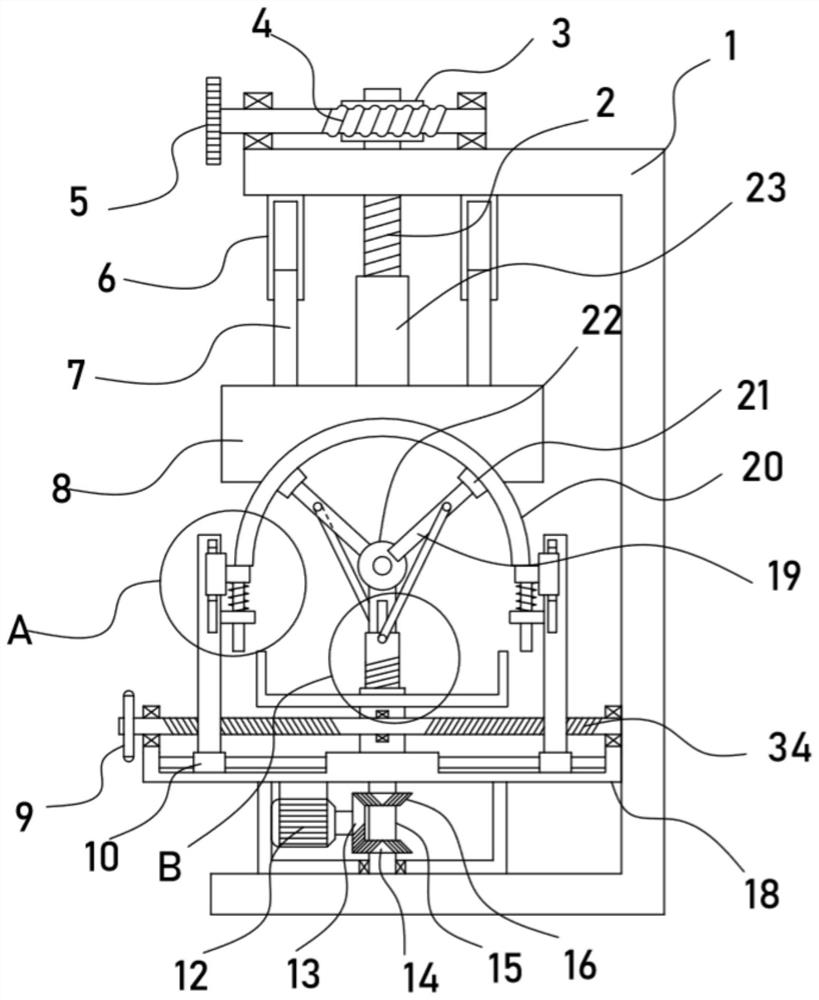

Pressure vessel spherical head inner wall polishing device

InactiveCN112264869AFull and thorough polishingStable inner wall polishingGrinding carriagesPolishing machinesElectric machineryDrive motor

The invention discloses a pressure vessel spherical head inner wall polishing device, and relates to the technical field of pressure vessels. The pressure vessel spherical head inner wall polishing device comprises a fixing frame, a driving motor is fixed to the bottom of a supporting frame, and a polishing mechanism for polishing the inner wall of a spherical head is arranged on a steering shaft.According to the pressure vessel spherical head inner wall polishing device provided by the invention, a supporting mechanism can be driven by a transverse adjusting mechanism to achieve the supporting adjusting effect of a transverse position, flexible adjustment is conducted according to the size of the spherical head to achieve stable supporting of the spherical head, a pressing disc can be driven by a lifting mechanism to be adjusted in the vertical height, and therefore the spherical head is pressed and clamped between the pressing disc and the supporting mechanism, the inner wall polishing stability can be ensured; the polishing mechanism can be driven by a forward and reverse rotating mechanism to achieve clockwise and anticlockwise alternate rotation, so that a polishing arc blockcan achieve the reciprocating swing effect while rotating in the spherical head, and the sufficient and thorough polishing effect on the inner wall of the spherical head is guaranteed.

Owner:韦楚旺

Multifunctional tin ore collecting, screening and packaging vessel

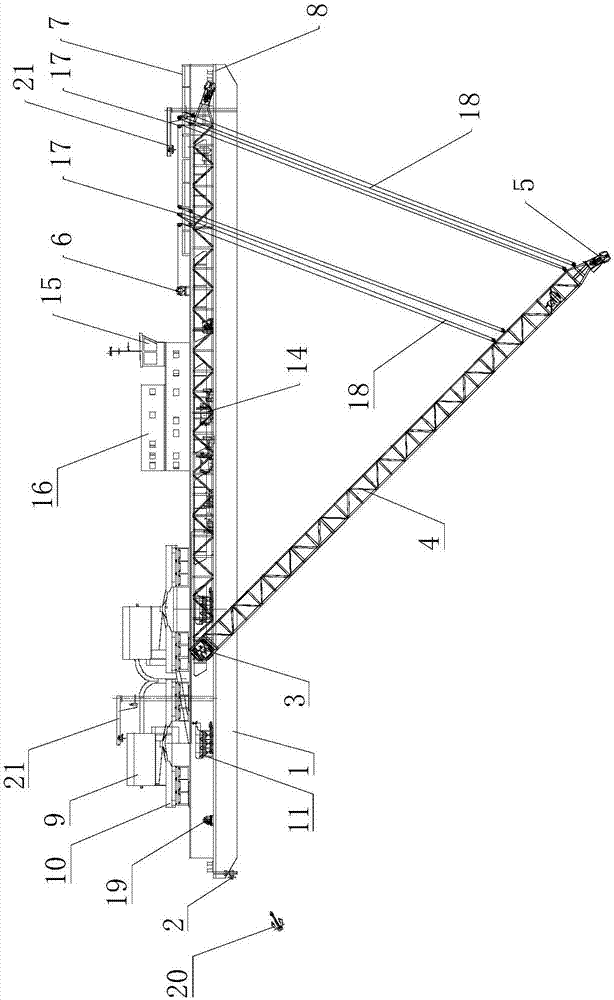

InactiveCN107284611ASolve the waste of powerSolve the problem of poor wind and wave resistanceWaterborne vesselsMineral miningPropellerWinch

The invention provides a multifunctional tin ore collecting, screening and packaging vessel and is suitable for offshore operation. The problem that in the prior art, a mining vessel is large in power waste and poor in wave resisting capability is solved. The multifunctional vessel comprises a vessel body, wherein a propeller is arranged at the tail portion of the vessel body, a bridge frame is hinged and connected to the vessel body through a bridge frame fixing base, a cutter suction head is arranged at the tail end of the bridge frame, a lifting winch for achieving lifting of the bridge frame is arranged on the vessel body, upper and lower layers of decks re arranged on the vessel body, a conical screen and a primary jigging machine which are vertically arranged are arranged on the upper layer of decks, and a secondary jigging machine located below the primary jigging machine is arranged on the lower layer of decks. The multifunctional tin ore collecting, screening and packaging vessel is suitable for tin ore collecting, screening and packaging in offshore zone operation, is small in power waste and has very good practicability.

