Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

527 results about "Shut down valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A shutdown valve (also referred to as SDV or emergency shutdown valve, ESV, ESD, or ESDV; or safety shutoff valve) is an actuated valve designed to stop the flow of a hazardous fluid upon the detection of a dangerous event. This provides protection against possible harm to people, equipment or the environment. Shutdown valves form part of a safety instrumented system. The process of providing automated safety protection upon the detection of a hazardous event is called functional safety...

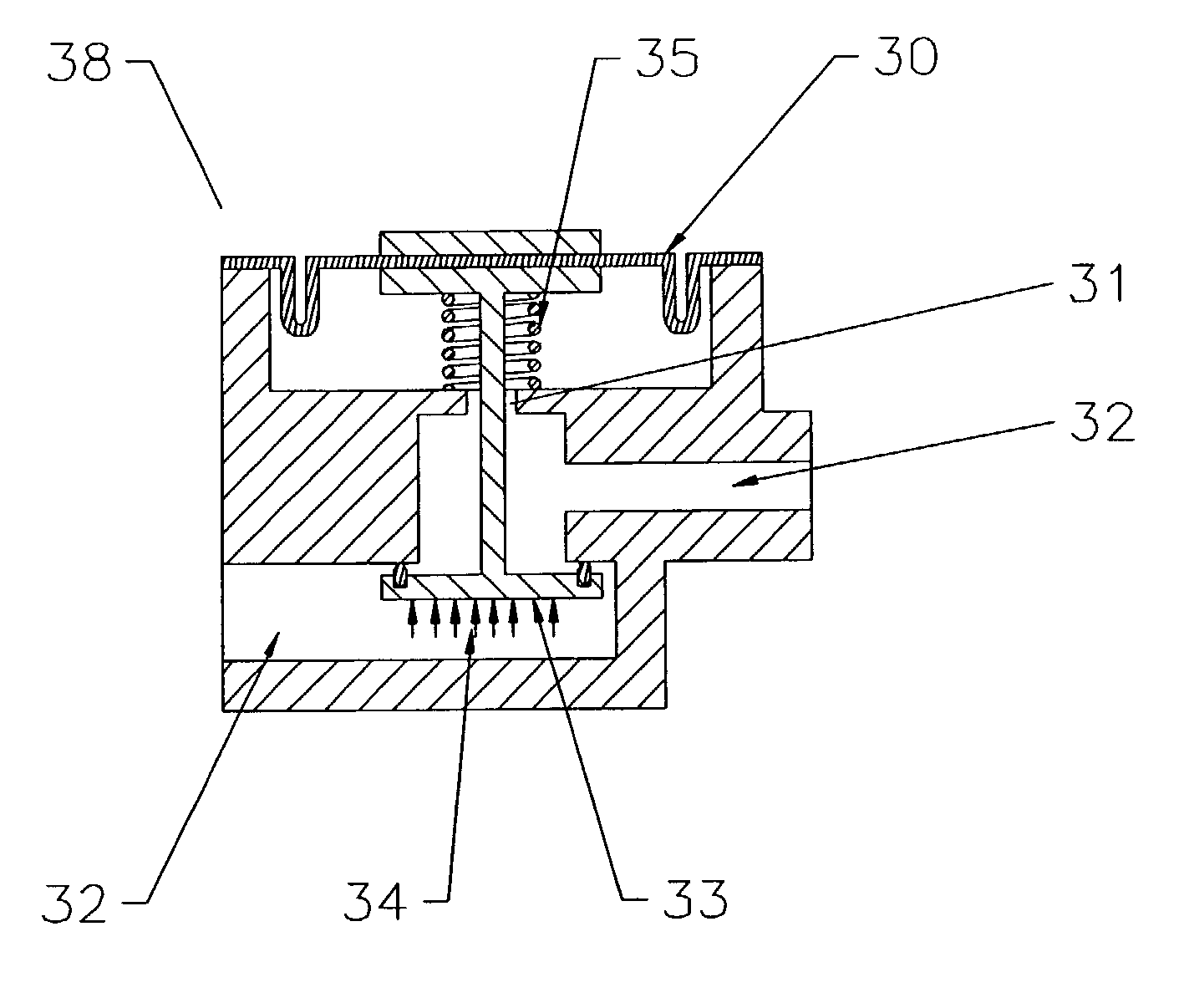

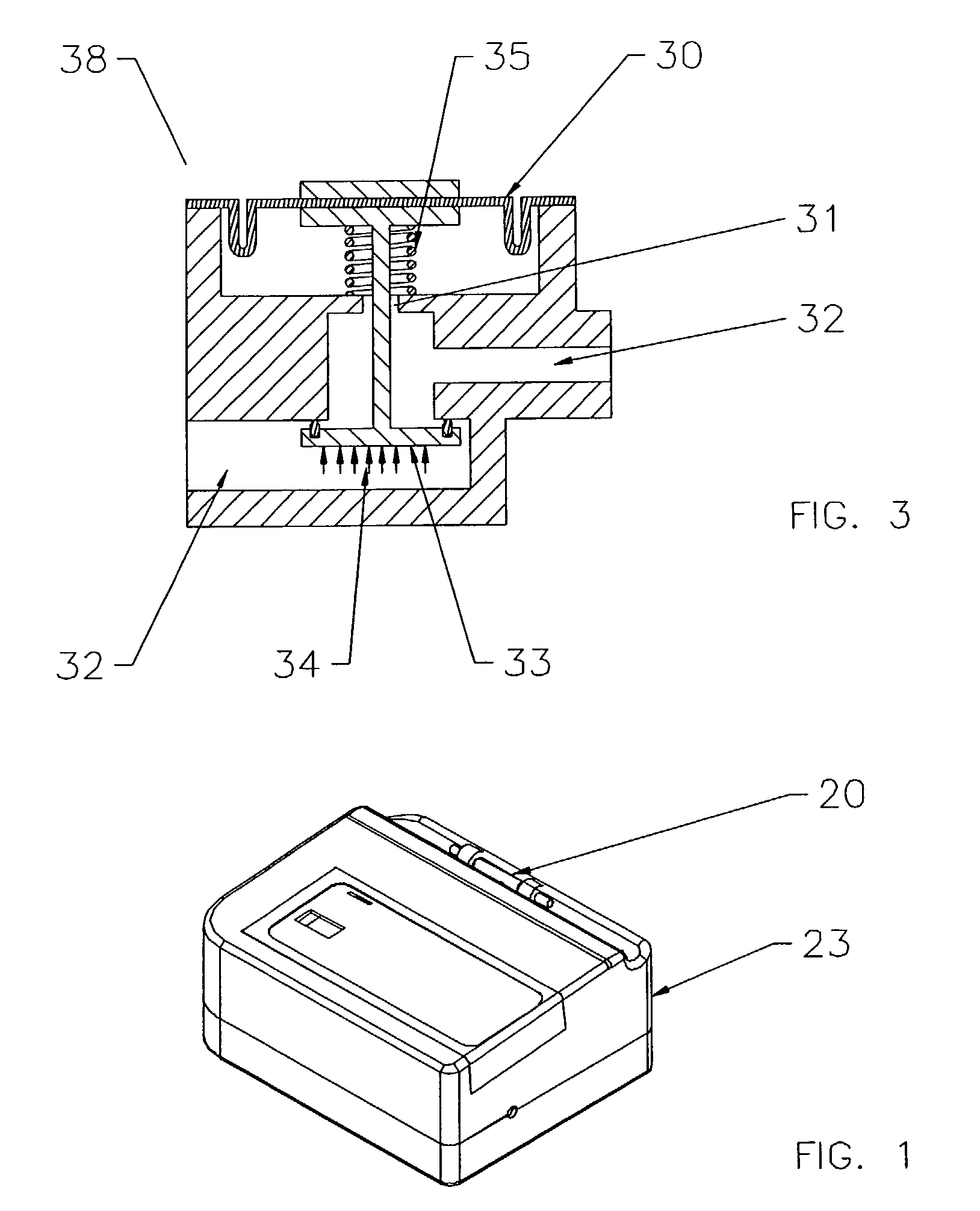

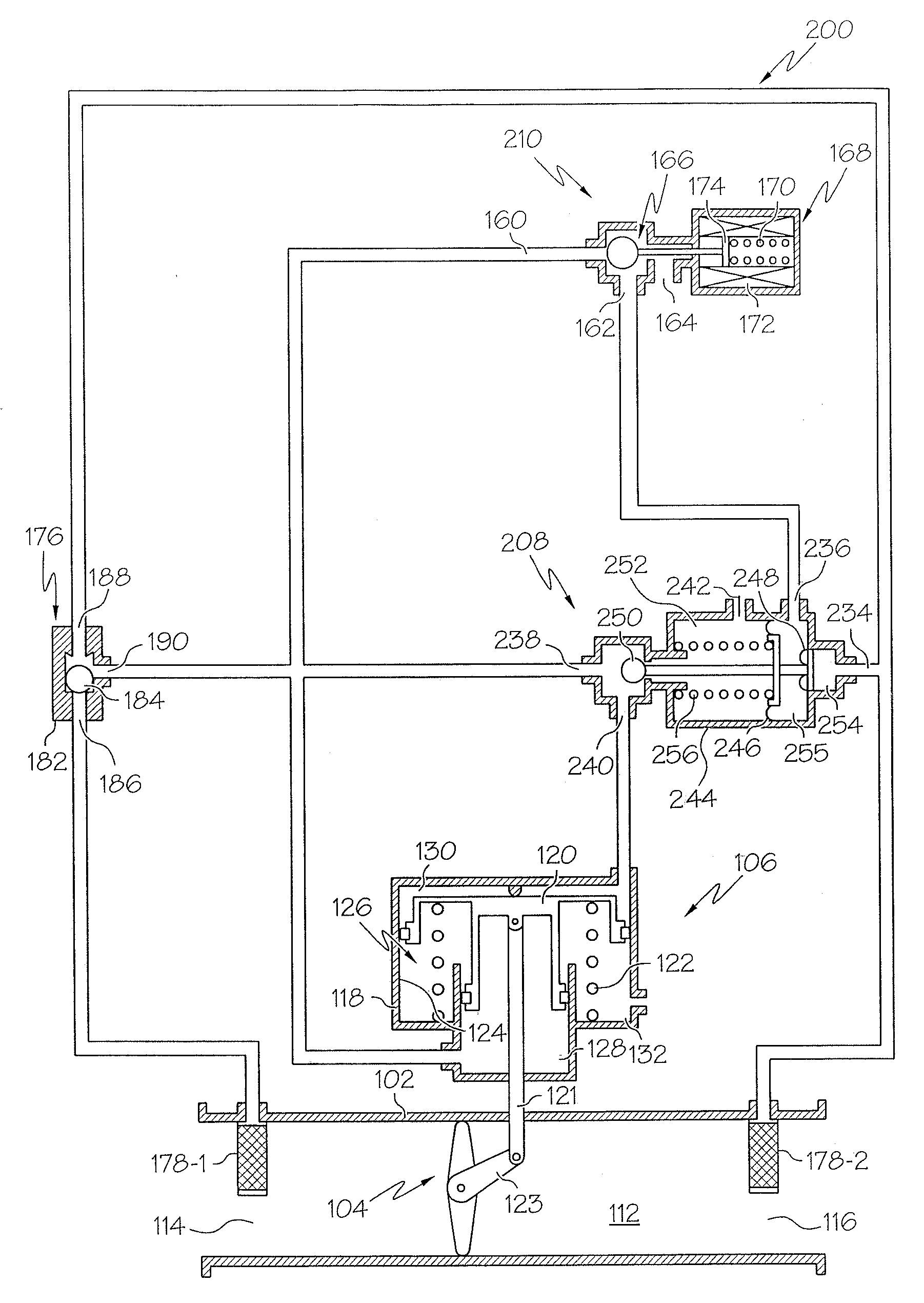

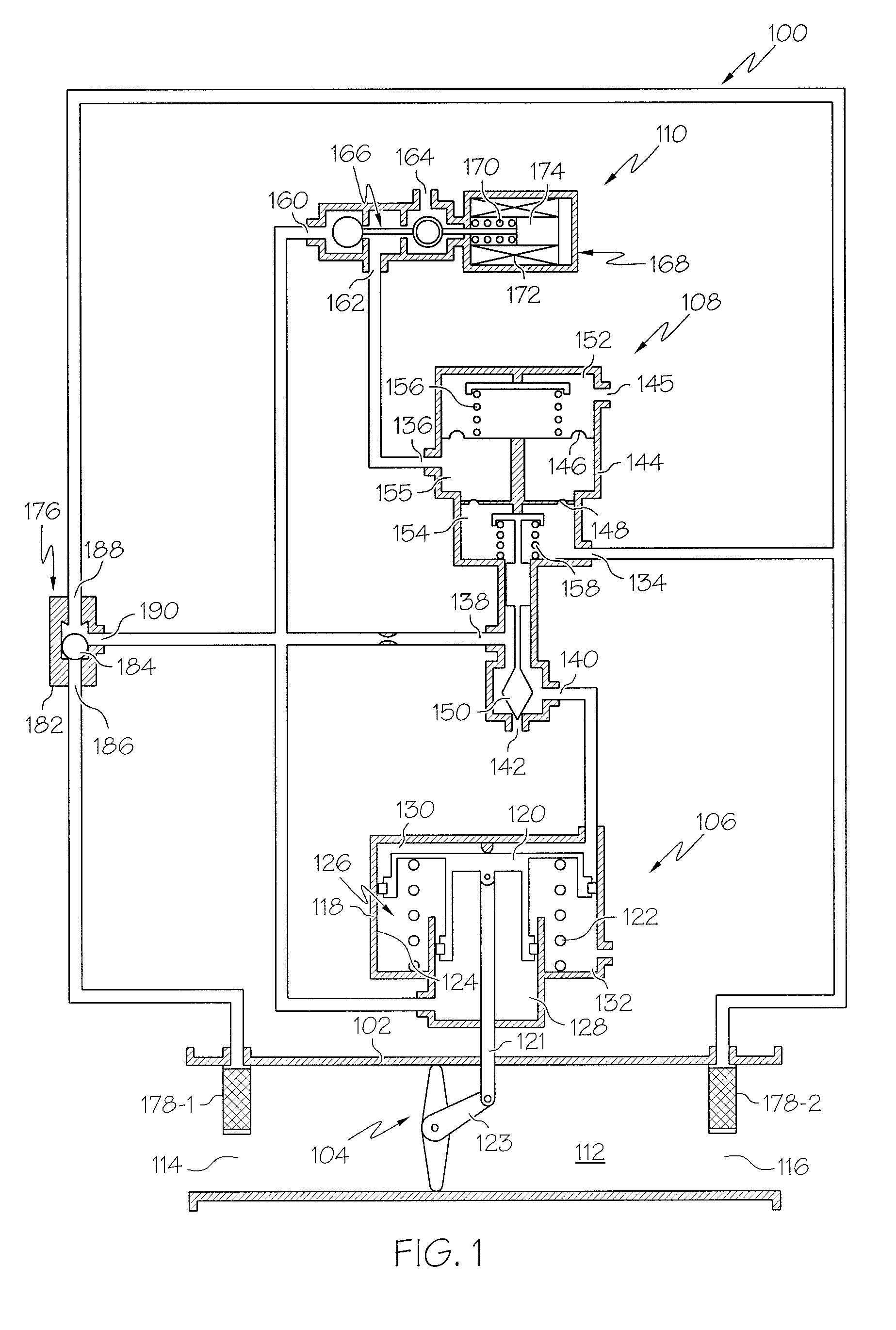

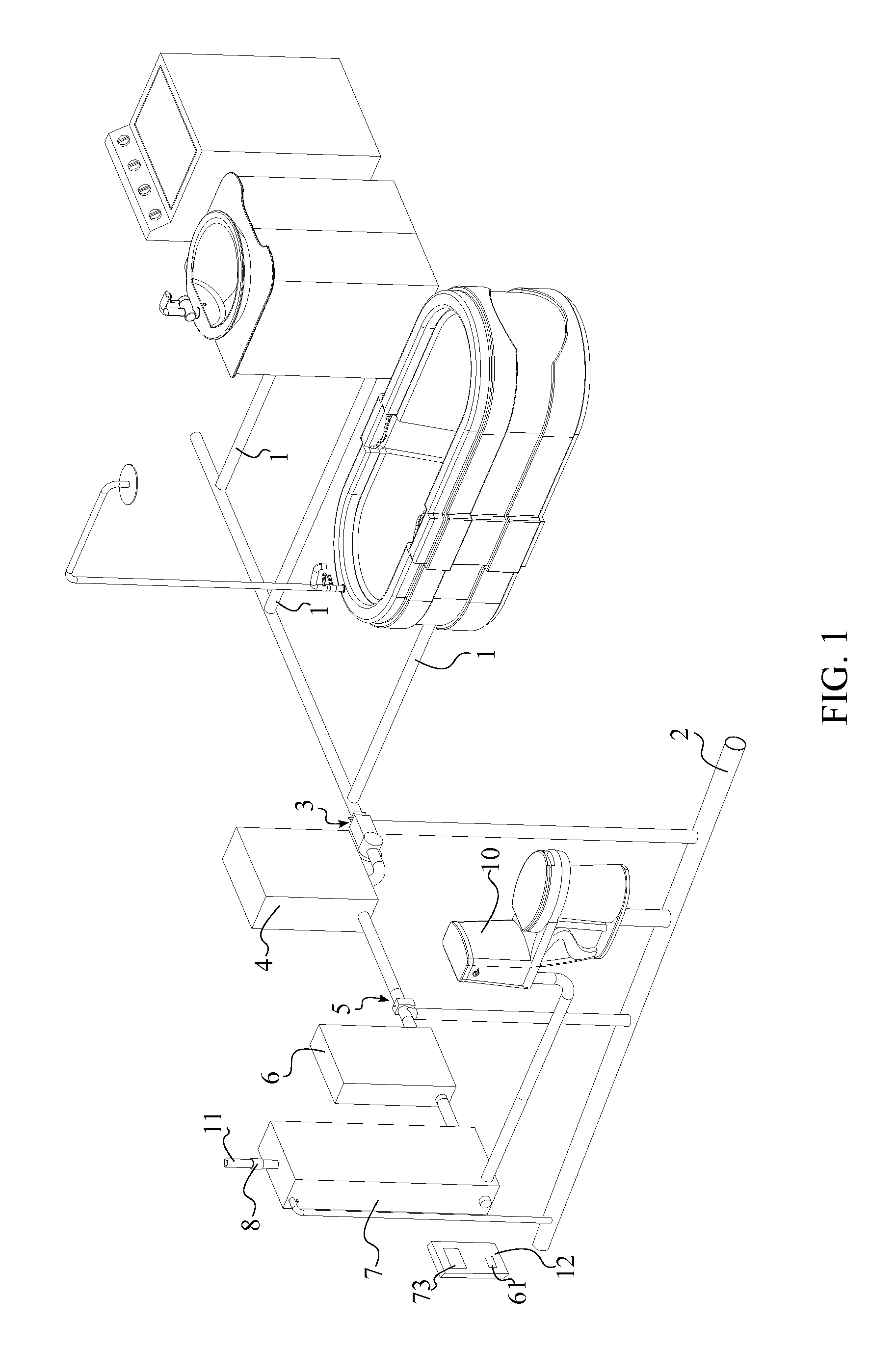

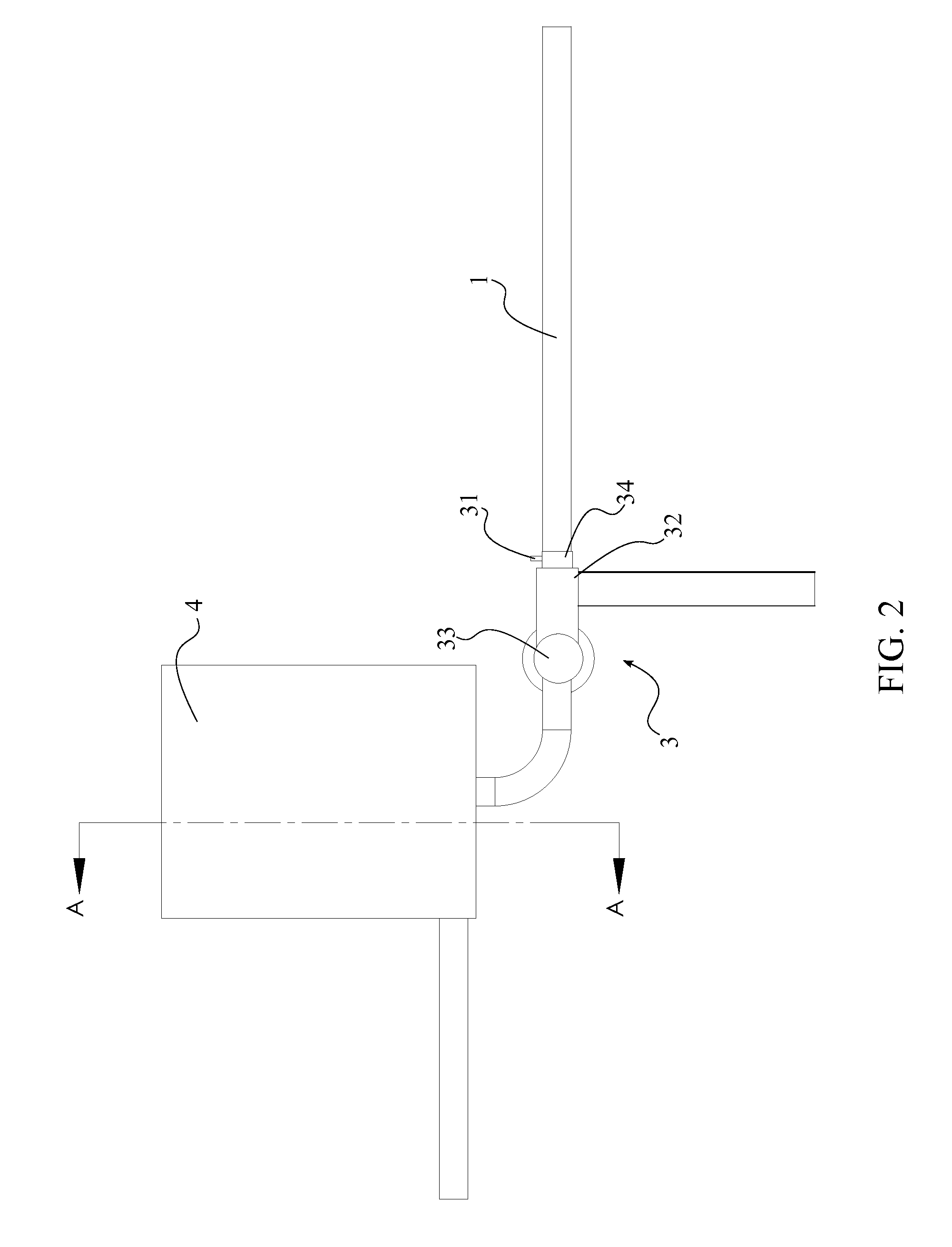

Interventional procedure drive and control system

InactiveUS20040059284A1Sufficiently compactSuppress fluctuationsIntravenous devicesSuction irrigation systemsReciprocating pumpSingle use

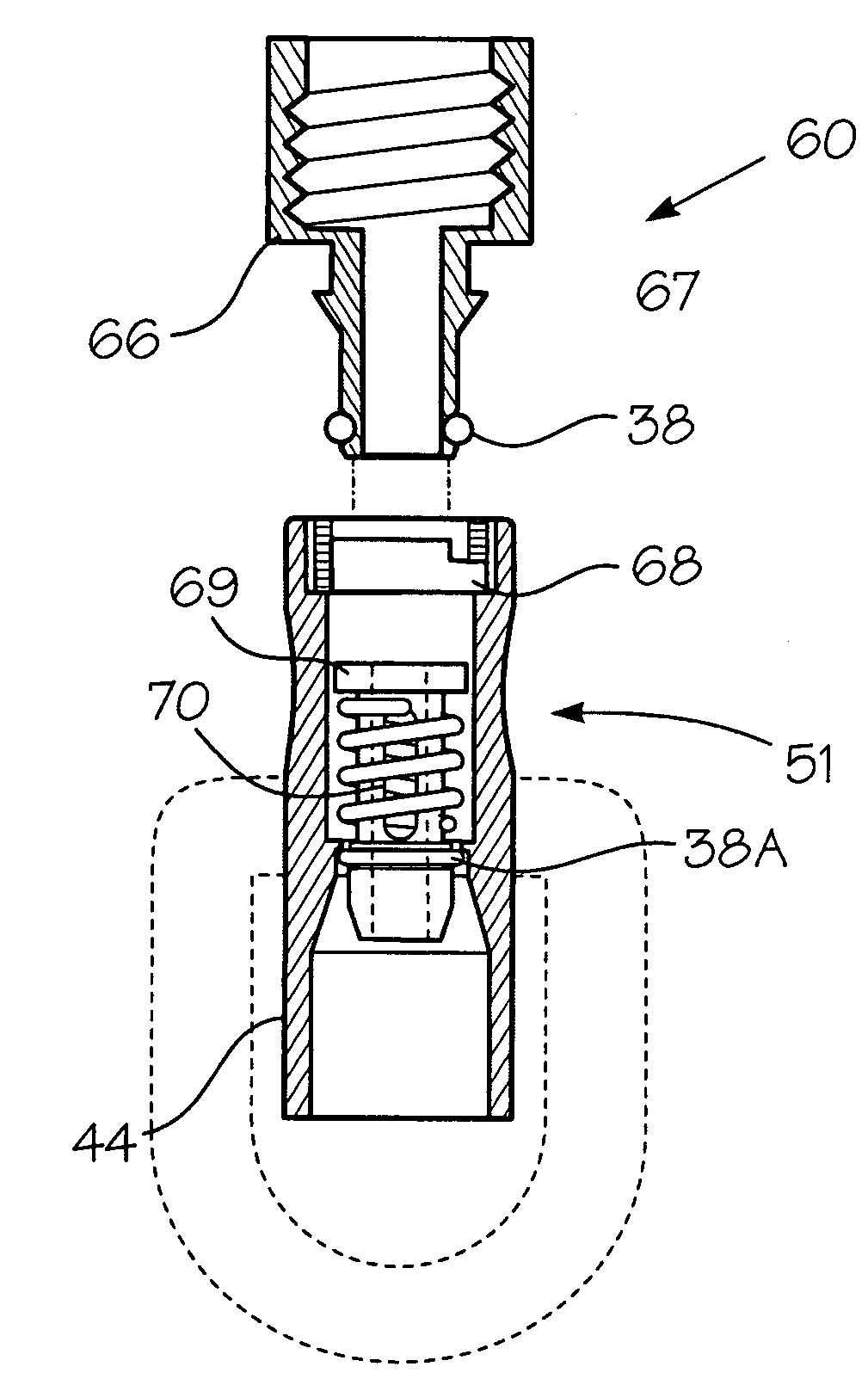

A pumping system for use in medical applications where liquids must be infused and aspirated from a mammalian patient, and whose economics are such that it is cost effective to simply dispose of it after a single use. The system features positive displacement pump(s) such as reciprocating pump(s) containing a damping mechanism to dampen out the peaks and valleys in the fluid pressure that is pumped, which is important for preventing cavitation. The system furthermore features a shut-off valve on the extraction side so that certain injected fluids such as contrast medium, are not immediately pumped out of the patient. In a preferred embodiment, the system also features means for independently controlling the fluid pressure / volume on the infusion and extraction sides, self-priming capability, a continuous fluid path, and visual air bubble detection, with viewports located at important points in the fluid path, such as at pumps and valves.

Owner:KENSEY NASH CORP

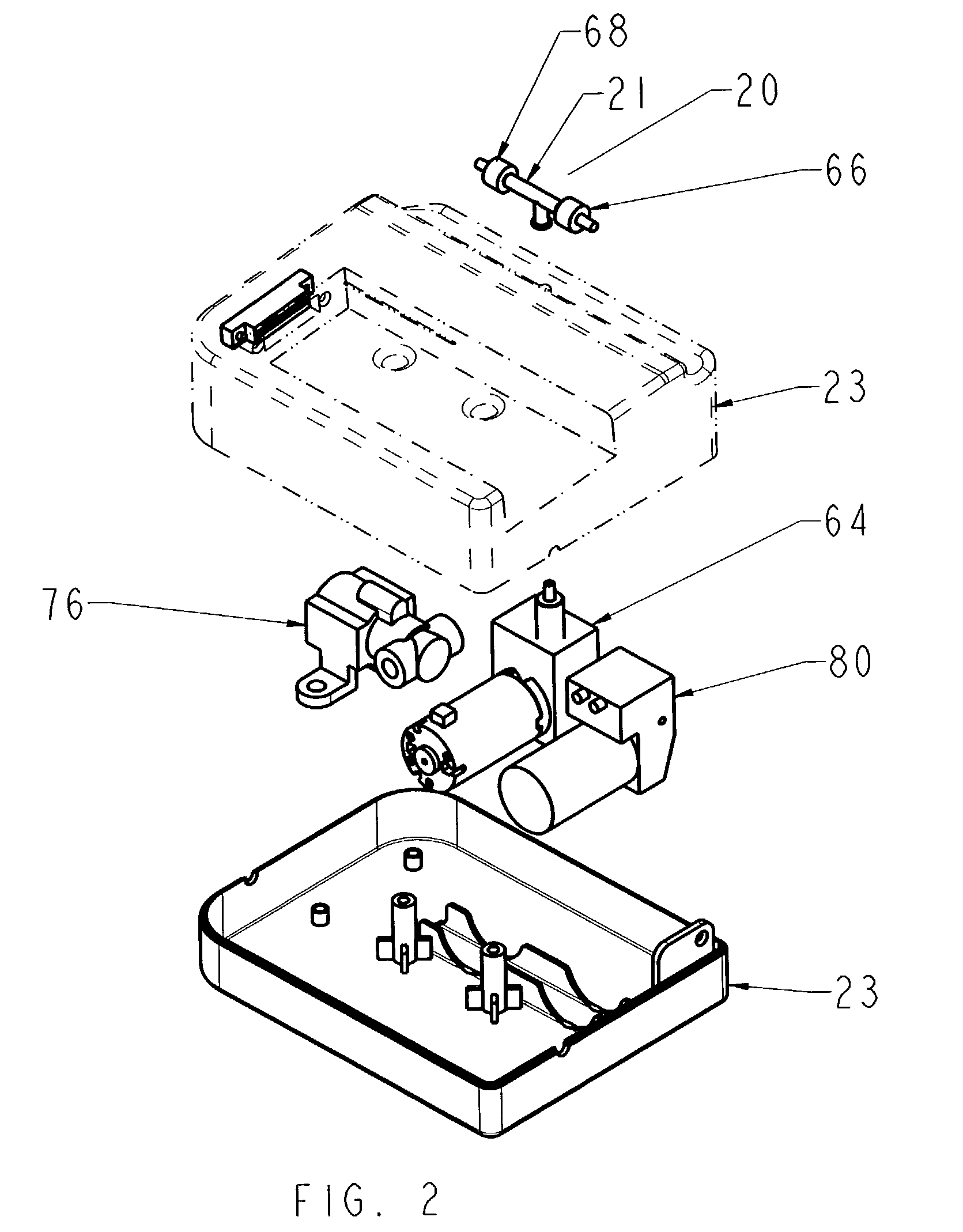

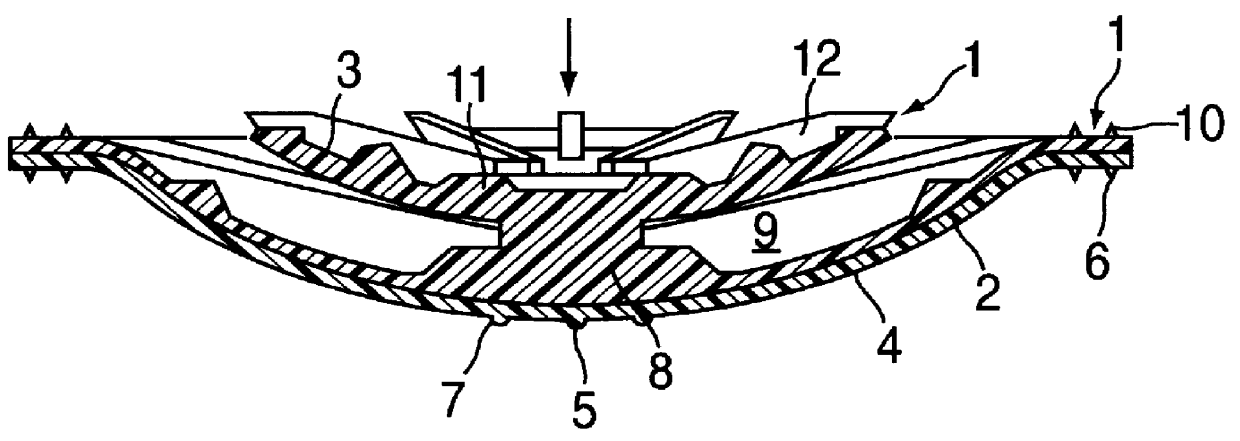

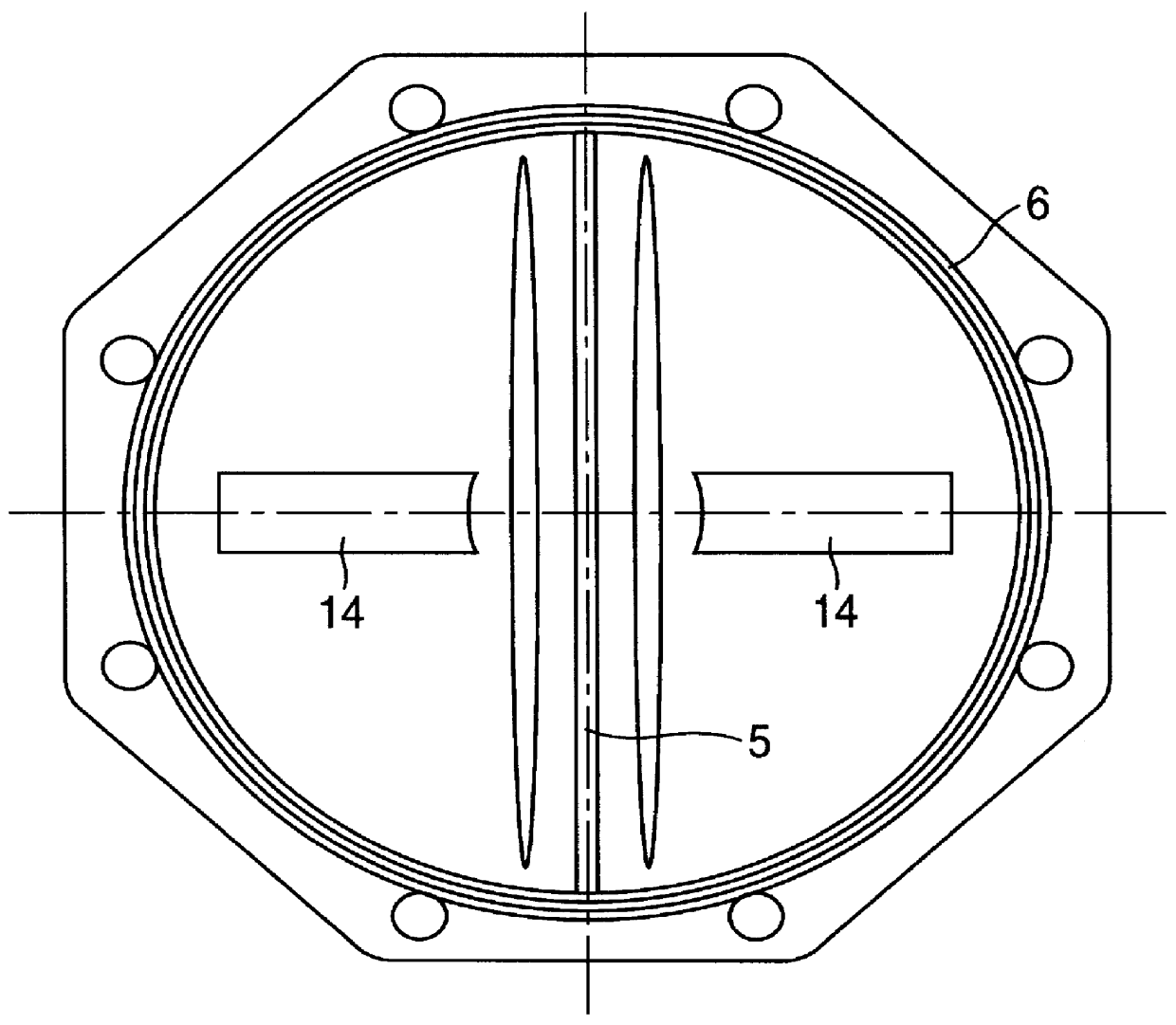

Spring diaphragm for shut-off valves and regulators

InactiveUS6095484AExtended service lifeDiaphragm valvesOperating means/releasing devices for valvesHermetic sealEngineering

A spring diaphragm for use in automatic hydraulic control valves of the type having a valve body having an inlet chamber, and an outlet chamber and a spring diaphragm interposed between the inlet and outlet chambers, which spring diaphragm, as a result of hydraulic pressure, is automatically moveable between an open and closed position, in which the diaphragm allows and prevents, respectively, communication between the inlet and outlet chambers, includes a two-part diaphragm element including a first lower part and second upper part generally spaced apart from one another, the first lower part being in the form of a flexible elastic disc which performs the function of a hermetic seal between the inlet and outlet chambers when the spring diaphragm is in the closed position and the second upper part being connected to the first part and being in the form of a resilient disc which performs the function of a spring to normally bias the spring diaphragm from the open to the closed position. The first and second parts each have resilient spring-like ribs on the first lower part serving to aid hermetic sealing when the diaphragm is in the closed position and the ribs on the second upper part serve to provide a main force to bias the diaphragm into the closed position.

Owner:RAPHAEL VALVES INDS 1975

Conductive fluid leak detection system & automatic shut off valve

InactiveUS20030066340A1Minimize fluid leakageBlock fluid flowDetection of fluid at leakage pointIndication/recording movementLine tubingAlarm state

A flood control device and system which controls conductive fluid(s) in a conductive fluid supply line and or path, using the conductivity of said fluid(s). The conductive fluid system comprises; a conductive fluid supply line, in-line conductive fluid shut-off valve, in-line conductive fluid detector, conductive fluid sensor(s) (attached in or to conductive fluid dependent appliances), a D.C. powered central processing unit, and control panel. The conductive fluid flows through said conductive fluid line, said in-line conductive fluid shut-off valve, intern reaching said in-line conductive fluid detector which detects the flow of conductive fluid, thereby sending data to said central processing unit. When said central processing unit receives said data, said central processing unit delays for a predetermined amount of time (example 3 seconds) waiting to receive data from one or more of said conductive fluid sensor(s). If said central processing unit doesn't receive said data from said conductive fluid sensor(s) within said predetermined, said central processing unit will automatically send data to said in-line conductive fluid shut-off valve, to close, therefore terminating the forward flow of conductive fluid(s). System also includes audible signal(s) to signal an alarm condition, timing mode(s) for water conservation and monitoring in-line conductive fluid shut-off valve movements, a phone notifier for notifying user of said termination of conduct fluid due to a conductive fluid leak detection, and for (user-set) excessive water usage, means for communicating with said central processing unit by way of telephonic communication (to close or re-open said in-line conductive fluid shut-off valve), a battery back up system, and means of operating by way of manual means.

