Apparatus and method for rapid determination of parameters of residual gas on mining working face of underground coal mine

An excavation face, rapid measurement technology, applied in the direction of analyzing materials, instruments, etc., can solve the problem of inability to accurately measure the residual gas pressure of coal seams, and achieve the effect of small workload, few influencing factors, and great development significance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

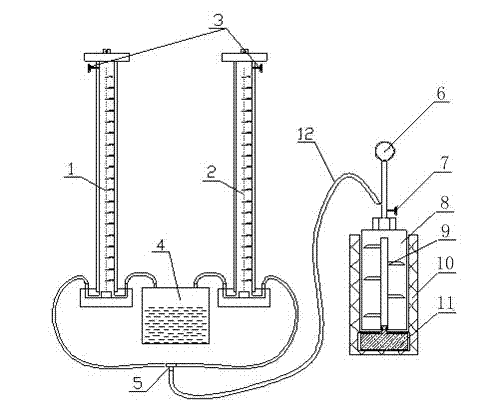

[0030] In the figure, the measuring device is provided with a cylindrical coal sample tank 8. The outside of the coal sample tank 8 is provided with a protective shell 10, and the lower part of the coal sample tank 8 is fixed with a pneumatic motor 11 and a pneumatic motor 11. The upper part of the air tube is matched with a rotating shaft. The side of the rotating shaft is uniformly displaced from top to bottom with a crushing cutter head 9. The upper part of the coal sample tank 8 is connected to one end of the air pipe, and the other end of the air pipe is connected with a high-precision pressure gauge 6 A gas stop valve 7 is provided at the interface between the gas guide tube and the coal sample tank 8. The side of the gas guide tube is connected to one interface of the three-way angle valve 5 through a connecting hose 12, and the other two interfaces of the three-way angle valve 5 are respectively The bottom of the measuring tube I1 and the measuring tube II2 are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com