Owner:SHANDONG HAOHAI DREDGING EQUIP CO LTD

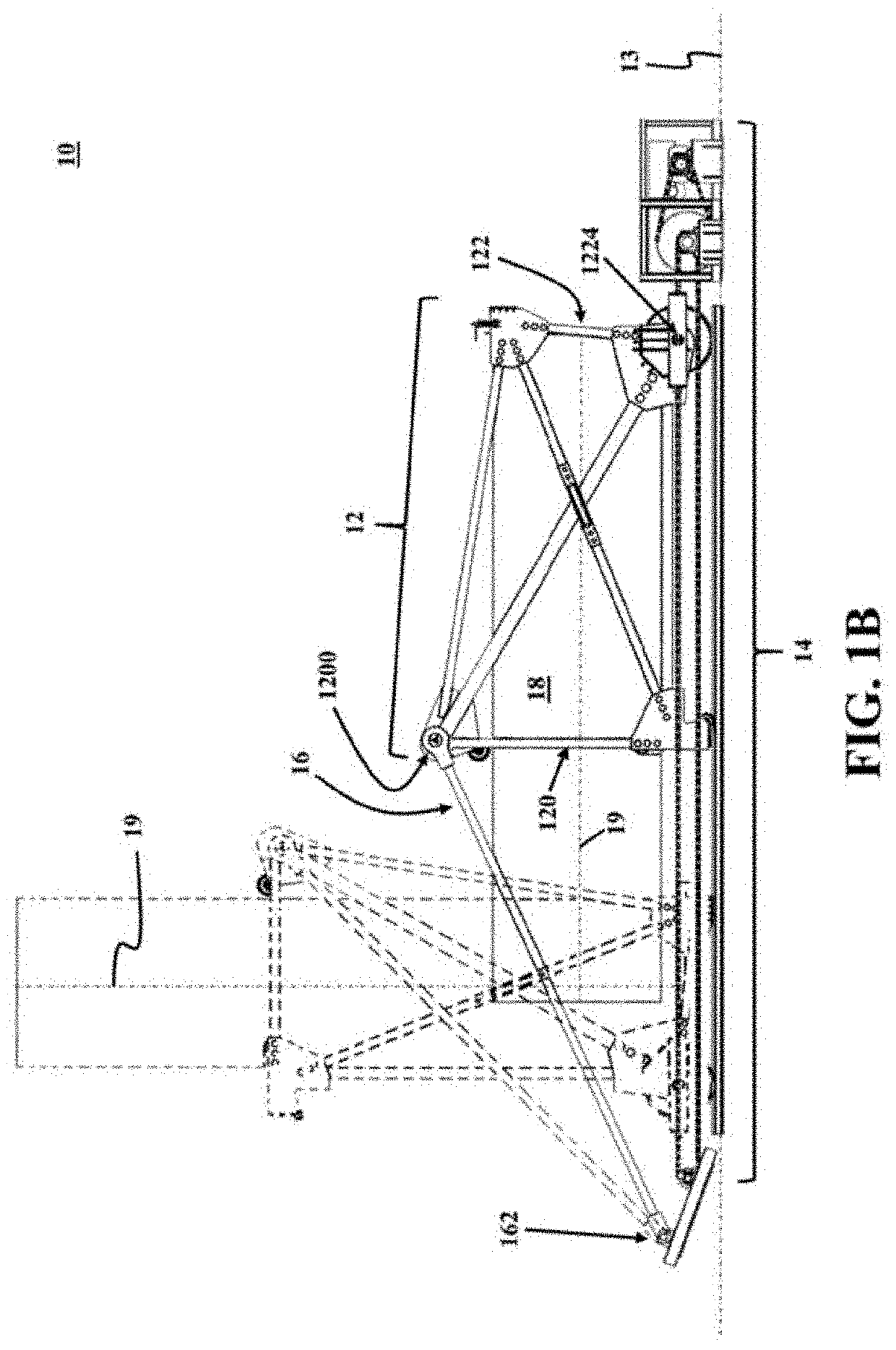

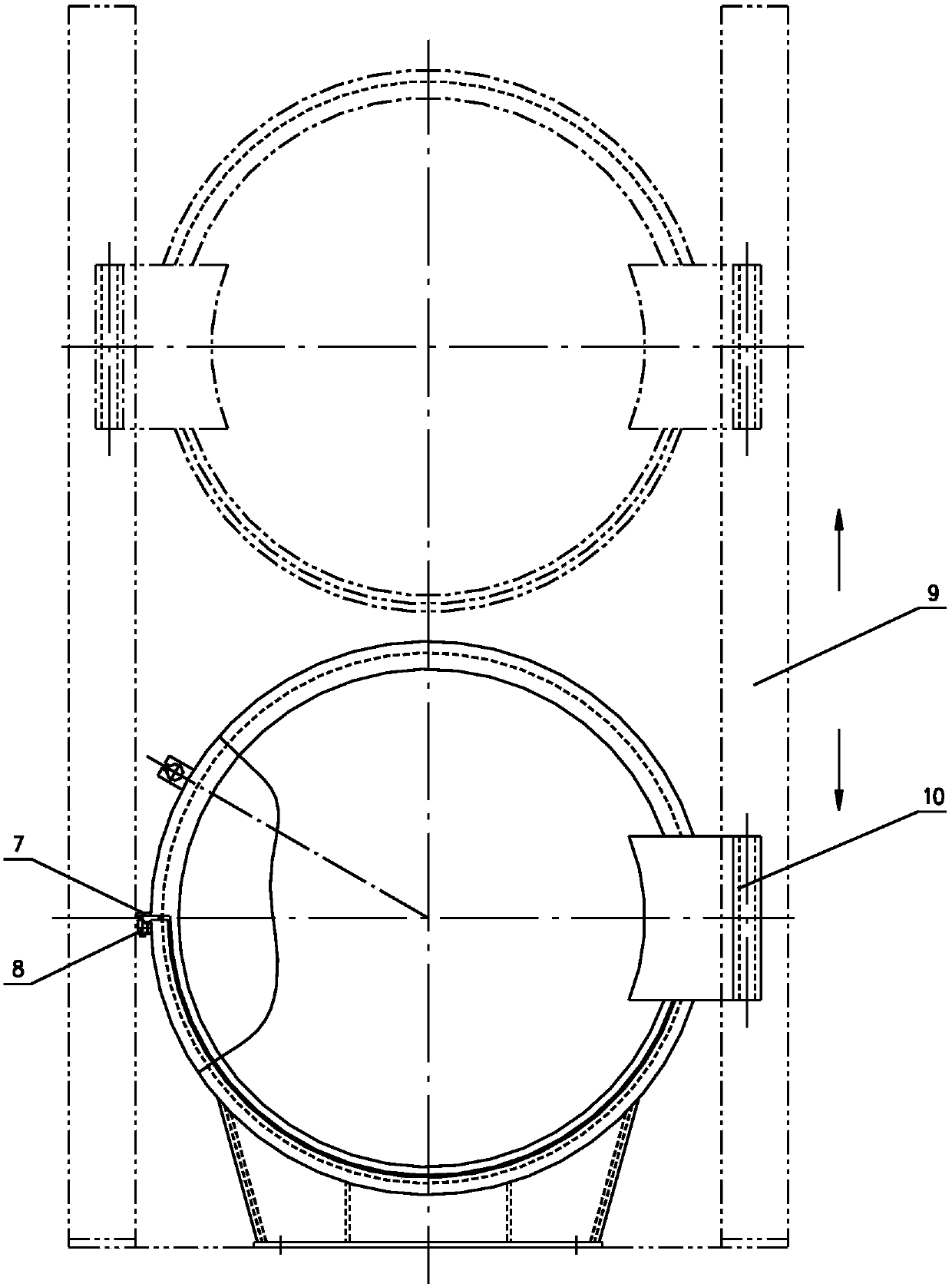

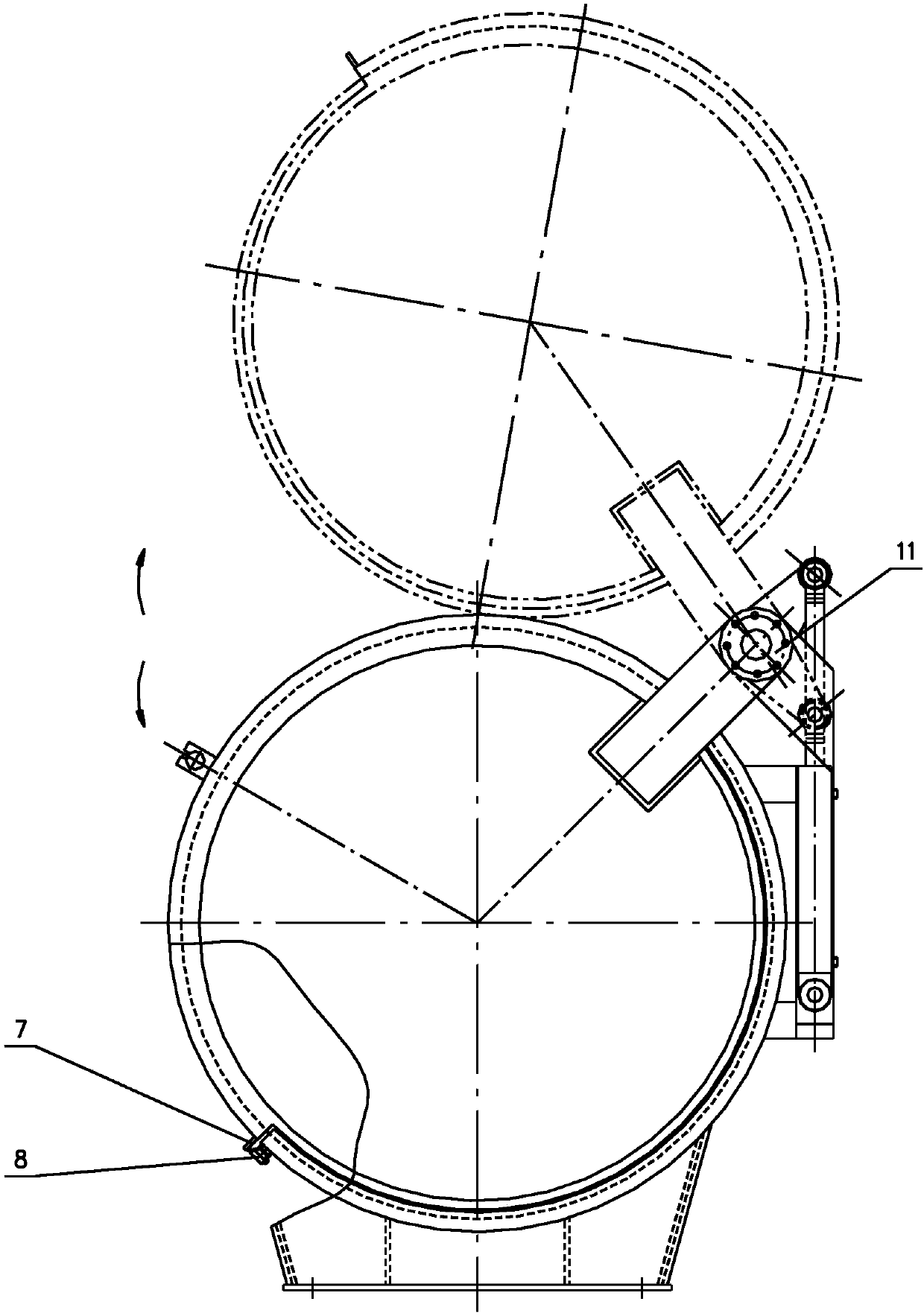

Rotating a long vessel

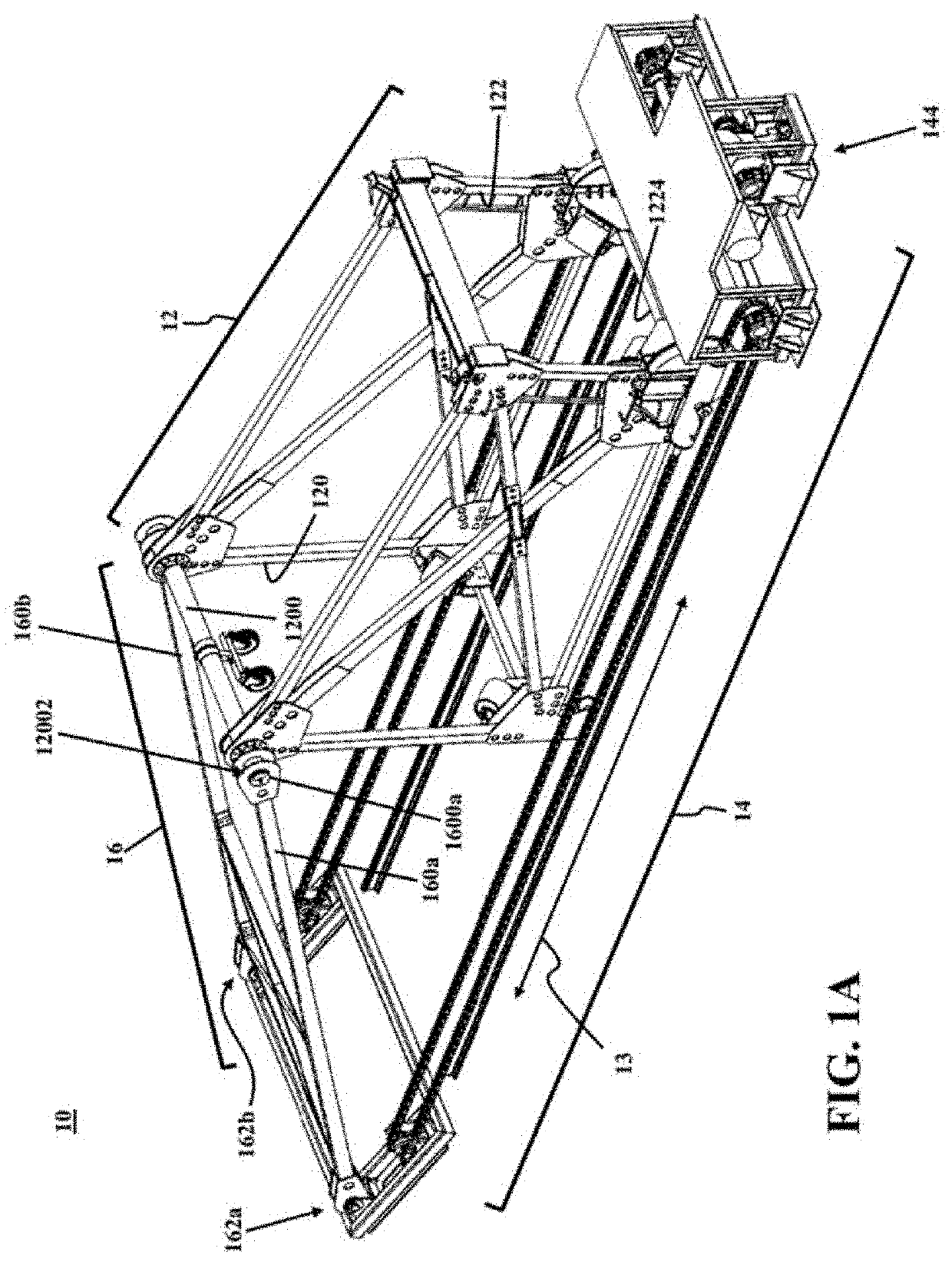

A system for rotating a vessel may include a container assembly. An exemplary container assembly may include a head end frame that may be spaced apart from and interconnected with a tail end frame. An exemplary container assembly may be configured to encompass and hold the vessel or a portion of the vessel. An exemplary system for rotating a vessel may further include a linear actuating mechanism that may be coupled to a bottom edge of the tail end frame. An exemplary linear actuating mechanism may be configured to drive a translational movement of the bottom edge of the tail end frame along a first axis. An exemplary system for rotating a vessel may further include a double-pivot link that may be pivotally connected between a top edge of the head end frame and a fixed revolute joint. An exemplary double-pivot link may be configured to rotate the top edge about the fixed revolute joint responsive to the translational movement of the bottom edge of the tail end frame along the first axis.