Owner:HASSENFLUG BRIAN EDWARD

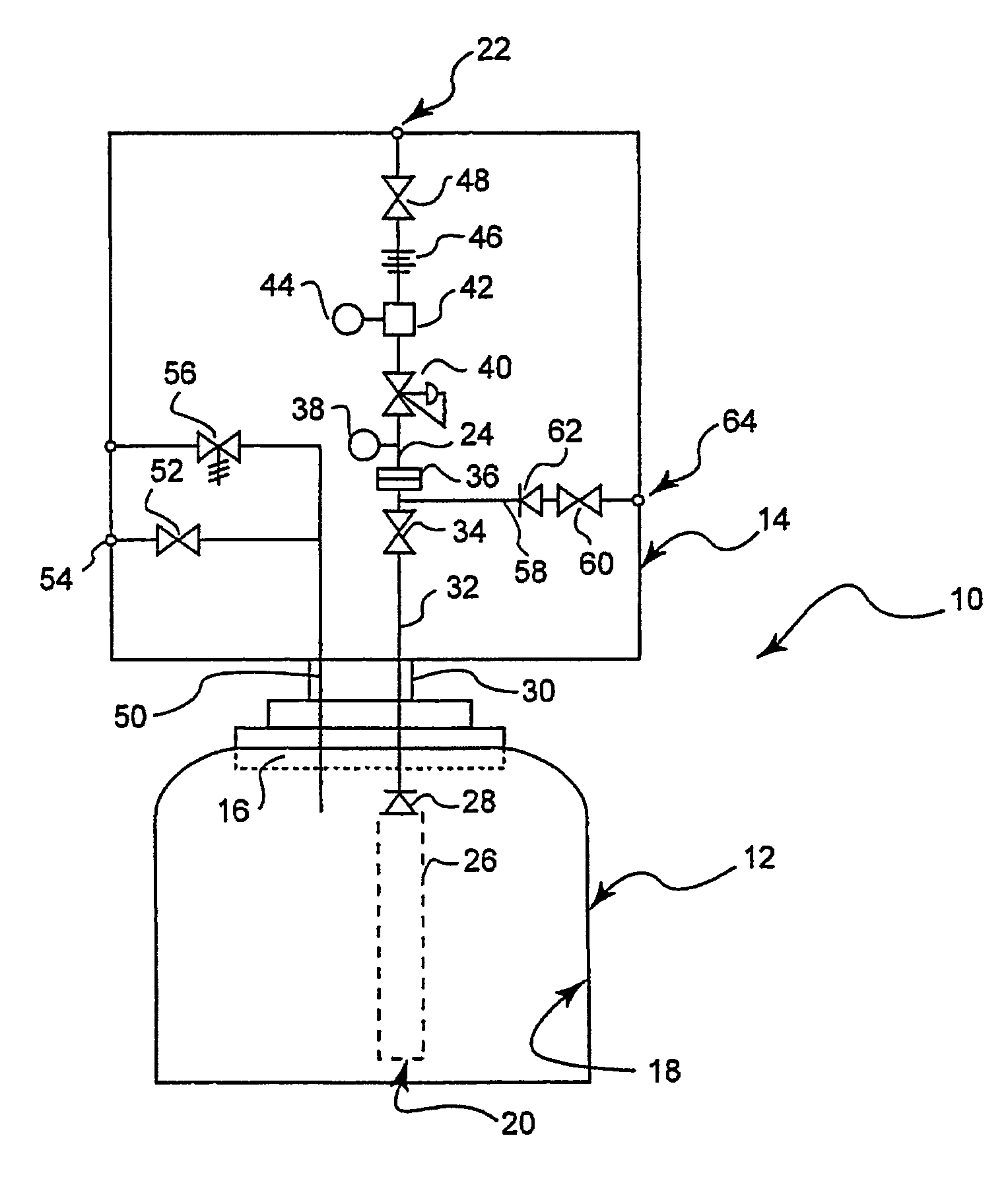

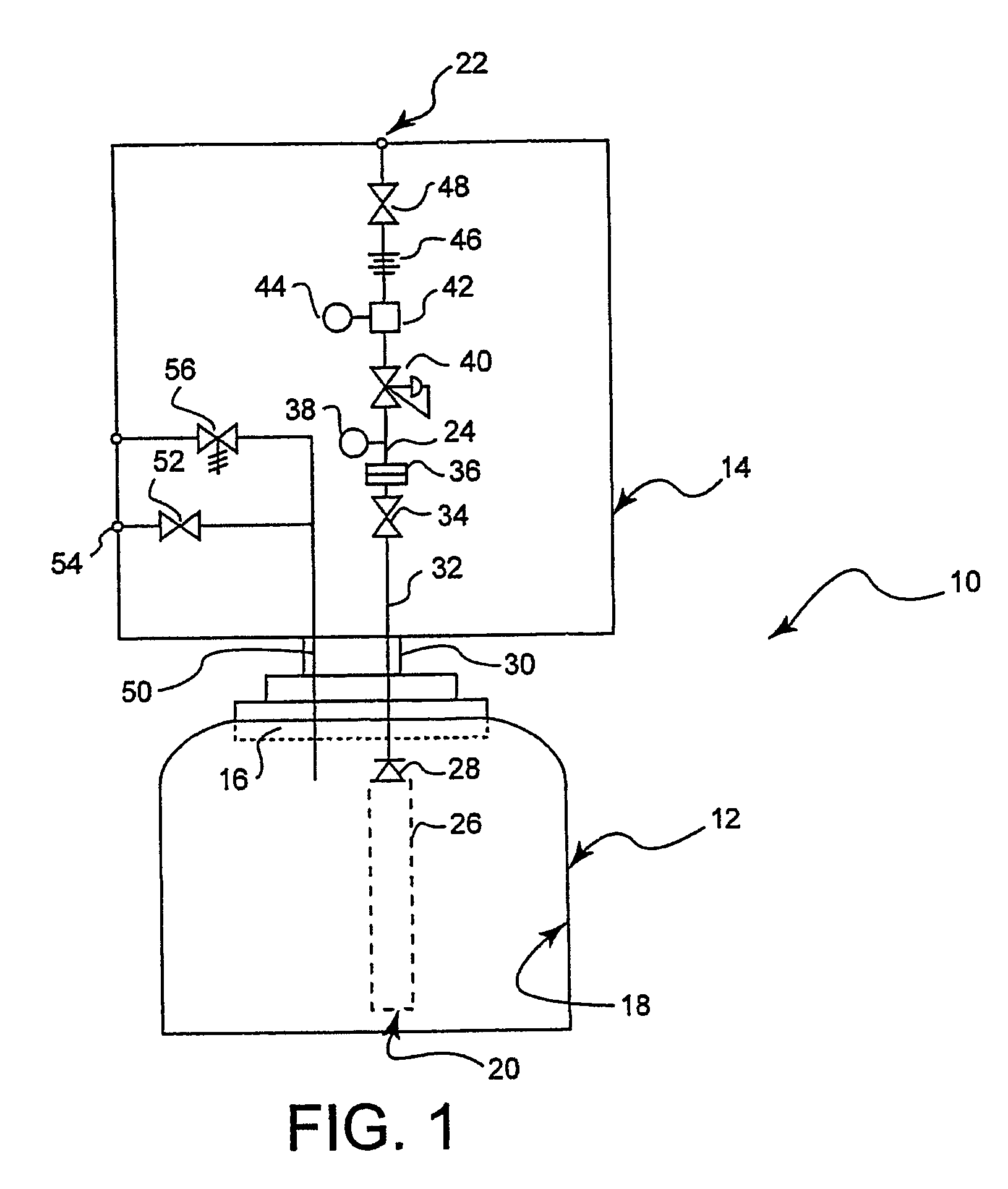

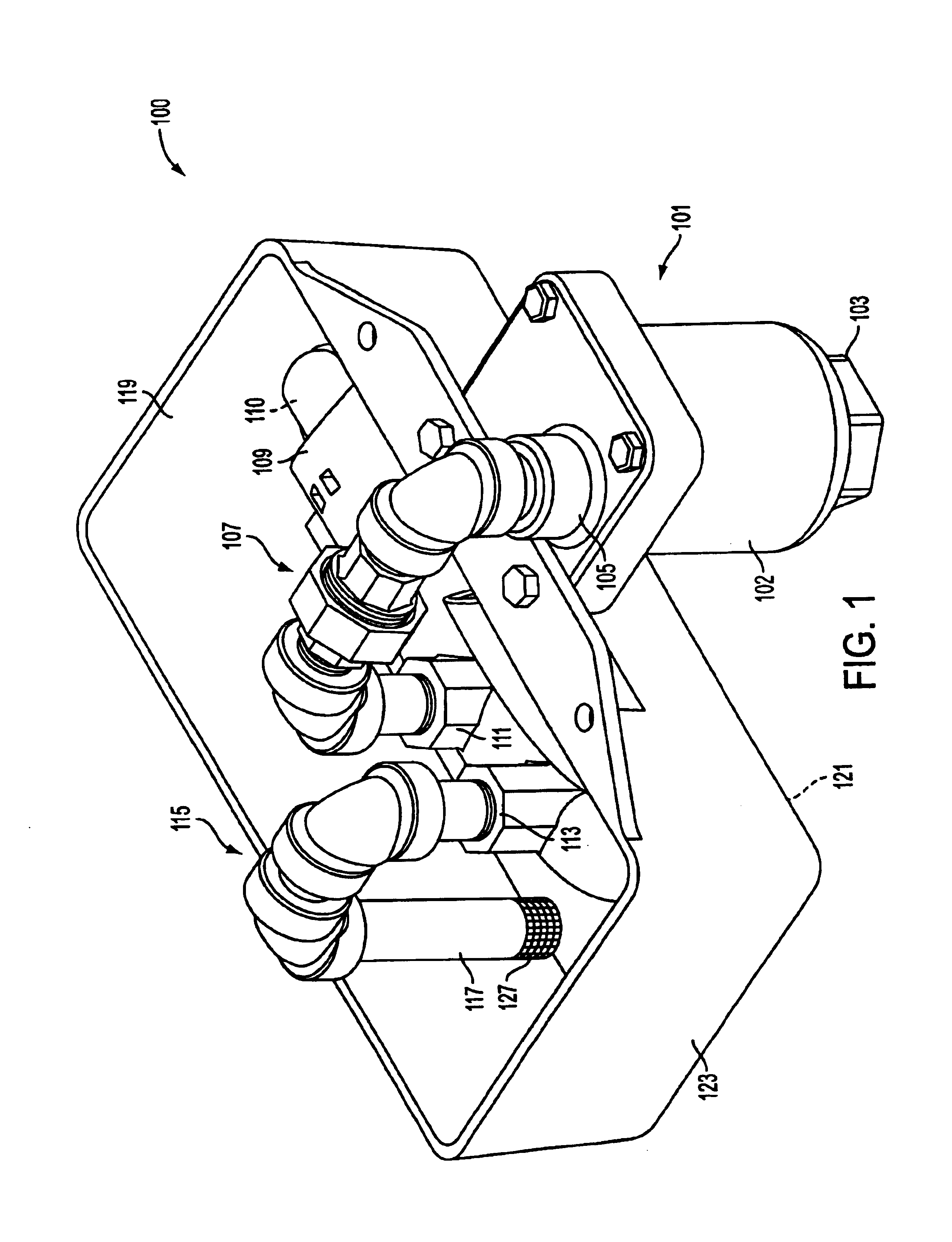

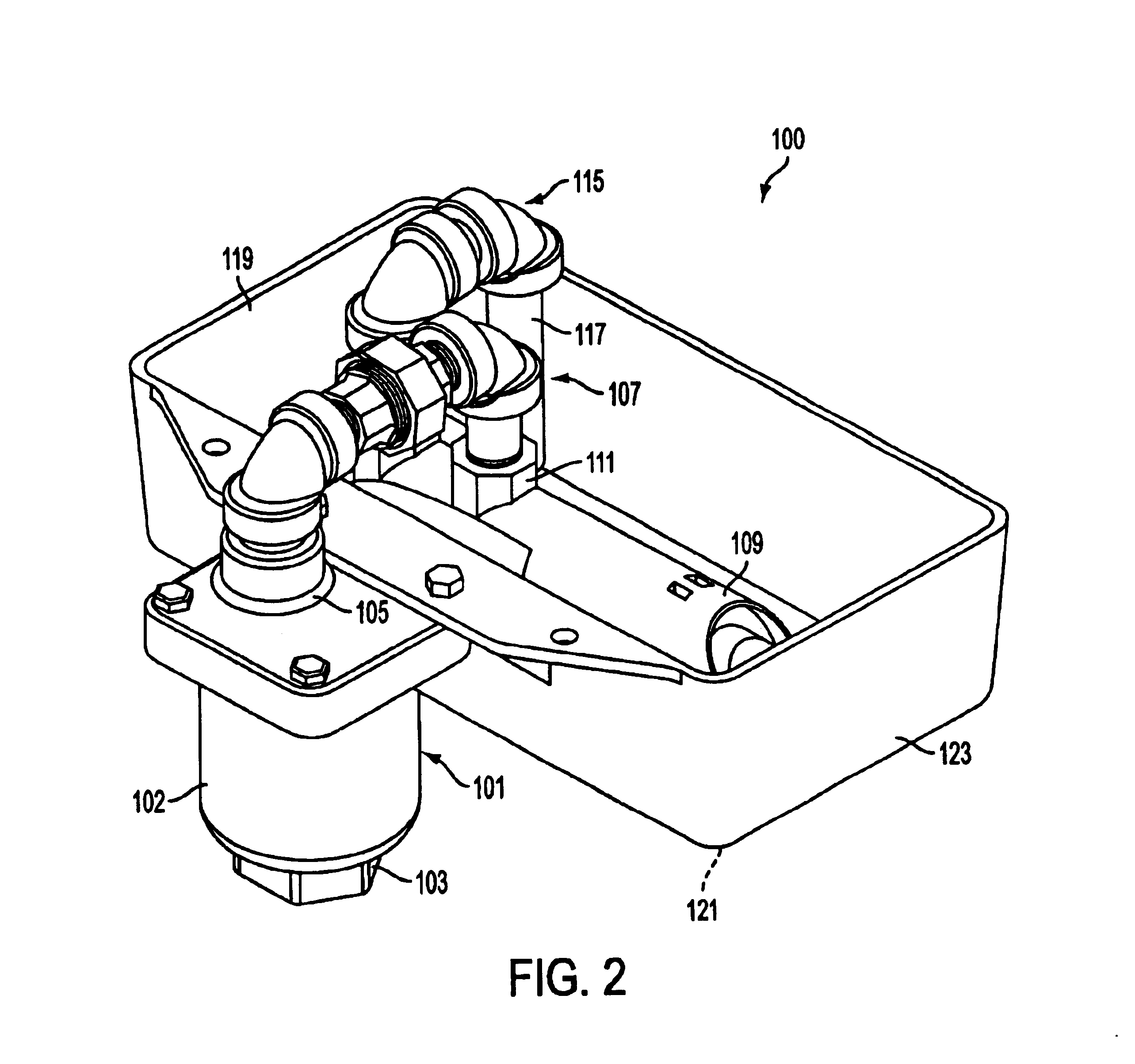

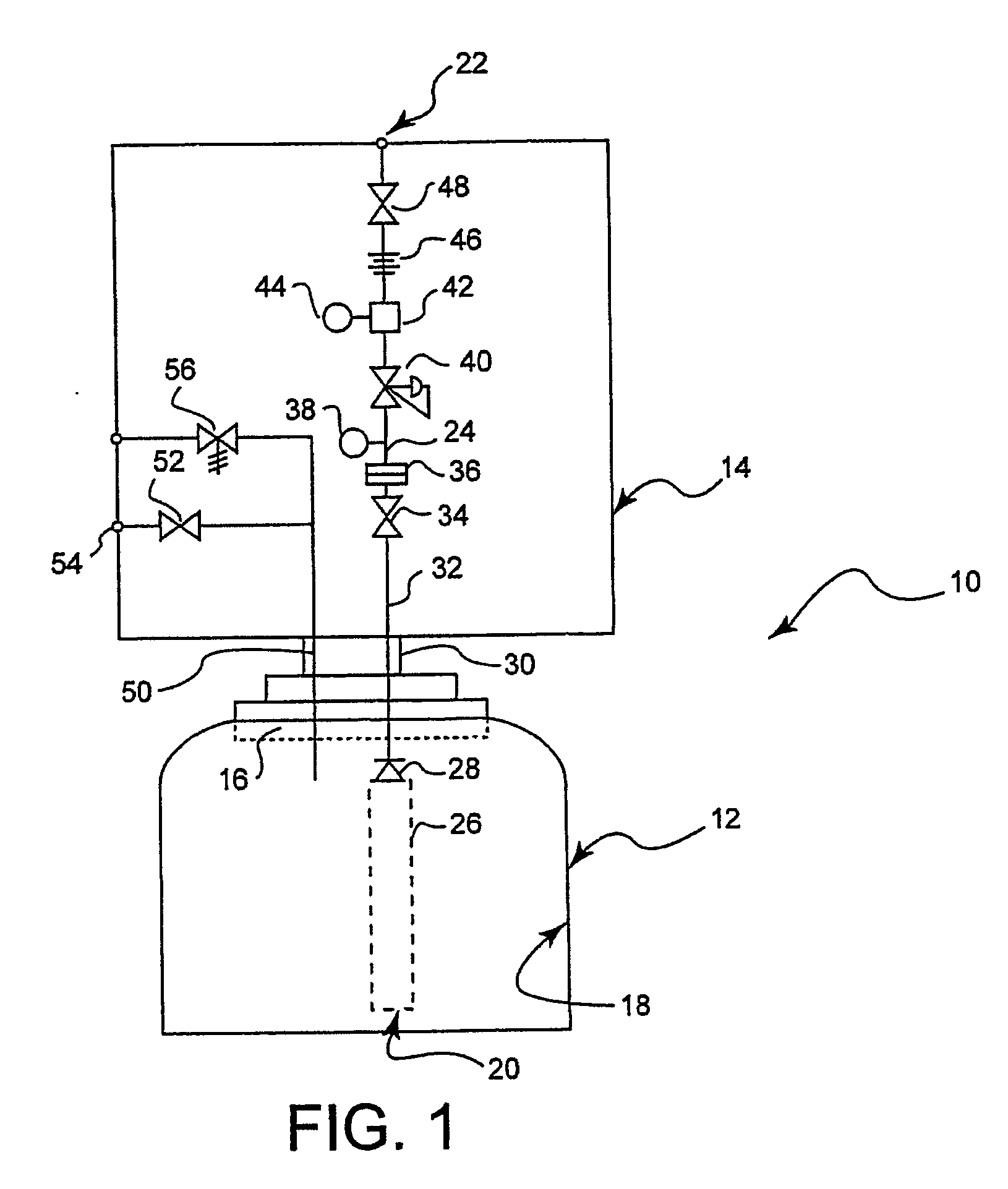

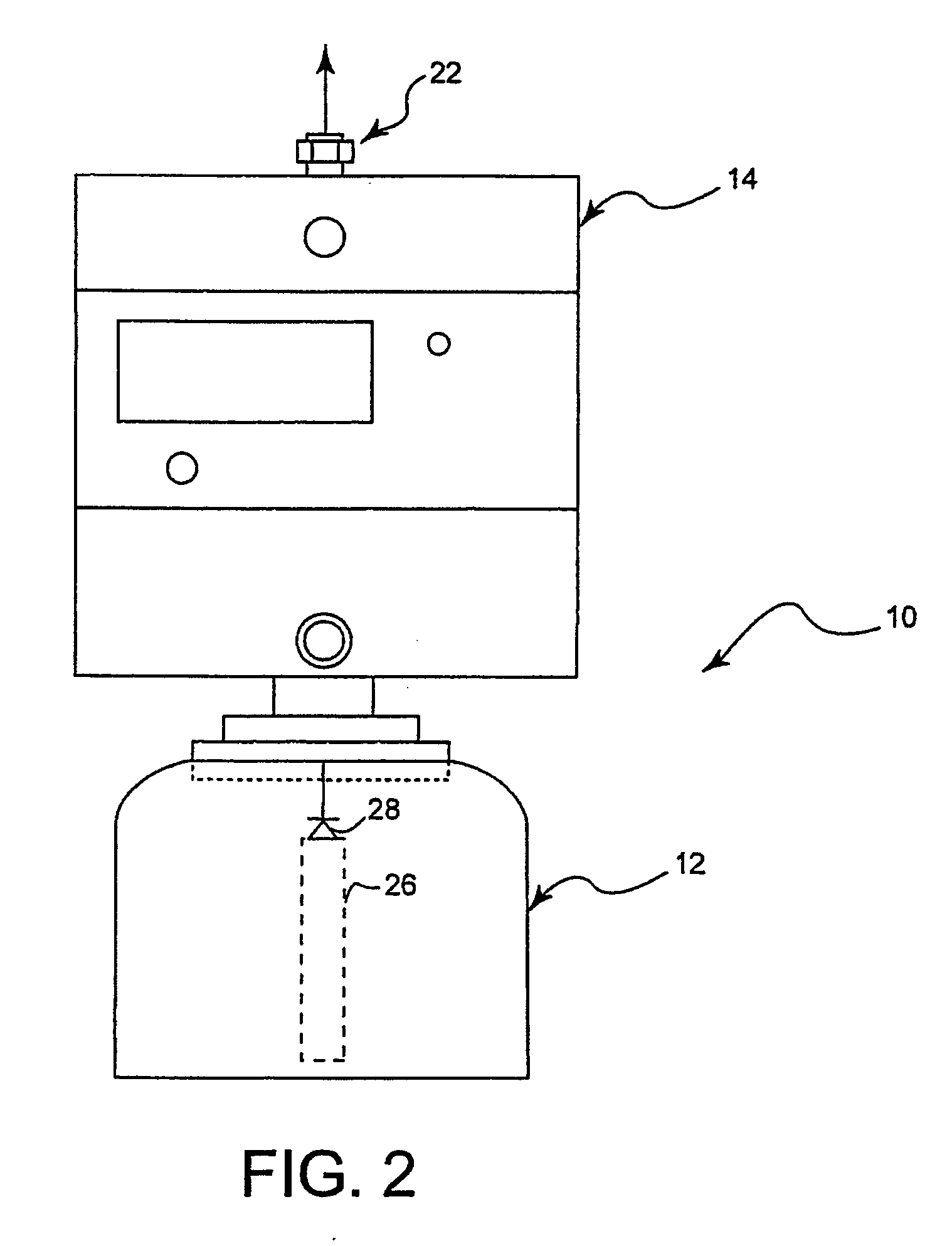

Assembly and method for containing, receiving and storing fluids and for dispensing gas from a fluid control and gas delivery assembly having an integrated fluid flow restrictor

A fluid control and gas delivery assembly and method for containing, receiving and storing hazardous fluids and for dispensing gas comprising a container, a fluid fill path, a gas dispensing path, a first shut-off valve, a pressure reducer, a fluid flow restrictor, a second shut-off valve and a fluid outlet connector. The first shut-off valve is positioned in said gas dispensing path upstream of a pressure reducer. A fluid flow restrictor downstream of the pressure reducer has a fluid flow restriction path configured to restrict the flow of the fluid delivered to the fluid flow restrictor at the delivery pressure to a maximum mass flow rate that is equal to or less than the allowable mass flow rate standard for the hazardous fluid. The second shut-off valve is positioned in said gas dispensing path downstream of said pressure reducer.

Owner:AIR PROD & CHEM INC

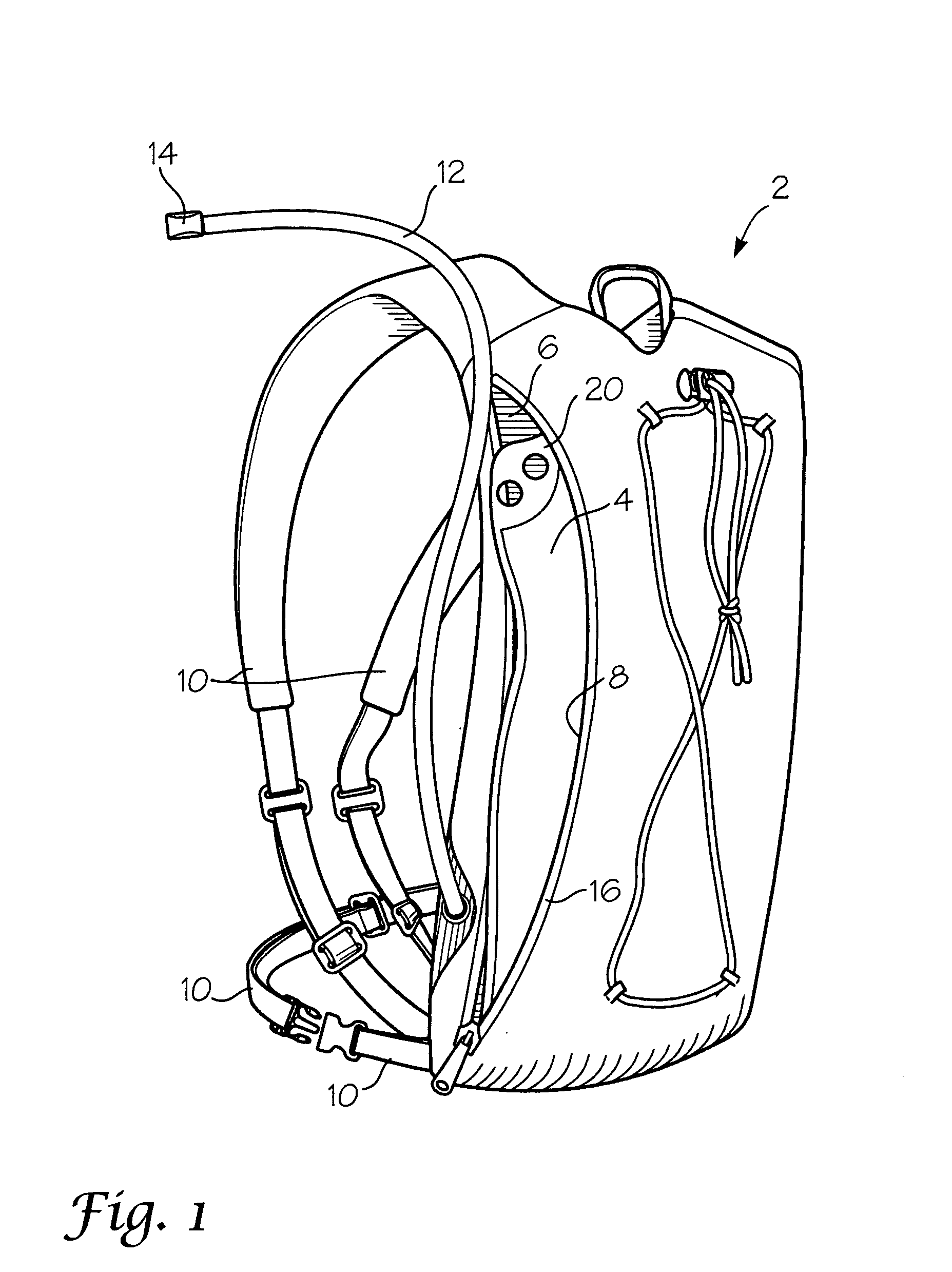

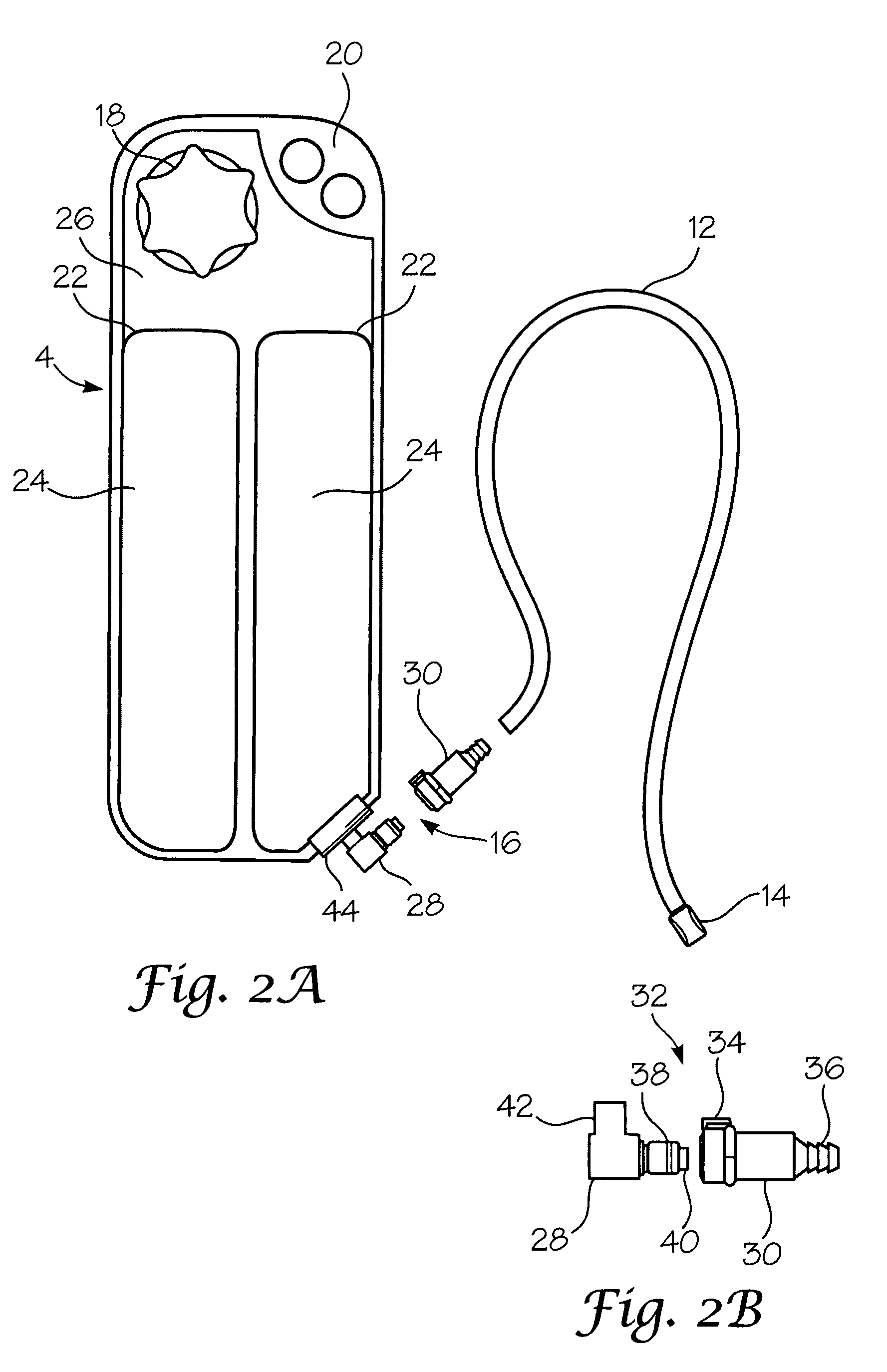

Disposable pouch hydration system

A hydration pouch with a releasable coupling is disclosed. In one embodiment, the hydration pouch is a flexible bag or pouch with a separate inlet and outlet. A hose or tube is provided for a user to draw refreshment from the pouch. A bite valve is provided at one end of the tube to be actuated by a user's teeth. A coupling is provided for attaching and detaching at least a portion of the hose at an opposite end of the hose. The coupling includes a shutoff or check valve that maintains the patency of the pouch when the hose is disconnected. In an alternative embodiment prefilled, disposable hydration pouches are removably coupled to the hose and then disposed and replaced following consumption of the liquid contained therein.

Owner:VISTA OUTDOOR OPERATIONS

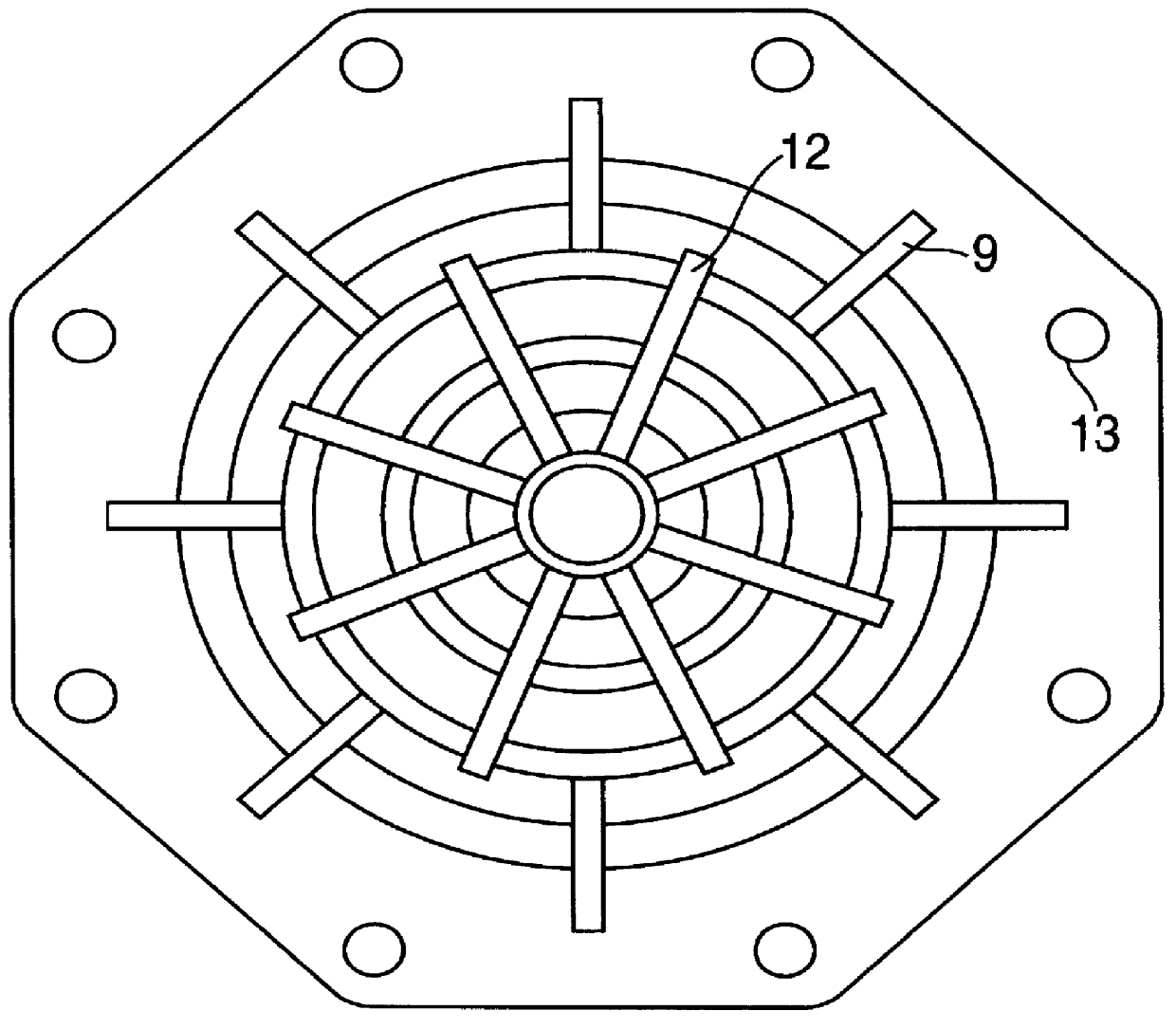

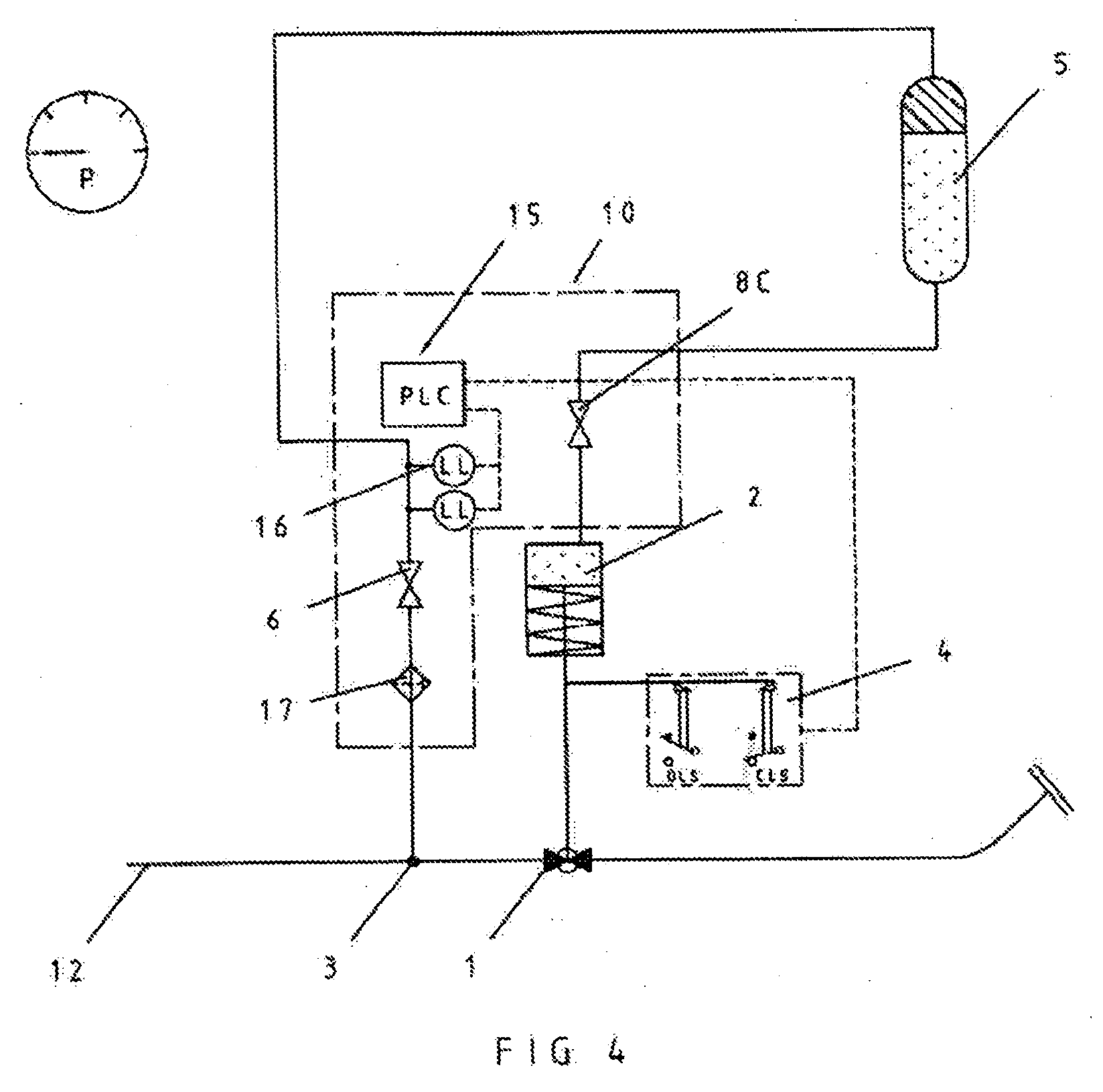

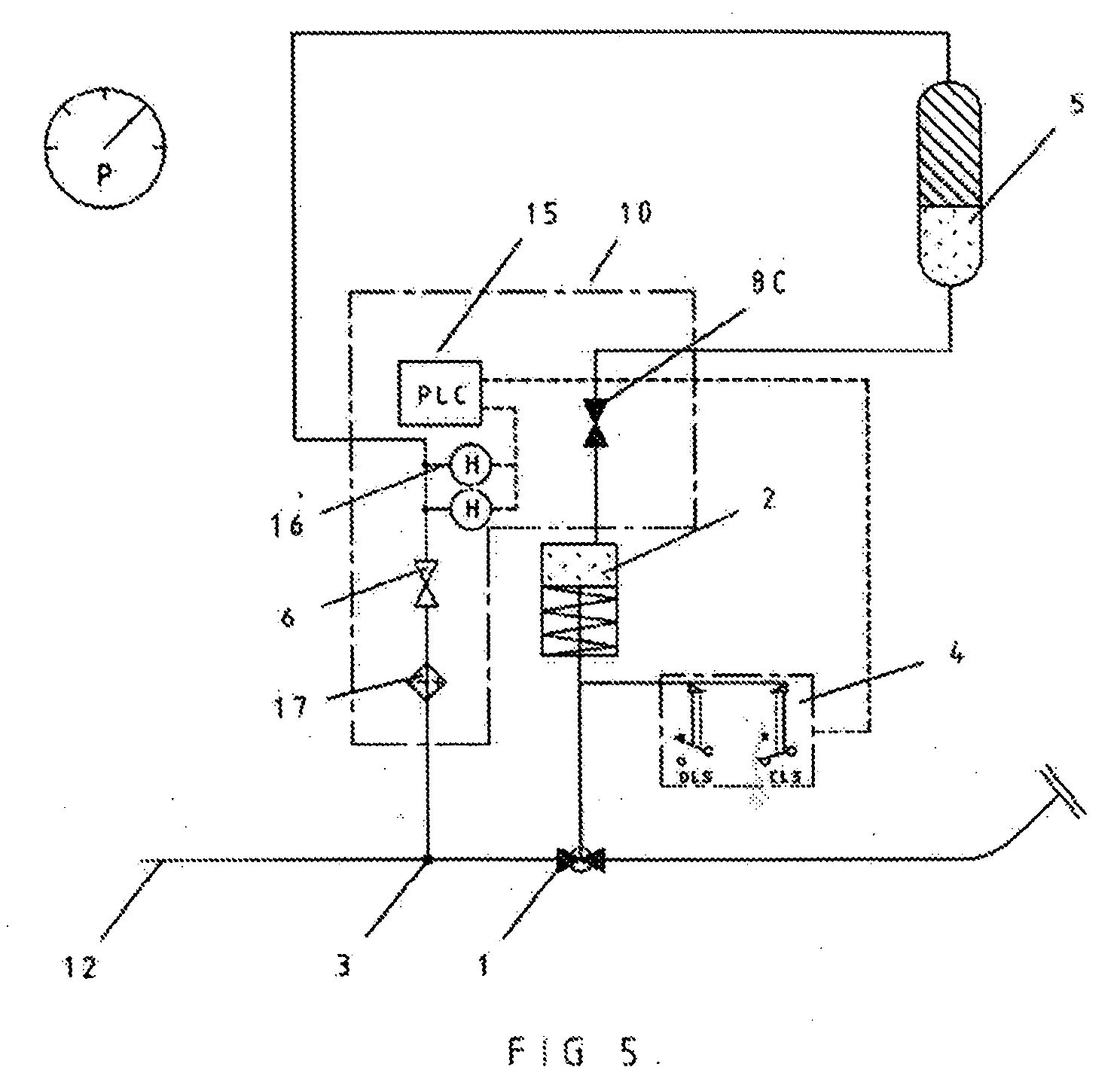

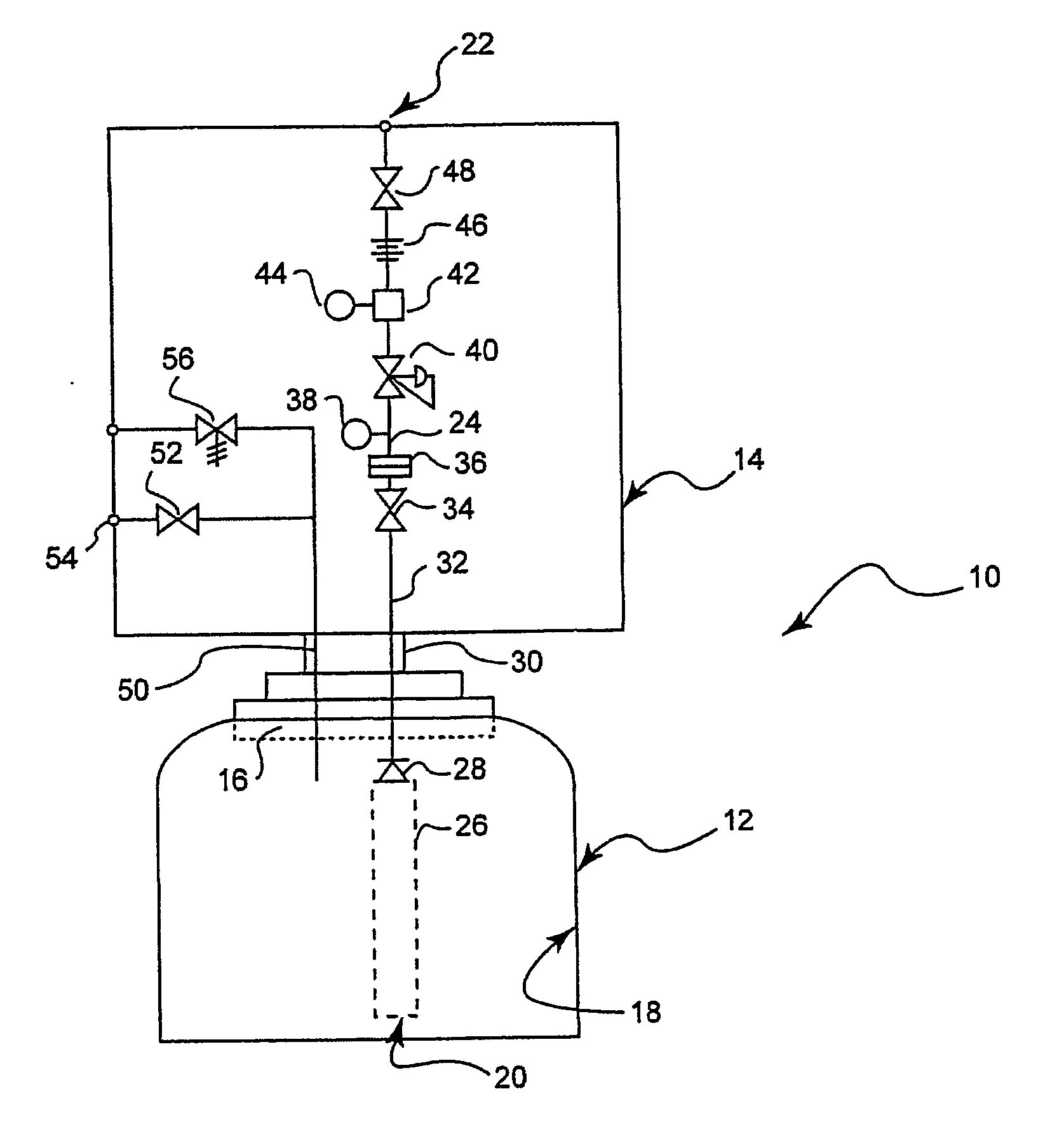

Autonomous Shut-Off Valve System

InactiveUS20090126798A1Little maintenanceLittle attendanceOperating means/releasing devices for valvesServomotor componentsValve actuatorEngineering

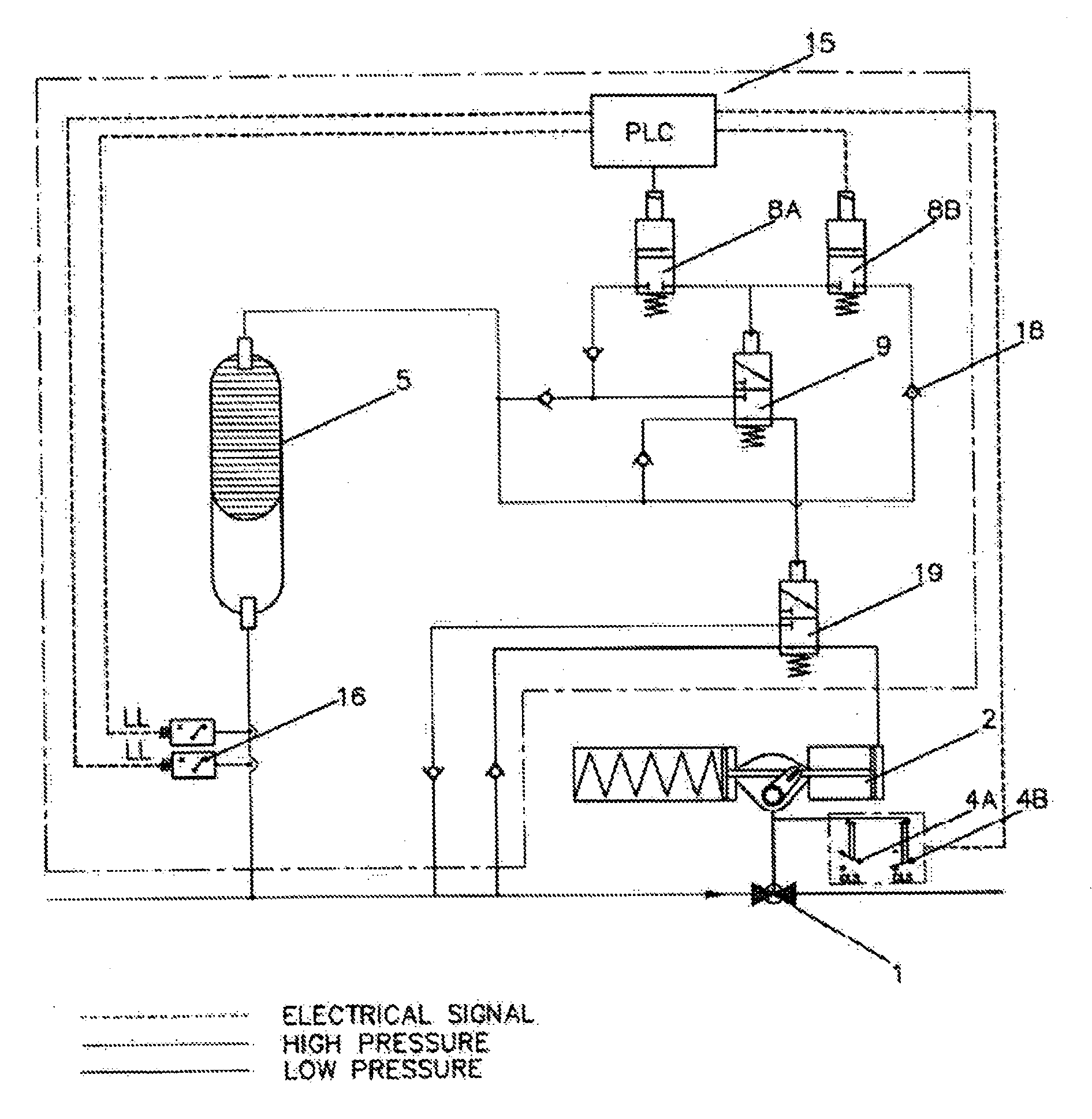

A pipeline (12) for the transportation of a process fluid comprises an autonomous shut-off valve system comprises a shut-off valve (1) including a fluid powered valve actuator (2) moveable between a closed and an open position by means of pressure generated by the process fluid, a pressure tapping (3) in the pipeline upstream of the shut-off valve, a fluid connection to the pressure tapping arranged to deliver process fluid to power opening of the said shut-off valve, at least one pressure sensor (16) arranged in a hydraulic line extending from the pressure tapping, at least one control valve (8A, 8B, 8C) operable to permit or prevent flow of pressurised fluid to the shut-off valve actuator; and a controller (15) arranged to open and close the control valve. The control valve is commanded to open and close when pressure thresholds are reached, the pressure thresholds being detected by the pressure sensor and the control valve being commanded to close by the controller.

Owner:MATHER SAM

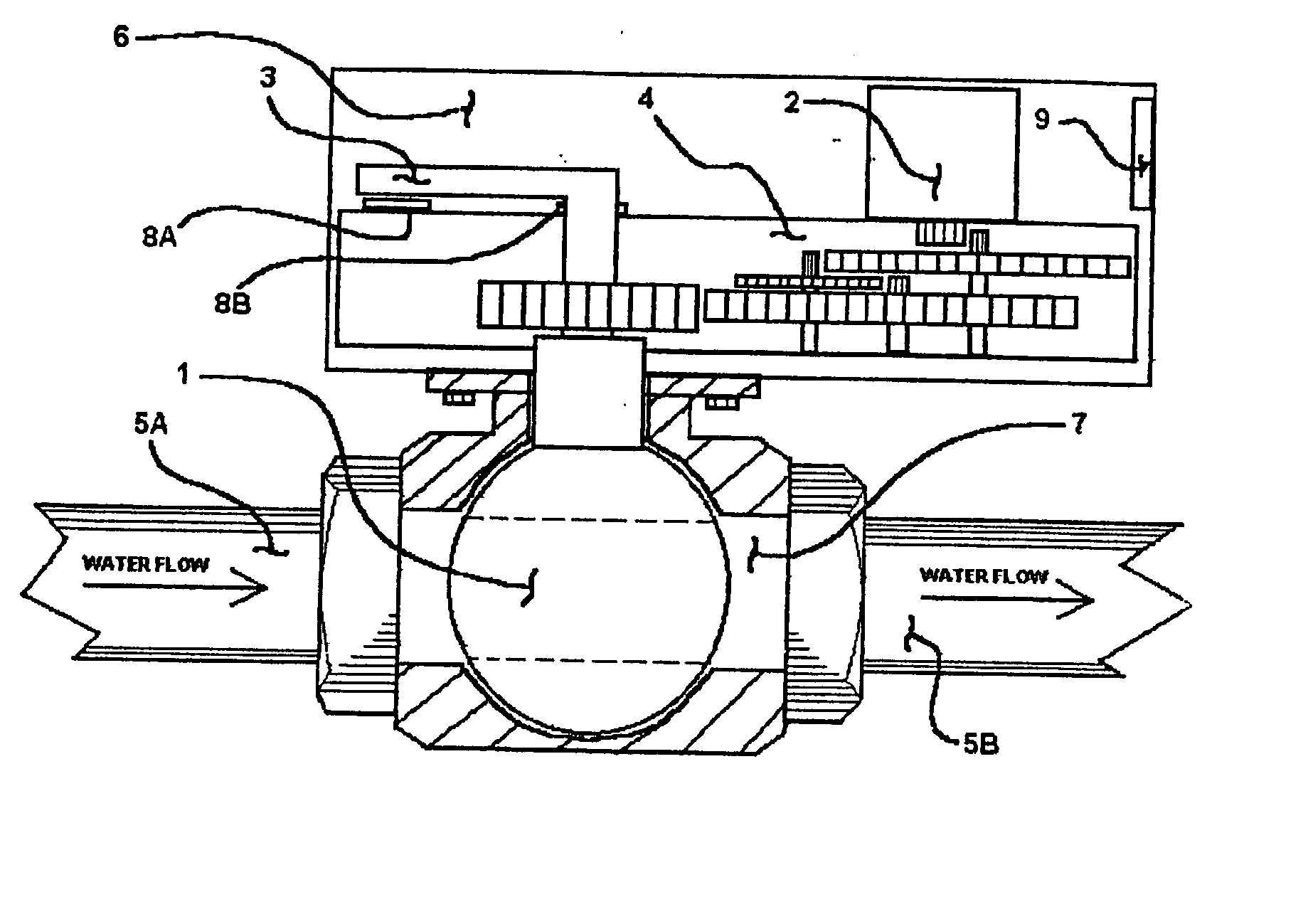

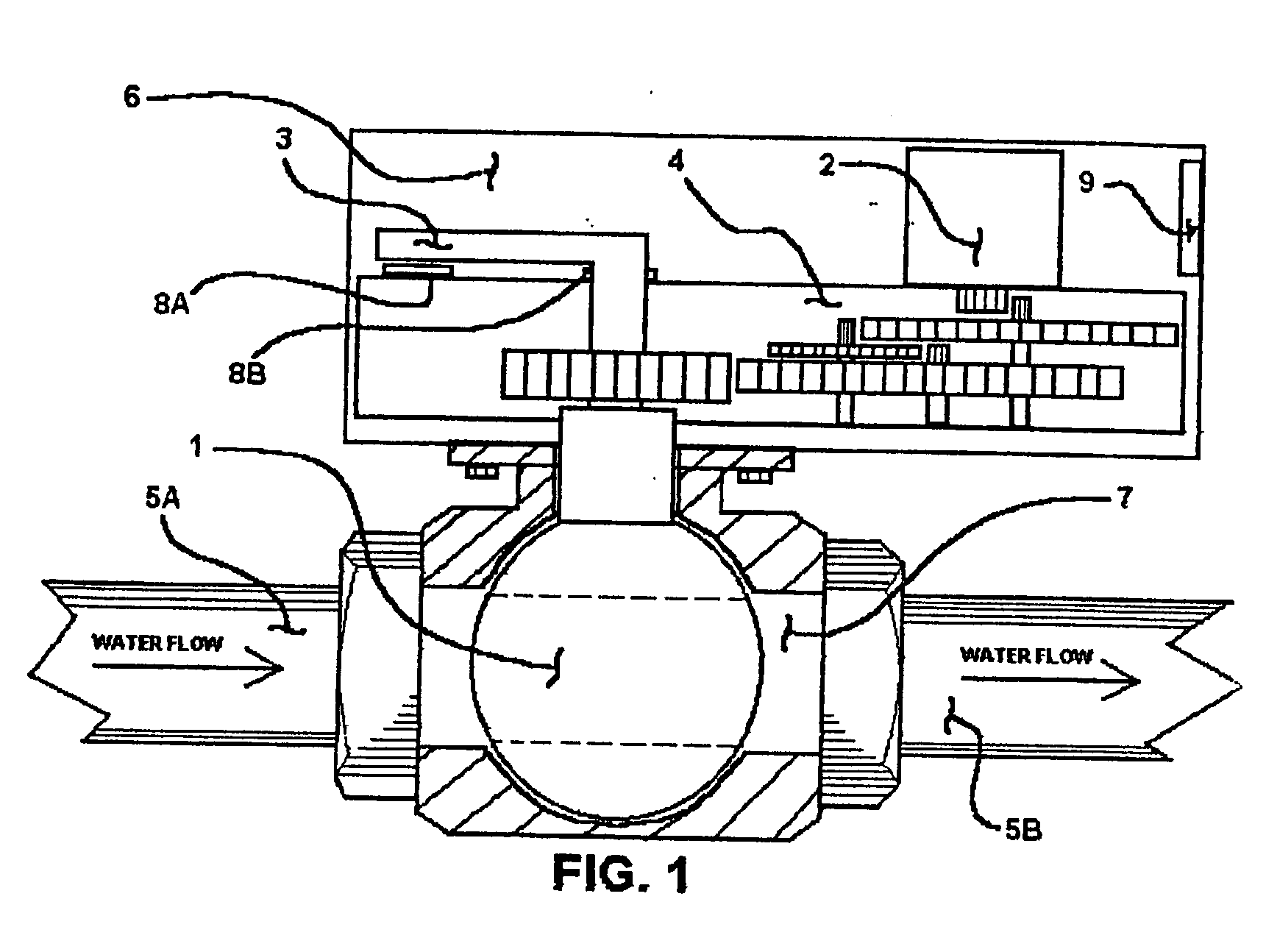

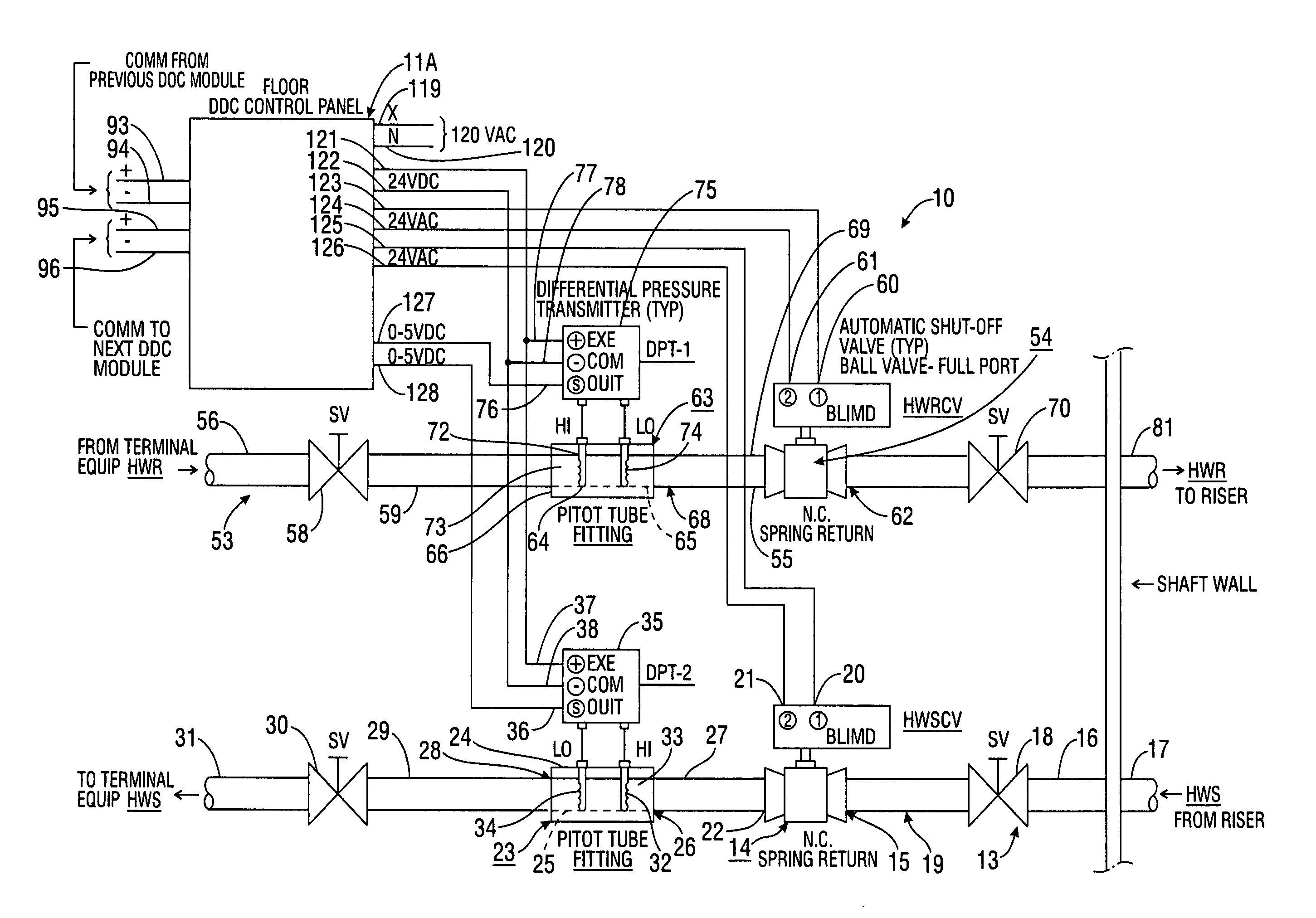

Water leak detection and shut-off method and apparatus using differential flow rate sensors

InactiveUS8749393B1Minimize damageMinimize injuriesDetection of fluid at leakage pointMeasurement of fluid loss/gain rateEngineeringWater leak

A method and apparatus for detecting leakage of flowing liquids from pipes includes an upstream flow-rate sensor positioned between a source of a flowing liquid which is conducted from a source to a destination terminal such as a VAV heat exchanger, and a downstream flow-rate sensor positioned between an outlet port of the destination terminal and a return line for the flowing liquid. The apparatus includes electronic control circuitry which is responsive to a differential flow-rate between upstream and downstream measured flow rates which exceeds a predetermined limit value in removing a valve-opening signal to the upstream shut-off valve, thus closing the valve to interrupt flow of liquid through the valve if the differential flow-rate signifies a leak. Optionally, the apparatus also includes a downstream shut-off valve positioned between the destination terminal and a return line, which is also closed in response to a differential flow-rate exceeding the limit value.

Owner:CONTROL AIR CONDITIONING

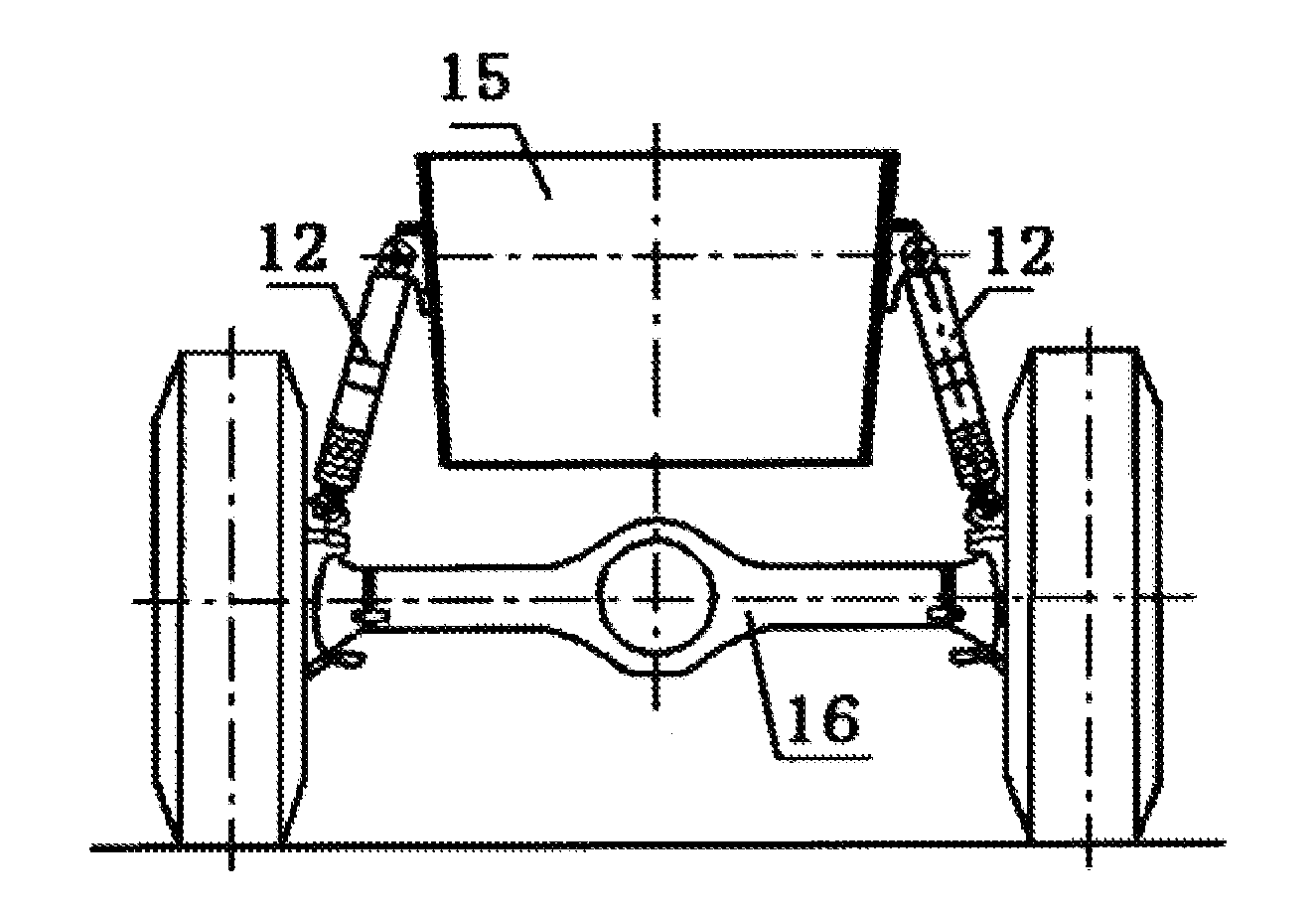

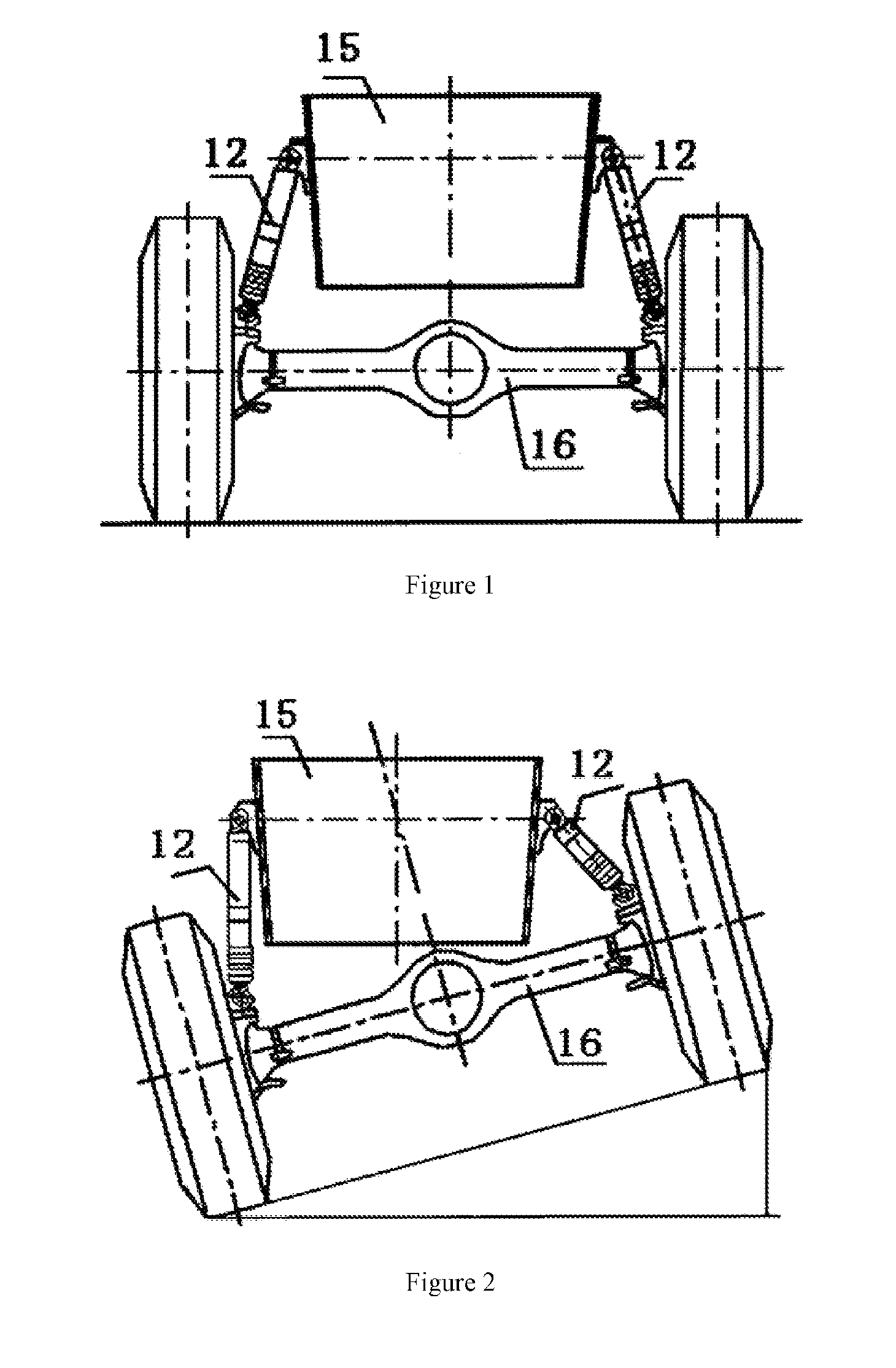

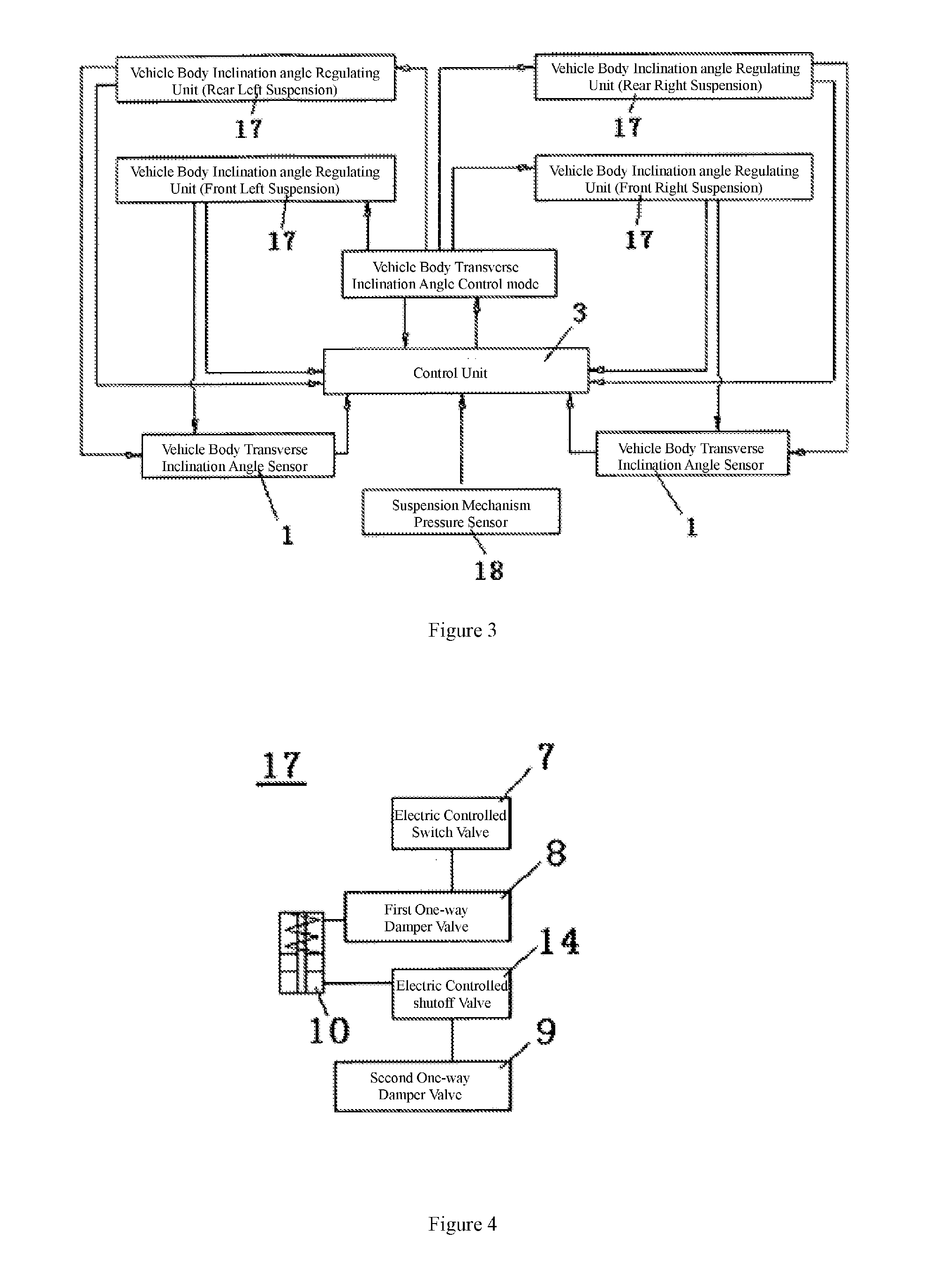

Vehicle body inclination-angle regulating uint, hydropneumatic suspension mechanism and mobile crane

InactiveUS20130220110A1Improve securityIncrease dynamicsServomotor componentsInterconnection systemsHydropneumatic suspensionFuel tank

A vehicle body inclination angle regulating unit (17) includes a balancing oil cylinder (10). One chamber of the balancing oil cylinder (10) is connected with an oil tank (5) and an oil source for leveling operation via a first one-way damper valve (8) and an electric controlled switch valve (7), and the other chamber of the balancing oil cylinder (10) is connected with a non-rod chamber of a suspension oil cylinder via an electric controlled shutoff valve (14) and a second one-way damper valve (9). In addition, an automatically-leveling hydropneumatic suspension mechanism includes at least two pairs of suspension oil cylinders (12), vehicle body inclination angle regulating units (17), a vehicle body transverse inclination angle sensor (1) and a control unit (3). Each suspension oil cylinder (12) is correspondingly provided with the vehicle body inclination angle regulating unit (17) including the balancing oil cylinder (10). The present invention realizes effectively dynamic leveling function of different road conditions, especially transverse slopes, of the mobile crane. The mobile crane is provided with simple operation that are all automatically performed by the control unit, which improves driving safety remarkably and prevents an accident of vehicle overturning.

Owner:ZOOMLION HEAVY IND CO LTD +1

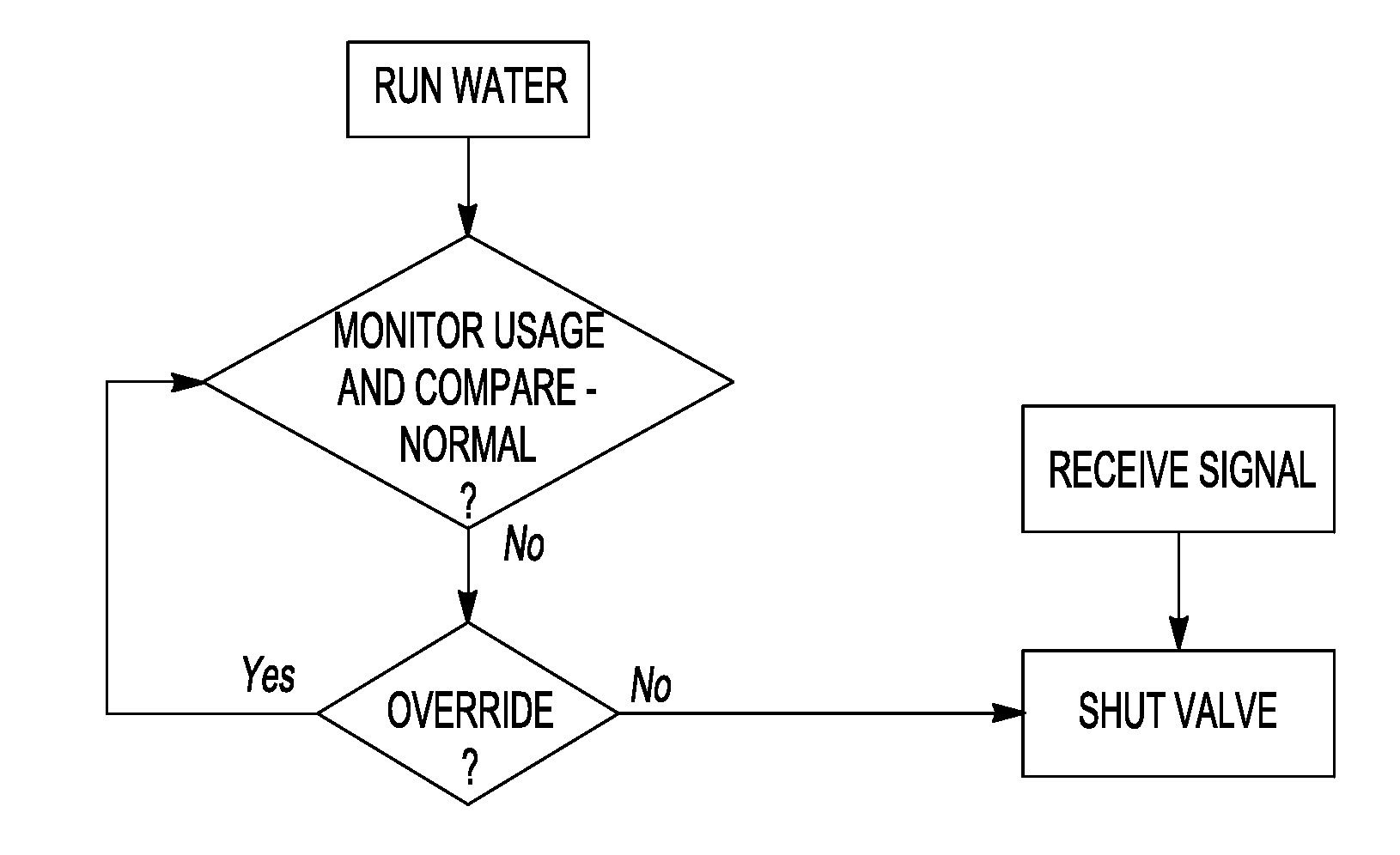

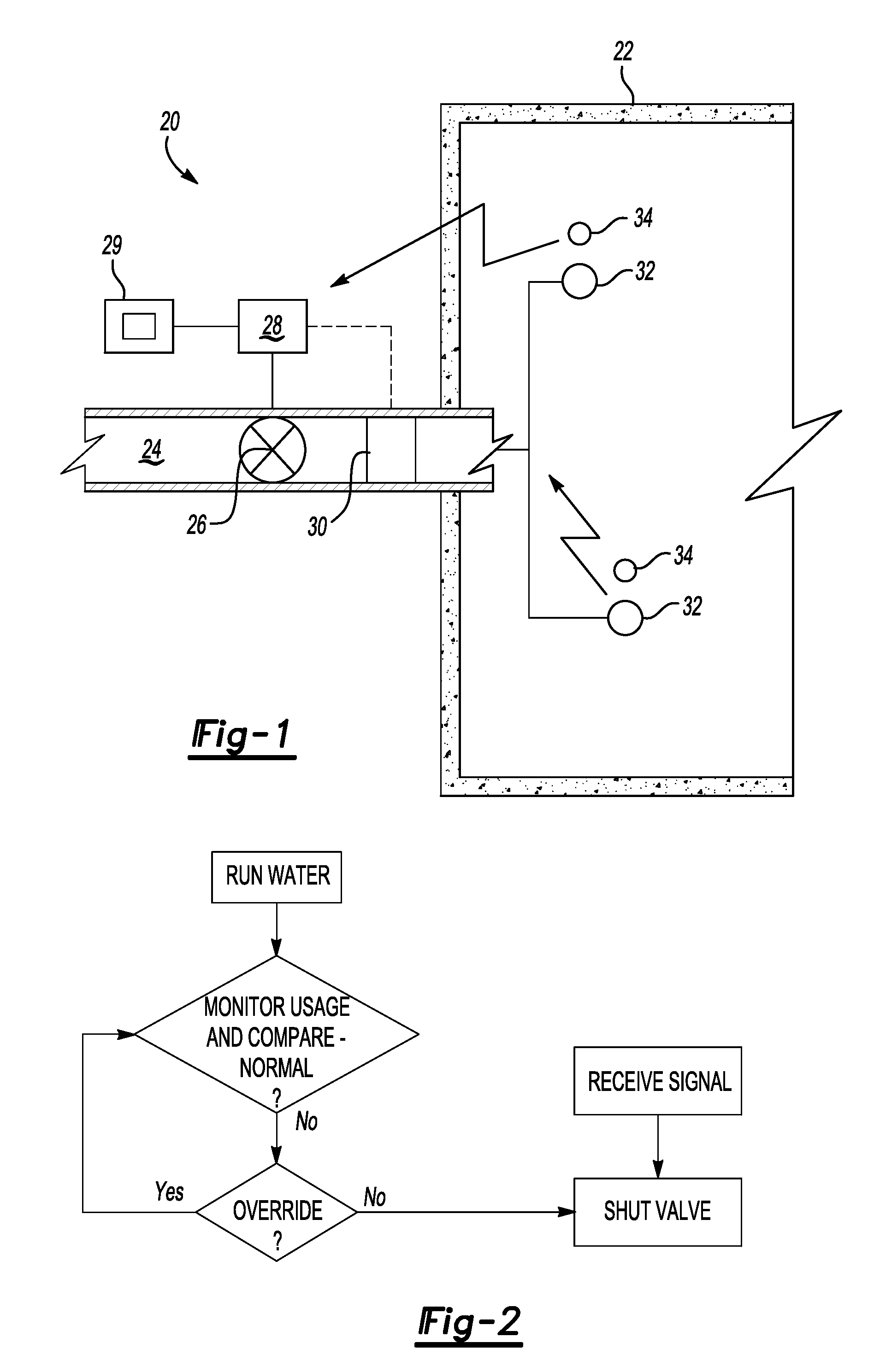

Water leakage and fault sensing system

A system is provided for monitoring leakage within a building. Remote sensors are placed at locations that are likely to have leaks occurring. If a leak is detected by one of the remote sensors, a signal is sent to a control for a main shut-off valve. The main shut-off valve is placed on the main water supply line leading into the building. Further, a flow meter is placed on the main water supply line. The flow meter monitors water being delivered into the building, and should an abnormal water flow be detected, the control will close the shut-off valve. The flow meter and control may learn normal water usage patterns for the building, or the patterns may be pre-programmed into the system. A manual override allows the control to be bypassed when it is intended for a large volume of water to be moved into the building, such as when a swimming pool is filled, etc.