Owner:DURALI SYST DESIGN & AUTOMATION CO +1

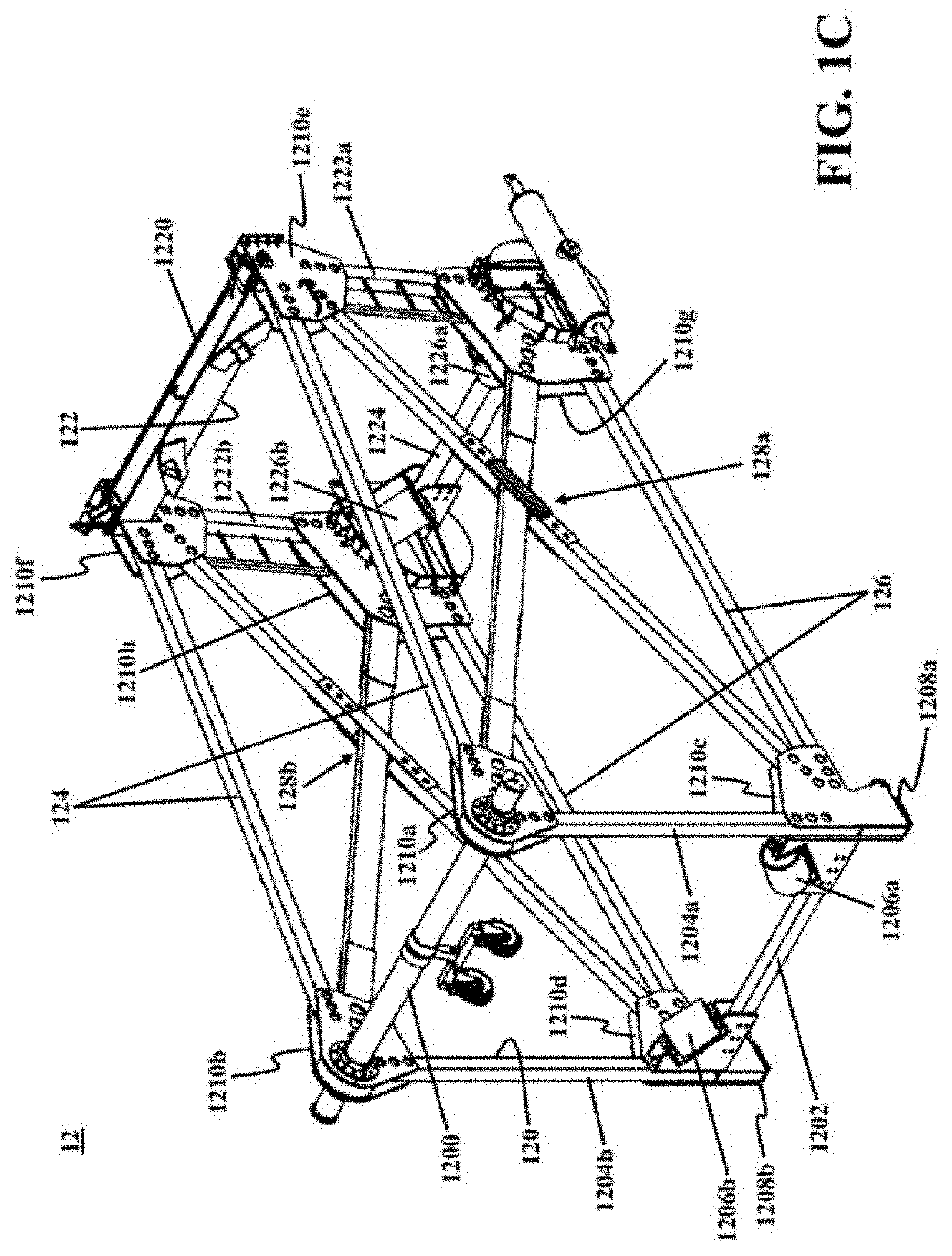

Liquid droplet size control apparatus

InactiveUS20040160857A1Shaking/oscillating/vibrating mixersRotary stirring mixersMechanical engineeringDroplet size

A mixer apparatus for use with a vessel (102) centered about a longitudinal axis is disclosed. The mixer has a tubular blade (106) which: defines a central head axis (H-H); has a first end (120) and a second end spaced from the first end (122) along the head axis; and tapers from the first end to the second end. The inner surface of the blade and the second end define an inside blade diameter "ID" and the outer surface of the blade and the first end define an outer blade diameter "OD". The blade is positioned within and coaxial to the vessel. A scotch yoke (144), operatively connected to the blade by a shaft, effects reciprocating longitudinal movement of the blade through a stroke "S", with a duration "T" for each stroke, wherein 175>=0.36xOD<2>xS / T<=250 when OD, ID and S are expressed in inches, and T is expressed in seconds.