Owner:MASCO CORP

No-spill, vapor-recovery, container spout

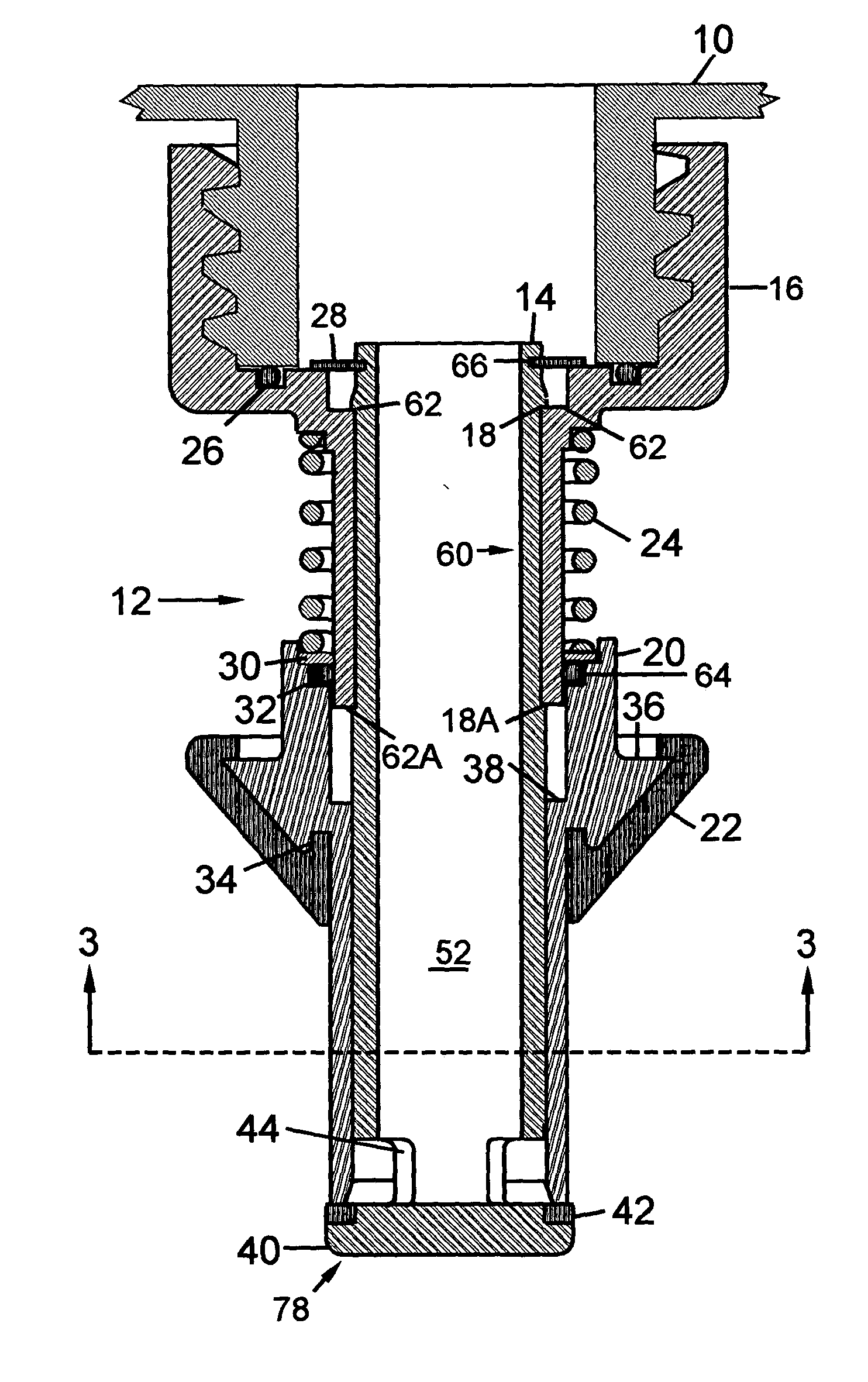

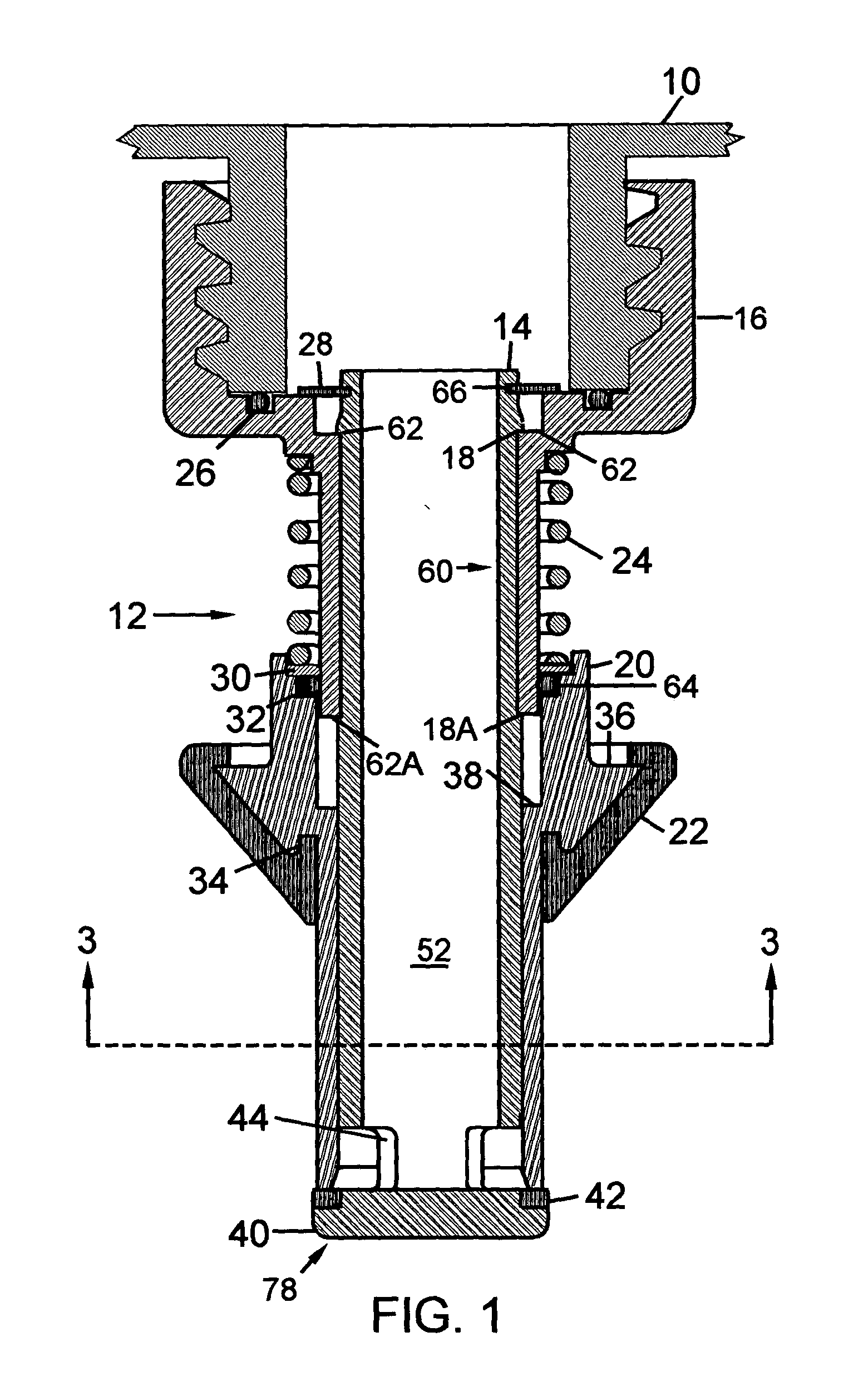

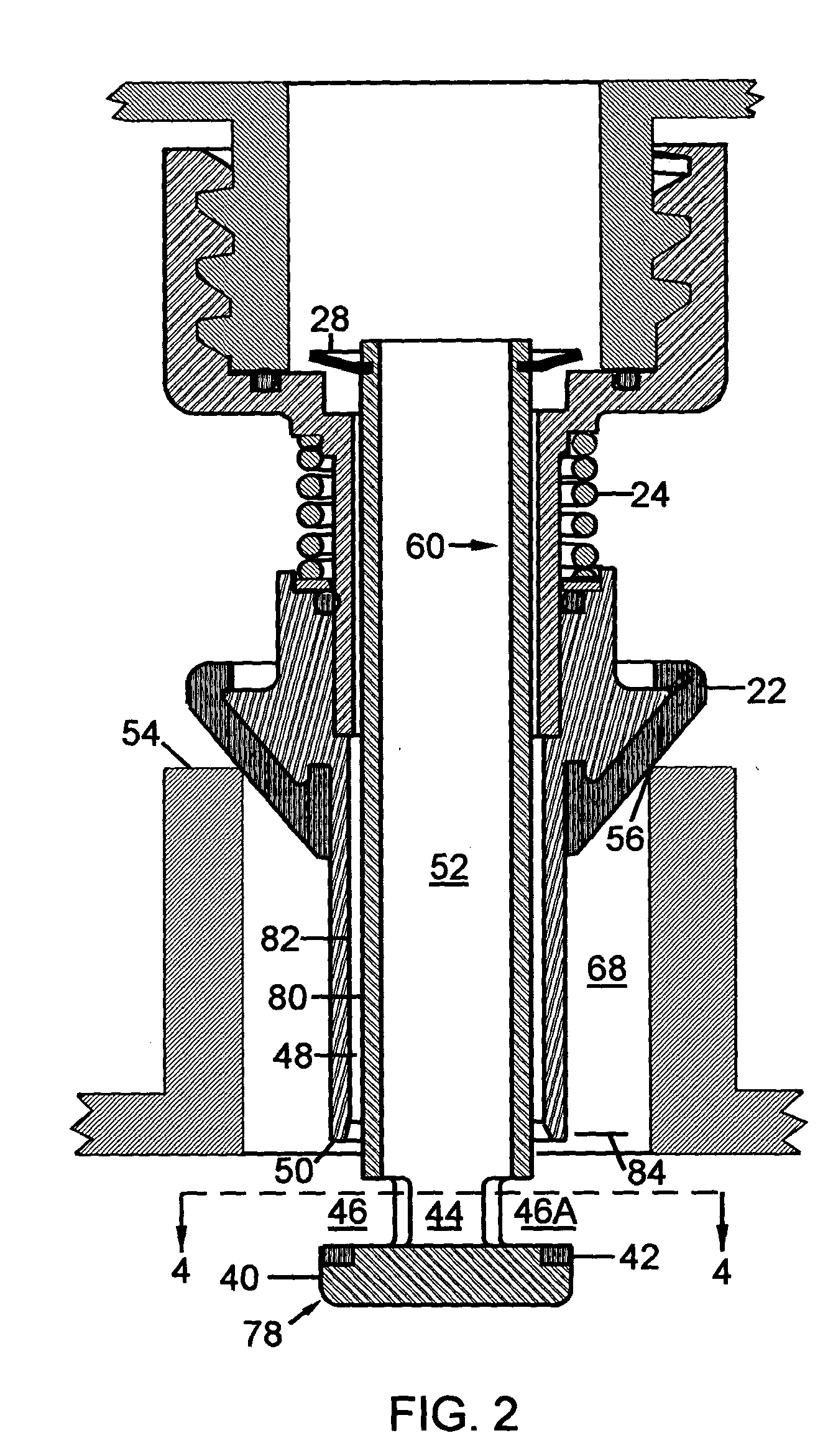

A no-spill, automatic-shutoff, vapor-recovery spout (12) for transmitting a volatile liquid, such as fuel, from a container (10) into a tank. The spout comprises a structure having one end connected to and sealed to said container (10), and a second end to be inserted into, and forming a tank seal (56) with, the opening (54) of said tank. The spout includes a conduit (52) which conducts said fuel from said container through said tank seal into said tank, and a second conduit (48) which conducts vapor and air, in the opposite direction, through said tank seal from said sealed tank into the container. Said tank seal is in the form of a cone-shaped collar integral with a spring biased sliding sleeve (20), with the smaller end of said cone facing said tank opening, and having a smooth, continuous, and resilient sealing surface. The cone-shaped collar fits into and seals the range of tank opening diameters normally used with off-road, internal combustion engines. Said sliding sleeve includes, at its distal end, a valve seat (50) which normally doses against a shutoff valve (78) while transmitting the biasing load to the valve head (40). When said sliding sleeve with its tank sealing surface (22) is pushed into the tank opening, the biasing load is transferred to the tank opening (54) forming a tight tank seal (56) isolating the tank from the atmosphere and opening the shutoff valve. Fuel flows from the container through the fuel conduit (52) into the tank and the vapor and air, being displaced by the incoming fuel, flows through the vapor / air conduit (48) into the container. When the fuel reaches a predetermined level in the tank it blocks the entrance to the vapor / air conduit (48), trapping the vapor and air remaining in the tank, where it is compressed by the head of fuel remaining in the container. A pressure balance is thus established between said tank and said container, automatically causing said fuel to stop flowing. Lifting said spout and said tank seal from said tank opening automatically transfers said biasing spring load back to said shutoff valve head dosing said valve simultaneously with the removal of said tank seal.

Owner:FLORENCE E ALLEN SUCCESSOR TRUSTEE OF THE CLIFFORD H ALLEN TRUST DATED JULY 22 1998

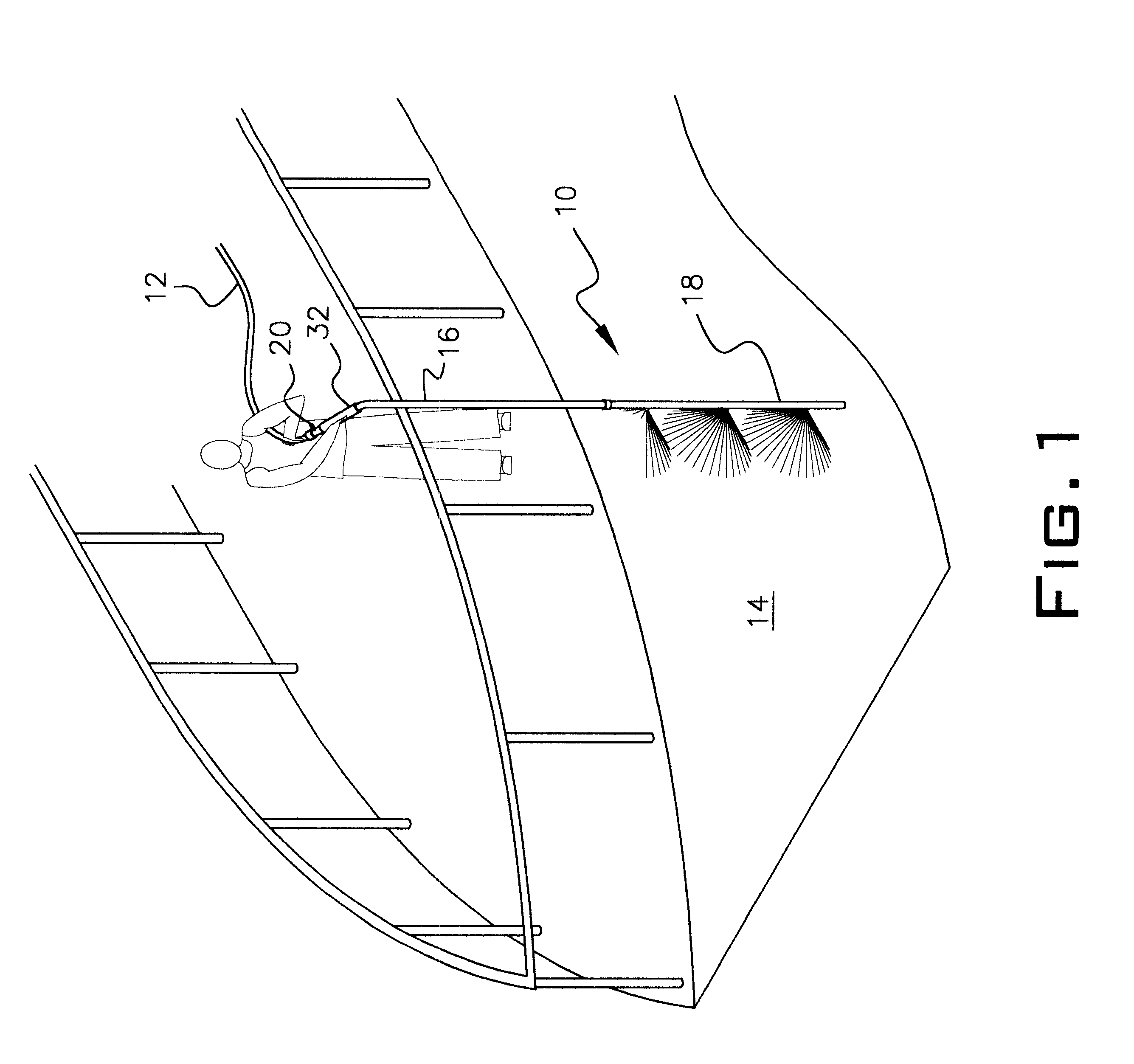

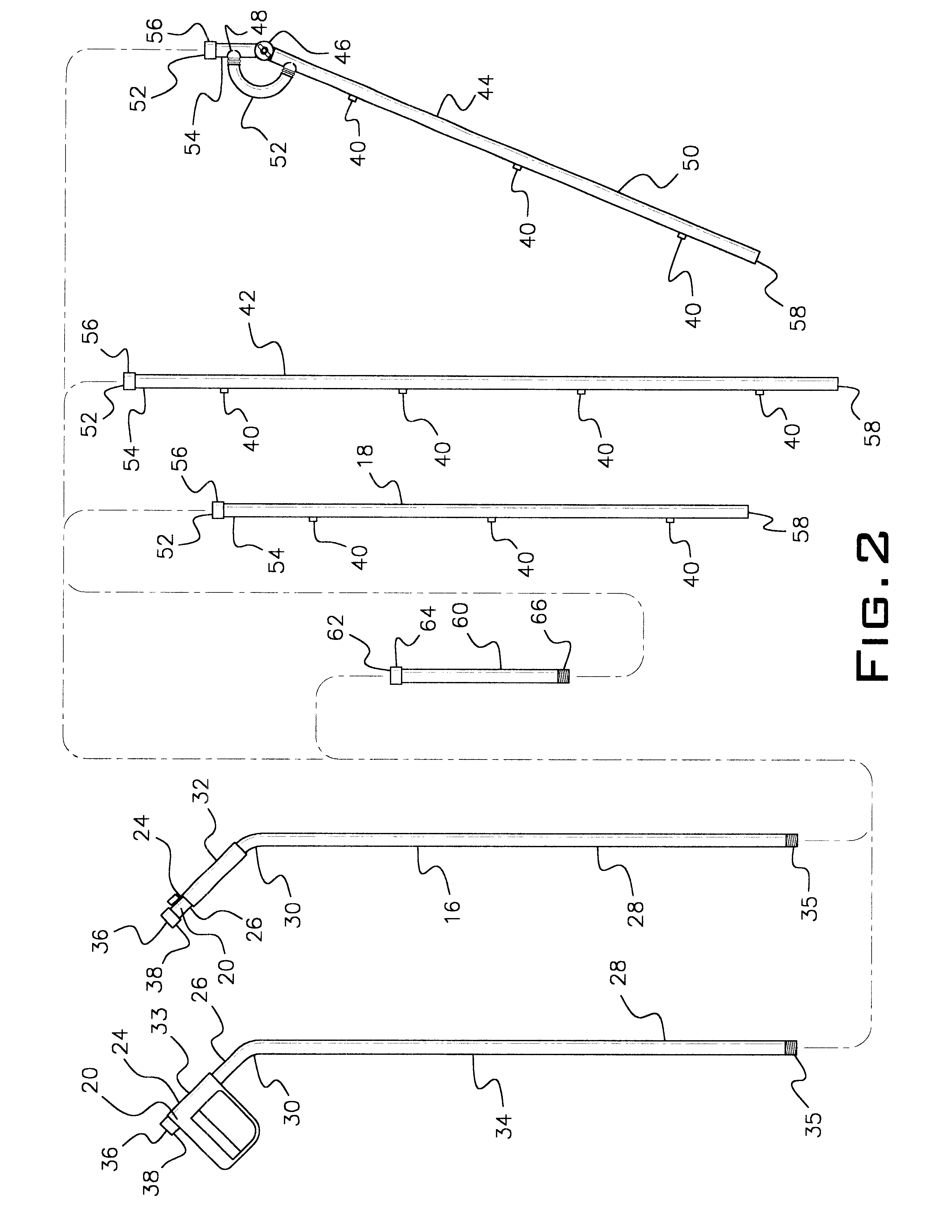

Spray wand for cleaning boat hulls

InactiveUS6378791B1Quickly and easily and thoroughly cleanVessel cleaningHullsWater sourceSpray nozzle

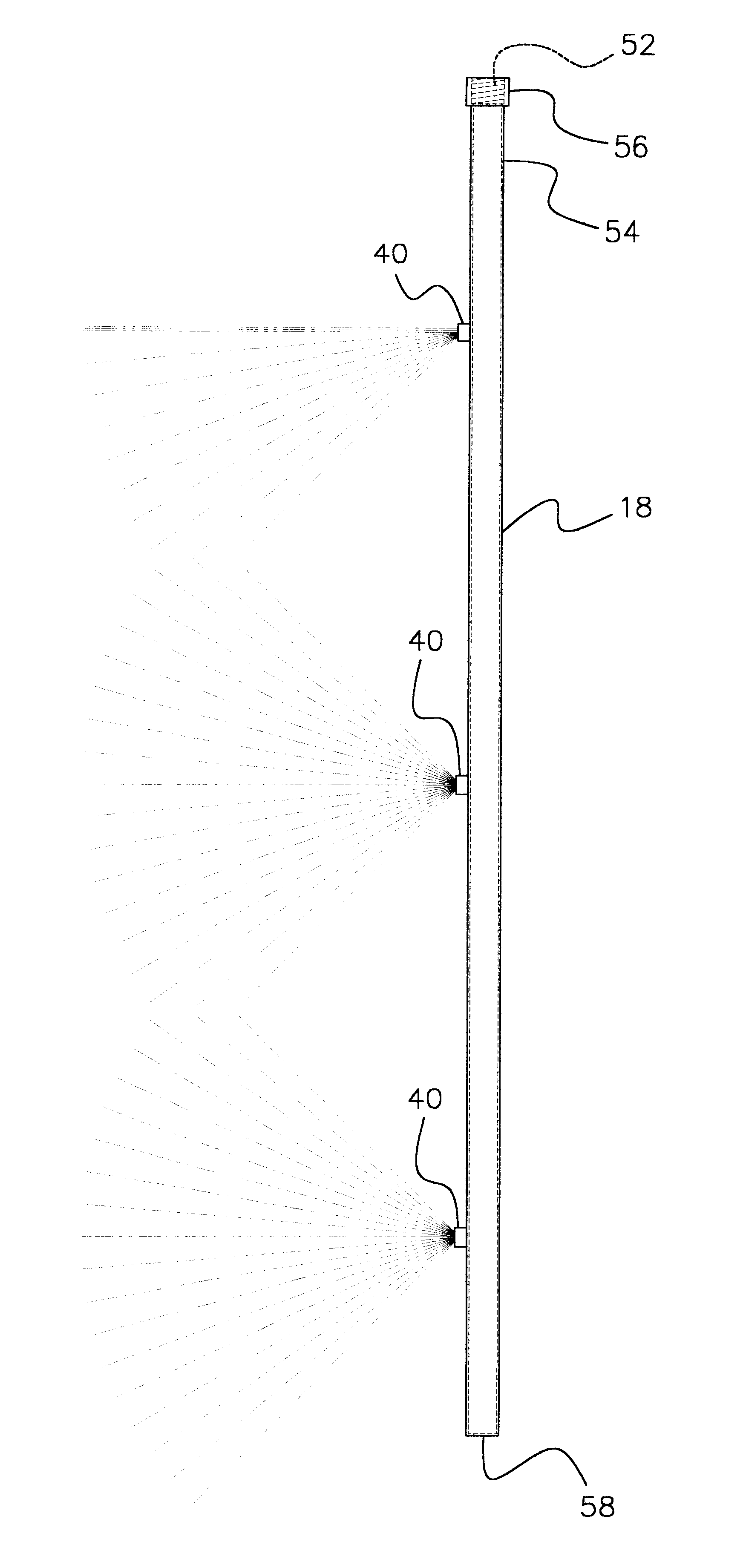

A water spray device for cleaning the hull of a boat is disclosed. The spray device includes a handle and wand portion. The handle portion has an angled portion separating an upper and lower part, a channel formed through the handle and a top and bottom open end. The top end engages a hose connected to a water source. A shut-off valve is disposed within the handle channel proximal to the top end. The wand portion is an elongated tube having an channel formed therein, an open top end for engaging the handle bottom end, a closed bottom end and a plurality of spray nozzles disposed along the wand. Water enters the handle portion, flows into the wand portion and out the spray nozzles. A user of the novel water spray device simply positions the spray nozzles towards the boat hull from the deck of the boat while holding the spray device and walks around the perimeter of the boat to quickly, easily and thoroughly clean the boat hull.