Owner:ENERSAVE FLUID MIXERS

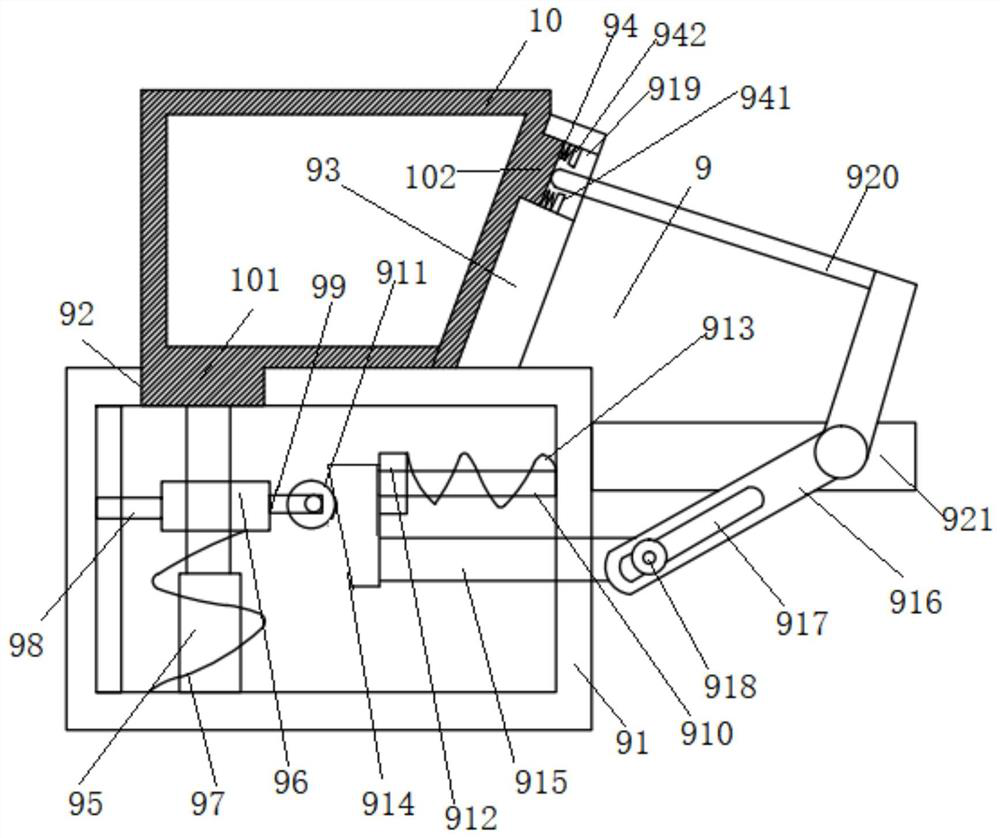

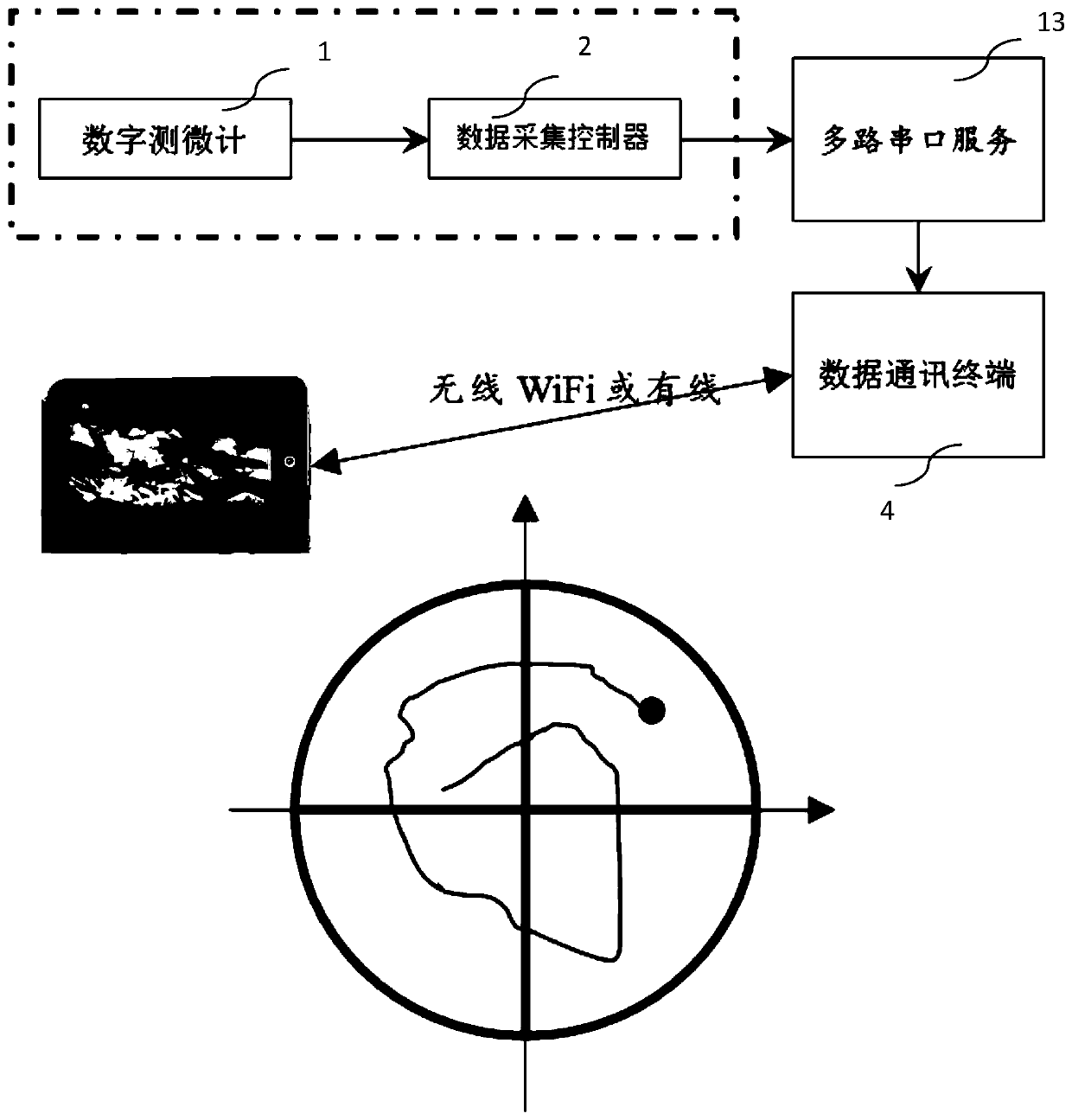

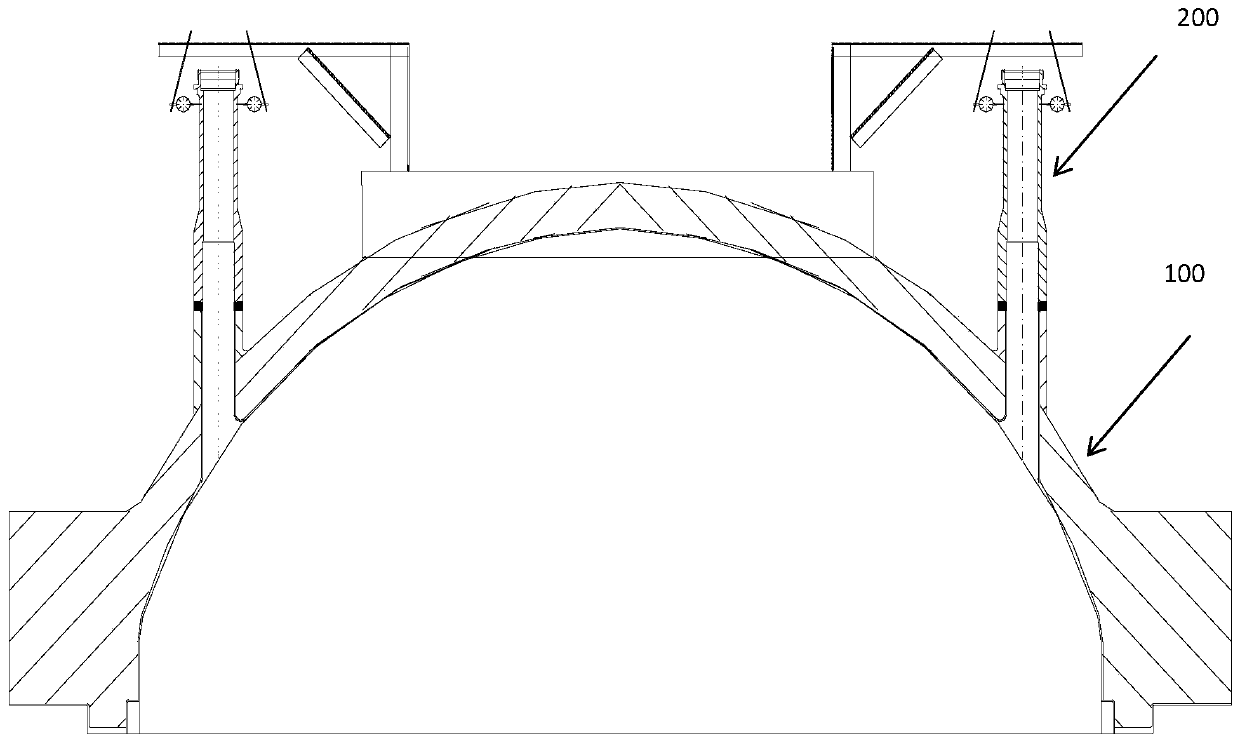

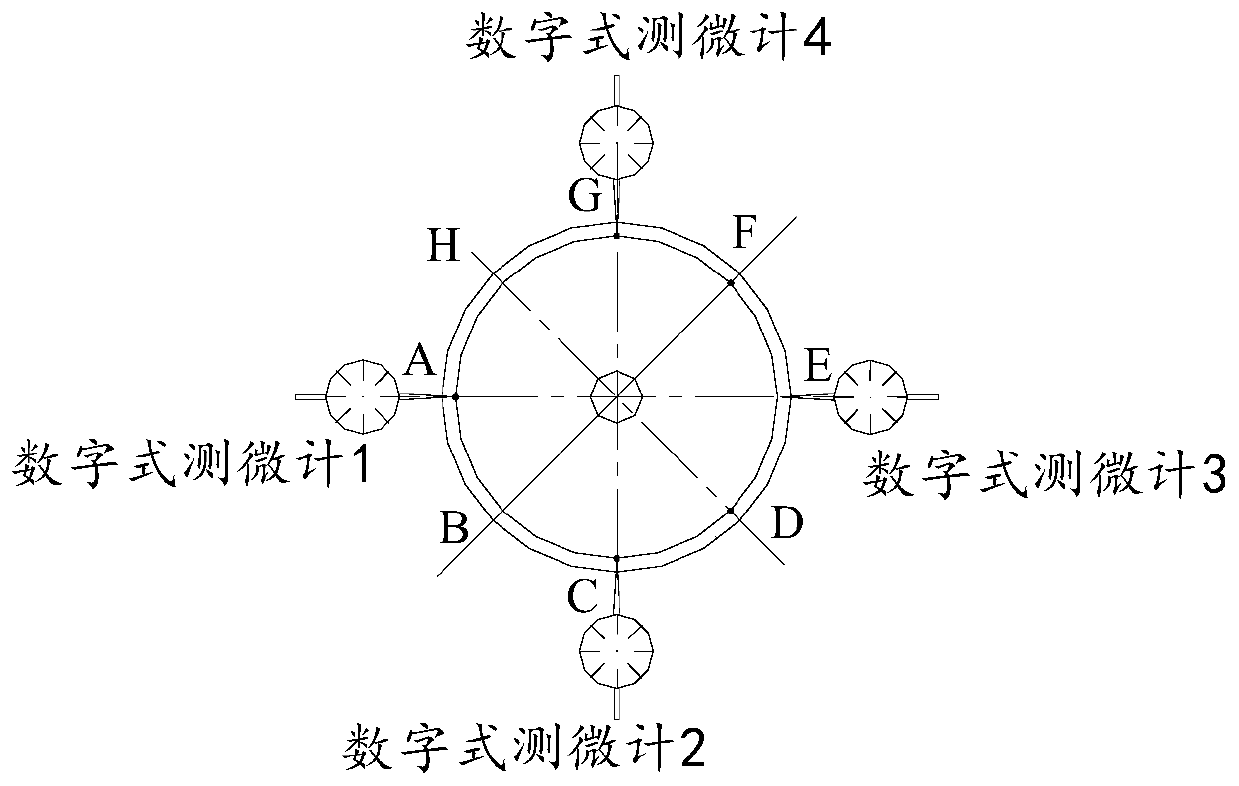

Welding monitoring and adjusting system and welding adjusting method for connecting pipe of sealing head of nuclear power pressure vessel

ActiveCN110576240AEasy to monitorConvenient monitoring and measurementMetal working apparatusTubular articlesMicrometerNuclear power

The invention discloses a welding monitoring and adjusting system and a welding adjusting method for a connecting pipe of a sealing head of a nuclear power pressure vessel. The system comprises a digital micrometer, a data acquisition controller and a measurement processing and displaying device, wherein the digital micrometer is arranged in a preset datum point position on the measured connectingpipe for measuring and recording the datum point position of the connecting pipe and the position change of the connecting pipe to obtain position change track data of the connecting pipe; the data acquisition controller is connected to the digital micrometer to acquire the position change track data of the connecting pipe measured and recorded by the digital micrometer; and the measurement processing and displaying device acquires and displays the position change track data of the connecting pipe sent by the data acquisition controller, automatically analyzes and resolves the position changetrack data of the connecting pipe to obtain a connecting pipe position adjusting result and display the connecting pipe position