Owner:PERRY MARVIN WAYNE +1

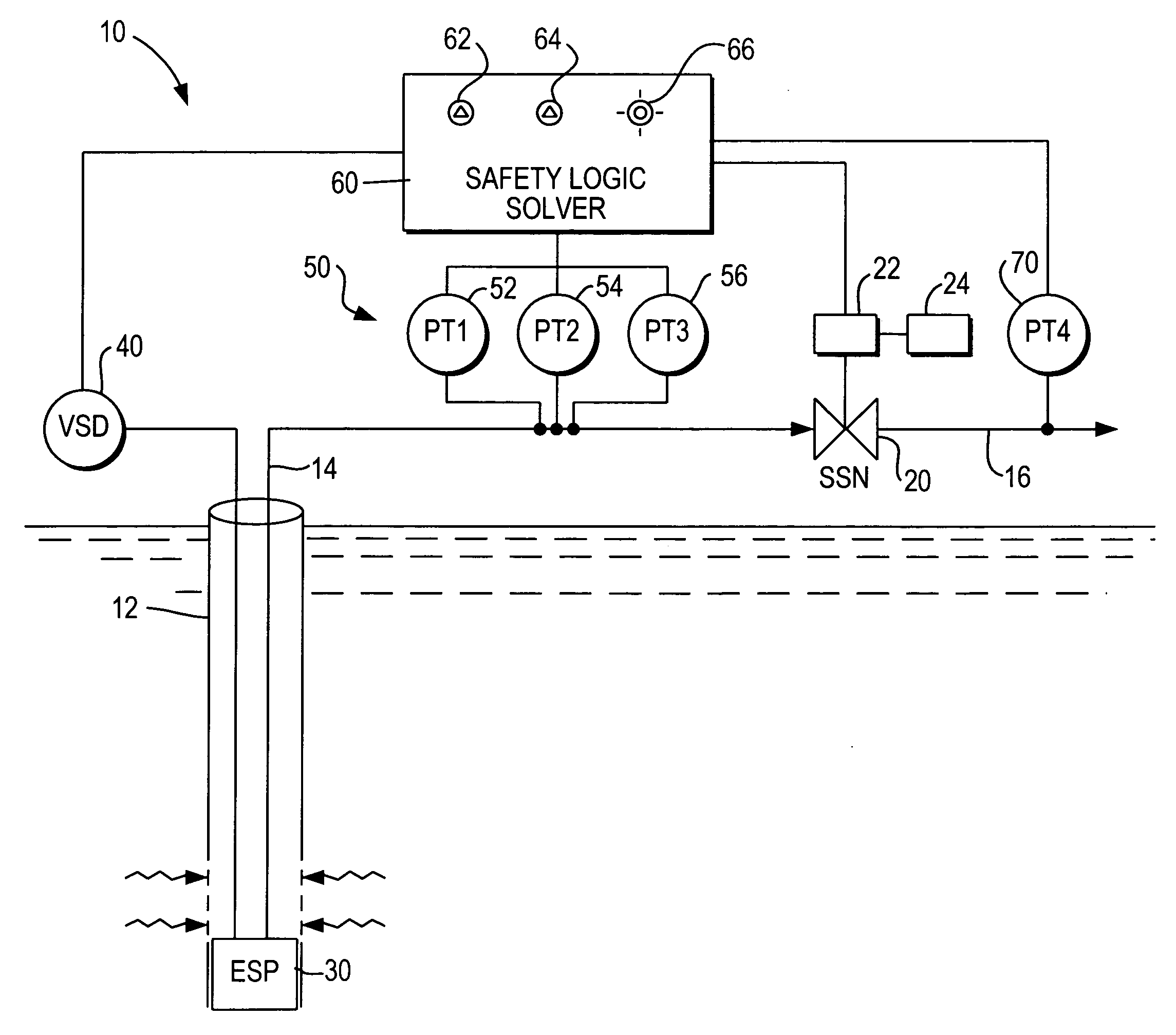

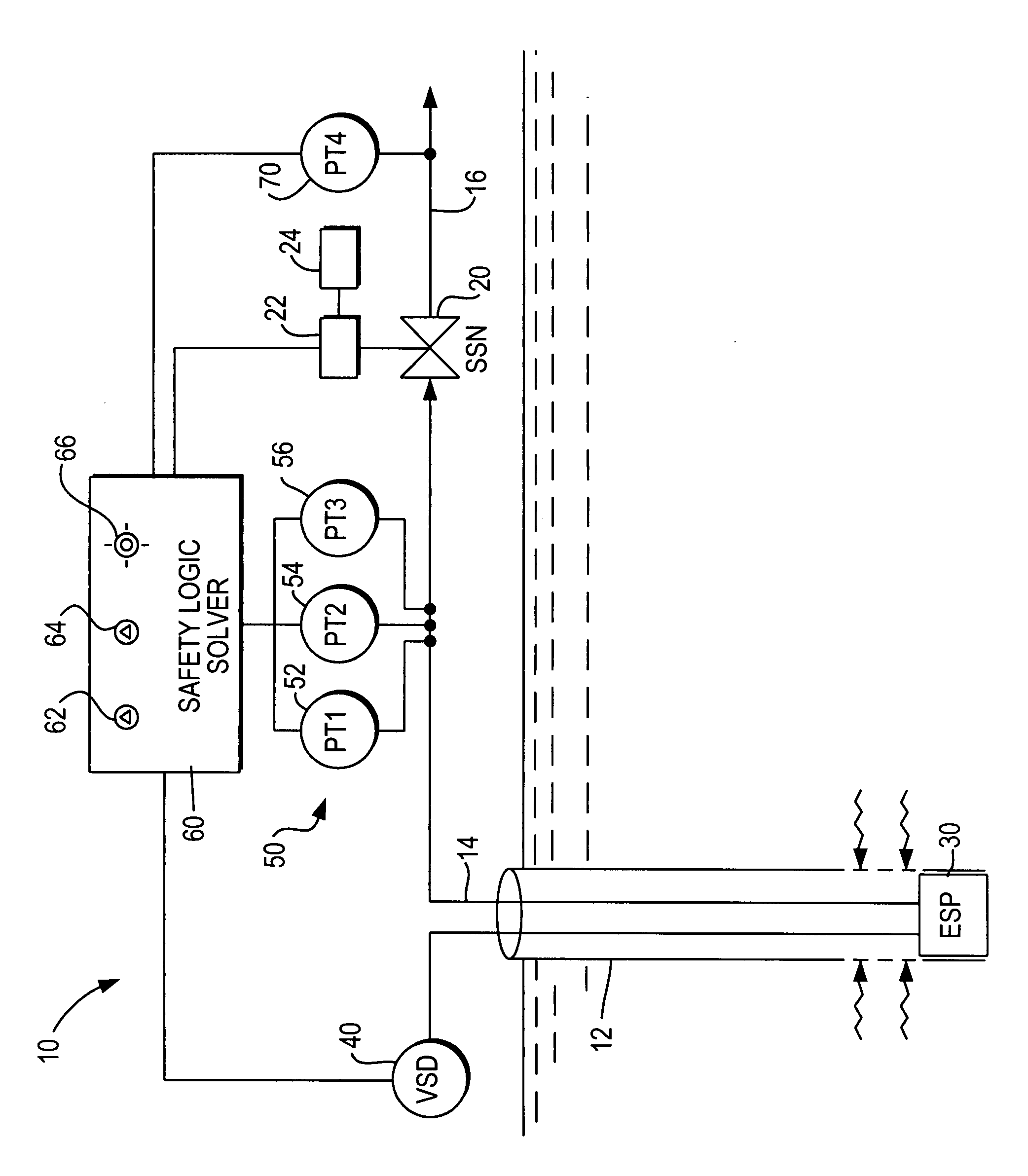

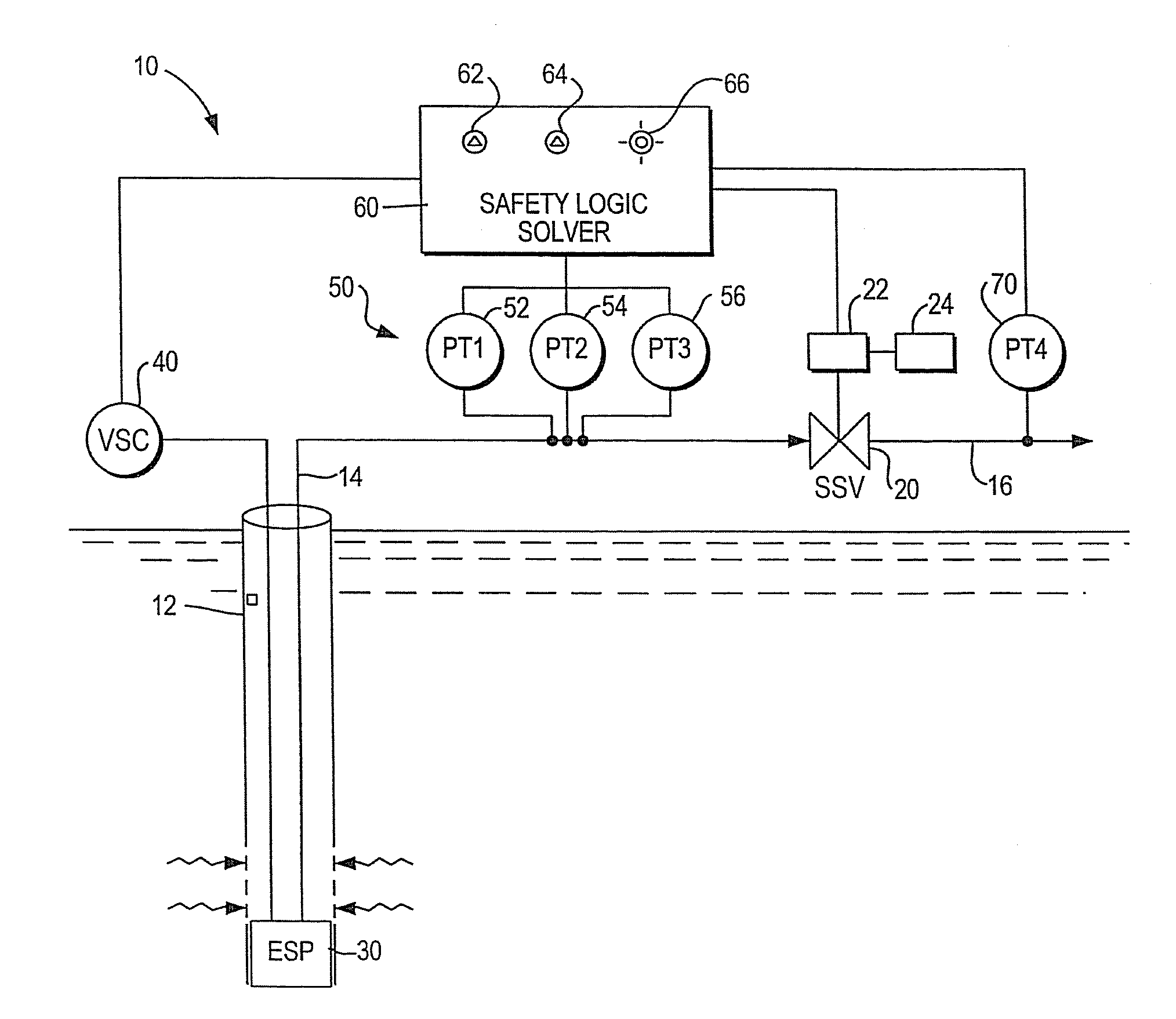

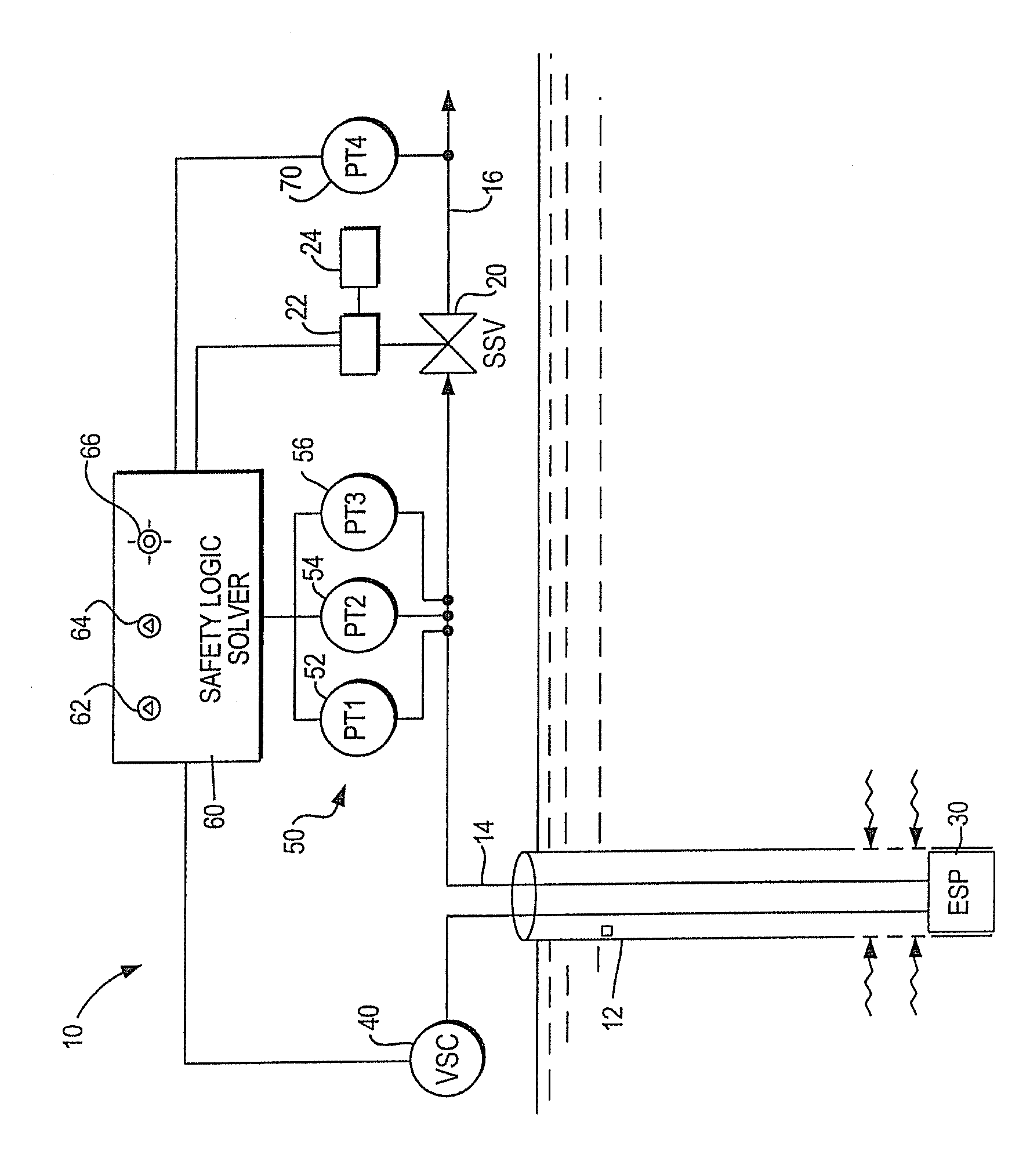

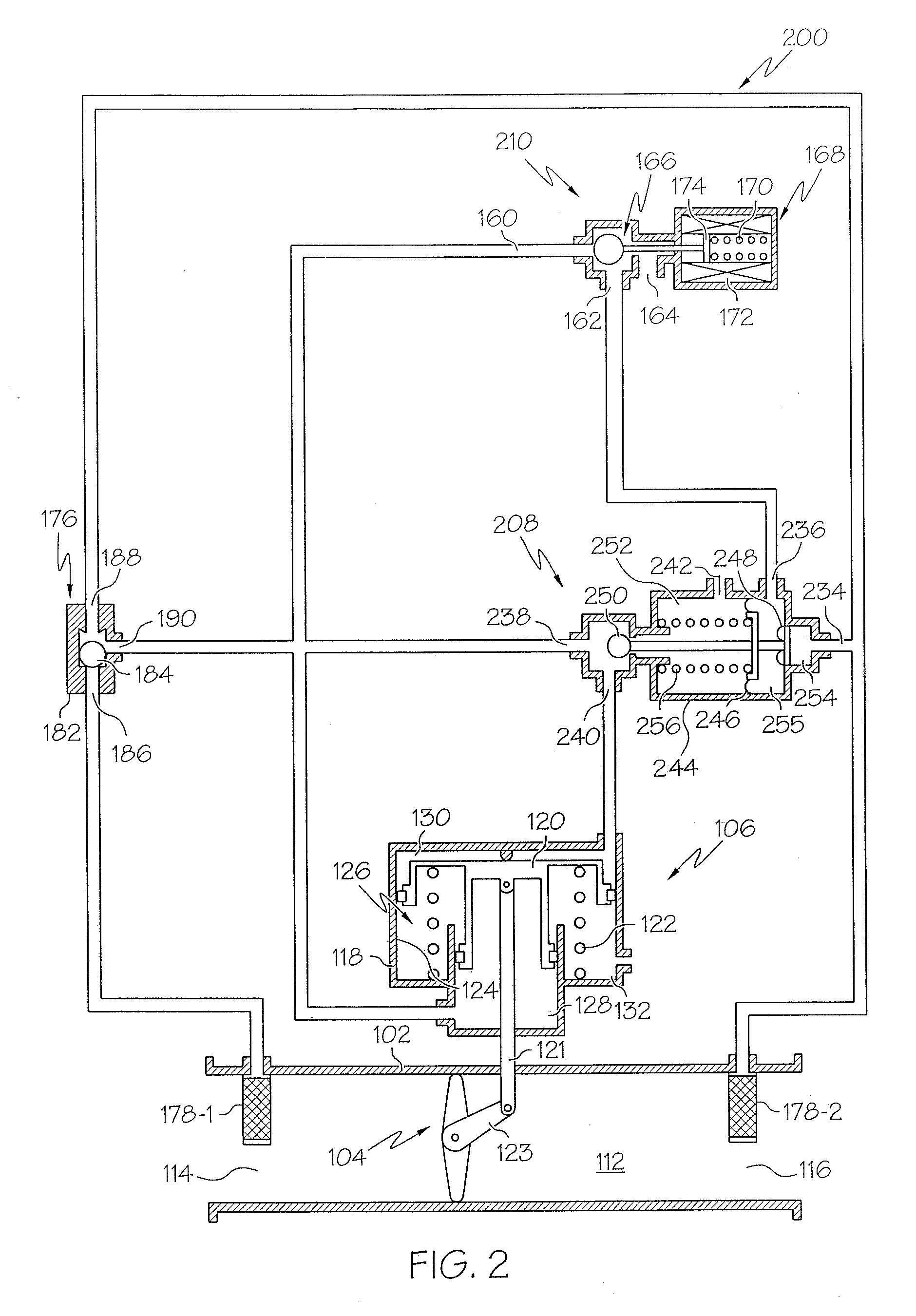

Wellhead flowline protection and testing system with ESP speed controller and emergency isolation valve

An ESP variable speed drive controller functions in conjunction with a safety logic solver, dedicated pressure sensors and a surface emergency isolation valve, or safety shut-off valve (SSV), to perform a full functional test of the complete wellhead flowline system. The method includes the step of using a plurality of pressure transmitters to monitor the flowline pressure during normal operations and during a full stroke test of the safety shutoff valve and adjusting the speed of the downhole ESP during the test to maintain the pipeline pressure within predetermined safe pressure limits. This wellhead flowline protection system and method utilizes the downhole ESP speed controller and an SSV to ensure that dangerous pressure levels are not reached and provides for full functional safety testing of the wellhead system. The ESP motor speed controller is used to permit functional testing and remove the pressure source from protected downstream flowline piping.

Owner:SAUDI ARABIAN OIL CO

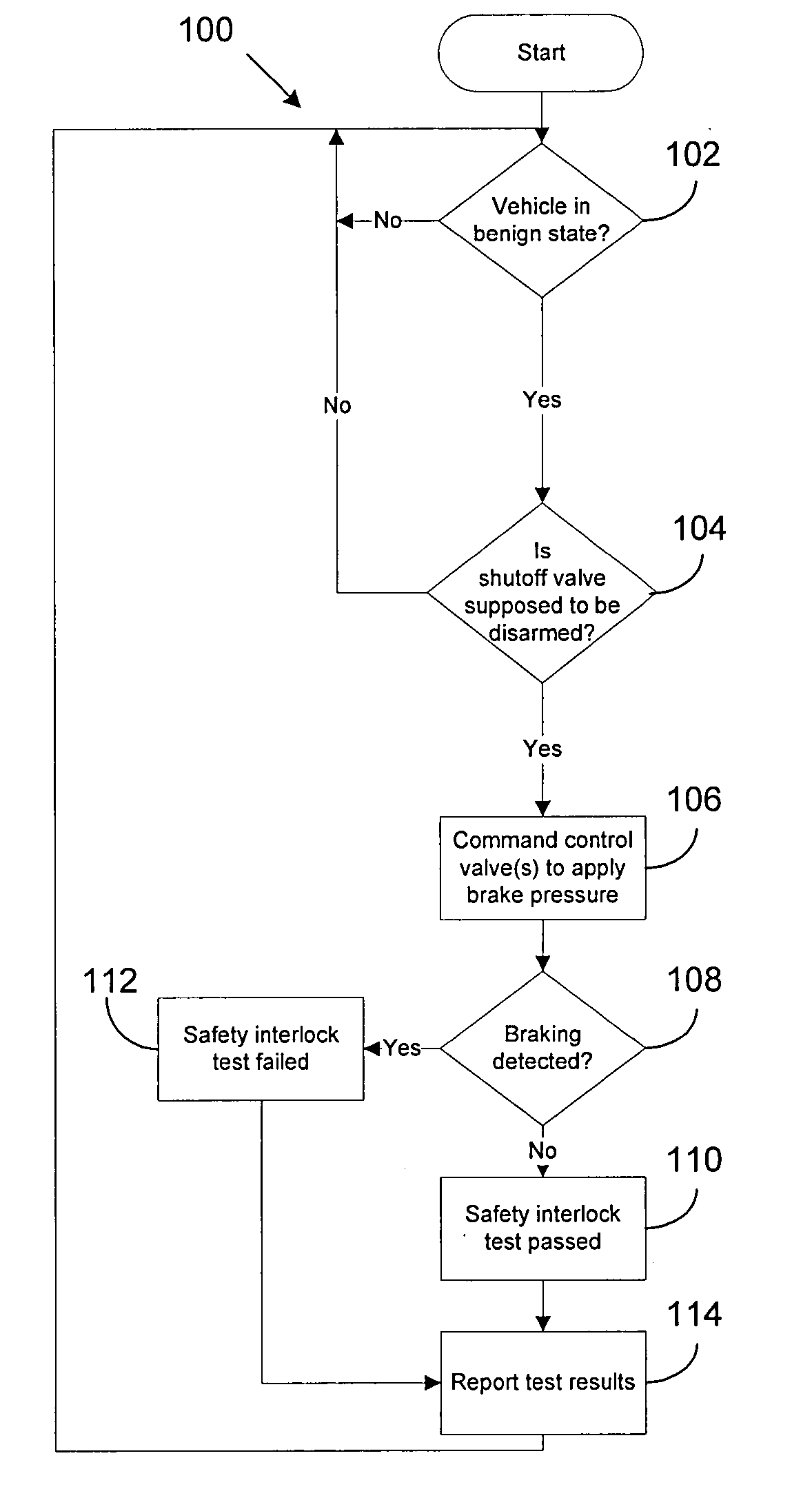

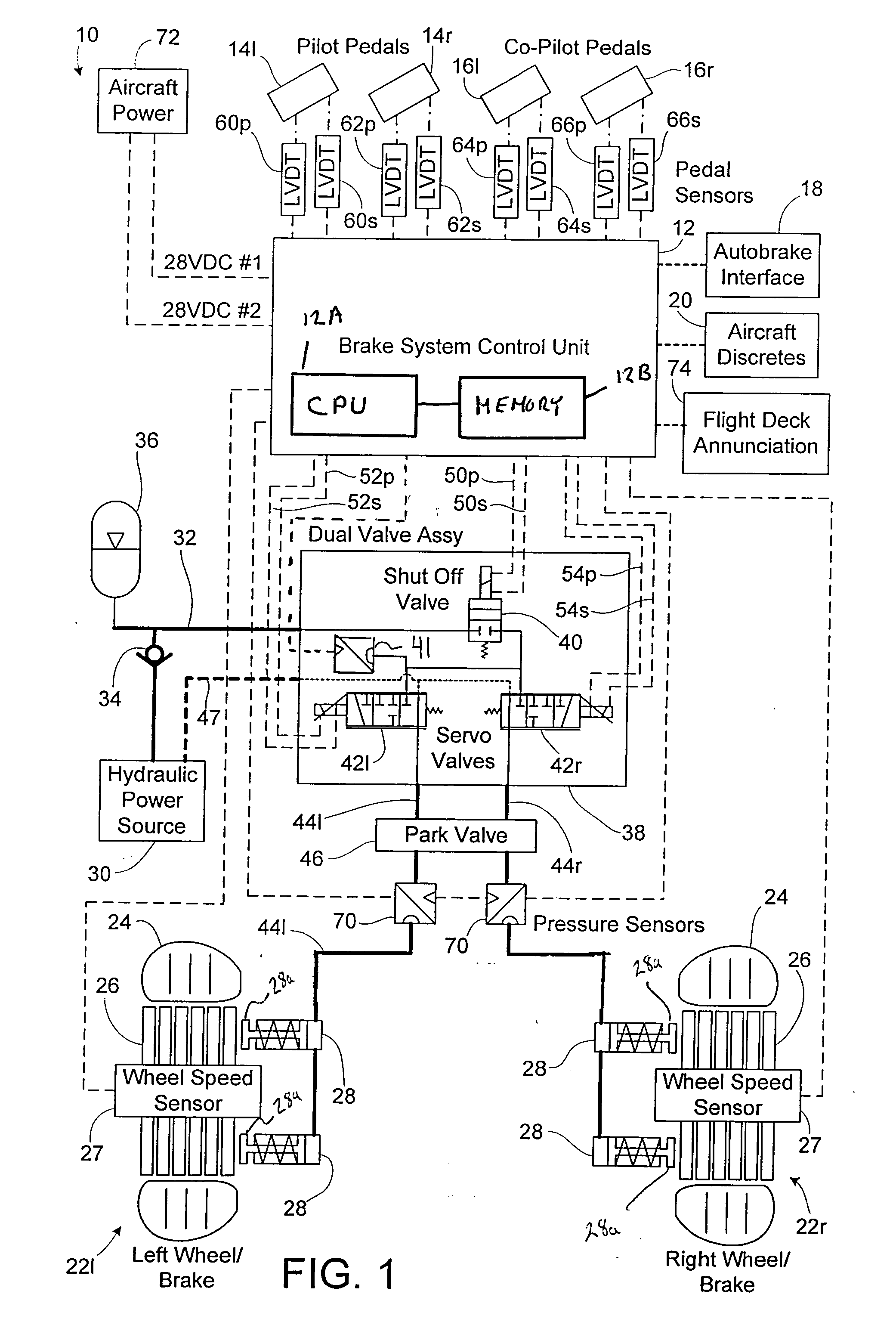

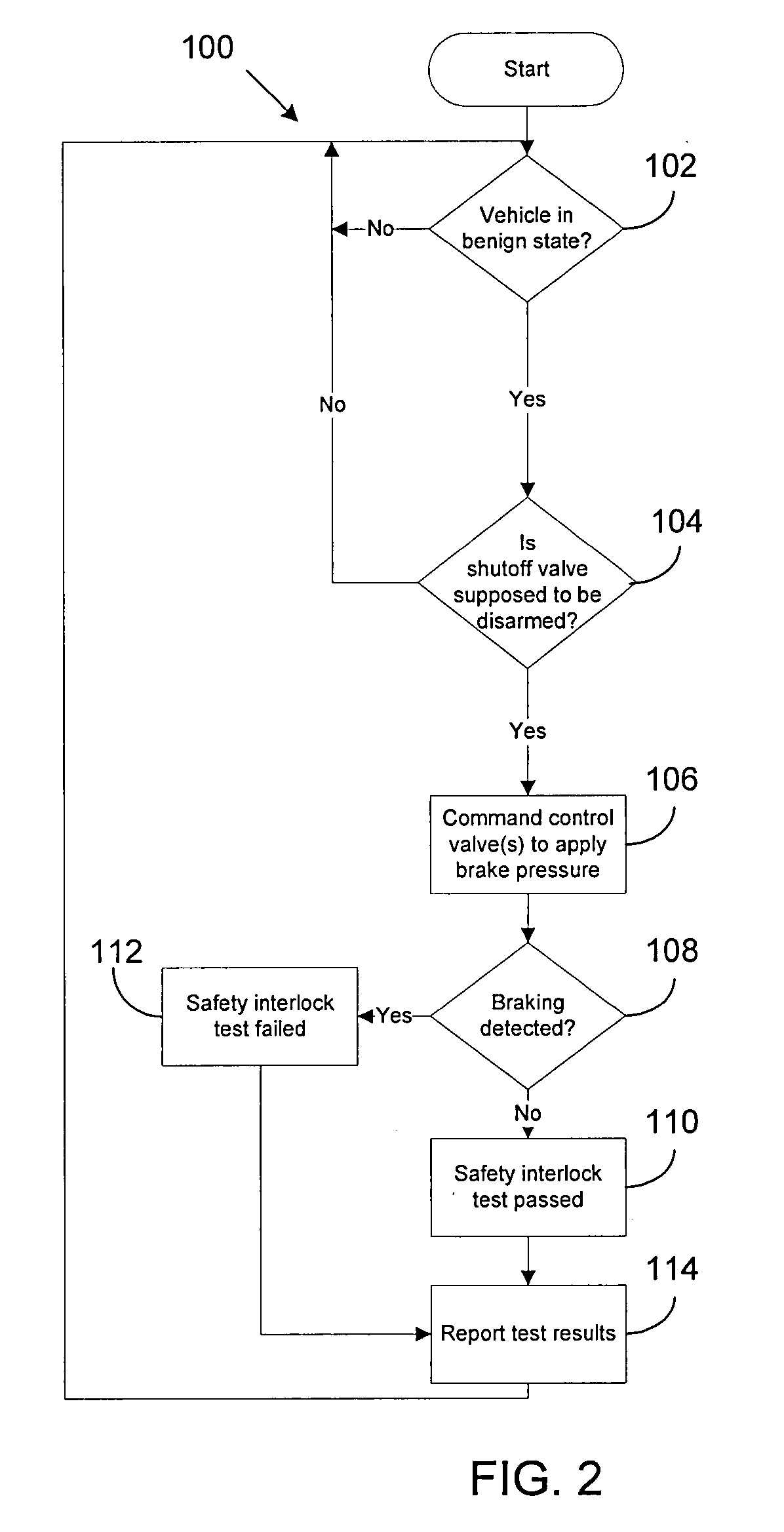

Brake shutoff valve test

ActiveUS20100090058A1Servomotor componentsDigital data processing detailsAutomotive engineeringFluid pressure

A system, apparatus and method of verifying operation of a vehicle fluid brake system shutoff valve is provided, wherein the shutoff valve is adapted to enable or inhibit the transmission of fluid pressure to at least one brake solenoid valve that controls operation of at least one brake actuator so as to effect wheel braking. In verifying operation of the system, the shutoff valve is commanded to inhibit the transmission of fluid pressure to the at least one brake solenoid valve, and the at least one brake solenoid valve is commanded to apply fluid pressure to the at least one brake actuator. An operational status of the shutoff valve is determined based on the absence or presence of wheel braking.

Owner:THE BF GOODRICH CO

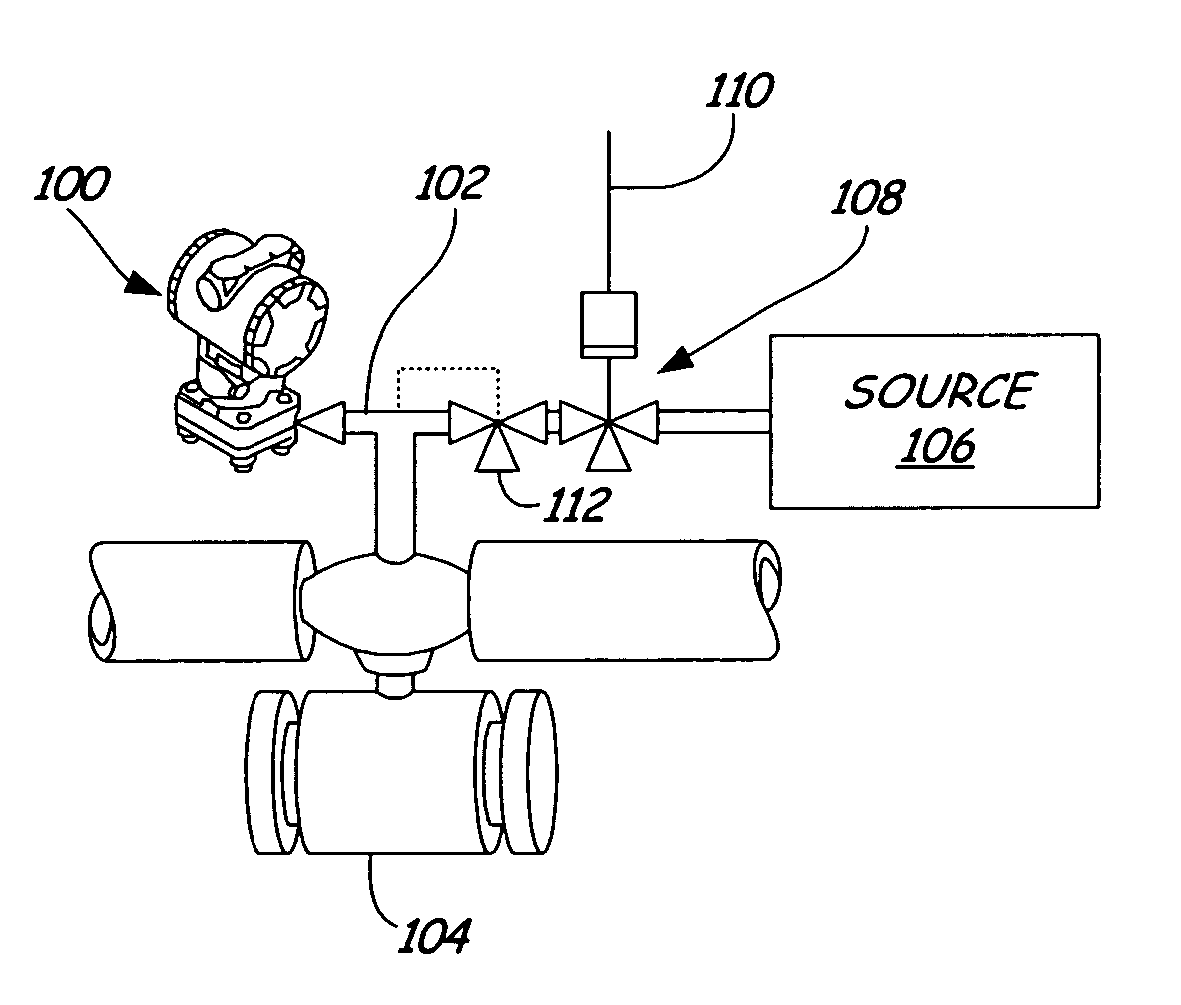

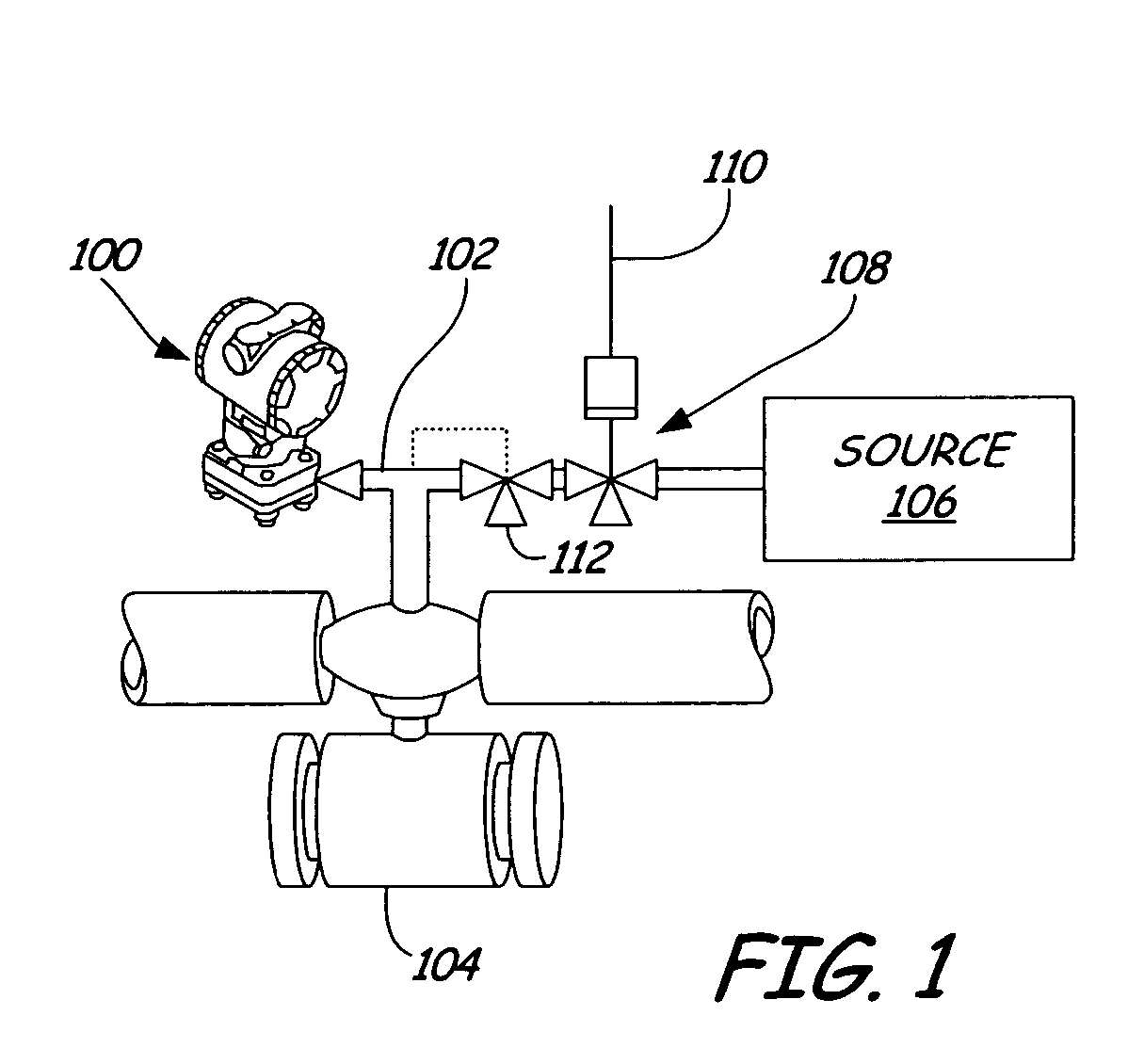

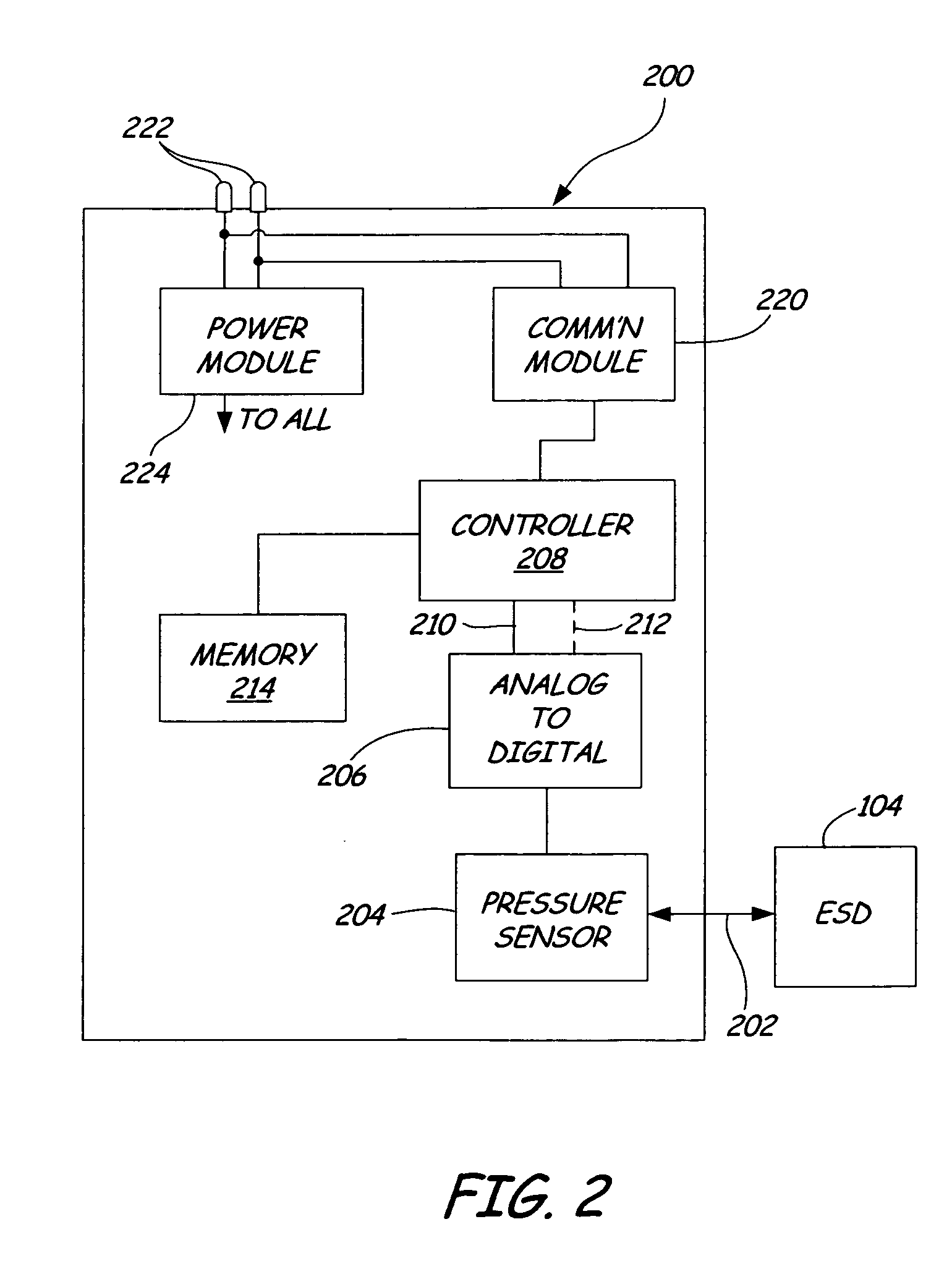

Emergency shutdown valve diagnostics using a pressure transmitter

InactiveUS20050189017A1Operating means/releasing devices for valvesFlow control using electric meansEngineeringVALVE PORT

An emergency shut down valve is operated using a pressurized fluid. A pressure transmitter is operably coupleable to the source of pressurized fluid and is configured to receive an indication relative to emergency shut down valve diagnostics. The pressure transmitter responsively captures pressure readings relative to the source of pressurized fluid for a selected duration. In some embodiments, the pressure transmitter may perform diagnostics upon the captured data. In other embodiments, the captured data is provided to an external device for analysis.

Owner:ROSEMOUNT INC

Wellhead flowline protection and testing system with ESP speed controller and emergency isolation valve

An ESP variable speed drive controller functions in conjunction with a safety logic solver, dedicated pressure sensors and a surface emergency isolation valve, or safety shut-off valve (SSV), to perform a full functional test of the complete wellhead flowline system. The method includes the step of using a plurality of pressure transmitters to monitor the flowline pressure during normal operations and during a full stroke test of the safety shutoff valve and adjusting the speed of the downhole ESP during the test to maintain the pipeline pressure within predetermined safe pressure limits. This wellhead flowline protection system and method utilizes the downhole ESP speed controller and an SSV to ensure that dangerous pressure levels are not reached and provides for full functional safety testing of the wellhead system. The ESP motor speed controller is used to permit functional testing and remove the pressure source from protected downstream flowline piping.

Owner:SAUDI ARABIAN OIL CO

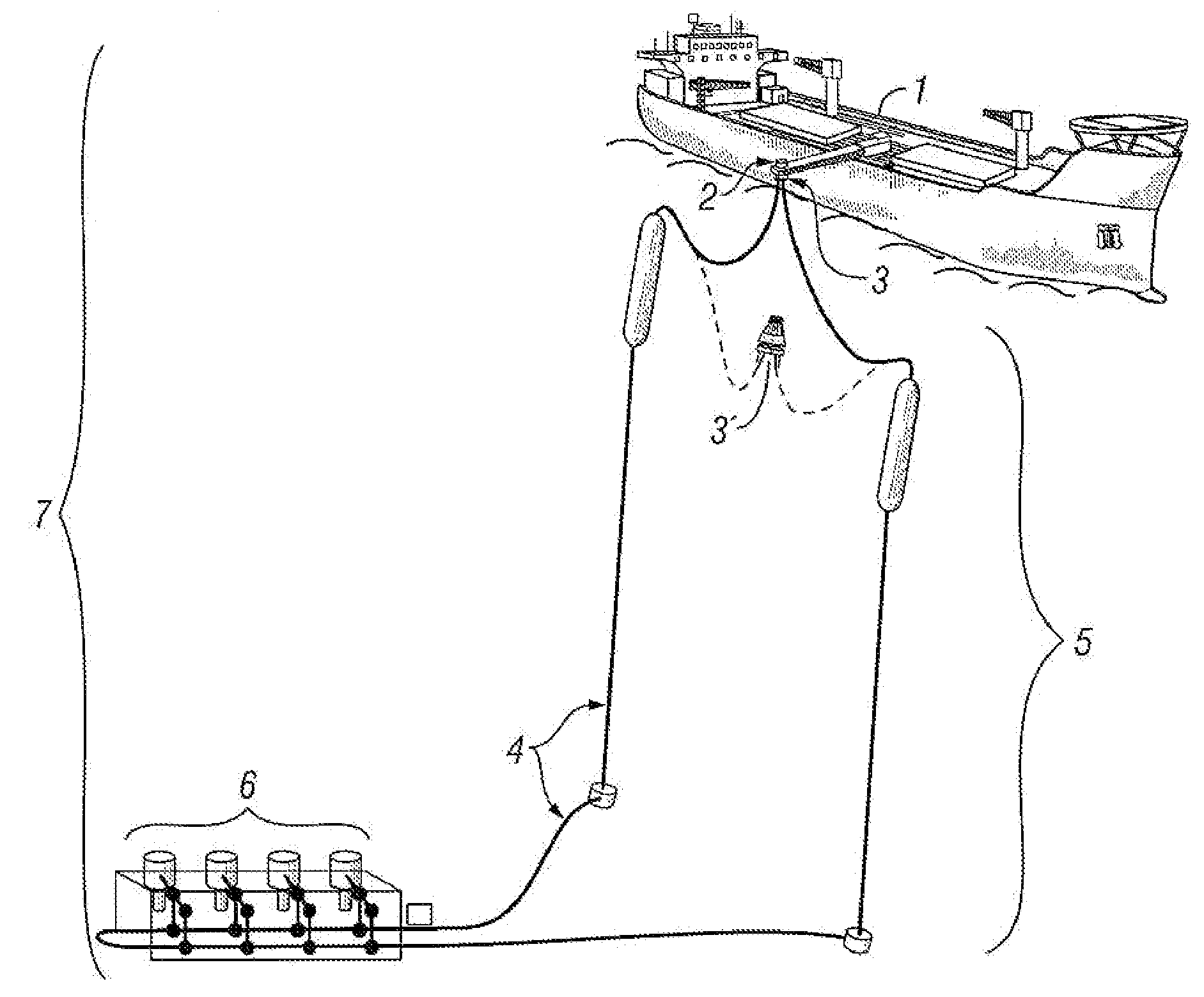

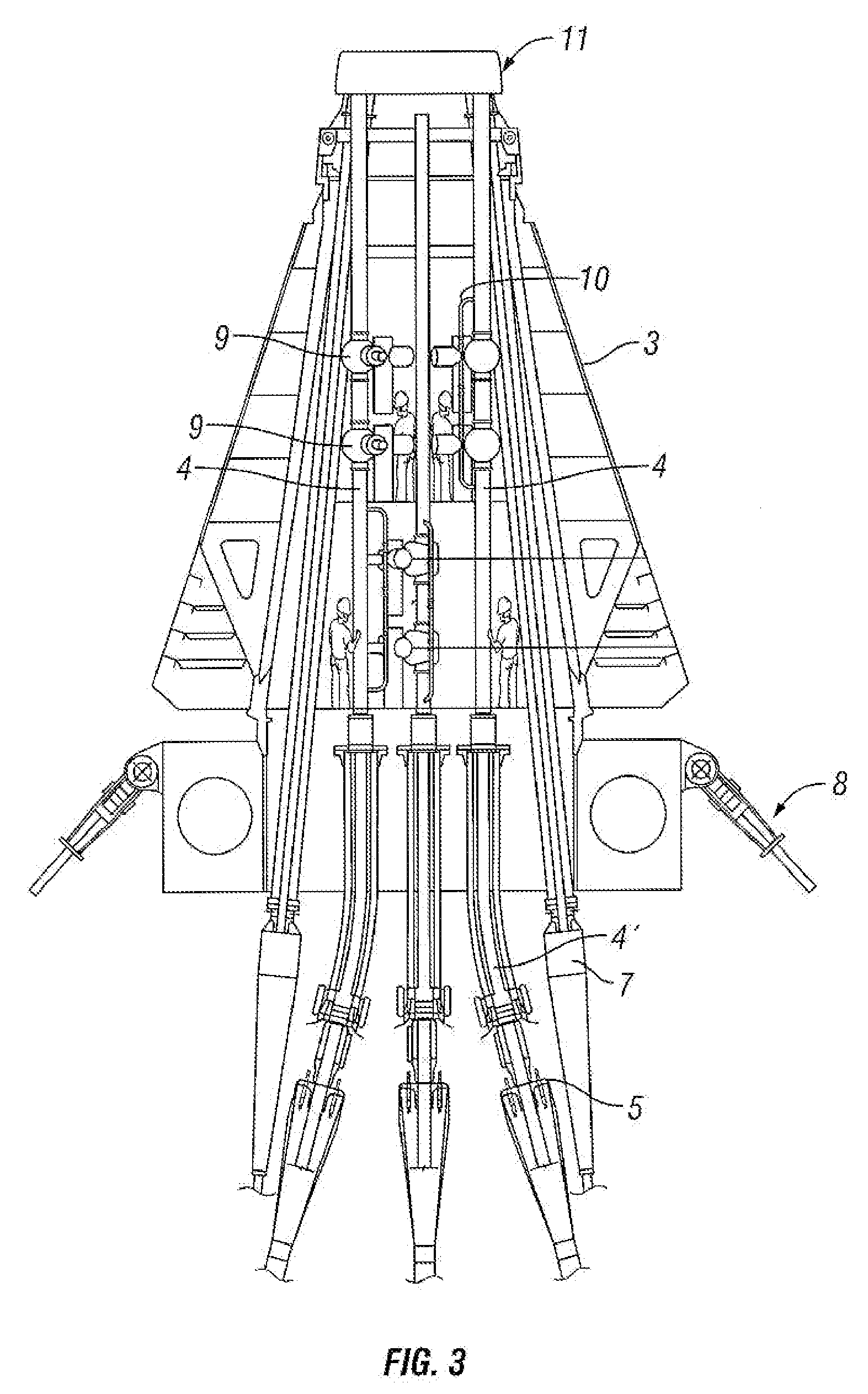

Method for Preventing Overpressure

InactiveUS20080135258A1Prevent overpressurePipe laying and repairWaterborne vesselsOcean bottomControl signal

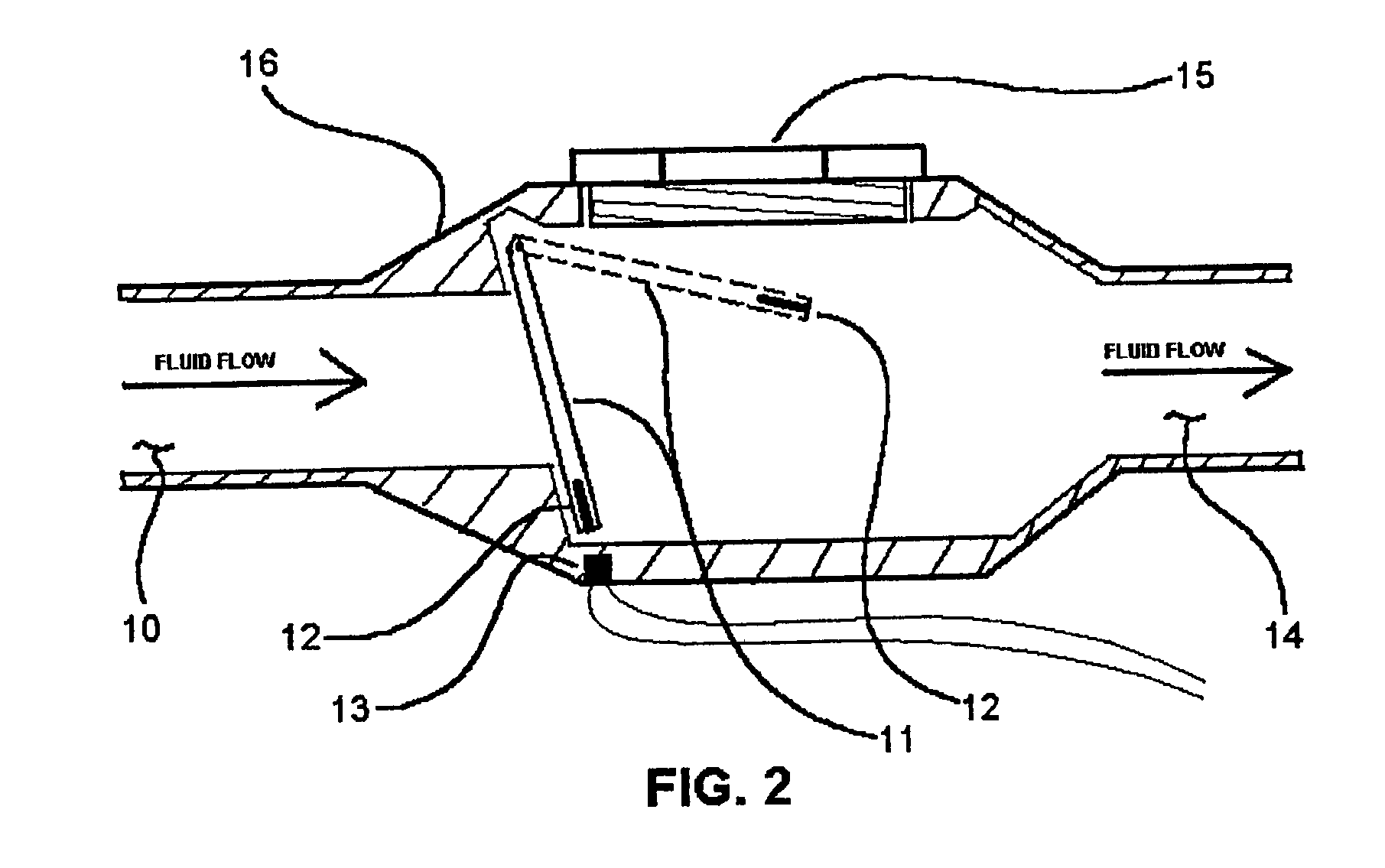

The present invention relates to overpressure protection systems and methods for use on a production system for transferring hydrocarbons from a well on the seafloor to a vessel floating on the surface of the sea. The production system includes a subsea well in fluid communication with a turret buoy through a production flowline and riser system. The turret buoy is capable of connecting to a swivel located on a floating vessel. The overpressure protection device is positioned upstream of the swivel, to prevent overpressure of the production swivel and downstream components located on the floating vessel. The device may include one or more shut down valves, one or more sensors, an actuator assembly, and a control processor. Each shut down valve and sensor is coupled to a production flowline. Each of the sensors is capable of generating a signal based upon a pressure sensed within the production flowline. The actuator assembly is connected to each of the shut down valves for operating the shut down valves. The control processor, which may be a programmable logic controller, receives a signal from the sensors and sends a valve control signal to the actuator assembly for operating the shut down valves in response to the received signals.

Owner:CHEVROU USA INC +1

Bi-directional overpressure shut-off valve

ActiveUS20100301238A1Operating means/releasing devices for valvesThin material handlingValve actuatorControl theory

A valve assembly includes a valve body, a valve element, a valve actuator, and a fluid-operated switch. The valve body defines a flow passage. The valve element is disposed at least partially within the flow passage and is moveable between an open position and a closed position. The valve actuator is coupled to the valve element and is responsive to pressurized fluid supplied thereto and vented therefrom to move the valve element between the open position and the closed position, respectively. The fluid-operated switch has a first fluid inlet, a second fluid inlet, a third fluid inlet, an actuator port, and an actuator vent port. The fluid-operated switch is in fluid communication with the valve actuator and is operable to selectively supply pressurized fluid to the actuator via the actuator port, and vent the pressurized fluid from the actuator via the actuator port and the actuator vent port.

Owner:HONEYWELL INT INC

Automatic air release system with shutoff valve

ActiveUS6926023B2Prevent liquid leakageFor quick maintenanceFire rescuePipeline systemsFire sprinklerEngineering

Owner:NAT CITY BANK CO

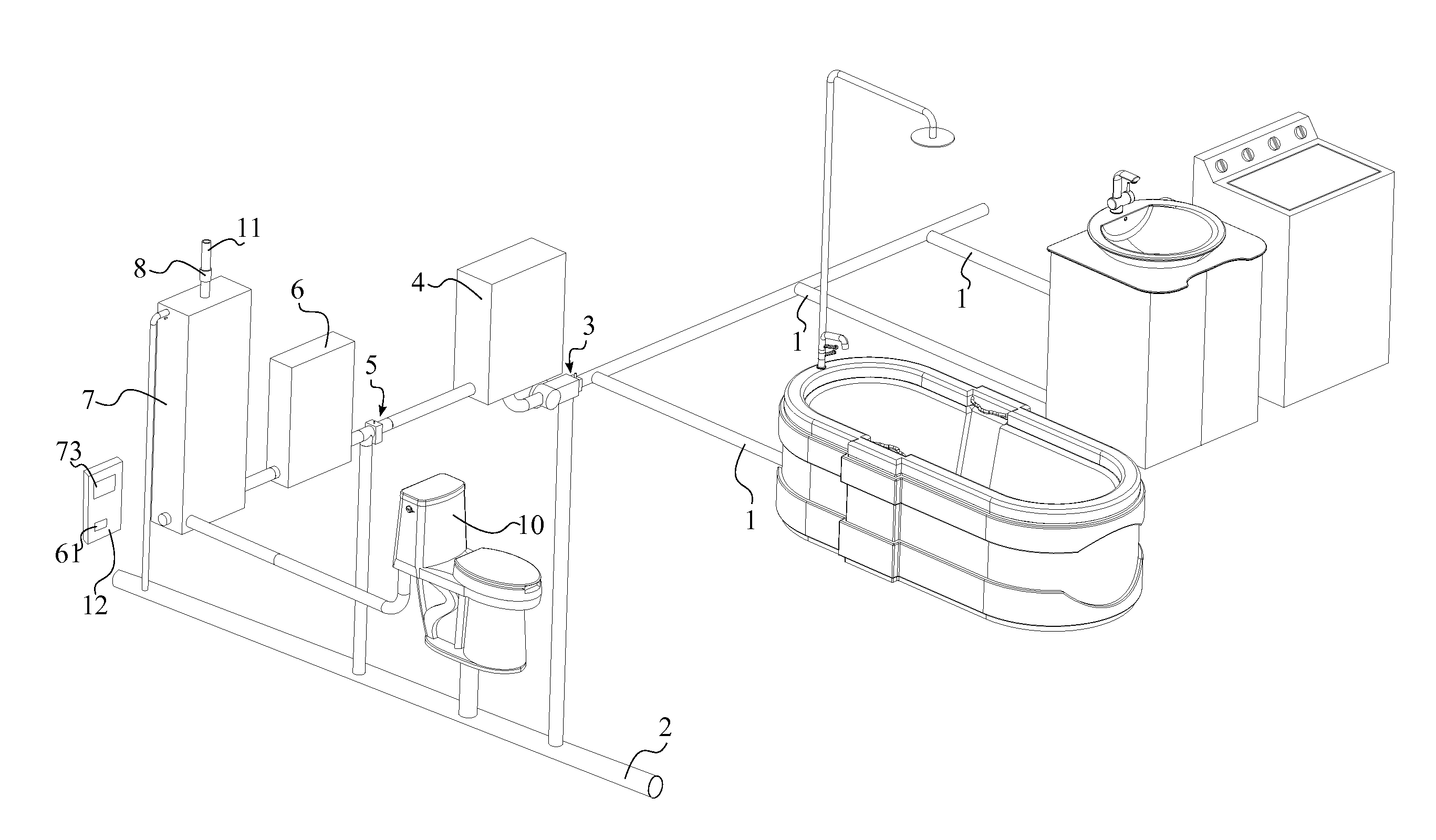

Personal Water Conservation System

InactiveUS20130180928A1Water treatment parameter controlIon-exchanger regenerationWater dischargeToilet flushing

A personal water conservation system includes gray water discharge lines, a main sewage line, an impurity measuring unit, a buffer tank, a directional control valve, a water treatment unit, a treated water tank, an automatic shutoff valve, and at least one toilet flush tank. The buffer tank and the water treatment unit purify the gray water in two different stages. The purified gray water is then stored in the treated water tank. If the gray water can't be purified within the personal water conservation system, the impurity measuring unit and the directional control valve redirect the gray water into the main sewage line. The purified water from the treated water tank can be used with the at least one toilet flush tank in order to conserve fresh water.

Owner:VIELMA MARCOS

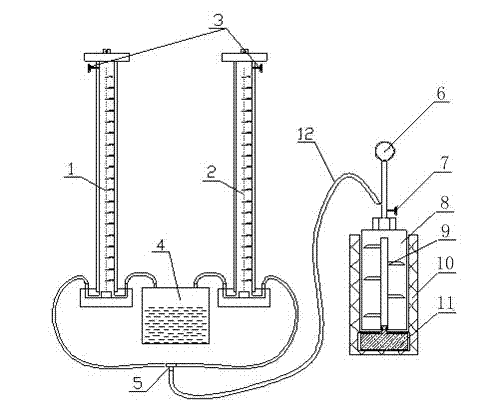

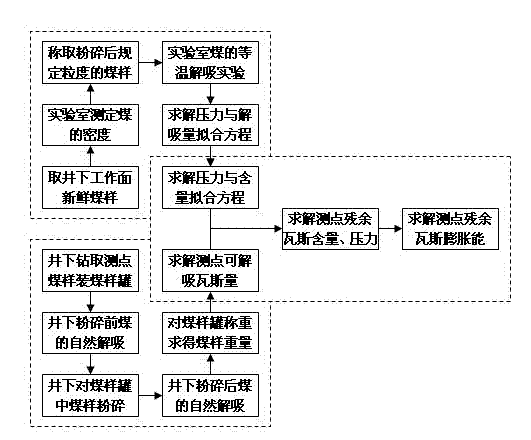

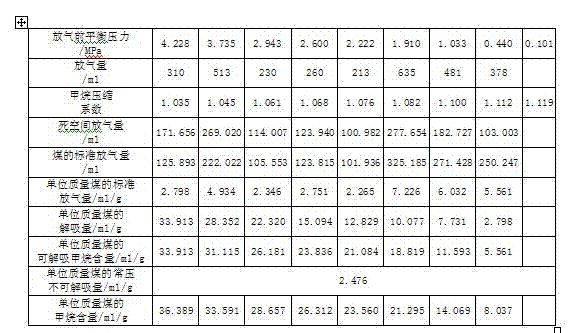

Apparatus and method for rapid determination of parameters of residual gas on mining working face of underground coal mine

The invention relates to an apparatus and a method for rapid determination of parameters of residual gas on a mining working face of an underground coal mine. The determination apparatus is provided with a coal sample tank; a pneumatic motor is arranged at the lower part of the coal sample tank; a rotating shaft is mounted on the upper part of the pneumatic motor; a crushing cutter head is installed at a side surface of the rotating shaft; the upper part of the coal sample tank is communicated with one end of a gas-guide tube, and the other end of the gas-guide tube is connected with a high precision pressure gauge; a gas stop valve is arranged at a joint position of the gas-guide tube and the coal sample tank; the side surface of the gas-guide tube is communicated with an interface of a three-way angle valve through a connection flexible pipe, and the other two interfaces of the three-way angle valve are respectively communicated with the bottoms of burette I and burette II through connection pipes. The determination method comprises the following steps: determination of curves representing the relationship between different balance pressures during adsorption of methane by coal and desorption quantity and the relationship between the different balance pressures and methane content; determination of desorbable gas quantity on the working face and calculation of content, pressure and expansion energy of residual gas on the mining working face. The determination method for residual gas on the mining working face has the advantages of a short period of time, small workload and high reliability of determination results, provides multi-parameter determination indexes for prediction of prominent dangers and examination of outburst prevention effects and has significant meaning to development of outburst prevention technology on a working face.

Owner:CHINA UNIV OF MINING & TECH

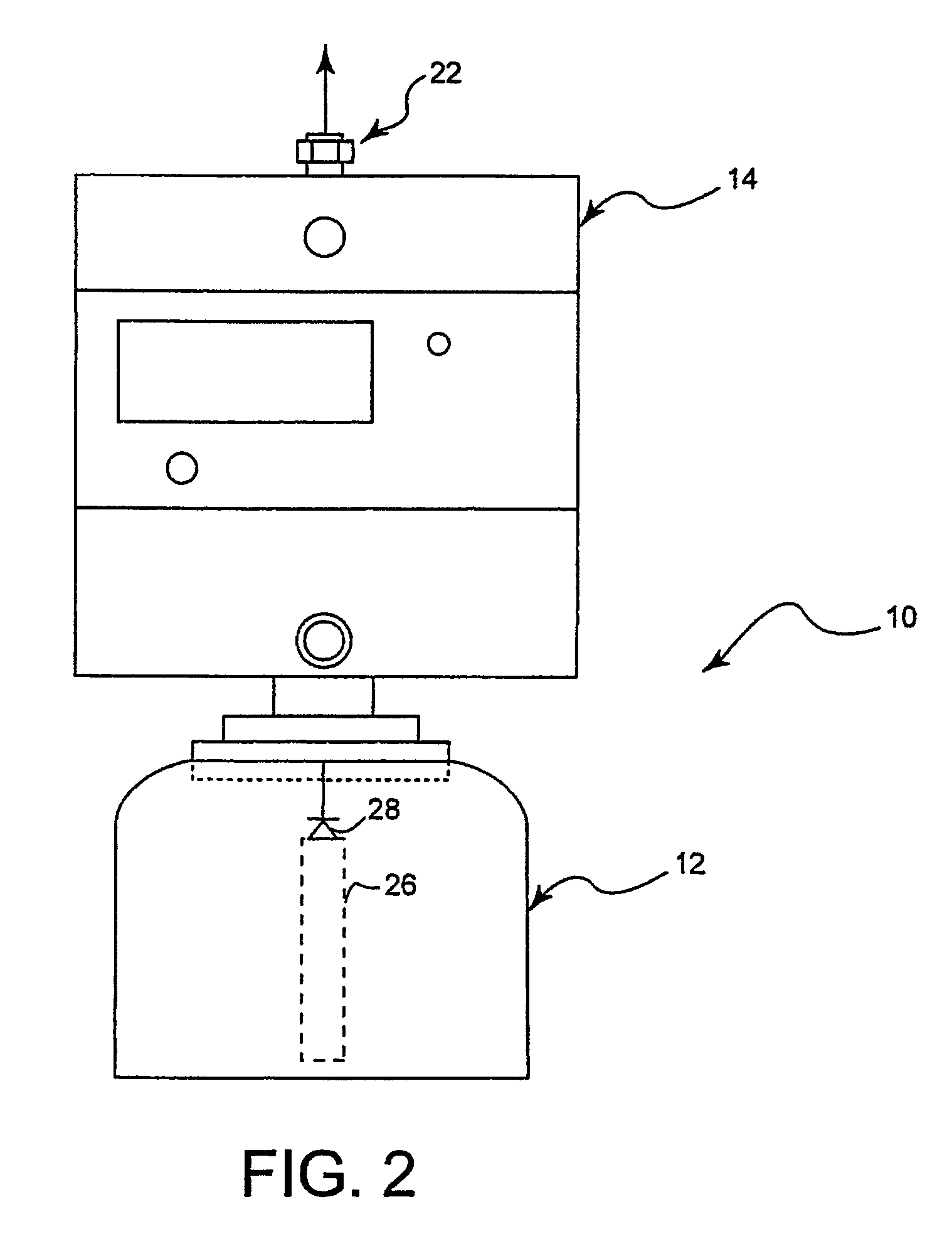

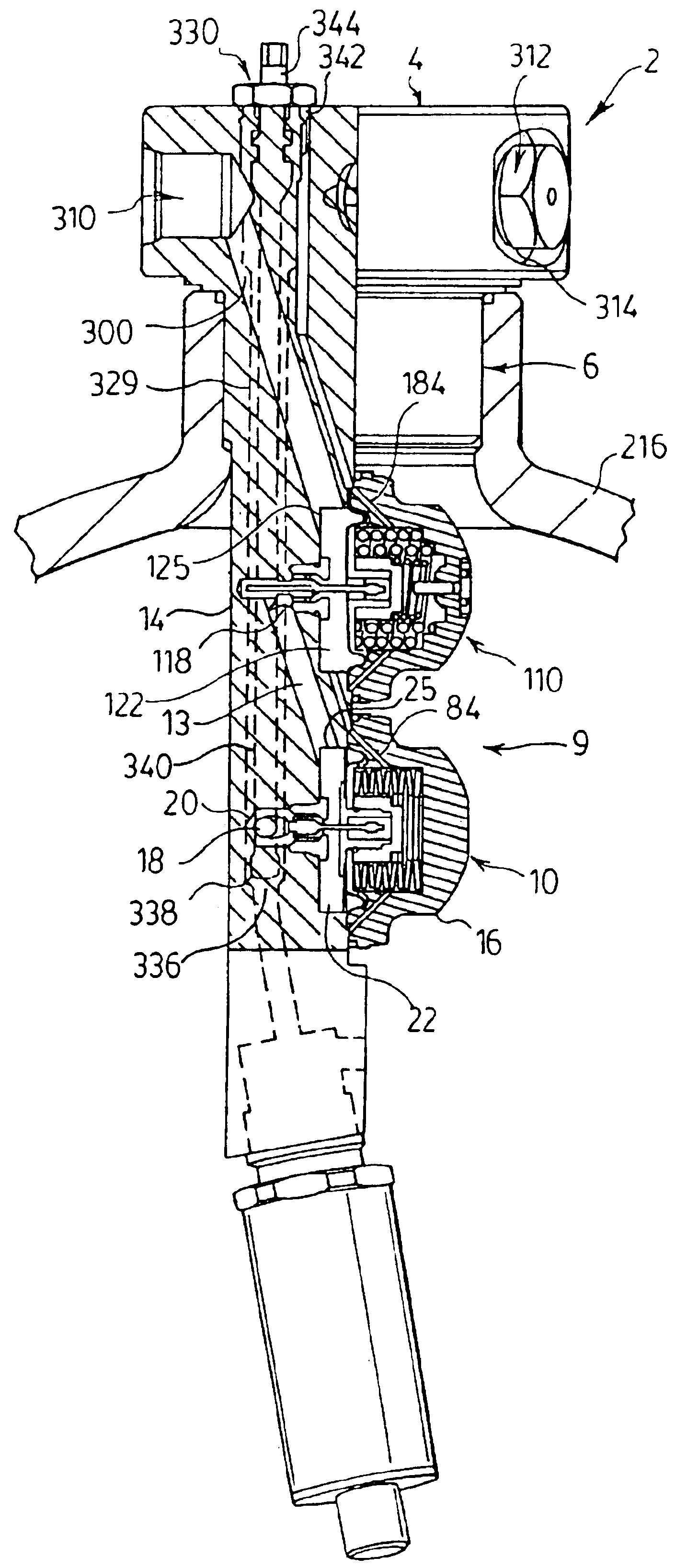

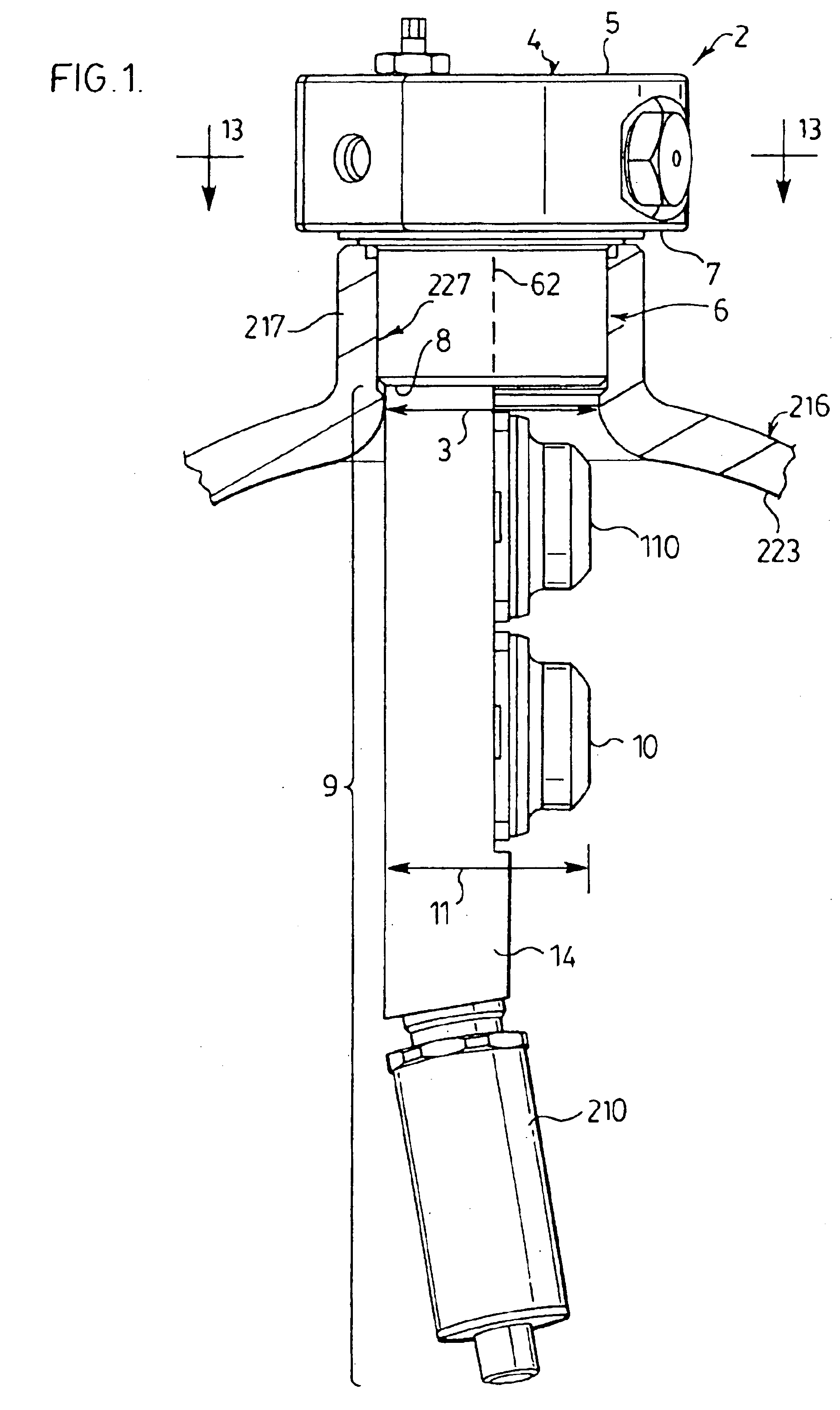

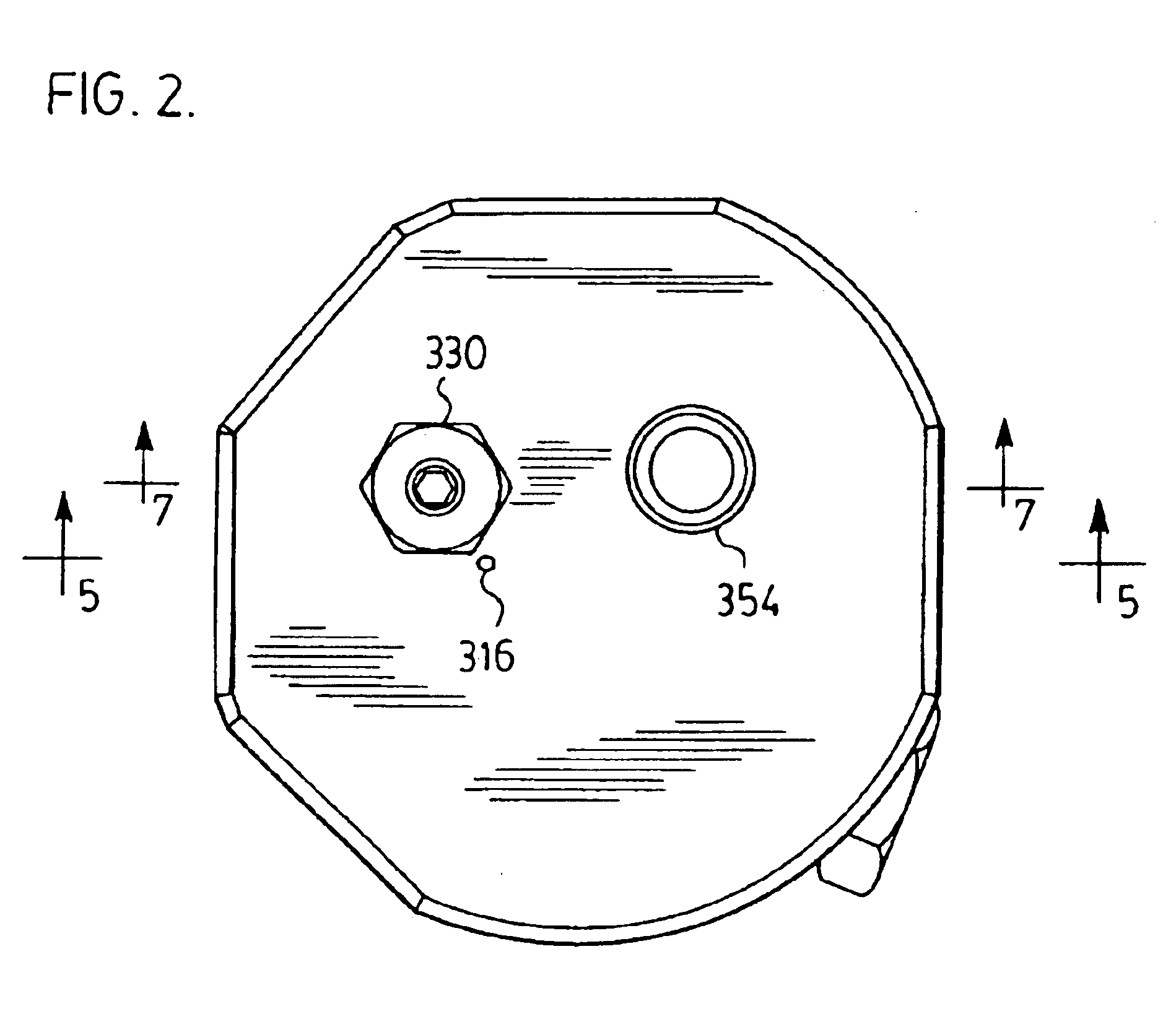

Gas flow regulation system

InactiveUS6901952B2Vessel mounting detailsOperating means/releasing devices for valvesInterior spaceMaximum diameter

A gas flow regulation module for use in a pressure vessel including a wall with an opening having a minimum opening diameter. The wall defines an interior space in the pressure vessel. The module includes a head portion, a neck portion, and a body portion. The body portion has a maximum diameter which is less than the minimum opening diameter, so that the body portion fits through the opening for positioning in the interior space. The gas flow regulation module includes a manual shut-off valve for controlling the flow of fluid through the module.

Owner:WESTPORT POWER

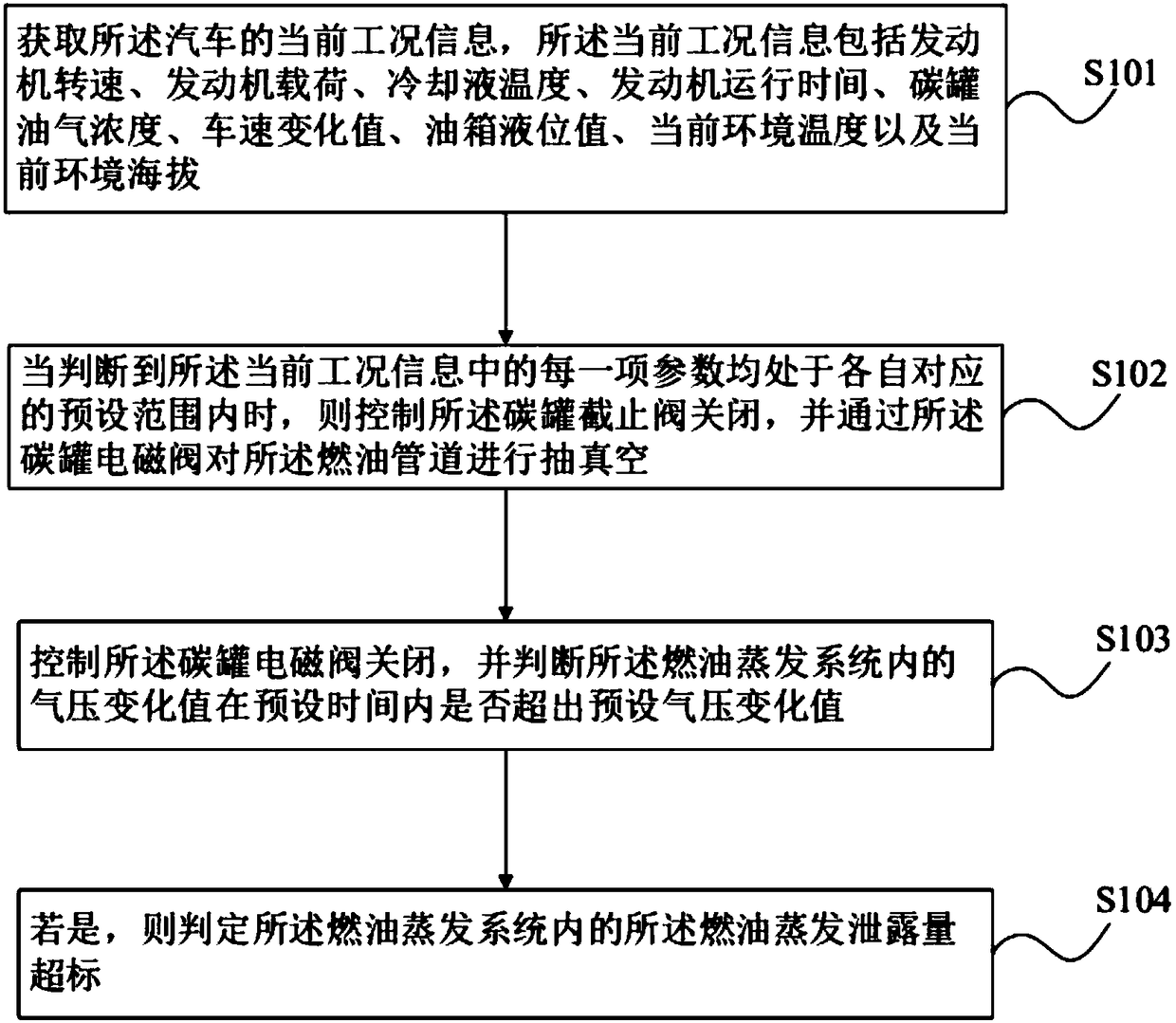

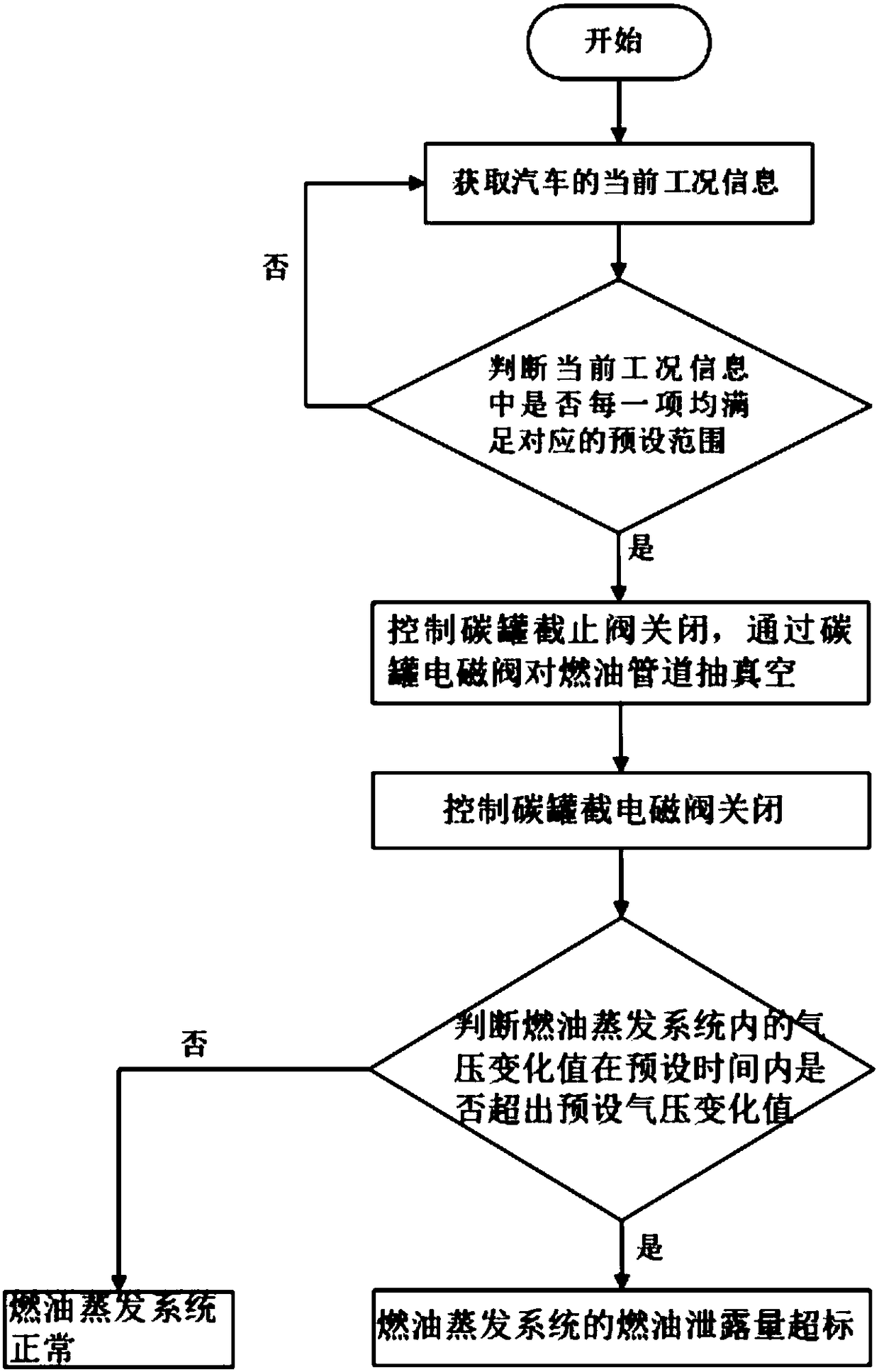

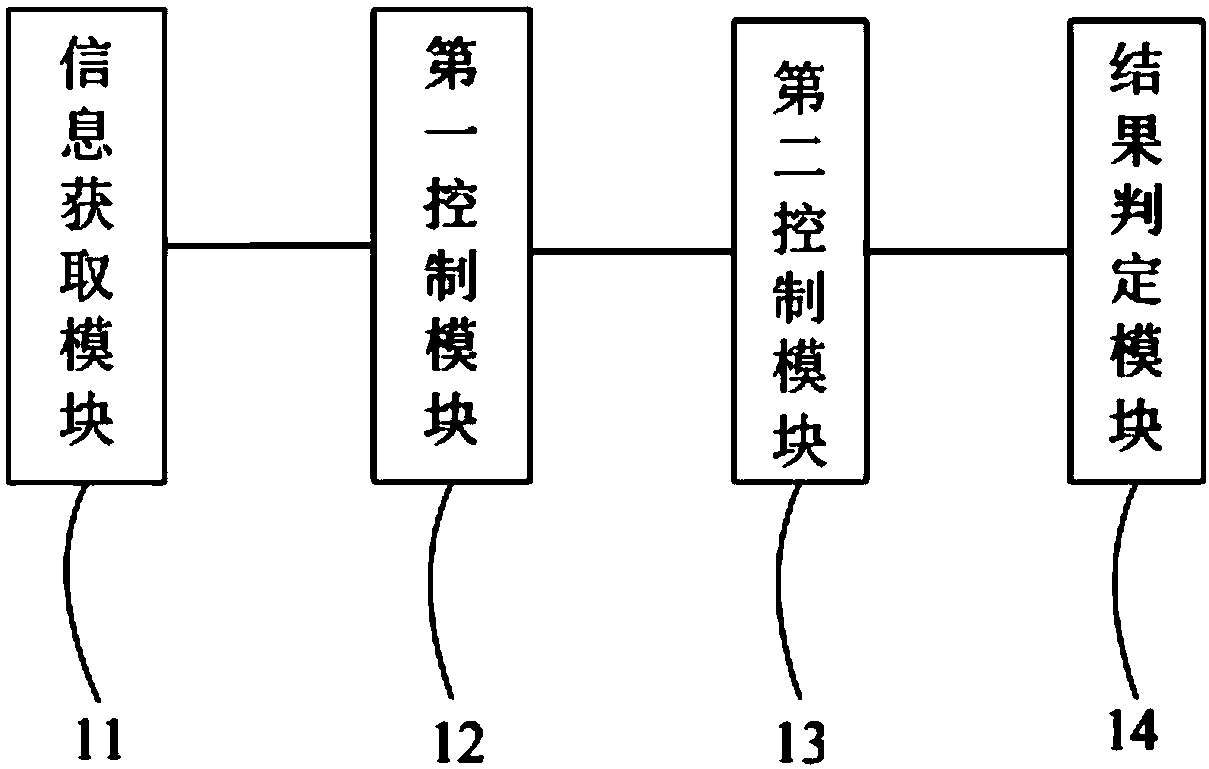

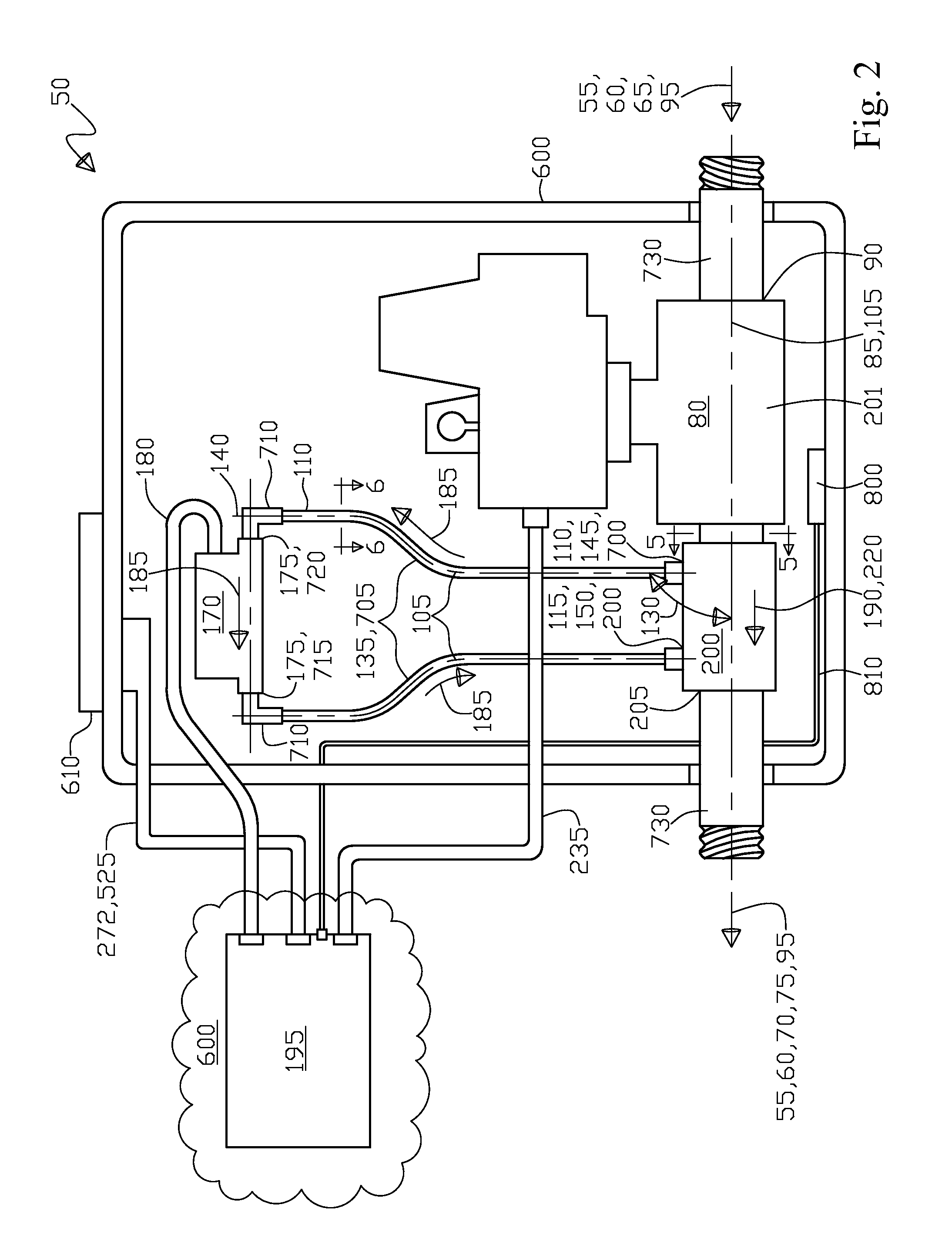

Method, device and system for diagnosing fuel evaporation leakage

InactiveCN108151987AQuality assuranceEfficient detectionMeasurement of fluid loss/gain ratePollutant emissionsEvaporation

The invention provides a method, device and system for diagnosing fuel evaporation leakage. The method comprises the steps that the current working condition information of a vehicle is obtained; whenit is detected that each item of the parameters of the current working condition is within respective corresponding preset ranges, a carbon shut-off valve is controlled to turn off, and vacuumizing of a fuel pipeline is conducted through a carbon tank electromagnetic valve; the carbon tank electromagnetic valve is controlled to turn off, and whether or not an air pressure variation in a fuel evaporation system exceeds a preset air pressure variation in a preset period of time is determined; if yes, it is determined that fuel evaporation leakage amount of the fuel evaporation system exceeds the standard. According to the method, whether or not the fuel evaporation leakage amount of the fuel evaporation system exceeds the leakage amount of a 1mm equivalent leakage hole can be timely and effectively detected to ensure regulation demands of OBD fuel evaporation leakage of Light Vehicle Pollutant Emission Limits and Measurement Methods (China Sixth Stage) are met.