adjusting result for indicating adjustment of a welding position and awelding quantity so as to make sure that deformation of the connecting pipe is controlled within a preset required range. According to the system, the welding position and the welding quantity are adjusted in real time, deformation of the connecting pipe is controlled within a tolerance required range, a welding adjusting scheme is put forward, and a product meets a design demand.

Owner:SHANGHAI ELECTRIC NUCLEAR POWER EQUIP CO LTD

Cylinder rounding device of pressure vessel

InactiveCN110834037AImprove the problem of large measurement error and many human factorsHigh degree of automationMetal working apparatusHollow articlesCircular discEngineering

The invention discloses a cylinder rounding device of a pressure vessel. The cylinder rounding device of the pressure vessel includes a hollow disk support, eight supporting rods and a detection mechanism. The supporting rods include steel rods, jacks, roller supporting heads and supporting arms. One ends of the steel rods are evenly connected to the hollow disk support by screw threads. The two ends of the jacks are separately welded to the steel rods and the supporting arms, and the supporting arms are connected with the roller supporting heads. According to the cylinder rounding device of the pressure vessel, the problems of large measurement errors and multiple human factors occurring in a traditional cylinder side rounding process are solved, meanwhile, the degree of automation of detection is improved, and the adjustment efficiency is greatly improved.

Owner:成都进禄永建材有限公司

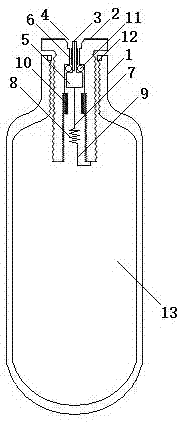

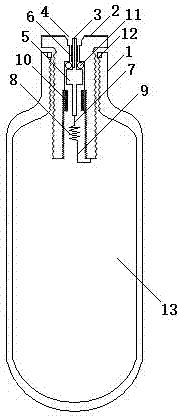

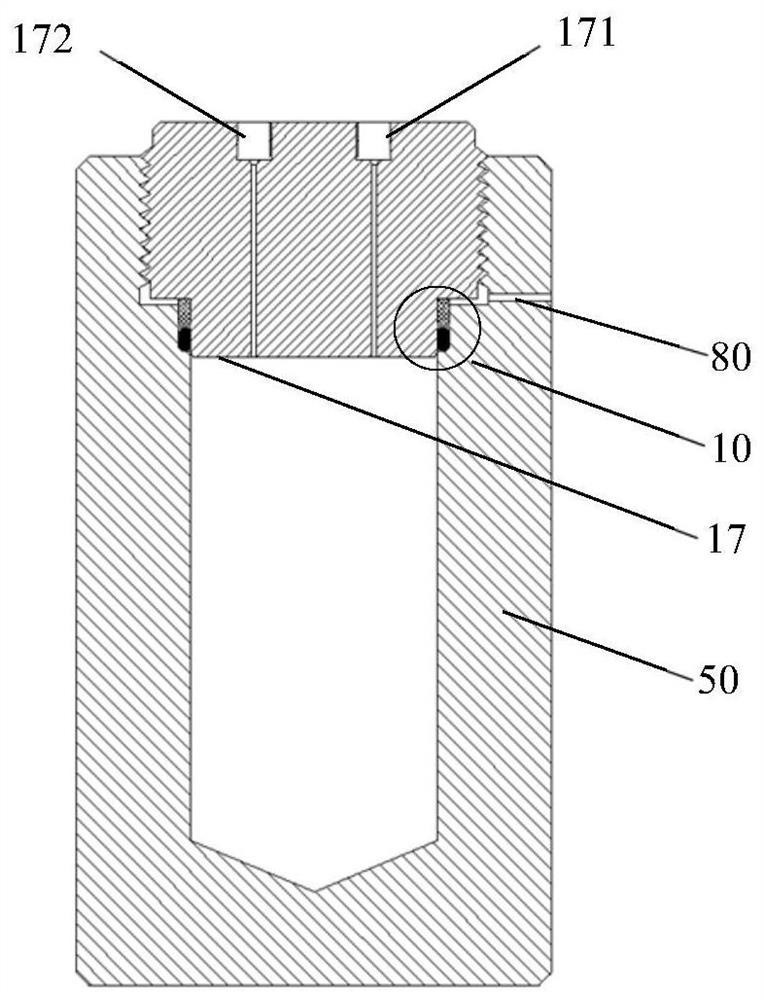

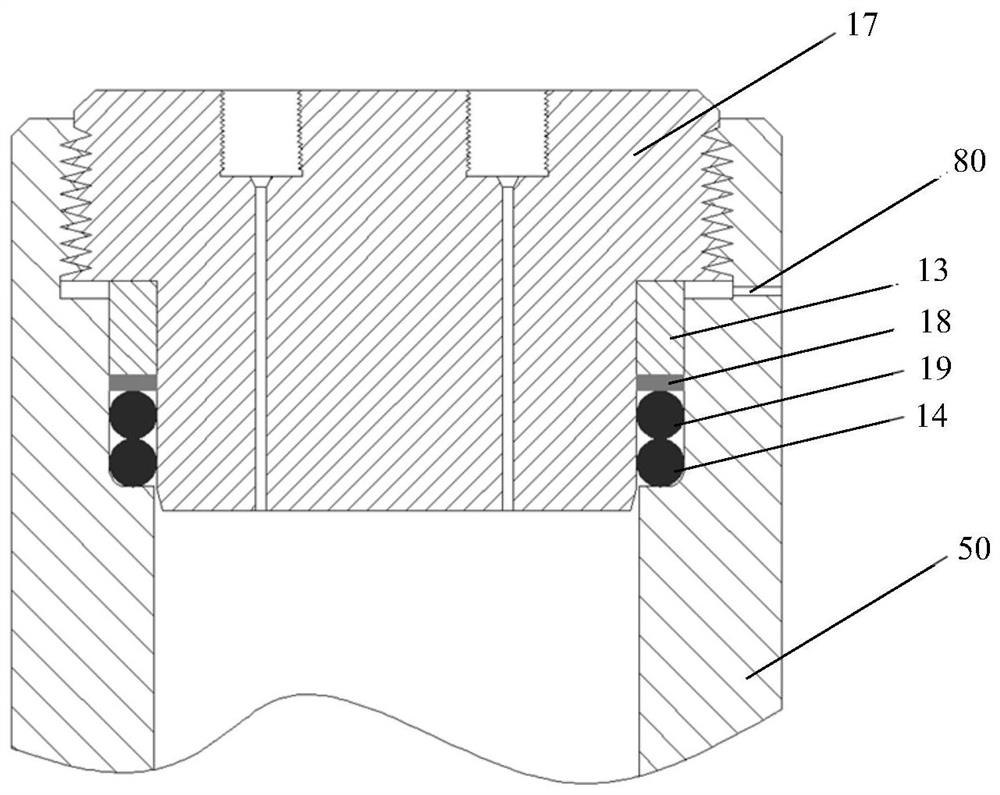

Static sealing structure and pressure vessel with static sealing structure

PendingCN111927951AThe molding process is safe and reliableReliable sealing structureEngine sealsPressure vesselsHead (vessel)Physics

The invention provides a static sealing structure and a pressure vessel with the static sealing structure. The pressure vessel comprises a vessel shell, a vessel cavity formed by a cavity inside the vessel shell and a groove structure opened at the top of the vessel shell and in communication with the vessel cavity; and the diameter of the groove structure in the horizontal direction is larger than that of the vessel cavity in the horizontal direction. The static sealing structure is assembled in the groove structure and comprises a sealing end and a sealing assembly, the sealing end comprisesa head and a sealing shaft rod connected with the head, the sealing assembly comprises a sealing ring and a sealing check ring which sleeve the sealing shaft rod part in an up-and-down contact manner, so that functional partitioning is achieved, and if a workpiece in a functional area goes wrong, a new workpiece can be used for replacement; the whole pressure vessel does not need to be scrapped,and the use cost is reduced.

Owner:INST OF GEOLOGY CHINA EARTHQUAKE ADMINISTRATION

Steel plate for seamless pressure vessel head and production process of steel plate

InactiveCN104561767AReduce welding processReduce production process costsWeld seamUltimate tensile strength

The invention relates to a steel plate for a seamless pressure vessel head and a production process of the steel plate. The steel plate comprises the following raw materials in percentage by weight: 0.08%-0.12% of C, 0.10%-0.30% of Si, 0.80%-1.20% of Mn, not more than 0.020% of P, not more than 0.005% of S, 0.01%-0.06% of Alt and the balance of Fe and inevitable mixed elements. The production process comprises a plate blank reheating procedure, a rolling procedure and a steel plate feeding procedure. Through reasonable component design and rolling process, a Q295A steel plate of which the width is greater than or equal to 3200mm is produced; the yield strength of the steel plate fluctuates within the range of 295-345MPa and does not exceed 50MPa; the steel plate is good in molding property; the overall plate is stamped and molded after feeding; a welding procedure and a weld joint detection procedure are concealed; the production procedure and the production cost are greatly reduced; and the quality risk of cracking of the weld joint is avoided.