Owner:JIANGLING MOTORS

Fluid Leak Detection and Shutdown Apparatus

InactiveUS20140196802A1Block fluid flowMinimal flow rateOperating means/releasing devices for valvesGeneral water supply conservationFlow transducerLine tubing

An apparatus and method for a fluid leak detection and shutdown for a fluid distribution system having a total system flow rate. The apparatus includes a solenoid shutoff valve having a normally open state and an activated closed state with a flow capacity matched to the total fluid distribution system flow rate. The apparatus also has a primary fluid flow line and a smaller capacity secondary fluid flow line. The apparatus includes a flow sensor in fluid communication with the secondary fluid flow line, wherein the flow sensor has a perceptible output and a flow rate capacity less than the solenoid shutoff flow capacity. Operationally, the flow sensor receives a portion of the solenoid shutoff valve flow capacity in priority over the primary fluid flow line, allowing the flow sensor to detect minimal flow rates and using the perceptible output to activate the solenoid shutoff valve into the closed state.

Owner:GUY KEVIN DUANE +1

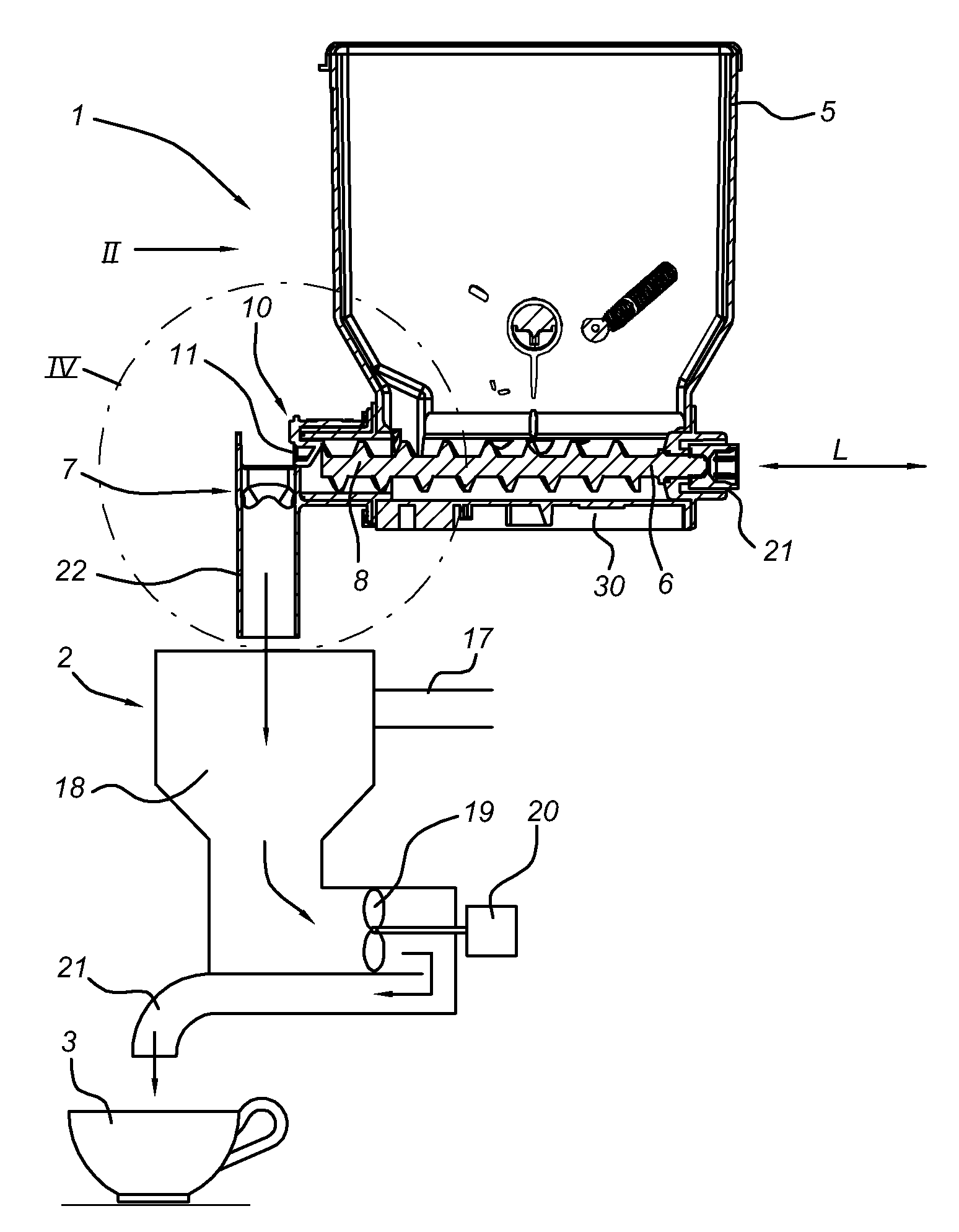

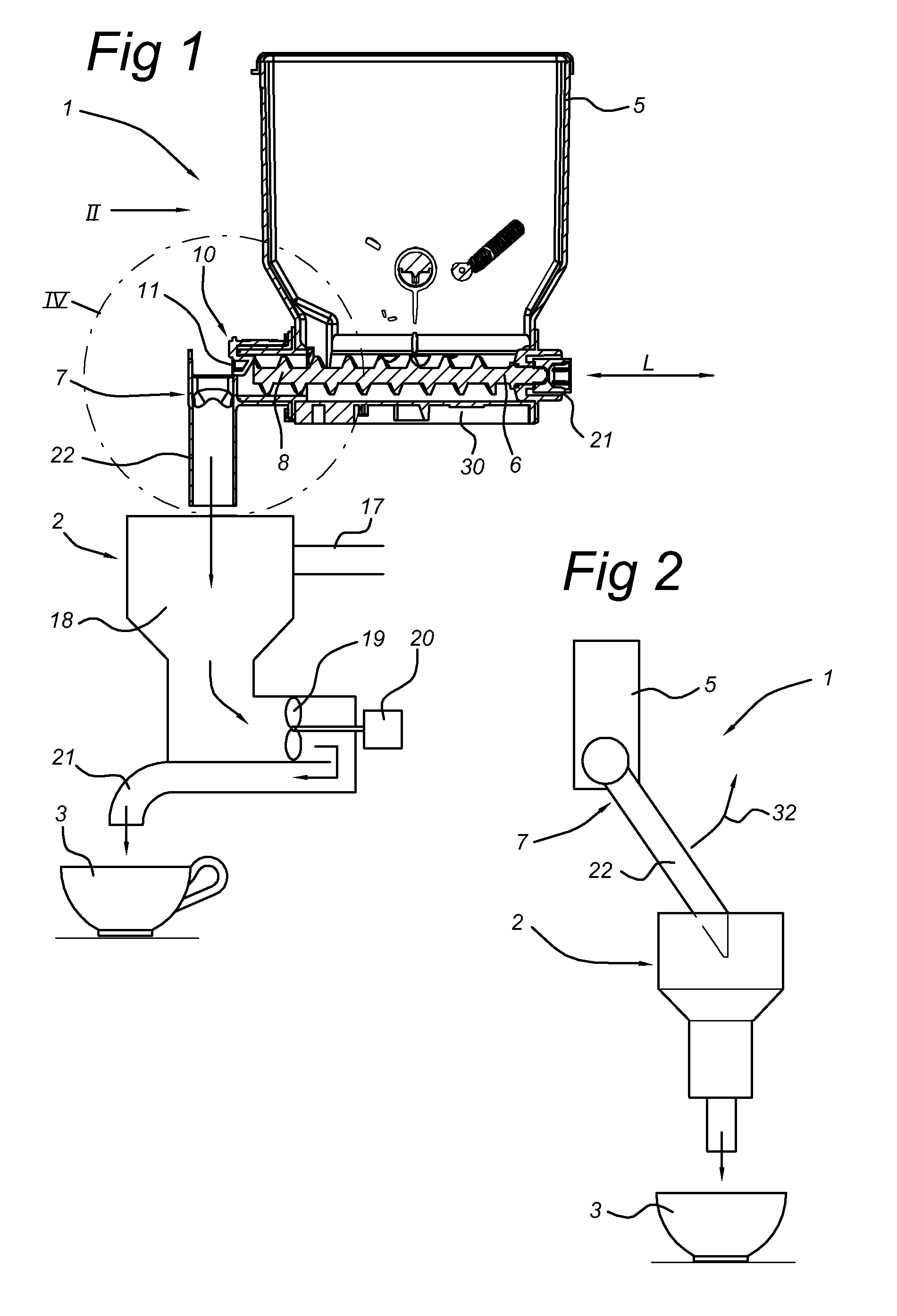

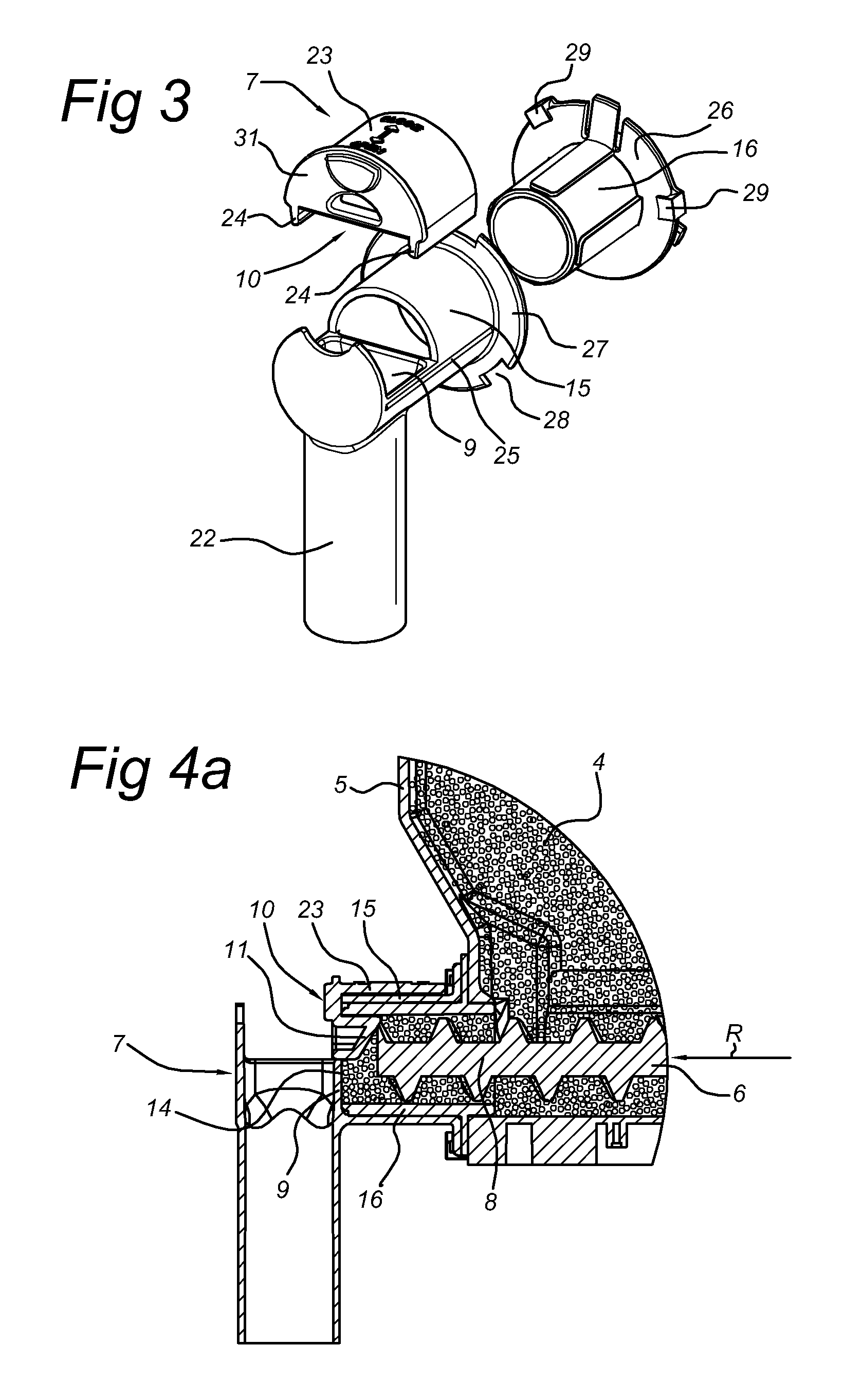

Holder assembly for a powdered ingredient for preparing an instant drink

ActiveUS20100199850A1Easy and reliable installationMovable measuring chambersLiquid transferring devicesMechanical engineeringMaterials science

The invention relates to a holder assembly (1) for a powdered ingredient (4) for preparing an instant drink. The assembly comprises a holder, a conveyor screw (6), an outflow channel (7) provided on the holder for dispensing ingredient (1), a threshold plate (9) extending into the outflow channel (7), and also a shut-off valve (10) for shutting off the outflow channel (7). The shut-off valve (10) comprises a shut-off body (11) which can be moved back and forth in the longitudinal direction of the conveyor screw (6) between a release position and a shut-off position. In the release position the shut-off body (11) is located downstream of the threshold plate (9), set apart therefrom. In the shut-off position the shut-off body (11) is located next to the threshold plate (9) in such a way that the shut-off body (11) and the threshold plate (9) together shut off the shut-off channel (7). The invention further relates to a drink preparation means comprising a holder assembly (1) according to the invention.

Owner:BRAVILOR HLDG

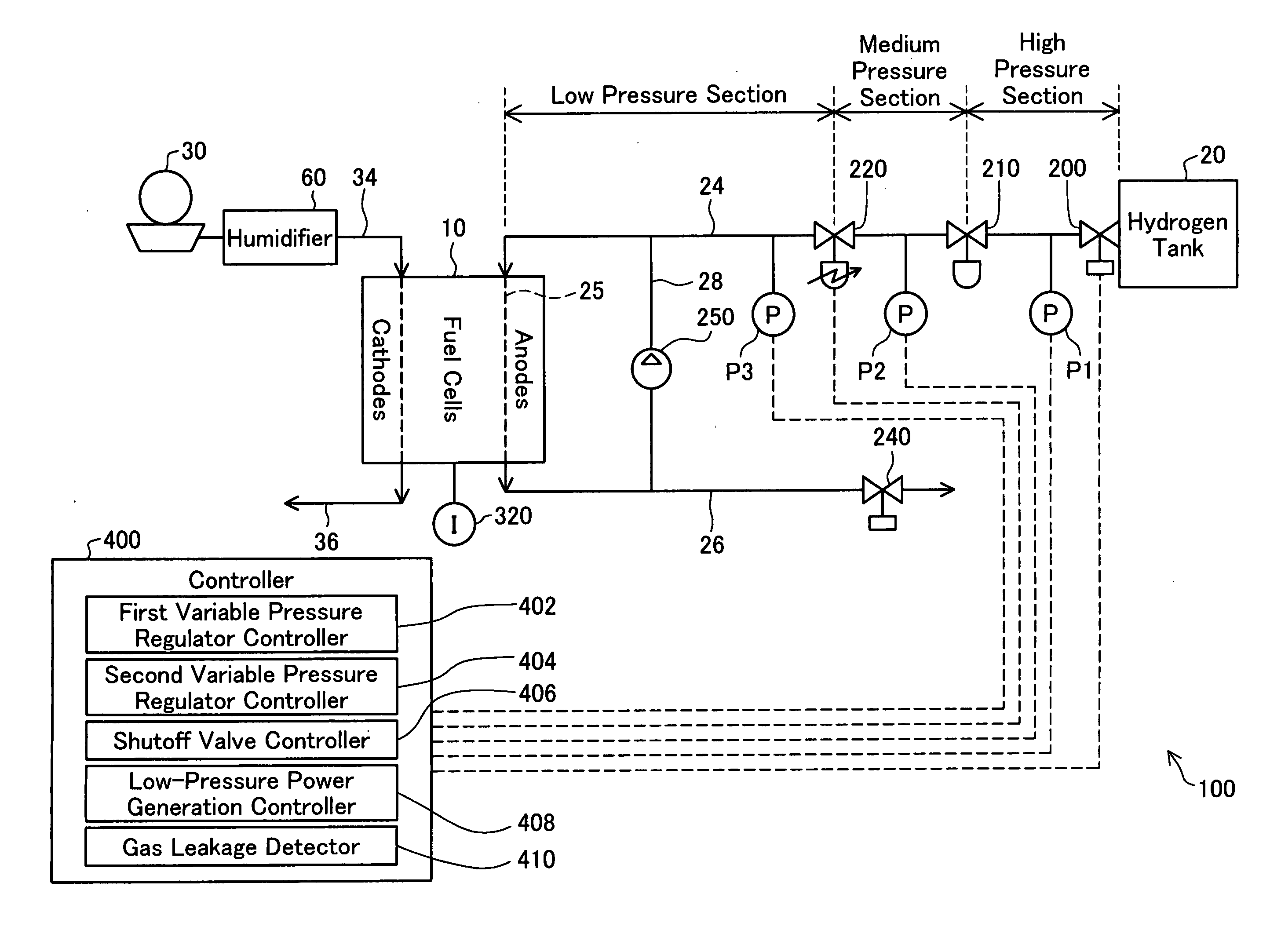

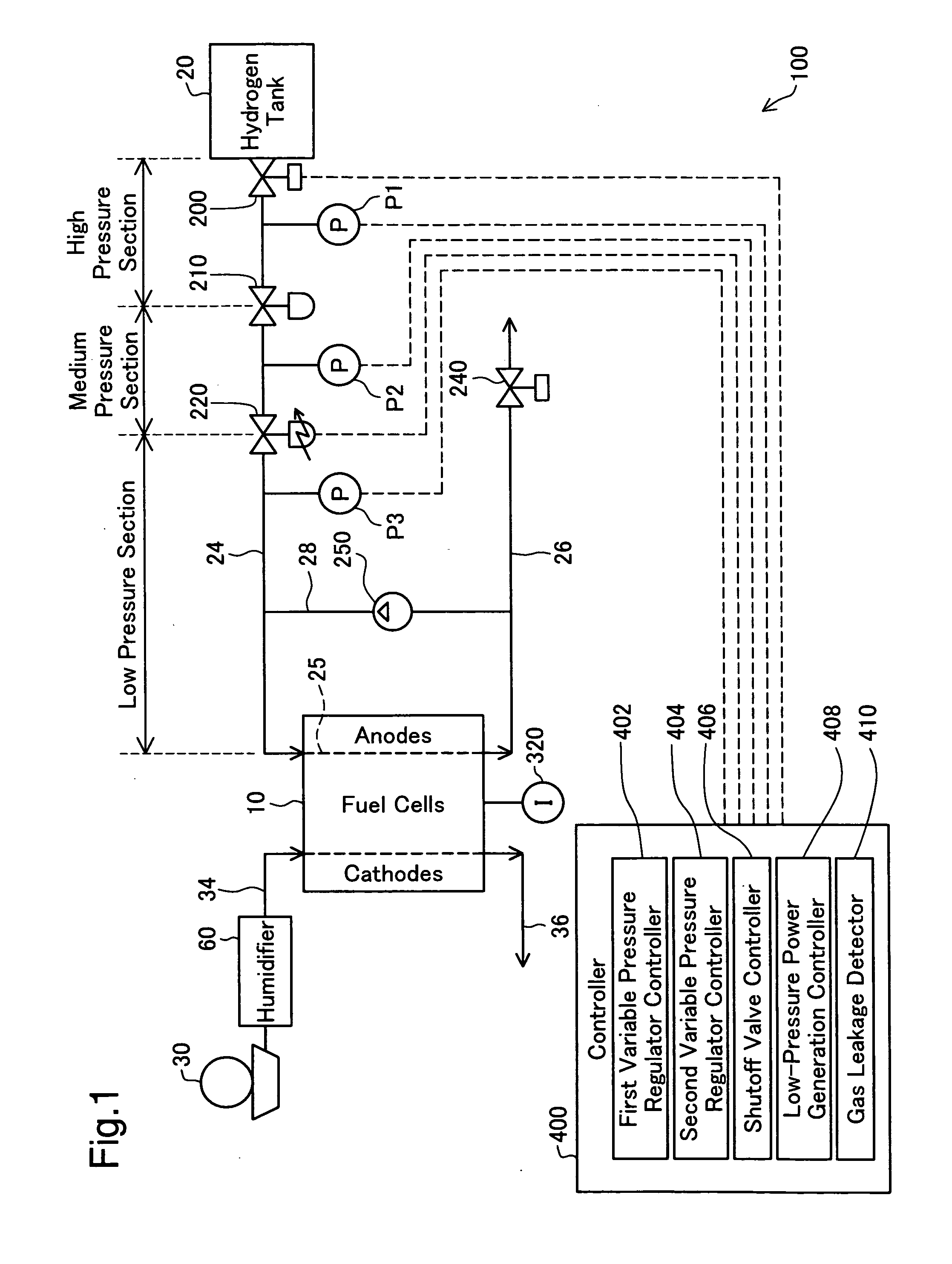

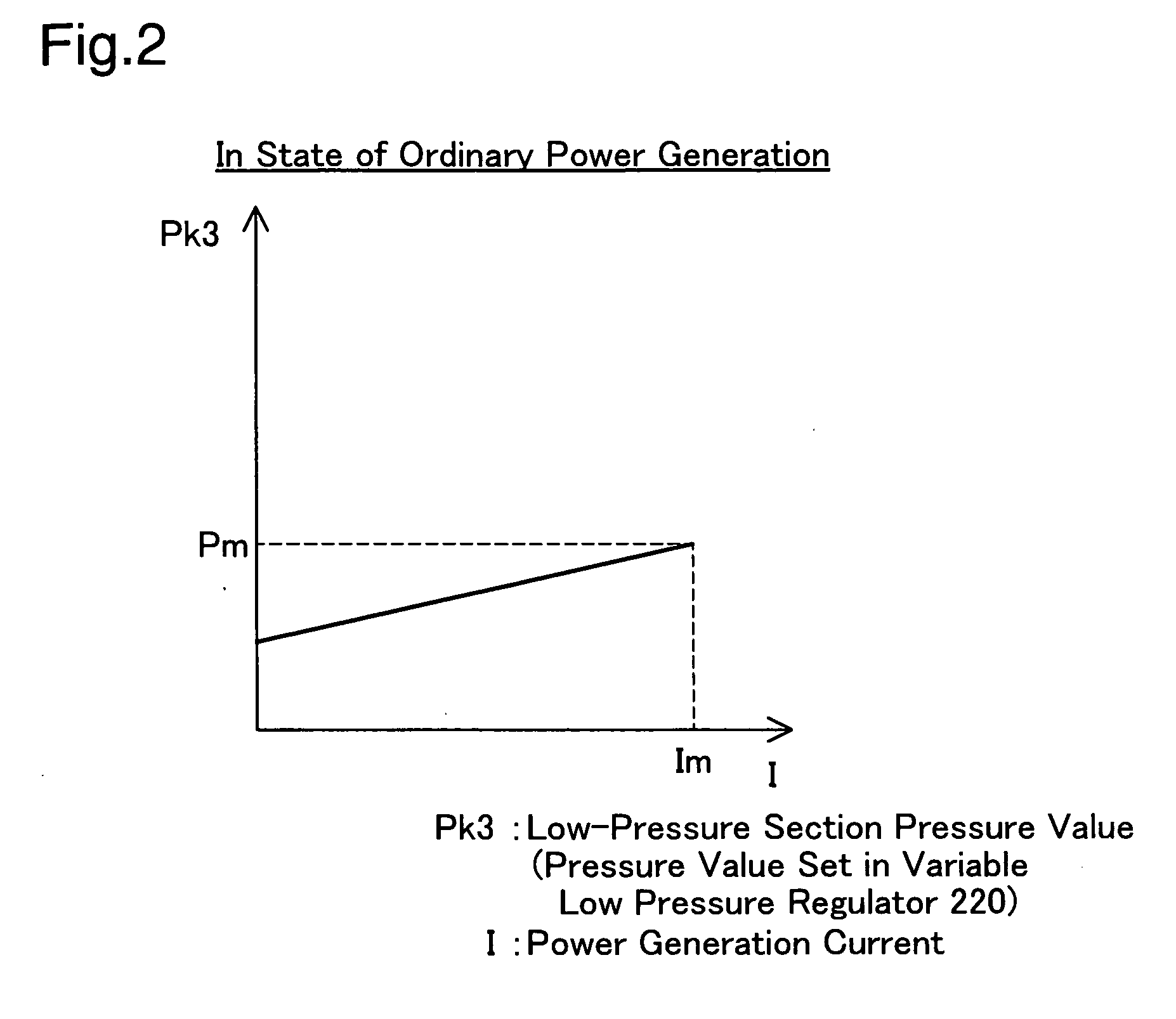

Fuel cell system and gas leakage detection device

ActiveUS20100151343A1Reduce pressureShorten the timeFuel cells groupingFuel cell auxillariesFuel cellsVariable pressure

A fuel cell system according to one aspect of the invention is operated in an ordinary mode and in a gas leakage detection mode. The fuel cell system includes fuel cells, a fuel gas supplier configured to supply a fuel gas to the fuel cells, a shutoff valve provided in a flow path for leading a flow of the fuel gas supply from the fuel gas supplier to the fuel cells and configured to shut off the fuel gas supply, and a variable pressure regulator provided in the flow path between the shutoff valve and the fuel cells to regulate a pressure of the fuel gas in a downstream in a flow direction of the fuel gas supply to a variable pressure value. In the ordinary mode, the fuel cell system sets the pressure value of the variable pressure regulator to an ordinary power generation pressure value for ordinary power generation. In the gas leakage detection mode, on the other hand, the fuel cell system closes the shutoff valve, sets the pressure value of the variable pressure regulator to a higher value than the ordinary power generation pressure value, and performs leakage detection of the fuel gas from the shutoff valve. Such setting of the pressure value in the variable pressure regulator desirably enables high-speed reduction of the fuel gas pressure in the flow path between the shutoff valve and the variable pressure regulator.

Owner:TOYOTA JIDOSHA KK

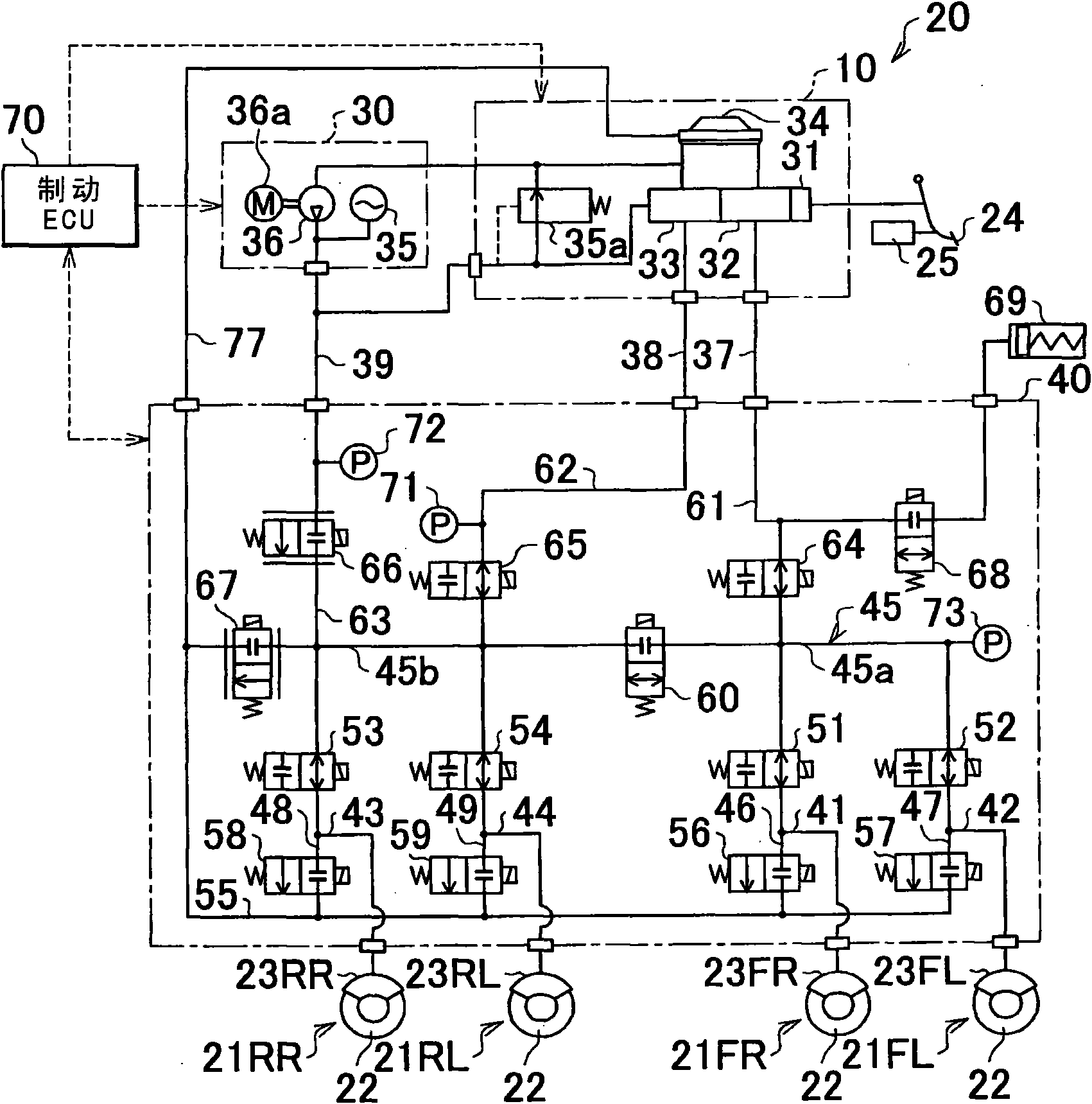

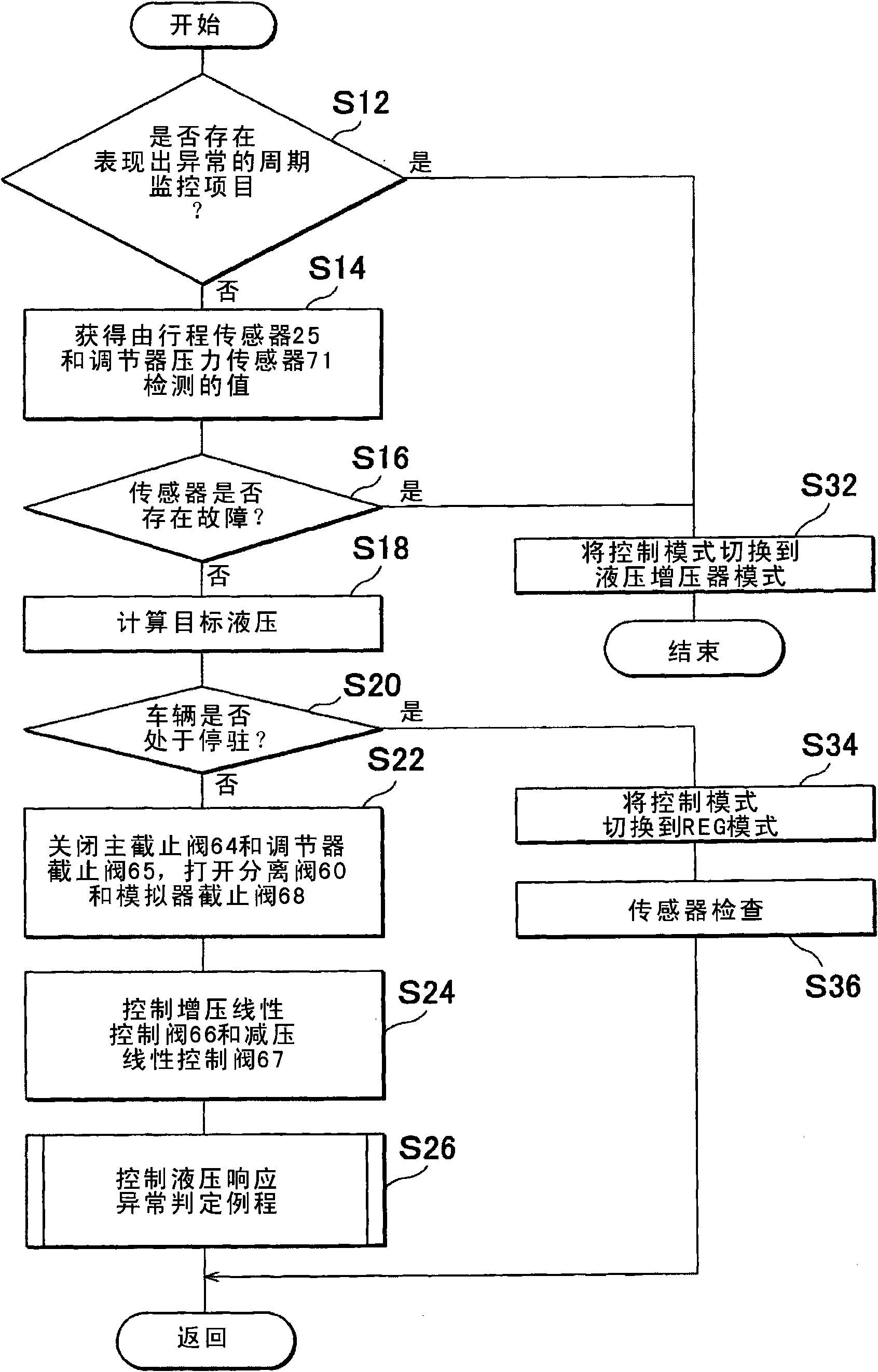

Brake control apparatus

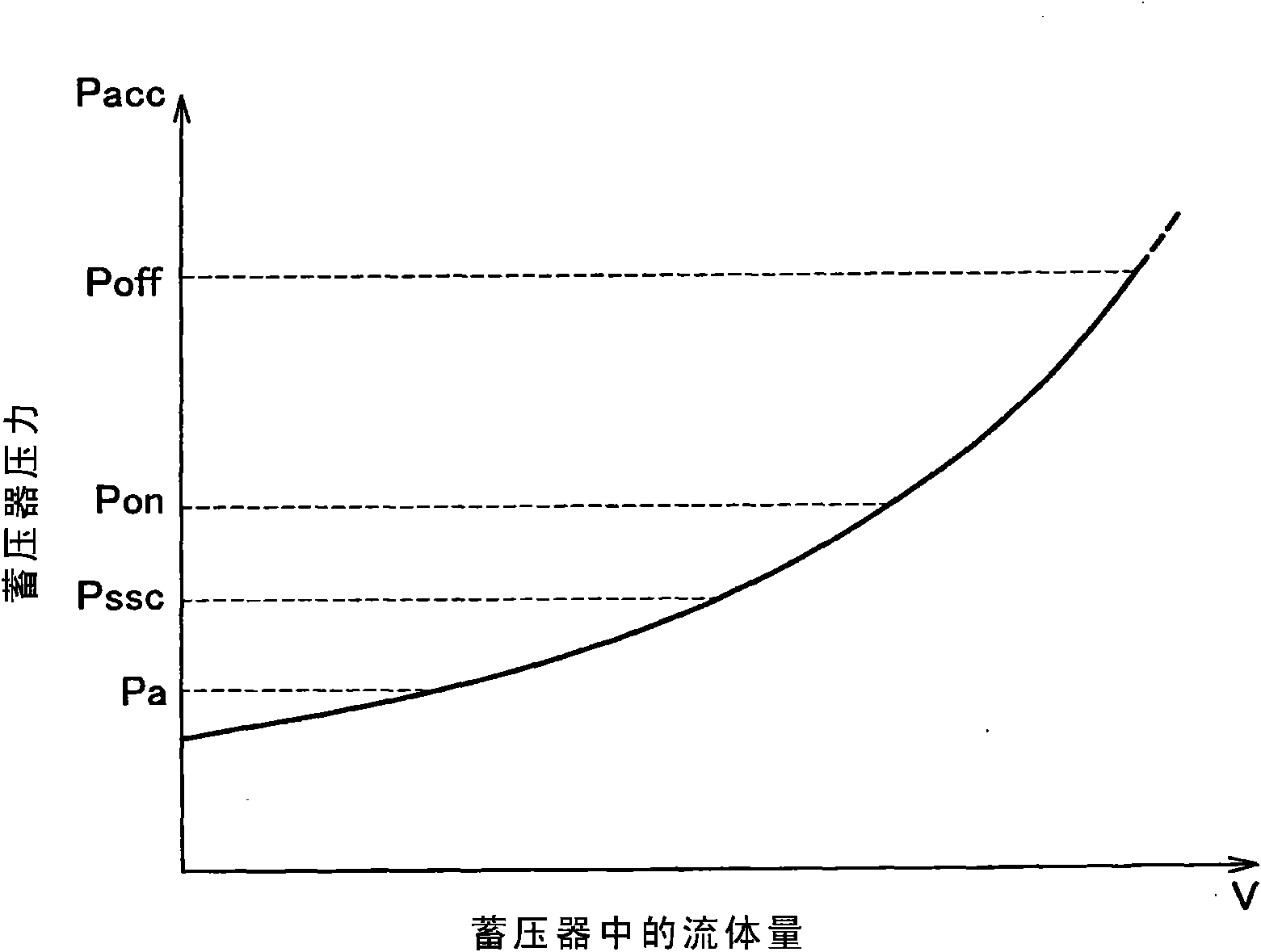

In a brake control apparatus (20) that controls braking forces which are applied to wheels based on the pressure of a brake fluid, when a hydraulic pressure actuator (40) controls the hydraulic pressure that is transferred to wheel cylinders (23) using the hydraulic pressure of the brake fluid in a power hydraulic pressure source (30), a brake ECU (70) closes a simulator cut valve (68) if the pressure of the brake fluid in the power hydraulic pressure source (30) falls below a predetermined value (Pssc) or if it is determined that the number of times the brake operation member (24) is operated within a predetermined value. In addition, the ECU (70) may change the timing for closing the simulator cut valve (68) based on the road surface condition estimated at the time of antilock control start. Thus, a driver is less likely to feel unusual brake feel when a braking control mode is changed.

Owner:TOYOTA JIDOSHA KK

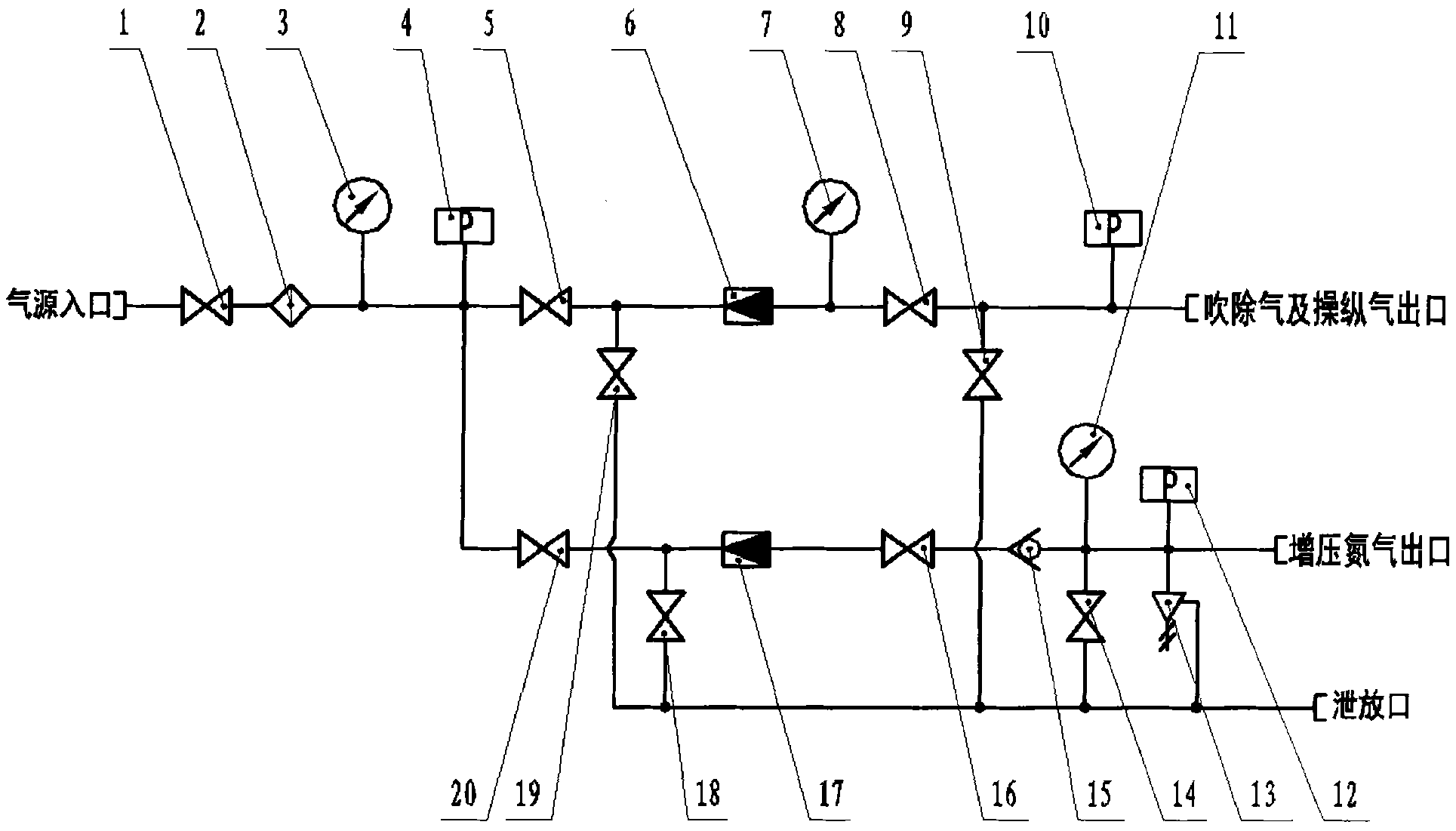

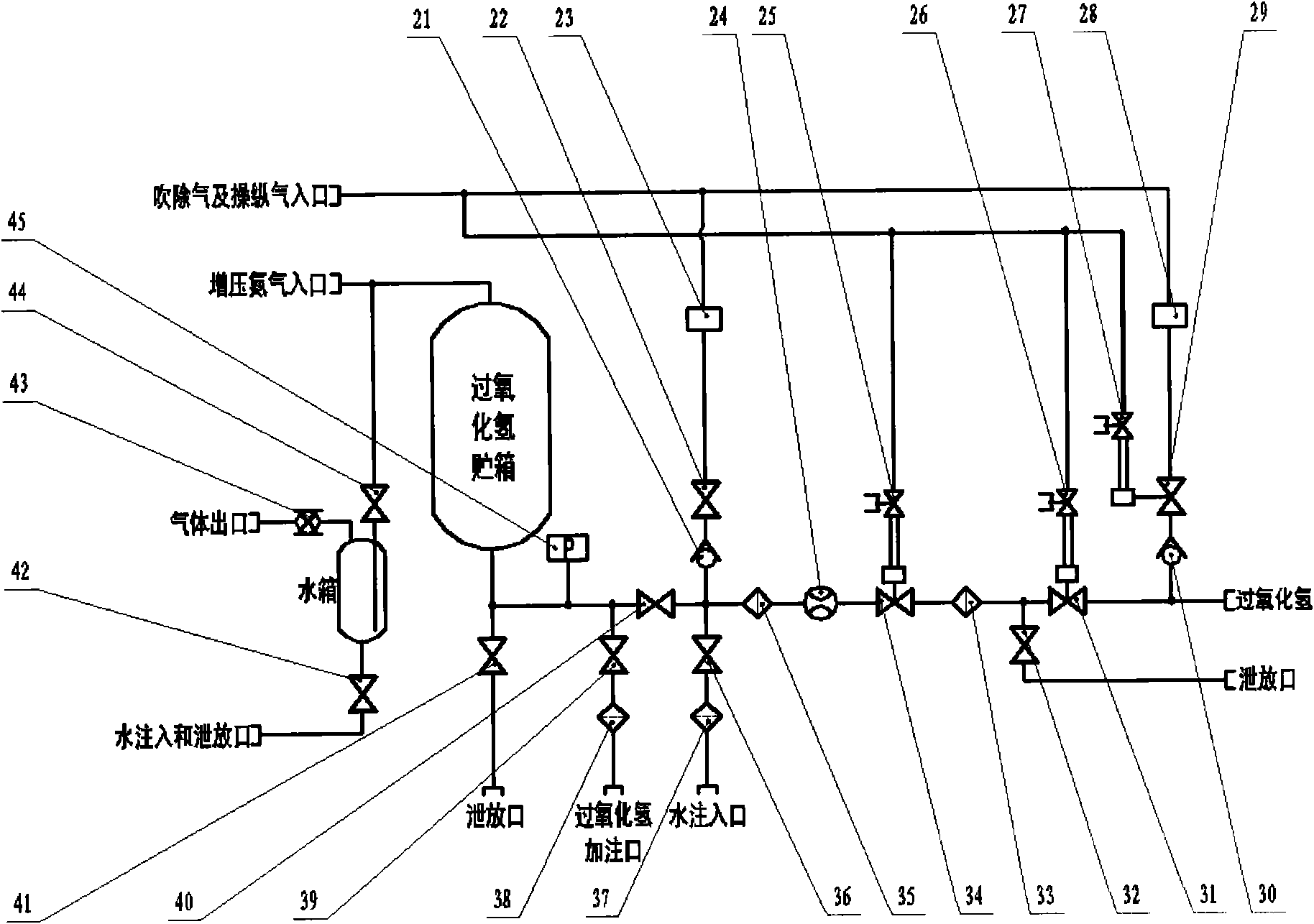

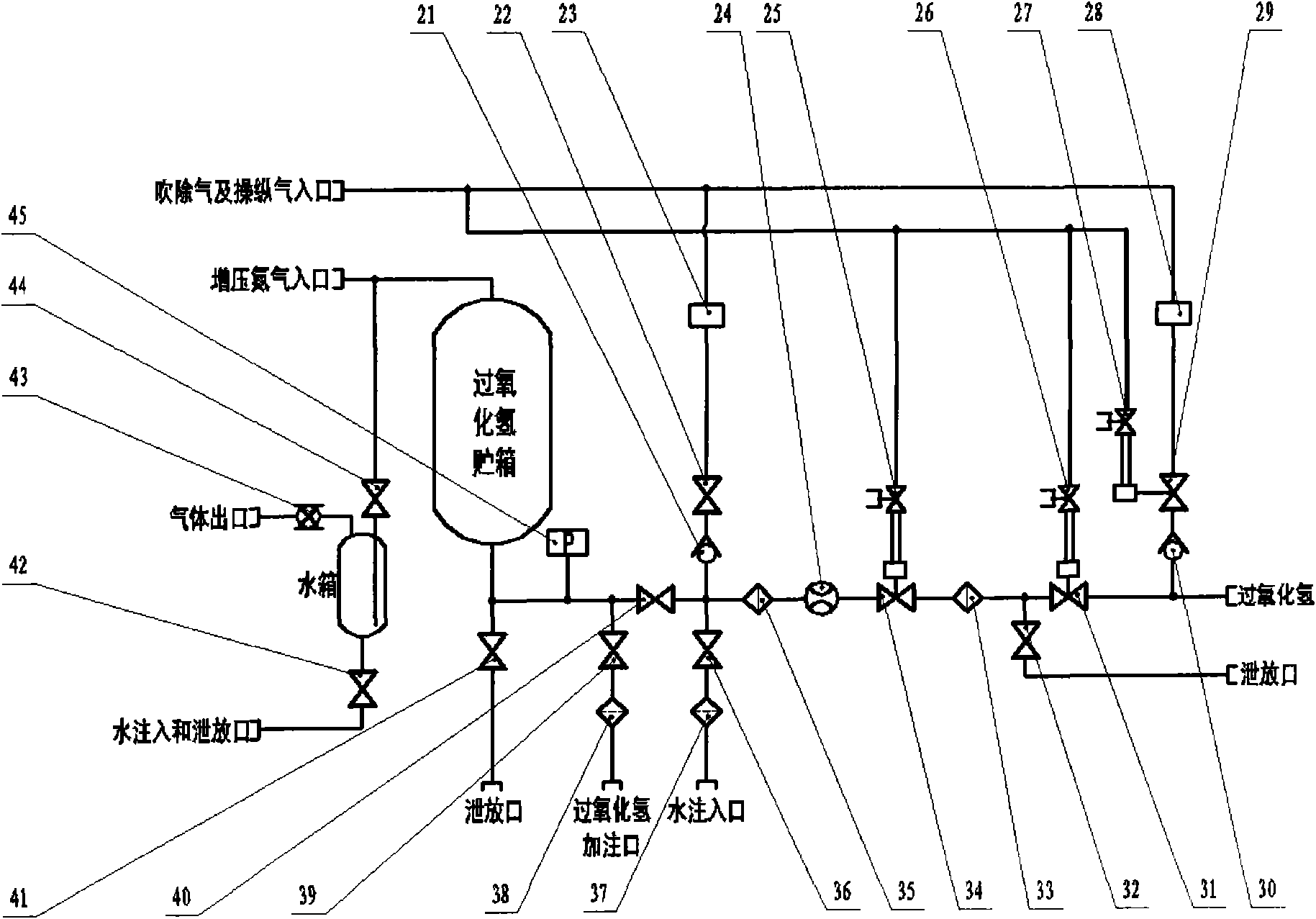

Peroxide supplying system and safety operation method

The invention relates to a peroxide supplying system which comprises an operation console and a pipeline system, wherein the operation console is provided with one path of a nitrogen source, and is used for simultaneously realizing pipeline blowdown, pneumatic valve operating gas supply and storage box pressurization. All pipeline systems in direct contact with peroxide are made of stainless steel, and all valves adopt stainless steel hand stop valves and pneumatic valves, wherein blowing gas and pneumatic valve operating gas share one pipeline, and storage box pressurization gas independently adopts one pipeline; the outlet of the storage box pressurization gas is provided with a one way valve and a safety valve. The pipeline system of the peroxide supplying system is provided with a distilled water inlet, one end of which can be led to the peroxide storage box and the other end of which can be led to the pipeline system. The pipeline system of the peroxide supplying system is provided with two paths of nitrogen blowdown, wherein one path is designed in the position of a storage box outlet and is controlled by the hand stop valves; the other path is designed in the pipeline outlet of the supplying system and is controlled by the pneumatic valves. The peroxide supplying system is operated by three steps: step one, injecting the peroxide; step two, pressurizing the storage box; step three, clean and blow distilled water in the pipeline system after the test is finished. The peroxide can be injected with a suction type scheme, gas in the storage box is pumped to reduce pressure in the storage box so that the peroxide is sucked into the storage box. When a vacuum pump is used for pumping the gas in the storage box, the gas enters the vacuum pump after passing through a water box.

Owner:BEIHANG UNIV

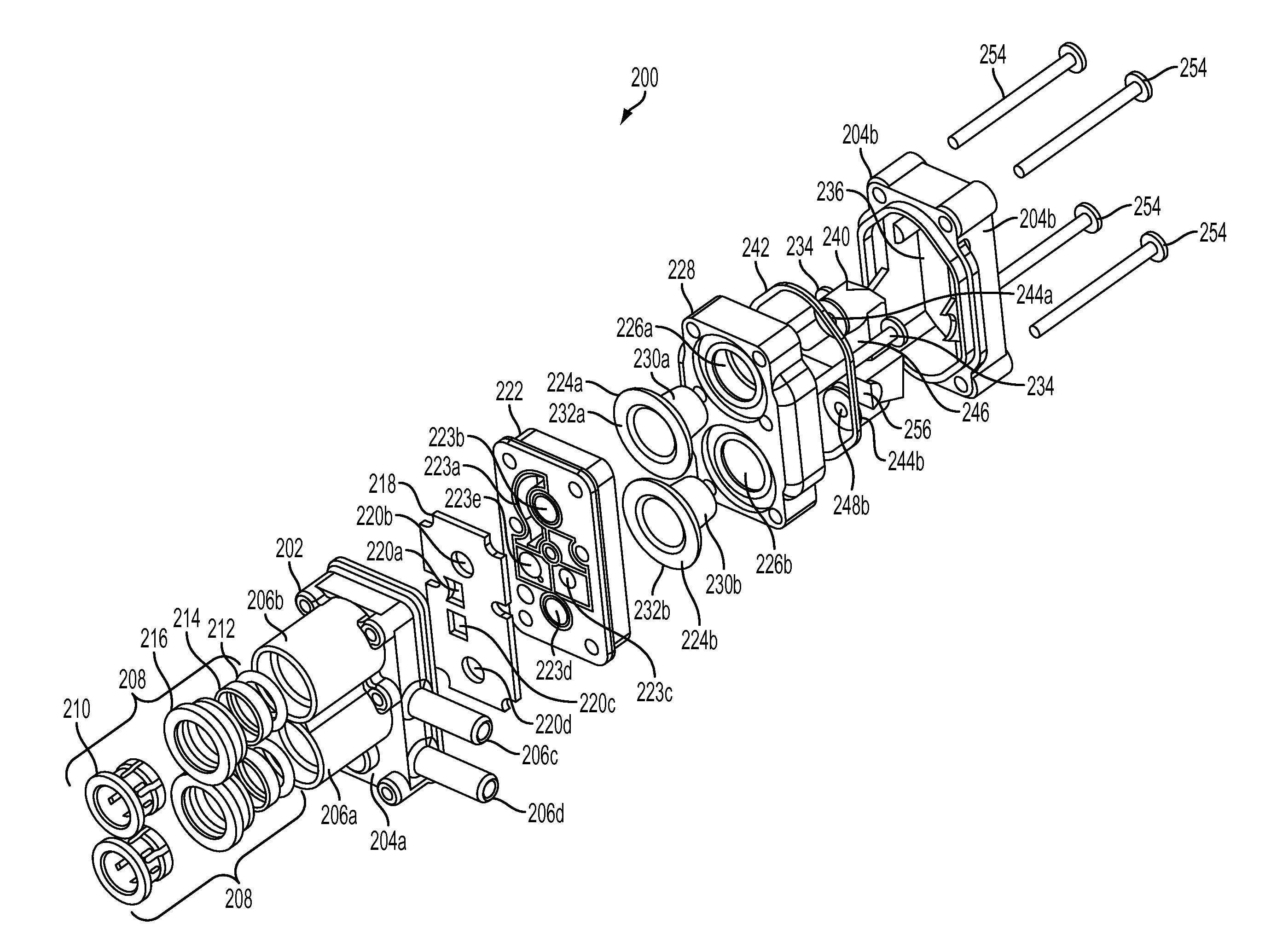

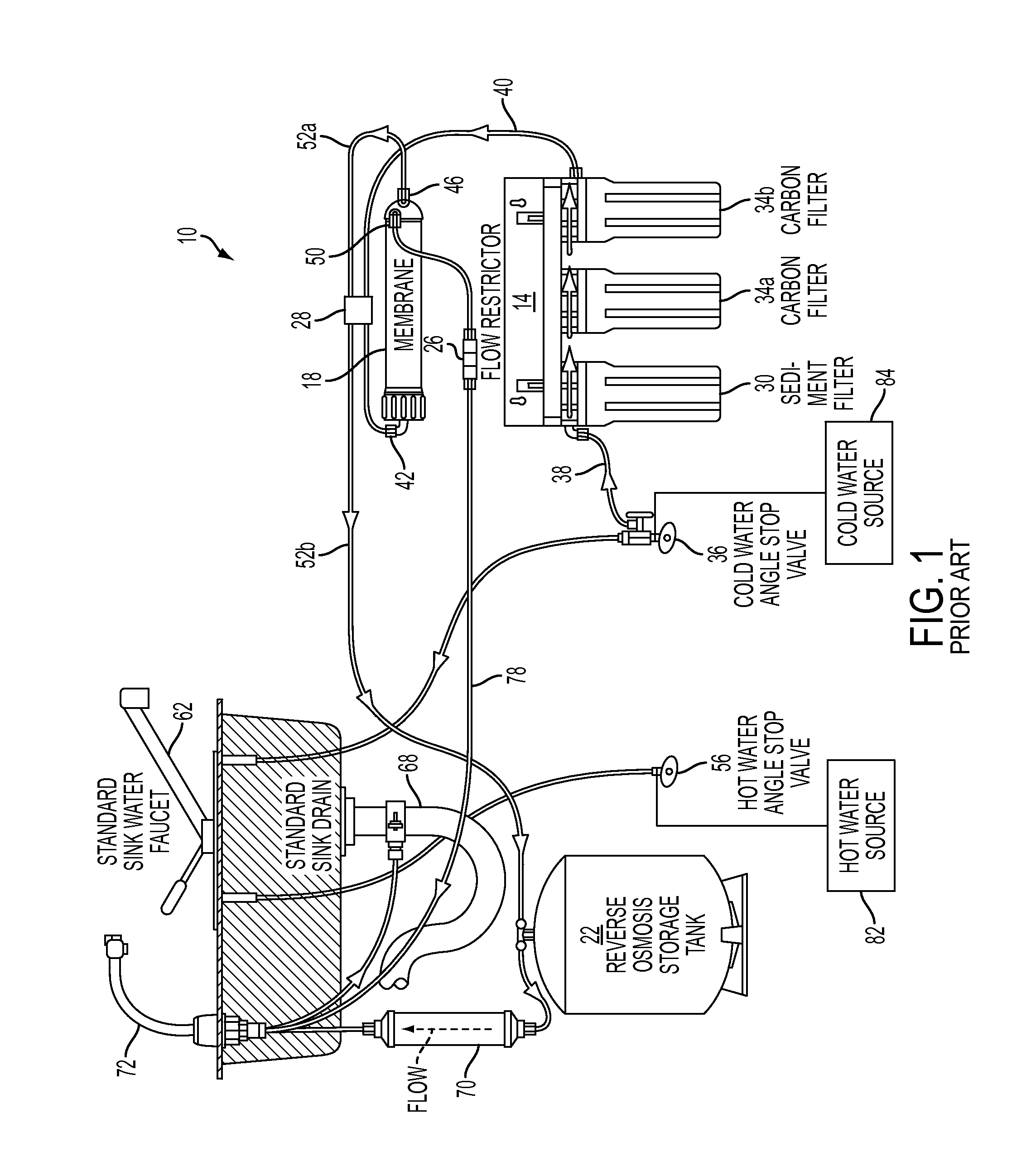

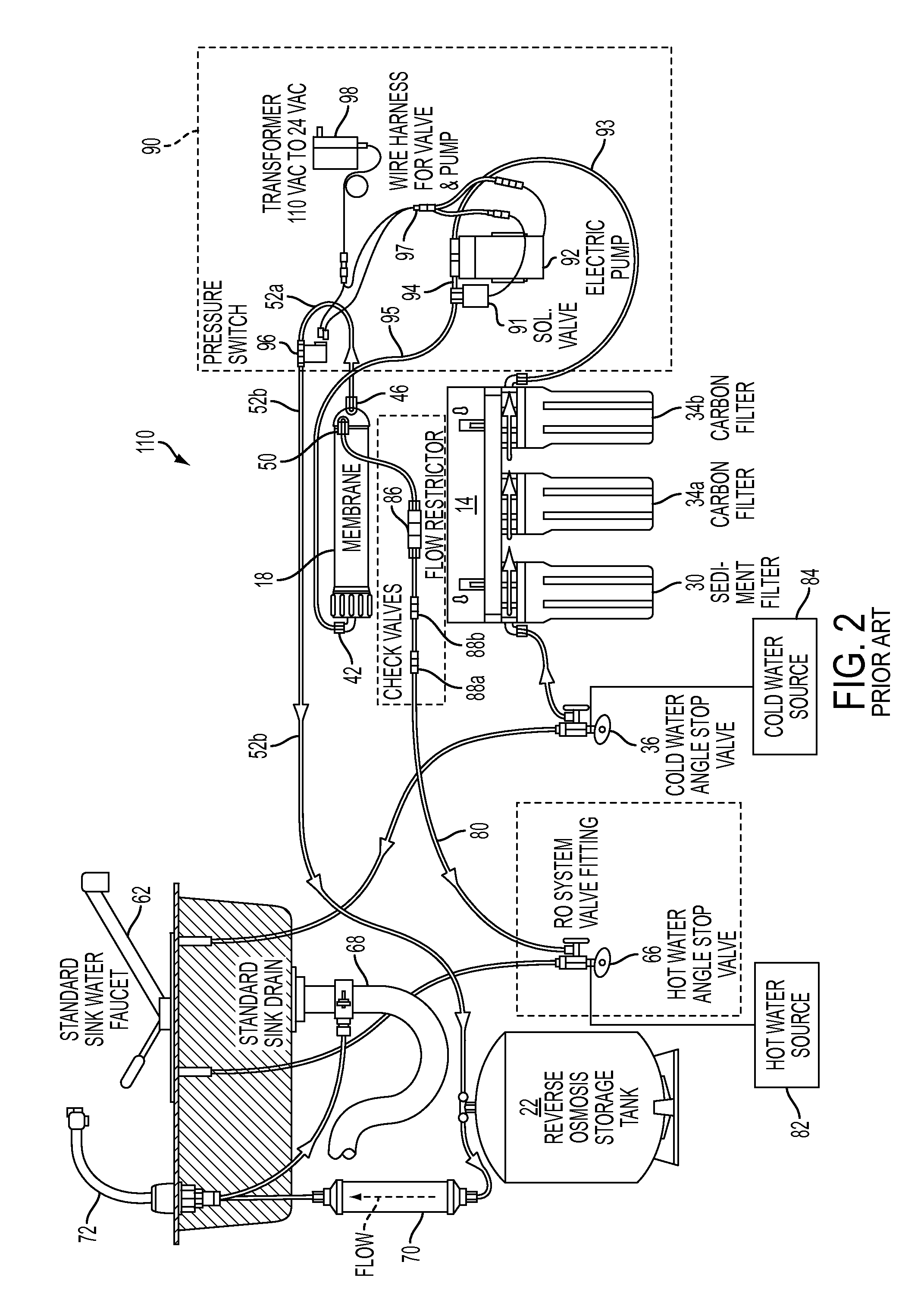

Shut off valve for a reverse osmosis water filtration system

A shut-off valve for use in a reverse osmosis filtering system including a housing defining an interior in fluid communication with a water inlet, a water outlet, and a permeate inlet, the housing having a fluidic network with a flowpath that connects the water inlet and the water outlet, a diaphragm plate forming a portion of the fluidic network within the interior, a piston within the interior for selectively opening and closing the flowpath, and at least one diaphragm coupling to the piston and the diaphragm plate such that as permeate pressure changes occur at the permeate outlet, the piston rocks between opening and closing the flowpath based on deflection of the at least one diaphragm in response to the permeate pressure changes.

Owner:WATTS REGULATOR

Assembly and method for containing, receiving and storing fluids and for dispensing gas from a fluid control and gas delivery assembly having an integrated fluid flow restrictor

A fluid control and gas delivery assembly and method for containing, receiving and storing hazardous fluids and for dispensing gas comprising a container, a fluid fill path, a gas dispensing path, a first shut-off valve, a pressure reducer, a fluid flow restrictor, a second shut-off valve and a fluid outlet connector. The first shut-off valve is positioned in said gas dispensing path upstream of a pressure reducer. A fluid flow restrictor downstream of the pressure reducer has a fluid flow restriction path configured to restrict the flow of the fluid delivered to the fluid flow restrictor at the delivery pressure to a maximum mass flow rate that is equal to or less than the allowable mass flow rate standard for the hazardous fluid. The second shut-off valve is positioned in said gas dispensing path downstream of said pressure reducer.

Owner:AIR PROD & CHEM INC

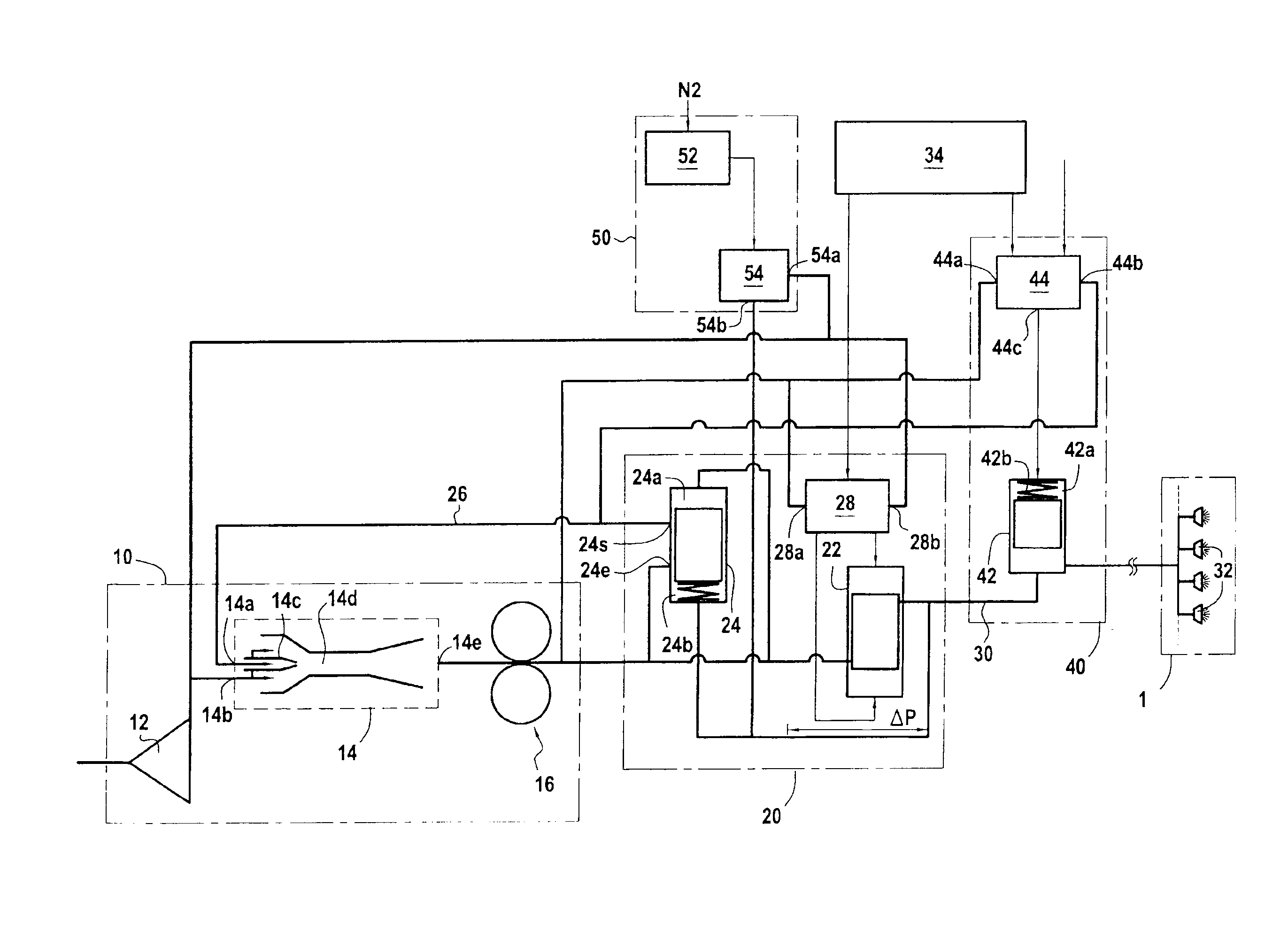

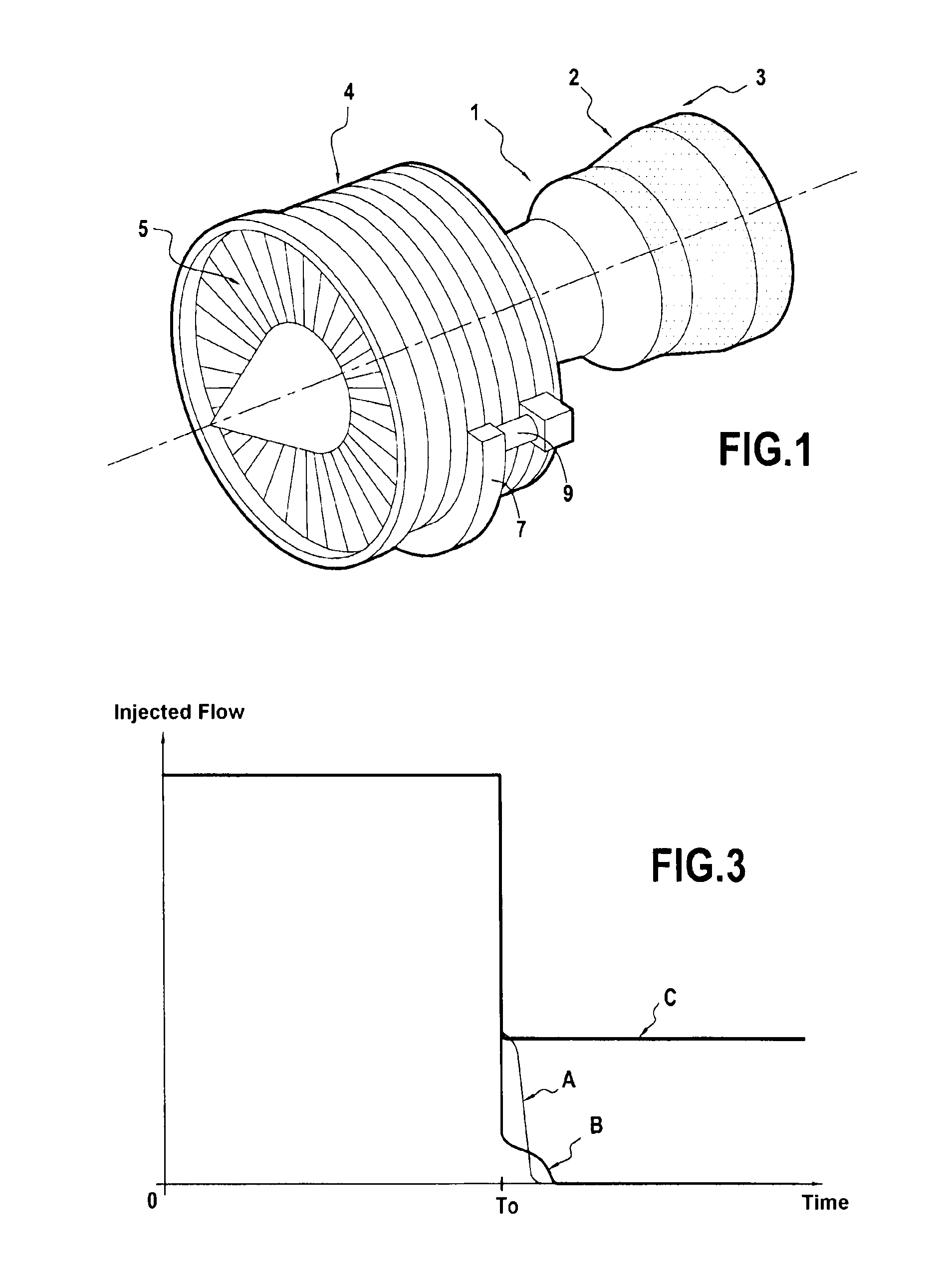

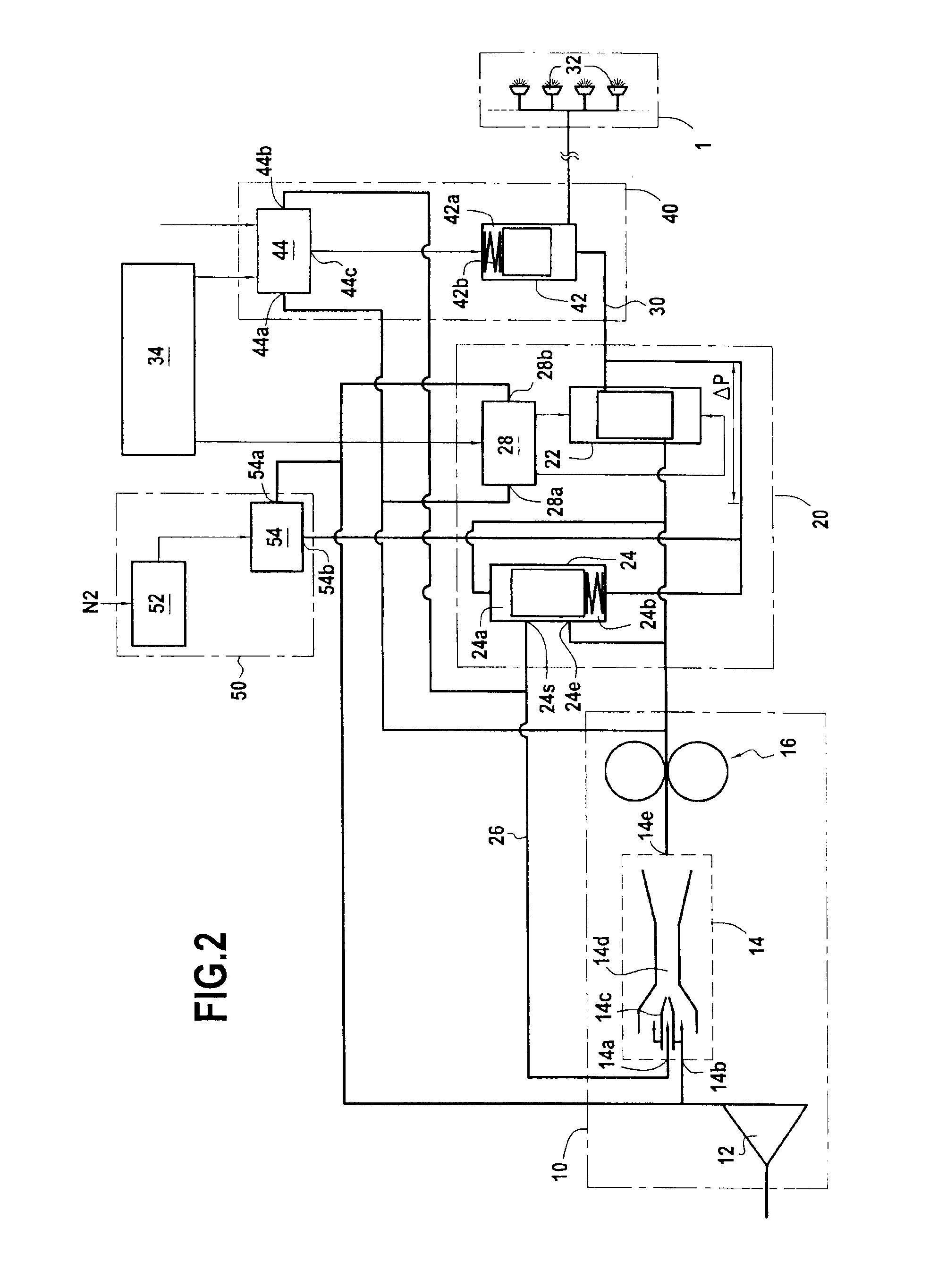

Fuel feed device for aviation engine

A jet pump (14) is inserted between the low-pressure pump and a high-pressure fuel pump (16). A fuel metering unit (20) includes a metering valve (22) which delivers a regulated fuel flow to a feed line (30), and a bypass valve (24) which diverts to a primary intake (14a) of the jet pump the excess fuel flow supplied by the high-pressure pump. An overspeed protection unit (50) includes a control element (54) of the bypass valve (24) which causes said to fully open in the event of an overspeed of the engine. A shutoff and pressurization checkvalve (42) is mounted on the feed line and controlled by a servo-valve (44) having a high-pressure port (44a) brought to the high fuel pressure, a low-pressure port brought to the pressure of the primary intake (14a) of the jet pump and an output setting the pressure in a control chamber (42a) of the shutoff valve (42) to a value between those prevailing at the high pressure and low pressure ports. In the event of overspeed, the restriction imposed by the jet pump causes a pressure rise at the primary intake of the jet pump, hence a pressure rise in the control chamber of the shutoff valve (42), favoring the closing thereof.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com