Owner:NANJING IRON & STEEL CO LTD

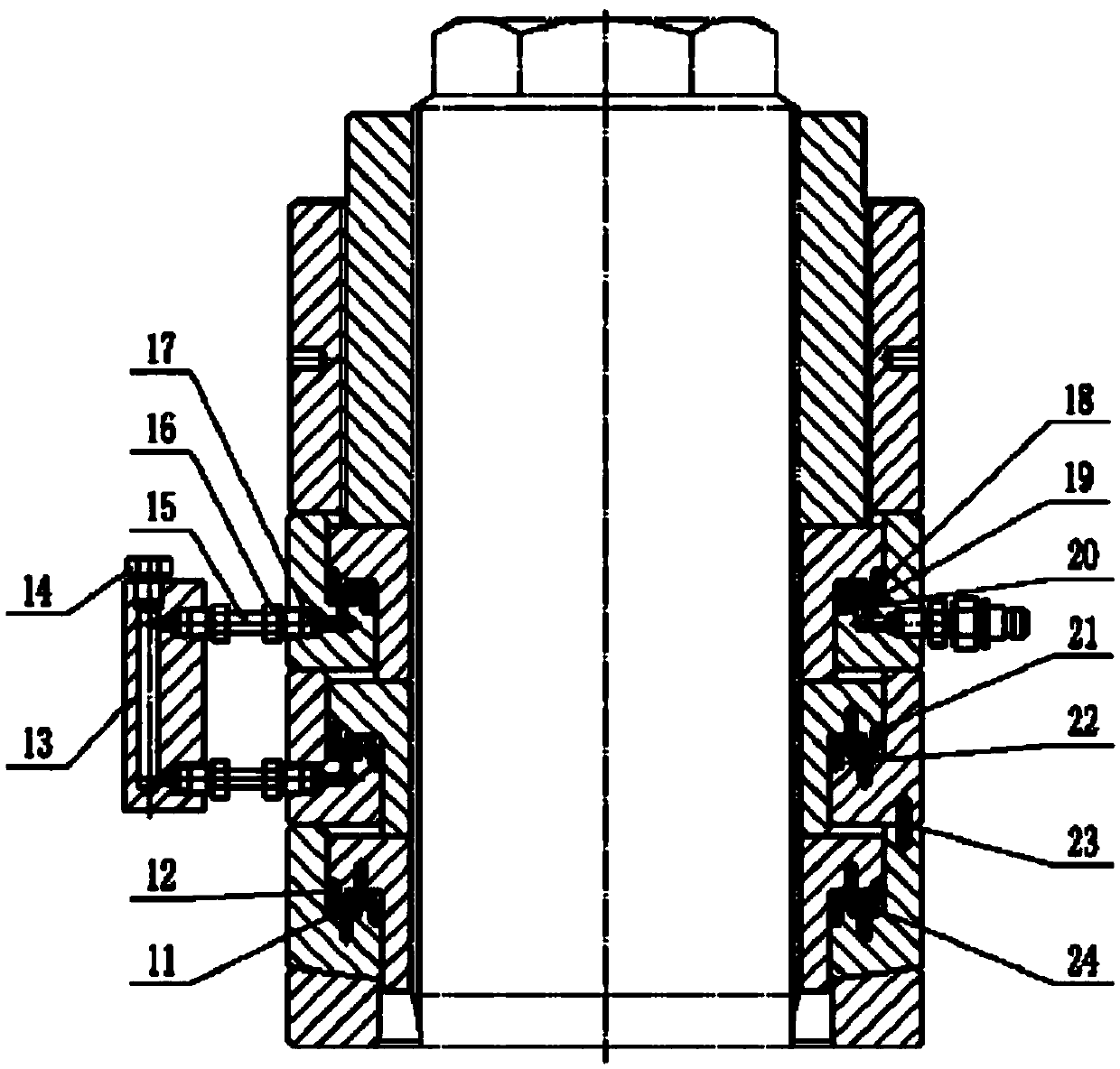

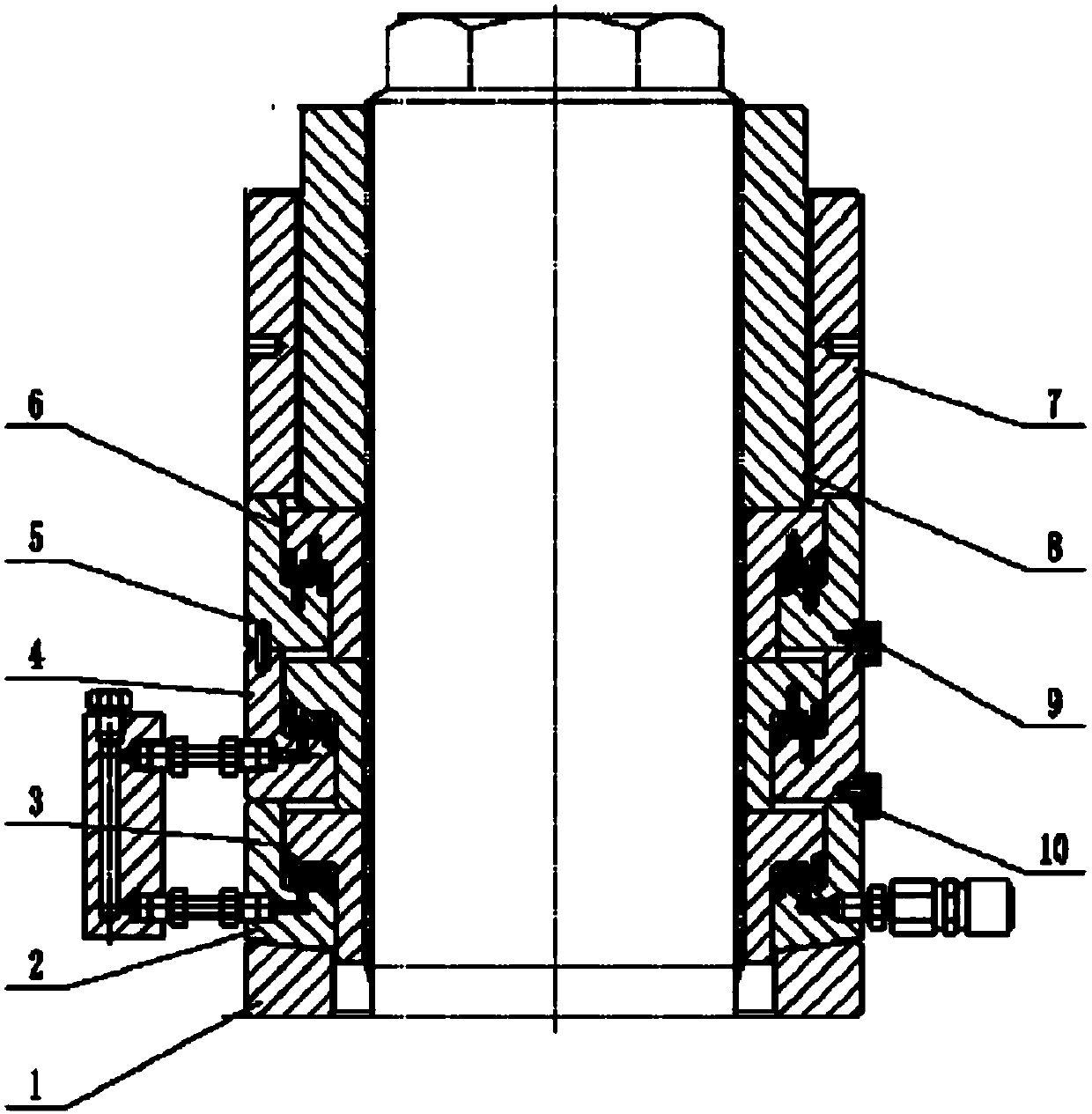

Hydraulic nut for reactor pressure vessel

PendingCN107763049AWith preload functionSimple processNutsFluid-pressure actuator componentsHydraulic cylinderReactor pressure vessel

The invention provides a hydraulic nut for a reactor pressure vessel. The hydraulic nut is provided with a hydraulic nut tandem cylinder structure, wherein the hydraulic nut tandem cylinder structurecomprises a primary oil cylinder, a primary piston, a secondary piston, a secondary oil cylinder, a tertiary oil cylinder, a tertiary nut, a pressing block, a pressing ring I, a pressing ring II, an oil path block, an inner hexagonal choke plug, a tapered threaded short tube, a threaded sleeve, a blocking ring, a pressing ring III, a pressing ring IV, a C-shaped sealing ring, a cylindrical pin, aninner hexagonal flat round head bolt, a female joint, a joint and a male joint. Compared with a conventional bolt stretcher design, the hydraulic nut for the reactor pressure vessel provided by the invention replaces a common nut in a main bolt assembly of the reactor pressure vessel, and has a pre-tightening function of a main bolt assembly.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD +1

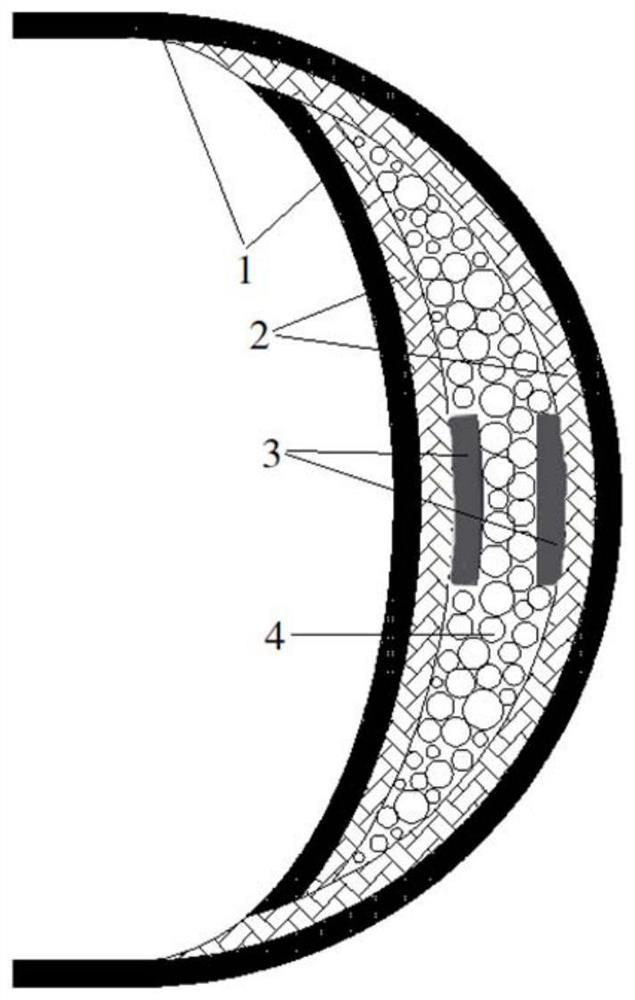

Seal head protection device for tank body of transportable pressure vessel

PendingCN111963885AImprove securityImprove the immunityNon-rotating vibration suppressionVessel wallsMulti materialEngineering

The invention belongs to the field of seal heads, and particularly relates to a seal head protection device for a tank body of a transportable pressure vessel. The seal head protection device comprises wear-resistant elastic layers, toughening layers and a foaming layer, wherein the foaming layer is positioned between the two toughening layers; one side, away from the foaming layer, of each toughening layer is connected with the corresponding wear-resistant elastic layer; the outer wall of each wear-resistant elastic layer is attached to the outer wall of a seal head; and the seal head protection device further comprises a pair of permanent magnets positioned in the foaming layer, wherein the two permanent magnets are arranged opposite to each other and the opposite sides are homopolar. The seal head protection device is arranged at the seal head of the tank body, and comprises a plurality of protection layers which are matched with one another, the strength, the elasticity and the buffering and shock-absorbing performance of various materials adopted by the plurality of protection layers are tightly combined, the capability of resisting collision and impact of the seal head of pressure vessels such as the tank body in the transportation process is improved, the safety of the pressure vessels such as the tank body in the transportation process is improved, and the potential risks and losses in the transportation process are reduced.

Owner:ZHEJIANG UNIV OF TECH

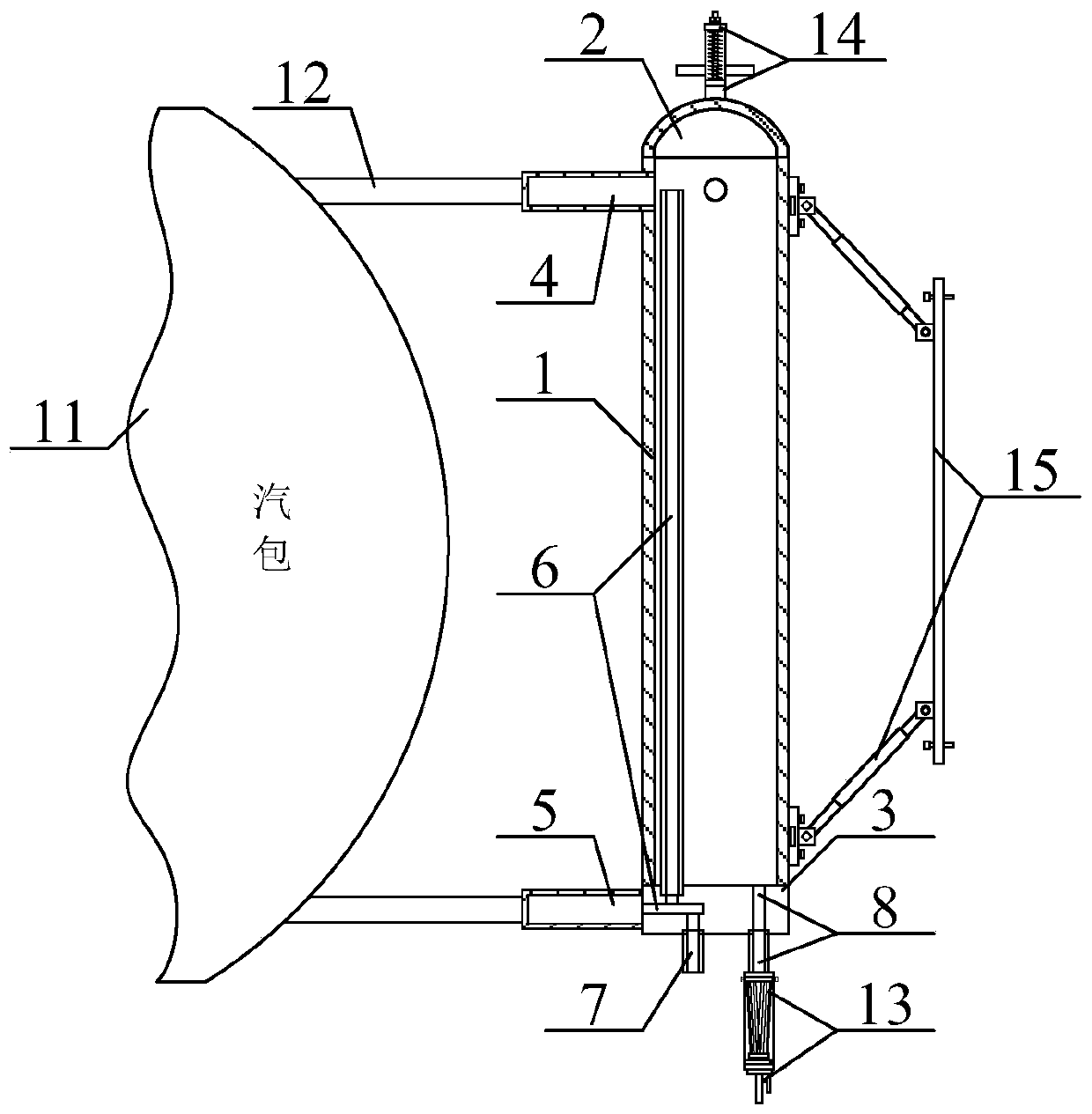

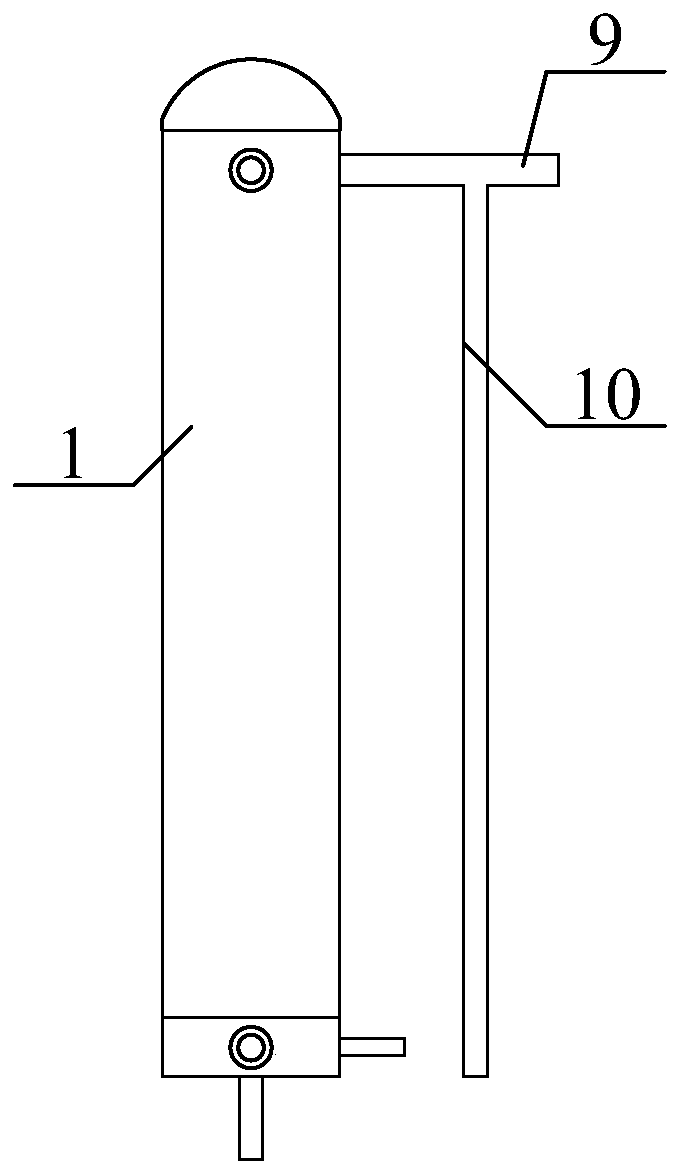

Liquid level measuring device for double-chamber balance container

ActiveCN111397688AAccurate dataReduce measurement errorSteam boilersSteam boilers componentsSteam pressureAutomatic control

The invention provides a liquid level measuring device for a double-chamber balance container. The device comprises a double-chamber balance container barrel body, an upper sealing head, a lower sealing head, an upper connecting pipe, a lower connecting pipe, a T-shaped communicating vessel, a positive pressure pipe, a blow-off pipe, a condensing coil, a negative pressure pipe, a boiler, a steam pocket steam phase guide pipe, a blow-off treatment antifouling discharge pipe structure, an automatic control release pipe structure capable of preventing steam pressure from being too high and an adjustable support mounting frame structure. According to the arrangement of the double-chamber balance container barrel, condensed water flowing back from the condensing coil can be collected and discharged into a descending pipe of a boiler, the whole container is heated and subjected to heat storage in the flowing process, it is guaranteed that the temperature in the container and the temperaturein a steam pocket are consistent, and then the accuracy of a measurement result is guaranteed. The arrangement of the T-shaped communicating vessel is beneficial to ensuring that the water level height of the communicating vessel changes along with the water level of the steam drum, so that the pressure of the positive pressure side changes along with the pressure change of the boiler steam drum,thereby ensuring the measurement accuracy, reducing the liquid level measurement error and improving the detection efficiency.

Owner:TANGSHAN CITY FENGRUN DISTRICT ZHANWANG AUTOMATION EQUIP CO LTD

Mutually-inserted and nested type vessel fast-open door

PendingCN107816551AImprove pressure bearing capacityReduce manufacturing costPressure vesselsEngineeringHead (vessel)

The invention discloses a mutually-inserted and nested type vessel fast-open door. The mutually-inserted and nested type vessel fast-open door comprises a vessel sealing head and a cylinder body flange welded to the end of a vessel cylinder body; a sealing head flange for being matched with the cylinder body flange to seal the vessel cylinder body is welded to the vessel sealing head; a horizontal-moving opening device or a horizontal-rotating opening device for horizontally moving of the vessel sealing head is mounted outside the vessel sealing head; one half of the cylinder body flange is arranged as a cylinder body flange protruding shoulder, and the other half of the cylinder body flange is arranged as a cylinder body flange hoop ring; and one half of the sealing head flange is arranged as a sealing head flange hoop ring matched with the cylinder body flange protruding shoulder, and the other half of the sealing head flange is arranged as a sealing head flange protruding shoulder matched with the cylinder body flange hoop ring. The mutually-inserted and nested type vessel fast-open door has the beneficial effects that opening and closing of a cover are realized only by radial horizontal moving or horizontal rotating, operation is convenient, and the axial space is saved due to the fact that axial moving or outward rotating is not required; and the flange of the fast-open door adopts whole forging, the protruding shoulders and the hoop ring parts of the fast-open door and the flange are a whole, notches are not formed in the protruding shoulders and the hoop rings, the entire circumference is subjected to force, and the pressure bearing capacity of the flange is very good.

Owner:温州市工业设计院有限公司

Reactor pressure vessel lower sealing head surfacing welding layer detection tool and method

PendingCN111354487AIncrease stiffnessGuaranteed repeatabilityNuclear energy generationNuclear monitoringStress concentrationReactor pressure vessel

The invention is mainly applied to the field of nuclear power station maintenance, and particularly relates to a reactor pressure vessel lower sealing head surfacing welding layer detection tool and method. In the prior art, harmful defects are easily generated due to stress concentration in wear areas of a reactor pressure vessel so as to reduce the service life of the vessel, and defect detection needs to be performed on the wear areas. The tool comprises a linear telescopic device and a tail end monitoring device, wherein the linear telescopic device is connected with the tail end monitoring device, and the tail end monitoring device is integrally located below the linear telescopic device. The invention discloses a reactor pressure vessel lower sealing head surfacing welding layer detection method, which specifically comprises the steps of detection sensitivity setting, device connection, ultrasonic eddy current detection and ultrasonic defect quantification. According to the invention, the defect detection of the worn area of the reactor pressure vessel can be effectively realized, the working efficiency is improved, and the operation cost is reduced.

Owner:RES INST OF NUCLEAR POWER OPERATION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com